ARI Armaturen DP34 Tridem User Manual

Operating and installation instructions

Pneumatic actuators

DP34 Tandem / DP34 Tridem

DP34T DP34Tri

Contents

1.0 General information on

operating instructions........................................2

2.0 Notes on possible dangers ...............................2

2.1 Significance of symbols ...................................2

2.2 Explanatory notes on safety information..........2

3.0 Storage and transport ......................................3

4.0 Description .........................................................3

4.1 Scope of applications.......................................3

4.2 Operating principles.........................................3

4.3 Diagram ...........................................................4

4.4 Technical data ..................................................8

4.5 Marking ............................................................9

5.0 Installation ..........................................................9

5.1 General notes on installation ...........................9

5.2 Requirements at the place of installation .........9

5.3 Valve with actuator.........................................10

5.4 Control pressure connection ..........................12

5.5 Assembling the valve, operating mode

„actuator stem extends by spring force“ ........ 12

5.6 Setting the starting point, operating mode

„actuator stem extends by spring force“ ........ 12

5.7 Assembling the valve, operating mode

„actuator stem retracts by spring force“......... 13

5.8 Setting the starting point, operating mode

„actuator stem retracts by spring force“......... 13

6.0 Putting the valve into operation .................... 14

7.0 Disassembly of the actuator unit

from the valve .................................................. 14

7.1 Disassembly of the actuator unit ................... 14

8.0 Care and maintenance.................................... 14

9.0 Troubleshooting.............................................. 15

10.0 Troubleshooting table .................................. 15

11.0 Warranty / Guarantee .................................... 16

Rev. 0040504001 2010 englisch

Operating and installation instructions

Pneumatic actuators - DP34T / DP34Tri

1.0 General information on operating instructions

These operating instructions provide information on mounting and maintaining the fittings.

Please contact the supplier or the manufacturer in case of problems which cannot be

solved by reference to the operating instructions.

They are binding on the transport, storage, installation, start-up, operation, maintenance

and repair.

The notes and warnings must be observed and adhered to.

- Handling and all work must be carried out by expert personnel or all activities must be

supervised and checked.

It is the owner’s responsibility to define areas of responsibility and competence and to

monitor the personnel.

- In addition, current regional safety requirements must be applied and observed when

taking the fittings out of service as well as when maintaining and repairing them.

The manufacturer reserves the right to introduce technical modifications at any time.

These Operating Instructions comply with the requirements of EU Directives.

2.0 Notes on possible dangers

2.1 Significance of symbols

ATTENTION !

. . .

2.2 Explanatory notes on safety information

In these Operating and Installation Instructions dangers, risks and items of safety

information are highlighted to attract special attention.

Information marked with the above symbol and “ATTENTION!” describe practices, a failure

to comply with which can result in serious injury or danger of death for users or third parties

or in material damage to the system or the environment. It is vital to comply with these

practices and to monitor compliance.

All other information not specifically emphasised such as transport, installation, operating

and maintenance instructions as well as technical data (in the operating instructions,

product documentation and on the device itself) must also be complied with to the fullest

extent in order to avoid faults which in turn can cause serious injury to persons or damage

to property.

Warning of general danger.

Exposed to injury!

Don‘t put your hand into the up or downwards moving

appliance.

Page 2 0040504001 2010

Operating and installation instructions

Pneumatic actuators - DP34T / DP34Tri

3.0 Storage and transport

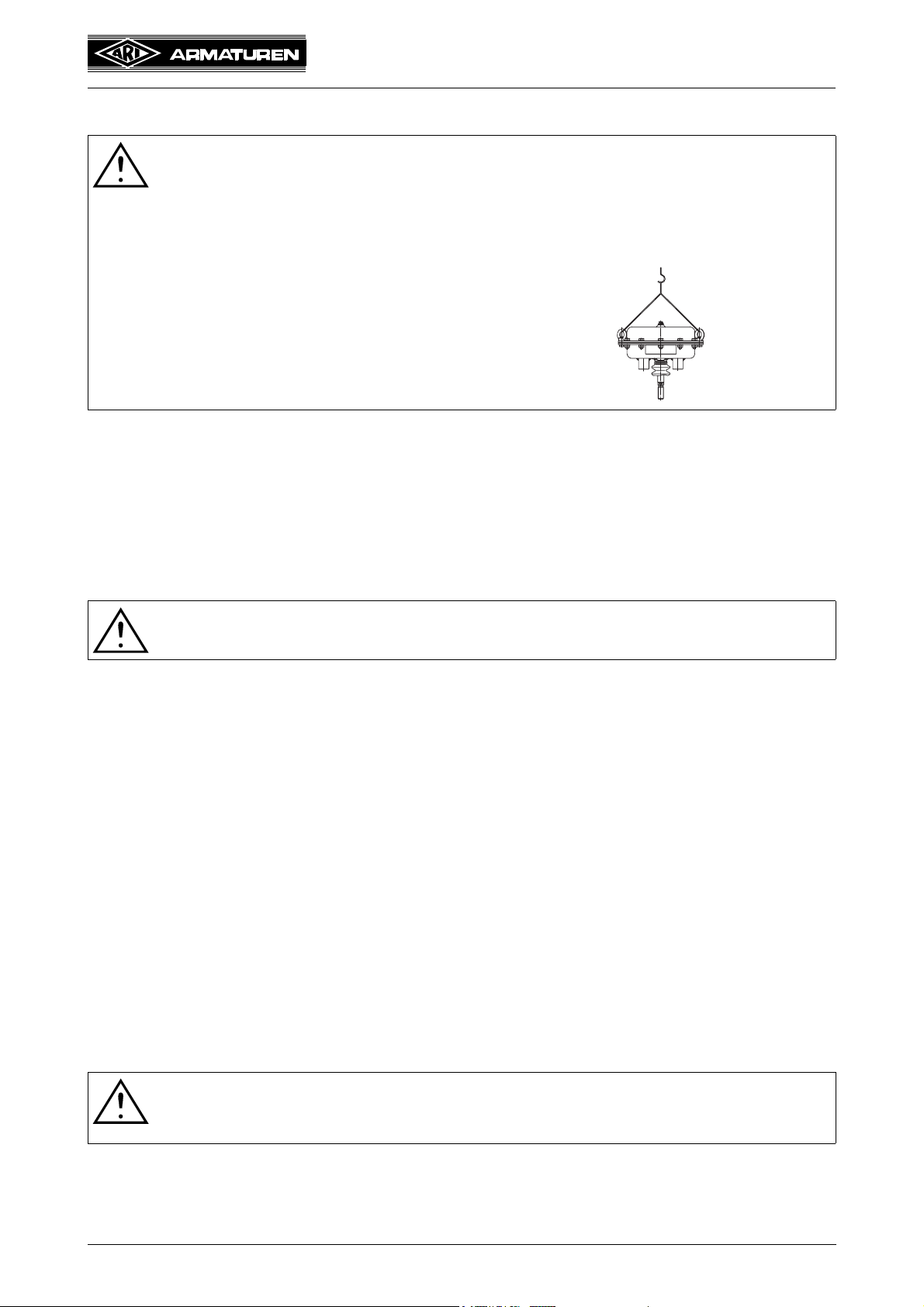

ATTENTION !

- Protect against external force (like impact, vibration, etc.).

- Valve mountings such as actuators, handwheels, hoods must not be used to

take external forces, e.g. they are not designed for use as climbing aids, or as

connecting points for lifting gear.

- Suitable materials handling and lifting equipment

should be used.

Observe max. load-carrying capacity of the eye

nuts: DP34T / DP34Tri = 170kg

(Refer to catalog sheet for weights)

- At -20°C to +65°C.

- Do not damage paint protection. (The actuators should rest in the packing till installation.)

4.0 Description

4.1 Scope of applications

The pneumatic actuators are to be mounted on the top of valves and are necessary to

operate the valves (stem movement) under service conditions.

The units are suitable for being employed in control systems used in the chemical industry.

ATTENTION !

- Refer to the data sheet for applications, limits on use and possibilities.

Please contact the supplier or the manufacturer if you have any questions.

4.2 Operating principles

By means of the pneumatic actuator units, pneumatic control signals are converted into a

translatory motion. The necessary restoring force is generated by means of the

compression springs on the bulk of the diaphragm plate.

In case of air fall-off, the actuator will be restored by means of the spring force in the

starting position.

By using a rolling diaphragm, linear rod forces during long lifts can be obtained.

The operating mode of the actuator is the following:

„actuator stem extends by spring force“(on air failure) or

„actuator stem retracts by spring force“(on air failure)

This operation is obtained and dependent on the assembly of the springs.

The pneumatic actuators with manual emergency adjustment can be operated without

operating pressure by turning the handwheel.

The transmission of power is made by a wormgear screw jack which transmit the rotation

into thrust.

ATTENTION !

- After engaging, the manual emergency adjustment has to be set in starting

position to avoid the deadlock with usual operating.

0040504001 2010 Page 3

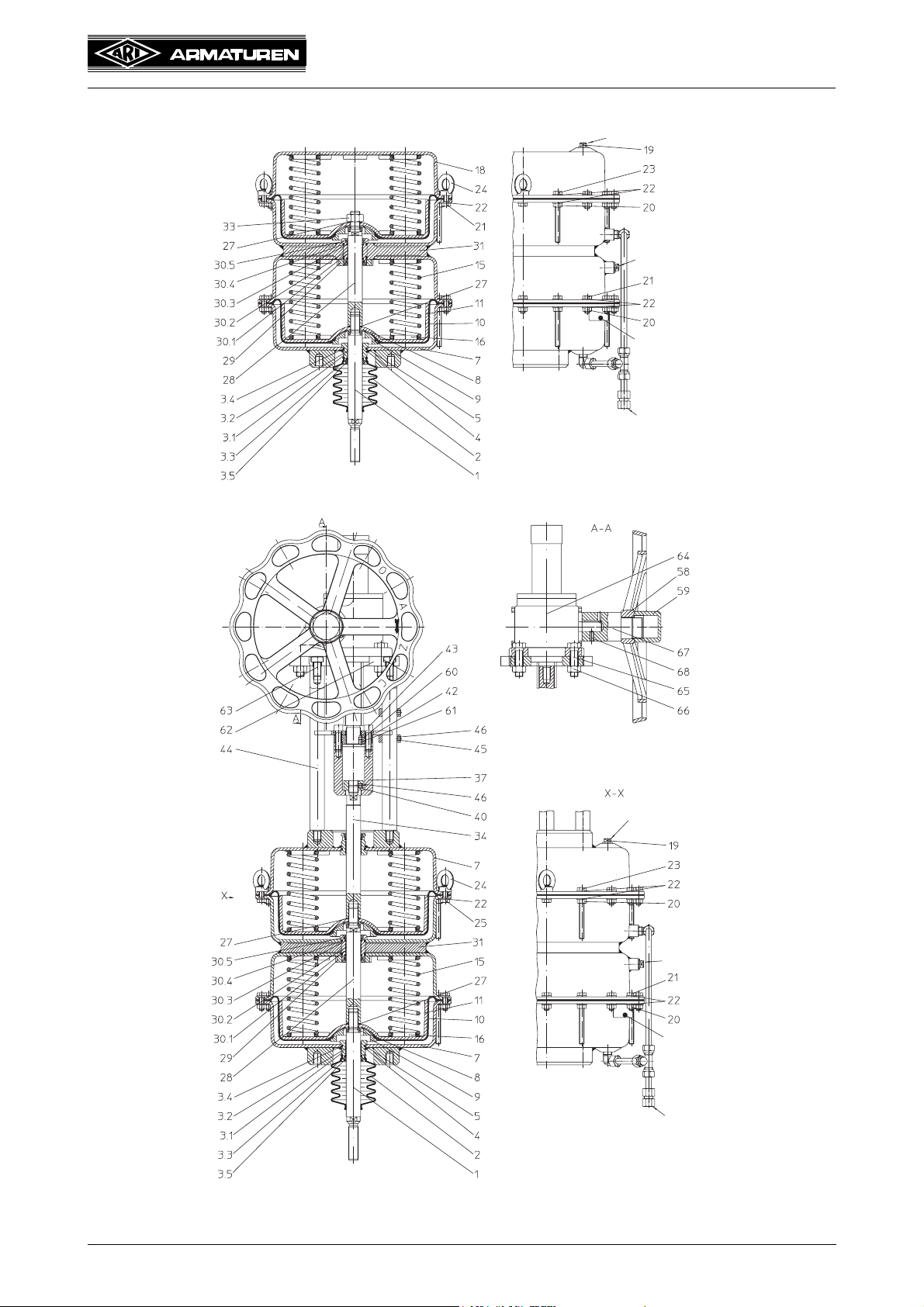

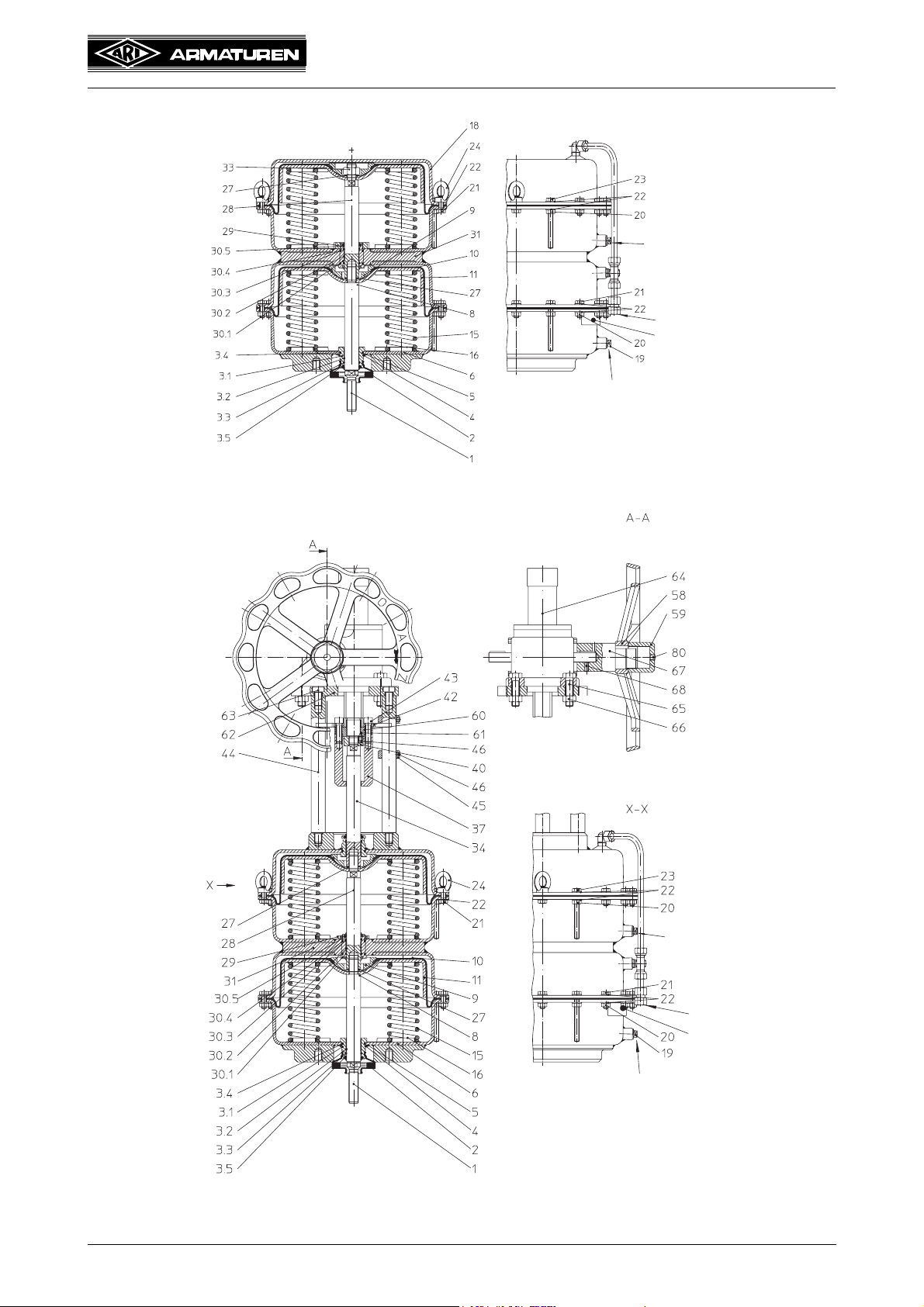

4.3 Diagram

Operating and installation instructions

Pneumatic actuators - DP34T / DP34Tri

Ventilation

Ventilation

Name plate

Air connection

G 3/8“

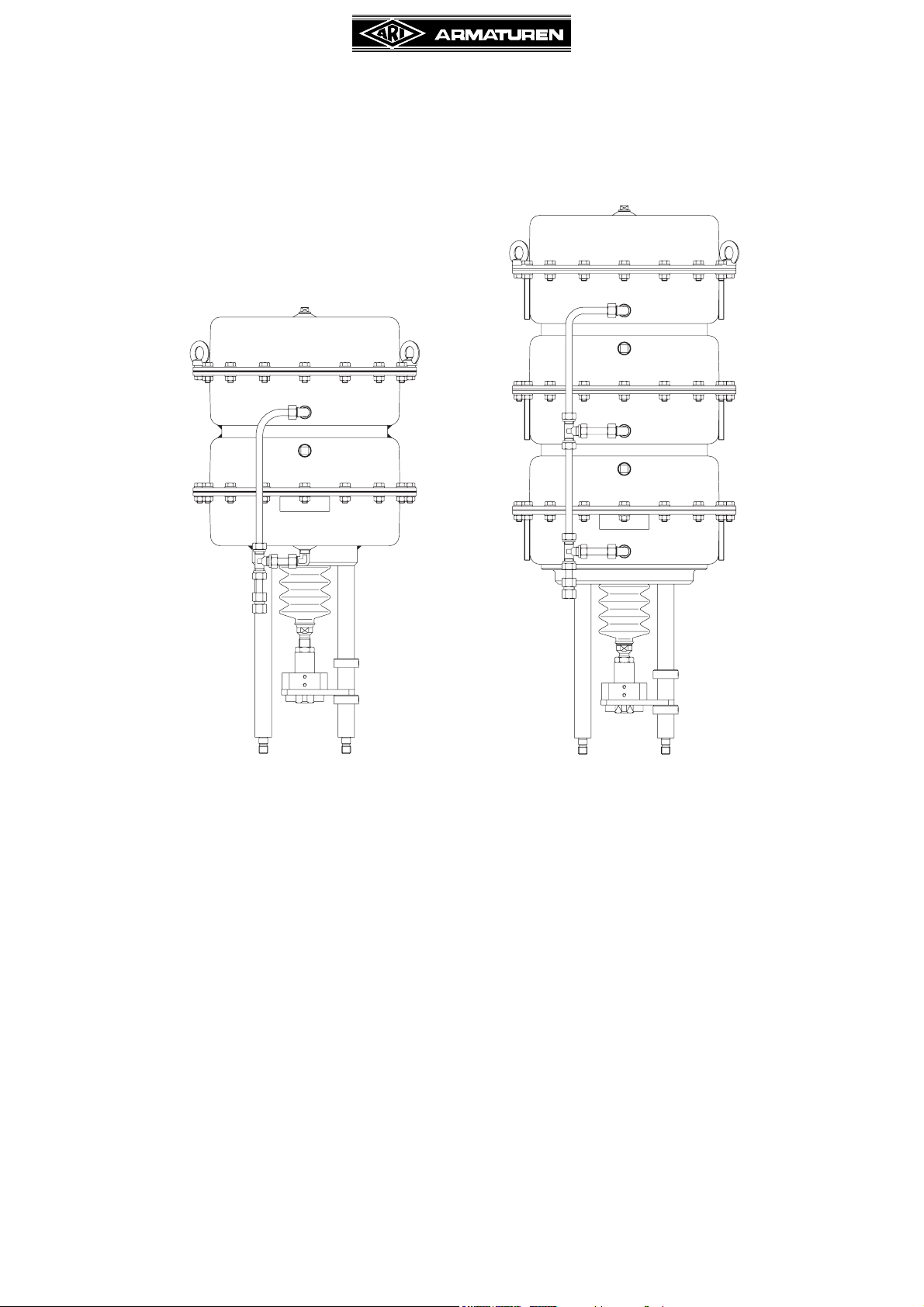

Fig. 1: DP34T „actuator stem extends by spring force“

Ventilation

Ventilation

Name plate

Air connection

G 3/8“

Fig. 2: DP34T with manual emergency adjustment „actuator stem extends by spring force“

Page 4 0040504001 2010

Operating and installation instructions

Pneumatic actuators - DP34T / DP34Tri

Fig. 3: DP34T „actuator stem retracts by spring force“

Ventilation

Air connection G3/8“

Name plate

Ventilation

Ventilation

Air connection G 3/8“

Name plate

Ventilation

Fig. 4: DP34T with manual emergency adjustment „actuator stem retracts by spring force“

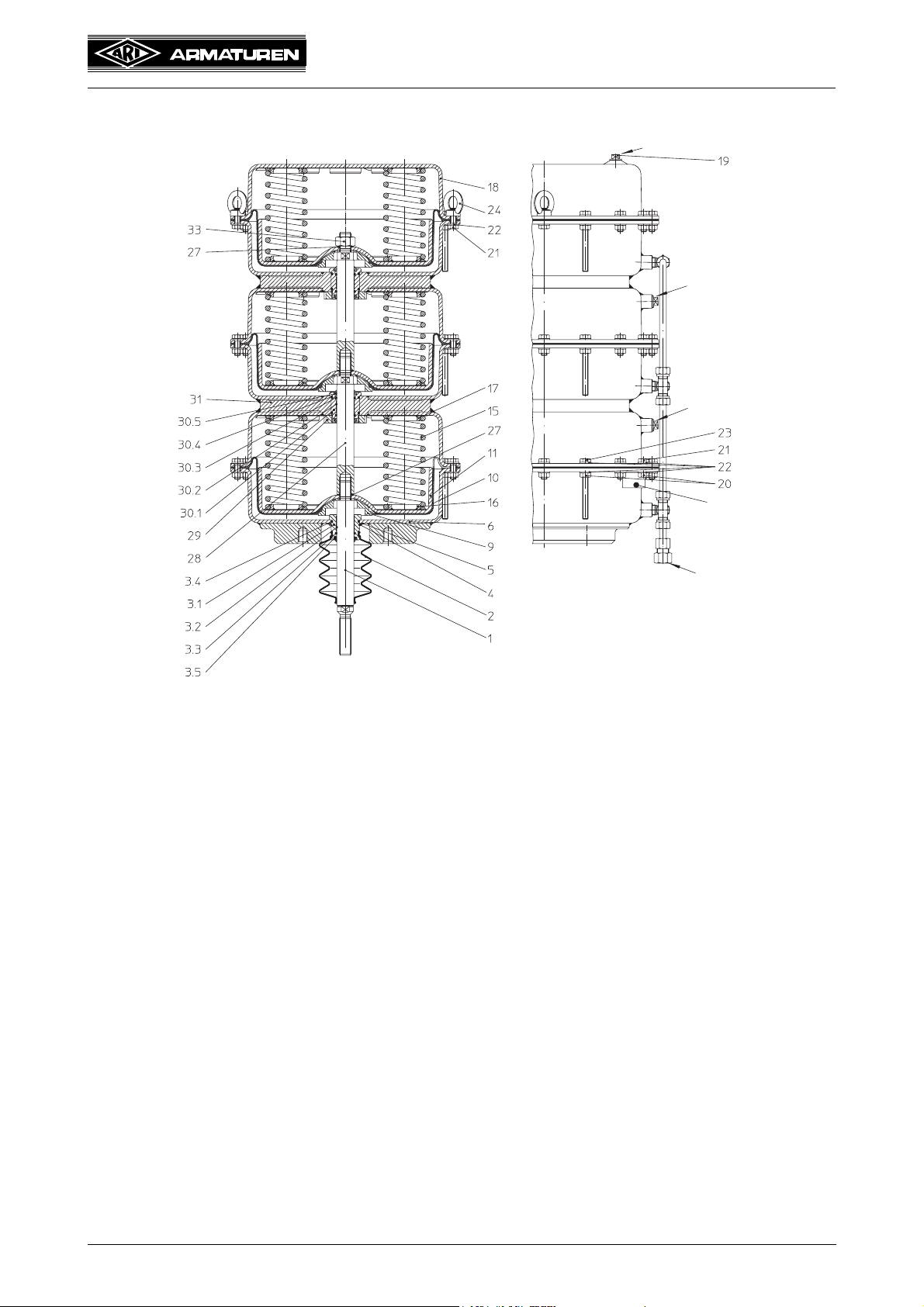

0040504001 2010 Page 5

Operating and installation instructions

Pneumatic actuators - DP34T / DP34Tri

Ventilation

Ventilation

Ventilation

Fig. 5: DP34Tri „actuator stem extends by spring force“

Name plate

Air connection G 1/2“

Page 6 0040504001 2010