ARI Armaturen STEVI BBD 415 DN 25-50 User Manual

Operating and Installation Instructions

Straight-through blow-down valves - STEVI®BBD 415

DN 25 - 50

Contents

1.0 General information about these

Operating Instructions ................................2-2

2.0 Notes on possible dangers.........................2-2

2.1 Meanings of the symbols used............................ 2-2

2.2 Explanatory notes on safety information ............. 2-2

3.0 Storage and transport ................................ 2-2

4.0 Description...................................................2-3

4.1 Applications......................................................... 2-3

4.2 Operating principle .............................................. 2-3

4.3 Diagrams ............................................................ 2-4

4.4 Technical data ..................................................... 2-6

4.5 Marking ............................................................... 2-6

5.0 Installation....................................................2-7

5.1 General notes on installation............................... 2-7

6.0 Putting the valve into operation.................2-8

7.0 Care and maintenance ................................2-9

7.1 Replacing the valve stem seals........................... 2-9

7.1.1 PTFE V-ring unit design ................................. 2-9

7.2 Replacing the valve trim.................................... 2-10

Series 415

7.3 Replacing the rolling diaphragm and springs .....2-11

7.4 Replacing the actuator stem seals .................... 2-13

7.5 Assembling the valve and the actuator ............. 2-13

7.6 Retrofitting the hand lever ................................. 2-13

7.7 Tightening torques............................................. 2-14

7.7.1 Tightening torques for hexagon nuts .......... 2-14

7.7.2 Tightening torques for flange nuts ............... 2-14

7.7.3 Tightening torques for studs ........................ 2-14

8.0 Troubleshooting ........................................ 2-14

9.0 Troubleshooting table ............................. 2-15

10.0 Dismantling the valve ............................ 2-16

10.1 Dismantling the actuator from the valve .......... 2-16

10.2 Dismantling the actuator.................................. 2-16

11.0 Warranty / Guarantee .............................. 2-17

12.0 EC declaration of conformity................. 2-18

Rev. 0040321000 0714 englisch page 2-1

Operating and Installation Instructions

Straight-through blow-down valves -

STEVI®BBD 415

1.0 General information about these Operating Instructions

These Operating Instructions provide information on mounting and maintaining the valves.

Please contact the supplier or the manufacturer in case of problems which cannot be

solved by reference to the Operating Instructions.

They are binding for transport, storage, installation, start-up, operation, maintenance and

repair.

The notes and warnings must be observed and adhered to at all times.

- Handling and all work must be carried out by expert personnel or all activities supervised

and checked by a suitably trained person.

It is the duty of the operator to define areas of responsibility and competence and to

supervise personnel.

- All currently valid local safety requirements must be additionally applied and observed

when removing the valves from service or when maintaining or repairing them.

The manufacturer reserves the right to introduce technical modifications at any time.

These Operating Instructions comply with the requirements of the relevant EU Directives.

2.0 Notes on possible dangers

2.1 Meanings of the symbols used

ATTENTION !

. . .

Warning regarding a general danger.

2.2 Explanatory notes on safety information

Dangers, risks and safety information are highlighted in these Operating and Installation

Instructions to attract the reader's attention.

Information marked with the above symbol and "ATTENTION !" describes behaviour or

procedures which - if ignored - can result in serious or fatal injury to users or third parties or

in material damage to the system or the environment. The behaviour and procedures

referred to must be complied with and suitable measures impemented to monitor such

compliance.

All other information not specifically emphasised, such as transport, installation, operating

and maintenance instructions as well as technical data (in these Operating Instructions, in

the product documentation or on the device itself) must likewise be complied with in order

to avoid faults which could directly or indirectly cause serious injury to persons or damage

to property.

3.0 Storage and transport

ATTENTION !

- Protect against external shocks (impact, vibration, etc.).

- Valve mountings such as actuators, handwheels, bonnets, etc. must not be

used to absorb external forces, e.g. they are not designed to be used as

climbing aids or as attachment points for lifting gear.

- Suitable handling and lifting equipment must always be used.

Refer to the data sheet for weights.

- Permissible temperature range: -20°C to +65°C.

- The paint is a base coat to protect against corrosion during transport and storage. Be

careful not to damage the paint protection.

Page 2-2 Rev. 0040321000 0714

Operating and Installation Instructions

Straight-through blow-down valves -

STEVI®BBD 415

4.0 Description

4.1 Applications

Blow-down valves are used to "blow down steam boilers".

ATTENTION !

- Refer to the data sheet for applications, limits of use and operating options.

- Certain media require or preclude the use of special materials.

- The valves are designed for standard operating conditions. If the actual

conditions exceed these requirements, e.g. aggressive or abrasive media, all

non-standard requirements should be indicated in the order.

All information provided here conforms to the Pressure Equipment Directive 97/23/EC.

It is the responsibility of the machine planner to ensure compliance.

Special markings on the valve must be taken into account.

Refer to the data sheet to see which materials are used in standard versions.

Please contact the supplier or the manufacturer if you have any questions.

4.2 Operating principle

The blow-down valves are specially designed for blowing down steam boilers with

compressed air. When opened for a short period by a pneumatic actuator or manually

operated with a lever, they form an eddy of water that entrains sludge from the boiler end.

Corrosion is effectively prevented.

The flow always approaches a blow-down valve in the closing direction. The closing force

of the springs is supported by the medium pressure.

Rev. 0040321000 0714 Page 2-3

Operating and Installation Instructions

Air

supply

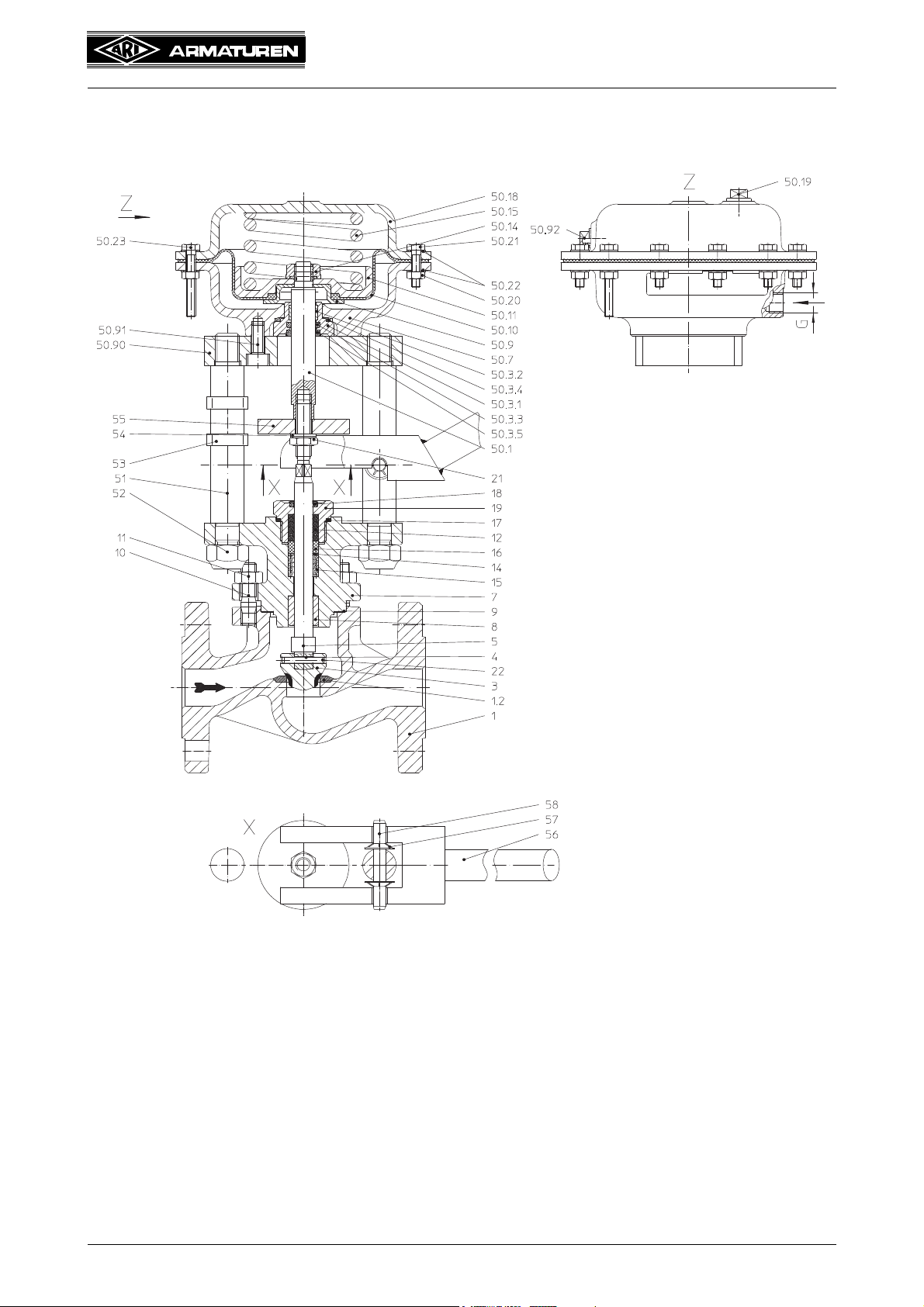

4.3 Diagrams

Straight-through blow-down valves -

STEVI®BBD 415

Fig. 1: Series 415 DN 25, 32

Page 2-4 Rev. 0040321000 0714

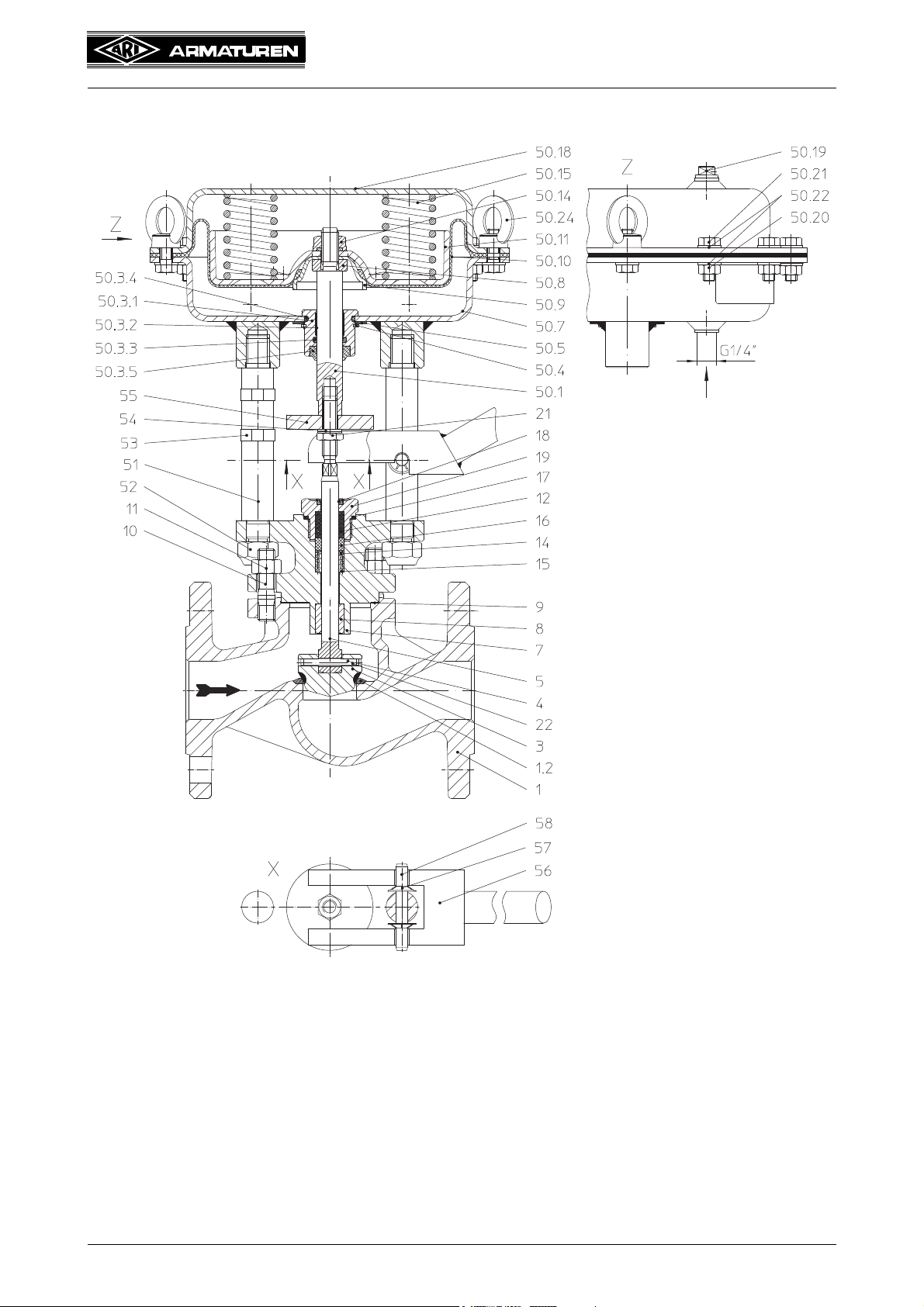

Operating and Installation Instructions

Air

supply

Straight-through blow-down valves -

STEVI®BBD 415

Fig. 2: Series 415 DN 40, 50

Rev. 0040321000 0714 Page 2-5

Operating and Installation Instructions

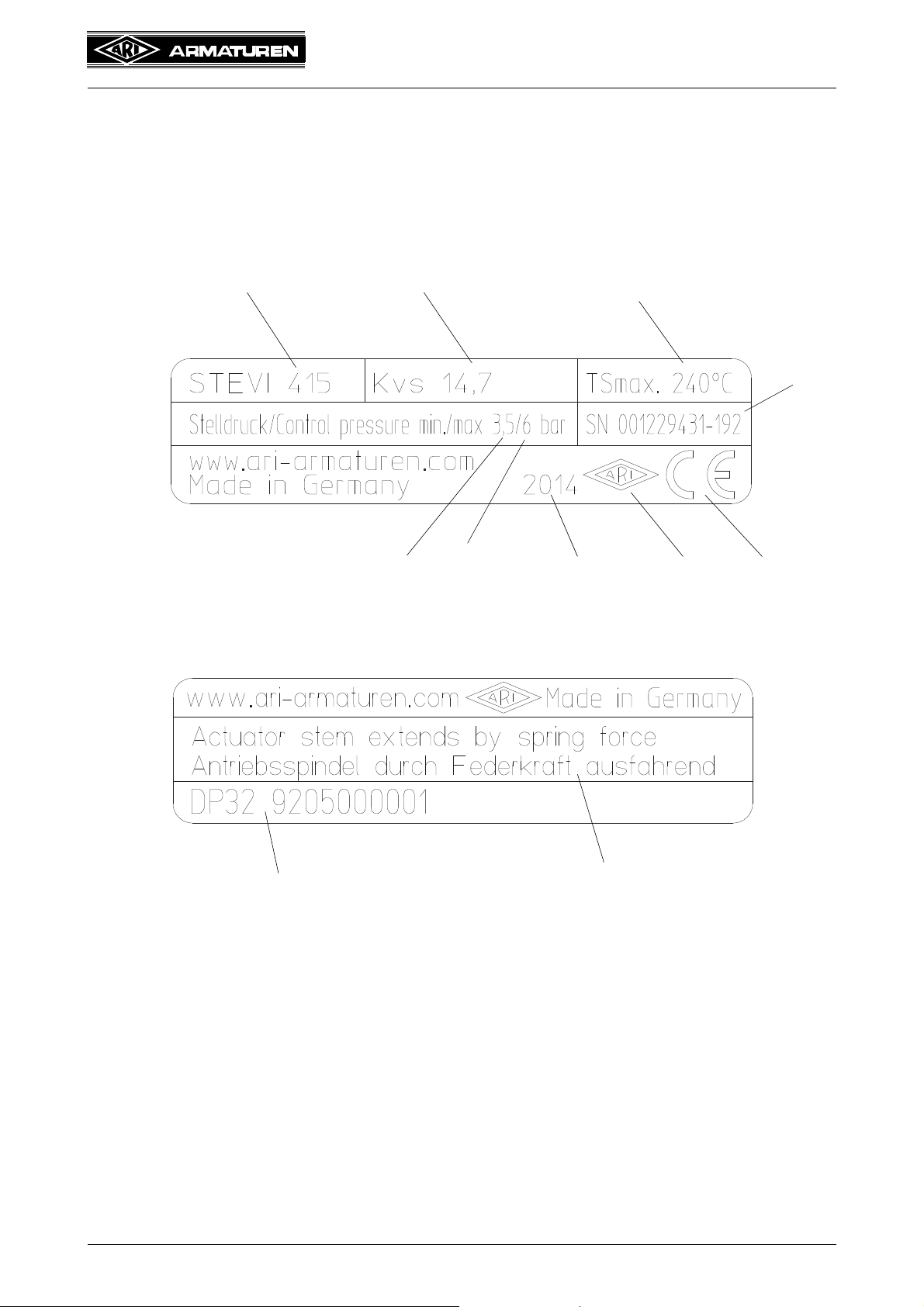

CE marking

Manufacturer

Kvs valueType No.

Actuator mode

of operation

Serial No.

Air supply

pressure min.

Air supply

pressure max.

Year of manufacture

max. operating temperature

Type No. / Figure No.

Straight-through blow-down valves -

4.4 Technical data

For

- Principal dimensions,

- Pressure-temperature ratings, etc. refer to the data sheet.

4.5 Marking

STEVI®BBD 415

Fig. 3

Address of manufacturer: refer to item 11.0 Warranty / Guarantee

According to the Pressure Equipment Directive (fluid group 2, diagram 7, annex II), valves

are only allowed to bear the CE marking upwards of PN 40 DN 40.

Page 2-6 Rev. 0040321000 0714

Loading...

Loading...