Ariston TVM631EUHA, AS600VXFR, AS600VKW, AS600VEX, AS600VXAG Service Information

Information

Indesit Company UK Limited

© 2008 Reg. Office: Peterborough PE2 9JB. Registered in London: 106725

Service

6 kg

Vented

Electro

Mechanical

Tumble Dryers

Models Comm.

Covered Code

Hotpoint-Ariston

TVM631EUHA 48890

Ariston

AS600VXFR 49613

AS600VKW 51893

AS600VEX 51891

AS600VXAG 51896

5407394 Issue 1 May 2008

2

SAFETY NOTES & GENERAL SERVICING ADVICE

1. This manual is NOT intended as a comprehensive repair/maintenance guide to the appliance.

2. It should ONLY be used by suitably qualified persons having technical competence applicable

product knowledge and suitable tools and test equipment.

3. Servicing of electrical appliances must be undertaken with the appliance disconnected (unplugged)

from the electrical supply.

4. Servicing must be preceded by Earth Continuity and Insulation Resistance checks.

5. Personal safety precautions must be taken to protect against accidents caused by sharp edges on

metal and plastic parts.

6. After Servicing the appliance must be rechecked for Electrical Safety. In the case of appliances which

are connected to a water supply (i.e.: Washing Machines, Dishwashers & Food Centres etc.) checks

must be made for leaks from seals gaskets and pipe work and rectification carried out where

necessary.

7. It can be dangerous to attempt ‘DIY’ repairs / maintenance on complex equipment and the Company

recommends that any problem with the appliance is referred to its own Service Organisation.

8. Whilst the Company has endeavoured to ensure the accuracy of the data within this publication they

cannot hold themselves responsible for any inconvenience or loss occasioned by any error within.

SERIAL NUMBER / INDUSTRIAL CODE EXPLANATION

Serial Number Example

3 10 02 0895

Four remaining digits = Build number that day 895

th

built

Third two digits = Day of manufacture 2

nd

of month

Second two digits = Month of manufacture October

First digit = Year of manufacture 2003

Industrial Code Example

37 24455 0010

Last four digits = 0000 original production.

Second five digits = COMMERCIAL CODE*

First two digits = Factory of origin

* Vital for correct model information and system identification

Other numbers denote major production changes

3

INDEX

Safety Notes & General Servicing Advice . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Serial Number / Industrial Code Explanation. . . . . . . . . . . . . . . . . . . . . . . . . .2

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Machine Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Programmes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Component Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 12

Dismantling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 17

Timer Sequence Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 - 19

Wiring Diagram - Models TVM631EUHA, AS600VEX, AS600VXFR

Invensys Timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

ELBI Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Wiring Diagram - AS600VXAG, AS600VKW

Invensys Timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

ELBI Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4

TECHNICAL SPECIFICATION

General All models Polar White

Features Reversing - Dual Heat - 140 minutes Programme Timer,

Easy Iron (crease removal) and Auto Drying options, 12 hour

Delay Timer and End of Programme Alarm (with Switch and

Start Switch).

Energy Efficiency C

Noise 69 dB

Country of Origin Great Britain

Dimensions

Height 850 mm

Width 595 mm

Depth 550 mm

Weight 35 kg (packed)

Drum Speed 55 rpm Reversing

Drying Load Dry Weight Maximum 6 kg

Drum Volume 100 litres

Door Operation Lever operated door catch

Heater High Heat - 2200W @ 230V

Low Heat - 1100W @ 230V

Heater Controls Heat Selection Push Button out for High Heat

Control Thermostats

Cycling Thermostat 120°C

One Shot 150°C

Eco Thermostats

Full Load 55°C White Spot

Half Load 60°C Purple Spot

All thermostats are rated at 10 amps @ 230 Volts

Timer Range up to 140 minutes including 7.5 minutes Cool Tumble.

Two Eco Programmes and Easy Iron (crease removal)

programme.

Motor - Type 358 Capacitor run, single phase, 2 Pole, induction type

Motor Speed 2800 rpm

Capacitor 7.5 uF

5

MACHINE FUNCTION

Cold air is drawn into the dryer cabinet interior thro ug h lo uvr es in the cabi ne t ba se, pa sse s throu gh

the large hole in the inner back panel adjac ent to th e fan a nd is driv en th rough the elemen t hous ing

on the inner back panel. After passing through the element windings and through holes in the drum

back plate into the drum interior, the now warm air is driven through the load to the front of the drum.

A webbing seal, fixed to the inside of the inner back panel, prevents warm air being driven into the

cabinet interior. As the drum revolves, the load is tumbled through the warm air stream, that extracts

moisture from the damp fabric. The now mo ist and coo led air passes through the filter in the air duct

on the back of the front panel, where any fluff picked up from the load is removed. The air then travels

through the front to rear air duct, leaving the dryer at the rear outlet.

If required, a vent hose may be attached to the outlet, to take exhaust air away from the dryer.

A cut-out on the element housing, cuts the electricity Live supply to the element, if the air temperature

in the housing becomes too high due to a restriction in the air flow, e.g a blocked filter. The cut-out

automatically resets when the air temperature drops to an acceptable level and cycles if the fault

persists.

A second 'one shot' cut-out, mounted alongside the 'auto reset' cut- out, is fitted as a safety device to

break the element Neutral connection, if the air temperature reaches an unsafe level due to failure of

the 'auto reset' cut-out.

There are two thermostats in the front air duct when only on e is in use at any one time de pending on

which programme is selected. These sense the exhaust temperature rise when the load becomes

dry and energise the timer motor on the main timer. This allows it to advance to cool run.

AIRFLOW DIAGRAM

6

AUTOMATIC DRYING - Fitted to some models only

To work correctly High Heat has to be enabled and between 3 kg to 6 kg of Cottons dried. If smaller

or delicate loads are dried using the automatic setting, erratic results will be achieved.

Automatic Drying Explanation

NOTE: - The heat switch must be set to the high p osition otherwise there will be no circuit to the timer

motor or heater when the exhaust thermostat signals tha t the clot he s are dry.

Sequence of Automatic Drying System

• First 20 minutes, full heat controlled by the timer. This is to pre -heat the clothes and drum before

the exhaust thermostats take control.

• The timer moves to its next cam position. The timer motor is now disconnected and the dryer

tumbles and heats.

• When the clothes are dry, the exhaust thermostat opens. This provides a Live supply to the timer

motor. The timer moves to the next cam position.

• 5 minutes of tumbling with the lower element only. The timer moves to the next cam position.

• Finally 7.5 minutes of tumble with no heat.

7

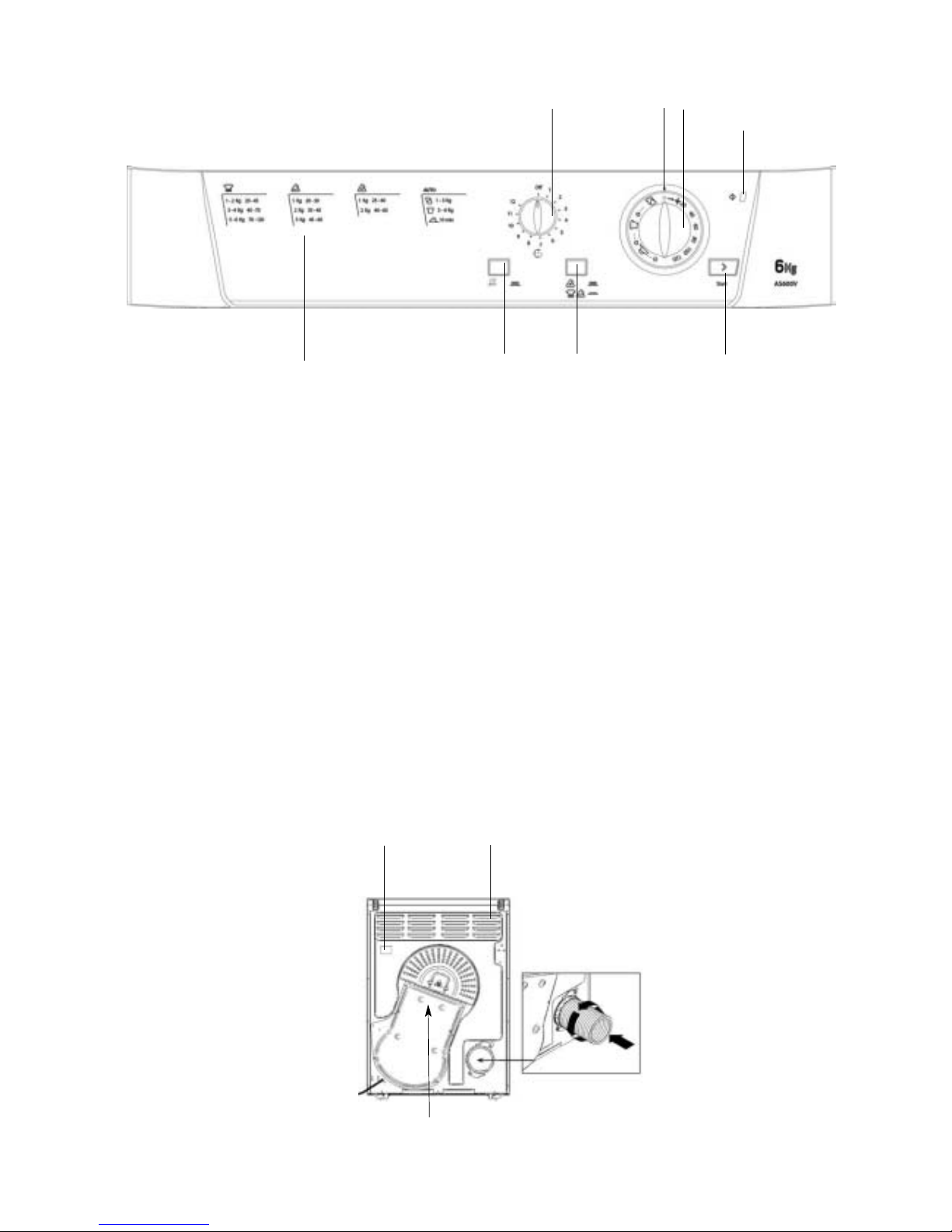

CONSOLE

NOTE: - Not all of the above functions and options are available on all models covered in this

manual.

The START button begins drying a selected

programme.

The HEAT button selects the drying

temperature.

OUT: Low Heat. IN: High Heat.

The ALARM buzzer signals the end of a

drying cycle.

OUT: Buzzer OFF. IN: Buzzer ON.

The ACTIVE indicator light signals that the

dryer is in use. This light will glow when the

START button is pressed. It will remain on

until the door is opened or the power is turned

off. this light will be on during a delayed start

programme.

The Drying Guide allows the customer to

consult a user friendly table of fabric types and

load capacities and shows a guide of the

programmes available.

The DELAY knob sets a delay on the dryers

start time, it can be rotated clockwise until you

reach the number of hours you want to delay

the start time. If you have gone too far, turn the

knob anti-clockwise.

The TIMER / PROGRAMMES knob sets the

drying time or programme. Rotate it clockwise,

never anti-clockwise, until the indicator is

pointing to the time or programme you want to

select.

p

Drying Guide

PROGRAMMES

Knob

TIMER

Knob

START

Button

Indicator

ACTIVE

Light

HEAT

Button

ALARM

Button

Air Intake Vent

Vent Tube fitted here

Caution: Hot!

Rating plate

Loading...

Loading...