User Instruction Book

for

ARISTON GAS HOB

Model

PF750AST(GH)

00550922

Congratualtions on choosing an Ariston appliance, which you will find is dependable and easy to use . W e recommend

that you read this manual for best performance and to extend the life of your appliance . Thank you.

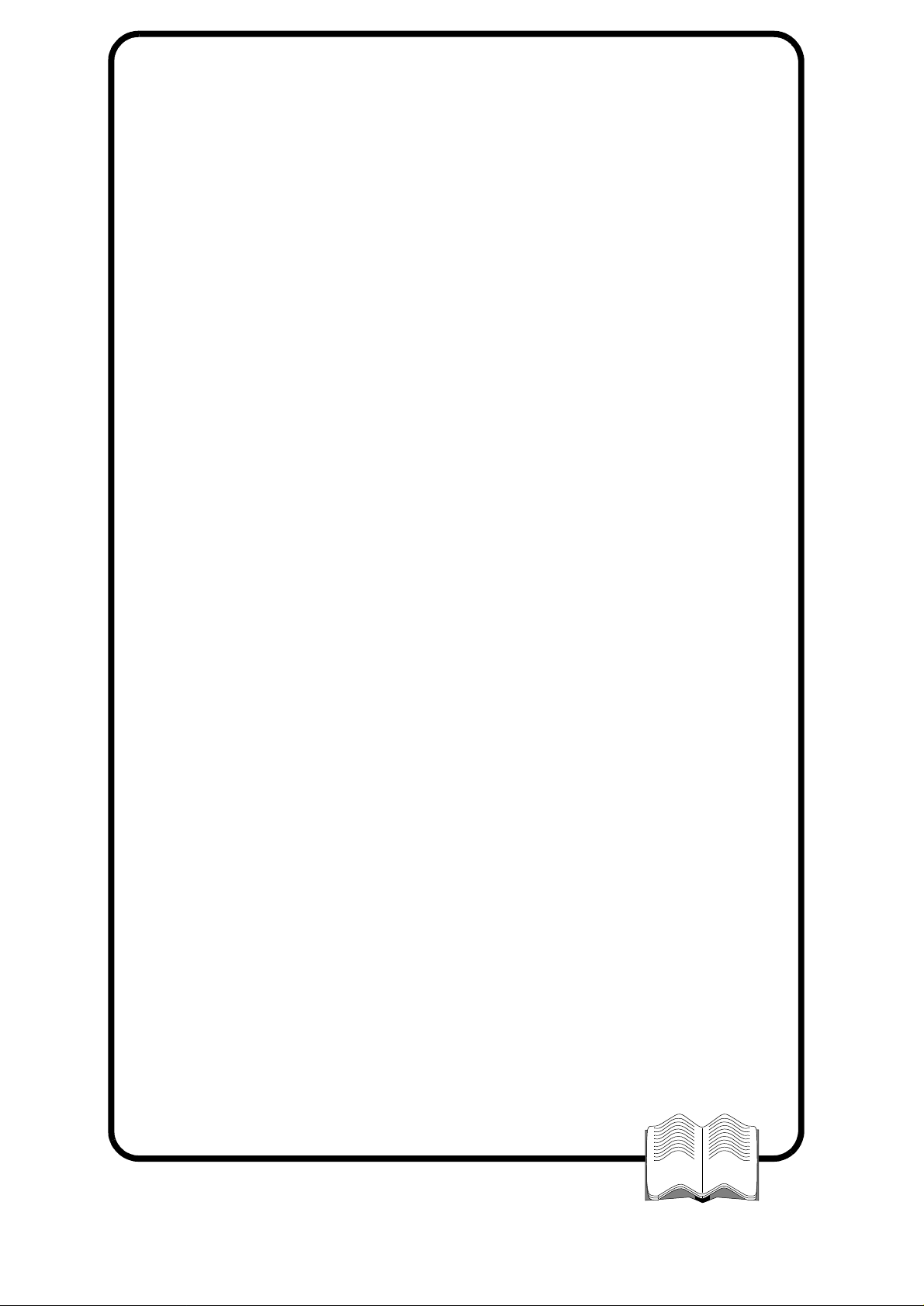

Close-up View

A

G

B

H

EC

A. Gas Burners

B. Support Grid for Cookware

C. Control Knobs for Gas Burners and Electric Hot

Plate

D. Ignitor for Gas Burners (only on certain models)

E. Ignition Button for Gas Burners (only on certain

models)

How T o Use Y our Appliance

F

D

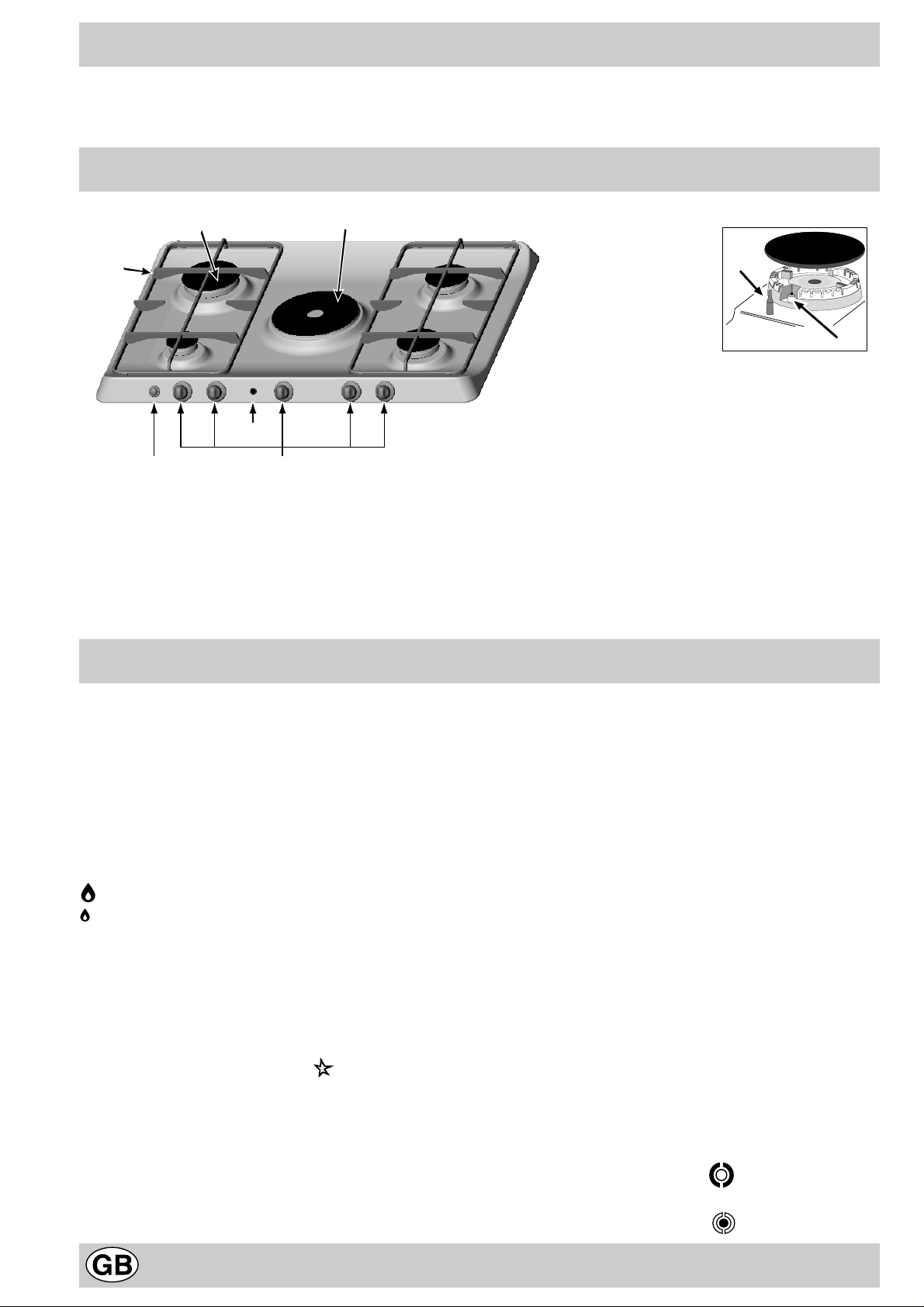

F. Safety Device (only on certain models) - Activates if

the flame accidentally goes out (spills, drafts, etc.),

interrupting the delivery of gas to the burner.

G. Electric Hot Plate (only on certain models)

H. Indicator Light for Electric Hot Plate (only on certain

models)

The position of the corresponding gas burner or electric

hot plate (if present) is indicated on each control knob.

Gas Burners

The burners differ in size and power. Choose the most

appropriate one for the diameter of the cookware being

used.

The burner can be regulated with the corresonding control

knob by using one of the following settings:

• Off

High

Low

T o turn on one of the b urners, place a lighted match or

lighter near the burner, press the knob all the way in and

turn it anti-clockwise to the "High" setting.

On those models fitted with a safety device (F), the

knob must be pressed in for about 6 seconds until the

device that keeps the flame lit warms up .

On those models fitted with an ignitor (D), the "E"

ignition button, identified b y the symbol, must fir st

be pressed and then the corresponding knob pushed

all the way in and turned anti-clockwise to the "High"

setting.

Some models are equipped with an ignition button

incorporated into the control knob. If this is the case, the

ignitor (D) is present, but not the "E" button.

T o light a burner , simply press the corresponding knob

all the way in and then turn it anti-clockwise to the

"High" setting, keeping it pressed in until the burner

lights.

Caution: If the burner accidently goes out, turn off the

gas on the control knob and wait at least 1 minute before

you try to to light it again.

T o turn off a burner , turn the knob clockwise until it stops

(it should be on the “•” setting).

The “separate double flame” burner (only on some

models)

This burner consists of two concentric burners which can

operate either together or separately.

Use of the double flame on the maximum setting gives a

very high power which reduces cooking times with respect

to conventional burners.

Moreover the double flame cro wn provides a more uniform

distribution of heat on the bottom of the pan, when using

both burners on minimum.

Pots and pans of all sizes can be used. In the case of the

smaller pots and pans we recommend the use of only the

internal burner.

There is a separate control knob for each of the “separate

double flame” burners.

The knob marked by the symbol operates the external

burner;

The knob marked by the symbol operates the internal

12

burner.

To turn on one of the rings, press the relative knob in all the

way and turn it anti-clockwise to the high setting . The burner

is fitted with an electronic igniter that automatically starts when

the knob is pressed in.

Since the burner is equipped with a safety device "F", after

lighting the burner keep the knob pressed in for about 6

seconds to allow the device which keeps the flame lit

automatically to heat up.

The selected burner can be regulated using the corresponding

knob, as f ollows:

• Off

High

Low

T o turn off a burner , turn the knob clockwise until it stops

(it should be on the “•” setting).

How to Keep Your Hob in Shape

Electric Hot Plate (only on certain models)

The hot plate can be: "normal" and "fast". The latter can

be identified by a red boss in the center of the hot plate

itself.

The hot plate can be regulated by turning the

corresponding knob in the clockwise or counter-clockwise

direction to any one of the 6 different settings:

0 Off

1 Low

2-5 Medium

6 High

The section entitled, "Practical Cooking Advise", provides

information on the recommended settings for various types

of food or cooking processes.

When the knob is on any of the settings other than "Off",

the "H" operating light comes on.

Before cleaning or performing maintenance on your

appliance, disconnect it from the electrical power supply.

To extend the life of the hob, it is absolutely

indispensable that it be cleaned carefully and

thoroughly on a frequent basis, keeping in mind the

following:

· Do not use steam equipment to clean the appliance.

• The enamelled parts and the glass top, if present, must

be washed with warm water without using abrasive

powders or corrosive substances which could ruin

them;

• The removable parts of the burners should be washed

frequently with warm water and soap, making sure to

remove caked-on substances;

• On hobs with automatic ignition, the end of the

electronic ignition device must be cleaned carefully and

frequently, making sure that the gas holes are not

clogged;

• The electric hobs should be cleaned using a damp cloth

and then rubbed with oil while still warm;

• Stainless steel can be stained if it remains in contact

with highly calcareous water or aggressive detergents

(containing phosphorous) for an extended period of

time. It is recommended that these parts be rinsed

thoroughly with water and then dried well. It is also a

good idea to clean up any spills.

Greasing the Taps

The taps may jam in time or they ma y become difficult to

turn. If so , the tap itself m ust be replaced.

N.B.: This operation m ust be performed by a technician

authorised by the manufacturer.

13

Practical Advice

Practical Advise on Using the Burners

For best performance, f ollo w these general guidelines:

• Use the appropriate cookware for each burner (see

table) in order to prevent the flame from reaching the

sides of the pot or pan;

• Alwasy use cookware with a flat bottom and keep the

lid on;

• When the contents come to a boil, turn the knob to

"Low".

Burner ø Cookware diameter (cm)

Rapid (R) 24 - 26

Reduced Rapid (RR) 24 - 26

Semi-Rapid (S) 16 - 20

Auxilliary (A) 10 - 14

Half-Fishburner (S P) 16 - 20

Triple Crown (TC) 24 - 26

Ultrarapid (UR) 24 - 26

Fishburner (P) Oval cookware

Double flame (DCDR

internal)

Double flame (DCDR

external)

N.B. On the models supplied with a reducer shelf, remember

that this should be used only for the Double flame internal

(DCDR internal) burner when you use casserole dishes with

a diameter under 12 cm.

Practical Advice on Using the Electric Hot Plates

In order to avoid heat loss and damage to the hot plate,

use cookware with a flat bottom the diameter of which is

not less than that of the hot plate.

10 -14

26 - 28

Before using the hot plates for the first time, you

should heat them at maximum temperature for

approximately 4 minutes, without any pans. During

this initial stage, their protective coating hardens and

reaches its maximum resistance.

Practical Advice on Using the Half Fish-Kettle

Burner

The two central burners, or Half Fish-Kettle burners, are

eliptic in form and can be turned up to 90°. This makes

the cooktop more flexible in terms of how it can be used.

To turn the two central burners 90°, proceed as follows:

• Make sure that the burners are cool;

• Lift the burner completely out of its housing;

• Replace it in its housing in the position desired;

• Make sure that the burners are positioned correctly

before use.

In addition, the two cetnral burners can be used in tandem

or speartely with cookware of different shapes and sizes:

• Double burner for a fish-kettle or oval cookware (Fig. A).

• Double burner for a griddle or rectangular/square

cookware with minimum dimensions of 28x28 cm

(Fig. B)

• Double burner for large cookware (diameter of 24-26

cm) (Fig. C).

• Single burner for medium size cookware (diameter of

16-20 cm) (Fig. D).

Setting Normal or Fast Plate

0 Off

1 Cooking vegetables, fish

2

3

4

5

6

Cooking potatoes (usin g stea m) sou ps,

chickpeas, bea ns.

Continuing the cooking of lar ge quan tities

of food, minestrone

For roasting (average)

For roasting (above a verage )

For browning and reachi ng a boi l in a

short time.

Fig. A Fig. B

Fig. C Fig. D

14

Is there a problem?

It may occur that the cooktop does not function or does

not function properly . Before calling customer service for

assistance, lets see what can be done.

First of all, check to see that there are no interruptions in

the gas and electrical supplies, and, in particular, that the

gas valves f or the mains are open.

The burner does not light or the flame is not uniform

around the burner.

Check to make sure that:

• The gas holes on the burner are not clogged;

• All of the movable parts that make up the burner are

mounted correctly;

• There are no draughts around the cooking surface.

The flame does not stay lighted on the model with

the safety device.

Check to make sure that:

• You press the knob all the way in;

• You keep the knob pressed in long enough to activate

the safety device .

• The gas holes are not clogged in the area

corresponding to the safety device.

The burner does not remain on when set to "Low".

Check to make sure that:

• The gas holes are not clogged.

• There are no draughts near the cooking surface.

• The minimum has been adjusted correctly (see the

section entitled, "Minimum Regulation").

The cookware is not stable.

Check to make sure that:

• The bottom of the cookware is perfectly flat.

• The cookware is centered correctly on the burner or

electric hot plate.

• The support grids have not been inverted.

If, despite all of these checks, the cooktop does not

function properly and problem persists, call the nearest

Merloni Elettrodomestici Customer Service Centre,

informing them of:

- The type of prob lem.

- The ab breviation used to identify the model (Mod. ...) as

indicated on the warranty.

Never call upon technicians not authorized by the

manufacturer, and refuse to accept spare par ts that are

not original.

Safety Is a Good Habit to Get Into

To maintain the EFFICIENCY and SAFETY of this appliance, we recommend:

• call only the Service Centers authorized by the manufacturer

• always use original Spare Parts

• This manual is for a class 3 built-in cooktop .

• This appliance is designed for non-professional use in

the home and its features and technical characteristics

must not be modified.

• These instructions are only valid for the countries the

symbols for which appear on the manual and the serial

plate.

• The electrical system of this appliance is safe only when

it is correctly connected to an adequate earthing

system, as required by current safety standards.

Prevent children and the disabled from coming into

contact or having access to the following, as the y

are possible sources of danger:

- The controls and the appliance in general;

- The packaging (plastic bags, polystyrene, nails, etc.);

- The appliance, during and immediately after use given

the heat generated by its use;

- The appliance when no longer in installed (in this case,

all potentially dangerous parts must be made safe).

The following should be av oided:

- T ouching the appliance with wet parts of the body;

- Using the appliance with bare feet;

- Pulling on the appliance or the power supply cord to

disconnect them from the electrical outlet;

- Improper and/or dangerous use;

- Obstructing the ventilation or heat dissipation slots;

- Allowing the power supply cord of small appliances to

come into contact with the hot parts of the cooktop;

- Exposure to atmospheric agents (rain, sun);

- Using flammable liquids nearby;

- Using adaptors, multiple outlet plugs and/or extensions;

- Using unstable or deformed cookware;

- Leaving the electric hobs on without cookware on top

of them;

- Closing the glass top (if present) while the gas burners

or electrical hot plates are still hot;

- Tr ying to install or repair the appliance without the

assistance of qualified personnel.

The assistance of qualified personnel must be called

upon in the following cases:

- Installation (in accordance with the manufacturer's

instructions);

- When in doubt about the operation of the appliance;

- Replacement of the electrical outlet becuase it is

incompatible with the plug.

Contact service centers authorized by the

manufacturer in the following cases:

- When in doubt about the condition of the appliance

after having removed the pac king;

- Damage to or replacement of the power supply cord;

- In the case of a breakdown or malfunction: ask for

original spare parts.

15

It is recommended that you follow the guidelines

below:

- Only use the appliance to cook food, avoiding all other

uses;

- Check the condition of the appliance after it has been

unpacked;

- Disconnect the appliance from the power supply in the

event of malfunction and always before cleaning or

maintenance;

- When not in use, disconnect the appliance from the

power supply and turn off the gas valve (if present);

Installation Instructions for b uilt-in

- Always check to make sure that the control knobs are

on the “•”/”o” setting when the appliance is not in use;

- Cut the power supply cord after disconnecting it from

the electrical mains when you decide to no longer use

the appliance.

• The manufacturer will not be held liable for any

damages arising out of : incorrect installation or

improper, incorrect or unreasonab le use..

The following instructions are intended for the installer so that

the installation and maintenance procedures may be f ollowed in

the most professional and expert manner possible . Important:

Disconnect the appliance from the electrical supply before

performing any maintenance or regulation upkeep work.

Positioning the Cooktop

Important: this unit may be installed and used only in

permanently ventilated rooms in accordance with British

Standard Codes Of Practice: B .S. 6172 / B.S . 5440, Par . 2 and

B.S. 6891 Current Editions. The following requirements must be

observed:

a) The room must be fitted with a ventilation system which vents

smoke and gases from combustion to the outside. This m ust

be done by means of a hood or electric ventilator that turns

on automatically each time the hood is operated.

Detail A Adjacent Room to be

Room Vented

A

Examples of ventilation holes Enlarging the ventilation slot

for comburant air . between window and floor.

Fig. A Fig. B

c) Intensive and prolonged use of the appliance may necessi-

tate supplemental ventilation, e.g. opening a window or

increasing the power of the air intake system (if present).

d) Liquidified petroleum gases are heavier than air and, as a

result, settle downwards. Rooms in which LPG tanks are

installed must be fitted with ventilation openings to the outside

in order to allow the gas to escape in the event of a leak.

Therefore, LPG tanks, whether empty or partially full, must

not be installed or stored in rooms or spaces below ground

level (cellars , ect.). It is also a good idea to keep only the tank

currently being used in the room, making sure that it is not

near sources of heat (ovens, fireplaces, stoves, etc.) that

could raise the internal temperature of the tank above 50°C.

In a chimney stack or branched flue . Directly to the Outside

(exclusively for cooking appliances)

b) The room must also allow f or the influx of the air needed for

proper combustion. The flo w of air for combustion purposes

must not be less than 2 m³/h per kW of installed capacity.

The supply of said air can be effected by means of direct

influx from the outside through a duct with a inner cross

section of at least 100 cm² which must not be able to be

accidentally block ed. Those appliances which are not fitted

with a safety device to prevent the flame from accidentally

going out must have a ventilation opening twice the size

otherwise required, i.e. a minimum of 200 cm² (Fig. A).

Otherwise, the room can be vented indirectly through adjacent

rooms fitted with ventilation ducts to the outside as described

above, as long as the adjacent rooms are not shared areas ,

bedrooms or present the risk of fire (Fig. B).

Installation of Built-in Cooktops

The appliance can be installed next to furniture units which

are no taller than the top of the cooker hob. The wall in

direct contact with the back panel of the cooker must be

made of non-flammable material. During operation the

back panel of the cooker could reach a temperature of

50°C above room temperature. Fo r proper installation of the

cooktop, the follo wing guidlines must be followed:

a) If the cabinet(s) located next to the cooktop are higher than

the cooktop itself, the cabinet(s) must be installed at least

110 mm from the edge cooktop;

b) Hoods must be installed in accordance with the instructions

contained in the installation manual for the hoods themselves,

and no less than 650 mm from the cooktop;

c) In the case of the 600 mm cooker hoods, besides following

the recommendations in point b), the cabinets should be

positioned next to the hood at a height of at least 540 mm

from the top since this will make it possible to install the lid

and move it correctly . The cabinet should always be installed

16

at a height from the top which allows easy use of pots and

pans on the cooker .

d) Should the cooktop be installed directly under a cupboard,

the latter should be at least 700 mm (millimetres) from the

top, as shown in Figure.

600mm min.

N.B: Use the clamps contained in the "accessory kit."

f) In the event the cooktop is not installed abov e a built-in oven,

a wood panel must be inserted as insulation. This panel must

be placed at least 20 mm from the bottom of the cooktop

itself.

Important: When installing the cooktop above a built-in oven,

the oven should be placed on two wooden strips; in the case of

a joining cabinet surface, remember to leav e a space of at least

45 x 560 mm at the back.

700mm min.

540mm min.

e) The dimensions of the cutout for the appliance must be those

indicated in the figure. Clamps are provided to fasten the

cooktop to counters measuring from 20 to 40 mm in thickness.

T o fasten the cooktop securely , it is recommended that all the

clamps be used.

55

mm

475

mm

555

mm

Fastening Clamps - Assembly Diagram

Clamp Position f or Clamp Position f or

H=20mm top H=30mm top

Front

45 mm.

560 mm.

When installing the cooktop above a built-in ov en without forced

ventilation, ensure that there are air inlets and outlets for v entilating

the interior of the cabinet adequately .

Gas Connection for Cooktop

The cooktop should be connected to the gas supply by an

authorized installer. During installation of this product it is essential

to fit an approved gas tap to isolate the supply from the appliance

for the convenience of any subsequent removal or servicing.

Connection of the appliance to the gas mains or liquid gas tanks

must be carried out according to the safety standards currently

in force, and only after it is ascertained that it is suitable for the

type of gas to be used. If not, f ollow the instructions indicated in

the section entitled, “Adapting the Cooktop for Diff erent T ypes of

Gas”. If the cooktop is to be connected to tanks containing liquid

gas, use pressure regulators that comply with current safety

standards.

Important: T o insure that the appliance operates saf ety, the gas

is regulated correctly and your appliance lasts over time, mak e

sure that gas pressure levels comply with the indications giv en

in Table 1, “Nozzle and Burner Specifications”.

Clamp Position f or

H=40mm top Back

Gas Connection to Non-flexible Pipe

(copper or steel)

Connection to the gas source must be done in such a way as to

not create any stress points at any part of the appliance.

The appliance is fitted with an adjustable, "L" shaped connector

and a gasket for the attachment to the gas supply. Should this

connector have to be turned, the gasket must be replaced

(supplied with the appliance).

The gas feed connector to the appliance is a threaded, male 1/

2" connector for round gas pipe.

17

Gas Connection to Flexible Steel Pipe

The gas feed connector to the appliance is a threaded, male 1/

2" connector for round gas pipe. Only use pipes, tubes and

gaskets that comply with current safety codes . The maximum

length of the flexible pipes m ust not exceed 2000 mm. Once the

connection has been made, ensure that the flexib le metal tube

does not touch any moving parts and is not crushed.

Check the Seal

Once the appliance has been installed, make sure all the

connections are properly sealed, using a soapy water solution.

Never use a flame .

Electrical Connection

The cooktops fitted with a tripolar electrical supply cord are

designed to be be used with alternating current according to the

indications on the rating plate located under the cooktop. The

earthing wire can be identified by its yellow-green colour .

In the case of installation over a b uilt-in electric oven, the

electrical connections for the cooktop and oven should be

independent, not only for saf ety purposes, but also to facilitate

removal of one or both in the future.

Electrical Connection for Gas Cooktop

Fit the supply cord with a standard plug for the demand rate

indicated on the rating plate or connect it directly to the electrical

mains. In the latter case, a single pole switch must be placed

between the appliance and the mains, with a minimum opening

between the contacts of 3 mm in compliance with current safety

codes (the earthing wire must not be interrupted by the switch).

The power supply cord must be positioned so that it does not

reach a temperature in excess of 50°C abov e room temperature at any point.

Before making the actual connection, make sure that:

• The fuse and electrical system can withstand the load

required by the appliance;

• That the electrical supply system is equiped with an efficient

earth hook-up according to the norms and regulations

prescribed by law;

• That the plug or switch is easily accessible.

Important: the wires in the mains lead are coloured in

accordance with the following code:

Green & Yellow - Earth

Blue - Neutral

Brown - Live

As the colours of the wires in the mains lead may not correspond

with the coloured markings identifying the terminals in your plug,

proceed as follows:

Connect the Green & Yellow wire to the terminal marked “E” or

or coloured Green or Green & Yellow.

Connect the Brown wire to the terminal marked “L” or coloured

Red.

Connect the Blue wire to the terminal marked “N” or coloured

Black.

replace them with those for the new type of gas. (See table 1,

“Burner and Nozzle Specifications”).

• Reassemble the parts following the instructions in reverse

order.

• On completing the operation, replace the old rating label with

the one showing the new type of gas; the sticker is av ailable

from our Service Centres.

If the gas pressure is different than that prescribed, a pressure

regulator must be installed at the source, in compliance with

national standards governing the use of piped gas regulators.

Replacing the nozzles on separate “doub le flame “

burners:

• remove the grids and slide the burners from their

housings. The burner consists of 2 separate parts (Fig.

C and fig. D);

• unscrew the burers with a 7 mm wrench spanner. The

internal burner has a nozzle, the external burner has

two (of the same size). Replace the nozzle with models

suited to the new type of gas (see table 1).

• replace all the components by repeating the steps in

reverse order.

Fig. C Fig. D

Regulation of Air Supply to the Burner

The burners do not need a primary air regulator.

Minimum Regulation

• T urn the gas valv e to minimum.

• Remove the knob and turn the regulator screw (positioned

either on the side of the top or inside the shaft) clockwise

until the flame becomes small but regular.

N.B.: In the case of liquid gas, the regulation screw must be fully

screwed in (clockwise).

• Make sure that, when the knob is turned rapidly high to low ,

the flame does not go out.

• In the event of a malfunction on appliances with the security

device (thermocouple) when the gas supply is set at

minimum, increase the minimum supply levels using the

regulator screw .

Once the adjustment has been made, apply sealing wax, or a

suitable substitute, to the old seals on the by-pass.

Adapting the Cooktop for Different Types of Gas

T o adapt the cooktop to a different type of gas than that f or which

it was designed, (see the sticker under the hob or on the

packaging), the burner nozzles must be changed, as follows:

• Remove the pan supports and slide the burners out of the

cooktop.

• Unscrew the nozzles using a 7mm socket wrench and

18

Characteristic of the burners and nozzles

Table1 (For Hungary)

(only model PF 760...)

Burner By-pass

1/100 (mm)

Thermal

power kW

G 20 G 25.1 G 30

Nozzle

1/100 (mm)

Thermal

power kW

Nozzle

1/100 (mm)

Thermal

power kW

1/100 (mm)

Nozzle

Semi-Fishburner (SP ) 63 1,50 88 1,20 88 1,30 60

Reduced Fast (RR) 41 2,60 110 2,00 110 2,30 80

Semi Fast (S) 30 1,90 106 1,50 106 1,70 70

Auxiliary (A) 30 1,00 79 0,70 79 0,90 50

Double flame (DCDR

internal)

30 1,00 70 0,85 70 0,90 44

Double flame (DCDR

external)

57 4,60 114 3,60 114 4,10 70

2 nozzle

Supply pressures 25 mbar 25 mbar 30 mbar

At 15°C and 1013 mbar-dr y gas

P.C.I. G20 35,9 MJ/m

3

Ta ble 1

Burner Diameter

(mm)

Thermal power

kW (p.c.s.*)

By-Pass

1/100

P.C.I. G30 122,8 MJ/m

P.C.I. G25.1 30,9 MJ/m

Liquid Gas Natural Gas

Nozzle

1/100

Flow*

g/h

3

3

Nozzle

Flow*

1/100

l/h

Nomin. Ridot. (mm) (mm) *** ** (mm)

Fast (R) 100 3,00 0,70 41 86 218 214 116 286

Reduced Fast

(RR)

100 2,60 0,70 41 80 189 186 110 248

Semi Fast (S) 75 1,90 0,40 30 70 138 136 106 181

Auxiliary (A) 55 1,00 0,40 30 50 73 71 79 95

Triple Crown

(TC)

130 3,60 1,30 57 94 262 257 137 343

Ultrarapid (UR) 100 3, 40 0,70 41 91 240 236 123 314

Fishburner (P) — 3,00 1, 30 63 86 218 214 116 286

Semi-Fishburner

(SP)

Double flame

(DCDR internal)

— 1,50 0,70 41 60 109 107 88 143

30 0,90 0,40 30 44 65 64 70 86

Double flame

(DCDR external)

130 4,10 1,30 57 70 298 293 114 390

2 nozzle

Supply

Pressures

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

28-30

20

35

37

25

45

20

17

25

* At 15°C and 1013 mbar-dry gas

** Propane P.C.S. = 50.37 MJ/kg.

*** Butane P.C.S. = 49.47 MJ/kg.

Natural P.C.S. = 37.78 MJ/m

3

This appliance conforms with the following Eur opean

Economic Community directives:

- 73/23/EEC of 19/02/73 (Low V oltage) and subsequent

modifications;

- 89/336/EEC of 03/05/89 (Electromagnetic

Compatibility) and subsequent modifications;

- 90/396/EEC of 29/06/90 (Gas) and subsequent

modifications;

- 93/68/EEC of 22/07/93 and subsequent modifications.

19

S

S

A

RR

P

S

S

A

RR

S

DCDR

R

A

S

RR

A

S

S

RR

A

SP

S

SP

S

PF 740 A / PF 740 AS PF 741 A / PF 741 AS

PF 740 A.1 / PF 740 AS.1 PF 741 A.1 / PF 741 AS.1

RR

A

UR

S

S

RR

TC

A

S

S

PF 750 A / PF 750 AS PF 750 AST

PF 750 AST R

PF 750 ASP PF 760 AS

PF 760 DR GH

20

Loading...

Loading...