ARI Armaturen SAFE-TCP, SAFE-TCS950 User Manual

Operating and installation instructions

Safety valves SAFE

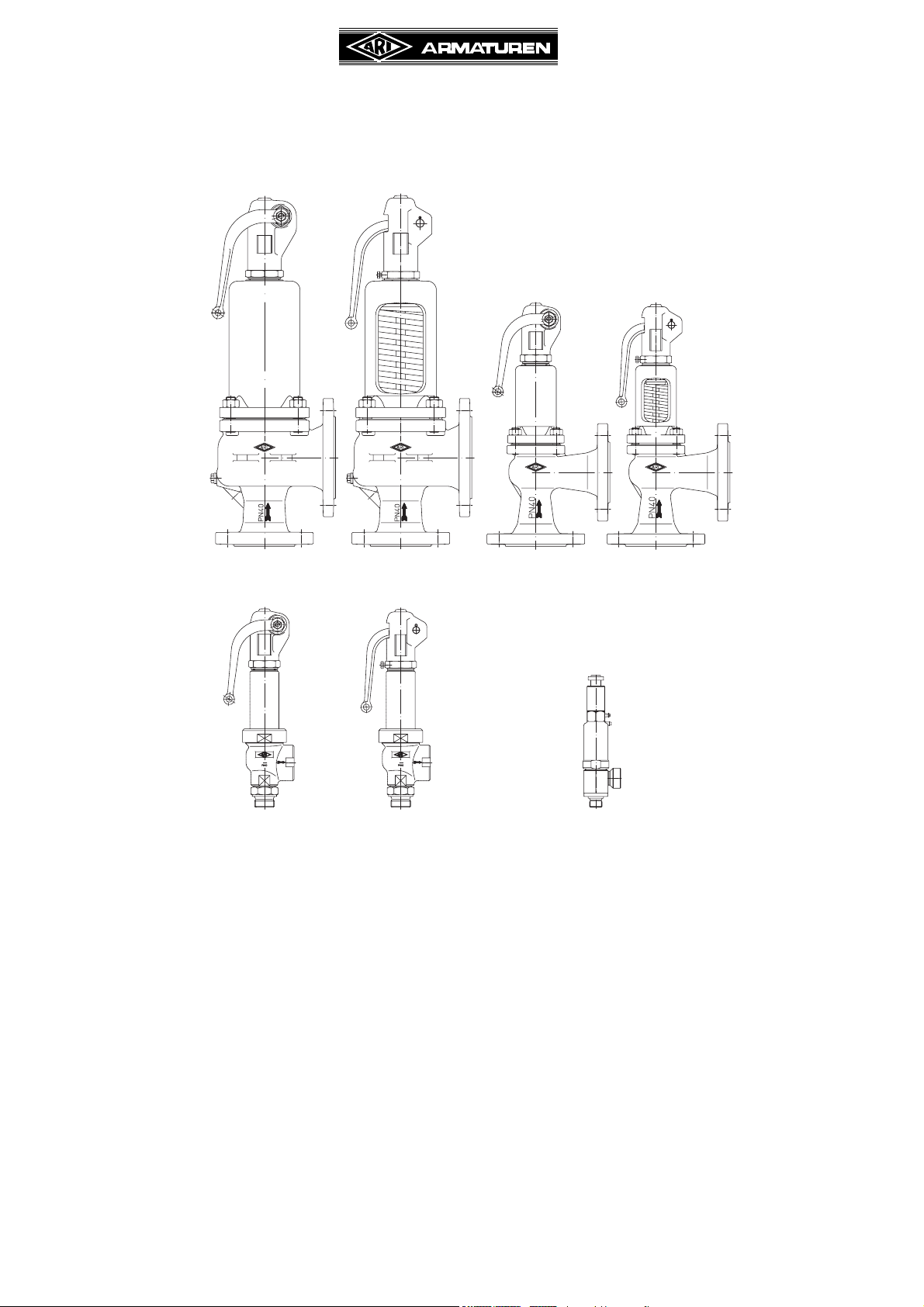

SAFE

(Series 900)

SAFE-TC

(Series 940)

Contents

1.0 General information on operating

instructions ..................................................2-2

2.0 Notes on possible dangers........................2-2

2.1 Significance of symbols ...................................... 2-2

2.2 Explanatory notes on safety information ............. 2-2

3.0 Storage and transport ...............................2-3

4.0 Description..................................................2-3

4.1 Scope of applications .......................................... 2-3

4.2 Operating principles ............................................ 2-3

4.3 Diagram............................................................... 2-4

4.3.1 Parts list ...................................................... 2-5

4.4 Technical data - remarks ..................................... 2-6

4.5 Marking ............................................................. 2-7

5.0 Installation...................................................2-8

5.1 General notes on installation............................... 2-8

6.0 Putting the valve into operation..............2-10

SAFE-P

(Series 920)

SAFE-TCP/TCS

(Series 960/950)

7.0 Care and maintenance............................. 2-11

7.1 Setting instructions ............................................ 2-11

7.1.1 Removing the cap .....................................2-11

7.1.2 Changing the set pressure “without” spring

change .................................................... 2-12

7.1.3 Changing the set pressure “with” spring

change .................................................... 2-12

7.2 Representation ................................................. 2-14

8.0 Troubleshooting ....................................... 2-15

9.0 Troubleshooting table ............................ 2-15

10.0 Dismantling the valve or the top part .. 2-17

11.0 Warranty / Guarantee ............................. 2-17

12.0 EC declaration of conformity................ 2-18

Rev. 0040401000 2913 englisch page 2-1

Operating and installation instructions

SAFE, SAFE-P, SAFE-TC, SAFE-TCP/TCS

1.0 General information on operating instructions

These operating instructions provide information on mounting and maintaining the fittings.

Please contact the supplier or the manufacturer in case of problems which cannot be

solved by reference to the operating instructions.

They are binding on the transport, storage, installation, start-up, operation, maintenance

and repair.

The notes and warnings must be observed and adhered to.

- Handling and all work must be carried out by expert personnel or all activities must be

supervised and checked.

It is the owner’s responsibility to define areas of responsibility and competence and to

monitor the personnel.

- In addition, current regional safety requirements must be applied and observed when

taking the fittings out of service as well as when maintaining and repairing them.

The manufacturer reserves the right to introduce technical modifications at any time.

These Operating Instructions comply with the requirements of EU Directives.

2.0 Notes on possible dangers

2.1 Significance of symbols

ATTENTION !

. . .

Warning of general danger.

Non-compliance with operating instructions is dangerous!

Read the operating instructions before installation, operation,

maintenance or disassembly and adhere to them strictly.

2.2 Explanatory notes on safety information

In these Operating and Installation Instructions dangers, risks and items of safety

information are highlighted to attract special attention.

Information marked with the above symbol and “ATTE NTIO N ! ” describe practices, a

failure to comply with which can result in serious injury or danger of death for users or third

parties or in material damage to the system or the environment. It is vital to comply with

these practices and to monitor compliance.

All other information not specifically emphasised such as transport, installation, operating

and maintenance instructions as well as technical data (in the operating instructions,

product documentation and on the device itself) must also be complied with to the fullest

extent in order to avoid faults which in turn can cause serious injury to persons or damage

to property.

Page 2-2 Rev. 0040401000 2913

Operating and installation instructions

SAFE, SAFE-P, SAFE-TC, SAFE-TCP/TCS

3.0 Storage and transport

ATTENTION !

- Protect against external force (like impact, vibration, etc.).

- Valve mountings such as actuators, handwheels, hoods must not be used to

take external forces, e.g. they are not designed for use as climbing aids, or as

connecting points for lifting gear.

- Suitable materials handling and lifting equipment should be used.

See catalog sheet for weights.

- At -20°C to +65°C.

- The paint is a base coat to protect against corrosion during transportation and storage. Do

not damage paint protection.

4.0 Description

4.1 Scope of applications

Safety valves are used to protect pressurised systems.

ATTENTION !

- Refer to the data sheet for applications, limits on use and possibilities.

- Certain media require or preclude the use of special materials.

- The valves are designed for standard operating conditions. If conditions exceed

these requirements, e.g. aggressive or abrasive media, the operator should

state the higher requirements when ordering

- Valves made from grey cast iron are not authorised for use in systems subject

to TRD 110.

- When media in Fluid Group 1 are used, seal exteriors must be designed so that

they pose no danger to humans or the environment.

- Open safety valves (open bonnet / open cap) are not permissible for fluids,

dusty atmospheres, open air use or for any Group 1 fluids in accordance with

Pressure Equipment Directive 97/23/EC.

The information complies to the Pressure Equipment Directive 97/23/EC.

It is the responsibility of the machine planner to ensure compliance.

The special markings on the valve must be taken into account.

Refer to the catalogue sheet to see which materials are used in standard versions.

Please contact the supplier or the manufacturer if you have any questions.

4.2 Operating principles

Safety valves are safety devices designed to prevent the pressure in any pressurised

system from exceeding the maximum permissible pressure by more than the permissible

tolerance of, usually +10%.

Rev. 0040401000 2913 Page 2-3

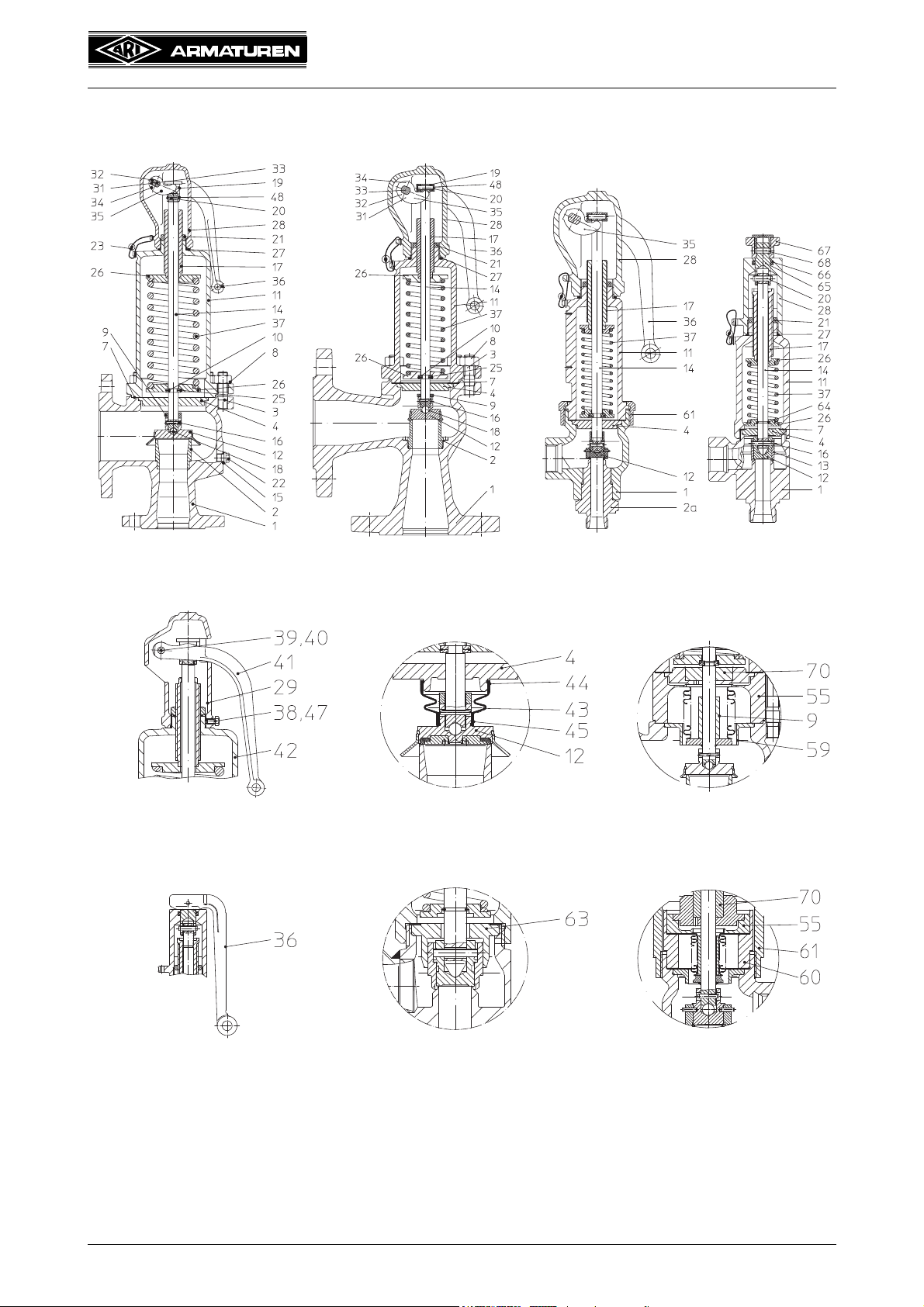

4.3 Diagram

Fig. 901 Fig. 941

Fig. 961

Fig. 921

Fig. 902 / 912 / 903 / 904 / 922 / 924 / 945 / 946

WEDI Bellow

Disc series 950 Bellow series 940

Lever

Fig. 951/952; 961/962

Operating and installation instructions

SAFE, SAFE-P, SAFE-TC, SAFE-TCP/TCS

fig. 1

fig. 2

Page 2-4 Rev. 0040401000 2913

Operating and installation instructions

SAFE, SAFE-P, SAFE-TC, SAFE-TCP/TCS

4.3.1 Parts list

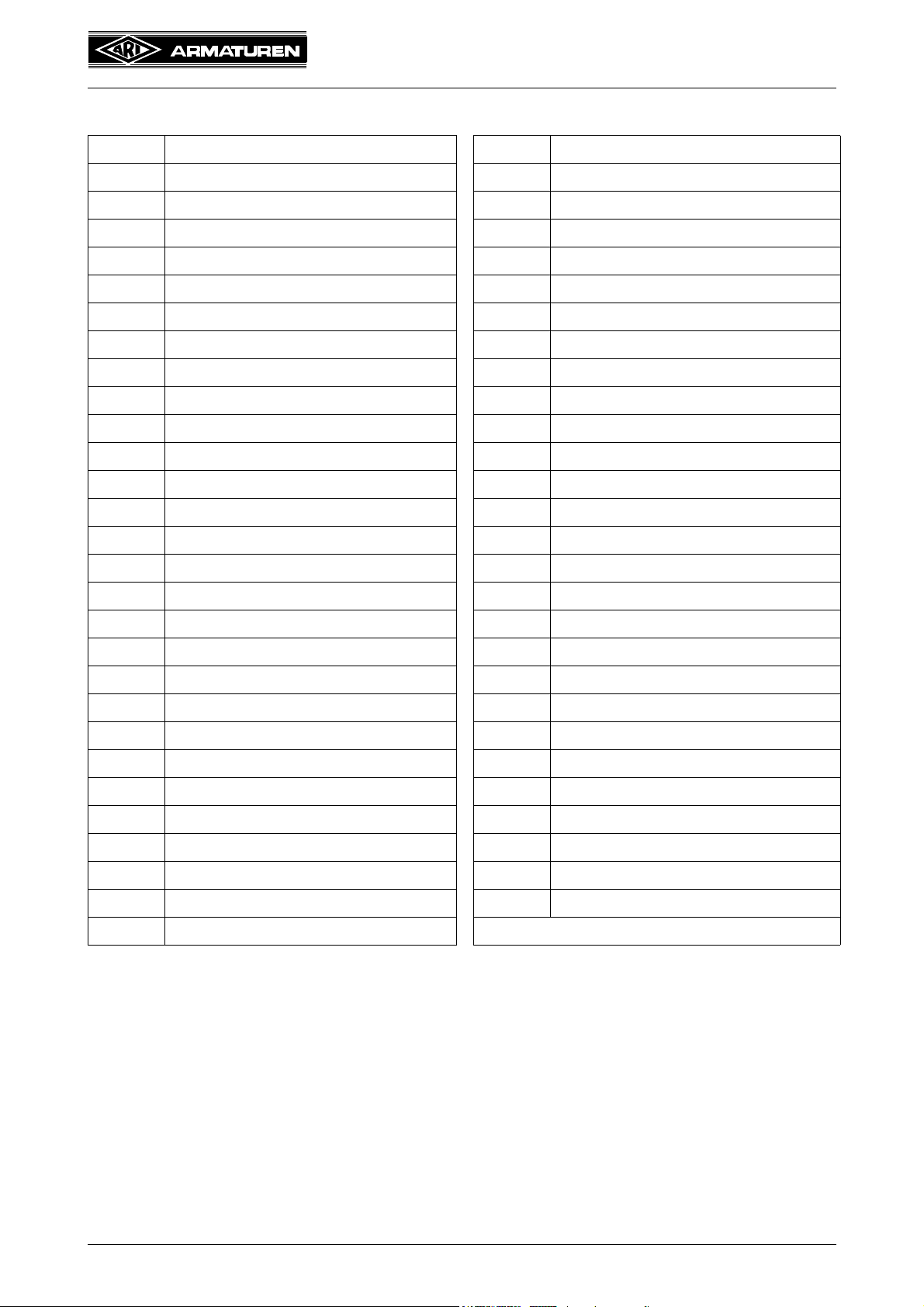

Pos. Description Pos. Description

1 Body 32 Hex. nut

2 Seat (not changeable) 33 Lift bolt

2 Screwed seat (SAFE-TC) 34 Screw

3 Stud 35 Lift fork

4 Spindle guide 36 Lifting lever

7 Gasket 37 Spring

8 Hex. nut 38 Screw

9 Lift limitation ring 39 Bolt

10 Spindle ring 40 Split pin

11 Bonnet, closed 41 Lever open

12 Disc unit 42 Bonnet, open

13 Lifting aid 43 Bellow

14 Spindle 44 Ring

15 Gasket 45 Ring

16 Spring type straight pin 47 Ball

17 Adjusting screw 48 Retaining ring

18 Ball 55 Bellow unit

19 Spindle cap 59 Protective rim

20 Parallel pin 60 Spacer

21 Lock nut 61 Coupling

22 Hex. head screw 62 Weight

23 Lead seal 63 Guide bush

25 Snap ring 65 Coupling

26 Spring plate 66 O-Ring

27 Gasket 67 Lift button

28 Cap, closed 68 Spring type straight pin

29 Cap open 70 Balanced piston

31 Ring

Refer to the data sheet for information about materials.

Rev. 0040401000 2913 Page 2-5

Operating and installation instructions

SAFE, SAFE-P, SAFE-TC, SAFE-TCP/TCS

4.4 Technical data - remarks

for

- Principal dimensions

- Pressure-temperature-ratings, etc. refer to datasheet.

Series 900: DN 15/25 - DN 150/250, 1”x2“ - 6”x10”

EN-JL1040, EN-JS1049, 1.0619+N, 1.4408, SA 216 WCB

PN 16/16, PN 40/16, ANSI 150/150, ANSI 300/150

Approval acc. to:

Figure 901, 902, 911,

912

Figure 903, 904, 990 -VdTÜV leaflet 100, -100/4, TRD 721, DIN EN 12828.

Series 920: DN 20 - DN 100

Approval acc. to:

Figure 921-924 - DIN EN ISO 4126-1, VdTÜV leaflet 100, AD2000-A2 and

Series 940: DN 15 - DN 25 (G 1/2“ - G 1“)

Approval acc. to

Figure 941-943 - DIN EN ISO 4126-1, VdTÜV leaflet 100, AD2000-A2 and

:

- DIN EN ISO 4126-1, VdTÜV leaflet 100, AD2000-A2 and

TRD 421.

Application letter D/G and F

- ASME Code Section VIII-Division 1 (UV-Stamp)

Application letter D/G/H and D (for Figure 904, 990)

EN-JL1040, 1.0619+N, 1.4408

PN 16, PN 40

TRD 421.

Application letter D/G and F

EN-JS1049, 1.4408

PN 40

TRD 421.

Application letter D/G and F

Figure 945-946 -VdTÜV leaflet 100, -100/4, TRD 721, DIN EN 12828.

Application letter D/G/H and D

Series 950/960: DN 15 - DN 25 (G 1/2“ - G 1“)

EN-JS1049, 1.4581

PN 100

Approval acc. to

Figure 951-953 - DIN EN ISO 4126-1, VdTÜV leaflet 100, AD2000-A2.

Figure 961-963

Accessories: Stainless steel bellow for back-pressure compensation;

Page 2-6 Rev. 0040401000 2913

:

Application letter D/G and F

elastomer bellow; soft sealing disc; lock bush; proximity switch;

heating jacket; test gag; rupture disc; support tongues;

removable lifting aid

Loading...

Loading...