Ariston ST ProTech 80, STD ProTech 500, ST ProTech 100, STD 125, STD 150 Instructions For Installation And Use Manual

...Page 1

Instructions for Installation,

Servicing and Use

LEAVE THESE INSTRUCTIONS WITH THE

END-USER

Unvented Hot

Water Storage

Cylinders

Countr

y of destination:

GB/IE

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 2

2

TABLE OF CONTENTS 1. GENERAL INFORMATION

1.1 DELIVERY

2. INSTALLATION

2.1 WATER REGULATIONS

2.2 BUILDING REGULATIONS

2.3 HOW THE APPLIANCE WORKS

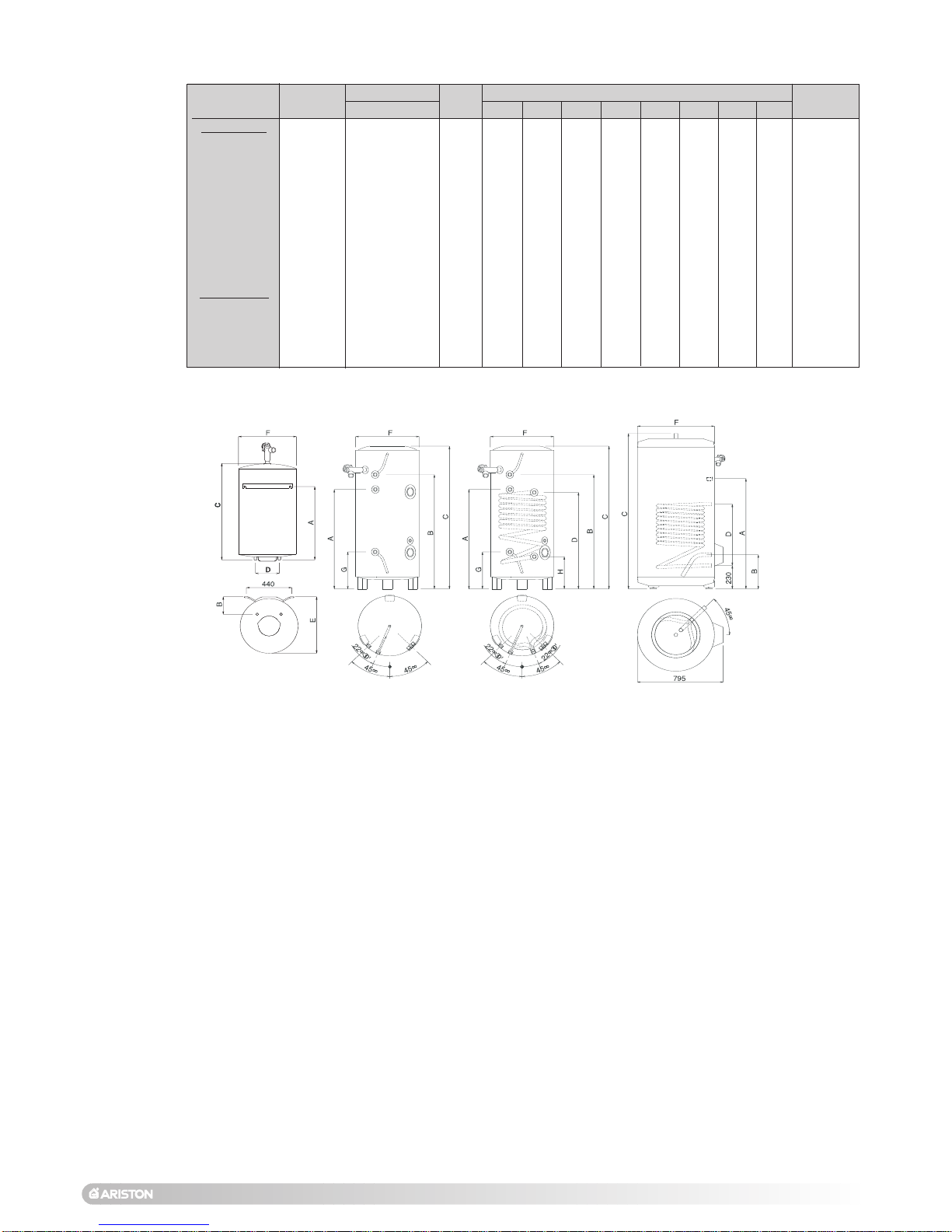

2.4 OVERALL DIMENSIONS

2.5 COLD WATER SUPPLY

2.6 SITING AND FIXING

2.7 CONNECTION OF MAINS WATER SUPPLY

2.8 COLD WATER COMBINATION VALVE

2.9 CONNECTION TO SERVICES

2.10 SECONDARY RETURN

2.11 DISCHARGE PIPEWORK

2.12 ELECTRICAL DIAGRAMS

3. COMMISSIONING

4. MAINTENANCE

4.1 PROTECH ANTI-CORROSION SYSTEM

4.2 THERMAL CUT-OUT(S)

4.3 IMMERSION HEATER(S)

4.4 U

NVENTED CONTROLS

4.5 THERMOSTATS

4.6 MAINTENANCE

5. FAULT FINDING

6. TECHNICAL INFORMATION

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 3

3

This manual is an integral and essential part of the product. It should be kept

with the appliance so that it can be consulted by the user and our authorised

personnel.

Please read carefully the instr

uctions and notices about the appliance

contained in this manual, as they provide important information regarding the

safe installation, use and maintenance of the cylinder.

Failure to do so may invalidate the guarantee.

The Ariston range is available in the following options:

The

Wall-hung ProTech range (50, 75, 100 litre models), which are supplied

as follows;

One box containing;

1) The cylinder with factory fitted temperature & pressure relief valve,

immersion heater and thermostat with thermal cut-out.

One bo

x containing;

1) Unvented control pack (expansion vessel, 2 piece cold water combination

valve and tundish), instructions for installation, servicing and use and the

Benchmar

k Log Book).

The Contract ProTech floor-standing range (100, 125, 150, 200 and 300 litre

models), which are supplied as follows;

One box containing;

1) The cylinder with factory fitted temperature & pressure relief valve.

One box containing;

1) Unvented control pack (expansion vessel, 2 piece cold water combination

valve and tundish), motorised valve (indirect only). Immersion heater(s)

and thermostat(s) with thermal cut-out(s), cylinder thermostat with

thermal cut-out (indirect only), feet (x3), instructions for installation,

servicing and use and the Benchmark Log Book.

The

High Capacity ProTech floor-standing range (500 litre models), which

are supplied as follows;

One box containing;

1)

The cylinder with factory fitted temperature & pressure relief valve.

1) Unvented control pack (expansion vessel, 2 piece cold water combination

v

alv

e and tundish), motor

ised v

alv

e (indirect only). Immersion heater(s)

and thermostat(s) with thermal cut-out(s), cylinder thermostat with

thermal cut-out (indirect only), feet (x 3), instructions for installation,

servicing and use and the Benchmark Log Book.

The

Classico and Primo floor-standing ranges (125, 150, 200 and 300 litre

models).

Are supplied with the f

ollo

wing;

One bo

x containing;

1) The cylinder with factory fitted temperature & pressure relief valve.

One bo

x containing;

1) Unvented control pack (expansion vessel, 2 piece cold water combination

valve and tundish), motorised valve (indirect only). Immersion heater(s)

and ther

mostat(s)

with ther

mal cut-out(s), cylinder ther

mostat with

ther

mal cut-out (indirect only), f

eet (x3), instr

uctions for installation,

servicing and use and the Benchmark Log Book.

1. GENERAL

INFORMATION

1.2 DELIVERY

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 4

4

2.3 HOW THE APPLIANCE

WORKS

2. INSTALLATION

These regulations (byelaws in Scotland) ensure a good supply of

wholesome water, and that only approved materials, pipes and fittings are

used to convey water.

These are a statutory document and take priority over all other regulations

and recommendations. The installation of an unvented hot water storage

cylinder is classified as a “Controlled Service” and Regulation G3 applies.To

meet the requirements of the Regulation, installation of an unvented system

should be undertaken by a “competent installer”.

All installations of unvented hot water storage systems having a capacity of

more than 15 litres should be notified to the relevant Local Authority by

means of building notice or by the submission of full plans. It is important to

note that it is a criminal offense to install an unvented hot water storage

system without notifying the Local Authority. The installation of the unvented

cylinder and hot water system must comply with BS 6700 and the HSE

Legionella Code of Practice.

The immersion heater(s) are controlled through a thermostat which senses

the water temperature. The operating temperature can be pre-set by

adjusting the spindle in the head of the thermostat. In addition to the

thermostat there is a thermal cut-out incorporated if the thermostat fails and

the water temperature rises too high. Once the cut-out operates it can only

be re-set manually after the fault has been rectified.

Indirect models have dual thermal controls. In addition to the above there is

a separate cylinder thermostat and thermal cut-out for controlling the indirect

circuit. Again the thermal cut-out operates if the cylinder thermostat fails, by

disconnecting the live feed (call for hot water) from the programmer.

Classico (STD/STI) models have magnesium anodes provided to prevent

corrosion of the cylinder tank.

All

High Capacity (STD/STI) 500 litre models, Wall-hung (ST) units and the

Contract (STD/STI) Floor-standing models utilise the ProTech anti-corrosion

system (electronic anode).

The factory fitted temperature & pressure relief valve at the top of the

cylinder is a safety device to back-up the thermostat(s) and thermal cutout(s). It works by sensing an excess in water temperature or pressure and

releasing the hot water into a discharge tundish and drain.

The cylinder will only work in the vertical position. The inlet pipe needs to

deliver cold water to the bottom of the tank. When water is heated it

expands. To accommodate this increase in volume an expansion vessel is

provided. A cold water combination valve is also provided in two pieces,

loose jointed for ease of installation. These comprise a combined line

strainer/pressure reducing valve and core non-return valve/expansion relief

valve.

The strainer prevents any debris entering the other controls. The pressure

reducer ensures the correct operation of the expansion vessel, and prevents

any damage to the control valves through too great a pressure.

The non-return valve ensures the water expansion is forced into the

e

xpansion v

essel and pre

v

ents contamination of the mains cold w

ater

supply

.

The e

xpansion relief v

alv

e will discharge e

xpanded w

ater to the

discharge tundish if the e

xpansion vessel fails.

2.1 WA

TER

REGULA

TIONS

2.2 BUILDING REGULATIONS

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 5

5

It is important to ensure that the cold water main is capable of supplying the

increased demand which will be imposed on it.

Hot and cold w

ater are both

drawn off the same source of supply. Remember, there will not be a storage

tank to help compensate for variations in the demand on the system.

A minim

um pressure of appro

ximately 1.5 bar and 20 litres per min

ute is

required f

or satisf

actor

y oper

ation.

85% of UK dw

ellings ha

ve a mains

pressure above 2.0 bar.

NOTE:

THE MAINS

W

A

TER SUPPL

Y MUST NOT EXCEED 16 BAR.

The cylinder should be left pac

k

ed until it is time to install.

When unpacking

the appliance follow the guidelines within the packaging and take care not to

damage the temperature and pressure relief valve.

The cylinder ma

y be installed at any convenient position, as it is connected

to the mains cold water supply, it is equally effective on any floor, however,

consideration must be given to allow ease of access for maintenance

purposes.

Ho

w

e

ver, do not install the unit in premises which may be subject to

freezing. Ensure that the floor load bearing strength is adequate to take the

weight of the cylinder when full of water (see

TABLE 1).

The ST50, ST80 and ST100 ProT

ech

models are w

all mounted. All other

models are free standing. These are supplied with feet which are attached to

the heater via self-tapping screws which are also supplied. All units must be

installed in the VERTICAL POSITION.

For maintenance purposes leave at least 500 mm free space in front of the

unit, for access.

2.5 COLD WATER SUPPLY

2.4 OVERALL DIMENSIONS

2.6 SITING AND FIXING

DIRECT RANGE

Wall-hung

ST 50

ST 80

ST 100

Floor Standing

STD ProTech

STD / STD ProTech / ITD 125

STD / STD ProTech / ITD 150

STD / STD ProTech / ITD 210

STD / STD ProTech / ITD 300

500 STD ProTech

INDIRECT RANGE

STI / STI ProTech / ITI 125

STI / STI ProTech / ITI 150

STI / STI ProTech / ITI 210

STI / STI ProTech / ITI 300

500 STI ProTech

50 l

75 l

100 l

100 l

125 l

150 l

200 l

300 l

495 l

125 l

150 l

200 l

300 l

495 l

1/2”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4"

1”

3/4”

3/4”

3/4”

3/4”

1"

410

590

550

530

700

840

990

1215

1390

700

840

990

1215

1390

-

-

-

-

-

-

-

-

-

0.75

0.9

0.9

0.9

1.5

120

175

175

650

805

965

1280

1555

335

805

965

1280

1555

335

580

740

700

890

1045

1205

1525

1790

1870

1045

1205

1525

1790

1870

160

230

230

-

-

-

-

-

-

675

815

815

815

700

475

475

575

-

-

-

-

-

-

-

-

-

-

-

460

460

560

505

505

505

505

560

714

505

505

505

560

714

77

115

141

129

158/138*

190/164*

245/220*

385/331*

630

166/143**

201/171**

256/227**

395/337**

641

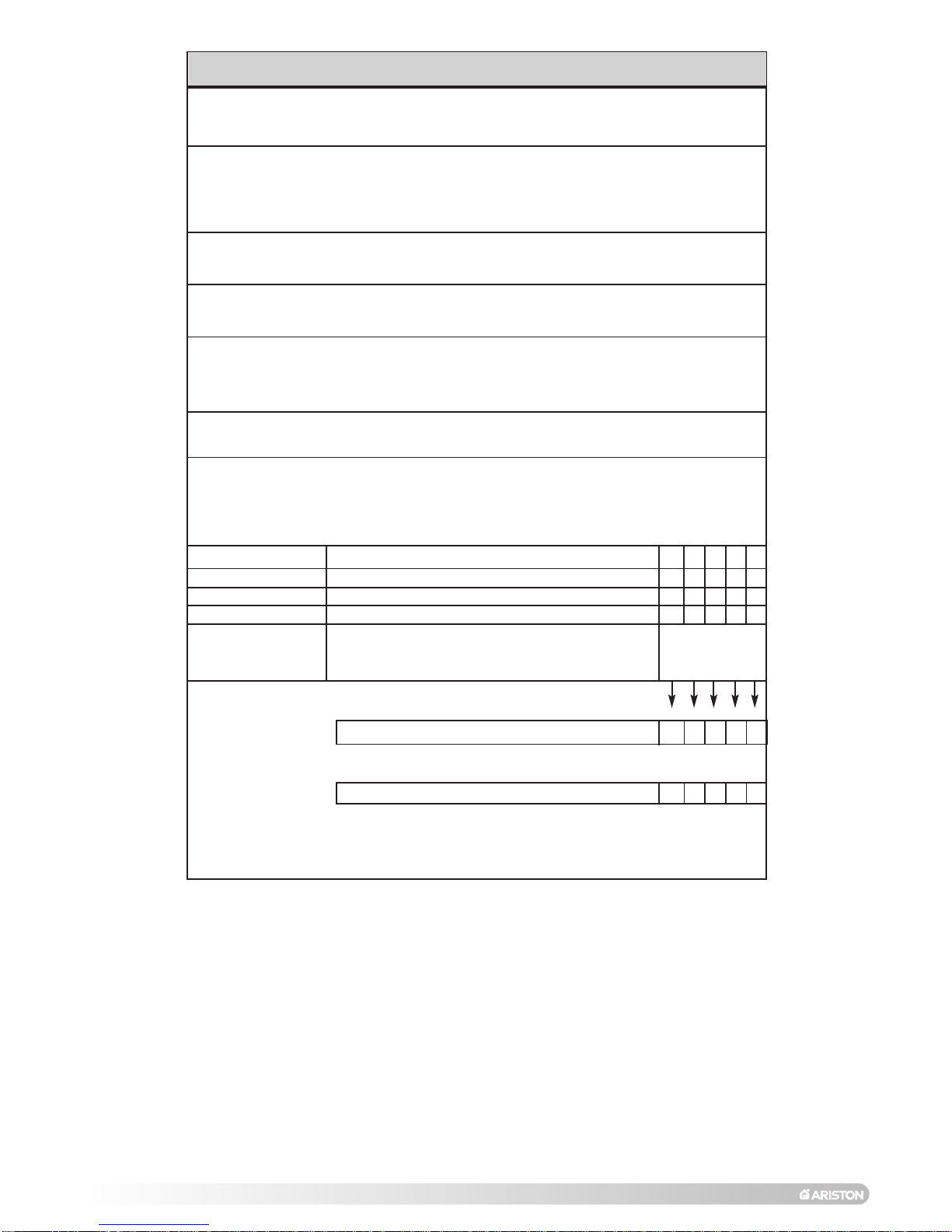

TABLE 1

Model Storage Units Pipe Size Coil Dimensions in mm Weight

Surface When Full

Capacity Inlet Outlet m

2

ABCDEFGH Kg

265

265

265

265

275

265

265

265

275

225

225

225

225

255

225

225

225

255

*ITD Models **ITI Models

ST ProT

ech

50-80-100

500 STD ProT

ech

500 STI ProT

ech

STD/STD ProT

ech/ITD

125-150-200-300

STI/STI ProT

ech/ITI

125-150-200-300

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 6

6

SECONDARY

RETURN

COMBINATION

V

ALVE

EXPANSION RELIEF

PIPE

COLD

M

AINS-IN

22mm

DRAIN

E

XPANSION

VESSEL

PRESSURE + TEMPERATURE

RELIEF VALVE

HOT SUPPLY

22mm

TUNDISH

22mm

MAX. 100mm

FIG.

2.2

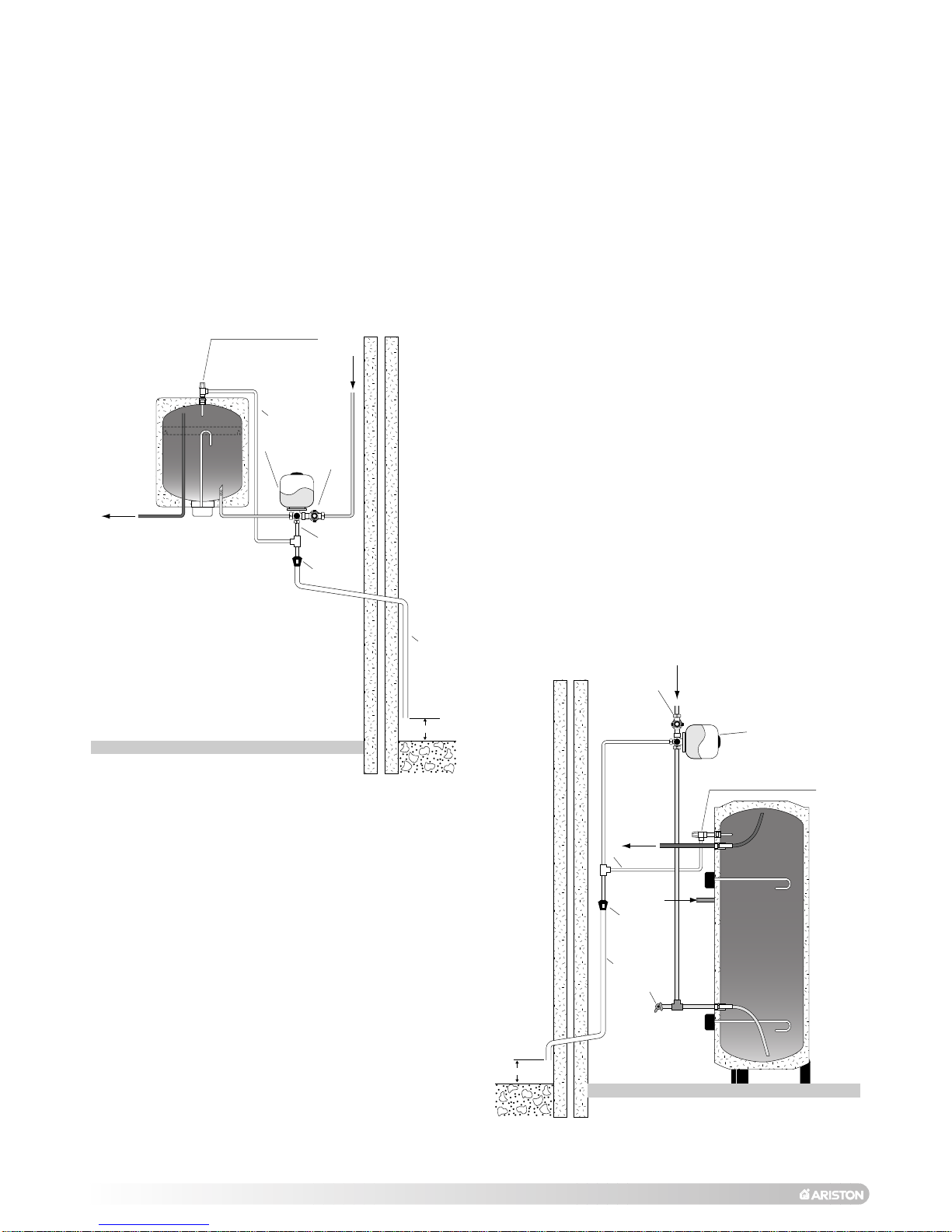

2.7 CONNECTION OF MAINS

WATER SUPPLY

For floor standing models:

On the front of the unit there is a label to identify the connection por

ts.

Please check this before making any connection to the unit.

For units up to 300 litres it is recommended that all mains cold water supply

pipe work is a minimum of 22mm, with the exception of model ST 50

ProTech where 15mm can be used. For 500 litre models the supply should

be 28mm.

An isolating valve should be installed between the cold water

supply and the cylinder f

or servicing. ALL PIPEWORK MUST BE FLUSHED

TO AVOID DAMAGE TO THE CONTROL VALVES.

Please refer to

FIGS. 2.1, 2.2, 2.3, 2.4, 2.5 for a suggested installation layout.

STD PROTECH 100

STD/STD PROTECH/ITD 125-150-210-300 DIRECT

COMBINATION

V

ALVE

EXPANSION

RELIEF

P

IPE

COLD

MAINS-IN

15/22mm

EXPANSION

VESSEL

P

RESSURE + TEMPERATURE

RELIEF VALVE

HOT SUPPLY

15/22mm

TUNDISH

15mm

22mm

MAX. 100mm

FIG. 2.1

ST P

ROTECH 50-80-100

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

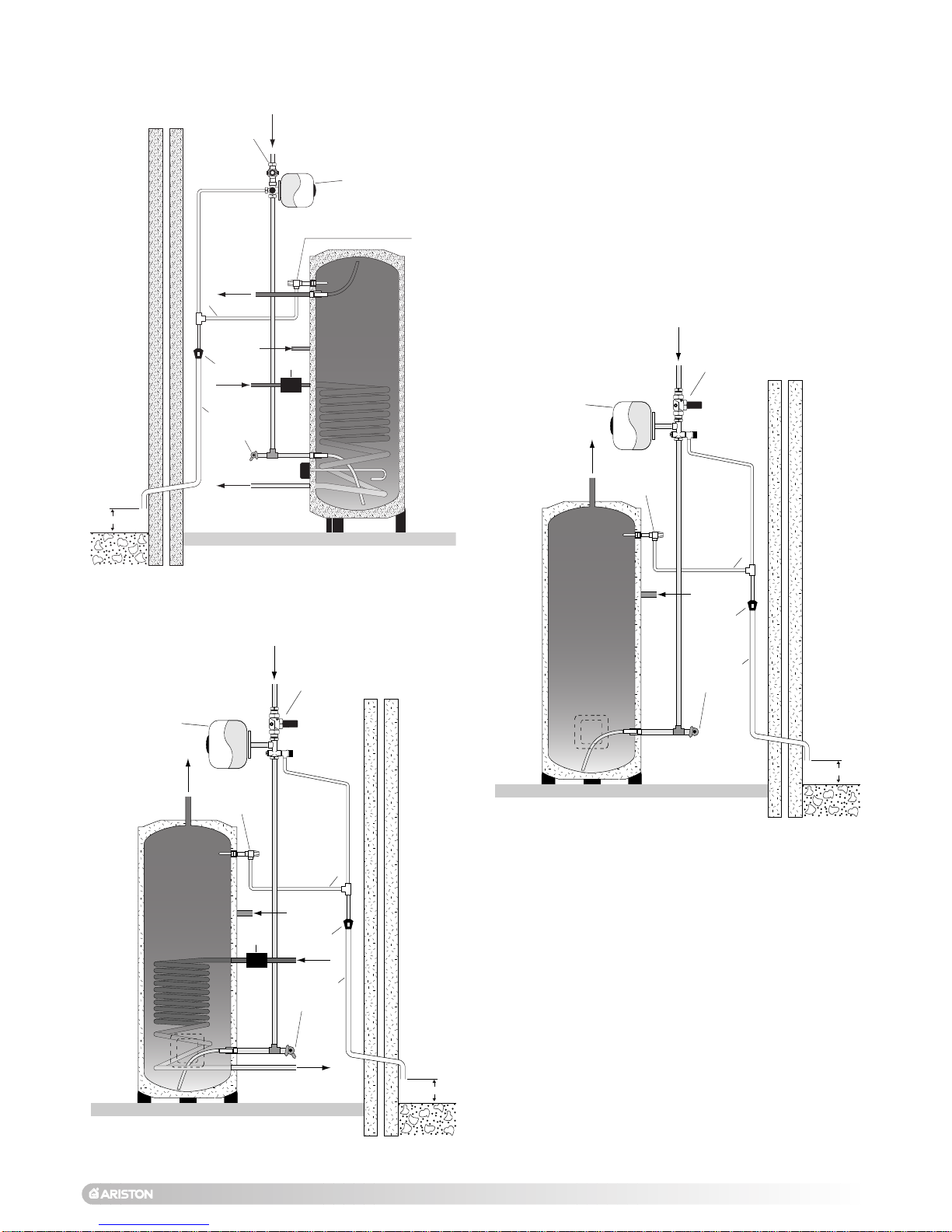

Page 7

7

RETURN

FLOW

SECONDARY

RETURN

COMBINATION

VAL

VE

EXPANSION RELIEF

PIPE

COLD

MAINS-IN

22mm

DRAIN

EXPANSION

VESSEL

PRESSURE + TEMPERATURE

RELIEF VALVE

ZONE

VALVE

HOT SUPPLY

22mm

TUNDISH

22mm

MAX. 100mm

FIG. 2.3

STI/STI PROTECH/ITI 125-150-210-300 INDIRECT

SECONDARY

RETURN

COMBINATION

VALVE

EXPANSION RELIEF

PIPE

COLD

MAINS-IN

28mm

DRAIN

EXPANSION

V

ESSEL

P

RESSURE +

TEMPERATURE

RELIEF VALVE

HOT SUPPLY

2

8mm

TUNDISH

22mm

MAX. 100mm

FIG. 2.4

500 STD PROTECH

RETURN

FLOW

SECONDARY

RETURN

C

OMBINATION

VALVE

EXPANSION RELIEF

PIPE

COLD

MAINS-IN

28mm

DRAIN

EXPANSION

V

ESSEL

PRESSURE +

TEMPERATURE

RELIEF VALVE

ZONE

VALVE

HOT SUPPLY

28mm

TUNDISH

22mm

MAX. 100mm

FIG.

2.5

500 STI PROTECH

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 8

8

The cold w

ater combination valve can be connected either close by

the unit or alter

natively it may be installed in a remote position from

the unit as there is no requirement to site it in close proximity to the

cylinder. This allows a flexible and convenient installation. However, it

is important to note allowances for the discharge pipe work from the

e

xpansion relief valve must be accounted for.

A balancing port is supplied on the 22mm valves (for units above 50

litres) and 28mm valves (for 500 litres units) allowing balanced cold

water supply to the rest of the building giving constant results for

mixer and shower valves. If the facility is not needed a plug is

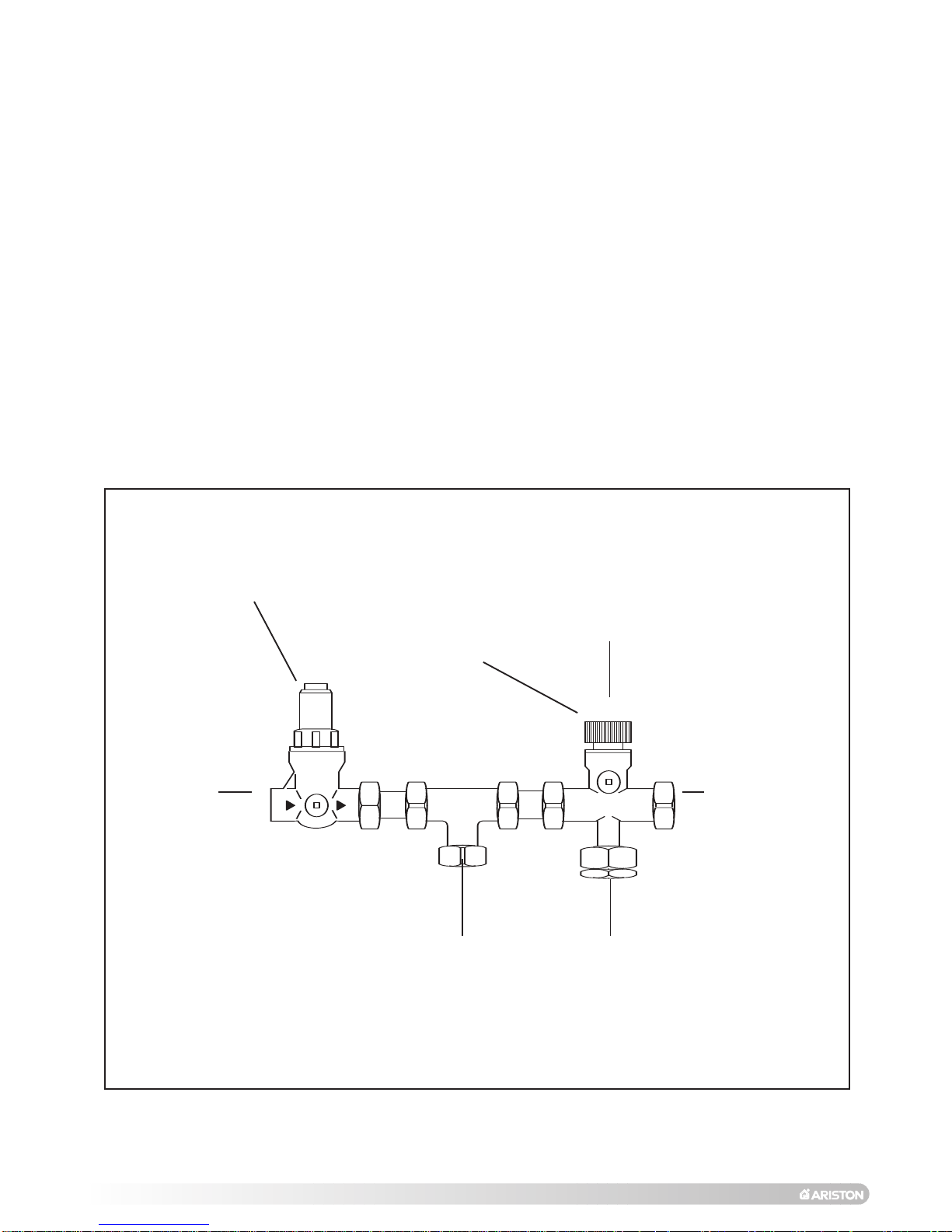

supplied. Refer to

FIG. 2.7 and FIG. 2.8

Although this facility is not built into the 15mm valve (supplied with

model ST50), a tee piece may be inserted between the two

components giving the same result. Refer to

FIG. 2.6

N

OTE!

T

HERE SHOULD BE NO OTHER VALVES FITTED BETWEEN THE CYLINDER AND

THE

EXANSION VALVE

.

2.8 COLD WATER

COMBINATION VALVE

15mm

COLD

MAINS IN

15mm

TO CYLINDER

3/4”

B

.S

.P

. CONNECTIONS

FOR EXPANSION VESSEL

EXPANSION RELIEF

VALVE (SET AT 6 BAR)

NON-RETURN

VALVE (WITHIN HOUSING)

TEE PIECE

FOR BALANCED

COLD WATER

TAKE OFF

(NOT SUPPLIED)

SERVICEABLE 1/2” PRESSURE

REDUCING CARTRIDGE AND

LINE STRAINER

For Model ST 50

FIG. 2.6

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 9

9

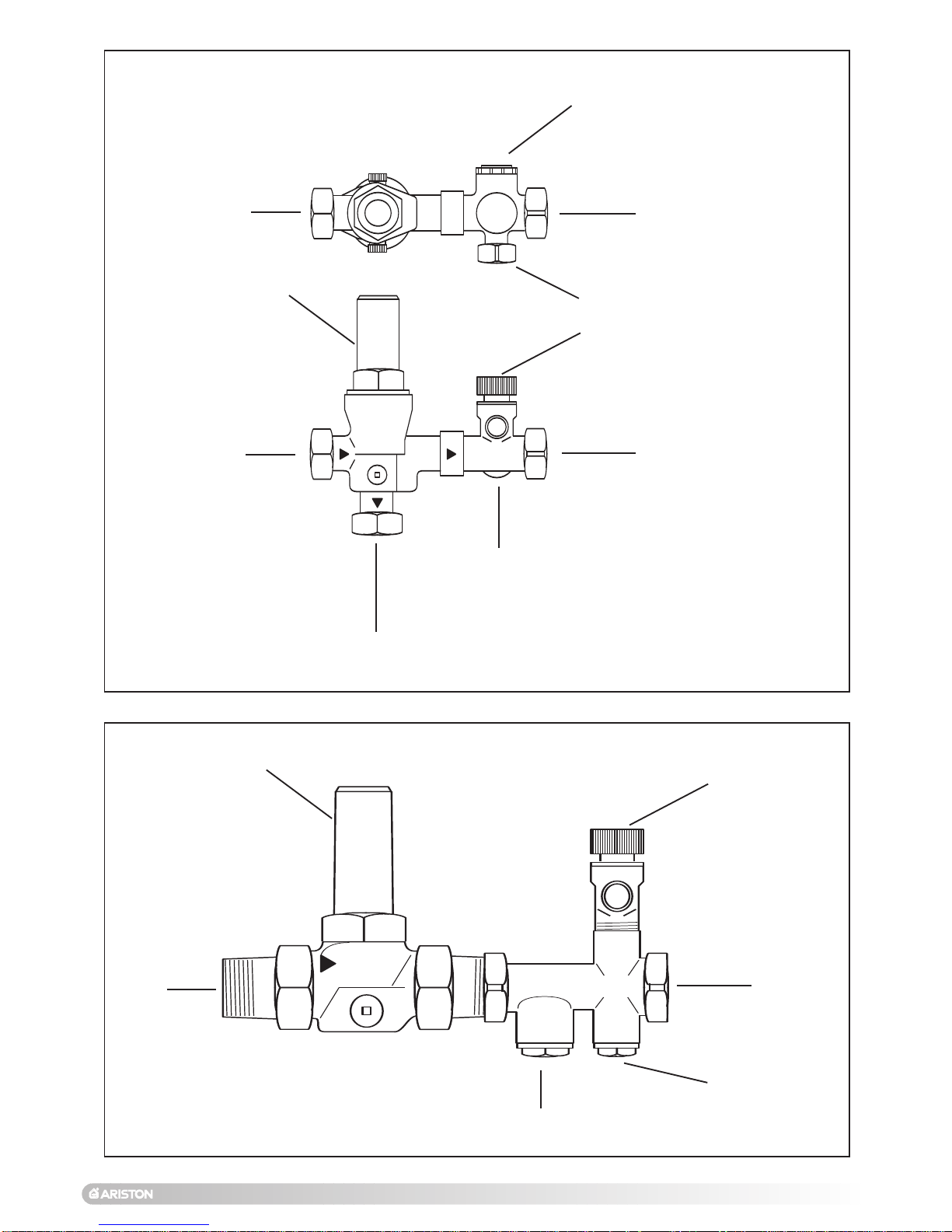

22mm COLD

MAINS IN

22mm COLD

MAINS IN

22mm TO WATER HEATER

3/4” B.S.P. CONNECTION

FOR EXPANSION VESSEL

22mm TO CYLINDER

NON-RETURN VALVE

(WITHIN HOUSING)

22mm BALANCED COLD WATER TAKE OFF

WITH NON-RETURN VALVE

15mm EXPANSION RELIEF

OUTLET TO TUNDISH

SERVICEABLE 3/4” PRESSURE REDUCING

CARTRIDGE AND LINE STRAINER

(SET AT 3.5 BAR)

EXPANSION RELIEF VALVE

(SET AT 6 BAR)

3.5

6 BAR

For 500 litre

Models

28mm COLD

MAINS IN

28mm

T

O

CYLINDER

SERVICEABLE 1” PRESSURE REDUCING

CARTRIDGE AND LINE STRAINER

(SET AT 3.5 BAR)

3/4”

B

.S

.P

. CONNECTION

FOR EXPANSION VESSEL

EXPANSION RELIEF VALVE

(SET AT 6 BAR)

1” BALANCED COLD WATER TAKE OFF

WITH NON-RETURN VALVE

FIG. 2.7

FIG.

2.8

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 10

10

2.9 CONNECTION TO SERVICES

It is recommended that a 22mm pipe run should supply the outlets

throughout the b

uilding, especially to baths and showers. Short runs of

15mm pipe may be used to connect basins and sinks.

On floor-standing models a secondary return may be fitted (consult the label

on the face of the unit for the correct location). A non-return valve (not

supplied) m

ust be fitted to prevent back flow and a bronze pump will be

needed in conjunction with a pipe ther

mostat to circulate the hot water (both

not supplied).

NOTE: an extra expansion vessel may be required where the additional

volume of the secondary return exceeds the capacity of the expansion

vessel supplied.

NOTE!

THE SAFETY RELIEF VALVES MUST NOT BE USED FOR ANY OTHER PURPOSE

1) The tundish must be vertical and fitted within 500mm of the temperature

& pressure relief valve and must be located with the cylinder. The tundish

must also be in a position visible to the occupants, and positioned away

from any electrical devices. The discharge pipe from the tundish should

terminate in a safe place where there is no risk to persons in the vicinity

of the discharge and to be of metal.

2) Discharge pipes from the temperature & pressure relief and expansion

relief valve may be joined together.

3) The pipe diameter must be at least one pipe size larger than the nominal

outlet size of the safety device unless it's total equivalent hydraulic

resistance exceeds that of a straight pipe 9m long.

I.e. Discharge pipes between 9m and 18m equivalent resistance length

should be at least 2 sizes larger than the nominal outlet size of the safety

device. Between 18m and 27m at least 3 larger, and so on.

Bends must be taken into account in calculating the flow resistance.

See

FIG. 2.9 and TABLE 2.

4) The discharge pipe must have a vertical section of pipe at least 300mm

in length, below the tundish before any elbows or bends in the pipework.

5)

The discharge pipe must be installed with a continuous fall.

6) The discharge must be visible at both the tundish and the final point of

discharge, but where this is not possible or practically difficult; there

should be clear visibility at one or other of these locations. Examples of

acceptance are:

i) Ideally below a fixed grating and above the water seal in a trapped

gully.

ii) Downward discharges at a low level; i.e. up to 100mm above

external surfaces such as car parks, hard standings, grassed

areas etc. These are acceptable providing that where children

may play or otherwise come into contact with discharges, a wire

cage or similar guard is positioned to prevent contact, whilst

maintaining visibility.

iii) Discharges at high level; I.e. into a metal hopper and metal down

pipe with the end of the discharge pipe clear

ly visib

le (tundish

visib

le or not).

Or onto a roof capab

le of withstanding high

temper

ature discharges of w

ater 3m from an

y plastic gutter

ing

systems that w

ould collect such a discharge (tundish visible).

iv)

Where a single pipe ser

v

es a n

umber of discharges

, such as in

b

loc

ks of flats

, the n

umber ser

v

ed should be limited to not more

than 6 systems so that any installation can be traced reasonably

easily

.

The single common discharge pipe should be at least one

pipe siz

e large than the largest individual discharge pipe to be

2.10 SECONDARY RETURN

2.11 DISCHARGE PIPEWORK

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 11

11

connected. If unvented hot water storage systems are installed

where discharges from saf

ety devices may not be apparent i.e. in

dwellings occupied by the blind, infirm or disabled people,

consideration should be given to the installation of an

electronically operated device to warn when d ischarge takes

place

. Note: The discharge will consist of scalding water and

steam. Asphalt, roofing felt and non-metallic rainwater goods may

5

00mm Max.

300mm

Min.

Temperature & pressure

relief valve

Metal discharge pipe (D1) from

temperature & pressure relief valve.

to tundish.

Metal discharge pipe (D2) from tundish

with continuous fall. See Table 2 and worked

example.

Tundish

Fixed grating

Trapped gulley

Discharge below

fixed grating.

(see page 10 for

alternative points

of discharge).

Valve outlet size Minimum size of

discharge pipe D1*

Minimum size of

discharge pipe D2*

from tundish

Maximum

resistance allowed,

expressed as a

length of pipe (i.e.

no elbow or bends)

Resistance created

by each elbow or

bend

G 1/2 15mm 22mm

28mm

35mm

Up to 9m

Up to 18m

Up to 27m

0.8m

1.0m

1.4m

G 3/4 22mm 28mm

35mm

42mm

Up to 9m

Up to 18m

Up to 27m

1.0m

1.4m

1.7m

G 1 28mm 35mm

42mm

54mm

Up to 9m

Up to 18m

Up to 27m

1.4m

1.7m

2.3m

TABLE 2. Sizing of copper discharge pipe “D2” for common temperature valve outlet sizes.

be damaged b

y such discharges

.

WORKED EXAMPLE

The e

xample below is for a G

1

/2temper

ature & pressure relief valve with a

discharge pipe (D2) having 4 no. elbows and length of 7m from the tundish to

the point of discharge.

F

rom

TABLE 2;

Maximum resistance allowed for a straight length of 22mm copper discharge

pipe (D2) from G

1

/2temperature & pressure valve is 9m. Subtract the resistance

for 4 no. 22mm elbows at 0.8m each = 3.2m. Therefore the maximum permitted

length equates to: 5.8m. As 5.8m is less than the actual length of 7m therefore

FIG. 2.9

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 12

12

calculate the next largest size.

Maximum resistance allowed for a straight length of 28mm pipe (D2) from G

1

/

2

temperature & pressure valve equates to: 18m. Subtract the resistance for 4 no.

28mm elbow at 1.0m each = 4m. Therefore the maximum permitted length

equates to: 14m

As the actual length is 7m, a 28mm (D2) copper pipe will be satisfactory.

WARNINGS

The outlet from the temper

ature & pressure relief valve must not be used for

any other purpose. This also applies to the expansion relief valve. No other

valve is to be fitted between the cold water combination valve and the

cylinder.

The temper

ature & pressure relief valve must not be removed in any

circumstances. Any of the above will totally invalidate the guarantee.

2.12 ELECTRICAL

CONNECTION

The electrical installation must be in accordance with the current I.E.E.

wiring regulations.

PROTECH ELECTRONIC ANTI-CORROSION SYSTEM

IMPORTANT: The ProTech anti-corrosion system MUST be permanently

connected to a 240V electricity supply see FIG 2.10.

240V~

Electronic anode

Anode circuit

N1L

The ProTech system, an exclusive solution, is an electronic anti-corrosion

protection system which ensures maximum longevity of the appliance,

regardless of w

ater quality

.

The electronic circuit creates a difference in

potential between the hot water tank and the titanium electrode, thereby

guaranteeing optimum protection of the tank and preventing corrosion.

T

o ensure the proper oper

ation of the protection system,

IT MUST BE

PERMANENTLY CONNECTED TO A FUSED NON-SWITCHED 240V, 3A

ELECTRICITY SUPPLY even in the event of shut-down of the system. To

FIG. 2.10

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 13

13

prevent risk to the appliance’s lifespan when disconnecting the protection

system f

or an extended period of time, it is necessary to drain the appliance

beforehand.

In addition to the 240V netw

ork, the electronic circuit is also connected to

the tank, which is to be protected, and to the titanium protection electrode,

INFORMATION FOR THE END USER

Proper operation of the protection system is shown by a continuous green

L.E.D

, indicating that the circuits terminals are being supplied with electricity.

In the e

vent of failure, a red L.E.D. indicates that there is a short-circuit

between the electrode and the cylinder tank, that one of the leads (tank or

electrode) is disconnected or that there is no water in the cylinder.

Your appliance is thus properly protected when the green L.E.D. is

illuminated and the red L.E.D. is off. Should this not be the case, please

contact your installer.

FITTING IMMERSION HEATER(S) (100 - 300 litre foor standing only)

These are supplied with but not fitted to 100 - 300 floor-standing models. A

sealing gasket is supplied with each element, however the use of a suitable

sealing compound is recommended to ensure a correct seal. Care must be

taken not to cross thread the immersion heater(s) when fitting. Each

immersion heater is supplied with a regulation thermostat and manual reset

thermal cut-out. This will activate if the regulation thermostat fails. Under no

circumstances should this be by-passed. The immersion heaters supplied

are rated at 3kW, there are 4kW upgrade kits available on request, (the part

number for which is 925392). Should the immersion heater(s) be ugraded to

the 4kW immersion, the electrical circuit and fuse must be checked to

ensure suitability with the higher output. Although the immersion heaters

are a standard 2

1

/4” thread, they must not be substituted with anything but an

original Ariston spare part.

NOTE!

T

HE IMMERSION HEATERS MUST NOT BE FITTED WITHOUT THE THERMOSTAT/THERMAL

CUT

-OUT.

DIRECT SYSTEMS

A mains supply of 240V, 3kW (13 amps) is required. Heat resistant cable,

round 3 or 4 core 2.5mm2(to BS6141 table 8) must be used to connect the

electrical supply through the Economy 7 time control switch using either

system ‘A’ or ‘B’ as illustrated in

FIG. 2.11.

SYSTEM A SYSTEM B

FIG.

2.11

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 14

14

The ther

mostat(s) on the immersion heater(s) should be adjusted to tr

ip at

60°C. This is the ideal temperature to prolong element life in hard water

areas. Scale on the sheath builds up more rapidly at temperatures above

this causing the element to overheat and premature failure can occur. Higher

temper

atures without additional controls w

ould result in scalding.

In addition to the thermostat the thermal cut-out will switch power off to the

element should the ther

mostat malfunction, causing an excessive rise in

water temperature. The thermal cut-out can be reset manually after the fault

has been corrected.

THERMAL

CUT-OUT

L2

N

L1

N

THERMOSTAT

DAY ELEMENT

3 kW 240V

~

NIGHT ELEMENT

3 kW 240V

~

ECONOMY 7

THERMAL

CUT-OUT

THERMOSTAT

THERMAL

CUT-OUT

L1

N

THERMOSTAT

ELEMENT

3 kW

240V

~

Single Element

2.11 ELECTRICAL DIAGRAM

Should the Economy 7 system not to be used, a separate 13 amp supply to

each element will be required. Through a double pole fused isolating switch

having a contact gap of at least 3mm on each pole.The immersion heater

shall be installed with 85°C rubber insulated HOFR-sheathed flexible cable

complying with

Table 8 of BS 6141: 1991. Make the connection(s) to the

immersion heater(s) as per

FIG. 2.12 and FIG. 2.13. For High Capacity 500

litre models consult the wiring diagram on the reverse of the inspection

panel.

FIG. 2.12

FIG. 2.13

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 15

15

INDIRECT SYSTEMS

F

or models up to 300 litres a mains supply of 240V, 3kW (13 amps) will be

required for the direct immersion heater. heat resistant cable, round 3 core

2.5mm2(to BS) m

ust be used. For

High Capacity 500 litre models consult

the wiring diagram on the reverse of the inspection panel.

For indirect controls a 240V, 3 amp supply is required.

On floor standing models it is necessary to fit the thermostat using P.T.F.E

tape (Please consult the label on the f

ace of the unit for the correct location

in both cases).

The cables must be clamped in position (as previously stated) and the

control thermostat should be set at 60°C for the reasons above. In addition

to the thermostat there is a thermal cut-out should the thermostat fail. Refer

to

FIG. 2.14.

The indirect coil must not be connected to an uncontrolled heat source e.g.

solid fuel and must be connected to a thermostatically controlled appliance.

WIRING SCHEME

FOR

2 X 2 PORTMO

TORISED

VAL

VES

T6360B

R

OOM

THERMOSTAT

14

35

22

OR

CM 41

CM 51

A

B

1

5

V4043H

HEATING VALVE

BROWN

5

BLUE

2

GREY

1

ORANGE

10

GREEN/YELLOW

3

V4043H

HO

T WATER VALVE

BROWN

8

BLUE

2

GREY

1

ORANGE

10

GREEN/YELLOW

3

Honeywell ST 699B 1002

6

3

N

L

Link L-5-8

ST 6400/ST 6300 ST 6200 3 4 N L

Drayton Tempus 7 3 4 N L

Horstmann 425, 525, 527

1 4 E N L

Link L-2-5

Landis & Gyr R

WB2

3 4 N L

Glowworm Mastermind

Landis & Gyr R

WB20

3 4 N L

Microgyr

Potterton Miniminder 3 4 N L

Potterton EP2000/3000 - 3 4 N L

Link L-5 EP2001/3001

Randall 102/102 E 1 2 E 5 6

Link 3-6

Randall 4033

4

2

E

7

6

Link 1-6

Randall 701, 702

3

1

E N L

Link L-6-5

Sangamo M5

1

8 E 4 3

Link 1-6

Sangamo 410 Form 1

1

8

E

4 3

Link 3-6

PR

OGRAMMER

6 4

3 2 1

Pegler Sunvic

2 5 E N L

SP 50/100 (Link L-3)

Switchmaster

1 4 N L

Symphony, Sonata

Switchmaster 400, 600 3 1 N L

SWITCHMASTER 805, 900

3 1 N L

Sunvic ET 1451

7 4 E 1 2

Link 2-3-6

Sunvic DHP 2201 6 3 E 1 2

Towerchron FP

6 10 2 1

Link 1-5/4-7-9

T

o

w

erchron MP

6 10 2 1

Link 1-4/6-11

Towerchron 2000 HW HTG

N L

ON ON

ACL LS522, LS722 3 4 N L

Randall 922, 972

3

6 E N L

Link L-2-5

Randall 3020 P

4 2 E N L

and 3060

PROGRAMMER

6

4 3 2 1

1

Cylinder

ther

mostat

Thermal

cut-out

ELEMENT

3 kW 240V

~

Thermal

cut-out

Thermostat

1

8

6

Not

used

L1

240V~

N

P

2

P

2

240V

MAINS INPUT (3 AMP)

L1

N2

E3

240V

MAINS INPUT (13 AMP)

E

L

N

• 1

• 2

• 3

• 4

• 5

• 6

• 7

• 8

• 9

• 10

TYPICAL

JUNCTION BOX

FIG. 2.14

Basic Boilers (see P

age 16)

L

E

N

L N E

Baxi Solo 2 30PF To 80PF

PL SL E N L L N E

and 30RS to 60RS

Glo

ww

or

m Econom

y Plus

7 SL E N L L N E

(remo

v

e link SL-9)

Glowworm Spacesaver KFB50

9 12 E N L L N E

(remove link 12-7)

Glo

ww

or

m Ultimate SS

P SL E N L L N E

(remove link SL - 4)

Glo

ww

or

m Fuelsaver 100FF

P SL

E

N

L

L N E

(remove link 7 - 12)

Halstead Best r

ange

2

1

E N L L N E

Halstead Balmoral range 9 6 E N 12 L N E

Halstead Blenheim range LP 2 E N L L N E

Ideal Mexico Super 2 PL LB E N L L N E

Myson Apollo

PL ON E N L L N E

(remove all links)

Potterton Profile/Suprima PL SL E N L L N E

For ARISTON, Vaillant, Vokèra,

Burco Maxol and other makes, refer

to manufacturers instructions.

BOILER PUMP

9 10 3 2 1

9

10 2 3

Based on Honeywell Controls

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 16

16

BASIC BOILER LIST

Baxi Bermuda range

Boston RS and OF range

Glowworm Complheat

Hideaway range 65 - 80

Ultimate 40 - 80

30B - 80B, 30CF - 60CF

Halstead Buckingham range

Potterton Kingfisher range

Statesman range (oil fired)

Caradon Ideal Classic range

Mexico Super range

Mexico Slimline range

Newflame Boilers Backboiler range

Condensing Boiler List

CARADON IDEAL

Minimiser FF30 - FF80 L E N

GLOWWORM Energysaver (Remove link SL-9) PL SL E N L

KESTON LE N

POTTERTON Envoy 30F - 80F PL SL E N L

refer to

VAILLANT VU 186, 226 manufacturers

instructions

Boiler Connections 2 Motorised valves 2 way (see Fig. 2.14) 9 10 3 2 1

Pump Connections 2 Motor

ised v

alv

es 2 way (see

FIG.

2.14

)

9

3 2

W

ARNING :THE APPLIANCE MUST BE EARTHED.

The earth continuity conductor of the electrical installation must be

effectively connected to all exposed parts of other appliances and services

in the room in which the water heater is to be installed, conformity with the

I.E.E. wiring regulations.

NOTE: Do not switch on the immersion heater or fire the boiler until the

cylinder is full of w

ater.

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 17

17

3. COMMISSIONING

Check for obvious signs of damage to the cylinder and controls, and also

that the controls fitted correspond with the ref

erences quoted in these

instructions.

Ensure that the Drain Cock at the base of the appliance is closed before

commencing.

1) ProTech Models Only.

Ensure that the

ProT

ech

anti-corrosion system is

connected to the electr

ical supply;

2) Open all outlet taps;

3) Turn on mains water supply and allow the water heater to fill;

4) Ensure that the hot water system is flushed in accordance with BS 6700;

5) Close taps in turn after having purged the system of air;

6) Check for leaks around the controls and immersion heaters and again

after the unit has heated up;

7) Check that no water is passing to waste through the relief valves;

8) Ensure that the line strainer (situated in the pressure reducing valve) is

clear of installation debris and clean if necessary;

9) Test the operation of the temperature & pressure relief and expansion

valves by lifting/turning the manually operated test lever/cap and

observing that water flows through freely and safely to waste;

10) Check that the pressure in the expansion vessel is correct;

11) Check that the discharge pipe is plumbed so that it falls continuously

and that no taps, valves or other shut off devices are installed in the

pipe;

12) Check that all thermostats are set at 60°C;

13) DIRECT UNITS. Switch on immersion heater(s) and allow unit to heat

up. Check operation of Thermostat(s);

14) INDIRECT UNITS. Fill the indirect (primary) circuit following the boiler

instructions. Switch on the boiler, ensure that the programmer is in the

domestic hot water position. Allow unit to heat up and check operation of

indirect thermostat on motorised valve(s);

15) Check the temperature of the hot water at the nearest outlet and record

in the Benchmark Log Book;

16) Demonstrate operation to user, including operation of temperature &

pressure relief valve and what to do if it operates;

17) Give this manual along with the completed Benchmark Log Book to the

user to retain for future reference and make the customer aware that

periodic checks of the equipment are essential for safety.

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 18

18

4.2 THERMAL CUT-OUT(S)

4.3 IMMERSION HEATER(S)

4.4 UNVENTED CONTROLS

4. MAINTENANCE

To ensure efficient safe operation, it is recommended that the appliance is

serviced annually by a competent person.

After servicing, preliminary electrical system checks must be carried out to

ensure electrical safety (i.e. polarity, earth continuity, resistance to earth and

short circuit).

W

ARNING:

SWITCH OFF

THE POWER SUPPLY BEFORE WORKING ON

THE APPLIANCE.

Trouble-shooting:

1) The green L.E.D. is NOT on:

- Check to see that the circuits electric plug is connected (if not,

connect);

- Check to see that the P.C.B, is supplied with electricity (if not, replace

the supply cab

le);

- Check to see that 230 V electricity is supplied (if not, ensure that 230 V

is supplied);

- If all these checks fail to locate the problem, replace the electronic

circuit (installer).

2) The red L.E.D. is on:

- Check to see that the tank is filled with water (if not, fill it before

carrying out the following checks);

- Check to see that the clip-on circuit connector is in the proper position

(if not, position correctly);

- Check to see that the electrodes connection lead is property connected

(to check this, gently pull on it) (if not, replace the electrode);

- Check to see that the connection lead to the tank is properly connected

to the tank (if not, connect properly); .

- Check to see that the two leads from the clip-on circuit connector are

not damaged, stripped, etc. (if so, replace the electrode);

- If all these checks fail to locate the problem, replace the electronic

circuit.

NOTE: To replace the P.C.B, there is no need to drain the cylinder;

1) Disconnect the two supply cables from the P.C.B. to the supply terminal;

2) Disconnect the clip-on circuit connector and polarising slot which

connects the circuit to the tank and the electrode;

3) Disconnect the P.C.B. from its supporting plate (plastic clips in the 4

cor

ners) and;

4) Replace the defective circuit with a new one, then re-install in reverse

order to the abo

v

e.

If the thermal cut-out has operated the cause must be found before resetting

(see section 5).

Should the immersion heater(s) become scaled, we would recommend that

the immersion heaters be replaced, also ensure that the ther

mostat is set

below 60

O

C to prevent further scale formation.

Check controls as per the following:

1) Line strainer - with the water supply turned off remove screen from

strainer and clean of any detritus;

2)

Expansion v

essel - with the w

ater supply tur

ned off and taps open, check

expansion vessel pressure and top up as necessary;

3) Temperature & pressure relief valve - with the water supply turned on,

chec

k man

ually by lifting the test lever/turning the test knob (ensure valve

closes after testing)

;

4.1 PROTECH

ANTI-CORROSION SYSTEM

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 19

19

4) Expansion relief valve - check manually by turning the test knob

(ensure

v

alve closes after testing)

;

5) Discharge pipes (D1) - from both temperature & pressure relief and

e

xpansion relief valve for obstructions;

6) Tundish & discharge pipe (D2) - open either valve gradually to produce a

full bore discharge into tundish and D2 without any back pressure;

7) Pressure reducing valve - check that the correct outlet pressure is being

maintained b

y recording the pressure at an in-line terminal fitting i.e. tap.

Ensure that all thermostats adjusted for the correct temperature setting, this

should be between 60 and 65°C.

To ensure efficient safe operation, it is recommended that the appliance is

serviced annually by a competent person.

After servicing, preliminary electrical system checks must be carried out to

ensure electrical safety (i.e. polarity, earth continuity, resistance to earth and

short circuit).

To drain the cylinder it is necessary to proceed as follows:

1) Close the mains supply service valve;

2) Open hot water taps;

3) Attach a hose and open the drain cock and allow the cylinder to empty.

Magneisum Anodes (Classico model only)

No longer than every 12 months, the installer should check the magnesium

anti-corrosion anodes (consult the label on the face of the unit for the correct

location). Assessment of the condition of the bottom anode (where fitted)

can be made by judging the condition of the top anode.

Removal of anodes;

1) Close the mains supply service valve;

2) Open hot water taps;

3) Attach a hose and open the drain cock and allow the cylinder to empty;

4)

The anodes are remo

v

ed by unscrewing;

EXAMINE THE ANODES AND REPLACE IF THE DIAMETER IS LESS

THAN 10mm.

The use of an approved P.T.F.E. sealing tape is recommended to ensure

w

ater

tight connection for anodes.

Thermal Cut-out(s)

If the thermal cut-out has operated the cause must be found before

resetting.

Immer

sion Heater(s)

Should the immersion heater be scaled, we would recommend it be

replaced.

4.5 THERMOSTATS

4.6 MAINTENANCE

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 20

20

Unvented Controls(s)

Check controls as per the following:

1) Line strainer - with the water supply turned off remove screen from

str

ainer and clean of any detritus;

2)

Expansion vessel - with the water supply turned off and taps open, check

expansion vessel pressure and top up as necessary;

3) Temperature & pressure relief valve - with the water supply turned on,

check manually by lifting the test lever/turning the test knob (ensure valve

closes after testing)

;

4) Expansion relief valve - check manually by turning the test knob

(ensure

valve closes after testing)

;

5) Discharge pipes (D1) - from both temperature & pressure relief and

expansion relief valve for obstructions;

6) Tundish & discharge pipe (D2) - open either valve gradually to produce a

full bore discharge into tundish and D2 without an

y back pressure;

7) Pressure reducing valve - check that the correct outlet pressure is being

maintained by recording the pressure at an in-line terminal fitting i.e. tap.

Thermostats

Ensure that all thermostats adjusted for the correct temperature setting, this

should be between 60 and 65°C.

NOTE!

WHERE THERE IS A POSSIBILITY OF SCALE FORMING, IT IS RECOMMENDED TO ADJUST

THE THERMOSTAT TO BELOW

60OC

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 21

21

FAULT POSSIBLE CAUSES REMEDY

1) Mains cold water Check and open Isolating

supply shut off and/or stop valve. Check

water, Local Water Authority

NO HOT WATER 2) Line strainer Turn off mains water supply,

FLOW blocked remove line strainer and

clean

3) Cold Water Check direction of flow

Combination valve arrows on valve, refit in

fitted incorrectly correct position if necessary

1) Lo

w mains water Check pressure, consult

pressure Local Water Authority if

necessar

y

REDUCED FLO

W

2) Line str

ainer Turn off mains water supply,

RATE partially blocked remove line strainer and

clean

3) Siz

e of service Increase to size stated on

pipe too small page 6

1) Direct immersion Check immersion heater,

heater is not

switch on if necessary

s

witched on

2) Direct thermal Test thermostat operation

cut-out has and wiring, if faulty,

operated correct/replace. Reset cut-out

WATER FROM 3) Boiler programmer Check switch on domestic

HOT TAPS set to central hot water if necessary

IS COLD heating only

(Indirect models)

4) Boiler is not Check boiler operation, if

functioning fault suspected consult

(Indirect models) manufacturer's instructions

5) Indirect thermal Test thermostat operation

cut-out has and wiring, if faulty,

operated correct/replace. Reset

cut-out

6) Motorised valve Check wiring and operation of

jammed or not motorised valve correct/

wired correctly

replace as necessar

y

(Indirect models)

DISCHARGE FROM 1) Pressure above 7 Shut down boiler or immersion

PRESSURE/ bar

, f

ailure of

heater

. Check pressure

TEMPERATURE pressure reducing reducing valve and thermal

RELIEF VALVE valve. Temperature controls. Replace if

above 90 C failure necessary

of ther

mal control

DISCHARGE FROM 1) Continually. Check pressure from valve.

EXPANSION Pressure reducing Replace if over 3.5 bar

V

AL

VE

v

alv

e faulty

2) When heater is heating. Check charge of vessel. ReFaulty expansion charge vessel to 3.5 bar or

v

essel or lost charge replace if necessary

5. FAULT FINDING

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 22

22

6. TECHNICAL INFORMATION

12

3.5

3.5

6

7/90

3.5

2403480

(1)

(3)

60

---

-

1.15

27

12

3.5

3.5

6

7/90

3.5

2403480

(1)

(3)

120

---

-

1.26

41

* To pressure reducing valve **Primary circuit 80°C, 1m

3

/h circulation.

(1)

Single Phase

(2)

Single Phase/Three Phase

(3)

BS 3456 Section 2.21

ST ProTech 50

ST ProTech 80

ST ProTech 100

STD ProTech 100

STD/STD ProTech 125

STD/STD ProTech 150

STD/STD ProTech 210

STD/STD ProTech 300

STI/STI ProTech 125

STI/STI ProTech 150

STI/STI ProTech 210

STI/STI ProTech 300

ITD 125

ITD 150

ITD 210

High Capacity

500 STD UK

High Capacity

500 STI UK

12

3.5

3.5

6

7/90

3.5

2403480

(1)

(3)

90

---

-

1.40

40

12

3.5

3.5

6

7/90

3.5

2403350

(1)

(3)

120

---

-

1.50

29

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

150

---

-

1.70

33

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

175

---

-

1.90

40

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

350

---

-

2.85

85

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

240

---

-

2.10

45

12

3.5

3.5

6

7/90

3.5

2403350

(1)

(3)

150

3.5

20.5

0.75182.00

41

12

3.5

3.5

6

7/90

3.5

2403350

(1)

(3)

175

3.5

26.7

0.90222.20

51

12

3.5

3.5

6

7/90

3.5

2403350

(1)

(3)

240

3.5

26.7

0.90262.40

56

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

150

---

-

1.70

13

12

3.5

3.5

6

7/90

3.5

2403350

(1)

(3)

350

3.5

26.7

0.90402.85

95

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

175

---

-

1.90

14

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

240

---

-

2.10

20

ITD 300

12

3.5

3.5

6

7/90

3.5

240

3+3

350

(1)

(3)

350

---

-

2.85

31

ITI 125

ITI 150

ITI 210

12

3.5

3.5

6

7/90

3.5

2403350

(1)

(3)

150

3.5

20.5

0.75182.00

17

12

3.5

3.5

6

7/90

3.5

2403350

(1)

(3)

175

3.5

26.7

0.90222.20

21

12

3.5

3.5

6

7/90

3.5

2403350

(1)

(3)

240

3.5

26.7

0.90262.40

27

ITI 300

12

3.5

3.5

6

7/90

3.5

2403350

(1)

(3)

240

3.5

26.7

0.90262.85

37

12

3.5

3.5

6

7/90

3.5

240/415

6

400

(2)

(3)

290

---

-

3.60

130

12

3.5

3.5

6

7/90

3.5

240/415

6

400

(2)

(3)

290

3.5

31.8

1.50543.60

149

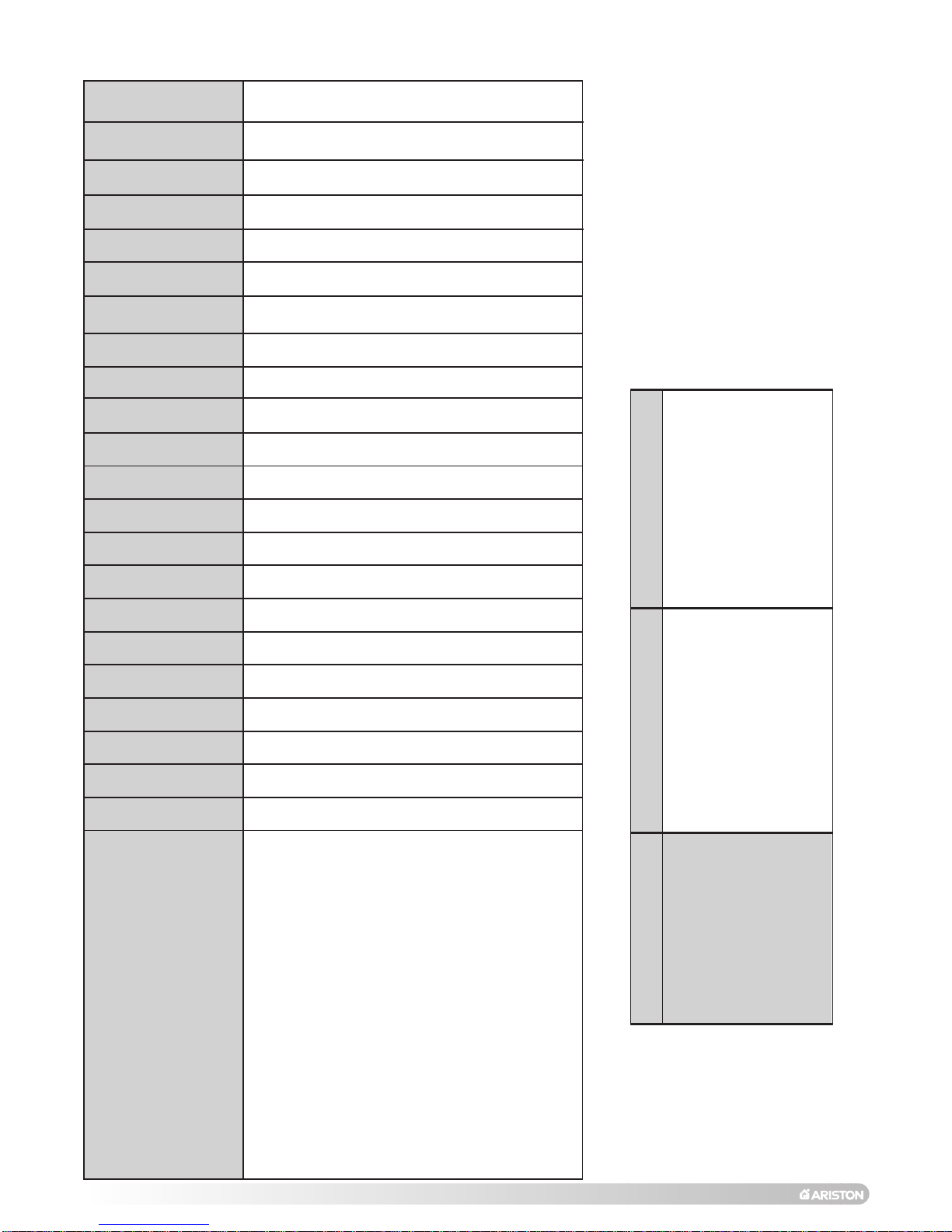

Model

Time taken to raise tempera

ture

from 15˚C to 65

˚

C

Time taken to raise 70% of the

stored volume to 65

˚

C

STI/STI ProTech 125***

15 mins

13 mins

STI/STI ProTech 210***

24 mins

21 mins

ITI 125***

?? mins

?? mins

ITI 300***

?? mins

?? mins

High Capacity 500 STI***

44 mins

38 mins

Contract STD 100

2 hrs 30 mins

1 hr 15 mins

Contract STD 210

Contract STD 300****

1 hr 58 mins

2 hr 47 mins

1 hr 39 mins

1 hr 45 mins

*** Indirectly heated. Figures obtained by WRc-NSF Limited in accorda

nce with Test Criter

ia 1-50-220 & 1-50-2

22.

**** With 4kW upgrade kit

fitted. Figures obtained

by WRc-NSF Limited i

n accorcdance with Test Criteria 1-50

-220 & 1-50-222.

ST ProTech

50*

**

63

mins

33

mins

ST ProTech 1

00

***

1 hr 56 mins

72 mins

Maximum Water Supply Pressure* bar

Oper

ating Pressure

bar

Expansion

V

essel Charge Pressure

bar

Expansion Relief Valve Setting bar

Pressure &

Temperature Relief Valve Setting bar/°C

Pressure Reducing

V

alv

e Set Pressure

bar

Electr

ical Supply

V

Immersion Heater Rating kW

Immersion Heater Length

mm

Immersion Heater

T

ype

Immersion Heater Refernce Number

Direct Reheat

Time

(Single Immersion Heater) (∆T 50

°

C) mins

Maxim

um Pr

imar

y Pressure bar

Indirect Coil Rating kW

Coil Surface Area m

2

Indirect Reheat Time (∆T 50°C)** mins

Heat Loss (kWh in 24h) @ 60

°

C

Nett Weight Kg

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 23

23

NOTES

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Page 24

24

Man

uf

acturer:

MTS Benelux sa/n

v - Belgium

Commercial subsidiary: MTS (GB) LIMITED

MTS Building

Hughenden Avenue

High Wycombe

Bucks. HP13 5FT

T

elephone:

(01494) 755600

Fax: (01494) 459775

Internet: www.ariston.co.uk

E-mail:

inf

o@uk.mtsg

roup

.uk

Technical Service Hot Line: (0870) 241 8180

Customer Service Help Desk: (0870) 600 9888

Ariston Unvented Cylinder Manual 22/7/2004

www.tradeplumbing.co.uk Call Sales On 08708034288

www.tradeplumbing.co.uk Call Sales On 08708034288

Loading...

Loading...