ARI Armaturen CONA all-in-one PN40 User Manual

Operating and installation instructions

Steam trap station

with integrated inlet and outlet valves

®

CONA

All-in-one

PN40

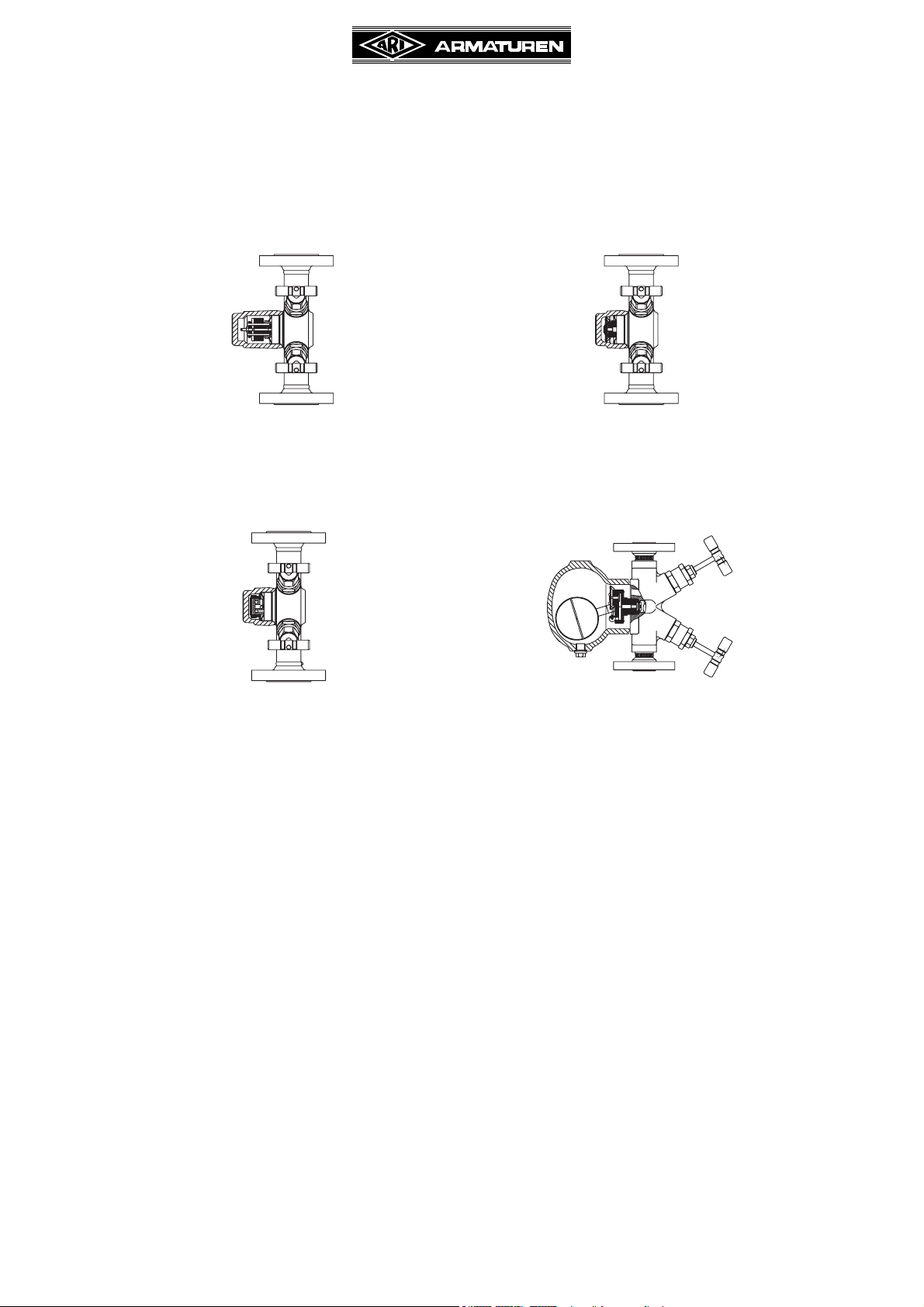

- with flanges (series 60a....1)

- with screwed sockets (series 60a....2)

- with socket weld ends (series 60a....3)

- with butt weld ends (series 60a....4)

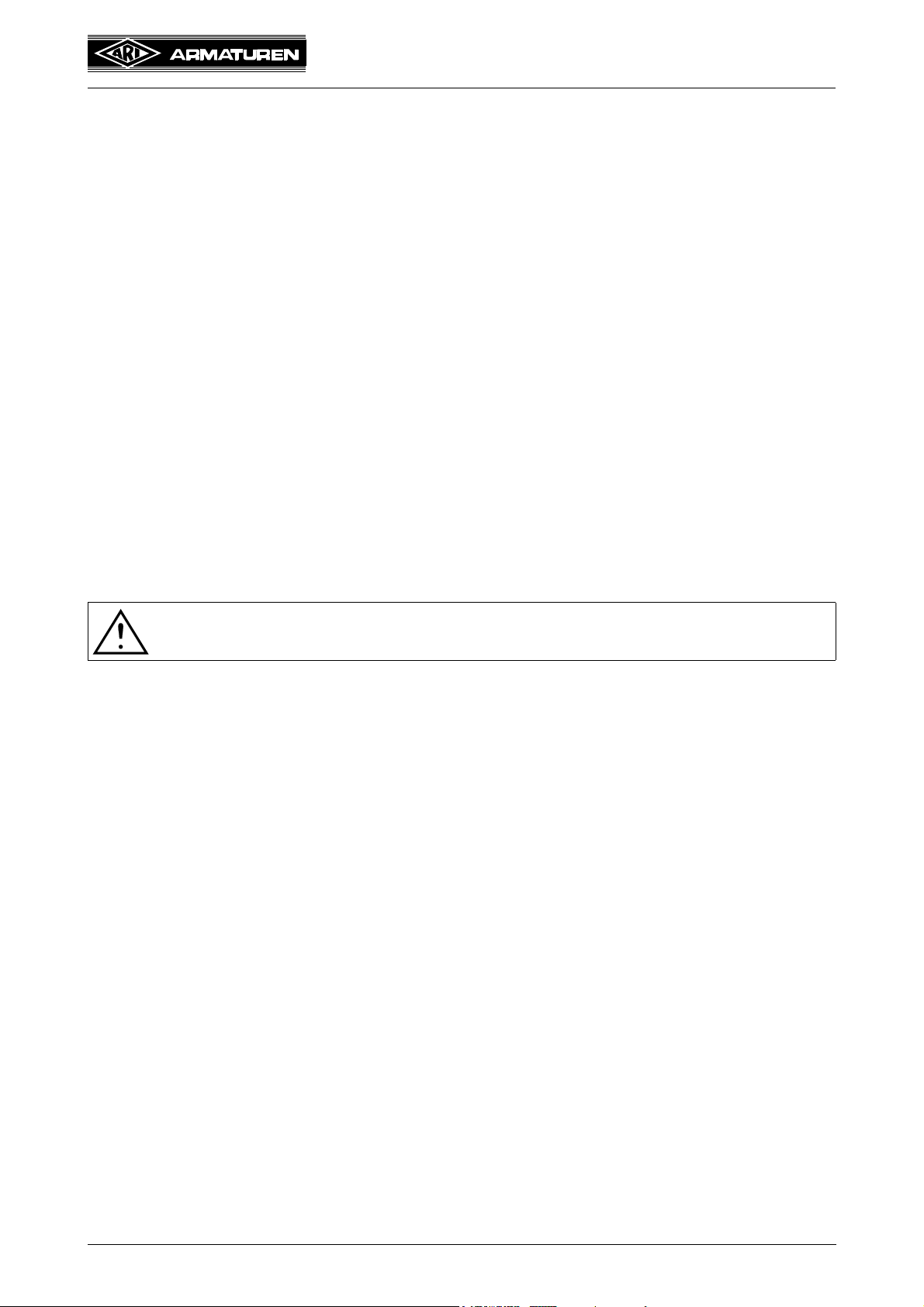

PN40

- with flanges (series 64a....1)

- with screwed sockets (series 64a....2)

- with socket weld ends (series 64a....3)

- with butt weld ends (series 64a....4)

Contents

1.0 General information on operating

instructions................................................... 2

2.0 Notes on possible dangers............................ 2

2.1 Significance of symbols ..........................................2

2.2 Explanatory notes on safety information .................2

3.0 Storage and transport ...................................2

4.0 Description...................................................... 3

4.1 Scope of applications ..............................................3

4.2 Operating principles ................................................4

4.3 Diagram...................................................................6

4.4 Technical data - remarks .........................................8

4.5 Marking ...................................................................8

5.0 Installation....................................................... 8

5.1 General notes on installation...................................8

5.2 Installation instructions for welding .........................9

5.3 Installation position..................................................9

5.4 Steam trap testing through

ultrasonic measurement..........................................9

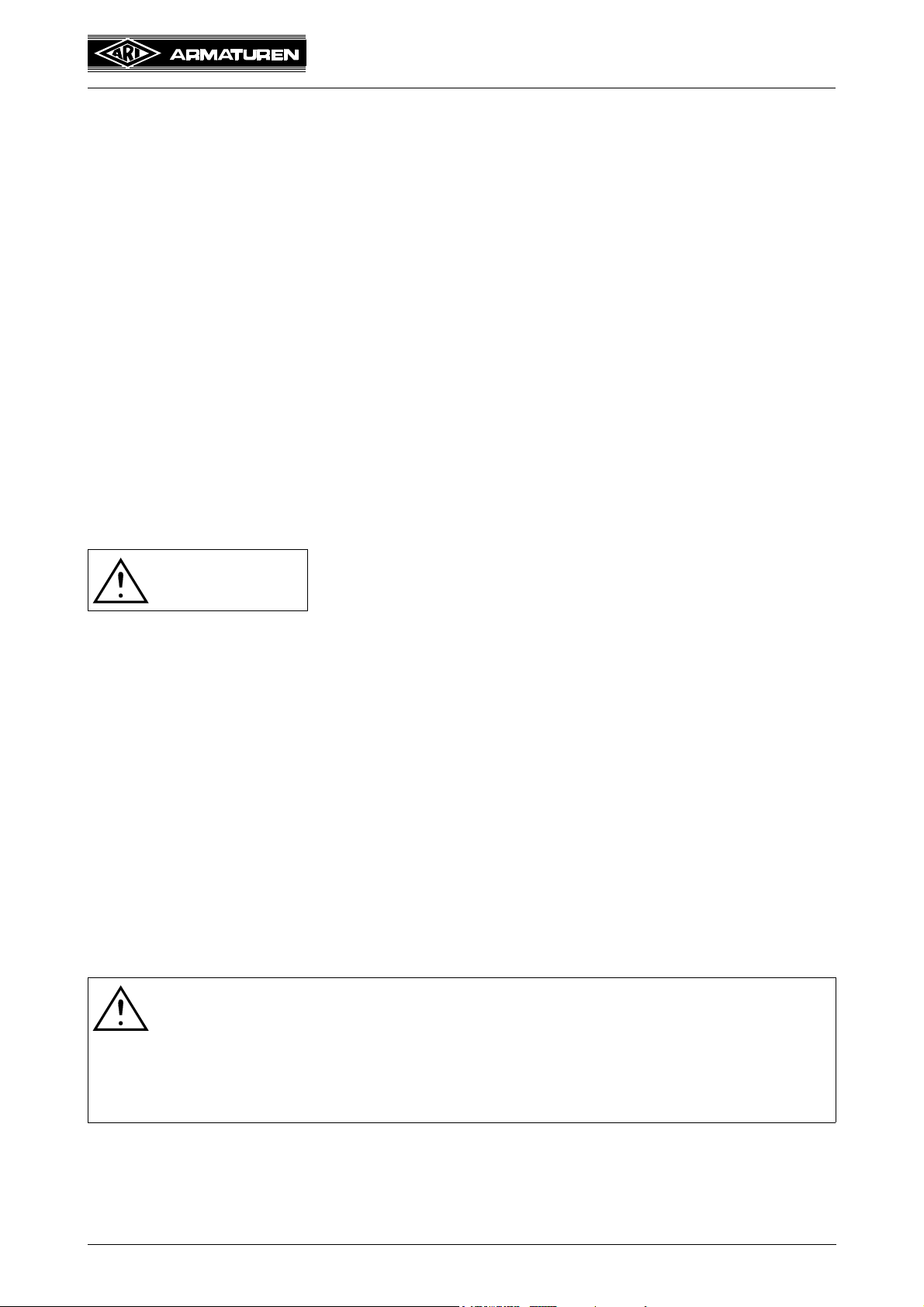

PN40

- with flanges (series 61a....1)

- with screwed sockets (series 61a....2)

- with socket weld ends (series 61a....3)

- with butt weld ends (series 61a....4)

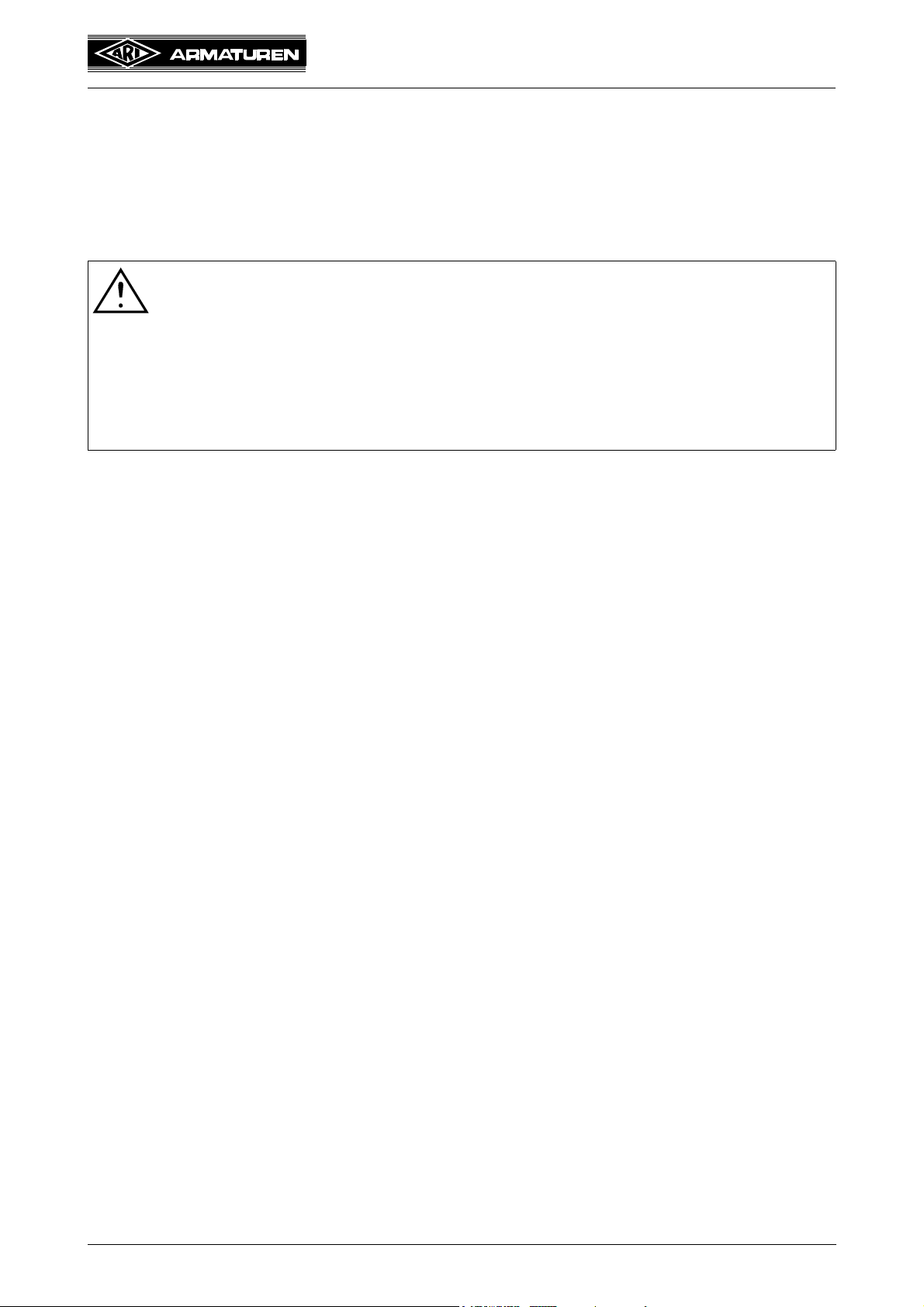

PN40

- with flanges (series 63a....1)

- with screwed sockets (series 63a....2)

- with socket weld ends (series 63a....3)

- with butt weld ends (series 63a....4)

6.0 Putting the valve into operation ................... 9

7.0 Care and maintenance................................. 10

7.1 Disassembling/assembling complete

shut-off valve assembly........................................ 10

7.2 Replacing the packing rings ................................. 10

7.3 Replacing packing rings of the

secondary sealing gland packing ..........................11

7.4 Cleaning/replacing controller assembly.................11

7.5 Changing the installation position......................... 14

7.6 Tightening torques................................................ 14

8.0 Troubleshooting ........................................... 15

9.0 Troubleshooting table.................................. 15

10.0 Dismantling the valve or the body ........... 17

11.0 Warranty / Guarantee ................................. 17

12.0 EC declaration of conformity.................... 18

Rev. 0040808000 0808 englisch

Operating and installation instructions

®

CONA

All-in-one

1.0 General information on operating instructions

These operating instructions provide information on mounting and maintaining the fittings.

Please contact the supplier or the manufacturer in case of problems which cannot be

solved by reference to the operating instructions.

They are binding on the transport, storage, installation, start-up, operation, maintenance

and repair.

The notes and warnings must be observed and adhered to.

- Handling and all work must be carried out by expert personnel or all activities must be

supervised and checked.

It is the owner’s responsibility to define areas of responsibility and competence and to

monitor the personnel.

- In addition, current regional safety requirements must be applied and observed when

taking the fittings out of service as well as when maintaining and repairing them.

The manufacturer reserves the right to introduce technical modifications at any time.

These Operating Instructions comply with the requirements of EU Directives.

2.0 Notes on possible dangers

2.1 Significance of symbols

ATTENTION !

. . .

Warning of general danger.

2.2 Explanatory notes on safety information

In these Operating and Installation Instructions dangers, risks and items of safety

information are highlighted to attract special attention.

Information marked with the above symbol and “ATTENTION!” describe practices, a failure

to comply with which can result in serious injury or danger of death for users or third parties

or in material damage to the system or the environment. It is vital to comply with these

practices and to monitor compliance.

All other information not specifically emphasised such as transport, installation, operating

and maintenance instructions as well as technical data (in the operating instructions,

product documentation and on the device itself) must also be complied with to the fullest

extent in order to avoid faults which in turn can cause serious injury to persons or damage

to property.

3.0 Storage and transport

ATTENTION !

- Protect against external force (like impact, vibration, etc.).

- Valves must not be used to take external forces, e.g. they are not designed for

use as climbing aids, or as connecting points for lifting gear.

- Suitable materials handling and lifting equipment should be used.

See catalog sheet for weights.

- At -20°C to +65°C.

- The paint is a base coat to protect against corrosion during transportation and storage.

Do not damage paint protection.

Page 2 Rev. 0040808000 0808

Operating and installation instructions

®

CONA

All-in-one

4.0 Description

4.1 Scope of applications

CONA All-in-one steam traps are used for "condensate-discharge from all kinds of steam

systems".

ATTENTION !

- Refer to the data sheet for applications, limits on use and possibilities.

- Certain media require or preclude the use of special materials.

- The valves are designed for standard operating conditions. If conditions exceed

these requirements, e.g. aggressive or abrasive media, the operator should

state the higher requirements when ordering.

- Valves made from grey cast iron are not authorised for use in systems subject

to TRD 110.

The information complies to the Pressure Equipment Directive 97/23/EC.

It is the responsibility of the machine planner to ensure compliance.

The special markings on the valve must be taken into account.

Refer to the catalogue sheet to see which materials are used in standard versions.

Please contact the supplier or the manufacturer if you have any questions.

Rev. 0040808000 0808 Page 3

Operating and installation instructions

®

CONA

All-in-one

4.2 Operating principles

(refer to Fig. 1 - Fig. 2 page 6)

The product concept is based on a robust modular design with integrated shut-off valves

(ball / seat chamfer). This modular design can be used as the basis for steam traps with

several control systems.

- Bimetallic steam trap series 60A

- Thermostatic steam trap series 61A

- Thermodynamic stam traps series 64A

- Ball float steam traps series 63A

The valve is based on a hard-sealing (metal on metal) construction:

(refer to Fig. 7 page 10 - Fig. 8 page 11)

- body (pos. 1) / screw fitting (pos. 15)

- seat (pos. 3) / body (pos. 1)

- valve plug (pos. 4) / seat (pos. 3)

- safety back-sealing mechanism

Stop valve with gland packing: spindle (pos. 11) / screw fitting (pos. 15)

Stop valve with bellows seal: spindle (pos. 11) / spindle guide (pos. 16)

There are also graphite rings (pos. 5) which take over external sealing in the position

between “OPEN” or “SHUT”.

ATTENTION !

Do not use shut-off valves for OPEN-SHUT function to throttle volume flow.

Valve position:

OPEN - Safety back-sealing mechanism effective when valve fully open.

SHUT - Valve plug (pos. 4) / chamfer at seat (Pos 3) seal effective.

a) Bimetallic steam trap series 60A

(refer to Fig. 3 page 7)

(for particular description of the control system, refer to the Operating and installation

instruction of CONA B series 600

For regulation the steam trap uses both condensate temperature as well as available

upstream pressure and back pressure. As the temperature of the medium rises the

bimetallic plates arch, automatically reducing valve lift. An intermediately mounted

compression spring also influences valve lift in the lower pressure range, so that when

acting together with the bimetallic plates the controller always opens and closes a few

degrees below the upstream pressure boiling temperature. A pendulum-form support for

the valve spindle ensures consistent operation, irrespective of the position in which the

steam trap is mounted.

The steam trap vents air automatically during system start-up and operation.

The steam trap has a corrosion-resistant, water hammer-proof bimetallic controller, nonreturn protection, and a factory setting for average condensate sub-cooling of approx. 15K

(PN16-40).

The built-in controller is marked on the type plate as well as on the securing component.

Page 4 Rev. 0040808000 0808

Operating and installation instructions

®

CONA

b) Thermostatic steam trap series 61A

(refer to Fig. 4 page 7)

(for particular description of the control system, refer to the Operating and installation

instruction of CONA M series 610)

The steam trap uses the condensate temperature and available upstream pressure for

control. It vents automatically during system start-up and operation. It has a corrosionresistant, water hammer-proof diaphragm capsule which always discharges the

consistently supercooled condensate a few degrees below the upstream pressuredependent boiling temperature.

c) Thermodynamic stam traps series 64A

(refer to Fig. 4 page 7)

(for particular description of the control system, refer to the Operating and installation

instruction of CONA TD series 640)

For control the steam trap uses the condensate temperature as well as the available

upstream pressure and back pressure.

In the controller (pos. 24) the valve plate is enclosed by the cap and the seat. When the

boiling temperature of the medium is reached, a cushion of steam forms over the valve

plate and presses the valve plate onto the seal faces of the seat.

To a very great extent the external sealing cap (pos. 6) frees the steam trap (in PN40) from

environmental influences. The steam cushion collapses as a result of condensate formation

and the associated temperature drop.

All-in-one

The system pressure lifts the valve plate from the seat face. The steam trap opens and

removes condensate.

The steam trap vents air automatically during system start-up and operation, but with a time

lag. The steam trap acts as a non-return valve.

d) Ball float steam traps series 63A

(refer to Fig. 6 page 7 and Fig. 9 page 14)

(for particular description of the control system, refer to the Operating and installation

instruction of CONA SC series 634)

The steam trap is controlled by a swivel-mounted ball float (pos. 24.16).

If condensate is flowing towards the steam trap, the ball float (pos. 24.16) rises and opens

the discharge valve using the lever mechanism.

An intercoupled diaphragm capsule (pos. 24.17) ensures automatic start-up air venting

when cold.

If the amount of condensate decreases or if there is no condensate, the float ball

(pos. 24.16) falls and shuts the discharge valve.

The compact float ball (pos. 24.16) exerts level-dependent control on the valve ball

(pos. 24.4) by means of a lever mechanism. As the level of condensate rises, the valve ball

(pos. 24.4) is rolled off the valve bore by the lever mechanism, thus opening the valve. The

condensate can now drain away.

If the amount of inflowing condensate is less than the possible valve output or if there is no

condensate flow, the ball float (pos. 24.16) falls and the valve ball (pos. 24.4) rolls back

onto the valve bore. The valve is now closed.

Rev. 0040808000 0808 Page 5

4.3 Diagram

Operating and installation instructions

®

CONA

All-in-one

Fig. 1: Stop valve with gland packing

Fig. 2: Stop valve with bellows seal

Page 6 Rev. 0040808000 0808

Loading...

Loading...