Page 1

Model type:

AVL82AG

Commercial code:

37916

Page 2

General notes

Technical Documentation guidelines

----------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------

You can find herewith some generic information to simplify cunsulting of technical documentation:

1. Models of same range share the same exploded views, which report the richest set of spare parts:generally, a model does not

necessarly have a related spare part for each particular shown on exploded views.

2. Some spare parts can not be represented directly on the exploded views (instruction booklets, specific kit, etc...). You can find

those codes in the spare parts list with the same reference of particular where spares are installed or with references 099, 999.

Instruction booklets, once managed, appear with 000 reference.

3. On the higher right site of each exploded view there is a serial number which indicates the beginning of the production of

certain range:some models might have more than an exploded view for a given category, each distinguished by a different serial

no.and linked to another spare parts list, In this case, serial no. is required to supply the right spare part code. Exploded view to be

considered is the one with a more recent serial no. but previous than the one of the model that needs assistance.

4.Exploded views might require further updates even after publishing. Addition of new spares will go on following the already

existing numeration references. Revision number of an exploded view is shown into last four digits of serial number into upper

right hand corner.

5.The spare parts list associated to an exploded view shows related codes of spares managed for a certain model; for each spare

part other informations are available:

REF: reference no of spare into a table; SUBSTITUTE: list of spare(s) which can replace a code but that keeps same functional

characteristics

INDUSTRIAL CODE: list of variables of a model (shown into model label) where such spare is used; NOTICE: code of

information(s) to refer to complete technical intervention, track for changes or to find correct spare part code.

6. Some notices, into a same section are generic therefore cannot be directly linked to a spare part. In order to assist a model in

the best way as possible, it is helpful to pay attention to all notices and constantly verify documentation updates

7.Technical documentation cover shows model name and its commercial codes

mod.AVL82AG page 2

Page 3

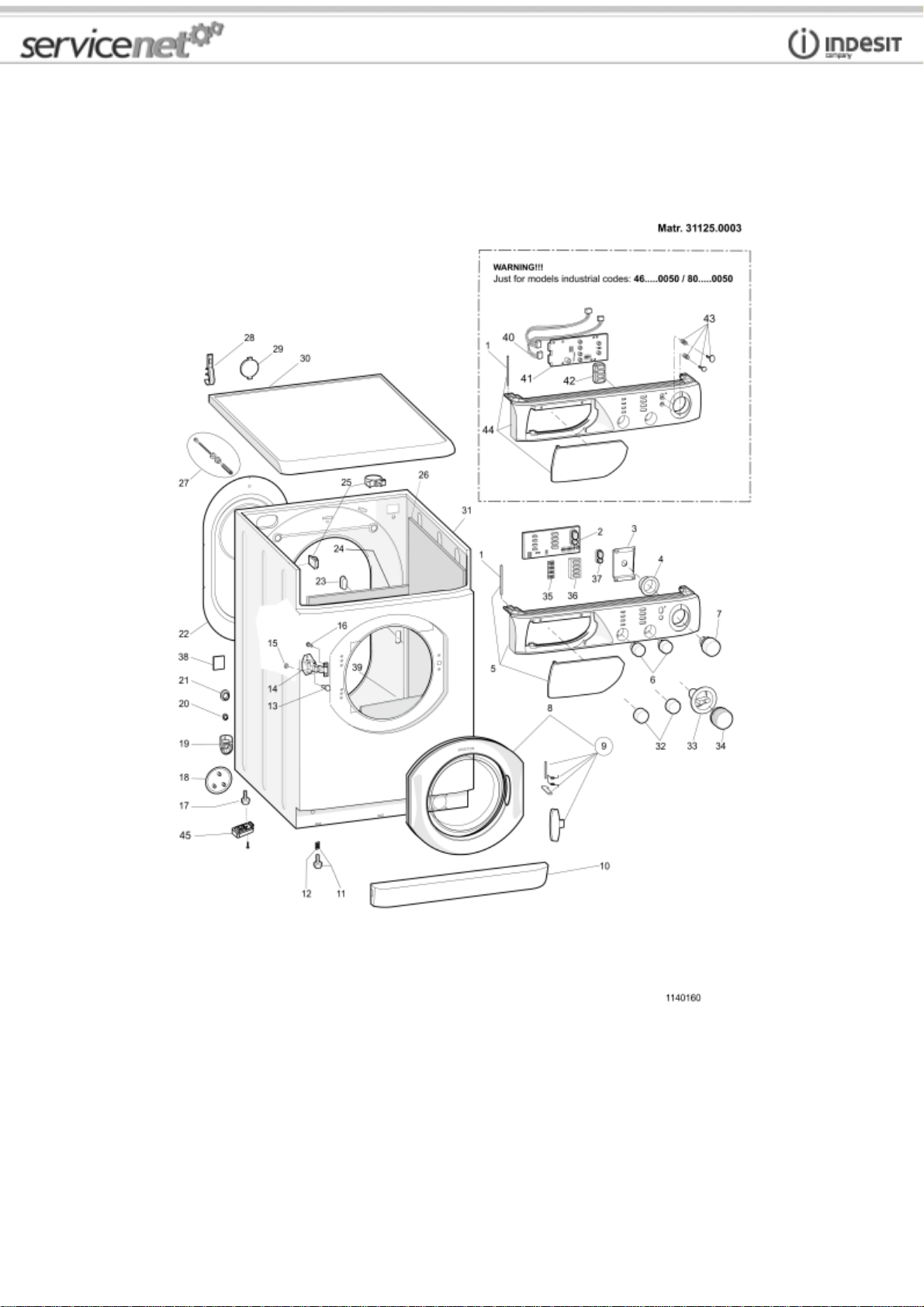

1140160 Exploded views

mod.AVL82AG page 3

Page 4

1140160 Spare parts list

Ref. Code From To S/N Substitute Description Notice Industrial

000 C00140776 user instruct.bookl es-gb

001 C00091882 pivot pin drawer front 106.5x5

003 C00091890 potentiometer support avd

004 C00116381 1 x C00203083 knob timer disc pw

006 C00115954 temperature knob pr28 white pw

006 C00116351 spin regulation knob set 800 pw

007 C00115953 wash timer knob white pw avd

008 C00116240 door frame+glass assy evoii pw

009 C00116576 door handle assy white pw

010 C00115934 plinth white pw

011 C00143730 1 x C00264036 foot m8 h=2,9 cm rohs thread 8 n4007j00

012 C00059869 spring for foot d =11 mm h = 21

013 C00019846 civata t 1/2 t m4x12

013 C00096210 screw self tapping

014 C00064541 outer door hinge assembly

016 C00012687 self-tapping screw hi-lo 3,5x13

016 C00065185 bolt m4,5 x 11

018 C00089803 blanking plug d = 53 mm

019 C00064755 drain hose collar

020 C00089419 blanking plug 6.5 mm

021 C00065871 blanking plug

022 C00115812 rear panel white pw

023 C00084817 blanking plate-rear(test plug)

025 C00019685 drain hose hook

025 C00091904 cable clamp hose

029 C00083796 cap for electrovalve

030 C00115932 top cover white(pw)

031 C00115975 cabinet white evoii pw n4007j00

040 C00109854 wiring console lbe evoii

041 C00143338 display pcb

042 C00110055 1 x C00116392 silicone push buttons

043 C00116359 1 x C00110115 push button on-off/start kit white

044 C00140770 control panel + handle pw avl82ag

045 C00254045 back foot - rear h= 10 mm n4007j00

mod.AVL82AG page 4

Page 5

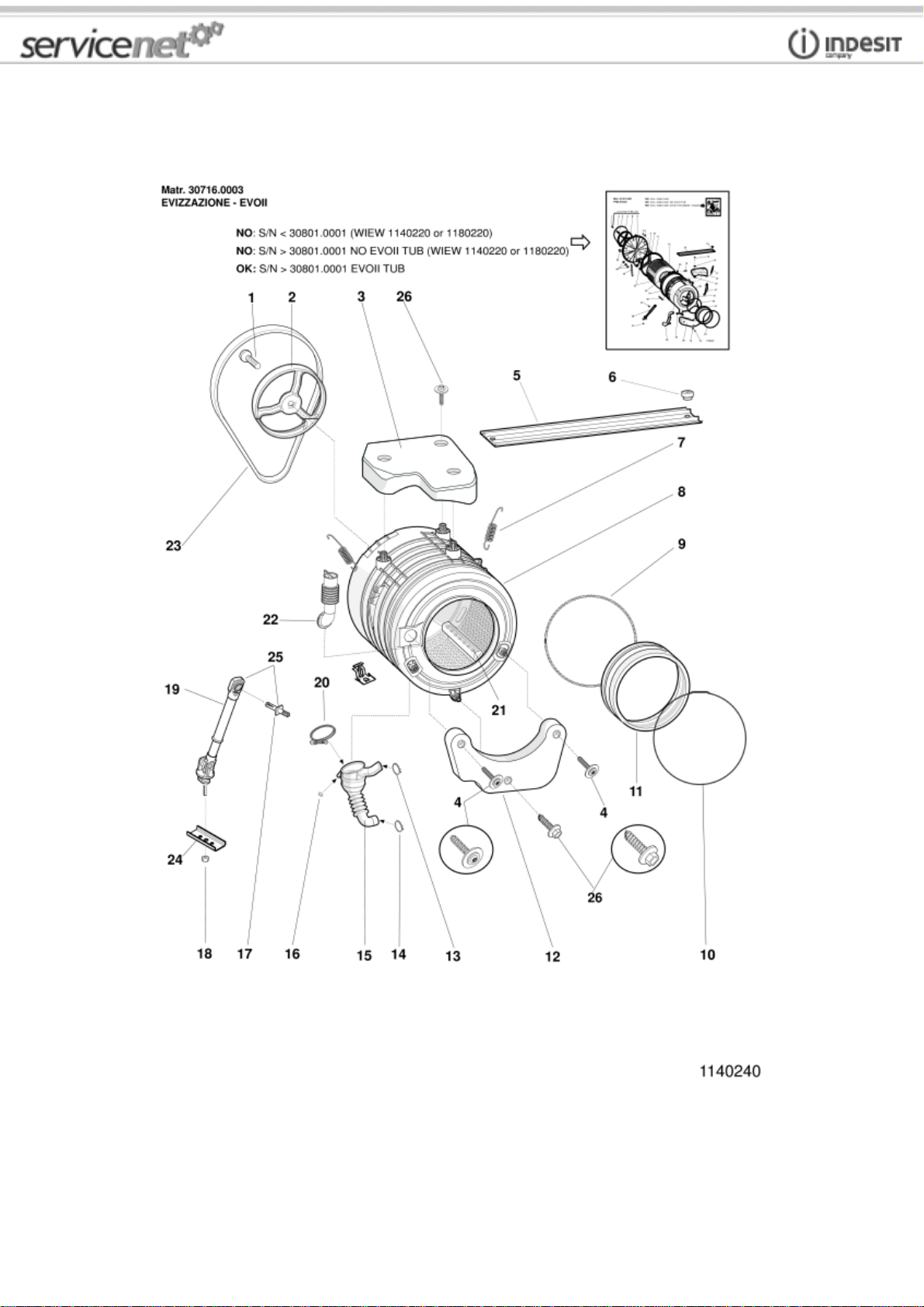

1140240 Exploded views

mod.AVL82AG page 5

Page 6

1140240 Spare parts list

Ref. Code From To S/N Substitute Description Notice Industrial

001 C00064786 1 x C00143260 bolt m8x23 torx tefl

002 C00097268 drum pulley d=280 mm h=15 mm

002 C00097269 drum pulley d=280 mm h=20 mm

003 C00094710 top ballance weight 15kg

004 C00118612 1 x C00194611 screw locking counterweight/tub

005 C00055397 tank cradle channel top

006 C00047133 spring support top white 1 per pick

007 C00096195 suspension spring

008 C00113810 46l plastic tank/pulley

009 C00092155 door seal- rear retainer

010 C00092156 door seal retainer front

011 C00111416 door seal (30cm) (hl)

012 C00094711 front ballance weight 9,4kg

013 C00008612 tube clamp 34,6-36,4

014 C00092411 1 x C00094908 hose clamp

015 C00092174 hose tank to filter with oko ball

017 C00055037 plastic expansion rivet

017 C00118593 1 x C00280757 plastic expansion peg

018 C00065152 nut romob m6x22x1,5

019 C00097259 1 x C00140744 shock absorber 100 n

020 C00094908 hose clamp

021 C00065463 lifter 40 - 46l

022 C00066183 hose dispenser to tank

023 C00082318 belt (1195 h8)

024 C00110233 cabinet plate

025 C00140744 shock absorber 100 n kit

026 C00094741 1 x C00118612 screw locking counterweight/tub

mod.AVL82AG page 6

Page 7

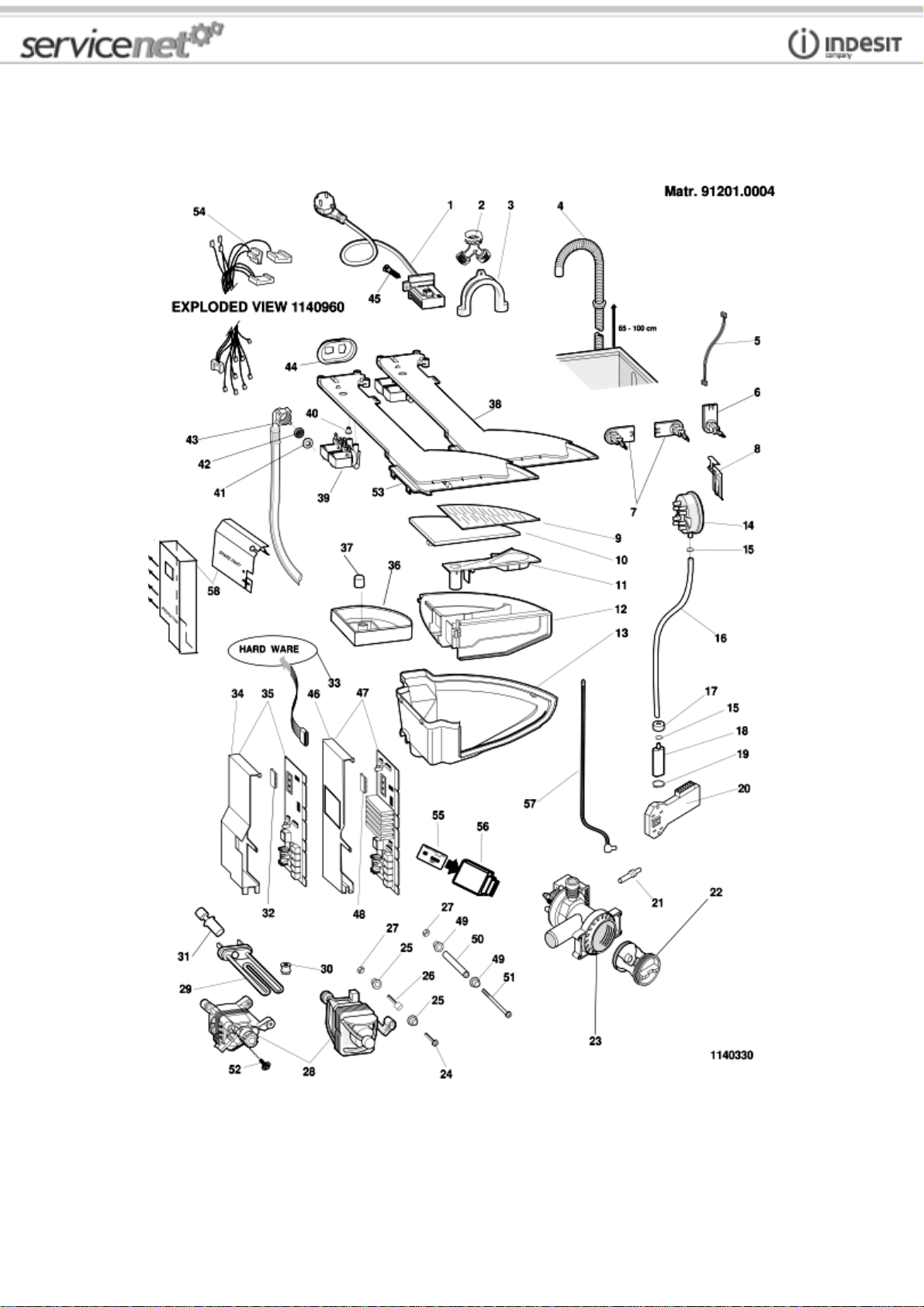

1140330 Exploded views

mod.AVL82AG page 7

Page 8

1140330 Spare parts list

Ref. Code From To S/N Substitute Description Notice Industrial

001 C00091689 supply cable l=2550mm ag + r.i.s.

003 C00019902 plastic -u- to make drain hose

004 C00027466 drain hose - to sink l=1860mm

005 C00109854 wiring console lbe evoii

006 C00087067 1 x C00143095 programme select bitron 16

007 C00085195 1 x C00143096 potentiometer 8 pos. idc rast 2,5

008 C00050186 bracket - pressure switch

009 C00099409 reading desk sp pr28

010 C00093813 support - programme guide evo ii

011 C00046154 additive cover

012 C00046148 soap dispenser drawer (rotary)

013 C00064529 dispenser body (hl)

014 C00096880 pressure switch (hl)

015 C00092412 hose clamp

016 C00094746 pipe pressostat l=505

017 C00019755 anti-vibration bush (foam)

018 C00092173 air trap x oko

019 C00008612 tube clamp 34,6-36,4

020 C00065185 bolt m4,5 x 11

020 C00085194 door interlock

022 C00045023 filter handle

022 C00045025 filter seal

022 C00045027 pump filter kit

023 C00085618 1 x C00119307 self cleaning pump 240v./50hz.idc

028 C00092153 motor collector 850-1000 rpm

028 C00097255 1 x C00196543 brush motor ceset 6170 a0946

028 C00097257 1 x C00140558 tacho generator for motor ceset

028 C00114885 carbon brush for motor sole

028 C00114886 tachogenerator for motor sole

028 C00273898 carbon brush for motor welling

028 C00273911 tacho generator for motor welling

029 C00094715 heating element 1700w

030 C00058523 pillar retainer-heating element

031 C00083915 thermistor ntc

033 C00066292 insulated tweezers

mod.AVL82AG page 8

Page 9

1140330 Spare parts list

Ref. Code From To S/N Substitute Description Notice Industrial

033 C00084943 1 x C00099862 serial cable lb2000 - pc n1040317

033 C00095669 1 x C00145046 hardware key mk1 n1040317

034 C00091908 bracket for module st

034 C00091909 support cover

035 C00254297 power board module (rhos) n4008c01

039 C00110333 fill valve 2 way (7lt rst 2.5)

040 C00064534 seal - dispenser to valve

041 C00005572 sealing washer-mains inlet hose

042 C00005781 inlet hose filter

043 C00003070 mains inlet hose cold 25c 10bar

045 C00092348 self-scraping screw 3,5x8

052 C00094744 screw locking motor/tub

053 C00116098 dispenser top rotary

055 C00263068 card avl82ag evoii 8kb sw n4008c01

056 C00263927 1 x C00272306 smart card reader

mod.AVL82AG page 9

Page 10

1140960 Exploded views

mod.AVL82AG page 10

Page 11

1140960 Spare parts list

Ref. Code From To S/N Substitute Description Notice Industrial

001 C00141139 wiring

003 C00093718 wiring pump-motor-module j9 (hl)

007 C00093720 wiring standard earth

008 C00093726 wiring display

008 C00111227 wiring display

012 C00093715 1 x C00259857 wiring door lock-module j4

014 C00093713 wiring ntc-evl+evp-module j8

mod.AVL82AG page 11

Page 12

Notices

n1040242: Power card with welded eeprom.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From serial number 20304.0001, IDC power card with welded eeprom is used to ensure the perfect connection of all parts, in the

Comunanza, Teverola and Brembate factories.

To replace the module with welded eeprom, it will be necessary to use the eeprom indicated in the SAT document of the model

concerned.

To replace the module on a unit with welded eeprom both the SAT module and the eeprom are required, because the latter cannot

be reused.

n1040296: List of EVOII FAULTS and troubleshooting.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

In case of washing-machine fault in carrying out the self-test function, the machine reproposes the fault previously signalled and

the same fault is shown on the display of the new hardware key.

The type of fault can be signalled in different ways:

- on AVD models the fault is shown directly on the machine display.

- on AVL models the fault is signalled by LEDs.

Reading of Faults signalled by LEDs

When the machine has a fault:

1. The window is locked

2. The door lock light flashes fast (> 1 Hz)

3. The control panel LEDs light up, to signal the fault, according to the table (fig. 01).

The example shown in fig. 02 (Example Fault F03) below indicates which LEDs are flashing if the machine has Fault F03

List of faults, malfunctions and Warnings:

F01: Triac Motor short circuit

- Check for water leaks that may affect connector J9 causing the relevant contacts to short

- Check the motor terminal block (possible problems due to chemical effects of work residuals on the contacts which may cause

short-circuiting)

- Replace Card

F02: Motor blocked, Tachometrics in Short Circuit/Open

- Check motor if blocked

mod.AVL82AG page 12

Page 13

- Check efficiency of J9 connector on card

- Check the tachometric winding verifying an ohmic resistance reading of 115 - 170 ohm between pins

1 and 2 on wiring connector J9. In case of short circuit/open circuit check the wiring between pins 1 and 2 of J9 relevant to the

tachometrics. With three-phase motor, make sure there is ohmic continuity between J9 pins 6 and 7.

- Replace motor

- Replace card

F03: NTC Open or in Short Circuit or washing heater relay stuck (signalled in presence of full load)

- Check efficiency of J8 connector contacts on card

- Check NTC verifying that the ohmic resistance value at room temperature 20°C is approx. 20Kohm on J8 wiring connector pin

11 and 12.

- If the measurement is incorrect check J8/NTC wiring continuity

Check the same parameter directly on NTC

- Replace NTC

- Replace Card

F04: Simultaneous empty and overflow (pressure switch stuck on empty).

If the pressure switch contact is stuck on empty the washing-machine loads water until reaching the overflow. The drain pump is

automatically started by the contact on the overflow pressure switch.

- Check efficiency of J3 connector contacts on card

- Check pressure switch status by checking ohmic continuity on wiring connector J3 pins 2 and 4 (it must only be present with tub

empty), pins 2 and 3 (it must only be present with water in the drum) and pins 2 and 1 (it must only be present with water in the

tub above normal level, more than halfway up door glass).

- Check wiring of connector J3/pressure switch

- Replace pressure switch

- Replace card.

F05: Pump Blocked or pressure switch empty not reached

- Check efficiency of J9 connector on card, verifying a voltage of 220V between pins 8 and 9

- Check that pump if being fed

- Check Pump Filter + wall drain

- Change Pump

- Replace Card

F06: No on AVD and AVL

F07: No Wash Heating Element Absorption (the fault is only signalled with the pressure switch on empty)

- Check efficiency of J3 connector contacts on card

- Check continuity of the wash heating element on J3 connector pins 5 and 6. The 1800W 230V heating element has a resistance

of 25 ohm.

- Check connection of pressure switch J3 connector pins 2 and 3: there must not be ohmic continuity (shared with full load).

Check connection of pressure switch J3 connector pins 2 and 4: there must be ohmic continuity

- Replace Heating Element

- Replace Pressure Switch

- Replace Card

F08: Wash Heater Relay Stuck (signalled in presence of empty) or pressure switch stuck on Full (simultaneously empty and full)

- Check efficiency of J3 connector contacts on card

- Check pressure switch status by checking ohmic continuity on wiring connector J3 pins 2 and 4 (it must only be present with

tub empty), pins 2 and 3 (it must only be present with water in the drum) and

pins 2 and 1 (it must only be present with water in the tub above normal level, more than halfway up door glass).

- Check wiring J3/pressure switch

- Check connection of heating element J3 connector pins 5 and 6.

- Replace pressure switch

- Replace Card

F09: Machine Setup Error (Eeprom error)

mod.AVL82AG page 13

Page 14

- In case of production card with Eeprom soldered: replace the card and Eeprom

- In case of replacement of Eeprom and card, check correct housing of Eeprom on card socket

F10: No full and empty signal

- Check efficiency of J3 connector contacts on card

- Check pressure switch status by checking ohmic continuity on wiring connector J3 pins 2 and 4 (it must only be present with

tub empty), pins 2 and 3 (it must only be present with water in the drum) and

pins 2 and 1 (it must only be present with water in the tub above normal level, more than halfway up door glass).

- Check wiring of connector J3/Pressure switch

- Replace Pressure Switch

- Replace Card

F11: No Pump Feedback (Drain pump disconnected or winding broken)

- Check efficiency of J9 connector on card

- Check continuity of the Pump on J15 connector pins 1 and 2 (in case of washing-machine with Easy Door door lock) or on J9

connector pins 8 and 9 (in case of conventional door lock), checking a resistive value equal to 170 ohm.

- Check wiring of connector J15 (or J9)/Pump

- Replace Pump

- Replace Card

F12: No Communication Display/LED Card-Main Board

- Check efficiency of contacts on card of J11 connector

- Check the continuity of J11 connector-display card 5-pin connector

- Replace Main Board

- Replace Display Card/LED

F13: Drying NTC sensor open / Drying system NTC wiring disconnected

Check efficiency of J10 connector on card

Check NTC on J10 connector pins 7 and 8 verifying that the ohmic value of the sensor at room temperature 20°C is approx.

20Kohm

Check continuity of NTC/J10 connectors wiring

Replace NTC

Replace card

F14: Drying heater open or not connected

Check efficiency of J2 connector contacts on card

Check continuity of drying heater on J2 wiring connector pins 1 and 2, verifying that the ohmic value of the 1300W 230V heating

element is approx. 40Kohm

Check wiring of connector J10/drying heater

Replace heating element

Replace card

F15: Drying heater always on (drying relay contact stuck or drying Triac short circuit)

Check efficiency of J2 connector contacts on card of

Check wiring of connector J2/drying heater

Check wiring of connector J3/pressure switch

Replace card

F16: Drum locking (top-loading only)

F17: Door lock unfed/open (with Easy Door)

- Check presence of 230V mains power on J4 wiring connector inserted on card between pins 3 and 4,

(not present with machine on standby) and presence of power from 230V door lock between pins 3 and 5

- Check ohmic continuity of the door microswitch on J4 connector inserted on card between pins 1 and 2 (with door closed/on

open/off)

- Check continuity of J4/door lock wiring

- Check door hooking

mod.AVL82AG page 14

Page 15

- Replace door lock

- Replace card

F17: Door lock unfed/open (conventional door lock, not Easy Door)

- Check presence of 230V mains power on J4 wiring connector inserted on card between pins 2 and 3,

(not present with machine on standby) and presence of power from 230V door lock between pins 3 and 1

- Check door hooking

- Replace door lock

- Replace card

F18 --> Communication error microprocessor / DSP (Digital Signal Processor)

- Replace card

mod.AVL82AG page 15

Page 16

mod.AVL82AG page 16

Page 17

n1040372: Introduction of new shock absorbers and expanders.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From serial no. 50725.0001, new shock absorbers and expanders have been introduced.

mod.AVL82AG page 17

Page 18

New codes:

C00140670 - shock absorber

C00118593 - expander

Premodification codes

C00097259 - shock absorber

C00055037 - expander

The new items can also be used (but not separately) when replacing shock absorber 100N - C00097259; in this case, it will be

necessary to replace both shock absorbers / expanders using kit C00140744, which is composed of two new shock absorbers and

two new expanders.

List of appliances affected by this modification

22484AB84PT

23295W63IT

23308W93TEX

23310W83TEX

23317W83SP

23320W83TK

23321W83TTK

23330W93UK

23332W104TEX

23334W103UK

23335W113UK

23337W103TTK

23386W104NL

23781AB95EU

23879AB95AUS

23909AB63EX5060HZ

23910AL109K60HZ

24415W104SP

24600W103NL

24833W83DE

24834W104DE

mod.AVL82AG page 18

Page 19

25379W9521E

25474W104TBE

25885W63TAUS

25886W83TAUS

26878WA6IT

26879WA8IT

26880WA10IT

27094AB107PT

27299AL102PFR

27639WA6PT

27640WA8PT

27641WA10PT

27647WE8EX

27648WE10EX

27699W85FR

27700W105FR

27757WP67EX

27761WP100EX

27914AB84IT

28016WA105UK

28119AB66IT

28193W104TCH

28305WE8IT.1

28306WE10IT.1

28382WAP61EX

28383W84TTK

28400W104TTK

28479AV82TK

28480AVL85TK

28481AV102TK

28482AVL105TK

28484AVD8TK

28485AVD10TK

28626W101UK

28674W83FR

28676W107FR

28876AL88EU

28877AL109EU

28940AVL68ITTE

29378LNA1000FR

29540W81EX

29541W101EX

29549WP80EX

29999LISA100FR

30000WI10FR

30001WIL12FR

30018WIL113UK

30028WIE127UK

30055AVL6EIT

30056AVL8EIT

30062AVL62EX60HZ

30063AVL61EX115/60

30092AVL66PIT

30093AVL86PIT

30139WI8FR

30144WIL106IT

30145WIL86IT

mod.AVL82AG page 19

Page 20

30146WIL66IT

30196WI101UK

30197WI121UK

30206AVL105SK

30222WIE107IT

30223WIE87IT

30228WIV80IT

30229WIV60IT

30233WIL105EU

30234WIL85EU

30235WILM64IT

30331W12GE

30352WI81EX

30353WI82EX

30354WIL85EX

30355WI101EX

30356WIL105EX

30357AVL100PR

30361AVL95AUS

30443WIL126NL

30444WIE128NL

30455WIL105DE

30459WIL125DE

30460WIE127DE

30484WI70TK

30486WI80TK

30488WI100TK

30490WIL81TK

30492WIL101TK

30503WI62AUS

30507WI82SING

30513WI82AUS

30515WI82EX60HZ

30517WI102PL

30520WI105EX

30522WI102EX

30523WI102AUS

30525WI122EX

30526WIL62EX

30535WIL95KW

30540WIL125EX

30545WIE87EX

30548WIE107EX

30551WIE127EX

30611AVL64EU

30612AVL65PT

31813WI8EU

31922WI102EU

31923WI122EU

31969WI600IT

31970AV102CSI

32251WIL123DE

32252WIL143DE

32538WI102CH

32539WIL125CH

32571WIL146NLTE

32572WIE148NLTE

mod.AVL82AG page 20

Page 21

32859LISA111FR

32860WI11FR

32861WIL13FR

33178WIL145DETE

33179WIE147DETE

33180AVL145DETE

33244AVL62EO

33612AVL145EUTE

33613WIL103IT

33622WIL145EU

33623WIE147EU

33624WIL133UKTE

33625WIE147UKTE

33685AVL62KW

33742WIA121UK

33754WIA122EX

33962WIL14NL

33968AV6EU

33979AVF10TK

34056WIL146SPIT

34214AVF8TK

34238WIL14FRTE

34412WIAV60IT

34413WIA600EU

34415WIAV80IT

34438WIA60TK

34439WIA82EX

34440WIA80TK

34442WIA82EX60HZ

34443WIA8EU

34444WIA100TK

34445WIA102PL

34446WIA102EX

34447WIA101EU

34448WIA102CH

34449WIA121EU

34450WIL8FR

34451WIL11FR

34452LISA10FR

34453WIE12FR

34471WIL1000OT

34472WIL1200OT

34479AVL14FR

34483WIA101UK

34486WIA101EX

34507WIL62AUS

34508WIL82AUS

34509WIL102AUS

34515WIU61CSI

34516WIU81CSI

34517WIU102CSI

34907WIL103UK

35010WIU82CSI

35248WIL10FR

35249WIE10FR

35397WIL85EXTE

35398AVL62EXTE

mod.AVL82AG page 21

Page 22

35399AVL82EUTE

35400AVL88ITTE

35913AVF88EUTE

35918AVL66PITTE

35919AVL84EUTE

35920WIL105EXTE

35921WIL85PLTE

35974AV8IT

35975AV10IT

36241WIL125NL

36243WIL124NL

36536AVL95EXTE

36537AVL125EUTE

36593WIA110EU

36594WIL105PLTE

36595WIL126ITTE

36596WIL113UKTE

36684AVL105EU

36685WIE107PLTE

36768AVL120FRTE

36887WIL106SPEU

37014WILB12EU

37335WIA64IT

37732WIA9FR

37916AVL82AG

38059LISA11FR

mod.AVL82AG page 22

Page 23

n4007j00: Rear feet changed

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From Serial Number 70403.0001 the two rear feet changed with new code C00254045, the cabinet fixing has been modified.

The new feet are not interchangeable with premodification.

CABINET

The spare part code isn't changed, in the warehouse stock we have the new cabinet.

If you fix it on premodification models you need to use the new feet.

n4008c01: Smart Card - LVB/DRYERS

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Beginning April 2008 spare parts warehouse started to manage the EVOII modules with eeprom fixed, these can only be

programmed with smart card/palmare/pc.

Attention!! The premodification with eeprom socket can be programmed with smart card/palmare/pc using a blank eeprom or

with pre programmed eeprom.

Spare parts of modules with eeprom fixed/eeprom socket:

C00265676 with eeprom fixed - C00143068 with eeprom socket - for models with conducibility sensor

C00254298 with eeprom fixed - C00143068 with eeprom socket - for models without conducibility sensor

C00254297 with eeprom fixed - C00259941 with eeprom socket

C00254531 with eeprom fixed - C00143058 with eeprom socket

C00254297 with eeprom fixed - C00143057 with eeprom socket - for models without blocking drum

C00265697 with eeprom fixed - C00143057 with eeprom socket - for models with blocking drum

C00254297 with eeprom fixed - C00143056 with eeprom socket

C00254530 with eeprom fixed - C00259738 with eeprom socket

C00254533 with eeprom fixed - C00143060 with eeprom socket

C00254535 with eeprom fixed - C00145013 with eeprom socket

C00254530 with eeprom fixed - C00145551 with eeprom socket

C00254529 with eeprom fixed - C00142293 with eeprom socket

C00257406 with eeprom fixed - C00143989 with eeprom socket

C00257409 with eeprom fixed - C00144151 with eeprom fixed

C00254530 with eeprom fixed - C00143069 with eeprom fixed

DRYERS

C00255835 with eeprom fixed - C00258789 with eeprom socket

C00255835 with eeprom fixed - C00194077 with eeprom socket

This notice has a "reference list" specific for each product where you can find the link between smart card and the eeprom code

with the same software.

mod.AVL82AG page 23

Page 24

Electric schemes and links

Cod. 16001840201

mod.AVL82AG page 24

Page 25

Legend

Legend: 16001840201

mod.AVL82AG page 25

Page 26

Electric schemes and links

Cod. 21500759100

mod.AVL82AG page 26

Page 27

Legend

Legend: 21500759100

mod.AVL82AG page 27

Loading...

Loading...