Page 1

Service Manual

CD82

Issue 1.0

DiVA CD82

Compact Disc Player (Text)

ARCAM

Page 2

Contents List

Section Issue

Service guide

! Technical specification -

!

CD82 upgrad e instructions -

Main board L934

! Circuit description -

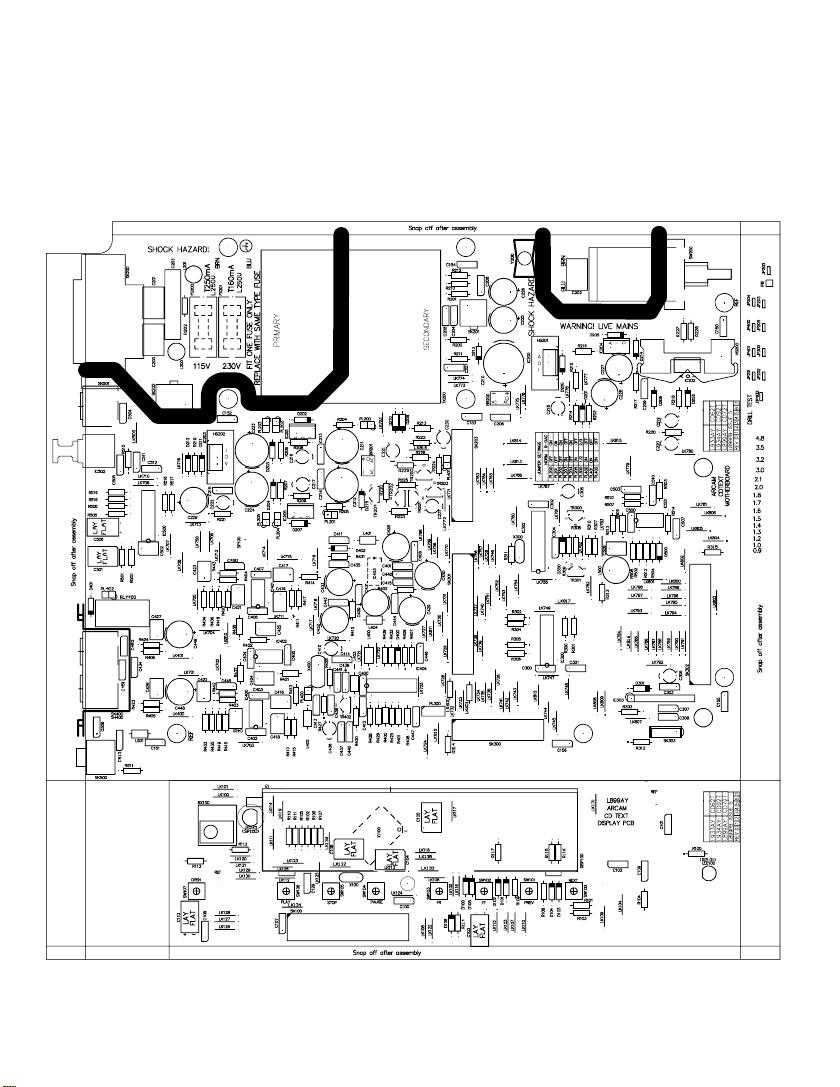

! Component overlay 5.0

! Parts list 4.1

! Circuit diagrams 4.1

DAC board L949

! Component overlay 3.0

! Parts list 3.05

! Circuit diagrams 3.0

Mechanical

Mechanical parts list -

Page 3

Service Guide

Contents

!

Technical

specification

!

CD82 Upgrade fitting

instructions

Page 4

CD82 Technical Specifications

Digital to Analogue conversion

DAC Dual mono 24 bit Wolfson

Laser pick-up 3 beam

Laser wavelength 780nm

Numeric aperture 0.45

Dynamic range 106dB

Signal to noise ratio (CCIR) >100dB

Harmonic distortion (0dB, 1kHz) <0.005%

Frequency response (+-0.5dB) 5Hz-20kHz

Output level (0dB) 2.3Vrms

Output impedance 50 ohm

Minimum recommended load 5k ohm

General

Digital output connection 75 ohm co-axial

Power consumption 35VA

Dimensions (including feet) W430 x D290 x H84mm

Weight (net) 5.5kg

Weight (packed) 7.0kg

Supplied accessories Mains lead

CR314 remote control

2 x AAA batteries

Page 5

DiVA CD82 UPGRADE FITTING

INSTRUCTIONS

Compatible with:

Alpha 7, 7SE, 8, 8SE CD players

DiVA CD72, CD72 (text) CD players

Note – When converting from 8SE to CD82 you will no

longer be able to decode the extra information on the few

HDCD discs available, however the sound quality offered by

the CD82 upgrade is significantly superior on all discs to

that of the original 8SE.

Kit Contents

1x CD82 DAC module L951AY

1x Upgrade instruction sheet E836UI

1x Silver CD82 drawer front assembly E993AY

1x Black CD82 drawer front assembly E993AYB

2x PCB support locking pillars H037

5x Self tapping screws HF4V09B

1x Product registration card SH000

1x CD82 authentication label E954SL

1x Surface cleaner wipe F227

Upgrading an Alpha 7/7SE, 8/8SE to CD82 DAC

For 7/7SE follow steps 1,2,3A onwards (not 3B)

For 8/8SE follow steps 1,2,3B onwards (not 3A)

1. Disconnect the mains supply from the Alpha CD player.

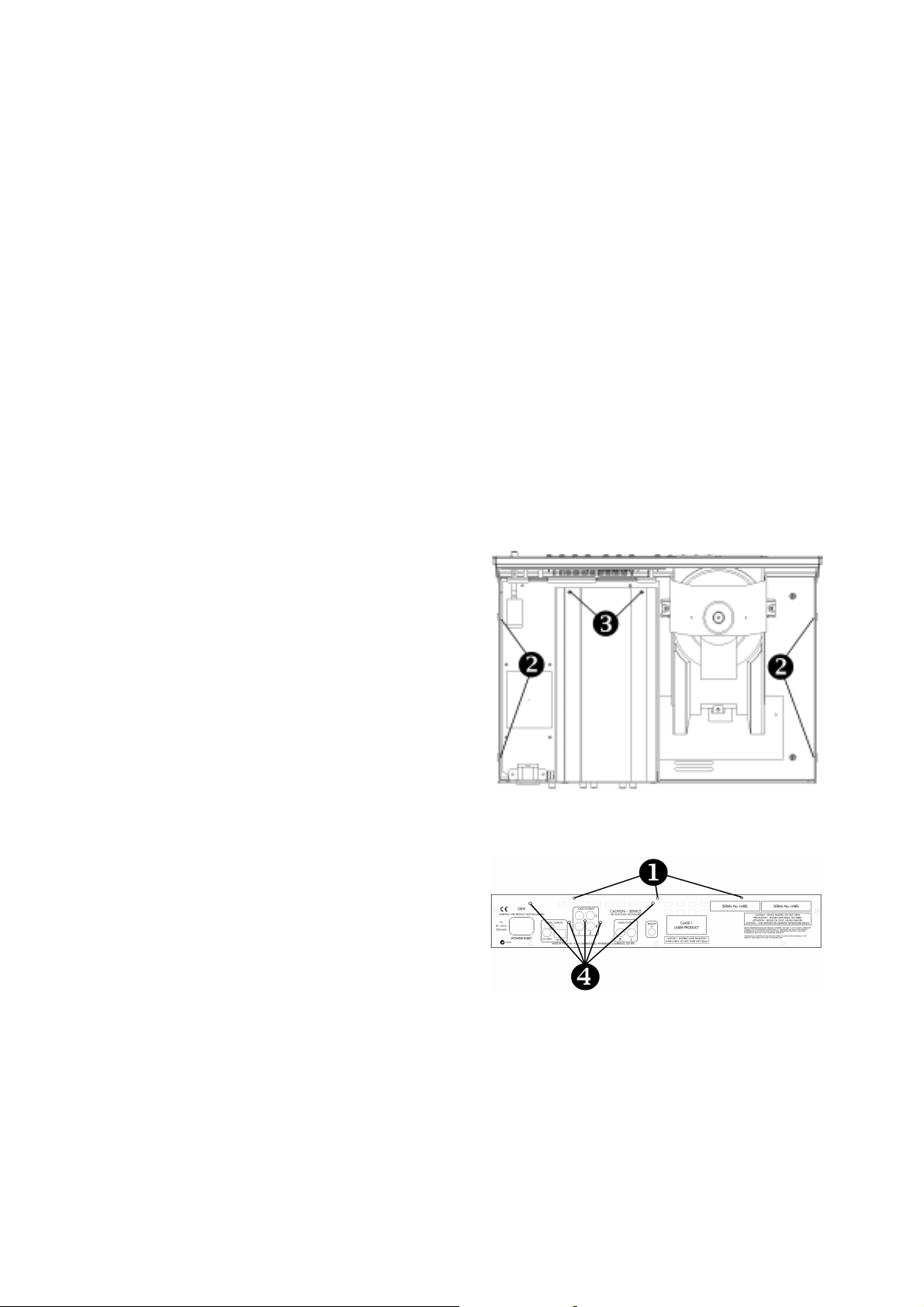

2. Remove the top cover by taking out the 2 screws from the

top edge of the rear panel marked ! (Pozi no.1 driver

required and on each side marked " (Pozi no.2 driver

required).

3A. For Alpha 7/7SE to DiVA CD82 DAC upgrade only

Pull off the st i ck y pla st ic gask et b et ween t h e d i gita l ou tp ut

socket and the audio output sockets to reveal the 4 audio

output socket holes through which the DAC sockets will

pass.

Any remnants of adhesive can be removed by rubbing it

gently with your finger and rolling it off. We do not

recommend the use of solvents.

Fit the 2 supplied PCB (printed circuit board) pillars to the

holes in the main board on either side of the flex foil

coming from the display board, these are marked # in

figure 1. The big end of each PCB pillar goes into the

main PCB, these push in and clip home. Take great care

not to damage th e main circuit boa rd .

Remove the Alpha 7/7SE Configuration Module (the

small vertically mounted PCB in the centre of the main

board). It will not be needed once the new DAC board is

fitted.

Note: The original n ickel-plated audio outp ut sockets are

no longer connected after the upgrade and cannot be used.

However the digit al output still functions.

3B. For Alpha 8/8SE to DiVA CD82 DAC upgrade only

Remove the 5 screws holding the Alpha 8/8SE board in

place. Squ eeze the t op of the t wo PCB pi llars supp orting

the end of the aluminium extrusion and lift the extrusion

up and out of the unit. If the flex foils do not come away

with the DAC board then remove them as well.

4. Take static precautions first. With the aluminium

extrusion of th e CD82 DAC module uppermos t fit the

flex foils from the module into the appropriate sock ets

in the main board, ensuring they are pushed fully home.

You may find it helps to slide the module into the uni t

so that the audio output sockets fit through th e ho les in

the rear pan el and angle the module slightly upwa r ds to

achieve this.

5. Push the modu le down firmly on to the support pillars,

ensure it is latched in place.

6. Fit the supplied screws with integral washers to the 5

points marked $ in figure 1 (T10 Torq driver required)

to hold the module in place.

7. Refit the top cover and attach the CD82 authentication

label to the underside of the CD player

Upgrading a CD72 to CD82

1. Disconnect the mains supply from the DiVA CD player.

2. Remove the top cover by taking out the 3 screws from

the top edge of the rear panel ma r ked ! (T10 Torq

driver required) and on each side marked " (T20 Torq

driver required) in figure 1.

3. Pull off t he sticky plastic gasket between the digita l

output socket and the audio output sockets to reveal t he

4 audio output socket holes through which the DAC

board sockets will pass.

4. Any remnants of adhesive can be removed by rubbing it

gently with your finger and rolling it off. We do not

recommend the use of solvents.

5. Fit the 2 supplied PCB (printed circuit board) pillars to

the holes in the main board on either side of the flex foil

coming fro m the display bo ard, these are marked # in

figure 1. The big en d of each PCB pillar goes into the

main PCB, these push in and clip home. Take great

care not to da mage the main circuit board.

6. Remove the Configuration Module (the small vertically

mounted PCB in the centre of the main board). It will

not be needed once the new DAC board is fitted.

7. Note: The original ni ckel-plated audio output sock ets

are no longer connected after the upgrade and cannot be

used. However the digital output still fu nctions.

8. Remove the following jumpers: - PL2, PL3, PL4, PL6

Fit the following jumpers: - PL5, PL7

9. Take static precautions first. With the aluminium

extrusion of the CD82 DAC module uppermost fit the

flex foils from the module into the appropriate sock ets

in the main board, ensuring they are pushed fully home.

If they are not pushed fully home, the uni t may not read

discs. You may find it helps to slide the module into

the unit so that the audio output sockets fit thr ough the

holes in the r ear panel and angle the module slightly

upwards to ac hieve this.

10. Push the module down firmly on to the support pillars,

ensure it is latched in place.

11. Fit the supplied screws with integral washers to the 5

points marked $ in figure 1 (T10 Torq driver required)

to hold the module in place. Refit the top cover.

Page 6

12. Removing the drawer front - connect a mains supply to the

unit; press load and allow the tray to fully open; remove

the mains supp ly from the unit. Hold the drawer tightly

with one hand and with the other pu ll the drawer front

forward away from the player (pull hard). Remove any

remnants of tape from the drawer front mechanism; clean

the drawer mechanism front using the 'surface cleaner'

wipe provided.

13. Fitting the new CD82 drawer front - connect a mains

supply to the unit and allow the drawer to close

automatica lly. Remove the backing from the tap e attached

to the new drawer front and carefully align the drawer

front with the mechanism and press gently together;

reposition the drawer front if necessary and press firmly to

the unit.

Upgrading a CD72 (TEXT) to CD82 (TEXT)

1. Disconnect the mains supply from the DiVA CD player.

2. Remove the top cover by taking out the 3 screws from the

top edge of the rear panel marked ! (T10 Torq driver

required) and on each side marked " (T20 Torq driver

required) in figure 1.

3. Pull off th e sticky plastic gasket between the digital output

socket and the audio output sockets to reveal th e 4 audio

output socket holes through which the DAC board sockets

will pass.

4. Any remnants of adhesive can be removed by rubbing it

gently with your finger and rolling it off. We do not

recommend the use of solvents.

5. Fit the 2 supplied PCB (print ed circuit board) pillars to the

holes in the m ain board on either side of the flex foil

coming fro m the display bo ard, these are marked # in

figure 1. The big en d of each PCB pillar goes into the

main PCB, these push in and clip home. Take great care

not to damage th e main circuit boa rd .

6. Note: The original ni ckel-plated audio output sock ets are

no longer connected after the upgrade and cannot be used.

However the digital output still func tions.

7. Set the ma in board jumper settings as listed below: -

PL200 ON

PL201 ON

PL202 ON

PL203 OFF

PL204 ON

PL205 OFF

PL300 2 and 3

PL400 OFF

PL401 OFF

PL402 OFF

8. Take static precautions first. With the aluminium

extrusion of the DAC module uppermost fit the flex foils

from the module into the appropriate sockets in the main

board, ensuring they are pushed fully home. If they are

not pushed fully home, the unit may not read discs. You

may find it helps to slide the module into the unit so that

the audio outp ut sockets fit through the holes in the rear

panel and angle the module slightly upwards to achieve

this.

9. Push the modu le down firmly on to the support pillars,

ensure it is latched in place.

10. Fit the supplied screws with integral washers to the 5

points marked $ on figure 1 (T10 Torq driver required)

to secure the module in place. Refit the top cover.

11. Removing the drawer front - connect a mains supply to

the unit; press load and allow the tray to fully open;

remove the mains supply from the unit. Hold the drawer

tightly with one hand and with the other pull the drawer

front forward away from the player (pull hard). Remove

any remnants of tape from the drawer front mechanism;

clean the drawer mechanism front using th e 'surface

cleaner' wipe provided.

12. Fitting the new CD82 drawer front - connect a mains

supply to the unit and allow the drawer to close

automatica lly. Remove the backing from the tape

attached to the new drawer front and carefully align the

drawer front with the mechanism and press gently

together; reposition the drawer front if necessary and

press firmly to the unit.

Figure 1

Page 7

Main

Board

L934

Contents

!

Circuit description

!

Component overlay

!

Parts list

!

Circuit diagrams

Page 8

CD72, CD82 & CD92 (text)

Circuit Description

Summary

The main Motherboard/Display PCBs for the Diva CD players

may be assembled as three different versions:

! DiVA CD62 (text) - With alternate components fitted

and the 92DAC upgrade connections omitted

(L933AY).

! DiVA CD72 (text) - With the standard set of

components fitted (L899AY).

! DiVA CD82/92 (text) - With analogue components

and connectors omitted, for use as a host motherboard

The CD72T version may be converted for use with an upgrade

All system s are based on a Sony kit, comprising CDM14BL5BD25 CD transport / loader / laser mechanism, micro-controller

and fluorescent display.

Power Supplies

The CD72, CD82 & CD92 transformers :-

The mains transformer has three secondary windings:

1. 13.7V – 0V – 13.7V to provide ±12V(A) supplies

2. 9V-0V-32V to produce the digital, motor drive and

All of these supplies are delivered also to the optional CD82 or

CD92DAC upgrade board via the DAC power connector SK203.

The supplies are conventional and are linearly regulated by 3terminal voltage regulators.

When the DAC upgrade board is used, analogue regulators IC201

and IC205 can be bypassed by rem oving JP203 and JP205, and

fitting JP202 and JP204

DAC board itself. Soft-charging resistors R204 and R205 are

bypassed similarly.

Relay Mute Control

This circuit drives a relay to un-mute the analogue output ~5

seconds after the unit is powered on, and quickly mutes the

output when the unit is switched off. Th e cir cu it works

effectively as an “AND” gate.

for the plug-in 82 or 92DAC (L934AY).

plug-in DAC board by changing on-board jumpers.

! 230/115VAC - part number L866TX

! 100VAC only - part number L851TX

(IC201 and IC205) for the audio output circuitry via

regulators IC201 and IC205.

fluorescent display grid supplies:

+11V(U) Unregulated supply for relay drive and

+7V (IC200) Mechanism and motor driver

+5V(D) (IC202) General digital logic supply

+5V(A) (IC203) Supply to DAC

-30V (IC204) Display grid voltage.

3. 0-5V to provide an AC supply for the display

filament.

+5V(D) supply

supply

since regulation is contained on the

If AC is present on the transformer secondary winding and the 5second timer composed of R222 and C221 has reached the

threshold voltage (Vbe of TR200 + Vbe of TR201 - Vce of

TR202, or ~1.0V), the relay coil is connected to +11V

(referenced to 0V_3 as required by the DAC’s internal circuitry)

via TR204.

When AC is removed, C231 discharges quickly through R225,

the base voltage of TR204 rises and the relay coil voltage is

removed, muting t he output.

TR203 resets the ‘timer’ by discharging C221 quickly at turn-off.

Remote Control/PIC Micro

Remote control data is received from the IREy e on the display PCB

and buffered by TR300 and TR301. The Programmable Interrupt

Controller converts the RC-5 format data into the NEC format

required by the Sony micro. The PIC al so control s the con fig ura tio n

of the digital filter/DAC on the DAC board.

Motor Driver

The status of the drawer is indicated to the micro by two micro

switches ‘INSW’ and ‘OUTSW’ on SK205. The micro controls

the drawer motor via driver IC303.

Clock Buffering

The clock and data signals LRCK, ADATA and BCLK from the

mechanism connector SK300 are double buffered by IC300

before being delivered to the D AC.

Power-On/Reset

The power-on reset signal XRST (or RESET) is generated by

R409, C410 and IC404. When the power is turned on, C410 is

initially uncharged and pin 11 of IC404 is at high voltage, and

thus the output is low. After a short time, C410 is charged via

R409; IC404 pin 11 is then low, and the output switches high

(RESET is de-asserted).

DAC & System Clock

The DAC is a Burr Brown PCM1716E, the DAC is configured

for hardware control.

Digital audio is input on pins 1, 2 & 3 in standard Red Book

Audio format, i.e. Word Cloc k, Bit Clock an d Data.

The system clock is based around 16. 9344 MH Z crystal X400

and transistor TR402. This produces a stable clock with low

jitter. IC404A & B buffer the clock as linear buffers. IC404C &

D buffer the individual mech & DAC clock lines.

The CD82 & CD92 system clock is generated on the DAC board.

The clock and data signals LRCK, ADATA and BCLK from the

mechanism connector SK300 are double buffered by IC300 before

being delivered to the DAC. The system clock is delivered to the

mech via two-position jumper PL300. The clo ck source is selected

to be either from the main board (CD62/72) or from the DA C bo ar d

(CD82/CD92) by the position of JP300.

When the 82 or 92DAC is fitted as an upgrade to a CD72, r emov ing

JP400 disables the main board clock

Page 9

Analogue Output

Left channel:

IC400A and IC400B are cascaded 69kHz 2

Bessel filters. The output devices internal to both op-amps in

IC400 are “pulled down” to the negative supply rail to force

operation in class A (one output device is conducting at all times

and crossover distortion is eliminated).

IC402A is a DC servo with a very low cut off frequency, acting

to impose a non-zero voltage ‘virtual earth’ at the non-inverting

input of IC400B, thus eliminating the offsets caused by the pulldown resistors and DC-coupling the output.

The right channel is the same as the left channel. IC401A & B

are used as the buffer and filter.

nd

order low-pass

Microcontroller & Display Board

The system microcontroller IC100 serves the following functions:

! Control of the mechanism & decoder on the CDM14

mechanism

! Control of mute, attenuation and de-emphasis for the

DAC

! Direct drive of the fluorescent display

! Remote control decoding

! Keyboard scanning

! 82/92DAC muting

The keyboard scanning works by connecting the keys to a resistor

ladder on an ADC input to the micro. Pressing a key presents a

unique voltage to this input, which the micro is pre-programmed

to interpret accordingly.

The remote control data contains a ‘Customer Code’ that

identifies this as an Arcam product. The diode network D100 to

D106 configures the micro to accept this code.

Remote Bus Carrier Filter & Demodulator

Remote control commands can be delivered over wire to SK500

for multi-room applications. Incoming signals are attenuated and

clipped by resistors and D500. L500 and C508 form a parallel

resonant circuit at approximately 37kHz. This dem odulates the

incoming signal and the output is passed to IC501A where it is

‘chopped’, low pass filtered and fed to IC501B to provide the

RC5 outp ut signal.

Digital Output

The decoder on the mechanism assembly generates an SPDIF

format digital output signal. This is passed to buffer IC500A.

IC500B through E are used in parallel to provide a transformer

less 75-ohm source impedance to a single phono socket SK501.

Optical digital output via IC502 is also tapped off the digital

output signal via IC500F.

Page 10

Page 11

L934 Main Board Parts List Issue 4.1

Designator Part Description

BR200 3BDF01M Bridge rectifier DF01M 1A 100V

BR201 3BDF01M Bridge rectifier DF01M 1A 100V

C100 2A210 CERD 1N0 63V 20% RA

C101 2A210 CERD 1N0 63V 20% RA

C102 2A210 CERD 1N0 63V 20% RA

C103 2N710 ELST 100U 25V

C104 2A410 CERD 100N 63V 20% RA

C105 2A410 CERD 100N 63V 20% RA

C106 2A410 CERD 100N 63V 20% RA

C107 2A410 CERD 100N 63V 20% RA

C108 2A410 CERD 100N 63V 20% RA

C109 2A410 CERD 100N 63V 20% RA

C110 2N610 ELST 10U 50V

C129 2A310 CERD 10N 63V 20% RA

C151 2A210 CERD 1N0 63V 20% RA

C152 2A210 CERD 1N0 63V 20% RA

C153 2A210 CERD 1N0 63V 20% RA

C154 2A210 CERD 1N0 63V 20% RA

C155 2A210 CERD 1N0 63V 20% RA

C156 2A210 CERD 1N0 63V 20% RA

C200 2K233 SUPPR CAP 3N3 250V

C201 2K233 SUPPR CAP 3N3 250V

C202 2K233 SUPPR CAP 3N3 250V

C203 2D422 220NF CLASS X2 CAP 275VRMS

C204 2A410 CERD 100N 63V 20% RA

C205 2A410 CERD 100N 63V 20% RA

C206 2A410 CERD 100N 63V 20% RA

C207 2AB410 CERD 100N 100V -20% +80% RA

C208 2AB410 CERD 100N 100V -20% +80% RA

C209 2A410 CERD 100N 63V 20% RA

C210 2N833 ELST 3M3 25V

C211 2N810C ELST 1M0 35V

C212 2N810C ELST 1M0 35V

C215 2K410 PEST 100N 63V 10%

C218 2N710 ELST 100U 25V

C219 2N710 ELST 100U 25V

C220 2N710 ELST 100U 25V

C221 2N710 ELST 100U 25V

C222 2N710 ELST 100U 25V

C223 2N810 ELST 1M0 25V

C224 2N810 ELST 1M0 25V

C225 2N710B ELST 100U 100V

C226 2N710B ELST 100U 100V

C227 2N710B ELST 100U 100V

C228 2N810A ELST 1M0 10V

C229 2N810A ELST 1M0 10V

C230 2N710 ELST 100U 25V

C231 2N610 ELST 10U 50V

C300 2A410 CERD 100N 63V 20% RA

C301 2A410 CERD 100N 63V 20% RA

C302 2A410 CERD 100N 63V 20% RA

C303 2A410 CERD 100N 63V 20% RA

C304 2A110 CERD 100P 50V -20% +80% RA

C305 2N710 ELST 100U 25V

C306 2N710 ELST 100U 25V

C307 2A310 CERD 10N 63V 20% RA

C308 2A410 CERD 100N 63V 20% RA

C400 2A410 CERD 100N 63V 20% RA

C410 2N710 ELST 100U 25V

C414 2A410 CERD 100N 63V 20% RA

C434 2A410 CERD 100N 63V 20% RA

C451 2AA210 CAP 1000PF 100V NPO CERD

Page 12

L934 Main Board Parts List Issue 4.1

Designator Part Description

C452 2AA210 CAP 1000PF 100V NPO CERD

C500 2A410 CERD 100N 63V 20% RA

C501 2A310 CERD 10N 63V 20% RA

C502 2K447 PEST 470N 63V 10%

C503 2A210 CERD 1N0 63V 20% RA

C504 2A310 CERD 10N 63V 20% RA

C505 2A410 CERD 100N 63V 20% RA

C506 2P622 ELST 22U 20V OSCON

C507 2A410 CERD 100N 63V 20% RA

C508 2D168 PPRO 680P 5% 63V RA

C509 2A410 CERD 100N 63V 20% RA

C510 2A110 CERD 100P 50V -20% +80% RA

C511 2A410 CERD 100N 63V 20% RA

C512 2A147 CERD 470P 50V -20% +80% RA

C513 2A110 CERD 100P 50V -20% +80% RA

CA1 L920CA CD...T MAINS JUMPER CABLE

D100 3A4148 SSDIODE 1N4148 75V

D101 3A4148 SSDIODE 1N4148 75V

D102 3A4148 SSDIODE 1N4148 75V

D103 3A4148 SSDIODE 1N4148 75V

D104 3A4148 SSDIODE 1N4148 75V

D105 3A4148 SSDIODE 1N4148 75V

D106 3A4148 SSDIODE 1N4148 75V

D200 3A4148 SSDIODE 1N4148 75V

D201 3A4148 SSDIODE 1N4148 75V

D205 3A4148 SSDIODE 1N4148 75V

D206 3A4148 SSDIODE 1N4148 75V

D208 3A4148 SSDIODE 1N4148 75V

D209 3A4148 SSDIODE 1N4148 75V

D210 3A4148 SSDIODE 1N4148 75V

D211 3A4148 SSDIODE 1N4148 75V

D212 3A4148 SSDIODE 1N4148 75V

D213 3B4003 RECTIFIER 1N4003F 1A 200V

D214 3C05104 Diode 5V1 400mW

D215 3A4148 SSDIODE 1N4148 75V

D300 3A4148 SSDIODE 1N4148 75V

D301 3C04704 ZENER 4V7 400MW

D400 3A4148 SSDIODE 1N4148 75V

D500 3C04704 ZENER 4V7 400MW

DISP100 B1015 DISP CD SONY 14-ST-20GK

E1 E102AY CDTEXT VFD SUPPORT

EL200 8M101 EARTH LEAD

FS200 F022 INS COVER PCB FUSEHOLDER

FS200 8S004 FUSEHOLDER 20mm PCB

FS201 C11166 FUSE 20mm 160mA T S504160mA

FS201 F022 INS COVER PCB FUSEHOLDER

FS201 8S004 FUSEHOLDER 20mm PCB

HS200 F006 HEATSINK CLIP TO220 13/8.6 DC/W

HS200 F008 HEATSINK TO220 8.6 DEGC/W

HS201 F007 HEATSINK TO220 CLIP 30

HS202 F007 HEATSINK TO220 CLIP 30

IC100 5G82832 IC CD CXP82832-031Q MICRO

IC200 5D1086A IC VREG LM1086CT-ADJ

IC202 5D317T IC VREG POS LM317T

IC203 5D317T IC VREG POS LM317T

IC204 5D337 IC VREG POS LM337T

IC300 5J7404 IC HCMOS 74HCU04

IC302 5H16C54X IC CMOS MICRO PIC16C54XT/P

IC302 8S018 IC SOCKET 18 PIN 0.3''

IC302SW L825SW A SOFTWARE

IC303 5Q1641 IC MOTOR DRIVER LB1641

IC404 5J7404 IC HCMOS 74HCU04

Page 13

L934 Main Board Parts List Issue 4.1

Designator Part Description

IC500 5J7404 IC HCMOS 74HCU04

IC501 5M393A IC COMPARITOR DUAL LM393A

IC502 5TG550T SPDIF OPTICAL TRANSMITTER

JP200 8K004 JUMPER SOCKET 0.1''

JP201 8K004 JUMPER SOCKET 0.1''

JP202 8K004 JUMPER SOCKET 0.1''

JP204 8K004 JUMPER SOCKET 0.1''

JP300 8K004 JUMPER SOCKET 0.1''

L200 7D968A 6U8H INDUCTOR

L201 7D968A 6U8H INDUCTOR

L400 7F003 FERRITE BEAD SINGLE AXIAL

L500 7D327 27mH INDUCTOR

L501 7F003 FERRITE BEAD SINGLE AXIAL

LED100 3D007 LED GREEN 3.1MM SLR-37MG3F

LED101 3D003 LED ULTRARED 5MM

LK600 1H000 RES MF W4 1% 0R0

LK601 1H000 RES MF W4 1% 0R0

MC200 E922MC MAGNETIC SHIELD PLATE

MC201 E923MC ADHESIVE PAD(ATTACH TO E922MC & TX)

PAD100 E802AP SORBOTHANE PAD 15X6X3 mm

PAD101 E802AP SORBOTHANE PAD 15X6X3 mm

PB L899PB_4 BLANK PCB

PL200 8K6201 2WAY MOLEX VERT MALE CONNECTOR

PL201 8K6201 2WAY MOLEX VERT MALE CONNECTOR

PL202 8K6201 2WAY MOLEX VERT MALE CONNECTOR

PL204 8K6201 2WAY MOLEX VERT MALE CONNECTOR

PL300 8K2103 3WAY MOLEX VERT MALE CONNECTOR

R100 1H122 RES MF W4 1% 220R

R101 1H310 RES MF W4 1% 10K

R102 1H310 RES MF W4 1% 10K

R103 1H268 RES MF W4 1% 6K8

R104 1H268 RES MF W4 1% 6K8

R105 1H268 RES MF W4 1% 6K8

R106 1H268 RES MF W4 1% 6K8

R107 1H268 RES MF W4 1% 6K8

R108 1H233 RES MF W4 1% 3K3

R109 1H222 RES MF W4 1% 2K2

R110 1H215 RES MF W4 1% 1K5

R111 1H210 RES MF W4 1% 1K0

R112 1H168 RES MF W4 1% 680R

R113 1H010 RES MF W4 1% 10R

R114 1H310 RES MF W4 1% 10K

R115 1H310 RES MF W4 1% 10K

R116 1H310 RES MF W4 1% 10K

R117 1H310 RES MF W4 1% 10K

R200 1G810 RES MF FU W3 1R0 5% NFR25

R201 1G810 RES MF FU W3 1R0 5% NFR25

R202 1K515 RES W25 5% VR25 1M5

R203 1H133 RES MF W4 1% 330R

R210 1G810 RES MF FU W3 1R0 5% NFR25

R211 1G010 RES MF FU W3 10R 5% NFR25

R212 1G810 RES MF FU W3 1R0 5% NFR25

R213 1G010 RES MF FU W3 10R 5% NFR25

R214 1H216 RES MF W4 1% 1K6

R215 1H322 RES MF W4 1% 22K

R216 1H210 RES MF W4 1% 1K0

R217 1H333 RES MF W4 1% 33K

R218 1H127 RES MF W4 1% 270R

R219 1H127 RES MF W4 1% 270R

R220 1H182 RES MF W4 1% 820R

R221 1H182 RES MF W4 1% 820R

R222 1H447 RES MF W4 1% 470K

Page 14

L934 Main Board Parts List Issue 4.1

Designator Part Description

R223 1H310 RES MF W4 1% 10K

R224 1H310 RES MF W4 1% 10K

R225 1H222 RES MF W4 1% 2K2

R226 1H310 RES MF W4 1% 10K

R227 1H110 RES MF W4 1% 100R

R228 1H110 RES MF W4 1% 100R

R229 1H215 RES MF W4 1% 1K5

R230 1H310 RES MF W4 1% 10K

R300 1H133 RES MF W4 1% 330R

R303 1H268 RES MF W4 1% 6K8

R304 1H133 RES MF W4 1% 330R

R306 1H133 RES MF W4 1% 330R

R307 1H310 RES MF W4 1% 10K

R308 1H310 RES MF W4 1% 10K

R309 1H310 RES MF W4 1% 10K

R310 1H310 RES MF W4 1% 10K

R311 1H410 RES MF W4 1% 100K

R312 1H268 RES MF W4 1% 6K8

R313 1H410 RES MF W4 1% 100K

R314 1H310 RES MF W4 1% 10K

R315 1H310 RES MF W4 1% 10K

R409 1H310 RES MF W4 1% 10K

R432 1H310 RES MF W4 1% 10K

R439 1H510 RES MF W4 1% 1M0

R500 1H010 RES MF W4 1% 10R

R501 1H010 RES MF W4 1% 10R

R502 1H218 RES MF W4 1% 1K8

R503 1H218 RES MF W4 1% 1K8

R504 1H210 RES MF W4 1% 1K0

R505 1H112 RES MF W4 1% 120R

R506 1H212 RES MF W4 1% 1K2

R507 1H310 RES MF W4 1% 10K

R508 1H310 RES MF W4 1% 10K

R509 1H310 RES MF W4 1% 10K

R510 1H310 RES MF W4 1% 10K

R511 1H147 RES MF W4 1% 470R

R512 1H410 RES MF W4 1% 100K

R513 1H410 RES MF W4 1% 100K

R514 1H215 RES MF W4 1% 1K5

R515 1H310 RES MF W4 1% 10K

R516 1H212 RES MF W4 1% 1K2

R517 1H212 RES MF W4 1% 1K2

R518 1H212 RES MF W4 1% 1K2

R519 1H110 RES MF W4 1% 100R

RX100 B2107 REMOTE RX PIC-26043TM2 38KHZ

SH400 E821MC PHONO EMC SHIELD

SK100 8K8132 32-WAY FFC CONN HORIZ

SK200 8A001 IEC MAINS CONN PCB INS PX

SK200 HP007 COPPER RIVET TCP/D48 BS

SK200 HP007 COPPER RIVET TCP/D48 BS

SK203 8K8023 23-WAY FFC CONN VERT

SK300 8K8023 23-WAY FFC CONN VERT

SK301 8K8032 32-WAY FFC CONN VERT

SK302 8K8032 32-WAY FFC CONN VERT

SK303 8K2005 5-WAY AMP CT CONN

SK500 8D228 MIN JACK SINGLE 3.5mm

SK501 8D220 PHONO SKT SINGLE EMC

SP102 F195 LED SPACER

SP103 F205 DS STICKY PAD 70 X 12mm

SP104 E822AP IR RX SUPPORT PAD

SW100 A1511 TACT SWITCH 2-PIN LOW PROF 9.5mm

SW101 A1511 TACT SWITCH 2-PIN LOW PROF 9.5mm

Page 15

L934 Main Board Parts List Issue 4.1

Designator Part Description

SW102 A1511 TACT SWITCH 2-PIN LOW PROF 9.5mm

SW103 A1511 TACT SWITCH 2-PIN LOW PROF 9.5mm

SW104 A1511 TACT SWITCH 2-PIN LOW PROF 9.5mm

SW105 A1511 TACT SWITCH 2-PIN LOW PROF 9.5mm

SW106 A1511 TACT SWITCH 2-PIN LOW PROF 9.5mm

SW107 A1511 TACT SWITCH 2-PIN LOW PROF 9.5mm

SW200 A1010 SWITCH PUSH MAINS DPST TV-8

TR200 4A549 TRANS LF SS N BC549B

TR201 4A549 TRANS LF SS N BC549B

TR202 4A549 TRANS LF SS N BC549B

TR203 4A549 TRANS LF SS N BC549B

TR204 4A557 TRANS LF SS P BC557B

TR300 4A549 TRANS LF SS N BC549B

TR301 4A549 TRANS LF SS N BC549B

TX200 L866TX 9 CD COOL FRAME TX MULTI-VOLTAGE

X100 7W008 CER RESON 8.00MHz

X300 7W005 CER RESON 4.00MHz

Y200 F185 TX WIRE RESTRAINT

Page 16

87654321

(NEAR SK100)

CHASSIS

D

C

B

FIX100

FIXING HOLE 3.2

FIX101

FIXING HOLE 3.2

C101

1N0 CD

0V

FIX102

FIXING HOLE 3.5

FIX103

FIXING HOLE 3.5

CHASSIS2

C100

1N0 CD

C102

1N0 CD

0V 0V

PAD100

SORBOTHANE PAD

15 X 6 X 3 mm

SORBO E802AP

PLACED BETWEEN C409 AND L401

PAD101

SORBOTHANE

HALF PAD

7 5 X 6 X 3 mm

SORBO HALF PAD E802AP

FITTED ON X400

SP102

LED

SPACER

SPACER F195

SP103

70mm x 12mm

DOUBLE SIDED

STICKY GASKET

70X12_DS STICKY TAPE

SP104

IR RX

SUPPORT PAD

IR RX SUPPORT PAD

+5V

(NEAR SK100)

0V

RX100

SBX1610-52/PIC-26043TM2

Connector to main PCB

PIN 1 TO LEFT

CABLE POINTING DOWN

IR_DISP

SK100

FFC32H

2

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

+

C103

100U EL

3

O/P

+5V

O/P

Case

Case

F1

SCOR_DISP

RMIN_DISP

LDOUT_DISP

LD N_DISP

SENS_DISP

XLT_DISP

AMUTE_DISP

CLK_DISP

LDON_DISP

DATA_DISP

SQCK_DISP

SUBQ_DISP

LOADSW_DISP

XRST_DISP

DEEM_DISP

HDCD_DISP

LPH_DISP

F2

R_DISP

DECOUPLING CAPACITORS FOR IC100

C104

100N CD

C107

100N CD

C105

100N CD

-30V

+5V

GND +5V

C108

100N CD

GND

+

C110

10U EL

1

+5V

0V

-30V

SW100 SW101 SW102 SW103 SW104 SW105 SW106 SW107

0V

R113

10R MF

0V

NEXT PREV FF FR PAUSE STOP PLAY OPEN

C106

100N CD

HDCD LED

LED101

LED ULTRARED

0V

R101

10K MF

R100

220R MF

LED100

LED GREEN3.1MM

POWER LED

R103

6K8 MF

R108

3K3 MF

CMO4

R109

2K2 MF

D100

1N4148

D101

1N4148

REMOTE CUSTOM CODE DIODE MATRIX

D102

1N4148

D103

1N4148

D104

1N4148

D106

1N4148

CMO3

CMO2

CMO1

0V

C109

100N CD

0V

R110

1K5 MF

R111

1K0 MF

R112

680R MF

D105

1N4148

R114

R115

R116

R117

+5V

10K MF

10K MF

10K MF

10K MF

R104

6K8 MF

C129

10N CD

0V

R105

6K8 MF

R106

6K8 MF

R107

6K8 MF

R102

10K MF

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

2

3

4

5

6

7

8

9

13G

14G

NC

CMI1

SCOR

CMI2

CMI3

RMIN

CMI4

NC

NC

LDOUT

LDIN

SENS

XLT

AMUTE

PGML

NC

NC

TIMER

NC

CLK

LDON

DATA

SQCK

SUBQ

NC

AVREF

KEY0

KEY1

DISP100

DISPLAY 14-ST-20GK

F11F1214G413G512G611G710G89G98G107G116G125G134G143G152G161G17NC18P119P220P321P422P523P624P725P826P927P1028P1129P1230P1331P1432P1533P1634P1735P1836P1937P2038P2139F241F2

+5V

871G88

100

10G9811G9912G

KEY231KEY332ADJ/AFADJ

LOADSW34NC35NC36AVSS37RST38EXTAL39XTAL40VSS41NC42NC43VDD44VDP45NC

33

892G903G914G925G936G947G958G969G97

VDD

-30V

+5V

0V

X100

CST800

S385S286S1

S484S583S682S7

NC47LPH48NC49NC

46

81

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

NC

NC

NC

NC

NC

NC

NC

NC

EMPHASIS

CMO4

CMO3

CMO2

CMO1

NC

NC

NC

50

S8

S9

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

IC100

CXP82832

CMO4

CMO3

CMO2

CMO1

0V

D

42

F2F1

C

B

E1

CDTXT VFD SUPP INSULATED

A

E102AY

1

2

3

4

0V

1 2 3 4 5 6 7 8

A & R Cambridge Ltd.

Pembroke Avenue

Denny Industrial Centre

Waterbeach

Cambridge CB5 9PB

Filename

J:\Change Control\ECO AGENDA\01 E007 Display Cradle see tgp\L934 4.1.DDB - Documents\L934C1 4.1.sch

23425

DRAWING TITLE

CD92T - DISPLAY AND SYSTEM MICRO

Circuit Diagram

Notes:

01_E007 4.1WAF/TGP 13/12/01

01_1123 TGP

CW 10

ECO No. DESCRIPTION OF CHANGE

INITIALS

DATE

Date Printed

DISPLAY CRADLE CHANGED TO NSULATED ASSY

UPDATE FOR EMC AND W LSONS REQUESTS01_1147 40WAF 24/10/01 & UPDATE PCB TO AIWA STD

Up-Issue for PCB 2.1

Ini ial Release

Drawn by:

JR14-Dec-2001

1 7Sheet of

DRAWING NO.

A

ISSUE

L934CT

Page 17

SK200

IEC3

EL200

N E L

L

E

N

C200

C201

3N3(X1Y2)

3N3(X1Y2)

R202

NEUTRAL LIVE

NEUTRAL2

SK202

3

2

1

MOLEXPWR6

(FOR AUX TOROID)

NF

L200

6U8H

1M5 VR25

C203

220N(X2)

CA1

L920CA

L920CA

6

5

4

L201

6U8H

BRN BRN

BLU

BLU

EARTH LEAD

8M101

EARTH LEAD

(IEC INLET TO CHASSIS)

LIVE2

C202

3N3(X1Y2)

FS200

T250MA115V

115V ONLY

FS201

T160MA

230V ONLY

NEUTRAL2

SW200A

A1010

SW200B

A1010

115V

230V

115V

10

230V

1

2

7

6

4

5

9

TX200

L866TX

16

TX_16

17

18

TX_18

11

13

15

AC_3

19

TX_19

R210

20

TX_20

NB: CABLE ASSEMBLY L920CA GOES BETWEEN

BRN BRN AND BLU BLU FROM MAINS SWITCH TO BACK OF PCB

FILA

FILB

Y200

TX WIRE CLIP

TX FIXING SCREWS

Y201

SCREW HF4V09B

Y203

SCREW HF4V09B

Y202

SCREW HF4V09B

Y204

SCREW HF4V09B

AC1

AC2

D209

1N4148

D210

1N4148

R213

10R FU

R200

1R0 FU

R201

1R0 FU

AC1

C206

100N CD

AC2

C207

100N CD 100V

R211

10R FU

1R0 FU

R212

1R0 FU

C230

100U EL

100N CD 100V

+

C204

100N CD

C205

100N CD

C208

R224

10K MF

SK201

MOLEXPWR4

(FOR AUX TOROID)

1

3

+11V(U)

BR200

DF01M +

D213

1N4003

R227

100R MF

R228

100R MF

R222

470K MF

C221

+

100U EL

0V_3

+

C231

10U EL

2

4

C210

3M3 EL

+

C225

100U EL 100V

R223

10K MF

R225

2K2 MF

NF

IC200

LM1086-ADJ

I

Vin

I

Vin

IC204

TR200

BC549B

D200

1N4148

HS201

TO220HS30REG

O

Vout

ADJ

R203

330R MF

A

+

C218

100U EL

+

C226

100U EL 100V

A

ADJ

LM337T

Vout

R214

1K6 MF

R215

22K MF

R216

1K0 MF

O

D205

1N4148

Relay control for AC detect

R226

10K MF

R229

1K5 MF

TR201

BC549B

TR202

BC549B TR203

TR204

BC557B

R230

10K MF

D201

1N4148

-30VF

+

+7V

+

C227

100U EL 100V

Filiament supply

BC549B

Motor drive supply

C228

1M0 10V

D215

1N4148

R217

33K MF

D214

5V1 400MW

+12V(A)

-12V(A)

+5V(A)

+5V(D)

RLYPWR

+11V(U)

BR201

DF01M

0V_2

PL200

2WVERTJUMPER

1

2

R204

NF

10R MF

R205

NF

10R MF

1

2

PL201

2WVERTJUMPER

SK203

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

FFC23V

Power connector for 9DAC PCB

0V_9DAC

JP200

JUMPER

JP201

JUMPER

+

C211

1M0 35V

+

C212

1M0 35V

Analogue op-amp supplies

IC201

I

Vin

C213

NF

100N PE

C214

NF

100N PE

I

Vin

+11V(U)

IC202

I

Vin

HS

C209

100N CD

IC203

I

Vin

C215

100N PE

NF

LM317T

A

A

LM337T

D206

1N4148

LM317T

A

D211

1N4148

LM317T

A

ADJ

+

C216

100U EL

+

C217

100U EL

IC205

ADJ

ADJ

+

C219

100U EL

ADJ

+

C222

100U EL

D202

1N4148

Vout

NF

Vout

D207

1N4148

Vout

Vout

NF

O

NF

NF

O

NF

O

O

PL202

2WVERTJUMPER

2

JP202

JUMPER

R206

NF

220R MF

R208

NF

1K8 MF

R209

NF

1K8 MF

R207

NF

220R MF

JP204

JUMPER

1

2

PL204

2WVERTJUMPER

HS200

TO220HS08REG

R218

270R MF

R220

820R MF

HS202

TO220HS30REG

R219

270R MF

R221

820R MF

D203

1N4148

D204

1N4148

D208

1N4148

D212

1N4148

2

JP203

JUMPER

NF

NF

JP205

JUMPER

1

+12V(A)

PL203

2WVERTJUMPER

1

NF

+

+

NF

2

2WVERTJUMPER

PL205

-12V(A)

+5V(D)

+

0V_2

+5V(A)

+

0V_1

NF

C223

1M0 25V

0V_1

C224

1M0 25V

NF

Digital +5V

C220

100U EL

DAC supply

C229

1M0 10V

AFFIX TO TX BETWEEN ANALOGUE CIRCUITRY & TX

MC200

E922MC

E922MC

MC201

E923MC

E923MC

0V_3

DRAWING TITLE

CD92T - POWER SUPPLIES

23425

A & R Cambridge Ltd.

Pembroke Avenue

Denny Industrial Centre

Waterbeach

Cambridge CB5 9PB

Notes:

Filename

J:\Change Control\ECO AGENDA\01 E007 Display Cradle see tgp\L934 4.1.DDB - Documents L934C2 4.1.sch

0V_3

Circuit Diagram

01_E007 4.1WAF/TGP 13/12/01 DISPLAY CRADLE CHANGED TO NSULATED ASSY

UPDATE FOR EMC AND W LSONS REQUESTS01_1147 4.0WAF 24/10/01 & UPDATE PCB TO AIWA STD

01_1123

ECO No. DESCRIPTION OF CHANGE

Date Printed

TGP Up-Issue for PCB 2.1

CW

INITIALS

DATE

Drawn by:

JR14-Dec-2001

L920CA ADDED TO SCM 10

2 7Sheet of

DRAWING NO.

ISSUE

L934CT

Page 18

87654321

Data connector to DAC PCB

SK301

FFC32V

+5V(D)

+5V(D)

0V_DIG

R301

330R MF

R300

330R MF

R302

330R MF

NF

R304

330R MF

R305

330R MF

NF

R306

330R MF

RA0

AMUTE

DEEM

RMIN

XRST

RESET

BCLK

ADATA

LRCK

R311

100K MF

+5V(D)

R313

100K MF

14

D

DIGOP

C

B

C300

100N CD

0V_DIG

Flex connector from CDM14BL-5BD25 mech

+5V(D)

0V_DIG

+7V

0V_DIG

IREYE

IC300G

74HCU04 NF

7

SK300

FFC23V

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R314

10K MF

CLK

XRST

DATA

LDON

SENS

XLT

SUBQ

SQCK

AMUTE

BCLK

SCOR

ADATA

LRCK

LPH

0V_DIG

R307

10K MF

RC5 IP

C301

100N CD

BCLK

ADATA

LRCK

PL300

3WVERTJUMPER

1

2

JP300

3

JUMPER

(Master clock select jumper)

R308

10K MF

TR300

BC549B

R310

10K MF

IC300A

1 2

74HCU04

IC300C

5 6

74HCU04

IC300E

74HCU04

17MHZ

+5V(D)

1011

(From crystal oscillator)

(From 9 DAC PCB)

R309

10K MF

TR301

BC549B

3 4

IC300B

74HCU04

IC300D

74HCU04

IC300F

74HCU04

C304

100P CD

89

1213

D300

1N4148

30

31

32

27

28

29

IC302

PIC16C54XT

17

RA0

18

RA1

1

RA2

2

RA3

3

RTCC

4

MCLR

16

25

26

OSC1

X300

CST400

0V_DIG

20

21

22

23

24

XRST

AMUTE

VSS

OSC2

5

15

19

RB0

RB1

RB2

RB3

RB4

RB5

RB6

RB7

18

14

16

17

DEEM

6

7

8

9

10

11

12

13

VDD

C302

100N CD

15

RA0

13

14

RB6

+5V(D)

+

11

12

RB5

RB4

RB0

RB4

RB5

RB6

C305

100U EL

10

RB0

123456789

0V_9DAC

HDCD

Flexfoil connector to Display PCB

SK302

FFC32V

+5V(D)

Motor Drive

IC303

LB1641

O/P 'Out'

Vcc

Vcc

LoadOut

LoadIn

Bias

O/P 'In'

GND

32

31

0V_DIG

FILA

10

9

8

7

6

5

4

3

2

1

28

29

30

SCOR

LDOUT

LDIN

D301

4V7 400MW

27

25

26

RMIN

LDOUT

C303

100N CD

24

LDIN

22

23

SENS

+7V

0V_MOT

21

XLT

+

19

20

AMUTE

C306

100U EL

HDCD

DEEM

LPH

R303

6K8 MF

LOADSW

R312

6K8 MF

123456789

IREYE

FILB

R315

10K MF

0V_DIG

SK303

8K2005

1

2

3

4

5

EMPHASIS

LOADOUT

LOADIN

GND

INSW

OUTSW

D

C

B

10

11

12

13

14

15

16

17

18

CLK

LDON

DATA

SQCK

SUBQ

LOADSW

XRST

-30VF

+5V(D)

C307

10N CD

C308

100N CD

0V_MOT

0V_DIG

A

A & R Cambridge Ltd.

Pembroke Avenue

Denny Industrial Centre

Waterbeach

Cambridge CB5 9PB

Filename

1 2 3 4 5 6 7 8

J:\Change Control\ECO AGENDA\01 E007 Display Cradle see tgp\L934 4.1.DDB - Documents\L934C3 4.1.sch

23425

DRAWING TITLE

CD92T - MECH CONNECTS, MOTOR DRIVE AND IR MICRO

Circuit Diagram

Notes:

01_E007 4.1WAF/TGP 13/12/01

TGP Up-Issue for PCB 2.101_1123

CW 10Initial Release

ECO No. DESCRIPTION OF CHANGE

INITIALS

DATE

Date Printed

DISPLAY CRADLE CHANGED TO NSULATED ASSY

UPDATE FOR EMC AND W LSONS REQUESTS01_1147 40WAF 24/10/01 & UPDATE PCB TO AIWA STD

Drawn by:

JR14-Dec-2001

3 7Sheet of

DRAWING NO.

ISSUE

L934CT

A

Page 19

87654321

NF

+12V(A)

84

-12V(A)

IC402C

TL072

NF

R413

4K7 MF

NF

0V_SIG

R410

6K8 MF

R415

2K7 MF

C416

560P PP

NF

NF

NF

C418

220P PP

2

3

IC400A

NJM2114

NF

NF

1

R416

2K7 MF

NF

C422

1N3 PP

NF

R435

680R MF

NF

R419

3K9 MF

R403

1K8 MF

C445

100N PE

NF

NF

NF

-12V(A)

R414

4K7 MF

NF

0V_SIG

R411

6K8 MF

R417

2K7 MF

C417

560P PP

NF

NF

NF

C419

2

3

NF

220P PP

IC401A

NJM2114

NF

1

R418

2K7 MF

C423

1N3 PP

NF

R436

680R MF

NF

R420

3K9 MF

R404

1K8 MF

C450

100N PE

NF

NF

NFNF

-12V(A)

1011

IC404F

74HCU04

1213

0V_SIG

0V_SIG

Output filter

R442

2K2 MF

NF

Output filter

R443

2K2 MF

NF

C420

220P PP

6

5

IC400B

NJM2114

R437

100K MF

NF

C421

220P PP

6

5

IC401B

NJM2114

R438

100K MF

NF

NF

NF

NF

NF

1

IC402A

TL072

7

IC402B

TL072

NF

7

C424

470N PE

NF

7

C425

470N PE

R433

1K0 MF

R421

1M0 MF

NF

R434

1K0 MF

NF

NF

2

3

NF

R422

1M0 MF

NFNF

6

5

-12V(A)

-12V(A)

LK400

NF

LINK10PAD

C448

+

10u CERA

NF

LK401

LINK10PAD

C449

+

10u CERA

NF

2WVERTJUMPER

0V_SIG

NF

0V_SIG

R405

120R MF

R423

22K MF

R406

120R MF

R424

22K MF

NF

JP402

JUMPER

PL402

NF

NF

EMC1

NF

NF

NF

EMC Shield

SH400

EMCPHONO

RLY400A

DPDT

NF

0V_SIG

SK400

PHONO2HG

EMC

C434

100N CD

RLY400B

DPDT

NF

0V_SIG

RLYPWR

1

2

RLY400C

DPDT

NF NF

0V_3

0V_SIG

0V_SIG

D401

1N4148

EMC1

0V_SIG

NF

1

0V_SIG

C426

3N3 PP

NF

C451

1NF NPO

1NF NPO

0V_SIG

C427

3N3 PP

NF

D

0V_SIG

C452

C

RESET

B

JP401

NF

JUMPER

PL401

NF

+5V(A)

D

LRCK

2WVERTJUMPER

1

2

(DAC enable jumper)

ADATA

BCLK

+5V(DAC)

L401

7F003

C401

100N PE

C408

100N PE

NF

NF

C433

10U SILMIC

0V_SIG

+

C429

10U SILMIC

NF

NF

+

C411

100N PE

NF NF

C428

10U SILMIC

NF

0V_DIG

C

+5V(DAC)

NF

+5V(DAC)

DACLK

+

0V_SIG

0V_DIG

100N PE

C415

100N PE

C435

NF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

R402

4K7 MF

NF

LRCIN

DIN

BCKIN

CLKO

XTI

XTO

DGND

Vdd

Vcc2R

AGND2R

EXT1R

NC

VOUTR

AGND1

C402

100N PE

C403

100N PE

IC403

PCM1716#

NF

NF

NF

ML/IIS

MC/DM1

MD/DM0

MUTE

MODE

CS/IWO

RST

ZERO

Vcc2L

AGND2L

EXTL

NC

VOUTL

Vcc

84

28

27

26

25

24

23

22

21

20

19

18

17

16

15

IC400C

NJM2114

NF

R412

4K7 MF

NF

+5V(DAC)

0V DIG

C442

100N PE

C443

100N PE

C409

100N PE

C406

100N PE

NF

C407

100N PE

NF

DEEM

R431

10K MF

+5V(DAC)

NF

0V_SIG

NF

0V_SIG

0V_SIG

NF

+

C430

10U SILMIC

NF

+

C432

10U SILMIC

NF

+

C431

10U SILMIC

NFNF

84

IC401C

NJM2114

NF

0V_SIG

D402

1N4148

L404

7F003

NF

+5V(DAC)

NF

100N PE

C404

100N PE

NF

C405

100N PE

NF

C444

0V_SIG

L400

7F003

14

C400

100N CD

IC404G

74HCU04

C414

100N CD

7

+5V(D)

NF

1

2

PL400

NF

2WVERTJUMPER

(Oscillator enable jumper)

L402

NF

JP400

JUMPER

B

D400

1N4148

+5V(D)

+

R409

10K MF

0V_DIG

C410

100U EL

R432

10K MF

R439

1M0 MF

IC404E

74HCU04

7F003

+C436

NF

C413

NF

100N CD

A

1 2 3 4 5 6 7 8

22U EL OS

0V_DIG

C437

NF

10N CD

X400

NF

16.9344MHZ

C441

33P CD

NF

R427

33K MF

R426

33K MF

NF

NF

TR402

BC547B

C438

100P CD

C439

100P CD

NF

NF

LINK05NP

R430

LINK10NP

L403

LINK10NP

CD92T - DAC, OSCILLATOR AND ANALOGUE OUTPUTS

A & R Cambridge Ltd.

Pembroke Avenue

Denny Industrial Centre

Waterbeach

Cambridge CB5 9PB

C412

NF

10N CD

0V_DIG

R428

C440

LINK10NP

DRAWING TITLE

23425

R429

NF NF NF

4M7 MF

1 2

IC404A

74HCU04 5 6

R400

LINK10NP

R425

1M0 MF

3 4

IC404B

74HCU04

R401

LINK10NP

R407

89

120R MF

IC404D

74HCU04

R408

120R MF

IC404C

74HCU04

01_E007 4.1WAF/TGP 13/12/01 DISPLAY CRADLE CHANGED TO NSULATED ASSY

Circuit Diagram

Notes:

Filename

J:\Change Control\ECO AGENDA\01 E007 Display Cradle see tgp\L934 4.1.DDB - Documents L934C4 4.1.sch

01_1123

ECO No. DESCRIPTION OF CHANGE

Date Printed

TGP

CW

INITIALS

NF

0V_DIG

0V_DIG

DATE

DACLK

(Master clock to DAC)

C446

NF

10P CD

17MHZ

C447

10P CD

UPDATE FOR EMC AND W LSONS REQUESTS01_1147 40WAF 24/10/01 & UPDATE PCB TO AIWA STD

NF

Drawn by:

JR14-Dec-2001

(Master clock to mech)

Up-Issue for PCB

Initial Release

4 7Sheet of

DRAWING NO.

A

2.1

10

ISSUE

L934CT

Page 20

87654321

OPTICAL OUTPUT

1

I/P

+5V(D)

84

2

3

100N CD

R515

10K MF

VCC

GND

C505

C511

IC501C

LM393A

C501

10N CD

SK501

PHONO1

EMC

C500

100N CD

0V_DIG

+ C506

22U EL OS

COAXIAL OUTPUT

C504

10N CD

LK500

LINK10NP

D

C

B

CARRIER FILTER AND DEMODULATOR

R508

C508

680P PP

5

6

10K MF

1213

1011

89

R502

1K8 MF

R514

1K5 MF

R503

1K8 MF

R505

120R MF

R506

1K2 MF

R516

1K2 MF

R517

1K2 MF

R518

1K2 MF

2

3

IC501A

LM393A

C507

100N CD

R510

10K MF

R519

100R MF

D

SK500

JACK3.5

C

B

C509

100N CD

EMC1

0V_DIG_EMC

R511

470R MF

C513

100P CD

L501

7F003

R504

1K0 MF

0V_DIG

+5V(D)

R500

10R MF

0V_DIG

R512

100K MF

D500

4V7 400MW

RC5RP

C502

470N PE

DIGOP

IC500G

7

74HCU04

R507

10K MF

14

1 2

IC500A

74HCU04

L500

27mH

7

IC501B

LM393A

C510

100P CD

IC500F

74HCU04

IC500E

74HCU04

IC500D

74HCU04

5 6

IC500C

74HCU04

3 4

IC500B

74HCU04

1

+5V(D)

C512

470P CD

R509

10K MF

R513

100K MF

R501

10R MF

C503

1N0 CD

GP1FA550TZ

IC502

0V_DIG

A

A & R Cambridge Ltd.

Pembroke Avenue

Denny Industrial Centre

Waterbeach

Cambridge CB5 9PB

Filename

1 2 3 4 5 6 7 8

J:\Change Control\ECO AGENDA\01 E007 Display Cradle see tgp\L934 4.1.DDB - Documents\L934C5 4.1.sch

23425

DRAWING TITLE

CD92T - REAR PANEL RC5 & DIGITAL OUTPUT

Circuit Diagram

Notes:

100N CD

01_E007 4.1WAF/TGP 13/12/01

TGP

CW 10

ECO No. DESCRIPTION OF CHANGE

INITIALS

DATE

Date Printed

DISPLAY CRADLE CHANGED TO NSULATED ASSY

UPDATE FOR EMC AND W LSONS REQUESTS01_1147 40WAF 24/10/01 & UPDATE PCB TO AIWA STD

Up-Issue for PCB 2.101_1123

Initial Release

Drawn by:

JR14-Dec-2001

5 7Sheet of

DRAWING NO.

A

ISSUE

L934CT

Page 21

87654321

D

POWER SUPPLIES

L934C2_4

L934C2_4.1sch

FILA

FILB

DISPLAY PCB

C

L934C1_4

L934C1_4.1sch

MECH INTERCONNECTS DAC AND OSCILLATOR

L934C3_4

L934C3_4.1sch

FILA

FILB

17MHZ

RESET

RC5 INPUT AND DIG OUTPUTS

L934C5_4

L934C5_4.1sch

DIGOP RC5RP

BCLK

ADATA

LRCKRC5 IP

DIGOP

EMPHASIS

L934C4_4

L934C4_4.1sch

DEEM

LRCK

ADATA

BCLK

RESET

17MHZ

0V_DIG

0V_MOT

DISPLAY AND MICROCONTROLLER

L934C7_4

L934C7_4.1sch

0V_SIG

0V_1

0V_30V_9DAC

0V_2

SP100

STARPOINT

LK600

0R0 MF

LK601

0R0 MF

0V_DIG 0V_9DAC

D

C

FIX152

FIXING HOLE 35

B

(EARTH BY IEC SOCKET)

FIX157

FIXING HOLE 32

C150

1N0 CD

NF

0V_DIG 0V_DIG 0V_DIG 0V_DIG 0V_DIG 0V_DIG 0V_DIG

FIX151

FIXING HOLE 3.2

C151

1N0 CD

FIX153

FIXING HOLE 3.5

C152

1N0 CD

FIX154

FIXING HOLE 3.5

C153

1N0 CD

FIX155

FIXING HOLE 35

C154

1N0 CD

FIX156

FIXING HOLE 35

C155

1N0 CD

FIX150

FIXING HOLE 3.5

C156

1N0 CD

B

NB:- THIS SCHEMATIC MUST ONLY BE MODIFIED AS A SUB CIRCUIT OF L899CT (CD72T)

USE EXCLUDE NF WHEN CREATING THE BOM

A

1 2 3 4 5 6 7 8

DRAWING TITLE

CD92T - TOP LEVEL SCHEMATIC

23425

A & R Cambridge Ltd.

Pembroke Avenue

Denny Industrial Centre

Waterbeach

Cambridge CB5 9PB

Notes:

Filename

J:\Change Control\ECO AGENDA\01 E007 Display Cradle see tgp\L934 4.1.DDB - Documents L934C6 4.1.PRJ

Circuit Diagram

01_E007 4.1WAF/TGP 13/12/01 DISPLAY CRADLE CHANGED TO NSULATED ASSY

UPDATE FOR EMC AND W LSONS REQUESTS01_1147 40WAF 24/10/01 & UPDATE PCB TO AIWA STD

TGP 2.1

CW 10

ECO No. DESCRIPTION OF CHANGE

Date Printed

INITIALS

DATE

Drawn by:

JR14-Dec-2001

Up-Issue for PCB01_1123

Initial Release

6 7Sheet of

DRAWING NO.

ISSUE

L934CT

A

Page 22

87654321

D

C

LK701

LINK10NP

LK707

LINK10NP

LK709

LINK10NP

LK710

LINK10NP

LK712

LINK10NP

LK713

LINK10NP

LK715

LINK10NP

LK718

LINK10NP

LK719

LINK10NP

LK720

LINK10NP

LK721

LINK10NP

LK722

LINK10NP

LK723

LINK10NP

LK724

LINK10NP

LK725

LINK10NP

LK726

LINK10NP

LK728

LINK10NP

LK729

LINK10NP

LK730

LINK10NP

LK731

LINK10NP

LK732

LINK10NP

LK733

LINK10NP

LK734

LINK10NP

LK735

LINK10NP

LK736

LINK10NP

LK737

LINK10NP

LK738

LINK10NP

LK739

LINK10NP

LK740

LINK10NP

LK741

LINK10NP

LK742

LINK10NP

LK743

LINK10NP

LK744

LINK10NP

LK745

LINK10NP

LK746

LINK10NP

LK747

LINK10NP

LK748

LINK10NP

LK749

LINK10NP

LK751

LINK10NP

LK752

LINK10NP

LK753

LINK10NP

LK754

LINK10NP

LK755

LINK10NP

LK756

LINK10NP

LK757

LINK10NP

LK758

LINK10NP

LK759

LINK10NP

LK760

LINK10NP

LK761

LINK10NP

LK762

LINK10NP

LK763

LINK10NP

LK764

LINK10NP

LK765

LINK10NP

LK766

LINK10NP

LK767

LINK10NP

LK770

LINK10NP

LK772

LINK10NP

LK773

LINK10NP

LK774

LINK10NP

LK775

LINK10NP

LK776

LINK10NP

LK777

LINK10NP

LK778

LINK10NP

LK779

LINK10NP

LK780

LINK10NP

LK781

LINK10NP

LK782

LINK10NP

LK783

LINK10NP

LK784

LINK10NP

LK785

LINK10NP

LK786

LINK10NP

LK787

LINK10NP

LK788

LINK10NP

LK789

LINK10NP

LK790

LINK10NP

LK791

LINK10NP

LK792

LINK10NP

LK793

LINK10NP

LK794

LINK10NP

LK795

LINK10NP

LK796

LINK10NP

LK797

LINK10NP

LK798

LINK10NP

LK799

LINK10NP

LK800

LINK10NP

LK801

LINK10NP

LK802

LINK10NP

LK803

LINK10NP

LK804

LINK10NP

LK805

LINK10NP

LK806

LINK10NP

LK807

LINK10NP

LK808

LINK10NP

LK809

LINK10NP

LK811

LINK10NP

LK812

LINK10NP

LK813

LINK10NP

LK814

LINK10NP

LK815

LINK10NP

LK816

LINK10NP

LK817

LINK10NP

LK818

LINK10NP

LK819

LINK10NP

D

C

LK100

LINK10NP

LK101

LINK10NP

B

A

1 2 3 4 5 6 7 8

LK102

LINK10NP

LK103

LINK10NP

LK104

LINK10NP

LK105

LINK10NP

EL1

Update Box

UPDATE_BOX

LK106

LINK10NP

LK107

LINK10NP

LK108

LINK10NP

PB

L899PB

LK109

LINK10NP

LK110

LINK10NP

LK111

LINK10NP

PCB

LK112

LINK10NP

LK113

LINK10NP

LK114

LINK10NP

LK115

LINK10NP

LK116

LINK10NP

LK117

LINK10NP

IC302SW

S/W

L825SW

LK118

LINK10NP

LK119

LINK10NP

LK120

LINK10NP

LK121

LINK10NP

LK122

LINK10NP

LK123

LINK10NP

LK124

LINK10NP

LK125

LINK10NP

LK126

LINK10NP

LK127

LINK10NP

LK128

LINK10NP

LK129

LINK10NP

LK130

LINK10NP

LK131

LINK10NP

LK132

LINK10NP

LK133

LINK10NP

LK134

LINK10NP

LK135

LINK10NP

LK136

LINK10NP

DRAWING TITLE

CD92T - LINKS AND MECH PARTS

A & R Cambridge Ltd.

Pembroke Avenue

Denny Industrial Centre

Waterbeach

Cambridge CB5 9PB

Filename

J:\Change Control\ECO AGENDA\01 E007 Display Cradle see tgp\L934 4.1.DDB - Documents\L934C7 4.1.sch

23425

Notes:

Circuit Diagram

01_E007 4.1WAF/TGP 13/12/01

01_1123 TGP

ECO No. DESCRIPTION OF CHANGE

INITIALS

DATE

Date Printed

DISPLAY CRADLE CHANGED TO NSULATED ASSY

UPDATE FOR EMC AND W LSONS REQUESTS01_1147 40WAF 24/10/01 & UPDATE PCB TO AIWA STD

Up-Issue for PCB 2.1

Ini ial Release

Drawn by:

JR14-Dec-2001

7 7Sheet of

DRAWING NO.

B

A

10CW

ISSUE

L934CT

Page 23

DAC

Board

L949

Contents

!

Component overlay

!

Parts list

!

Circuit diagrams

Page 24

Page 25

L949 CD82 DAC Board Parts List Issue 3.05

Designator Part Description

C100 2N747 Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 470UF 25V

C101 2N747 Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 470UF 25V

C102 2N710 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 100UF 25V

C103 2N710 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 100UF 25V

C104 2N710 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 100UF 25V

C105 2N747 Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 470UF 25V

C106 2P710ZA Capacitor Radial Electrolytic Rubycon ZA Series 100UF 25V

C107 2N747 Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 470UF 25V

C108 2J310 Capacitor SM 0805 X7R Ceramic 10% 50V 10N

C109 2J310 Capacitor SM 0805 X7R Ceramic 10% 50V 10N

C110 2J310 Capacitor SM 0805 X7R Ceramic 10% 50V 10N

C111 2J310 Capacitor SM 0805 X7R Ceramic 10% 50V 10N

C112 2J310 Capacitor SM 0805 X7R Ceramic 10% 50V 10N

C113 2J310 Capacitor SM 0805 X7R Ceramic 10% 50V 10N

C114 2J310 Capacitor SM 0805 X7R Ceramic 10% 50V 10N

C117 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C118 2L033 Capacitor SM 0805 NPO Ceramic 5% 100V 33P

C119 2L033 Capacitor SM 0805 NPO Ceramic 5% 100V 33P

C120 2L033 Capacitor SM 0805 NPO Ceramic 5% 100V 33P

C121 2L033 Capacitor SM 0805 NPO Ceramic 5% 100V 33P

C122 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C123 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C124 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C125 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C126 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C127 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C128 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C129 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C200 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C201 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C202 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C203 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C204 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C205 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C206 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C207 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C208 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C209 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C210 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C211 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C212 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C213 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C214 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C215 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C216 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C217 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C218 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C219 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C220 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C221 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C222 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C223 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C224 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C225 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C226 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C227 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C228 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C229 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C230 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C231 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C232 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C233 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C234 2L047 Capacitor SM 0805 NPO Ceramic 5% 100V 47P

Page 26

L949 CD82 DAC Board Parts List Issue 3.05

Designator Part Description

C235 2L110 Capacitor SM 0805 NPO Ceramic 5% 100V 100P

C236 2L110 Capacitor SM 0805 NPO Ceramic 5% 100V 100P

C237 2J210 Capacitor SM 0805 X7R Ceramic 10% 50V 1N

C238 2L010 Capacitor SM 0805 NPO Ceramic 5% 100V 10P

C300 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C301 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C302 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C303 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C304 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C305 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C306 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C307 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C308 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C309 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C310 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C311 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C312 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C313 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C314 2L147 Capacitor SM 0805 NPO Ceramic 5% 100V 470P

C315 2L147 Capacitor SM 0805 NPO Ceramic 5% 100V 470P

C316 2L147 Capacitor SM 0805 NPO Ceramic 5% 100V 470P

C317 2D110N Capacitor Boxed Polyprop 5mm Pitch 63V 5% 100P

C318 2D110N Capacitor Boxed Polyprop 5mm Pitch 63V 5% 100P

C319 2D110N Capacitor Boxed Polyprop 5mm Pitch 63V 5% 100P

C320 2D110N Capacitor Boxed Polyprop 5mm Pitch 63V 5% 100P

C321 2D110N Capacitor Boxed Polyprop 5mm Pitch 63V 5% 100P

C322 2D110N Capacitor Boxed Polyprop 5mm Pitch 63V 5% 100P

C323 2D210 Capacitor Boxed Polyprop 5mm Pitch 63V 5% 1N0

C324 2D210 Capacitor Boxed Polyprop 5mm Pitch 63V 5% 1N0

C325 2D210 Capacitor Boxed Polyprop 5mm Pitch 63V 5% 1N0

C326 2D210 Capacitor Boxed Polyprop 5mm Pitch 63V 5% 1N0

C327 2D122 Capacitor Boxed Polyprop 5mm Pitch 63V 5% 220P

C328 2D122 Capacitor Boxed Polyprop 5mm Pitch 63V 5% 220P

C329 2K510 Capacitor Boxed Polyester 5mm Pitch 10% 63V 1U0

C330 2K510 Capacitor Boxed Polyester 5mm Pitch 10% 63V 1U0

C331 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C332 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C333 2P710ZA Capacitor Radial Electrolytic Rubycon ZA Series 100UF 25V

C334 2P710ZA Capacitor Radial Electrolytic Rubycon ZA Series 100UF 25V

C335 2L147 Capacitor SM 0805 NPO Ceramic 5% 100V 470P

C336 2P710ZA Capacitor Radial Electrolytic Rubycon ZA Series 100UF 25V

C337 2P710ZA Capacitor Radial Electrolytic Rubycon ZA Series 100UF 25V

D100 3A4148 Diode Small Signal 1N4148 DO-35 Package

D101 3A4148 Diode Small Signal 1N4148 DO-35 Package

D102 3A4148 Diode Small Signal 1N4148 DO-35 Package

D103 3A4148 Diode Small Signal 1N4148 DO-35 Package

D104 3A4148 Diode Small Signal 1N4148 DO-35 Package

D105 3A4148 Diode Small Signal 1N4148 DO-35 Package

D106 3A4148 Diode Small Signal 1N4148 DO-35 Package

IC100 5D317T IC VOLTAGE REGULATOR ADJ LM317T TO-220 PACKAGE

IC101 5D317T IC VOLTAGE REGULATOR ADJ LM317T TO-220 PACKAGE

IC102 5D337 IC VOLTAGE REGULATOR NEG ADJ LM337T TO-220 PACKAGE

IC200 5A8740 IC AUDIO DAC XWM8740EDS SSOP-28 PACKAGE

IC201 5A8740 IC AUDIO DAC XWM8740EDS SSOP-28 PACKAGE

IC202 5K7404 IC HEX INVERTER 74HCU04D SMT

IC300 5B103 IC Instrumentation Amp Burr Brown INA103KU SO-16W Package

IC301 5B103 IC Instrumentation Amp Burr Brown INA103KU SO-16W Package

IC302 5B2134 Opamp OPA2134UA SO-8 Package

IC303 5B2134 Opamp OPA2134UA SO-8 Package

IC304 5B2134 Opamp OPA2134UA SO-8 Package

L200 7F004 Ferrite Bead SM1206 70R@100MHz

L201 7F004 Ferrite Bead SM1206 70R@100MHz

L202 7F004 Ferrite Bead SM1206 70R@100MHz

Page 27

L949 CD82 DAC Board Parts List Issue 3.05

Designator Part Description

L203 7F004 Ferrite Bead SM1206 70R@100MHz

L204 7F004 Ferrite Bead SM1206 70R@100MHz

L205 7F004 Ferrite Bead SM1206 70R@100MHz

L206 7B033 Inductor Surface Mount 33U

L300 7F004 Ferrite Bead SM1206 70R@100MHz

R100 1M122 Resistor 0805 Surface Mount 0.125W 1% 220R

R101 1M122 Resistor 0805 Surface Mount 0.125W 1% 220R

R102 1M127 Resistor 0805 Surface Mount 0.125W 1% 270R

R103 1M218 Resistor 0805 Surface Mount 0.125W 1% 1K8

R104 1M218 Resistor 0805 Surface Mount 0.125W 1% 1K8

R105 1M182 Resistor 0805 Surface Mount 0.125W 1% 820R

R200 1M333 Resistor 0805 Surface Mount 0.125W 1% 33K

R201 1M333 Resistor 0805 Surface Mount 0.125W 1% 33K

R202 1M210 Resistor 0805 Surface Mount 0.125W 1% 1K0

R203 1M510 Resistor 0805 Surface Mount 0.125W 1% 1M0

R204 1M110 Resistor 0805 Surface Mount 0.125W 1% 100R

R205 1M110 Resistor 0805 Surface Mount 0.125W 1% 100R

R206 1M110 Resistor 0805 Surface Mount 0.125W 1% 100R

R207 1M110 Resistor 0805 Surface Mount 0.125W 1% 100R

R208 1M412 Resistor 0805 Surface Mount 0.125W 1% 120K

R209 1M410 Resistor 0805 Surface Mount 0.125W 1% 100K

R210 1M233 Resistor 0805 Surface Mount 0.125W 1% 3K3

R211 1M233 Resistor 0805 Surface Mount 0.125W 1% 3K3

R212 1M233 Resistor 0805 Surface Mount 0.125W 1% 3K3

R213 1M233 Resistor 0805 Surface Mount 0.125W 1% 3K3

R214 1M233 Resistor 0805 Surface Mount 0.125W 1% 3K3

R215 1M233 Resistor 0805 Surface Mount 0.125W 1% 3K3

R216 1M233 Resistor 0805 Surface Mount 0.125W 1% 3K3

R217 1M233 Resistor 0805 Surface Mount 0.125W 1% 3K3

R300 1M218 Resistor 0805 Surface Mount 0.125W 1% 1K8

R301 1M218 Resistor 0805 Surface Mount 0.125W 1% 1K8

R302 1M110 Resistor 0805 Surface Mount 0.125W 1% 100R

R303 1M110 Resistor 0805 Surface Mount 0.125W 1% 100R

R308 1M047 Resistor 0805 Surface Mount 0.125W 1% 47R

R309 1M047 Resistor 0805 Surface Mount 0.125W 1% 47R

R310 1M047 Resistor 0805 Surface Mount 0.125W 1% 47R

R311 1M047 Resistor 0805 Surface Mount 0.125W 1% 47R

R312 1M256 Resistor 0805 Surface Mount 0.125W 1% 5K6

R313 1M256 Resistor 0805 Surface Mount 0.125W 1% 5K6

R314 1M220 Resistor 0805 Surface Mount 0.125W 1% 2K0

R315 1M220 Resistor 0805 Surface Mount 0.125W 1% 2K0

R316 1M227 Resistor 0805 Surface Mount 0.125W 1% 2K7

R317 1M227 Resistor 0805 Surface Mount 0.125W 1% 2K7

R318 1M227 Resistor 0805 Surface Mount 0.125W 1% 2K7

R319 1M227 Resistor 0805 Surface Mount 0.125W 1% 2K7

R320 1M275 Resistor 0805 Surface Mount 0.125W 1% 7K5

R321 1M275 Resistor 0805 Surface Mount 0.125W 1% 7K5

R322 1M447 Resistor 0805 Surface Mount 0.125W 1% 470K

R323 1M447 Resistor 0805 Surface Mount 0.125W 1% 470K

R324 1M410 Resistor 0805 Surface Mount 0.125W 1% 100K

R325 1M410 Resistor 0805 Surface Mount 0.125W 1% 100K

RLY100 A215 Relay 2P2T 12V SM

SH300 E821MC SHIELD EMC PHONO SOCKET TIN PLATE

SK100 8K8032 CON 1.25MM VERTICAL FFC 32WAY

SK101 8K8023 CON 1.25MM VERTICAL FFC 23WAY

SK300 8D225 PHONO SKT 4-WAY GOLD

TR200 4D17H Transistor BFS17H SOT23 Package

X200 7X012 Crystal 16.9344MHz HC49

PCB L949PB BLANK PCB CD82 DAC

SCREW HA3V10A M SCREW TORX M3x10MM ST ZP

NUT HJ3A00A NUT M3 FULL STZP (1000)

WASHER HL3AB WASHER M3 PLAIN ST BLK

Page 28

TP100

ITEM100

C118

33P NPO 0805

C122

100N 0805

C125

100N 0805

C126

100N 0805

C119

33P NPO 0805

C123

100N 0805

C124

100N 0805

C127

100N 0805

C128

100N 0805

SK100

FFC32V

SK101

FFC23V

C129

100N 0805

DACs and oscillator

TP101

TP102

TP103

TP104

TP105

L949C2_2.0 0.sch

BCKIN

DIN

LRCIN

RESET*

DE EMPH

I

+

C100

470U EL 25V

+

C101

470U EL 25V

I

IC100

LM317T

Vin

Vin

IC102

LM337T

17MHZ OUT

LEFTPOS

LEFTNEG

RIGHTPOS

RIGHTNEG

D100

1N4148

ADJ

A

+

C102

100U EL

+

C104

100U EL

A

ADJ

D105

1N4148

Vout

Vout

O

R100

220R 0805

R103

1K8 0805

R104

1K8 0805

R101

220R 0805

C105

470U EL 25V

O

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

TP106

C120

33P NPO 0805

C121

33P NPO 0805

AGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

+-RLY100C

RLY DPDT SM A215

TP108

TP109

TP110

TP111

D104

1N4148

TP107

AGND

Output stage and phono sockets

L949C3_2.0.0.sch1

LEFTPOS

L949PB

ITEM101

LEFTNEG

HA3V10A

ITEM102

RIGHTPOS

RIGHTNEG

HA3V10A

ITEM103

HA3V10A

D102

1N4148

IC101

+12V +5V

D101

1N4148

TP112

+

+

C107

470U EL 25V

D106

1N4148

LM317T

I

Vin

C117

100N PE

ADJ

A

+

Vout

C103

100U EL

O

R102

270R 0805

R105

820R 0805

TP113

-12V

ITEM104

HJ3A00A

ITEM105

HJ3A00A

ITEM106

HJ3A00A