Page 1

ASKO

USE AND CARE GUIDE

IMPORTANT!

IMPORTANT!

To get the best performance from

To get the best performance from

your dryer, read all operating

your dryer, read all operating

instructions before using it for

instructions before using it for

the first time.

the first time.

DRYER

ENGLISH

ENGLISH

CONTENTS

Important Safety Instructions 2

Safety Features 2

ASKO Dryer Features 3

Care and Maintenance Instructions 4

Overheat Protection 6

Troubleshooting 6

Energy Saving Tips 6

Customizing the Preset Programs – T760/T780 7

Error Messages – T760/T780 9

Installation Instructions 10

ASKO Product Warranty 15

Index 16

ÇAIS

ÇAIS

FRAN

FRAN

AÑOL

AÑOL

ESP

ESP

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

Page 1

Page 2

IMPORIMPORTTANT SAFETY INSTRANT SAFETY INSTRUCTIONSUCTIONS

To reduce the risk of fire, electric shock, or injury to

persons when using your appliance, follow basic

precautions, including the following:

♦ Electrical installation, if required, must be done by

a licensed electrician.

♦ Read all instructions before using the appliance.

♦ Do not allow children to play on or in the appliance.

Close supervision of children is necessary when

the appliance is used near children.

♦ Before the appliance is removed from service or

discarded, remove the door to the drying compartment.

♦ Do not reach into the appliance if the drum is

moving.

♦ Do not install or store this appliance where it will

be exposed to the weather.

♦ Do not tamper with controls.

♦ Do not use fabric softeners or products to eliminate

static unless the manufacturer gives written assurance

that the product will not damage a tumble dryer.

♦ Do not heat dry items containing:

• vinyl, plastic, foam rubber or similarly textured

rubberlike materials

• fiberglass

• wool unless the label specifies “washable”

♦ Do not heat dry items that have been dry-cleaned

at home.

♦ Clean the lint filter before or after each load.

♦ Keep the area around the exhaust opening and

adjacent areas free from the accumulation of lint,

dust, and dirt.

♦ The interior of the machine and exhaust duct

should be cleaned periodically by an authorized

ASKO service agent.

♦ Do not attempt to repair or replace any part of the

appliance or perform any servicing unless

specifically recommended in this guide.

♦ The dryer is made and marked to facilitate

recycling. When it is no longer useful, contact your

local refuse collection service for advice on how to

properly dispose of the dryer for purposes of

recycling.

WARNING!

This appliance must be properly grounded.

Improper connection of the equipment grounding

conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman

if you are in doubt as to whether the appliance is

properly grounded.

The plug must be plugged into an appliance outlet

that is properly installed and grounded in

accordance with all local codes and ordinances.

To reduce the risk of fire, this appliance must be

exhausted outdoors or the equivalent. Do not

exhaust into a chimney, wall, ceiling or concealed

space in a building.

WARNING!

Do not wash or dry articles that have been

previously cleaned in, washed in, soaked in, or

spotted with gasoline, dry-cleaning solvents,

cooking oils, other flammable or explosive

substances as they give off vapors that could

ignite or explode.

NOTE: This manual does not cover every possible

condition and situation that may occur. Use

common sense and caution when installing,

operating, and maintaining any appliance.

SAFETY FEASAFETY FEATURESTURES

Magnetic Door Lock

ASKO dryers have a magnetic door lock that allows the

door to be opened from the inside.

Automatic Door Switch

A door switch automatically stops the dryer when the

door is opened. The dryer will not start again until you

close the door and press the Start button.

Page 2

Overheat Protection

ASKO dryers have an overheat protection switch that

automatically turns off the machine if the temperature

gets too high. Refer to page 6 for more information.

Child-Safe Start Feature

You can program Models T760 and T780 not to start

unless the Start button is held down for three seconds.

This is to prevent children from inadvertently starting

the machine. Refer to page 9 for instructions on how to

program this safety feature.

Page 3

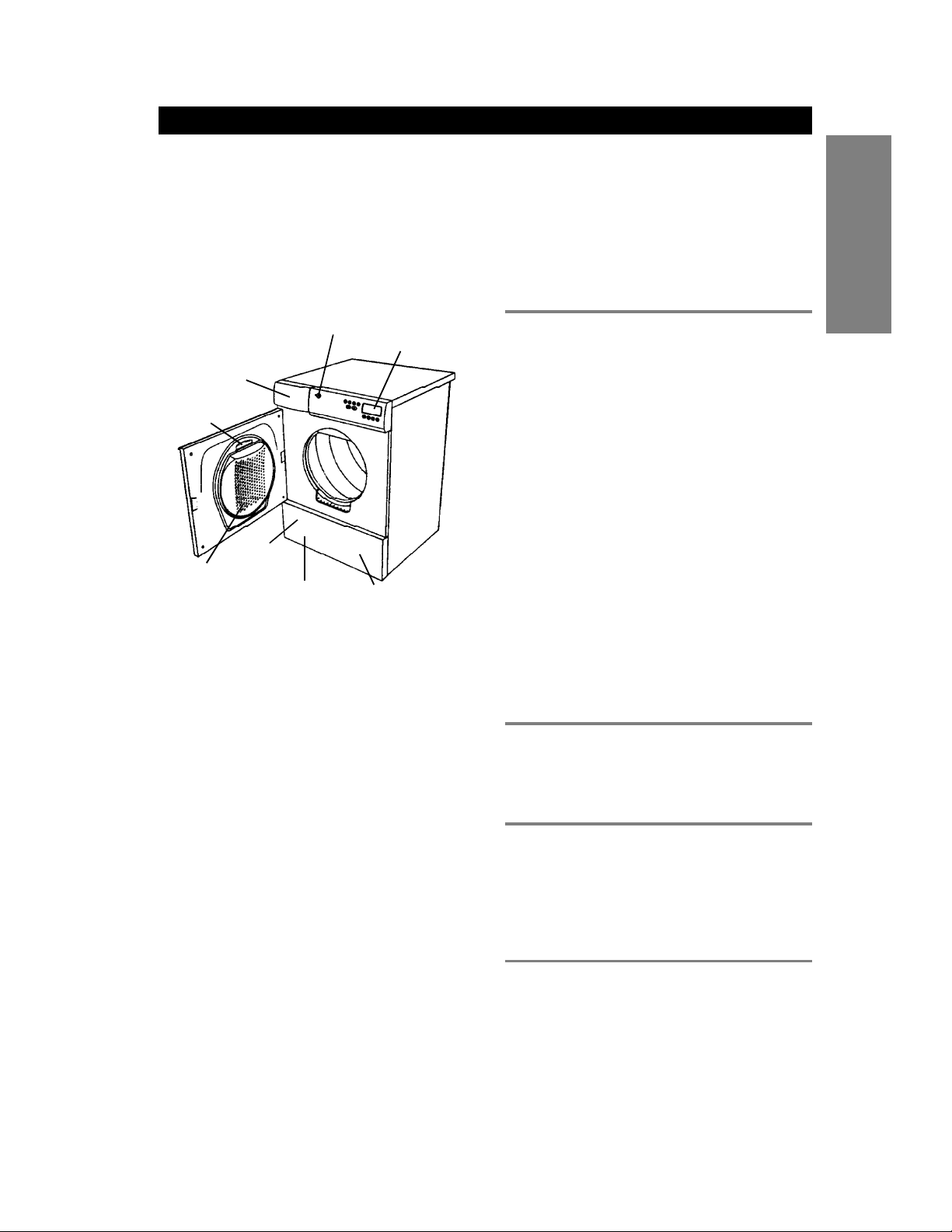

ASKASKO DRO DRYER FEAYER FEATURESTURES

Your new energy-efficient ASKO dryer is designed to

give you maximum drying performance using less

energy. To make the most of the dryer’s functions and

features, we recommend that you read this manual

carefully before using your machine for the first time.

For operating instructions specific to your model, refer

to the Quick Start Guide enclosed with this manual.

Below is an illustration of the parts and features of your

ASKO dryer.

Power

Button

Condensed Water

Container

(Models T720 & T780)

Lint Filter

Front

Lint Filter

Cover

ASKO dryers come with three different drying systems:

Panel

Cleanable Fan

(behind panel)

Control

Panel

Condenser Unit

(behind panel)

Sensidry™

Models T760 and T780 have our state-of-the-art

Sensidry system. These machines are equipped with

a humidity sensor that ensures different fabrics always

dry thoroughly. This sensor turns off the heat when the

laundry has reached the appropriate dryness.

Thermostat-Control

Model T700 has a thermostat that controls the

temperature by turning the heating element on and off

to maintain the selected drying temperature (Normal or

Low) within +/- 5° F.

Timer-Control

Model T720 offers only timed drying. You can set the

dryer to run from 30 minutes to 190 minutes.

Model T700 has timer-controlled drying in addition to

the two automatic (thermostat-controlled) programs.

When using a timed drying program, be careful not to

leave the clothes in too long. It’s best to use a shorter

time; then if the load isn’t dry, you can set the timer for a

few more minutes.

CARE LABEL INSTRCARE LABEL INSTRUCTIONSUCTIONS

Read all permanent care labels carefully. If the label

says “Drip dry,” “Line dry” or Dry flat,” do not dry that item

in the dryer. Certain fabrics will melt or become

dangerously flammable if heated, while others may lose

their shape.

NOTE: Refer to “Important Safety Instructions” on the

previous page for a list of specific materials that should

never be put in a tumble dryer.

SORSORTING TING THE LATHE LAUNDRUNDRYY

For best drying results, clothes should be sorted

properly. Below are some suggestions on how to sort

your laundry for drying.

♦ Permanent press items should be dried together.

For the most wrinkle-free results when drying

permanent press items, you should fill the machine

only half full. These items also should be removed

promptly from the dryer and hung up or folded right

away.

♦ Dry heavy fabrics together and lightweight fabrics

together.

♦ Dry fabrics that shed lint (chenille, terry cloth, etc.)

separately from fabrics that collect lint (synthetics,

velveteen, corduroy, etc.).

♦ Separate non-colorfast fabrics from light-colored

items.

♦ If the care label says "Wash Separately," the fabric

is likely to lose color (excess dye) for the first few

washings. To minimize the possibility of the dye

transferring to white or lighter colored items, dry

new colored garments with items of similar color

or alone. Bright reds and oranges on cottons are

the dyes most likely to transfer colors.

FFABRIC SOFTENER SHEETSABRIC SOFTENER SHEETS

We recommend that you do not use fabric softener

sheets in the dryer. Over time, the chemicals on these

sheets can build up inside the lint filter and clog the

holes that circulate the air.

DRDRYING PRYING PROGRAMSOGRAMS

Refer to the Quick Start Guide that came with your dryer

for specific instructions and programs available with

the model you purchased.

Models T760 and T780: Refer to the “Customizing

the Preset Programs” on page 7 of this guide for

instructions on how to change the preset programs.

DRDRYING YING TIMESTIMES

Drying times will vary due to the amount of laundry in

the machine, moisture content, type of fabric, air

temperature and humidity. The length of the vent hose

can also affect drying times. (See “Connecting to a

Ventilation Duct (T700/T760)” on page 11 for the

recommended installation.)

ENGLISH

ENGLISH

Page 3

Page 4

RECOMMENDED RECOMMENDED TEMPERATEMPERATURE SETTINGS TURE SETTINGS AND LOAND LOAD SIZESAD SIZES

Different fabrics require different load sizes and drying

temperatures. The table below gives recommended

temperature settings and load sizes for different fabrics.

Fabric TypeFabric Type SettingSetting SizeSize

TempTemp LoadLoad

Cotton w/out elastic and/or decorative trim Normal Full

Linen – white and colorfast Normal Half

Cotton/polyester blends Low Half

Polyester/acrylic blends Low Half

Rayon and acetate Low Half

Washable silk and nylon * Low Third

Washable wool and wool blends * Low Third

Handwash wool and silk * Low Third

* Always refer to the care label on the garment to determine if it can be

tumble dried. Some wool and silk and hand-washable items should not

be tumble dried. These items should be removed from the washer then

pressed out in a terry towel to remove excess water before being hung up

or laid flat to dry.

CARE CARE AND MAINTENAND MAINTENANCE INSTRANCE INSTRUCTIONSUCTIONS

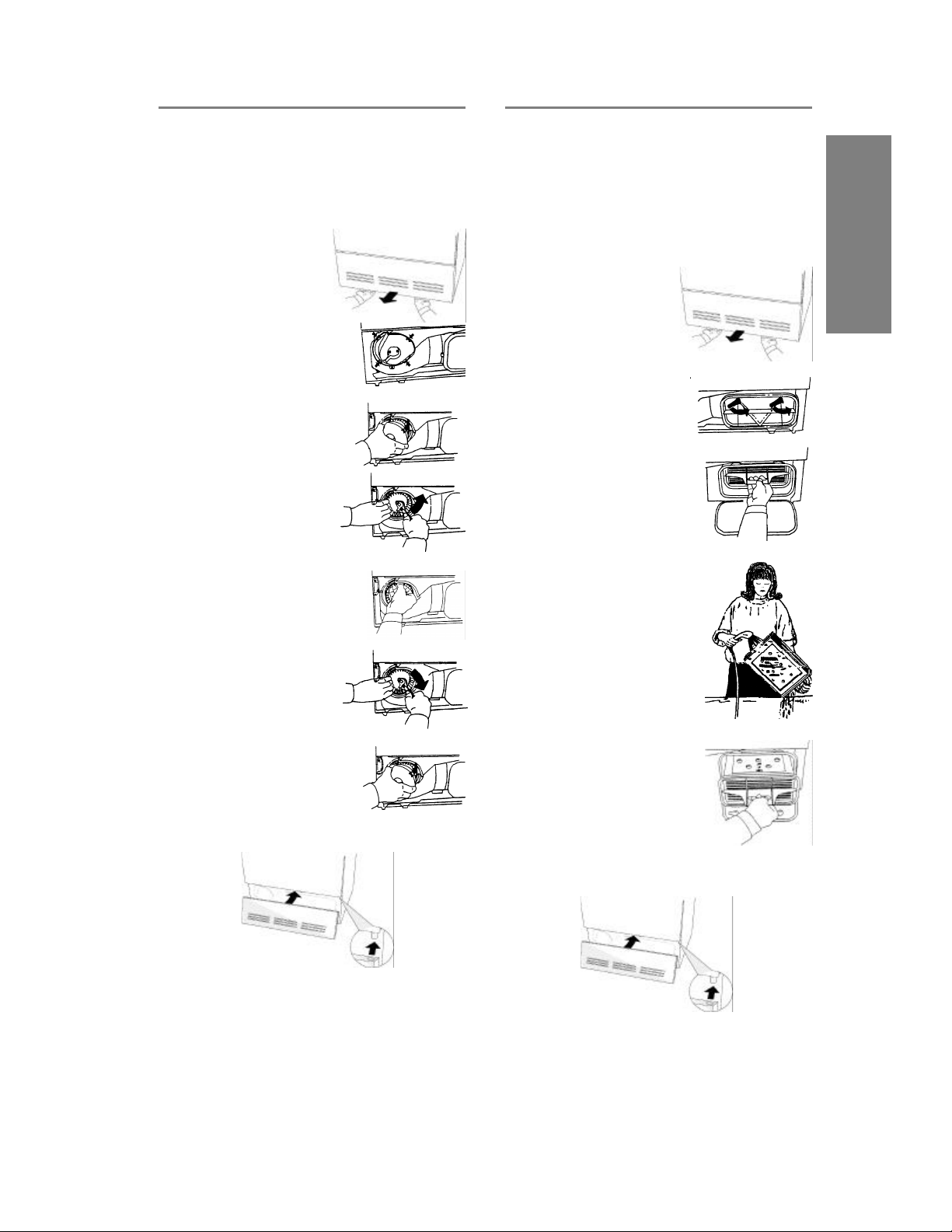

CLEANING THE LINT FILTERCLEANING THE LINT FILTER

The wear on fabrics in a tumble dryer is insignificant.

The lint caught in the lint filter is dust and fiber residue

that has been formed when the garments have been

worn. The lint filter must be cleaned after each load. If

this is not done, drying performance will suffer, as

insufficient air will pass through the drum. The machine

may also overheat after a while, which will cause it to

stop automatically.

To clean the lint filter, follow the steps below:

1. Grasp the handle and pull it

toward you.

2. Remove the filter

from the holder.

3. Open the filter and

gently brush away

any lint.

4. Fold the filter

together and return

it to the holder on

the door.

5. Push the holder in

until it snaps into

place.

CLEANING CLEANING THE CONTRTHE CONTROL POL PANELANEL

To clean the control panel, use only a soft, warm, damp

(not wet) rag. To prevent penetration of water into the

door lock and electrical components, do not use a spray

cleaner of any kind. Also, never use abrasive cleaners

or scouring pads on the outer surfaces because they

will scratch the finish and possibly remove the writing

on the control panels. Some paper towels may also

scratch the finish.

Page 4

CLEANING THE EXHAUST HOSECLEANING THE EXHAUST HOSE

About once a year you should remove the exhaust hose

and clean it. At this time, you should also clean the

exhaust outlet on the machine and the ventilation duct.

Periodically, you should check the dryer exhaust outside

to be sure the air flow is strong and nothing is blocking

the vent.

T720 AND T780 – EMPTYINGT720 AND T780 – EMPTYING

THE THE WWAATER CONTTER CONTAINERAINER

If the dryer is not installed to pump out the condensed

water into a drain or sink, the condensation water collects

in the water container to the left of the control panel. You

should empty the container every three to five dryer

loads, depending on the spin speed you use when you

wash the clothes. For example, clothes spun at 800 rpm

will have more moisture when you take them out of the

washer than clothes spun at 1400 rpm. Therefore, the

dryer will have to remove more water.

NOTE:

1. Pull out the container.

2. Pour out the water.

3. Replace the container.

NOTE:

If the container becomes too full, the machine will shut

down. To restart the program, empty the container and

press Start. It may be a few minutes before the machine

starts because it drains the excess water from the sump

before it restarts.

Do not remove the water container while the

machine is running.

You should hear it snap

into place.

The condensed water is soft and safe to use

for watering plants.

Page 5

CLEANING CLEANING THE FTHE FANAN

The fan should be cleaned at least once a year. If you

have pets, you should clean it more often. To clean the

fan, follow the steps below:

1. Turn off the main power to the machine.

T720 AND T780 - CLEANINGT720 AND T780 - CLEANING

THE CONDENSERTHE CONDENSER

The condenser should be cleaned on a regular basis,

preferably monthly. If you have pets, you should probably

clean it more often. To clean the condenser, follow the

steps below:

2. Remove the two 20 torx

screws on the bottom of

the front panel then grasp

the bottom of the panel and

pull it forward and down.

3. Unscrew the 10 torx safety

screw on the bottom of the fan

cover and fold out the four tabs.

4. Remove the fan cover.

5. Hold the fan in place while

you unscrew the nut.

6. Pull out the fan and clean it with

a brush and water.

7. Replace the fan and screw

the nut securely.

1. Turn off the main power to the machine.

2. Remove the two 20 torx

screws on the bottom of

the front panel then grasp

the bottom of the panel and

pull it forward and down.

3. Turn the levers on the

condenser cover counterclockwise to release it then

pull it down.

4. Pull out the condenser.

5. Spray the fins with warm water

until all of the lint is removed.

WARNING!

Do not put the condenser

into a dishwasher. Do not

use any sharp metal objects

or a wire brush to clean the

condenser. Also, do not

poke anything between the

fins.

ENGLISH

ENGLISH

8. Replace the fan cover and fold

the lugs back into place.

Replace the safety screw.

9. Replace the front panel.

10. Turn back on the main power.

6. Make sure the side marked

“UP” does face up and

carefully replace the filter into

the unit.

7. Replace the condenser cover and the front panel.

8. Turn back on the main power.

Page 5

Page 6

TRTROUBLESHOOOUBLESHOOTINGTING

If you experience a problem with your dryer, you should

review the following list of frequently encountered

situations. It could save you the cost and inconvenience

of a service call.

Even though the product is under warranty, if the problem

The machine won’t start.

♦ Make sure the door is closed securely.

♦ Make sure the Power is turned on.

♦ Check that you set the program or time correctly.

♦ Check that the electric plug is securely in the

socket.

♦ Check the house breaker/fuses and the fuses on

the back of the dryer.

♦

If all of the above options are eliminated, the

overheat protection has probably been activated.

(See below.)

The machine starts but it stops when

I release the power button.

♦ The overheating protection has probably activated.

Clean the lint filter and let the machine cool down

before trying again. (See below.)

The machine takes too long to dry

my laundry.

♦ Check that the lint filter is clean.

♦ If you use dryer sheets (not recommended), you

may need to wash the lint filter with warm water

and a soft brush to clean any blocked holes.

♦ Be careful not to overload the dryer because the

warm air needs sufficient room to circulate properly

is not caused by defective product workmanship or

materials, you will be charged for a service call. Refer

to page 15 to determine what is and is not covered

under your warranty. If you’re still not sure, contact the

ASKO Advisory Center before you call a serviceman.

and the clothes need room to tumble freely.

♦ The laundry should only be damp when it comes

out of the washer. If it seems too wet, try using a

faster or longer spin cycle.

♦ Make sure the outside vent exhaust is not blocked.

My clothes are coming out wrinkled.

♦ You should remove the clothes as soon as the

dryer signals the end of the cycle. If you can’t remove

the clothes right away, use the Anti-crease option.

♦ Dry heavy fabrics together and light fabrics together.

♦ Dry only permanent press items together.

♦ Dry in smaller loads.

♦ Use slower spin speeds.

♦ Use fabric softener in the rinse program.

♦ You may be using the wrong wash temperature.

Try using a lower wash temperature, especially

for permanent press and delicate items.

The motor is running but the drum

isn’t turning.

♦ This usually means a belt is broken. Call a servicer.

The machine makes a funny noise.

♦ A slight rumbling may be heard when you first turn

on the dryer. This is normal and it should only last

a few seconds.

OOVERHEAVERHEAT PRT PROOTECTIONTECTION

ASKO dryers are designed with an overheat protection

switch that automatically turns off the machine if the

temperature is too high. This could happen if the lint

filter or exhaust hose becomes clogged with dust.

Should the machine turn itself off because of

overheating, make sure the lint filter and exhaust hose

and vent duct are clean.

If the overheat protection switch is activated, you have

to reset it before the machine will run. To do this, press

the reset button (rubber disk) on the back of the

machine, as illustrated to the right. You should hear a

click when it engages. The machine will not start until it

has cooled sufficiently.

ENERENERGY SAGY SAVING VING TIPSTIPS

♦ Dry consecutive loads to avoid reheating the dryer.

♦ Do not overload the dryer.

♦ Use the highest spin speeds allowed for the

garments.

♦ Do not put extremely wet clothes into the dryer.

Page 6

Press the reset

button to start the

machine.

NOTE:

If your dryer overheats frequently, it may not be

vented properly or the room in which it is located

may not have sufficient air circulation. Contact

an installer to have these issues checked out.

♦ Dry like fabrics together (i.e., heavy fabrics together,

light fabrics together).

♦ Clean the lint filter after each load.

♦ Do not overdry clothes when using the timed program.

♦ Spin the clothes at no less than 800 rpm.

Page 7

T760/T780 – CUSTOMIZING THE PRESET PROGRAMST760/T780 – CUSTOMIZING THE PRESET PROGRAMS

ASKO’s EasyControl™ panel makes it simple to

customize the preset programs to perfectly fit your

laundry needs. You needn’t worry about making an error

THE PRESET PROGRAMS THE PRESET PROGRAMS

Before we tell you how to customize the preset programs,

you need to review what these programs are. The table

below lists the four preset programs and the pre-

Preset Dry Cooling Anti Program Dry Cycle Temp Time Buzzer Crease

P1 Extra Dry Normal Normal

P2 Dry Normal Normal On 1 hr.

P3 Normal Dry Normal Normal On 1 hr.

P4 Iron Dry Normal

(1) The Normal cooling time is 20 minutes.

(2) Model T760 is preset for Low dry temperature.

WARNING!

NOTES:

Some fabrics may not be able to withstand extremely hot temperatures. Please refer

to the “Recommended Temperature Settings and Load Sizes” chart on page 4.

P1 P2 P3 P4

because you can easily restore the original program

settings. (See page 9.)

programmed settings for each. To select a program, simply

press one of the program buttons then press Start.

(1)

(2)

Normal On 1 hr.

On 1 hr.

CUSTOMIZING THE PROGRAMSCUSTOMIZING THE PROGRAMS

Below are the basic instructions for changing a preset program. The following page explains the menus and options

and how to navigate through them.

1. Press the button for the preset program

you want to change (P1–P4). The program

you select will display in the lower left

corner of the LED window.

2. Press MENU to display different program

and option settings.

3. Press the Arrows to move forward or

backward through the menu settings.

4. Press ENTER to choose your selection.

P1 P2 P3 P4

Start Stop

Menu Enter

ENGLISH

ENGLISH

THE PROGRAM MENUTHE PROGRAM MENU

The following table lists all of the programs on the

Program menu as well as the settings and options

available with each. It’s a good idea to scan through the

ProgramsPrograms Available OptionsAvailable Options

Extra Dry Normal Cooling (20 min.) or Quick Cooling (10 min.); Buzzer On/Off;

0–3 hr. Anti-crease; Normal or Low Temperature, 1–12 hr. Delay Start

Dry Normal Cooling (20 min.) or Quick Cooling (10 min.); Buzzer On/Off;

0–3 hr. Anti-crease; Normal or Low Temperature, 1–12 hr. Delay Start

Normal Dry Normal Cooling (20 min.) or Quick Cooling (10 min.); Buzzer On/Off;

0–3 hr. Anti-crease; Normal or Low Temperature, 1–12 hr. Delay Start

Iron Dry Normal Cooling (20 min.) or Quick Cooling (10 min.); Buzzer On/Off;

0–3 hr. Anti-crease; Normal or Low Temperature, 1–12 hr. Delay Start

Air Fluff 5–90 min. cycle time; Buzzer On/Off; 0–3 hr. Anti-crease, 1–12 hr. Delay Start

Timed Dry All drying programs; 5–90 min. cycle time; Normal Cooling (20 min.) or

Quick Cooling (10 min.); Buzzer On/Off; 0–3 hr. Anti-crease; Normal or

Low Temperature; 1–12 hr. Delay Start

menus a couple of times and familiarize yourself with

the options before you make any changes. And

remember, it’s easy to restore the preset programs.

Page 7

Page 8

NNAAVIGAVIGATING TING THE MENUSTHE MENUS

The following paragraphs explain how to navigate

through the menus and change the preset programs.

If you don’t want to make changes in all of the menus,

continue to press MENU until the one you do want to

change displays.

To restore a preset program to its original settings, simply

press the button for the preset program (P1–P4) you

want to restore and hold it down while you press ENTER.

The program will instantly revert to its original settings.

We recommend that you make two or three trial changes

to understand how easy it is to customize these

program.

Remember, the first step to customizing a preset

program is to press the button for the program you

want to customize (P1–P4).

The Program Menu

The Program menu lets you set the dry program you

prefer. You would also use this menu to set the machine

for a Timed Dry or Air Fluff program. (See “Timed Dry

and Air Fluff” on this page.)

The Temperature Menu

This menu lets you set the dry temperature. Only the

temperatures available for the dry program you selected

will display.

Select

temperature

Temperature low

< Next >

P1

Menu Enter

1. Use the Arrow buttons to toggle between the

Normal and Low temperature settings.

2. When the setting you prefer displays, press ENTER.

The LED will display the new temperature setting.

Press MENU to advance to the next menu or press

START to begin the program.

Select

Program

Extra dry

< Next >

P1

Menu Enter

1. Use the Arrow buttons to move through the program

choices (Extra Dry, Dry, Normal Dry, etc.)

2. When your preference displays, press ENTER. The

LED will display the new program setting.

Press MENU to advance to the next menu or press

START to begin the program.

The Options Menu

This menu lets you set several options (such as, turning

the buzzer off and on, setting the anti-crease run time,

etc.) Only the options available with the program you

selected will display. (See “The Program Menu” on page

7.)

Select

options

Normal Cooling

< Next >

P1

Menu Enter

Timed Dry and Air Fluff

When you select Timed Dry or Air Fluff on the program

menu, the word “Time” and a number (of minutes) will

flash in the upper right corner of the LED window. This

indicates you must select a program time (5 to 90

minutes).

Select

time

< Next >

P1

Menu Enter

1. To change the number, simply press an Arrow button

until the length of time you want the program to run

displays.

2. Press ENTER to program your change.

Press MENU to advance to the next menu or press

START to begin the program. When you press START,

the time remaining for the program to run displays in

the bottom right-hand corner of the LED window, as

illustrated below:

Air fluff progr.

Anti-Crease 1h

Air fluff

Time

60

Time

60

30

1. On this menu, you press ENTER to advance through

the options, rather than pressing MENU.

2. Press an Arrow button to toggle between Off and On.

3. When your preference displays, press ENTER. The

LED will display the new options.

Press MENU to advance to the next menu or press

START to begin the program.

Page 8

Menu Enter

NOTE: The remaining time toggles between the

minutes remaining (e.g., 23) and the hour(s)

remaining (e.g., 1h).

Page 9

The Delayed Start Program

This program lets you delay starting the dryer for up to

12 hours. This feature is useful in areas where utility

companies offer discount rates during certain hours.

When you select Delayed Start on the program menu,

you must select a delay time (1 to 12 hours).

Select time

for delayed start

< Next >

P1

Menu Enter

1. In the bottom right corner of the LED window, a

clockface and a zero will flash. To change the zero,

simply press an Arrow button until the number of

hours you want to delay starting the program displays

(1–12 hours).

2. Press ENTER to program your change.

Press MENU to advance to the next menu or press

START to begin the program. When you press START,

the clockface and the hours you set for the delay will

display, as illustrated below:

Extra dry

Anti-Crease 1h

Temperature normal

P1

Menu Enter

0

9

RESTORING A PRESETRESTORING A PRESET

PROGRAMPROGRAM

To restore a preset program to its original settings,

simply press the button for the preset program you want

to restore and hold it down while your press ENTER.

The program will revert to its original settings.

CHANGING CHANGING THE LANGUTHE LANGUAAGEGE

ON ON THE LED DISPLATHE LED DISPLAYY

There are eleven languages available for the LED

window:

♦ English

♦ French

♦ Spanish

♦ Portuguese

♦ Italian

♦ Swedish

♦ Danish

♦ Norwegian

♦ Netherlands

♦ Finnish

♦ German

To change the language, follow the steps below:

1. Turn the machine off then on again.

2. Press ENTERENTER five times in succession then press

P1 five times. (This must be done within 15 seconds.)

3. When the Language menu displays, press an Arrow

button to advance through the menu to the desired

language.

4. Once the correct language displays, press ENTER

to program the LED window to display the language

you selected.

CHILD-SAFE STCHILD-SAFE STARARTT

As a safety measure, you can program the T760 and

T780 not to start unless the Start button is held down

for three seconds. To do this, follow the steps below:

1. Turn the machine off then on.

2. Press ENTER five times, then press P3 five times.

(This must be done within 15 seconds.)

3. “Delayed start” displays with “0” flashing in the lower

right corner. Press the right Arrow button to toggle

the display to “3.”

Child-Safe Menu Button

Please note that when you set the child-safe Start button,

the Menu button is automatically programmed to delay

for three seconds before it becomes active. This

prevents a child from accidentally changing the program

settings.

When you want to change a program, press the Menu

button for three seconds to activate the menus. The

Menu button will work normally (without the 3-second

delay) until you have completed your changes. If it is not

pressed for two minutes, it will automatically revert back

to the child-safe mode.

ENGLISH

ENGLISH

ERRERROR MESSAOR MESSAGES – GES – T760/T780T760/T780

Error messages will display in the LED window if a

fault occurs while a program is in progress. The table

below defines each possible error message. If the

ERROR MESSAGE SOLUTION

Three hours

Overflow (T780)

Sensor

Thermistor

Make sure both fuses are intact.

Clean the lint filter.

Make sure exhaust hose is clear (T760).

Clear message by turning the power off then on.

Make sure the condensed water container is empty. If draining into a drain pipe,

make sure the black rubber hose is not kinked or blocked. The drain should not be

higher than 40 inches from the floor.

Make sure the condensation pump is not blocked.

This can appear if there are dry clothes in the drum when the unit is started. Cancel

the error message by opening the door or turning the power off then on.

Call a service technician.

message still displays after you have checked the

possible solutions, call a service technician.

Page 9

Page 10

INSTINSTALLAALLATION INSTRTION INSTRUCTIONSUCTIONS

Read these instructions carefully and completely before

you install the machine. The installation should be

carried out by a qualified person who is familiar with all

local codes and ordinances for electrical and plumbing

connections.

NOTE:

Cosmetic damage must be reported to your

dealer within five days from the date of

purchase. After unpacking the dryer, thoroughly

check the unit for cosmetic damage.

SPECIFICASPECIFICATIONSTIONS

Height 33-1/2”–34-1/2 (850–876 mm)

Width 23-7/16” (595 mm)

Plus exhaust hose connection

Depth T760/T780: 23-7/16" (595 mm)

T700/T720: 24-7/16” (620 mm)

Weight 86 lbs (39 kg)

Drum material Stainless Steel

Outer casing Stove-enamelled hot-dipped

Power requirement 2800 watts

For connection Single-phase, 230 V, 30 Amp

Internal fuse 15 amp.

Heating element 2500 watts

CONNECTING CONNECTING AIR EXHAAIR EXHAUST (T700 UST (T700 AND AND T760)T760)

The exhaust hose can be connected at the rear or on

either side of the dryer. When the machine is delivered,

the exhaust outlet at the rear is open.

The exhaust hose

can be connected at

the rear or on either

side of the dryer.

Rear Exhaust Outlet

Stub

Side Exhaust Outlet

Clamp

The dryer is shipped with a stub pipe already installed

on the rear exhaust outlet. The consumer or installer

must purchase a UL-CSA-approved exhaust hose.

Hose

(not supplied)

Connecting the Vent Hose to the

Left or Right Side Outlet

To connect the exhaust hose to the left or right side

outlet, follow the steps below:

1. Using a flathead screwdriver, turn the exhaust

outlet cover to align the tabs

holding the cover in place.

Remove the cover.

2. Remove the stub pipe from

the rear exhaust outlet.

3. Place the stub pipe in the

outlet you plan to use.

4. Follow the instructions for the rear outlet hose

connection.

5. Use the exhaust outlet cover you removed from the

side to cover the rear exhaust outlet.

galvanized steel

Vent

T-Tube

Rear Outlet Hose Connection

To connect the exhaust hose to the rear outlet, follow

the steps below:

1. Push the hose onto the stub pipe and secure it with

a clamp.

2. With the hose attached, insert the stub pipe into the

hole. It should snap into place.

NOTE: After you push the dryer into place, check for

kinks in the hose. (Be careful not to use too

much hose.)

WARNING!

To reduce the risk of fire, this appliance must be

exhausted OUTDOORS or the equivalent.

Never cover the end of the dryer stub or vent hose

with anything to catch lint, except for UL approved

vent basket.

CONDENSACONDENSATION DRAIN CONNECTION (T720 TION DRAIN CONNECTION (T720 AND AND T780)T780)

If possible, you should install the dryer so the

condensed water will continuously flow into a drain or

sink. To do this, follow the instructions below:

1. Disconnect the short hose (1) from the blue

connection. (It’s okay to let the hose hang down.)

2. Connect the rubber hose supplied with the dryer to

the blue nipple (2).

3. Run the hose to a drain or sink, as illustrated.

NOTE:

Page 10

The drain hose must not be more

than 40” above the floor.

Back of dryer

Page 11

CONNECTING CONNECTING TTO O A A VENTILAVENTILATION DUCT (T700/T760)TION DUCT (T700/T760)

1. Connect the exhaust hose to a ventilation exhaust

fitting or to a discharge through the wall.

2. Secure the hose joint to the outlet stub on the

machine.

3. Run the hose with as few bends as possible to the

point of discharge. If necessary, it can be extended

to a maximum of 22 feet (660 cm) of 4” (10 cm)

diameter ridged pipe.

Make any bends as gentle as possible. A maximum of

four 90° bends may be fitted in the hose. The more

bends and the longer the hose, the less air will circulate

through the machine, which will impede drying

performance. Subtract 4 feet (120 cm) for every 90°

elbow.

Installation Examples

Subtract 4 feet

(120 cm) for

every 90° elbow.

NOTE: When installing in warm climates (77°F and

above) with high humidity levels, do not

route the air exhaust hose upwards.

If more than 22 feet of hose is needed, the diameter

must be increased to 6” or 8” (152 mm or 203 mm).

WARNING!

This appliance should not be exhausted into a

chimney, a wall, a ceiling, or a concealed space of a

building. Only a metal ventilation grill should be used.

If the hose is taken to a wall outlet, a ventilation grill

should be fitted to prevent reverse flow of cold air. Fit the

ventilation grill to the outside or inside of the wall.

Ventilation grill

NOTE:

Make sure nothing is

blocking the ventilation grill.

If there is only one vent duct from the room, a vent spacer

must be fitted.

Vent spacer

ENGLISH

ENGLISH

FREESTFREESTANDING INSTANDING INSTALLAALLATIONTION

The dryer can be placed next to the washing machine.

It is essential that the machine is leveled and the

locknuts are tight to eliminate vibration.

There should be at least 1/2” (12.5 mm) of space

between the washer and dryer.

BBUILUILTT-IN INST-IN INSTALLAALLATIONTION

MODELS T700/T760

These models can be installed beneath a cabinet or

worktop with a minimum height of 34” (864 mm). There

must be a gap of about 1/4” (.64 mm) all around the

machine, including between the rear edge of the

machine top panel and the back wall. The opening width

must be at least 24” (600 mm).

Space must also be available for the exhaust hose on

the left, right or rear of the machine. See the diagram for

hole sizes and positions. Note that the hole

measurements are to the center of the hole.

MODELS T720/T780

The condensing models work best when they have

good air circulation. Therefore, we don’t recommend

that they be installed beneath a cabinet. If it is necessary,

however, be sure to leave a gap of at least 1/2” on all

sides.

NOTE:

All hole measurements are

to the center of the holes.

NOTE: The height adjustment for the dryer is

33-1/2” to 34-1/2” (850 mm to 876 mm).

Do not raise it higher than 34-1/2”.

Page 11

Page 12

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

The power supply cord must be grounded. If the

machine is to be used in a wet area, the supply must

be protected by a residual current device.

NOTE: In Canada, the dryer is delivered ready-fitted with

a four-prong plug intended for connection to a singlephase supply.

Remove cover to

access terminal box.

(Requires a 20-Torx

screwdriver.)

Connection to a permanently wired supply point must

be made only by a qualified electrician.

As supplied: Single-phase, 230 V, 60 Hz,

2500 Watt heater rating

30 A fuse required

CAUTION:

The receptacle on the rear of the machine is designed

to accommodate ASKO washers ONLY (rated 208–

240 V.) To use this receptacle, you must use the readyfitted plug supplied with the washing machine or an

equivalent. The supply connection must be 208–240 V,

20 A.

ASKO washers rated 208–240 V have two internal

fuses of 15 A each.

Connecting a Three-wire Power Cord

WARNING! Before starting this procedure, be sure

the power is turned off at the breaker/fuse box.

Power Supply Cord

You will need a three-wire power supply cord with three

No. 10 copper wires and a matching three-wire

receptacle of NEMA Type 10-30R, as illustrated below:

THREE-WIRE CORD

This blade connects

to this conductor.

Neutral

Spade terminals

with upturned

ends

3/4” UL-listed

strain relief

Ring

terminals

Neutral

(white)

Connecting a Four-wire Power Cord

WARNING! Before starting this procedure, be sure

the power is turned off at the breaker/fuse box.

Power Supply Cord

You will need a four-wire power supply cord with four

No. 10 copper wires and a matching four-wire

receptacle of NEMA Type 14-30R, as illustrated below.

The fourth wire must be identified with a green cover

and the neutral conductor by a white cover.

FOUR-WIRE CORD

Neutral

Ground

prong

Page 12

Spade terminals

with upturned

ends

3/4” UL-listed

strain relief

Ground

(green)

Ring

terminals

Neutral

(white)

1. Turn the power off at the breaker/fuse box.

2. Remove terminal block cover.

3. Use the strain relief attached below the terminal

block opening.

4. Loosen or remove center terminal block screw.

5. Connect neutral wire

(white ) of power

4

supply cord to the

center, silver-colored

terminal screw.

Tighten screw.

6. Connect the other

wires to outer screws.

7. Tighten the strain

6

5

relief screws.

8. Replace terminal box

7

cover on back of dryer.

9. Plug dryer into wall

receptacle.

10. Turn power on at

breaker/fuse box.

1. Turn the power off at the breaker/fuse box.

2. Remove terminal block cover.

3. Use the strain relief attached below the terminal

block opening.

4. Remove center terminal block screw.

5. Remove ground wire

(green with yellow stripes)

from external ground

connector screw. Fasten

5

6

4

under center, silvercolored terminal block

screw.

6. Connect ground wire

(green) of cord to external

7

ground conductor screw.

7. Connect neutral wire (white)

of cord under center screw

8

9

of terminal block.

8. Connect the other wires

to outer screws.

9. Tighten the strain relief screws.

10. Replace terminal box cover on back of dryer.

11. Plug dryer into wall receptacle.

12. Turn power on at breaker/fuse box.

Page 13

STSTAACKED INSTCKED INSTALLAALLATIONTION

ASKO dryers can be mounted on top of any matching

ASKO washer. Mounts are supplied with the machine.

Two metal brackets for

securing the dryer to

the washer

To install the dryer on top of the washer, follow the steps

below:

1. Remove the two outside screws (20 torx) from the

back of the washer and use them to secure the metal

brackets, as illustrated.

Washer

back

2. To ensure the dryer is correctly positioned on top of

the washer, align the plastic cups with the front top

edge of the washer.

Two plastic cups to

secure the dryer legs.

Metal brackets

5. Lift the dryer into

position. Raising the

front edge, push the

dryer backwards until it

engages with the

brackets on the back of

the washer.

6. Carefully lower the front

of the dryer, making sure

the feet fit into the plastic

cups.

Stacked Installation

ENGLISH

ENGLISH

Plastic cups

To position the plastic cups, break off the left tab (A)

on the cup to be placed on the right side of the washer

and break off the right tab (B) on the cup to be placed

on the left side of the washer.

3. Remove the protective

paper from the selfadhesive surface

beneath the cups. Being

careful not to press the

adhesive surface against

the top of the washing

machine, use the tabs to

position the cups (as illustrated) then press them

firmly into place.

4. Once the cups are in place, break off the remaining

plastic tabs.

Tumble dryer

Washer

Total height 67”.

Adjustable to 69”.

WARNING!

Never stack a washer on top of a dryer!

Page 13

Page 14

REVERSING THE DOOR HINGESREVERSING THE DOOR HINGES

The door hinges on ASKO dryers are reversible. The

dryers are shipped left-hinged. To reverse them, follow

the steps below:

WARNING!

1. Remove the two 20 torx

screws on the bottom of

the front panel then

grasp the bottom of the

panel and pull it forward

and down.

2. Remove the three

screws holding the

hinge.

3. Supporting the door from the bottom,

pull it out and to the left as you turn

the hinge counter clockwise.

4. Remove the top hinge pin

then turn the hinge

upside down and put the

hinge pin into the top

hole.

Switch off the main power supply

before you start this procedure.

11. Using a flathead screwdriver,

remove the plastic plugs in the

upper and lower edge of the door

and place them in the empty

holes on the opposite side.

12. Remove the screw in the top right

corner of the front panel, as

indicated in the illustration. (If you

have a condenser dryer, you will

need to open the condenser

container door.)

13. Now you are ready to mount the door on the right

side. Holding the door at an angle (as illustrated),

fit the hinge pin into the top hole.

14. Tighten the screws in the order

illustrated at right (a, b, c).

15. Replace the screw you removed

in step 12 (d).

5. Repeat steps 1–4 for the bottom hinge.

6. Loosen the two screws on both sides of the door

so you can remove the magnetic door latch and the

cover plate.

7. Remove the door

latch by pushing it up

then lifting it out from

the bottom.

8. Remove the cover

plate by pushing it

down then lifting it out

from the top.

9. Reverse steps 6 and 7 to place the door latch and

cover plate into their new positions.

10. Tighten the screws on the sides of the doors to

hold the latch and cover plate in place.

16. Close the condenser container door and replace

the front panel.

17. Turn back on the main power.

Page 14

Page 15

ASKO PRODUCT WARRANTY

MODELS T700, T720, T760, T780

Be sure to complete the Warranty Registration Card you received with your appliance and mail it to ASKO to

validate your appliance warranty.

FOR RESIDENTIAL INSTALLATIONS ONLY

ASKO WILL PAY FOR:LENGTH OF WARRANTY

Three-Year Full Warranty

From date of purchase.

Fourth & Fifth Year Limited Warranty

Three year full plus fourth and fifth year limited

from date of purchase.

Lifetime Warranty

ASKO replacement parts and/or repair labor to correct

defect in materials or workmanship. Service must be

provided by an authorized ASKO service agent.

ASKO replacement parts for any defective solid-state

controls, timers, motors, or pumps.

ASKO will replace the stainless steel inner or outer

drum if it rusts or fails to hold water.

ASKO WILL NOT PAY FOR:

A. Service calls to:

1. Correct the installation of the appliance.

2. Repair damage due to shipment, delivery, installation, misuse or abuse.

3. Instruct how to use the appliance.

4. Replace house fuses or correct house wiring.

5. Correct house plumbing, including drain problems related to improper installation.

6. Clean or service air device in drain line.

B. Repair and/or replacement parts for failure of product if appliance is used for other than home/residential use.

C. Damage resulting from accident, fire, floods, acts of God, alteration, misuse, abuse, improper installation, or

installation not in accordance with local electrical or plumbing codes.

D. Any shipping costs for parts during the limited warranty period.

E. Replacement parts or repair labor costs for units operated outside the Continental United States.

F. Pickup and delivery. ASKO washers are designed to be repaired in the home.

ENGLISH

ENGLISH

IN NO EVENT SHALL ASKO USA INC. BE RESPONSIBLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states will not allow the exclusion or limitation of incidental or consequential damages, so this exclusion or

limitation may not apply to you. This warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

For warranty service, contact the dealer from whom you purchased the unit or an authorized ASKO service agent.

Service will be provided during normal business hours. Should you have a service problem that can not be resolved

locally, write:

ASKO USA Inc.

P. O. Box 851805

Richardson, Texas 75085-1805

Customer Service Center at

800-898-1879 or 972-238-0794

or call our

Page 15

Page 16

INDEXINDEX

AA

Advisory Center phone number 15

Air exhaust, connecting 10

Air fluff, programming 8

Automatic door switch 2

BB

Built-in installation 11

CC

Care and cleaning 4

Care label instructions 3

Changing the LED readouts 9

Child-safe start (T760/T780) 2, 9

Child-safe temperature knob 2

Condensation container, emptying 4

Condensation drain connection 10

Condenser, cleaning 5

Control panel, cleaning 4

Cosmetic damage 10

Customizing the preset programs 7

DD

Delayed start, programming 9

Door, cleaning 4

Door hinges, reversing 14

Door switch 2

Dryer features 3

Drying problems 3, 6

Drying times 3

EE

Electrical connections 12

Error messages (T760/T780) 9

Exhaust hose, cleaning 4

FF

Fabric softener sheets 3

Fabric types 4

Fan, cleaning 5

Freestanding installation 11

HH

Hazardous materials 2

II

Installation instructions 10–14

LL

Languages, changing the LED 9

Lint filter 4

Load sizes, recommended 4

MM

Maintenance instructions 4

Magnetic door lock 2

Menus, programming 8

OO

Options menu 8

Overflow error message 9

Overheat protection 2, 6

PP

Power cord connection 12

Preset programs 7

restoring 9

Problems, solving 6

Program menu 7, 8

Program options 7

RR

Restoring a preset program 9

SS

Safety features 2

Safety instructions 2

Sensidry 3

Sensor error message 9

Service 15

Solutions to problems 6

Sorting the laundry 3

Specifications 10

TT

Temperature menu 8

Temperature settings 4

Thermostat Control 3

Thermistor error message 9

Three hours error message 9

Timed dry, programming 8

Timer control 3

Troubleshooting 6

VV

Ventilation duct connection 11

WW

Warranty information 15

Wash programs 7

Water container, emptying 4

Page 16

Loading...

Loading...