Page 1

Suction Pumps

MASTER 45

SENATOR 30

SERVICE MANUAL

Ardo medical AG, Gewerbestrasse 19, CH-6314 Unterägeri/Switzerland

Tel. +41-(0)41 754 70 70 - Fax +41-(0)41 754 70 71 - info@ardo.ch - www.ardo.ch

11/2005

Page 2

TABLE OF CONTENTS

8. INTRODUCTION

Safety

Responsibility

Guarantee

Service

9. TECHNICAL DESCRIPTION AND DIAGRAMS

Mechanical Layout

Electrical Layout

Wiring Diagram/Block Diagram

10. MAINTENANCE

General Maintenance

Maintenance Works for Technical Personnel

11. SERVICING AND REPAIRS

Troubleshooting

Accessories/Spare Parts

Replacing Spare Parts

Cylinder

Belt Drive

Wearing Parts

12. TECHNICAL INFORMATION

Specifications

Transport and Storage

Disposal after Service Life

Please also follow the enclosed

OPERATING INSTRUCTIONS (chapter 1-7)!

COPYRIGHT © 2005 Ardo medical AG

3

4

4

5

5

7

8

9

9

10

11

17

17

18

18

18

19

19

Ardo medical AG 2 Service Manual

MASTER/SENATOR

Subject to change

Page 3

8. INTRODUCTION

Safety

The suction pumps are designed and constructed according to the safety regulations of

IEC 601-1, the EMC standard IEC 60601-1-2 and EN 10079-1. For the user's and the

patient’s safety as well as to prevent equipment damage, please observe these safety

rules:

Safety Rules

• The suction pumps MASTER/SENATOR may only be installed and operated by

competent personnel.

• Use the suction pumps with the ARDO hydrophobic bacterial filter only.

• To ensure the proper venting of the pumps, the feet must be installed on the bottom

of the pumps if used without trolley.

• Never start operating the suction pump when the housing is open (rotating parts –

hazard of injury and electric shock).

• Capacitors may be charged even if device is without power. Discharge capacitors with

discharge set!

• Check contact points of the housing for tears. If there are any tears, exchange housing.

• See that MASTER/SENATOR are set into operation according to Chapter 4 - Installation -

in the operating instructions.

• Store the service manual in a safe place, so that it is available to the trained technical

personnel at all times.

General Safety Regulations

• Never use MASTER/SENATOR in the presence of ignitable gases as anesthetic

agents. Explosion hazard!

• The suction pumps may only be opened by qualified technical personnel.

Electric shock hazard!

• Always switch the suction pump off and disconnect from mains power before

cleaning and opening. Electric shock hazard!

• Do not use solvents for cleaning. Otherwise the surface of the housing or the

synthetic material parts may be damaged.

Ardo medical AG 3 Service Manual

MASTER/SENATOR

Subject to change

Page 4

Responsibility

ARDO is only responsible for effects on safety, reliability and performance of the device, if:

• Installation, new adjustments, alterations or repairs and maintenance works are carried

out by authorized persons.

• For repairs and replacements of spare parts use original parts by ARDO only.

• The electric installations of the respective room meet the requirements of the standards

IEC 601 and MPG (German Medicinal Products Act), and if the devices are maintained

and repaired according to this standard and to EN 10079-1.

• The pump is used in accordance with the operating instructions.

Guarantee

The suction pumps MASTER/SENATOR have a guarantee period of 2 years.

General Conditions

Maintenance

Ardo medical AG warrants for material and production faults of

the manufactured products. The guarantee period can be taken

from the respective operating instructions. Faulty material is

replaced free of charge within the guarantee period, assumed

the device was not used improperly. Wearing parts are

excluded. For ensuring guarantee and faultless functioning of

the device, the notes of the operating instructions have to be

observed. Furthermore, only original spare parts by

Ardo medical AG may be installed and/or used.

The right to guarantee is waived, when non-authorized persons

interfere with the device or alterations not conforming to the

standard IEC 601 and EN 10079-1 are carried out. There is no

right to guarantee exceeding the described scope of guarantee,

as liability to consequential damages etc.

Read operating instructions Chapter 5 - Maintenance and Care,

Cleaning -.

Ardo medical AG 4 Service Manual

MASTER/SENATOR

Subject to change

Page 5

Service

Please contact to the following addresses for service, maintenance or any questions

about this product or any other product of Ardo medical AG:

Switzerland

Germany

International

Ardo medical AG

Gewerbestrasse 19

CH-6314 Unterägeri

Switzerland

Tel. +41-(0)41 754 70 70

Fax +41-(0)41 754 70 71

info@ardo.ch

www.ardo.ch

Ardo medical GmbH

Argelsrieder Feld 10

D-82234 Oberpfaffenhofen

Germany

Tel. +49-(0)8153 / 40 66 00

Fax +49-(0)8153 / 40 66 01

info@ardomedical.de

www.ardomedical.de

Authorized Importer

9. TECHNICAL DESCRIPTION AND DIAGRAMS

Mechanical Layout

The ARDO suction pumps MASTER/SENATOR work according to the principle of a piston/

cylinder system.

Both power units are based on a modular driving concept, equipped with 2 cylinder units.

MASTER 45 2 cylinder power unit (approximately 300 rpm)

SENATOR 30 2 cylinder power unit (approximately 220 rpm)

A two-stage belt transmission was developed for driving the cylinder units that may be

used for both power units (MASTER and SENATOR).

Transmission reduction for the two power units can be adjusted with the two belt pulleys

of the first reduction level (motor pinion + belt wheel = 1. level).

Ardo medical AG 5 Service Manual

MASTER/SENATOR

Subject to change

Page 6

For both power units a bipolar capacitor motor with built-in temperature sensor is used.

This protects the motor coil from heating to more than 125°C.

The piston is driven over a linear unit (slide). By using this system, the piston system is

exposed to only minimal thrust forces, which ensures low wear and high service life.

In MASTER/SENATOR the pistons work in angles of 90° to each other. This ensures a

well-balanced run of the pump with low vibration levels.

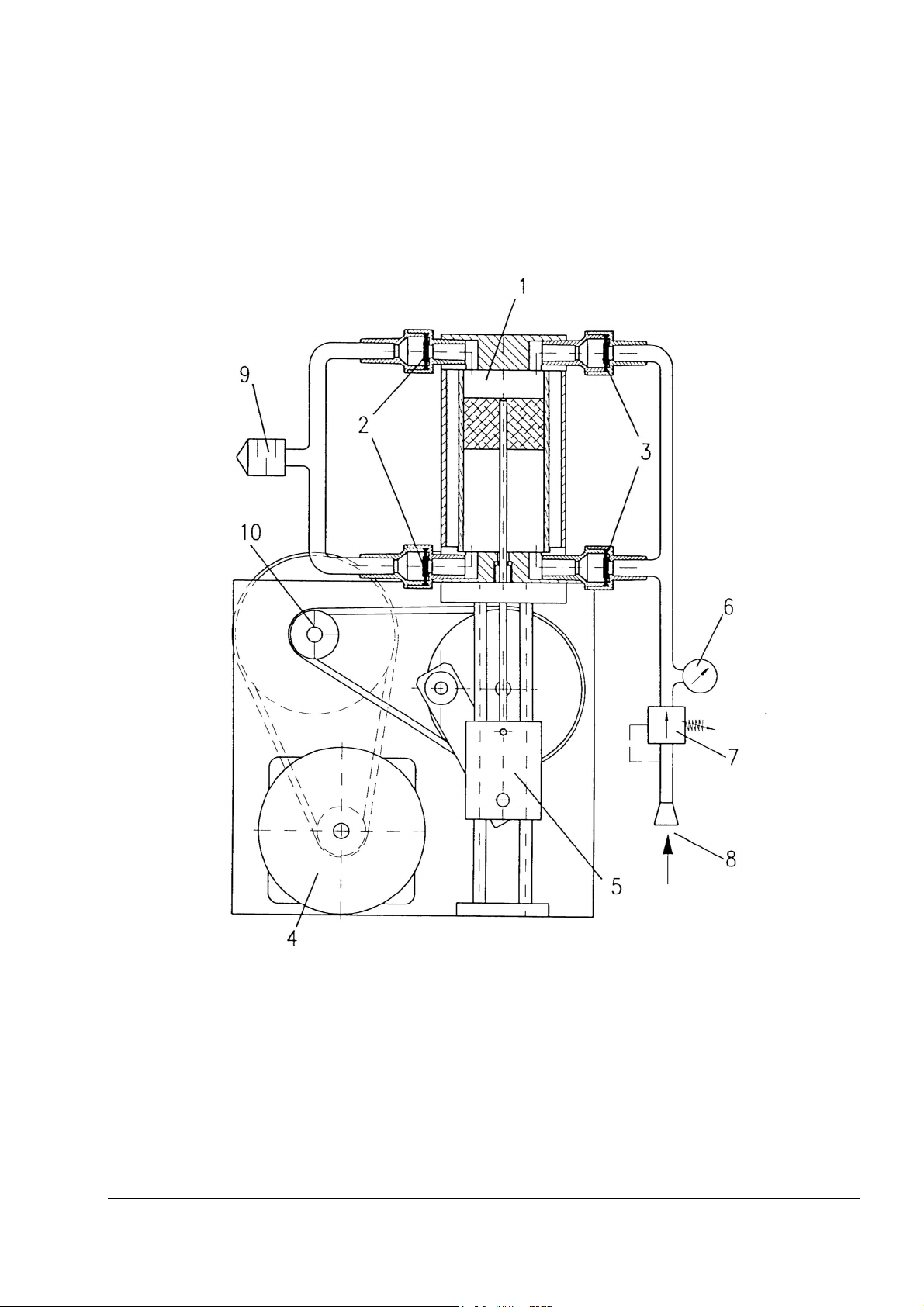

1 Cylinder unit 6 Vacuum-meter

2 Discharge valve 7 Vacuum regulator

3 Inlet valve 8 Vacuum connector

4 AC motor 9 Exhaust

5 Linear drive 10 2-stage belt transmission

Ardo medical AG 6 Service Manual

MASTER/SENATOR

Subject to change

Page 7

Electrical Layout

The driving motor is a bipolar capacitor motor and may be used for both power units

(MASTER and SENATOR).

MASTER is equipped with a electronically controlled start-up circuit (Pushstart), so that

the power unit starts also under difficult conditions (high vacuum with simultaneous

mains undervoltage). This start-up circuit is also used in the SENATOR with 115V motor.

This circuit increases the motor torque momentarily by parallel switching in a second

start-up capacitor.

After approximately 3 seconds this second capacitor is switched off again, so that the

motor is not overloaded during continuous operation.

This start-up circuit is activated each time the motor is powered up or mains power is

interrupted.

Ardo medical AG 7 Service Manual

MASTER/SENATOR

Subject to change

Page 8

Wiring Diagram/Block Diagram

grounded model

Circuit board "Pushstart"

MASTER 230V / 115 V

SENATOR 115V

Ardo medical AG 8 Service Manual

MASTER/SENATOR

Subject to change

Page 9

10. MAINTENANCE

General Maintenance

It is the user’s obligation to perform a maintenance check at least once per year. If the

manufacturer performs the maintenance check, a service confirmation is placed on the

suction pump.

If you do not observe the procedures and cleaning instructions there is a danger of

contamination!

Maintenance Works for Technical Personnel

General Maintenance

Checking of

Leak Test

Check of Tubing

Safety Check

Maintenance works include the following tests:

• Checking of vacuum level, liter performance, function of

vacuum regulator

• Leak test

• Check of tubing

• Safety check (electrical and mechanical parts)

Vacuum level, liter performance, function of vacuum regulator:

There are no specifications for these checks.

The permitted tolerances are:

- vacuum level ± 5%

- liter performance ± 15%

• Connect 1 liter or 2 liter suction jar

• Pinch off the patient tubing

• Switch pump on and turn vacuum regulator to maximum

vacuum level

• When maximum vacuum level of approximately 85kPa has

been reached, switch pump off and observe vacuum meter.

After 1 minute, vacuum level should not have decreased more

than 10kPa, otherwise complete sealing is not guaranteed.

• Check tubings on cleanness* and damages.

*If an overflow has occurred, pack suction pump in a synthetic

material bag and dispose of, after clarification with the

customer.

Electrical and mechanical parts

• Check power connection on damages. Check moving power

unit parts on abrasion or damage (cylinder system, ventilator).

• According to IEC 601 and EN 10079-1, the measuring of the

leakage current (using the safety tester) has to be carried out

after maintenance or service works.

Ardo medical AG 9 Service Manual

MASTER/SENATOR

Subject to change

Page 10

Access to power unit

The device must be disconnected from mains power

before opening the housing!

- Dismount fitting rail

- On each side, unscrew two Phillips screws

- Unscrew another two Phillips screws on the bottom side

of the device

- Pull back housing backplane

- The power unit can now be accessed

Caution! Capacitors may be charged even if device is

without power. Discharge capacitors with discharge set!

11. SERVICING AND REPAIRS

For repairs and replacements of spare parts use original parts by ARDO only. The item

numbers can be found in the Accessories/Spare Parts list. Technical documentations

from ARDO including diagrams, descriptions and adjustment instructions are available to

authorized personnel.

Troubleshooting

Problem Cause Remedy

Green signal lamp on the

ON/OFF switch is not illuminated

after activation

Signal lamp is illuminated, but

device is not working or does not

start up

Poor or no suction capacity or

not enough vacuum

- Power plug does not sit

properly in the socket

- No power supply

- Power unit overheated

- Faulty electronics

- Leak in vacuum system

- Defective cylinder system

- Missing or defect o-ring on

plug nipple or filter housing

- Check connection in wall socket

- Check power supply (main fuse)

- Check device fuse

- Check ventilation inlets on bottom and

handle side for free airflow

- Overheat protection may respond, if

the device is poorly ventilated

- Replace Pushstart

- Motor defect

- Replace Capacitor

- Check internal tubing connections and

replace if necessary

- Replace retention valves (mind correct

placing of blocking side)

- Replace complete cylinder unit if

necessary

- Replace o-ring

Ardo medical AG 10 Service Manual

MASTER/SENATOR

Subject to change

Page 11

Accessories/Spare Parts

Product Item No.

- Hydrophobic bacterial filter 50.00.05

- 1 liter suction jar, TPX, graduated 50.00.50

- 2 liter suction jar, TPX, graduated 50.00.51

- 3 liter suction jar, polysulfone, graduated 50.00.52

- 5 liter suction jar, polysulfone, graduated 50.00.53

- Lid with handle and mechanical overflow safety device, 50.00.08

for suction tubing ND 8 mm

- Lid with handle and mechanical overflow safety device, 50.00.10

for suction tubing ND NW 12.7 mm

- Connection tubing with 2 angled coupling connectors, 0.5 m 50.00.01

- Seal for lid 99.00.544

- Coupling connector, angled, ND 8 mm, green 50.00.85

- Coupling connector, angled, ND 8 mm, transparent 50.00.86

- Coupling connector, angled, ND 12.7 mm, transparent 50.00.87

- O-Ring in silicone Ø 8.1 mm, white 99.00.303

- O-Ring in silicone Ø 14 mm, white 51.00.17

- Silicone tubing, transparent, Ø 7/13 mm, sterilisable, per meter 50.00.47

- Silicone tubing, transparent, Ø 12.7/18 mm, sterilisable, per meter 50.00.46

- Retainer for float 50.00.83

- Float 50.00.84

Ardo medical AG 11 Service Manual

MASTER/SENATOR

Subject to change

Page 12

Overview on Spare Parts shown on pages 13-16

MASTER 45 (230V/115V)

Pos. Item No. Product

1 32.00.02

10 32.00.12

10 32.00.24

15 32.00.16

15a 32.00.17

17 32.00.06

Housing MASTER

Power unit MASTER 230V

Power unit MASTER 115V

Capacitor set 230V MASTER (3.5µF /400V and 6µF /400V)

Capacitor set 115V MASTER/SENATOR

(14µF /250V and 18µF /250V)

Circuit board "Pushstart" (SENATOR only for 115V)

SENATOR 30 (230V/115V)

Pos. Item No. Product

1 32.00.18

10 32.00.19

10 32.00.23

Housing SENATOR

Power unit SENATOR 230V

Power unit SENATOR 115V

14 32.00.20 Capacitor 230V / 3.5µF/400V

15a 32.00.17

Capacitor set 115V MASTER/SENATOR

(14µF /250V and 18µF /250V)

MASTER 45 and SENATOR 30 (230V/115V)

Pos. Item No. Product

# 32.00.03 Main socket complete

# 32.00.04 Fuse T630mA (230V) 10 pcs

# 32.00.25 Fuse T1.6A (115V) 10 pcs

4 99.00.693 Power switch

5 32.00.07 Vacuum-meter

6 32.00.08 Pneumatics set

7 32.00.09 Rubber shock-absorber set

8 32.00.10 Vacuum regulator complete

# 32.00.11 Valve set 8 pcs

11 32.00.13 Slide block 1

12 32.00.14 Slide block 2

13 32.00.15 Cylinder

17 32.00.06

# 32.00.21 Turn knob with pointer

# 32.00.01 Unit bases

# 99.00.328 Shipping packaging complete

# 32.00.22 Ground-compensate set

# = not shown in the pictures

Circuit board "Pushstart" (SENATOR only for 115V)

Ardo medical AG 12 Service Manual

MASTER/SENATOR

Subject to change

Page 13

MASTER 45 (230V/115V)

Pos. Item No. Product

Pos. 10 Pos. 15 (15a) Pos. 17 Pos. 1

1 32.00.02

10 32.00.12

10 32.00.24

15 32.00.16

15a 32.00.17

17 32.00.06

Housing MASTER

Power unit MASTER 230V

Power unit MASTER 115V

Capacitor set 230V MASTER (3.5µF /400V and 6µF /400V)

Capacitor set 115V MASTER/SENATOR (14µF /250V and 18µF /250V)

Circuit board "Pushstart" (SENATOR only for 115V)

Ardo medical AG 13 Service Manual

MASTER/SENATOR

Subject to change

Page 14

SENATOR 30 (230V/115V)

Pos. Item No. Product

Pos. 14 (15a) Pos. 10 Pos. 1

1 32.00.18

10 32.00.19

10 32.00.23

Housing SENATOR

Power unit SENATOR 230V

Power unit SENATOR 115V

14 32.00.20 Capacitor 230V / 3.5µF/400V

15a 32.00.17

Capacitor set 115V MASTER/SENATOR (14µF /250V and 18µF /250V)

Ardo medical AG 14 Service Manual

MASTER/SENATOR

Subject to change

Page 15

Tubing MASTER 45 / SENATOR 30

Pos. 17 Pos. 4 Pos. 5 Pos. 8 Pos. 6

Pos. Item No. Product

4 99.00.693 Power switch

5 32.00.07 Vacuum-meter

6 32.00.08 Pneumatics set

8 32.00.10 Vacuum regulator complete

17 32.00.06

Circuit board "Pushstart" (SENATOR only for 115V)

Ardo medical AG 15 Service Manual

MASTER/SENATOR

Subject to change

Page 16

Power unit MASTER 45 / SENATOR 30

Pos. 13 Pos. 11 Pos. 7 Pos. 12

Pos. Item No. Product

7 32.00.09 Rubber shock-absorber set

11 32.00.13 Slide block 1, complete

12 32.00.14 Slide block 2

13 32.00.15 Cylinder, complete

Ardo medical AG 16 Service Manual

MASTER/SENATOR

Subject to change

Page 17

Replacing Spare Parts

Always disconnect the suction pumps MASTER/SENATOR from mains power

before opening.

Only technical personnel may replace components or repair the suction pumps MASTER/

SENATOR. Due to reasons of functional safety and testing, replacement is limited to

mechanical parts and individual electrical components. When using foreign parts or

carrying out non-authorized works on the suction pump, we refer to operating instructions

Chapter 6 - Guarantee -. Replacing components shall be carried out according to the

specification, the processes and/or the photographic illustrations. If difficulties arise,

please contact the manufacturer Ardo medical AG.

Cylinder

Dismantling

Assembly

Initial position; power unit tray is dismantled from the

housing

• Loosen the two fixing screws on the cylinder base

• Loosen mounting of the piston rods on the slide

• Slide complete cylinder with piston rod up and out

• Place cylinder from above on the cylinder holder

• Insert a 0.3 mm feeler gauge between cylinder holder

and cylinder

• Set slide to the lower dead center

• Pull piston rod all the way down (do not damage

mechanically!)

• Fix on slide with Allen screw

• Pull out feeler gauge and adjust cylinder

• Tighten both Allen screws on the cylinder foot

Assembly of the second cylinder is done analogously.

CAUTION! Glass cylinders and graphite pistons must never

be exchanged or combined with another cylinder. These two

components are specially designed for alignment.

Valves

If device is contaminated or vacuum performance is poor,

check valves on cleanness and damage.

• The valves are fixed in place by a two-component epoxy

adhesive (araldite)

Ardo medical AG 17 Service Manual

MASTER/SENATOR

Subject to change

Page 18

Belt Drive

The belts must be checked annually for extensive wear.

Wearing Parts

Ardo medical AG recommends to check the following wearing parts annually and replace

them if necessary:

- Inlet and outlet valves on the cylinder

- Mechanical drive

- All tubing connections

- Rubber cushions of the power unit

12. TECHNICAL INFORMATION

Specifications

Suction Pump

MASTER 45

Suction Pump

SENATOR 30

MASTER 45 suction pump 230 Volt, 50/60 Hz

MASTER 45 suction pump 115 Volt, 60Hz

SENATOR 30 suction pump 230 Volt, 50/60Hz

SENATOR 30 suction pump 115 Volt, 60Hz

SENATOR 30 double protection on request

- Dimensions without trolley: 345 x 245 x 282 mm

- Dimensions with trolley: 1000 x 470 x 680 mm

- Weight without trolley: 7,4 kg

- Weight with trolley: 21 kg

- Protection class grounded: Class l (with ground safety wire)

- Protection level: BF

Drip-proof IPX1

- Double protection SENATOR 230V: Class II

- Protection level: BF

Drip-proof IPX1

- Classification acc. to MDD93/42: Class 2a

- Rated voltage: 230/115 Volt AC +/- 15%

- Rated current: 50/60Hz

- Power consumption 230V Æ 100W/0.45A

115V Æ 100W/1.00A

- Fuse: 230V Æ T630mA

115V Æ T1.6A

- Suction capacity: MASTER 45 Æ 45 l/min.

SENATOR 30 Æ 30 l/min.

- Vacuum range: 10 to 85kPa

75 to 640mmHg

Ardo medical AG 18 Service Manual

MASTER/SENATOR

Subject to change

Page 19

- Conformity: 0123

to the standard MDD 93/42 EEC

of 14.7.1993 concerning medical devices

EN 60601-1, EN60601-1-2, EN 10079-1

- UL 2601-1 (115V)

Transport and Storage

MASTER/SENATOR shall be transported and stored in the original packaging only.

We recommend a separate storage, protected from UV, heat and dust.

Transport and

storage up to

15 weeks

For transport and storage periods up to 15 weeks, the following

storage conditions are valid:

- Temperature: -25°C to +70°C

- Relative humidity: 10% to 75%

- Air pressure: 500hPa to 1060hPa

Transport and

storage for more

than 15 weeks

After this period, the operating condition values are valid:

- Temperature: +10°C to +40°C

- Relative humidity: 30% to 75%

- Air pressure: 700hPa to 1060hPa

Disposal after Service Life

For disposal of a disused MASTER/SENATOR, the decontaminated suction pump may be

sent back to the manufacturer or, after disinfection, separated into materials (metals,

synthetics) and disposed of environment-friendly by an electronics recycling company.

After decontamination, there are no special or increased risks.

Manufacturer:

Ardo medical AG

Gewerbestrasse 19

CH-6314 Unterägeri

Switzerland

Ardo medical AG 19 Service Manual

MASTER/SENATOR

Subject to change

Loading...

Loading...