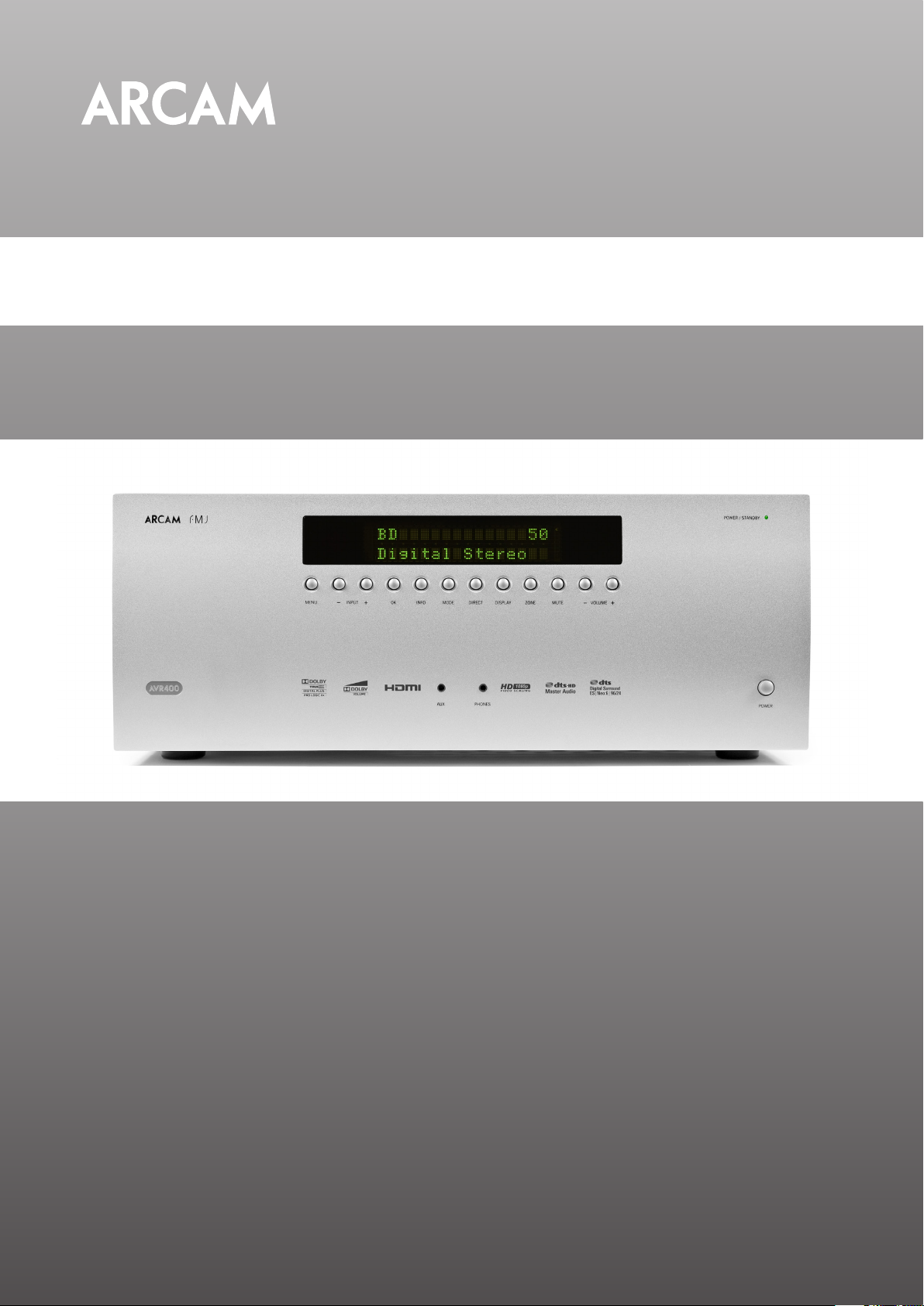

Page 1

AVR400 Service Manual Issue 1

Page 2

1

F

2

3

3

4

2

5

ECO NR.

--

--

--

--

--

6

DATE

--

--

--

--

-- --

CHG.

-- --

--

--

--

ZONE

--

--

--

--

7

DESCRIPTION OF CHANGE

--

--

--

--

--

8

DR.

CHK.

--

--

--

--

--

--

--

--

--

--

F

REL.

--

--

--

--

--

E

D

C

E

D

C

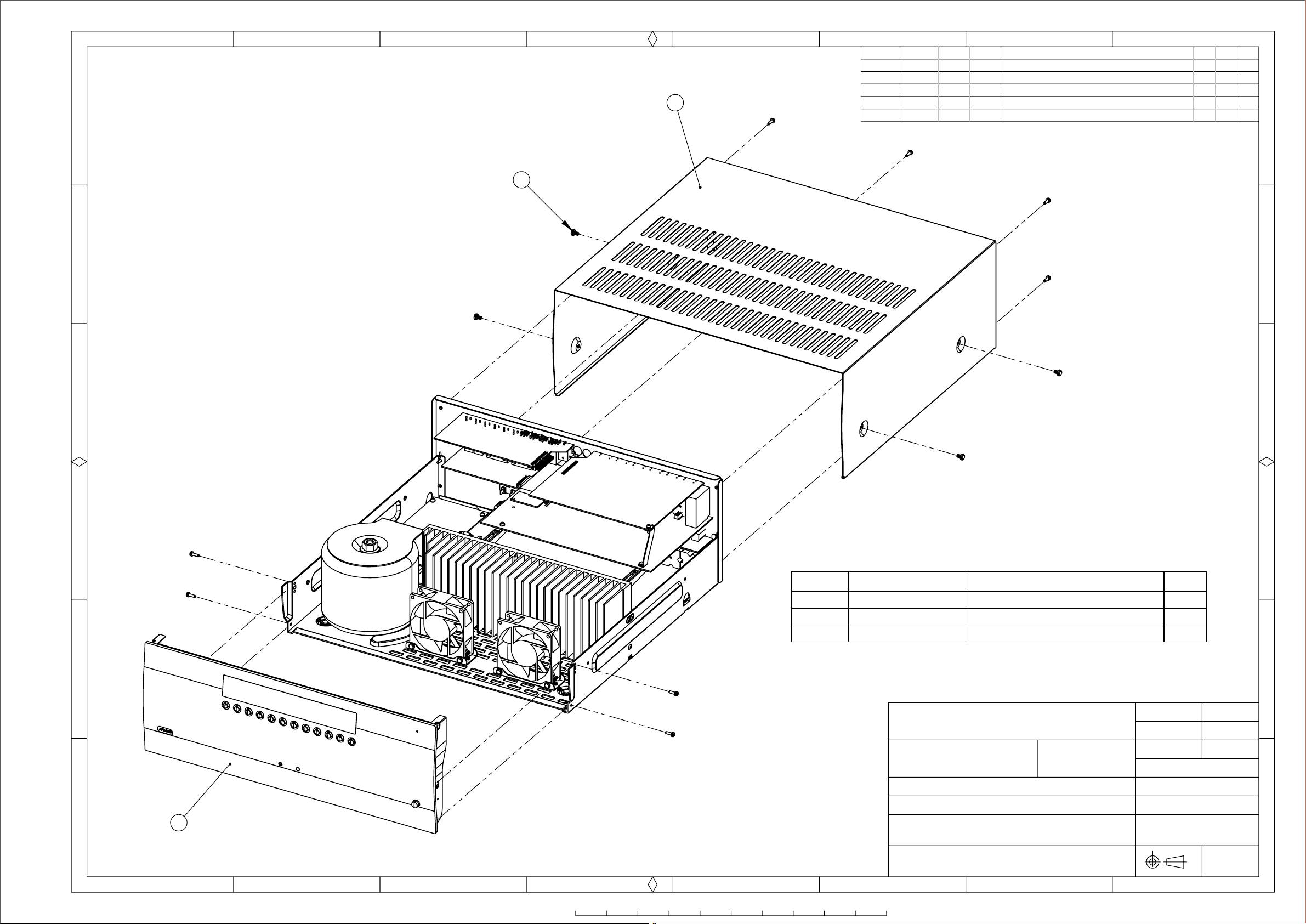

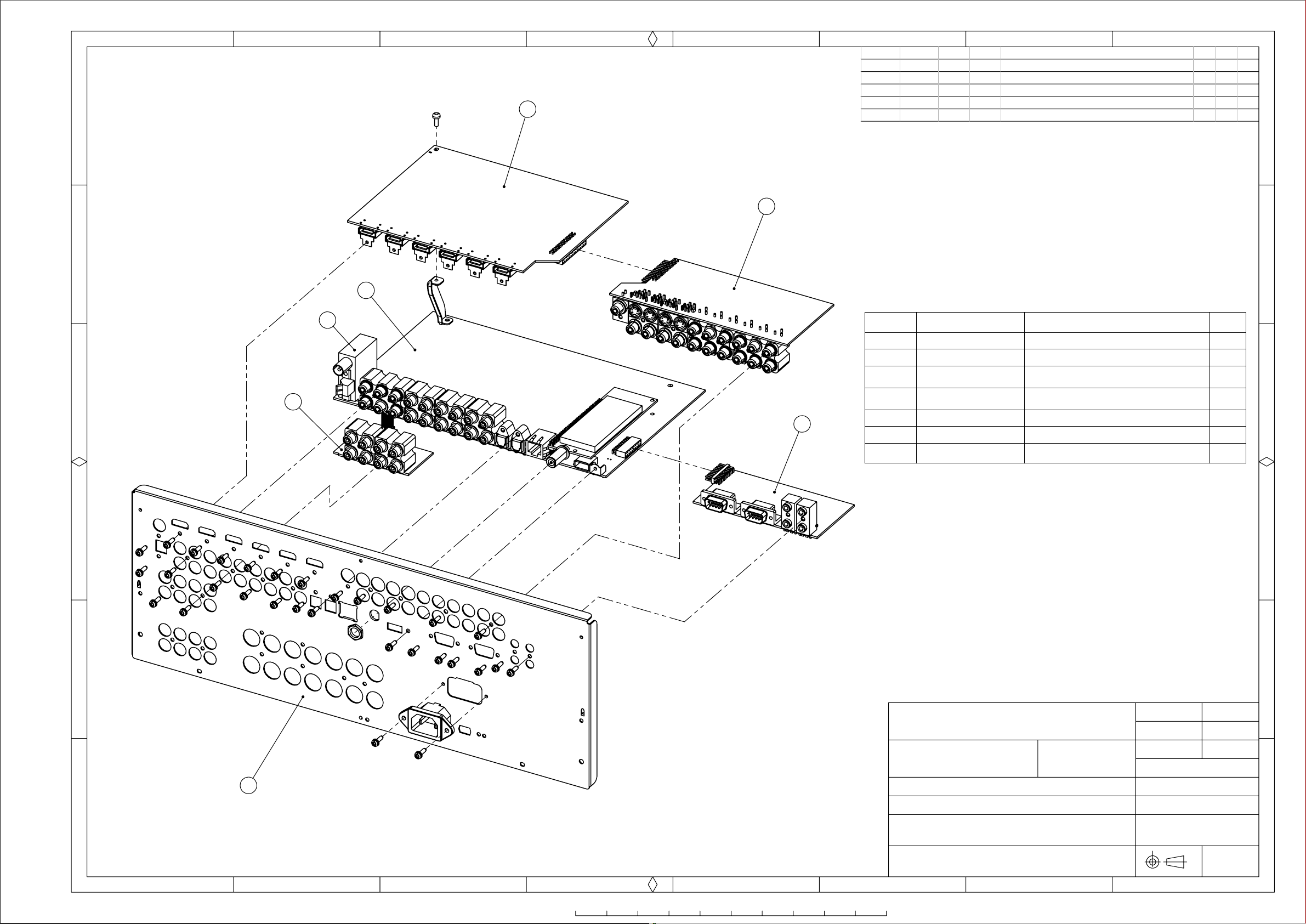

ITEM NO.

1

2

3

B

A

1

TGP3523 / TGP3524

TGP3526 / TGP3527

HA4V06S

PART No.

FASCIA ASSEMBLY BLACK / SILVER

COVER BLACK / SILVER

TORX SCREW M4 x 6

23425

TOLERANCES UNLESS 0.00±0.10

OTHERWISE STATED 0.0 ±0.20

ANGULAR TOL. +2 DEGREES

MATERIAL:

FINISH:

PART NUMBER AND DRAWING NUMBER

DESCRIPTION

A & R CAMBRIDGE LTD

ALL DIMENSIONS IN

MILLIMETERS UNLESS

OTHERWISE STATED

QTY

1

1

4

DRAWN BY:

DATE:

CHECKED BY:

ORIGINAL SCALE 1:4

SHT 1 OF 4

B

MCM

7-9-2010

MGB

A

AVR400 MAIN ASSEMBLY

DRAWING TITLE

COVER + FASCIA

1

2

3

4

5

6

7

8

A3

10

0

30

20

50

40

60

80

70

90

100

Page 3

1

F

2

3

4

5

ECO NR.

--

--

--

--

--

6

DATE

--

--

--

--

-- --

CHG.

-- --

--

--

--

ZONE

--

--

--

--

7

DESCRIPTION OF CHANGE

--

--

--

--

--

8

DR.

CHK.

--

--

--

--

--

--

--

--

--

--

F

REL.

--

--

--

--

--

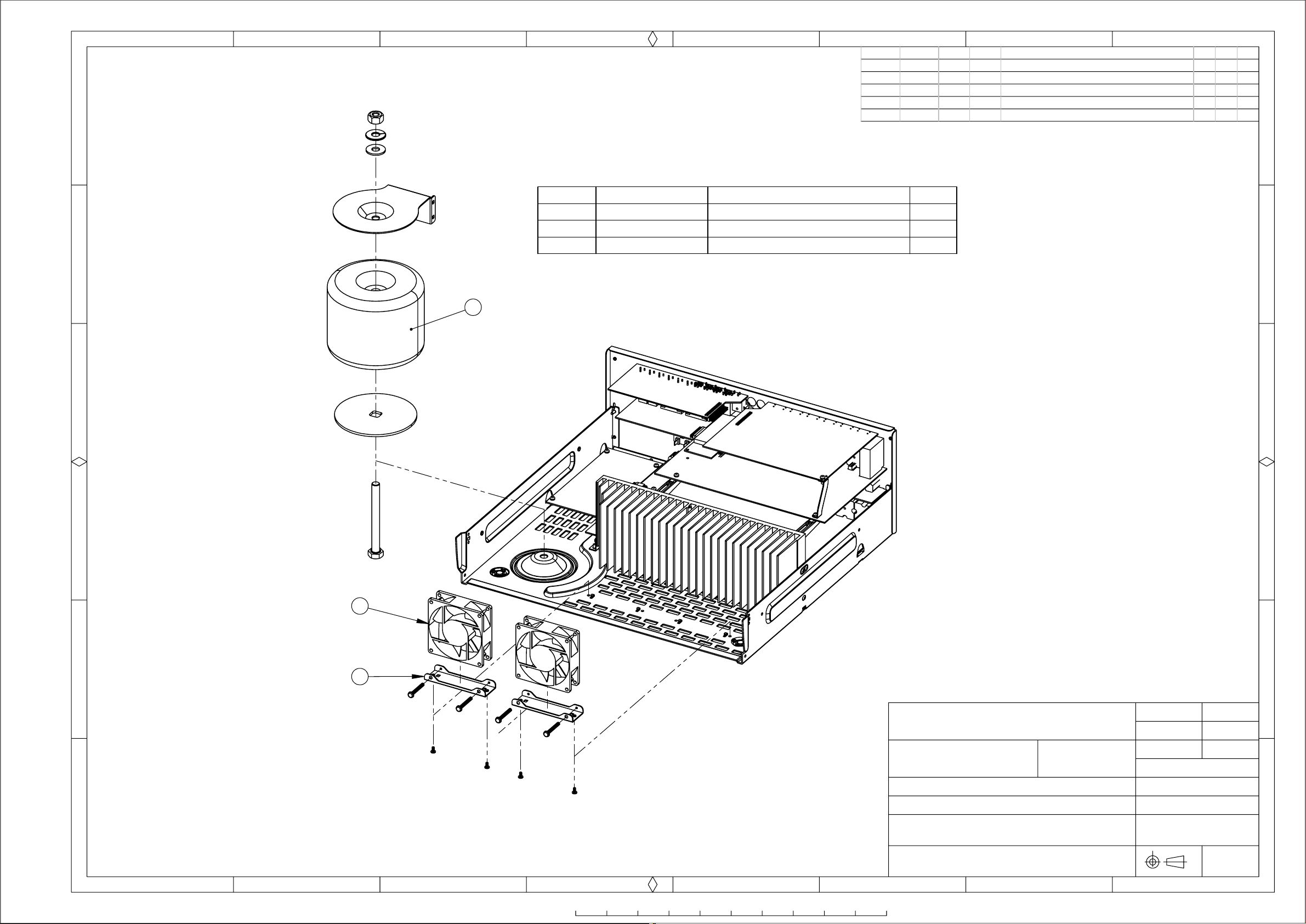

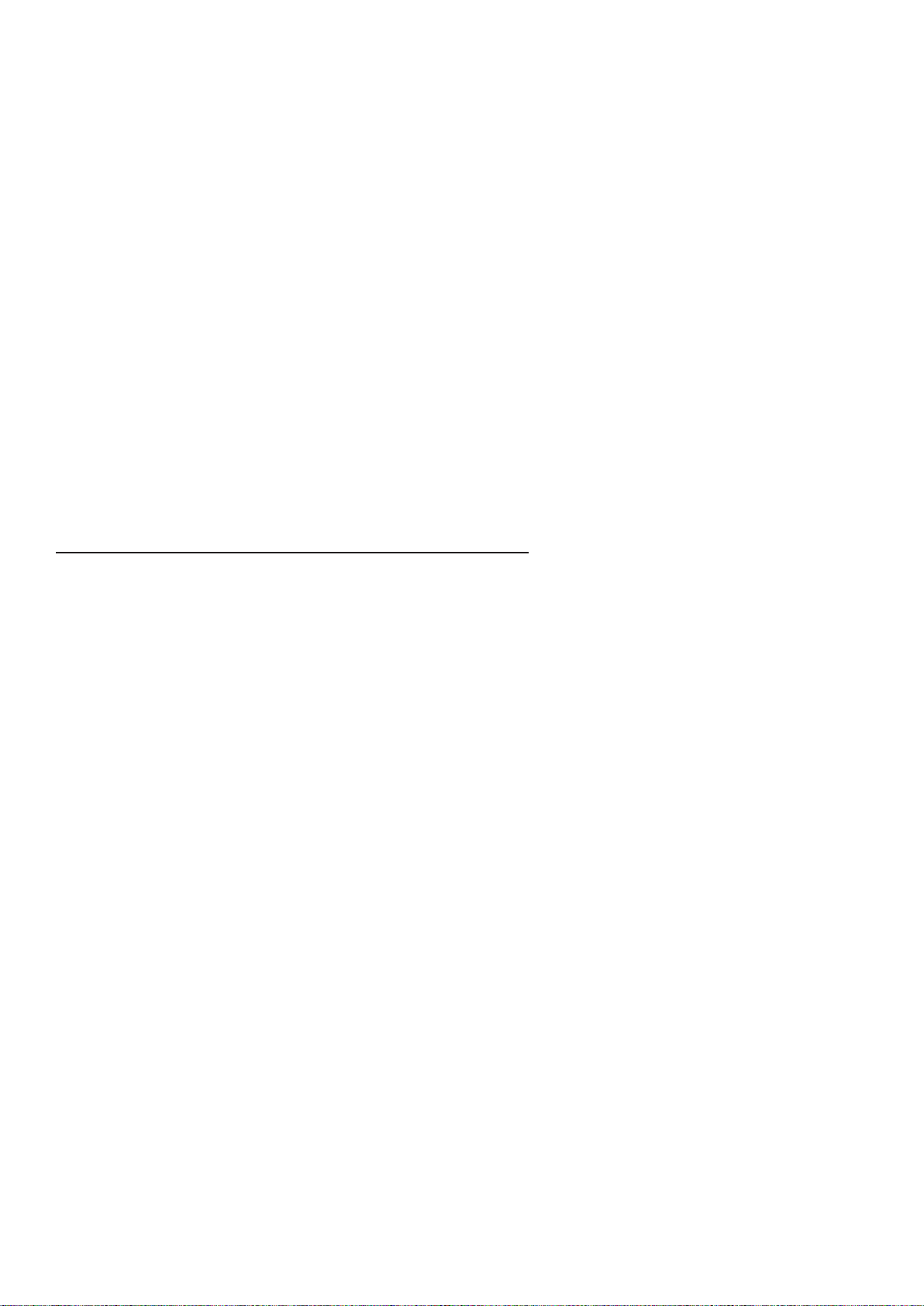

ITEM NO.

1

2

E

1

D

3

PART No.

TGP3539

DESCRIPTION

TRANSFORMER - POWER

FAN 80 x 80 x 25mm

FAN MOUNTING BRACKET

QTY

1

2

2

E

D

C

2

B

A

3

MCM

7-9-2010

MGB

23425

TOLERANCES UNLESS 0.00±0.10

OTHERWISE STATED 0.0 ±0.20

ANGULAR TOL. +2 DEGREES

MATERIAL:

FINISH:

PART NUMBER AND DRAWING NUMBER

A & R CAMBRIDGE LTD

ALL DIMENSIONS IN

MILLIMETERS UNLESS

OTHERWISE STATED

DRAWN BY:

DATE:

CHECKED BY:

ORIGINAL SCALE 1:4

SHT 2 OF 4

C

B

A

AVR400 MAIN ASSEMBLY

DRAWING TITLE

FANS + TRANSFORMERS

1

2

3

4

5

6

7

8

A3

10

0

30

20

50

40

60

80

70

90

100

Page 4

1

F

2

3

4

5

ECO NR.

--

--

--

--

--

6

DATE

--

--

--

--

-- --

CHG.

-- --

--

--

--

ZONE

--

--

--

--

7

DESCRIPTION OF CHANGE

--

--

--

--

--

8

DR.

CHK.

--

--

--

--

--

--

--

--

--

--

F

REL.

--

--

--

--

--

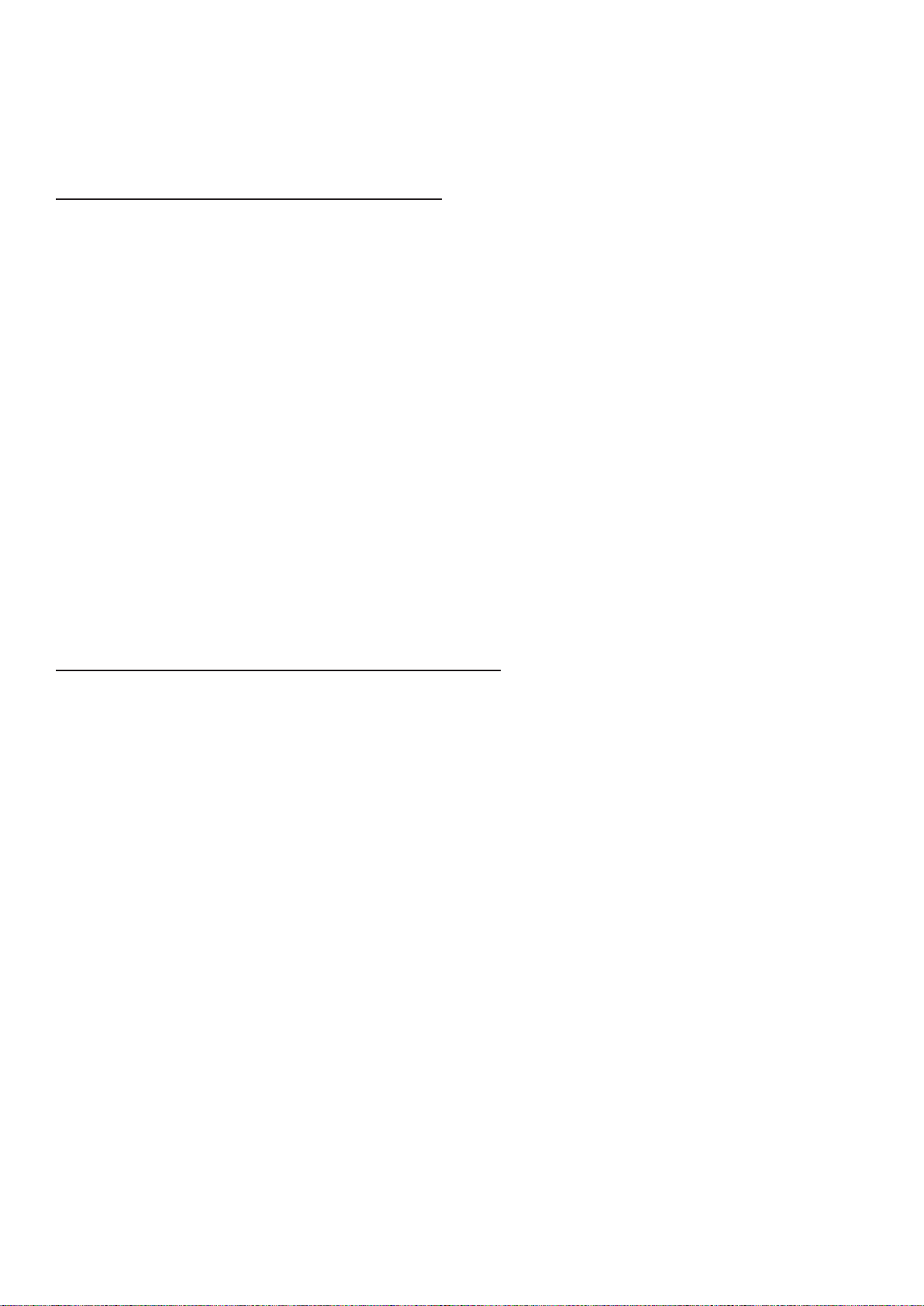

SOLDERED TO

E

2

D

C

1

POWER AMP PCB

5

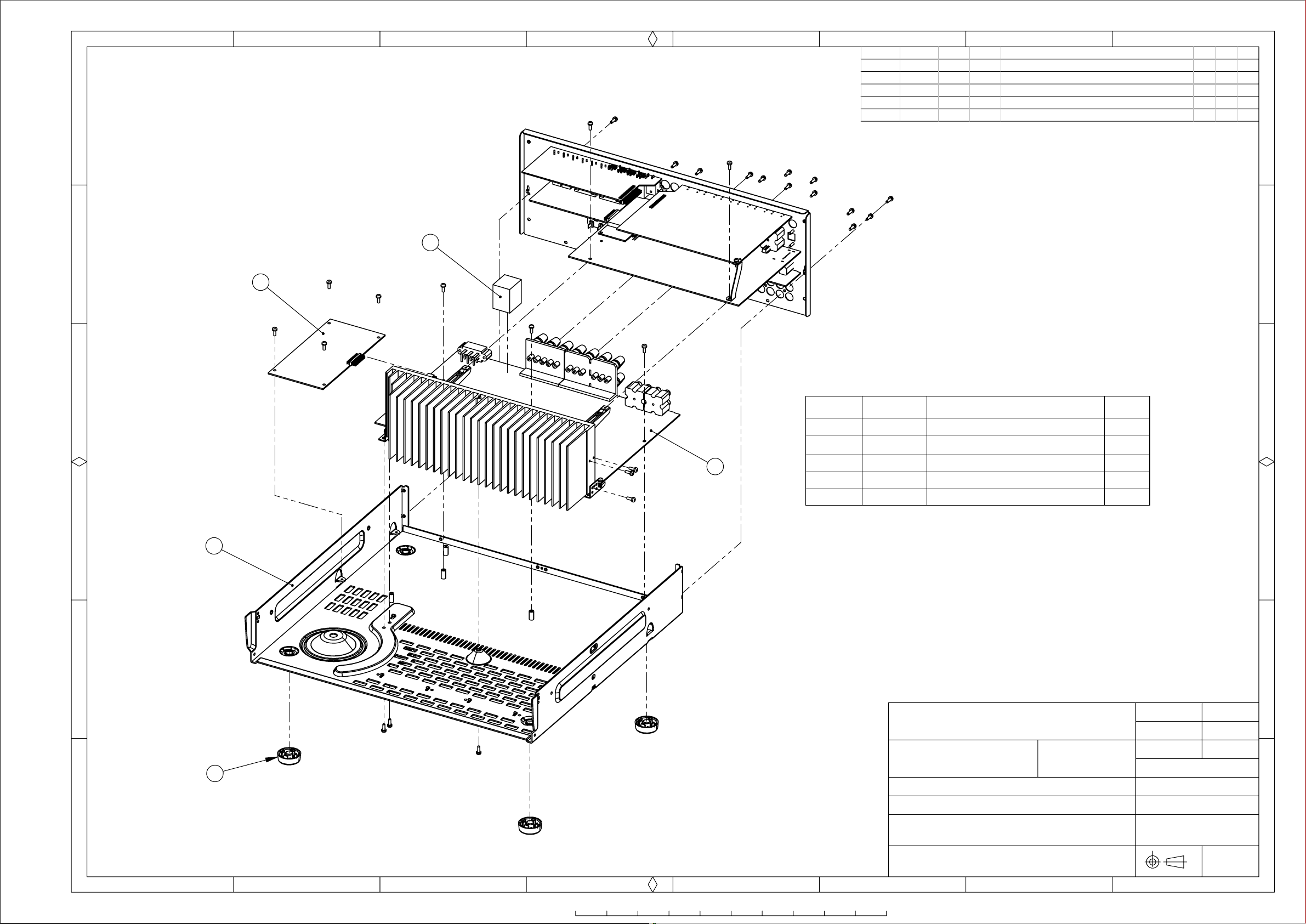

ITEM NO.

1

2

3

3

4

5

PART No.

TGP3534

TGP3535

TGP3538

TGP3525

TGP3540

DESCRIPTION

CHASSIS ASSY

FRONT PCB ASSY

POWER AMP PCB ASSY

FOOT ASSY

TRANSFORMER - STANDBY

QTY

1

1

1

4

1

E

D

C

B

DRAWN BY:

23425

TOLERANCES UNLESS 0.00±0.10

OTHERWISE STATED 0.0 ±0.20

4

A

ANGULAR TOL. +2 DEGREES

MATERIAL:

FINISH:

PART NUMBER AND DRAWING NUMBER

A & R CAMBRIDGE LTD

ALL DIMENSIONS IN

MILLIMETERS UNLESS

OTHERWISE STATED

DATE:

CHECKED BY:

ORIGINAL SCALE 1:4

SHT 3 OF 4

MCM

7-9-2010

MGB

B

A

AVR400 MAIN ASSEMBLY

DRAWING TITLE

POWER PCBs + FEET

1

2

3

4

10

0

30

20

40

5

50

60

80

70

90

100

6

7

8

A3

Page 5

1

F

2

3

5

4

5

6

ECO NR.

--

--

--

--

--

6

DATE

--

--

--

--

-- --

CHG.

-- --

--

--

--

ZONE

--

--

--

--

7

DESCRIPTION OF CHANGE

--

--

--

--

--

8

DR.

CHK.

--

--

--

--

--

--

--

--

--

--

F

REL.

--

--

--

--

--

E

2

7

D

4

3

C

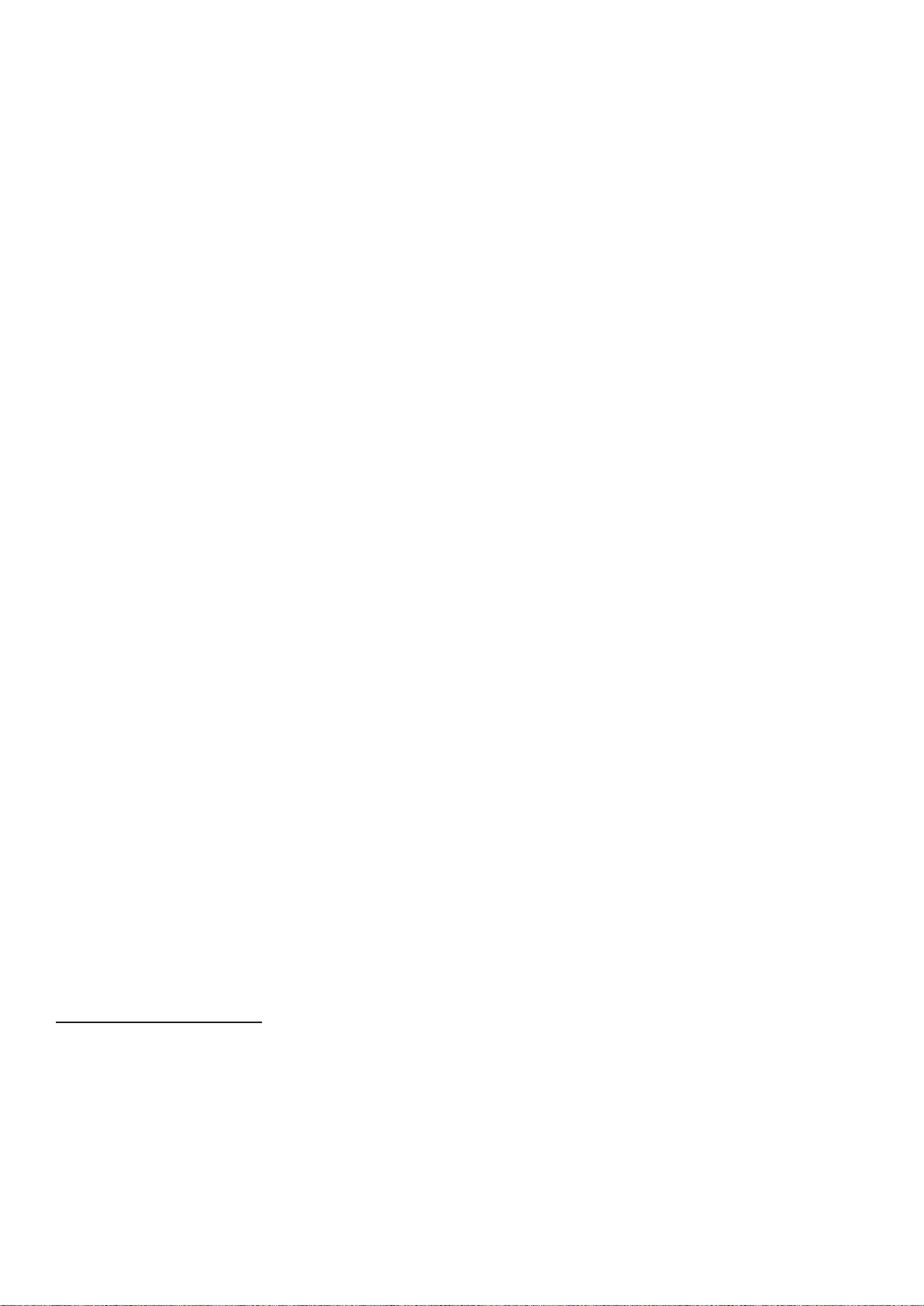

ITEM NO.

1

2

3

4

5

6

7

PART No.

TGP3528

TGP3536

TGP3536 (part)

TGP3536 (part)

TGP3537

TGP3537 (part)

TGP3529 / TGP3530

DESCRIPTION

QTY

REAR PANEL ASSY

INPUT PCB ASSY - MAIN 1

INPUT PCB ASSY - ETHERNET

INPUT PCB ASSY - CONNECTORS

HDMI PCB ASSY - MAIN

HDMI PCB ASSY - VIDEO

AM/FM TUNER EU / US

1

1

1

1

1

1

E

D

C

B

DRAWN BY:

23425

TOLERANCES UNLESS 0.00±0.10

OTHERWISE STATED 0.0 ±0.20

ANGULAR TOL. +2 DEGREES

1

A

MATERIAL:

FINISH:

PART NUMBER AND DRAWING NUMBER

A & R CAMBRIDGE LTD

ALL DIMENSIONS IN

MILLIMETERS UNLESS

OTHERWISE STATED

DATE:

CHECKED BY:

ORIGINAL SCALE 1:2.5

SHT 4 OF 4

MCM

7-9-2010

MGB

B

A

AVR400 MAIN ASSEMBLY

DRAWING TITLE

REAR PANEL + PCBs

1

2

3

4

10

0

30

20

40

5

50

60

80

70

90

100

6

7

8

A3

Page 6

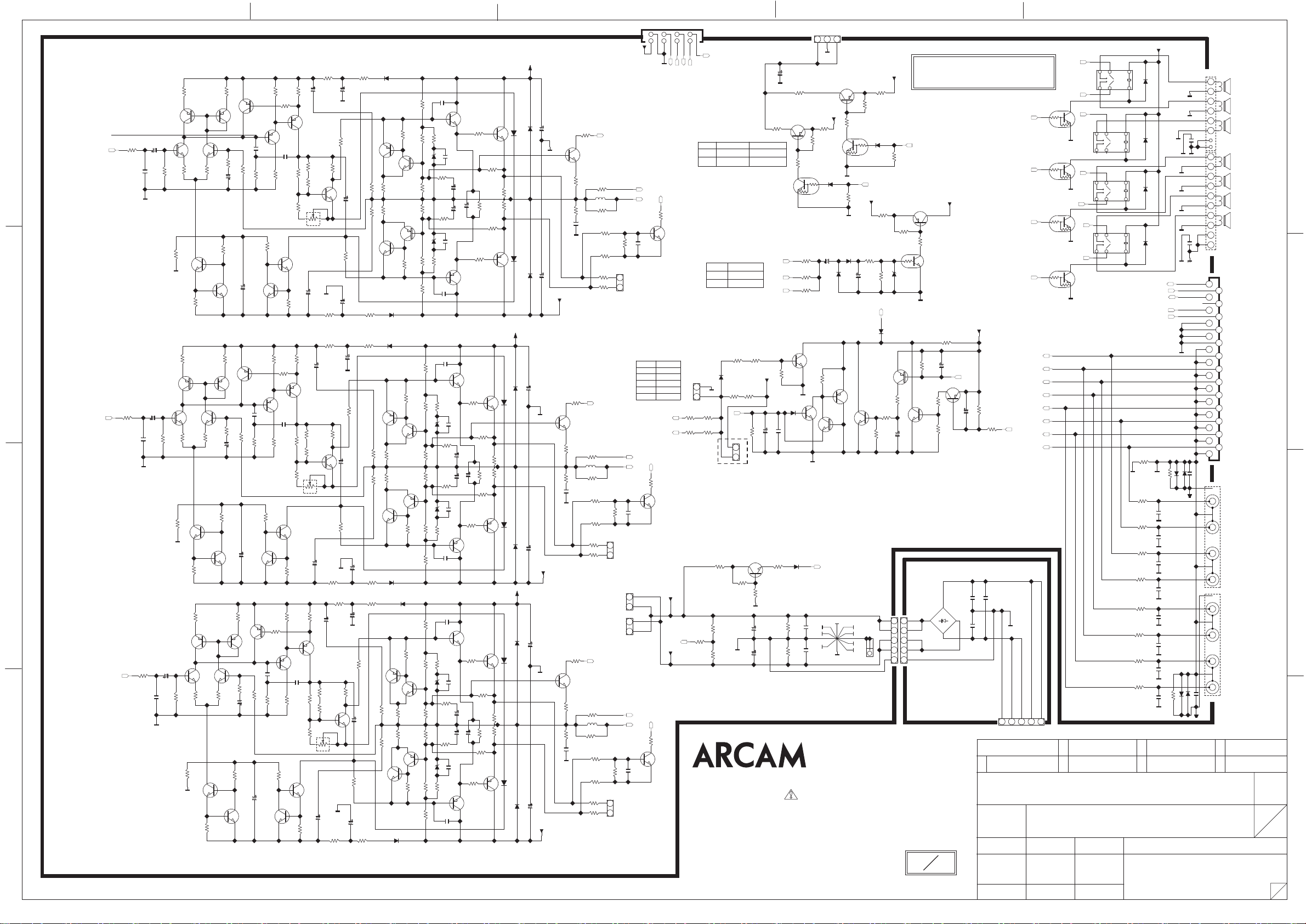

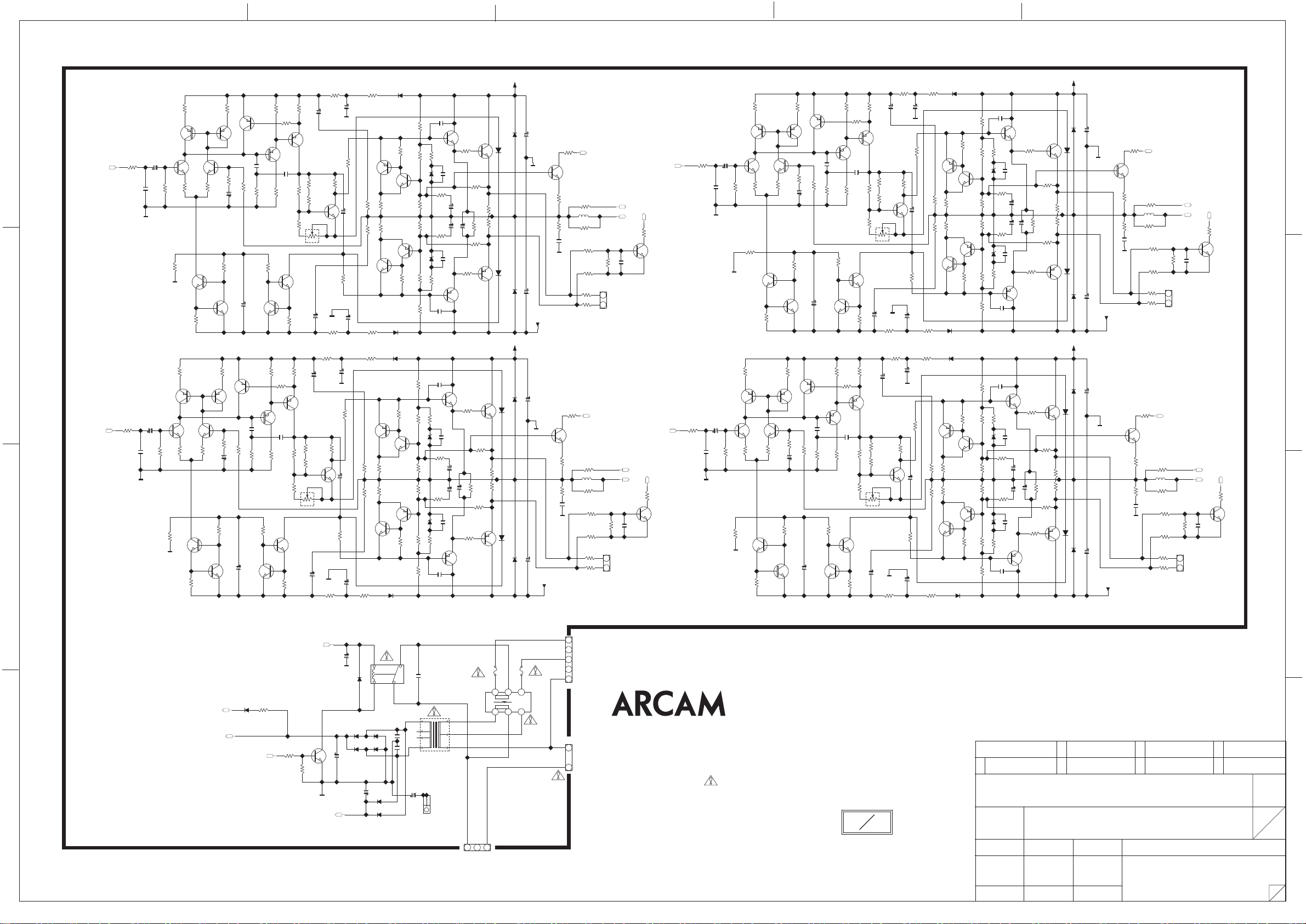

AVR400 Power Amplier Circuit Description

Apart from the power transformer, the power amplier electronics is fully contained on the large

double sided PTH PCB and heatsink located at the bottom of the AVR400. This is called the Main Board

on the schematic diagrams (pages 11 and 12). The Main Board also contains the mains input circuitry, in-

cluding the safety fuses and standby power transformer, so great care should be exercised when probing this

area of the board.

Note that some small surface mount components are soldered to the underside of this PCB.

The 7 power ampliers are identical in terms of circuitry, although necessary compromises in the physical layout may give rise to slight dierences in measured noise, crosstalk and distortion performance.

The two channels at the extreme ends of the heatsink have less radiating area available to them and will

run hotter under load – this is not normally an issue as these are assigned to the SBL and SBR channels.

Looking from the rear of the AVR, facing the at face of the heatsink, the channel order is SBR, SR, FR,

C, FL, SL and SBL, the same order as the loudspeaker terminals. The SBL and SBR channels can also be

assigned to zone 2 or as duplicates of the FL and FR channels for when passively biamping the main

stereo loudspeakers. In this latter condition we recommend assigning the SBL and SBR outputs to the

tweeters of the FL and FR speakers, in order to minimize the power ampliers’ heat dissipation.

Note that the 8 pre-amplier outputs are also on this PCB – apart from SUB their phono sockets are

eectively in parallel with the power amplier inputs, which are fed from the Input Board via a ribbon

cable and CON103. This connector also carries 5 power supply and power amplier control signals to

and from the system microprocessor (μP) IC151 situated on the Input Board above the Main Board.

The ampliers’ power supply is provided from a centre-tapped secondary winding on the toroidal

power transformer, via the connector BN508, to the bridge rectier D5830. This is mounted on a

small PCB near the top of the heatsink. The rectied AC is then sent to the main PCB via connectors

BN581/582. To avoid induced hum and distortion it is important to keep these cables twisted tightly

together and well away from the actual power amplier circuitry. The main 15,000μF 80V reservoir

capacitors, C835 and C836, are positioned on the main PCB well away from the power amplier input

traces and close to the system star ground. The smoothed DC is fed to the power ampliers’ Vcc and

Vee lines near the centre of the heatsink via a twisted-pair cable, again to minimize induction into the

power ampliers. Vcc and Vee are typically +/- 52V at 234VAC with no signal. Q5845 sends a fraction of

Vcc to the muting control on the Input Board.

The FL (front left) channel will now be described in detail.

The input stage is a long tailed pair Q5101 and Q5102, with local degeneration provided by R5105 and

R5107. The tail is fed from the negative rail via an approx 3mA ring-of-two constant current source,

Q5109 and Q5110. R5101 and C5101 at the input provide high frequency rollo and help keep residual

DAC ultrasonic noise above 100kHz out of the power amplier. DC blocking is provided by C5102 at

the input and C5107 in the feedback loop so that the whole power amplier has unity gain at DC. The

midband AC gain is 22000/680 = 32.35 after allowing for the attenuation provided by R5101 and R5102.

Thus 875mV at the input produces 100W into 8 ohms at the output.

The long tailed pair’s collectors are loaded by a current mirror, Q5103 and Q5104. The resistors R5103/4

and R5105/6 are 1% tolerance to minimize even order distortion. The collector of Q5101 also feeds the

Darlington class A voltage amplier stage (VAS) made up of Q5115 and Q5116. Q5113 is loaded by the

output stage and the 8mA constant current source made up by Q5125 and Q5126. The amplier’s main

frequency compensation network (for stability) comprises C5115 plus the combination of C5116 and

R 5115. This adds gain inside the loop (two pole compensation) at high audio frequencies so that the

Page 7

additional feedback further reduces high frequency distortion and crossover distortion within the audio

band.

These stages are partially decoupled from the Vcc and Vee power supplies by D5130/R5130/C5130 and

D5129/R5129/C5129 respectively. They are also bootstrapped to the amplier output via the networks

R5118/C5128/R5128 and R5117/C5127/R5127. This raises the supply lines by approximately 3V at full

output to avoid clipping the driver stage prematurely.

The output stage comprises classic complementary emitter followers Q5150/Q5170 (NPN) and Q5160/

Q5180 (PNP). The On Semiconductor output transistors have a current gain that is sustained to about

10 amps and a very large safe operating area, which allows the ampliers to drive low impedances well.

They also have built-in thermal compensation diodes which helps stabilize the quiescent current both

statically (when hot) and dynamically (when playing music at high level) – this minimizes crossover

distortion and improves sound quality.

The output stage biasing is performed in the network around the amplied diode Q5120, which is

mounted in intimate thermal contact with the driver transistor Q5130, plus the two built-in diodes

associated with the output transistors. The thermistor R5122 is positioned on the PCB close to the

heatsink and provides extra downward compensation at very high temperatures. Bias is set by VR51 and

is largely independent of temperature – it should be set to16-20mV when measured across the outer

terminals of the compound emitter resistor R5175, using the 2 pin connector CN51, 5 minutes or more

after the AVR400 is powered up.

The power amplier output is routed across the PCB to the back panel. It includes a Zobel network

(sometimes called a Boucherot cell) R5183/C5183 and a series inductor L5185 damped by a 4.7R 2W resistor R5184. These components help isolate the amplier from reactive loads to ensure high frequency

stability. One half of the normally-o relay RL52 is used to switch the load in and out.

Each power amplier is protected against overload in a number of ways. The complementary transistors

Q5130 and Q5131 protect the NPN half of the output stage and Q5140 and Q5141 the PNP half. They

operate as Sziklai pairs, passing negligible current until a threshold voltage of approx 600mV is reached

across R5132 and R5142. Between 600 and 700mV the pairs then ramp up current smoothly, diverting it

away from the bases of Q5150 and Q5160 to limit the output stage drive to a safe level, within the power

transistors’ SOA (safe operating area). The 600mV threshold voltage depends upon both the instantaneous current and voltage across the output transistors, set by the networks R5132/R5136/R5137/R5138/

R5175 for the top half and R5142/R5146/R5147/R5148/R5175 for the bottom half. R5135/R5145 and the

zener diodes D5135/D5145 change the slope of the protection locus at high Vce voltages. R5134/R5135

plus C5134/C5145 prevent fast transients and brief overloads from prematurely triggering the protection.

The above dual slope SOA protection is self resetting but if a gross overload persists for more than a

second or two (such as when a channel’s output is short circuited with music playing at a moderate to

loud level) then the open collector transistor Q5181 sinks current for long enough to initiate the amplier’s full shutdown procedure via the line SOA_PROTECT. This can also be triggered by a total output

stage failure (which passes enough current through R5175 to turn on Q5188) via OVERLOAD or by an

excessive DC oset at the output terminals (via R5185) via V_DET. All these signals, and others, feed into

the protection module, described below.

The protection module comprises 8 transistors and associated parts positioned at the back of the PCB

near the preamplier output sockets. It has a single output line named PROTECT which, when pulled

down from Vcc to ground, instructs the system μP IC151 to shut down the whole amplier. This occurs

when any of the following events happen:

Page 8

1) Any amplier channel pulls current through the SOA_PROTECT line for long enough to charge

up capacitors C5871 and then C5872 so that Q5874 turns on.

2) Any amplier channel pulls current through the OVERLOAD line for long enough to charge up

C5882 and turn on Q5882 and thus Q5884.

3) Any amplier channel has a large long term (DC) oset (typically greater than +/-3V) sμFcient

to charge up C5861 enough to turn on either Q5862 (positive oset) or Q 5864 (negative oset).

These then turn on Q5863. N.B. This circuit is also used to detect imbalances in both the Vcc/Vee

and +/-15V power supplies (the latter is generated on the Power Supply board).

4) When the PTC thermistor TH585 mounted at the top centre of the heatsink gets sμFciently hot

(around 100C) and thus high resistance enough to cause Q5855 to turn on via the +12V supply.

Intermediate temperatures will not activate PROTECT but will provide signals to the level detectors associated with the FAN_1 and FAN_2 lines, to run the cooling fans at high or low speeds

respectively.

Note that the fans’ 12V supply is gated via Q5909 and Q5911. This means the fans will not run when

no signal is present on the FL, C or SR channels, so that during quiet passages no fan noise should be

audible.

AVR400 Main Power Supplies Circuit Description

The main DC power supplies are located on the Power Supply Board - a double sided PTH PCB adjacent

to the Main Board. Note that the mains input switching, mains fuses, standby power transformer with

its associated unregulated DC supply and the relay for enabling the power amplier supply rails are

located on the Main Board. The two boards communicate via CON501.

Considering the Main Board rst, the mains voltage switching uses a double pole double throw slide

switch accessible from the back panel. One pole addresses the standby transformer and the other the

toroidal power transformer. Ensure the switch setting matches the supply voltage before switching on the

AVR400. Nominal settings are 115 and 230V +/- 15%. The 20mm 115V fuse in line with the toroidal transformer is rated at 15A T (Time delay) and the 20mm 230V fuse is rated at 8A T. Always replace these fuses

with the same type and value. The standby transformer T5941 is not fused but is designed to go open

circuit in case of overheating (e.g. if left connected to a 230V supply for longer than a few minutes when

the mains voltage selector is set to 115V).

The standby transformer generates approximately +9V DC via the bridge rectier diodes D5495/6/7/8

and the 1,000μF reservoir capacitor C5947.This is sent via pin 7 of CN501 to the Power Supply PCB

(confusingly marked as 5V). The rail voltage is also routed to the system microprocessor (μP) via D5965/

R5965 and pin 6 of CN103 as POWER_MUTE.

The 5V relay RY594 is normally open. When the mains switch is closed then the SUB_POWER rail (approx

+4.3V) is activated from the Power Supply PCB via the standby transformer. When the system has

booted correctly, without any shutdown signals, then the POWER_RELAY signal from the system μP also

goes high, pulling down Q5947 hard. Only then does the relay close and switch on the main toroidal

power transformer, enabling the rest of the system to boot up.

Now consider the Power Supply Board, found on page 14 of the schematic. This generates all the main

DC supplies for the AVR400 except +Vcc and -Vee for the power ampliers and the non-logic part of the

VFD display requirements of the Front Panel Board. Note that additional local regulation also takes place

on the other PCBs, e.g. for large digital ICs.

Page 9

Two secondary windings from the toroidal power transformer are fed in via CN63. Pins 1, 2 and 3 connect to a centre-tapped secondary winding used to generate approx +/- 20VDC via the bridge rectier

diodes D603/3/4/5 and the 2,200μF 35V reservoir capacitors C609 and C610. R603 and R604 are 0.47R 1W

fusible resistors for circuit protection – if they fail replace only with the same type and value.

The 3 terminal regulators IC63 and IC62 are mounted on two of the larger heatsinks near the back of the

amplier. These provide +/-15V to the op amps on the amplier’s Input Board via the 11-way connector

BN62. The Input Board also then routes the +/-15V onwards to the Front Panel Board.

Pins 4 and 5 of CN63 receive AC from another transformer secondary to generate approx +15VDC via the

heatsink mounted bridge rectier D601 and the 18,000μF 25V reservoir capacitor C631. F601 and F602

are hard wired 6.3Amp T (time delay) fuses for circuit protection – if they fail replace only with the same type

and value.

This +15V unregulated supply has 4 main outputs:-

1) It is regulated down to +12V with the low dropout (LDO) 3 terminal regulator IC64. This is situated on the heatsink closest to the Main Board, near the back panel. Its output goes to BN62 for

the +12V triggers and also to CN501, to drive the power ampliers’ cooling fans.

2) It supplies the HDMI Board via CN61. To minimize ripple currents in the ground return, Q643 is

wired as a low dropout voltage follower with low pass ltering via R650 and C569.

3) It feeds the switched mode buck regulator IC61 via L631 and C615. The tank circuit comprises

L632, C640 and C641, discharged via D631. R636 and C643 make up a snubber to reduce overshoot. This provides a high current +5V supply to the Input Board via pins 4 and 5 of BN62. This

5V supply also feeds two 3V3 linear regulators, IC67 and IC68. These in turn supply the audio DSP

ICs on the Input Board via pins 10 and 11 of BN62.

4) It feeds the +5V 3 terminal LDO regulator IC66 via the diode D616, which itself is preceded by the

smoothing network comprising R615 (2W 15R) and C615. Note IC66’s output is actually approx

+5.7V because of D644 in its ground line; this is brought back to +5V after D643, to feed the relay

IC66 is noteworthy because it continues working when the amplier is in standby.

It takes a second input from the +9V standby power supply on the Power Amplier PCB – D616 acts as a

gate to prevent this from feeding back to the +15V supply when the system is in standby. It also allows

the +15V supply to override and remove the load from the +9V supply when the amplier is fully booted

up.

D606 and D607 form half of a second bridge rectier (with the other two diodes coming from the full

bridge rectier D601). These diodes charge up the 1μF/50V capacitor C604 to +15V, generating a “mains

power present” signal. The 10K resistor R614 in parallel with C604 continually discharges it so that this

signal eectively disappears within about 50 milliseconds of the mains being switched o. This +15V

goes to the Main Board via pin 8 of BN62, where it is used as a “pull up” signal to help control the various audio muting circuits.

AVR400 Front Panel Board Circuit Description

The Front Panel Board is a double-sided PTH PCB. It contains the VFD (Vacuum Fluorescent Display) and

its associated electronics, plus the keyboard, power status LED, IR remote receiver and headphones

amplier. A daughter board carries the front panel I/O socketry. See page 1 of the schematic diagram.

Page 10

It communicates with the Input Board via CN101 and a 31 way ribbon cable. Other connectors comprise

CN94 which connects to two secondaries of the main power transformer and the hard wired BN93

which connects up the daughter board.

There are two associated break o boards. One houses the front panel mounted single pole mains

switch plus its suppression capacitor C901 and a connector BN502. The second is mounted on the

power ampliers’ heatsink and is used to route power to the cooling fans and also to guide the 31 way

ribbon cable.

The VFD draws AC lament power from a centre tapped winding of the power transformer connected

to pins 1, 2, and 3 of CN94. The centre tap connects to ground via the zener diodes D901/2 and C903

to provide the lament with its required DC oset. Pins 4 and 5 connect to a relatively high voltage

transformer secondary which is half wave rectied by D916 and smoothed by C907 and C960. The zener

diodes D903 and D904 in series with R906 generate +40V which is then coupled to the emitter follower

Q901 to provide a nominal regulated 40V HT power rail for the VFD.

The VFD’s internal driver IC and external data bμFfer IC901 run from the main +5V supply generated in

the Power Supply board and routed onwards through the Input Board. The drive signals (data, clock,

chip select and reset) come directly from the system microprocessor via CN101.

The 12 front panel switches are arranged in 2 blocks of 6 with resistive divider chains connected to two

ADC inputs on the system micro. These have 10K pull-up resistors at the system μP end to complete the

potential divider chains. The pnp switching transistors Q906 and Q907 turn on the 3V3 supply from the

system μP via another 10K pull-up resistor at the μP end to provide interrupt control.

The power status LED D905 is a tri-colour type. The green side indicates power on and the red side

standby. A high signal on the LED net turns on Q902 and Q903. This turns o the npn Q913 to disable

the red LED and turns on the pnp Q912 to enable power to the green LED. The reverse is true when the

LED line is low. Pulling the STB(LED) line low when the LED line is also low powers both LEDs and gives

a yellow light to show when the unit is booting up. Note that the power supply is STBY+5V to allow the

red LED to operate in standby mode.

RC901 is a Kodenshi KSM603TH5B encapsulated infra red receiver for processing commands from an

external IR remote control. It is designed to work with the 36-38kHz carrier frequencies associated with

the Philips RC5 protocol. Note that it operates from the ST+5V rail to enable the AVR400 to be woken up.

It does not demodulate the IR – this is done by the system microprocessor.

The headphones amplier IC902 drives external headphones directly via the 330μF series capacitors

C935 and C936. IC902 has a gain of about 4, meaning that the headphones output will be about 4V rms

when the volume control is set to clip the L and R main power ampliers (equivalent to about 120WPC

into 8 ohms). IC902 is a JRC NJM5556AL capable of driving 7V rms into150 ohm loads and about +/100mA peak current into lower impedances. Mute transistors Q904/905 in series with 100R resistors are

tted in front of its input to minimize switching transients and it is powered from the +/-15V supplies

generated on the Power Supply Board.

The L and R headphones outputs go via BN93 to the Headphones Board, after passing through relay

RL902 which is normally o. A positive voltage from the μP at the emitter of pnp Q911 turns on Q911

and generates the same positive voltage at the base of the npn transistor Q909. Because its emitter is

connected to the -15V rail this pulls the relay on.

The FRONT AUX and MIC inputs come from the Headphones Board and through the microphone relay

RL901. When the relay is o the AUX line level L and R signals are switched through to the unity gain

bμFfer IC904 and then on to the Input Board via pins 3 and 1 of CON101. When the relay is closed (in

Page 11

the same manner as described above for RL902) then the L front input is routed to the low noise microphone amplier IC903. This operates as two cascaded virtual earth ampliers, each with a voltage gain

of approximately 21 (R961/960 and then R965/962). Note the MIC line is biased at +6V via resistors R956,

R957 and R958. The amplied signal is output to the Input Board on pin 5 of CON101.

AVR400 Input Board Circuit Description

The Input Board comprises a 4 layer PCB; this is attached directly to the back panel via its various sockets and to the heatsink by two steel brackets. It is positioned underneath the HDMI Board and above

the Main Board. 5 ribbon cable sockets connect it to the other 4 boards. CN71 connects it to a daughter

board containing two 9 Pin D socket connectors (an RS232 serial port and an iPod dock interface), plus

two 12V trigger sockets and 2 IR receiver sockets. Note some passive components are mounted on the

underside of the PCB.

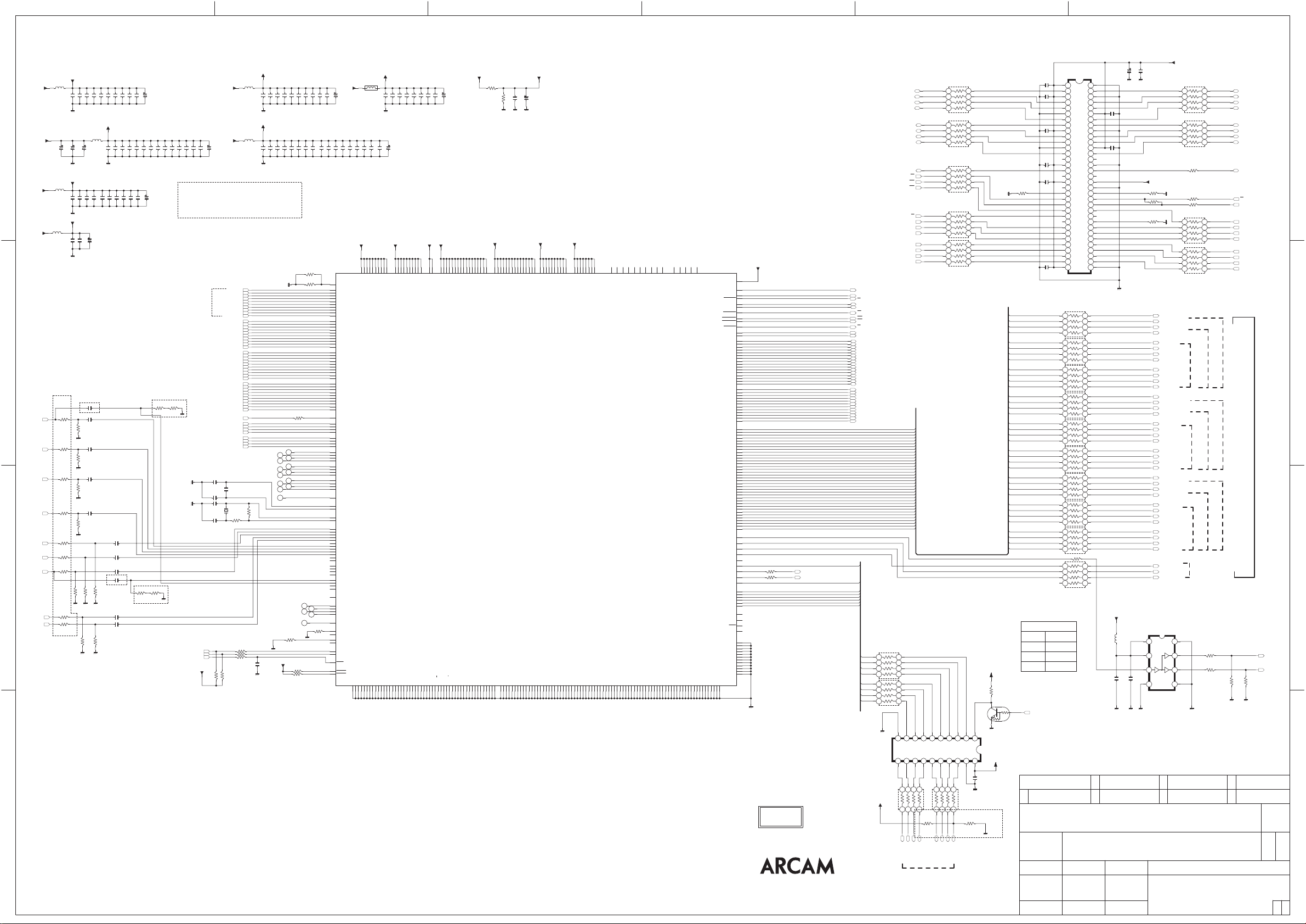

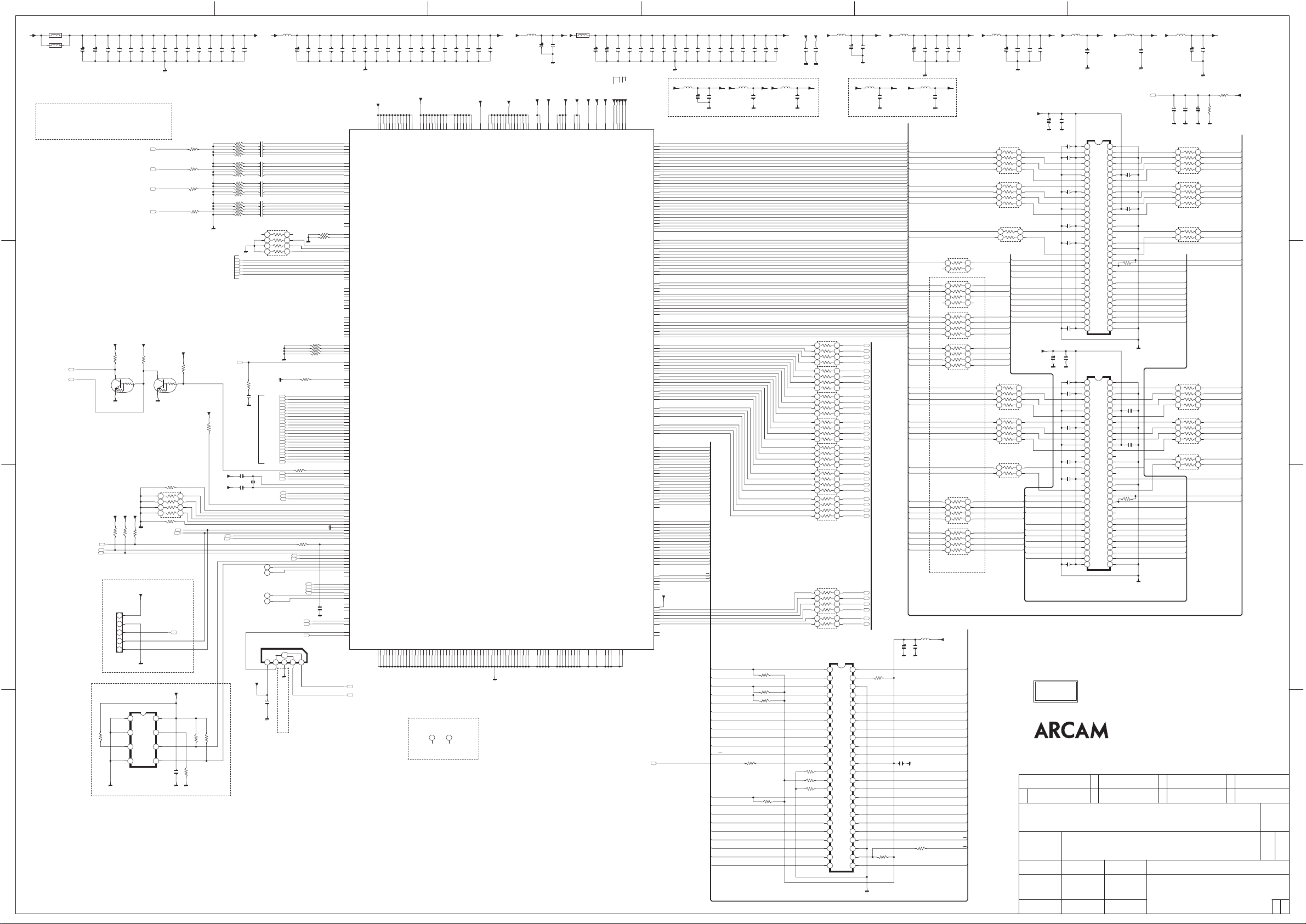

The Input Board circuitry is shown on pages 2 – 5 of the schematic diagram.

Page 2 covers the analogue inputs, volume control and line level outputs.

Page 3 covers the SPDIF (digital) inputs, clock recovery, audio DSPs and the codec (stereo ADC plus

8-channel DAC).

Page 4 covers the system microprocessor and a slaved support microprocessor

Page 5 covers interfaces to the DAB/Ethernet module, and the boot loader microprocessor used to

update the system SW via USB.

Analogue inputs, volume control and outputs

IC101 is a Renesas R2A15218FP analogue multiplexer and volume control, with a gain range of +42 to

-95dB in 0.5dB steps. It is digitally controlled from the system microprocessor via the I2C bus on pins 49

and 50. A high logic signal on pin 51 enables the system mute. IC101 has +/- 7V supplies generated from

the +/-15V rails with the regulators IC102 and IC103.

All stereo external line level inputs using phono sockets are routed to IC101 via 100R/220pF low pass

CR lters. IC101 also handles the AUX-L, AUX-R and the (mono) MIC_SIGNAL setup microphone inputs

coming from the front panel, plus the internal stereo outputs from AM/FM tuners (TUN-L and TUN-R)

and the DAB/ethernet receiver (VENICE_L and VENICE_R). IC101 additionally switches two multichannel

signals - the 8 channel direct input and the outputs from the 8 post-DAC lters. Note that the +/- 7V

power supply limits the input signals to approximately 4V rms before overload occurs.

The post-DAC lters comprise 4 low noise NJM2068 dual op amps, running from the +/- 7V supplies.

One op amp is assigned to each channel and performs the dual functions of converting a dierential

input from the DAC to a single ended output, whilst simultaneously functioning as a three pole 50kHz

active lter.

The AM/FM tuner module’s outputs pass through the inductors L310 and L302 (providing 19kHz notch

and 38 kHz low pass ltering) and the shunt mute circuits formed by the 330R resistors R354/R369 and

the two halves of Q306 plus Q307.

IC101 has a xed level stereo output for Zone 2 (SUB_L and SUB_R) and a second one, adjustable from

0dB to -18dB in 6dB steps, for the AVR400’s analogue to digital converter (ADC_L and ADC_R).

Page 12

IC101 has one 8 channel variable level output bus labelled VOL01 through to VOL08. Capacitors C295-8

and C231-4 oat the ground ends of the associated internal potentiometers to minimize clicks This bus

goes via specially selected 100μF/25V capacitors to the dual op amps IC121-124, wired as voltage followers and running from the +/- 15V supplies. The C, SL, SR, SBL and SBR outputs are shunt muted when

required via the 560R resistors R383-388 and the dual transistors Q303-305.

The subwoofer output SW has two shunt mute circuits. One using Q311 works in parallel with the rest of

the channels. The other, using Q308 and half of Q303 allows muting of the SW channel alone.

The FL and FR channels take o the stereo headphones amplier feed from IC121 (it goes via the connector WF101 to the Front Panel Board), then add an extra dual voltage follower IC125 and a double

pole shunt mute switch using 4 x 270R resistors and Q301-302. All the above ICs are JRC NJM2068s or

equivalent.

All 8 of these outputs go to via the connector WF103 to the preamplier output sockets and (except for

the subwoofer output) to the 7 power amplier inputs located on the Main Board.

The ADC input ampliers use a JRC NJM2068 for each channel, operating as a single-ended input to

dierential output converter, with HF ltering above about 400kHz. This is sμFcient for anti-aliasing

purposes as the analogue modulator of the ADC samples at 6.144 MHz and only needs to keep out

frequencies above 6MHz.

The array of 12 switching transistors in the bottom right hand corner of the schematic is arranged in

4 blocks of 3 devices (two npn and one pnp per block). The array is used to control the muting of 4

specic groups of audio outputs, taking into account the presence of AC mains via P_U (the pull up line

from the Power Supply board) and the MUTE_POWER line derived from the power ampliers’ Vcc rail

– this is normally high when Vcc is high. The output lines are SB_MUTE2 (for the surround back channels SBL and SBR), ZONE2_MUTE2, HP_MUTE2 (for the headphones relay on the Front Panel board) and

FUNC_MUTE2 (for the 6 main audio channels excluding SBL and SBR).

Zone 2 volume is independently adjustable in 1dB steps via IC131 (rohm BD3812F). Its outputs are

bμFfered and amplied 15dB by the dual op amp IC132 and can be muted when required by Q402. The

output goes directly to two phono sockets forming half of JK11 on the back panel.

SPDIF inputs, ADCs, DACs and Audio DSPs

The AVR400 has 4 coaxial 75 ohm SPDIF (Sony/Philips Digital InterFace) inputs and 2 TOSLINK optical

inputs on its back panel. A further optical input is located on the front panel as part of JK92 (this socket

also includes the AUX and MIC inputs). There are 6 further external SPDIF inputs - one per HDMI input

socket and one on the HDMI output socket (the Audio Return Channel or ARC).

Each of the 4 coaxial inputs is bμFfered by two NOR gates, contained in IC159 and IC160, before being

switched by one half of the dual 4 input multiplexer IC147. The output on pin 7 is then sent to the 8

input multiplexer IC140. Its other 6 inputs comprise the 3 optical receivers already mentioned, the HDMI

input (multiplexed down from 5:1 on the HDMI board), the HDMI ARC and the output of the Venice 6

DAB/Ethernet module. The 8th input is unused. The output MUX_SPDIF is sent to the SPDIF receiver

IC153.

IC153 is a Wolfson WM8804 run in hardware mode. It uses X707 to generate its own 12MHz internal

clock. IC153 automatically identies and dejitters incoming SPDIF signals with sample rates of 32kHz,

44.1kHz, 48kHz, 88.2kHz, 96kHz and 192kHz. Its output, still in SPDIF format, WM_SPDIF, is sent to pin 43

of the system codec IC143.

Page 13

IC143 is the Cirrus Logic CS42548. It includes an SPDIF receiver, 2 channel ADC and 8 channel DAC. Only

one input (pin 43) of the SPDIF receiver is used; the others are grounded.

IC143 has +5V analogue supplies, locally decoupled to analogue ground by C721/722 for VA (pin 24)

and C703/704 for VARX (pin 41). The digital supply is also +5V, decoupled to digital ground by C705/706

(pin 5) and C750/756 (pin 51). The control port power VLC (pin 6) is 3V3, decoupled to digital ground by

C752/773 and the serial port power VLS (pin 53) is also +3V3, decoupled to digital ground by R726 and

C753/754. The 3V3 is generated from the +5V supply by the linear regulator IC148.

The system master audio clock is generated by IC143 on pin 55 whenever an SPDIF signal is present (i.e.

in all cases except when an HDMI multichannel signal in I2S is required to be processed or when using

the ADC). Although IC143 has no jitter rejection below 20kHz its master clock is kept clean from incoming jitter by IC153. The PLL lter is located at pin 39. When SPDIF is not in use IC143 inputs its clock on

pin 59 – this can be 24.576 MHz from the crystal oscillator X701 associated with DSP1 when ADC mode is

engaged, or the recovered clock from the HDMI Board. This is switched by the 4 way change over multiplexer IC145 on pins 9, 10 and 11. IC145 also routes IC143’s recovered master clock or the HDMI master

clock to DSP1 on pins 5, 6 and 7.

Pins 1, 62, 63 and 64 receive the 24 bit serial audio data that has been processed by the DSPs.

The DAC’s 8 analogue outputs are in dierential mode, so making 16 output lines in total, from pins

20-23 and 26-37. These feed the post-DAC lters IC111-114, described above.

The main audio DSP is a Cirrus Logic CS 497024, IC141.This is a 300MIPS dual core 32 bit xed point DSP,

with 72 bit accumulators. The rst core is used for decoding standard and high denition audio formats

(Dolby, DTS etc) and the second is reserved for post processing such as bass management, delay and

room correction. The secondary DSP, IC142, is a Cirrus Logic CS49DV8, responsible for the Dolby Volume

processing. IC141 gets the 1.8V for its core from the 3-terminal regulator IC149. IC142 gets its 1.8V from

IC150. The 3V3_1 and 3V3_2 supplies for these regulators are generated on the Power Supply Board.

IC141, 142 and 143 communicate with the system microprocessor via an SPI bus. For IC141 and IC142

the chip select lines are on pin 6, the clock is on pin 126, the MISO line on pin 124 and the MOSI on

pin 123. For IC 143 the corresponding pins are pins 10, 7, 8 and 9. Note that the 3 chips receive data on

a common line but transmit to the μP on two separate ones (DSPDATA for both DSPs and D_OUT for

IC143).

IC141 communicates with its external memory via a 36 line data bus running at 150MHz. This is needed

when providing lip sync delay for audio accompanied by video. IC144 is a 200MHz 16Mbit SDRAM, organized as 512Kbits x 16bits x 2. It is powered from the board’s 3V3 line via 6 pins, with local decoupling

provided by C758-763.

The DSPs’ programs are stored in two external 3V3 SPI ash memory chips – IC106 (8Mbit) for IC141 and

IC107 (4Mbit) for IC142.

IC141 has two sets of I2S data inputs. DAI (pins 23, 24, 26, 27 for data, pin 29 for the system clock and pin

30 for the LR clock) is for up to 8 channels from the HDMI Board via connector WF104.

DA2 (pins 32 for the LR clock, 33 for system clock and 34 for data) is for audio from the codec IC143. This

includes bitstream SPDIF such as Dolby Digital, uncompressed two channel I2S audio decoded from

SPDIF and ADC generated I2S two channel audio.

The DSP master clock is input on pin 40 of IC141 from pin 9 of IC145 as noted earlier.

Page 14

IC141 also has two sets of I2S data outputs. DA1 is an 8 channel I2S signal (pins 47, 48, 49 and 51) shown

as part of the bus DA0(04:07). This feeds the input of the second DSP IC142 (on pins 23, 24, 26 and 27).

The system clock is on pin 52 of IC141 and the LR clock on pin 54. These go to pins 29 and 30 of IC142.

DA2 is a stereo I2S output (pin 43 for data, pin 44 for the system clock and pin 46 for the LR clock). This

feeds the HDMI board via WF104 and the octal bus switch IC146. The DSP master clock output from

pin 9 of IC145 follows the same route. An SPDIF output from pin 35 of IC141 goes directly to pin 12 of

WF104.

There is one set of 8 channel I2S outputs from IC142 – DA1 (pins 47, 48, 49 and 51). These form part of

the data bus DA0(00:03) where they are routed back to the DACs in IC143 (pins 62, 64, 63 and1 respectively). The I2S system clock and LR clock (pins 52 and 54) also go directly to IC143 (pins 2 and 3).

System Control Microprocessors

There are 3 microprocessors on the Input Board, the main, the sub and the USB micro. The latter is also

kept separate in order to perform upgrades over USB.

The AVR400’s main system microprocessor IC151 is a Toshiba T5CN5 microcontroller. This has an ARM

Cortex 3 core with 512KB of ROM and 32KB of ash memory. It is a 3V3 part, with this power supply

being derived from the main 5V supply via the 3-terminal regulator IC156. It has a 40MHz system clock

derived from crystal X702 and a real time clock from the 32.768 kHz crystal X708.

IC152 is a 32Kbit EEPROM for retaining system settings at power down.

IC155 is a MOSFET switch to enable the HDMI CEC (Consumer Electronic Control) bus when the unit is

powered up, and to isolate the parts of the bus external to the AVR400 when it is powered down.

IC151 has several sets of comms busses - SPI, I2C and UARTs - depending on which system or peripheral

ICs are being addressed. SPI (Serial Peripheral Interface) is a fast 3-wire interface (clock, transmit and

receive) with chip select being addressed by individual I/Os. I2C (Inter Integrated Circuit) is a relatively

slow bidirectional 2-wire interface, with open-collector/source clock and transmit/receive busses, each

with a pull up resistor, and a limited number of embedded chip addresses. UART stands for Universal

Asynchronous Receiver/Transmitter and is a form of bus that takes bytes of information and turns them

into serial data on a bus before reassembling them into bytes at the other end.

SPI is used to talk to the codec IC143 and the two DSPs IC141 and IC142.

I2C is used for both the main and zone 2 volume controls IC101 and IC131. I2C also connects to the sub

micro IC154 and to the NJW1321 video input decoders IC81 and IC81.

IC151’s UARTs are used for USB Tx/Rx, the Torino (video processor) Tx/Rx and the external RS232 Tx/Rx.

Further UARTs on the sub micro IC154 communicate with the Venice 6.2 DAB/Ethernet receiver and

the iPod external interface. IC154 is a Toshiba M333FWFG ARM Cortex 3 microcontroller with 128K ROM

and 8K of ash, eectively used as a helper for IC151. Its 3V3 power supply regulator IC158 runs from the

board’s main 5V supply.

The USB micro (“Bolero”) IC162 is a Toshiba TMP92FD28FG, a 32-bit CISC microcontroller with a built-in

USB2 host controller capable of supporting 12Mbps. Its primary function is to provide a “bullet-proof”

system updating process via an external USB stick. When the AVR400 is powered up IC162 rst self

boots, then interrogates the rest of the system – if it receives the wrong response (e.g. if a previous

update failed part way through) then the unit will appear dead. However IC162 will be constantly inter-

Page 15

rogating the USB socket and insertion of a clean USB stick containing only the system rmware will

initiate a complete recovery automatically.

IC164 is a MiniLogic ML61C282PR precision voltage detector, with a threshold of 2.8V, built in hysteresis

and a CMOS output, used to reset IC162 at power on.

IC163 is an Intersil USB switch, type ISL54220, which routes the USB socket on the rear panel either to

the Venice 6.2 module, for normal audio applications, or to IC162 when the system SW is being upgraded from a USB stick. Note that it is positioned underneath the Venice 6.2 module, close to the USB

socket.

The USB high side power switch IC168 is close to IC163. It is a Richtek RT9702A fed from the main +5V

power supply. It is rated at 1.1 amps output and can ag up a fault condition on the USB bus from pin 3;

this is routed to IC162.

The Frontier Silicon Venice 6.2WB module is plugged into the input board via a 64 way connector CN62. This WB version of the module supports Band 3 DAB/DAB+ digital radio for use in Europe,

Australia, Canada, Korea and other Digital Radio markets. It also supports USB2, and Ethernet up to 100

Mb/s, enabling the AVR400 to be a network audio client. A spare copy of the AVR400’s unique MAC

(Media Access Controller) address can be found on the screening can of the Venice 6.2 module. Its FM

radio function is not used.

The Venice 6.2 is operated in slave mode via the UART pins 9 and 10 on CN62. These connect to the sub

micro IC154. The USB I/O signal pins are 11 and 12, routed to the USB switch IC163. The other USB pins

are not used. Pins 26, 27, 28 and 29 make up an SPI bus to work with the Ethernet PHY IC161 (pin 33

receives interrupts from IC161).

Audio is decoded inside the Venice 6 (i.e. from AAC, FLAC, MP3, WMA or WAV) and sent out by two

routes. Pin 32 carries an SPDIF signal (at 48ks/s) for the main system and pins 64 and 63 carry L/R linear

audio for zone 2 to the volume control IC101.

The Venice 6.2 requires +3V3 at up to 300mA average and +1V2 at 200mA average for the core of its

main processor. 3V3 is provided from the main +5V supply via the three terminal regulator IC165 – this

also provides the soft start signal to pin 2 of the 1V2 regulator IC167 (also fed from +5V with some voltage drop provided by diodes D803/4). Both regulators are SM types, positioned underneath the Venice

6.2 module.

IC161 is a Micrel KSZ8851 single port Fast Ethernet MAC/PHY controller with an SPI interface. It has a

12KB receive bμFfer and a 6KB transmit bμFfer. It has its own 25MHz crystal oscillator X777. Its 4 I/Osgo

to the Ethernet socket JK52 on the back panel. Its +3V3 power rail is derived from the board’s +5V

supply via the three terminal regulator IC166.

AVR400 RS232 board

This is a daughter board connected to the Input Board via an 18 way plug and socket BN71. The circuitry

is shown on page 14 of the schematic diagram.

It contains two 9 way D-type board mounted plugs JK71 and JK72. JK71 is for RS232 control of the

AVR400. JK72 is used to control an iPod or iPhone via an Arcam rDock or rLead (the latter also supports

iPads).

The RS232 dual transmitter and receiver IC73 is an ST3232 run from the standby +5V supply via D721/

R727 and a series pnp transistor Q722 in common emitter mode referred to the +12V rail. Q721 provides

Page 16

the necessary level shifting. IC73 includes internal charge pumps to convert CMOS logic level inputs

to +/-5V RS232 level outputs and +/-25V tolerant RS232 inputs to CMOS logic level outputs. Maximum

rated speed is 300kb/sec.

JK73 is a dual mono 3.5mm jack socket providing two +12V trigger outputs Z_1 and Z_2. The series pass

transistors Q712/715 are pnp T0-92 types with emitters referred to the +12V rail via the paralleled 4.7R

resistors R714/715 and R711/712. In conjunction with the pairs of diodes D711/712 and D714/715 this

provides current limiting at approximately 200mA if the trigger outputs are inadvertently shorted to

ground.

JK72 is a dual 3.5mm mono jack socket providing inputs for two modulated infra-red remote control

signals. These are connected to the opto-isolators IC72 and IC71. Note the use of the standby power

supply ST+5V for the subsequent logic.

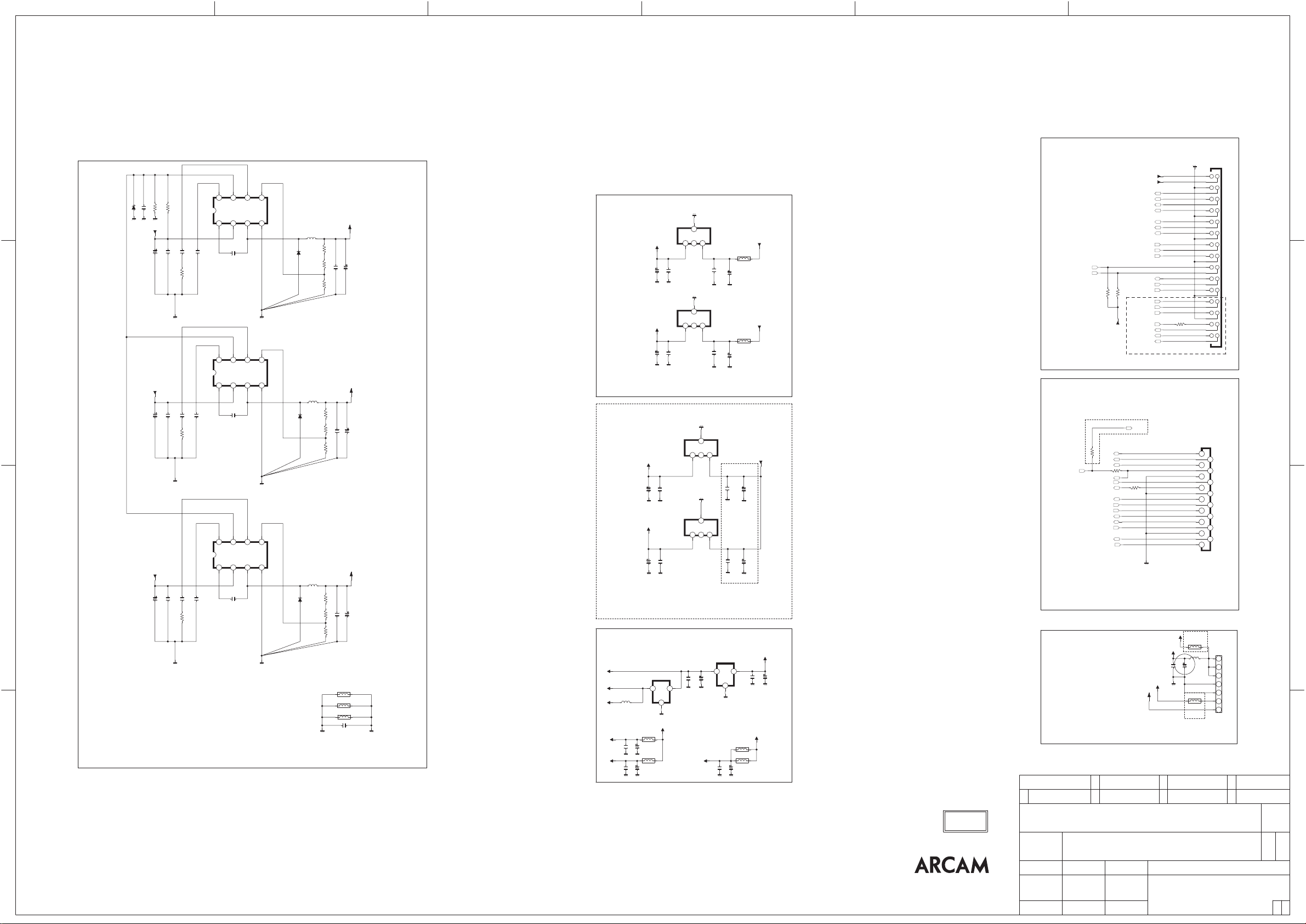

AVR400 HDMI Input/Output Board

The HDMI Board is described on pages 6 – 10 of the schematics diagrams. Note that it has components

tted to both sides of the PCB. HDMI stands for High Denition Multimedia Interface. The AVR400’s

system supports certain parts of the HDMI 1.4a specication (3D video compatibility and Audio Return

Channel)

The HDMI Board has 5 type A HDMI input sockets and one type A HDMI output socket, which are ush

with the back panel. It gets its power via the hard wired connector and ribbon cable CN61 and communicates with the Input Board via two ex foil cables attached to connectors CN104 (17 ways) and

CN105 (19 ways). It is tted with a 30 way socket BN301 which attaches to a daughter board handling all

analogue video I/O signals (the Analogue Video Board).

The HDMI Board contains 10 separately regulated local power supplies, mostly derived from the

unregulated but hum ltered +15V supply on the Power Supply Board. This is input on pins 3 and 4 of

the hard wired connector CN61 for +15V and pins 5, 6 and 7 for the ground returns. Pins 1 and 2 are not

used. See page 10 of the schematic diagram for all but the last of these supplies, as described below.

IC923, IC927 and IC930 are all Sanken SI-8005Q 3.5 Amps step-down switching regulators operating at

500kHz +/-10% and drawing power from the +15V line. They are used to generate +3.3VDD, +1.8VDD

and +1.8VH1 (video processor supply) respectively. The potential dividers in their outputs (R839+R844/

R847, R838+852/R851 and R841+843/840) are used to set the required voltages.

All other local power supplies use linear SM 3-terminal regulators.

IC922 and IC929 provide +2.5VH1 and +2.5VH2 for the two DDR memory chips supporting the video

processor. The source supply is +3.3VDD.

IC925 is a KIA7809 generating +8VA from the system’s +15VA line (NOT the unregulated +15V used

elsewhere on the board). This is further dropped to +5VA by IC924, a KIA1117S50. Inductor L860 provides

decoupling for the +5VH1 line. The video processor digital power supply lines +3.3VH1, +3.3VH2 and

+1.8VH2 are sourced from the +3.3VDD and +1.8VDD lines via L-C decoupling.

The video ADC’s analogue supplies, +3.3VA and +1.8VA, are generated from the +5VA line via IC926

(NJM2845DL133) and IC928 (NJM2845L118) respectively.

The 10th regulator, IC917, an NJU7754 found on sheet 9 of the schematic, is used to provide +5V to the

HDMI output socket. It is enabled via SW_P+5V and derives its input from the +8VA supply described

abov

Page 17

The HDMI input SOC, IC901, is a 144 pin LQFP Analog Devices ADV3014B. This is a 4 into 1 HDMI 1.4a

multiplexer and is connected to inputs 4 and 5 (VCR and PVR) on the rear panel (JK95 and JK96). The

other two inputs on IC901 are not used. The core power supply is +1.8V and the receiver terminator

supply voltage is +3.3V. Note that most power supply decoupling components are on the underside of

the PCB. +5V detect and hot plug assert control is carried out by the complementary pairs of switching

transistors Q904/907 and Q910/909. The video system clock is provided by a 28.63636MHz crystal X901

connected across pins 101 and 102.

Pin 63 is set low by R602 meaning IC 901 is controlled by I2C at 3.3V via pins 78 (HDMI_SDA) and 79

(HDMI_SCL) from IC902. The HDMI output from IC901 is sent to input A of IC902.

IC902 is an Analog Devices ADV7844, packaged in a 425 pin BGA. It has a 4-input HDMI 1.3 receiver and

one video input supporting standard analogue video formats, from 525/625i up to 1080p, with 12-bit

ADCs. Its primary function is to prepare these signals for the main video processor IC906. Its second

function is to extract digital audio from the HDMI signals, including the reconstruction of a good quality

master clock, and to output all this in I2S or SPDIF format to the DSPs on the Input Board.

JK92 (AV), JK93 (SAT) and JK 94 (BD) connect to 3 of IC902’s HDMI input ports. Hot plug detect on

these 3 inputs is carried out by the complementary pairs of switching transistors Q905/906, Q908/901

and Q902/903. The 4th input receives the output of the HDMI switch IC 901. The core power supply is

+1.8VH2 and the receiver terminator supply voltage is +3.3VH2, with heavy local L-C decoupling. Note

that most of these power supply decoupling components are on the underside of the PCB. The video

system clock is provided by a 28.63636MHz crystal X902.

IC902 has a 256Mb SDRAM IC904 connected via 9 x 4-way 33 ohm resistor packs. This is used as a line/

frame store for digitizing the analogue video signals (CVBS, S-Video and Y, Cr, Cb) received from the

external video inputs and also separate i-Pod derived analogue video signals. It runs from the +2.5VH2

supply with further local decoupling components mounted on both sides of the PCB.

The 12-bit RGB video outputs are sent via 10 x 33ohm resistor packs to the tri-state bμFfers IC911 and

IC912. A 10-bit subset of these is also sent to the video processor IC906. Note that the critical video clock

is expanded to drive two output lines HD_VCLK1 (for IC906) and HD_VCLK2 (for IC911) via IC905 and 3 x

33ohm resistors.

The extracted digital audio outputs are sent as I2S and SPDIF signals to the audio DSPs on the input

board via 2 x 33 ohm resistor packs and the switch IC903. IC903 is enabled via Q913.

The video processor IC906 is an ST (formerly Genesis) “Torino” type FLI30336AC in a large 416 pin

BGA package. It is used to de-interlace and scale all the AVR400’s video inputs to the required output

resolution(s) up to 1080p and also to generate the system OSD (on screen display). Note that IC906’s

analogue video inputs are not used in this application and are either grounded via an array of resistors

and coupling capacitors close to one long edge of the heatsink or left open (R879-882 are no ts).

IC906 dissipates considerable power (about 4 watts) and is thus equipped with a heatsink soldered

to the PCB via two pins. Its core voltage is +1.8VH1, with +2.5V_DDR being used for its RAM bus and

+3.3VH1 for I/O and 19.66MHz crystal clock X903, all followed by copious local L-C decoupling. Note that

the decoupling capacitors and series inductors required are mounted on the underside of the PCB.

IC906 supports two 256Mbit DDR-1 500MHz 2.5V SDRAMs (IC908 and IC909) via a mix of 33R and 0R

series resistors in the data busses. On the other side of IC906 is its 32Mbit 3.3V ash memory IC907 (Macronix MX29LV320). IC931 is an Atmel AT24C64C 64K EEPROM with +3.3VH1 power.

Page 18

Q914 and Q915 (on the underside of the PCB) send BYPASS_ON and BYPASS_OFF logic signals from

IC906 to the array of 4 x 20-bit non-inverting line driver/bμFfers with tri-statable outputs, IC911/912 and

IC915/916. These are arranged as a 40 way 2-in, 1-out fast switch to bypass IC906 when required (e.g.

if 3D video is present). The video is in 12-bit RGB format and 4 more bμFfers are required for the video

clock, H and V syncs and the DE (data enable) line, thus using up all of the available 40 ways. See sheet 9

of the schematic diagram. Power is provided via local L-C decoupling from +3.3VH2.

The HDMI output is handled by IC918, an Analog Devices ADV7511 in a 100 pin LQFP package. It is a

225MHz output part that can handle 12-bit 1080p video (up to 165MHz clock speed) and embedded HD

audio. It is compatible with certain parts of the HDMI 1.4 specication, supporting 3D video and an ARC

(audio return channel).

As with the other Analog Devices parts IC918 uses two power rails, namely +1.8VH2 and +3.3VH2. The

necessary decoupling capacitors are mounted on the underside of the PCB.

In the AVR400’s implementation the HDMI audio output is limited to stereo rather then 8 channels – via

I2S0 (pin 12), plus MCLK (pin 11), SCLK (pin16) and LRCLK (pin 17). SPDIF from the AVR400 is input to pin

10.

The ARC signal, if received from a downstream sink such as a TV, is output from pin 46 of IC918 and sent

via back to the input board. Note that IC921 is not tted.

The HDMI output is via JK97, a type A HDMI socket. As the AVR400’s output is partly HDMI 1.4 compliant,

pin 14 now becomes the HEAC+ and pin 19 HEAC- as well as HPD (Hot Plug Detect). However, because

the Ethernet part of the HDMI1.4 specication is not supported by the AVR400, the ARC is congured

by the sink to be carried in single (i.e. non-dierential) mode using HEAC+ as the signal line. HEAC+ and

HEAC- are then AC coupled to pins 52 and 51 of IC918 via the 1μF series capacitors C439 and C428. R771,

R777, R785, R795 and R799 bias the inputs and load the cable correctly.(Note – HEAC is short for HDMI

Ethernet and Audio (return) Channel).

Q916 is a twin n-channel MOSFET which only turns on when +5VH1 is present. This isolates the DDC

clock and data lines when the AVR400 is turned o.

IC917 is a low dropout voltage regulator feeding +5V power to pin 18 of JK97 from the +8VA supply,

when enabled by the SW_P+5V line.

Analogue video output of digitized and processed 10-bit video from IC906 is available from the AVR400

via the video encoder IC919 – an Analogue Devices ADV7342B. Composite, s-video and component

video are supported, although only component analogue video is output by the AVR400.

IC919 is in a 64 pin LQFP powered from the +18VA and +3.3VA lines. Once again most decoupling components are on the underside of the PCB.

The 6 x 11-bit video DACs inside IC919 are each loaded with 300R to ground before being AC coupled to

IC913. This is a JRC NJM2566 6-channel video amplier for SD and HD signals, powered from the +5VA

line. The FS_SEL signal on pin 17 sets the bandwidth on component video to 13.5MHz or 30MHz, to suit

progressive SD or HD signals respectively. The composite and s-video bandwidths are xed at 6.75MHz.

The outputs go to the analogue video daughter board via the 30 way socket BN301.

Note that the composite and s-video outputs are not actually used in the AVR400 so are not wired

beyond CN301 on the daughter board. The Y, Cr, Cb component video outputs are terminated with 75

ohm series resistors on the Analogue Video daughter board described next.

Page 19

AVR400 Analogue Video Board

This is connected into the rest of the system via the HDMI board using CN301.The circuitry is shown on

sheet 13 of the schematic diagram.

The purposes of this PCB are:

(1) to switch between the various analogue video inputs (comprising 4 each composite and s-video

and 3 component video)

(2) to route the chosen video signal to the HDMI board for processing

(3) to provide one set of zone 1 video component video outputs

(4) to provide one zone 2 video output (composite video, with its own OSD) from any of the 4 com-

posite video signal inputs.

The PCBs power supplies are +9VV and +5VV, generated from the three-terminal regulators IC88 and

IC89 from the system’s +15VA supply on pin 1 of CN301. Pin 2 carries the system’s -15VA supply – this is

unused on this PCB.

Note that all video inputs are terminated with 75ohm resistors to ground close to the actual sockets.

IC81 is a JRC NJW1321 – a wide bandwidth video switch with 4 inputs, 2 outputs and a 6dB amplier.

It is used to select between the 4 composite and 4 s-video inputs routed to the HDMI board and also

to output any one of the 4 composite video inputs to the On-Screen Display Controller IC83. IC81 runs

from the +9VV supply, consuming about 85mA so it gets quite hot. It is controlled by i2C commands on

pins 15 and 16.

IC82 is also an NJW1321. It selects between the 3 component video inputs and its fourth input is

unused. Its Y, Cr, Cb outputs and the Y, C and CVBS outputs of IC81 are then AC coupled to IC84 – an

NJM2566 6 way video amplier/lter with 6dB gain, powered from the +5VV rail. Its outputs are also AC

coupled and terminated with 75 ohm series resistors before being routed to CN301.

IC86 is a hex inverter used to bμFfer the 3V3 logic level OSD control signals from the HDMI board and

convert them to 5V level for IC83. This is a Sanyo LC74763 in a 30 pin SM package running from the +5VV

rail. It has two crystal oscillators X801 (17.734MHz) and X802 (14.318MHz) to provide composite video

outputs for both PAL and NTSC standards.

IC86’s video input signal is AC coupled to and bμFfered by the emitter follower Q802 before pin 18.

Similarly its output signal (which now includes an OSD) is bμFfered by the pnp transistor Q801 and AC

coupled to the video amplier/switch IC85 (NJM2244), used here purely as a composite video amplier/

lter with 6dB gain. Its AC coupled output to the Z 2 OUT single phono socket JK85 is terminated with a

68 ohms series resistor.

Page 20

6

12345

FROM POWER TRANS

CN94

54321

GND

GND

V DISP

Filament V(AC)

M_GND

10

R902

4.3V

D901

47/25V

D902

M_GND

C908

3.3

R901

3.9V

D916

1N4003

2010.04.12

C903 : 100uF/63V -> 47uF/63V 2EA

100K

0.01uF

R905

OPEN

C906

C960

C907

47/63V

47/63V

FAN

321

GND

CN91

FAN

CUP12326Z-3

FAN

GND

CN96

2 1

GND

21

FAN

CN95

D

FROM FAN

FROM AMP BD

A_GND

Q912

HVTKRA107MT

R959

D906

M_GND

STBY+5V

10K

R989

L.E.D

STBY

PWR ON

220

R978

OPEN

R980

+15V

100

R963

100K

C940

47/25V

C941

47/25V

A_GND

R964

100

-15V

Q909

C107M

RED

GREEN

D905

G R

0.01uF

C927

M_GND

-15V

Q908

C107M

Q913

C107M

Q903

330

R979

OPEN

0.01uF

R981

C928

C107M

M_GND

BN93

HP_L

HP_GND

HP_GND

HP_GND

HP_R

HP_DETECT

FRONT AUX_L(MIC)

A_GND

A_GND

A_GND

FRONT AUX_R

+5VD

+5VD

GND

D_

F_OPT

D_GND

CWB1B01312047

13 12 11 10 9 8 7 6 5 4 3 2 1

TO AMP BD

SWITCH

C901

BN502

2 1

CWB4F032950UZ

470P

S913

KSH1A001ZV

CUP12326Z-2

C

B

TO HEADPHONE BD

MP

REVISION12

3

SCHEMATIC DIAGRAM

MODEL

AVR400

APPROVECHECKDESIGN DRAWING NO

4

5

6

7

A

SHEET

1

15

R903

0

R904

3.3

C903 : 47uF/50V -> 47uF/25V

Q901

C1027Y

47/63

C909

R961

10K

C939

47P

A

- +

L-CH

A-INPUT

A=-Rout/Rin=-10K/1K=-10

FRONT AUX_L(MIC)

271

FRONT AUX_R

HP_RELAY_ON

8

Filament V(AC)

C903

C902

0.022u

M_GND

2010.04.12

R906

1.2K

13V

D903

27V

D904

Q902

C107M

M_GND

R960

470

R-CH

-+

B-INPUT

B

B+INPUT

-15V

V-

A+INPUT

4321

MIC_RELAY_ON

8

D907

M_GND

FRONT

1.25mm Angle FFC

CN101

CUP12326Z-1

M_GND

3123

LED

30

STBY(LED)

VOL_EN1

28

VOL_EN2

27

KEY1

262414 16

KEY2

25 29

VFD_CS

VFD_CLK/Z2 OSD CLK

VFD_DATA/Z2 OSD DATA

22

VFD_RST

21

IR_IN

20

MIC_IN

1915

HP_IN

18

HP_MUTE2

17

ST +5V

+5VD

D_GND

F_OPT

1393 7

D_GND

12

HPL_OUT

11

HP_GND

HPR_OUT

KEY_INPUT_INT

8 10

+15V

-15V

6

MIC_SIGNAL

5

HP_RELAY_ON

42

AUX_L

A_GND

AUX_R

1

FIP91

ESD

C953 OPEN

R977 OPEN

D908

D909

M_GND

REMOTE_IN

D917

ST+5V

KEY_INPUT_INT

R932

OPEN

D_GND

A_GND

100

R984

47/25V

C958

A_GND

100

R985

C959

47/25V

8 7 6 5

IC904

V+

A OUTPUT

B OUTPUT

A

- +

A-INPUT

R934

OPEN

JW901

OPEN

OPEN

CHGND

OPEN

RC901

VccGNDVOUT

321

150P

C922

C924

100/16V

OPEN

R986

M_GND

4.7

R931

0.1uF

C926

C925

10/16V

M_GND

Q906

HVTKRA107MT

M_GND

Q907

HVTKRA107MT

M_GND

LED

KEY1

KEY2

MIC_RELAY_ON

HP_IN

H/P MUTE

+5VD

D_GND

F_OPT

D_GND

HPL_OUT

HP_GND

HPR_OUT

+15V

-15V

MIC_SIGNAL

HP_RELAY_ON

R933

OPEN

56K

R987

-+

B-INPUT

B

B+INPUT

V-

A+INPUT

A_GND

4321

56K

R988

+5VD

S901

KEY_1

HPL_OUT

GND

HPR_OUT

KEY_2

R937

100

R938

100

MENU

1K

R921

1000P

C920

M_GND

S907

DIRECT

1K

R926

1000P

C921

M_GND

+15V

-15V

MIC SIGNAL

C929

10/50V

R935

4.7K

Q904

C2874

HP_GND

R936

4.7K

Q905

C2874

C930

10/50V

INPUT-

DISPLAY

VFD_CS

VFD_CLK

VFD_DATA

VFD_RST

F2

F2

LGND

VDISP

5862

61

C905

0.022u

10

R911

M_GND

0.1uF

C913

0.1uF

C914

C957

100/16V

+5VD_SYS

R912

4.7

S902

S908

-15V

S904

S903

INPUT+

1.5K

R922

ZONE

1.5K

R927

INFO

OK

1.8K

2.7K

R923

R924

S909

S910

MUTE

VOL-

1.8K

2.7K

R928

R929

IC902

8 7 6 5 4 3 2 1

J966

+15V

C931

47/25V

C932

47/25V

J967

CS

VDD

OSCO

DGND

RESET

5354

8.2K

R910

39P

C912

S906

S905

MODE

3.3K

M_GND

R925

S911

S912

VOL+

3.3K

M_GND

R930

R917

R918

1K

R919

1K

R920

1K

1K

IC902 NJM4556AL

A=1+(Rout/Rin)=1+(3.9K/1K)=4.9

-

L-CH

C933

680P

R941

3.9K

56K

56K

HP_GND

FRONT AUX_L

FRONT AUX_R

+

CP

R942

R943

DA

DO

C915 0.1uF

C916

C917 1000P

C918 1000P

+15V

-15V

MIC SIGNAL

-15V

HP_GND

TEST

1000P

0.1uF

C919

M_GND

R-CH

1K

R944

1K

R945

CFLHCA16S202T

R909

10

47

R913

47

R915

IC901

HVITC74HCT7007F

1 2 3 4 5 6 7

-++15V

C934

680P

R946

3.9K

VFD_DATA

47

VFD_CLK

R914

VFD_CS

47

VFD_RST

R916

C935

330uF/10V

56K

R947

56K

R948

C936

330uF/10V

HP_IN

D_GND

F_OPT

D_GND

IC

IC

F1

F1

NC

25556

1674849505152 557

C904

0.022u

M_GND

40V

47K

47/63

C910

0.01uF

C911

8 7 6 5

+15V

V+

IC903

NJM2068M

A OUTPUT

HP_L

RL901

A_GND

65

RL902

34

HP_R

Q911

A107M

Q910

A107M

R907

C943

150P

R965

10K

271

M_GND

100K

B OUTPUT

65

34

R908

M_GND

891011121314

M_GND

HIGH : PWR_ON(LED)

LOW : STBY(LED)

R956

R957

MIC SIGNAL OUT

MIC SIGNAL IN

-15V

2.2K

1.5K

A_GNDA_GND

HP_RELAY_ON

MIC_RELAY_ON

C938

10/50V

10K

R958

470

R962

0.047

C937

470P

C942

A_GND

M_GND

MIC SIGNAL IN

C944

10/50V

56K

R955

A_GND

FRONT AU

X_L

HP_L

HP_R

FRONT AUX_R

D

C

B

TO INPUT BD

A

J.I.H

10.11.17

L.J.H S.H.S

10.11.17 10.11.17

2326SCMZ

(FRONT)

1

1

Page 21

Page 22

Page 23

Page 24

Page 25

6

12345

ADV3014 Decoupling Capacitor

CVDD_1V8_3014

9R005Z

L803

L806

9R005Z

47K

R635

C119

TVDD_3V3_3014

C121

1K

R636

R659

1K

R661

R638

C151

C148

10uF/6.3V

0.1uF / 16V

10uF/6.3V

0.1uF / 16V

22K

22K

Worst Measured Currents

428mA

C113

C116

25V/0.01UF

Worst Measured Currents

238mA

C102

C109

25V/0.01UF

KRA102S

Q903

0.1uF

KRA102S

Q908

0.1uF

C115

C122

0.1uF / 16V

C106

C125

0.1uF / 16V

#21: HPD Part

#21: HPD Part

C131

C117

0.1uF / 16V

25V/0.01UF

C126

C123

0.1uF / 16V

25V/0.01UF

KRC103S

Q902

KRC103S

Q901

+1.8VH2

D

+3.3VH2

47K

HP DET

+5V

GND

DDC DATA

DDC CLK

C

B

CE REMOTE

D1 SHIELD

INPUT-3

D1 SHIELD

D2 SHIELD

D2 SHIELD

DDC DATA

DDC CLK

CE REMOTE

D1 SHIELD

D1 SHIELD

INPUT-2

D2 SHIELD

D2 SHIELD

HP DET

NC

CK-

CK+

D0-

D0+

D1-

D1+

D2-

D2+

+5V

GND

NC

CK-

CK+

D0-

D0+

D1-

D1+

D2-

D2+

CEC

R658

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

JK94

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

JK93

DVDD_1V8_3014

C130

L805

9R005Z

0.1uF / 16V

25V/0.01UF

R660

R639

47K

Worst Measured Currents

390mA

C120

10uF/6.3V

+3.3VH2

C128

1K

R632

10K_NC

#7: Added pull-up

1K

10K_NC

R633

#7: Added pull-up

0.1uF / 16V

L804

9R005Z

C107

C108

DVDDIO_3V3_3014

0.1uF / 16V

25V/0.01UF

C142

C110

C134

Worst Measured Currents

2.3mA

10uF/6.3V

0.1uF / 16V

R657

100

R634

100

C135

C133

0.1uF / 16V

25V/0.01UF

25V/0.01UF

C132

C129

C136

0.1uF / 16V

25V/0.01UF

HDMI_HPD2

PWR2

HDMI2_DDC_SDA

HDMI2_DDC_SCL

HDMI2_CK-

HDMI2_CK+

HDMI2_D0-

HDMI2_D0+

HDMI2_D1-

HDMI2_D1+

HDMI2_D2-

HDMI2_D2+

HDMI_HPD3

PWR3

HDMI3_DDC_SDA

HDMI3_DDC_SCL

HDMI3_CK-

HDMI3_CK+

HDMI3_D0-

HDMI3_D0+

HDMI3_D1-

HDMI3_D1+

HDMI3_D2-

HDMI3_D2+

+1.8VH2

25V/0.01UF

C124

0.1uF / 16V

25V/0.01UF

R655

47K

R656

PVDD_1V8_3014 TXAVDD_1V8_3014

Worst Measured Currents

35mA

L808

+1.8VH2 +1.8VH2

9R005Z

C139

C112

C137

0.1uF / 16V

Worst Measured Currents

4.33mA

C127

C114

0.1uF / 16V

C118

0.1uF / 16V

25V/0.01UF

+1.8VH2+1.8VH2

25V/0.01UF

10uF/6.3V

L801

9R005Z

C140

10uF/6.3V

Option : Front HDMI Input port

CN63

HP DET

CE REMOTE

DDC DATA

DDC CLK

CK SHIELD

D1 SHIELD

FRONT_HDMI

D1 SHIELD

D2 SHIELD

D2 SHIELD

TX_EN

+3.3VA

+3.3VA

D2+

+5V

+5VA

GND

CK-

CK+

D0-

D0+

D1D1+

CJP23GB210ZY NC

2

4

6

810

1214

16

1820

D2-

22

L866

TXEN

1

2

3

CEC

3

4

5

5

6

7

7

8

911

9

10

11

12

1315

13

14

15

16

17

17

18

1921

19

20

21

22

23 1

23

DDC DATA

DDC CLK

CE REMOTE

D1 SHIELD

INPUT-5

D1 SHIELD

D2 SHIELD

D2 SHIELD

+3.3VH2+5VA

9R005Z_NC

HP DET

Worst Measured Currents

22.7mA

L807

9R005Z

C138

C104

C105

10uF/6.3V

0.1uF / 16V

TXPLVDD_1V8_3014TXPVDD_1V8_3014

ed Currents

Worst Measur

24.3mA

L802

9R005Z

C141

C101

C103

10uF/6.3V

0.1uF / 16V

1K_NC

47K_NC

L865

9R005Z_NC

R640

R643

22K_NC

R642

0.1uF_NC

C149

1K

47K

R647

R650

19

+5V

GND

NC

CK-

CK+

D0-

D0+

D1-

D1+

D2-

D2+

JK96

R646

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

ADV7844 Worst Measured Currents

1.8V Total : 904.33mA

3.3V Total : 240.3mA

C111

0.1uF / 16V

25V/0.01UF

25V/0.01UF

KRA102S_NC

#21: HPD Part

Q912

Q911

KRA102S

Q909

22K

0.1uF

C146

KRC103S_NC

#21: HPD Part

CEC

D

DVDDIO_3V3_3014

ADV3014_RESET

2.2K

R614

C144

X901

105

DDCA_SCL

CVDD

CGND

0.1uF_NC

0

28.6363MHz

PVDD_1V8_3014

R612

100

101

102

103

104

XTAL

PVDD

PVDD

PGND

PGND

XTAL1

HP_CTRLA

RTERM

5V_DETA

DDCA_SDA

DDCC_SCL

CGND

CVDD

CGND

RXC_1-

RXC_0+

TVDD

RXC_0-

RXC_C+

RXC_C-

101112131415161718192021222324252627282930313233343536

#12: Added Pull-down 500 ohm

R645

1K_NC

R641

47K_NC

R644

100_NC

R858

0_NC

10K

R857

R857 : Front HDMI don`t used

KRC103S

Q910

1K

R631

R654

47K

R652

100

R610

R611

R603 10K

DVDD_1V8_3014

1K(1%)

1K(1%)

47P

C145

47P

C143

106

107

108

108 107 106 105 104 103 102 101 100 99 98 97 96 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81 80 79 78 77 76 75 74 73

109

109

110

110

111

111

112

112

RXA_C-

113

113

RXA_C+

114

114

TVDD

115

115

RXA_0-

116

116

RXA_0+

117

117

CGND

118

118

RXA_1-

119

119

RXA_1+

120

120

TVDD

121

121

RXA_2-

122

122

RXA_2+

123

123

HP_CTRLB

124

124

5V_DETB

125

125

DGND

126

126

DVDD

127

127

DDCB_SDA

128

128

DDCB_SCL

129

129

CVDD

130

130

CGND

131

131

RXB_C-

132

132

RXB_C+

133

133

TVDD

134

134

RXB_0-

135

135

RXB_0+

136

136

CGND

137

137

RXB_1-

138

HP_CTRLC

138

RXB_1+

5V_DETC

139

DDCC_SDA

139

TVDD

140

140

RXB_2-

141

141

RXB_2+

142

142

143

143

144

144

123456789

R867

0

R613

TEST16

RESETB

PWRDNB

TVDD

RXC_2-

RXC_1+

DVDDIO_3V3_3014

10K

DVDD

DGND

TEST13

TEST14

TEST15

IC901

CVIADV3014BSTZ

HP_CTRLD

5V_DETD

DGND

DVDD

RXC_2+

DVDD_1V8_3014

ADV3014_INT2

ADV3014_INT

ADV3014_INT_TX

HDMI_SCL

2.2K

R620

R606

10K

R866

0

TEST9

INT_TX

TEST10

TEST11

TEST12

DVDDIO

DGNDDIO

DDCD_SDA

TVDD

RXD_C+

DDCD_SCL

CVDD

CGND

RXD_C-

HDMI_SDA

R605

R619

DVDD_1V8_3014

0

0

R618

R604

100

100

SCL

INT

INT2

DVDD

DGND

TXPLGND

TXPGND

TXPLVDD

TXPVDD

CVDD

CGND

RXD_1+

RXD_1-

CGND

RXD_0+

RXD_0-

DVDDIO_3V3_3014

737475767778798081828384858687888990919293949596979899

72

72

TEST7

TEST8

SDATA

71

71

70

70

TEST2

69

TEST6

TEST5

69

DVDDIO

DGNDIO

TEST1

68

68

TEST4

EP_MISO

TEST3

67

67

EP_MOSI

66

66

EP_CS

65

65

EP_SCK

64

64

CSB

63

63

ALSB

62

62

DVDD

61

61

DGND

60

60

CEC

59

59

TXGND

58

58

TX2+

57

57

TX2-

56

56

TXAVDD

55

55

TX1+

54

54

TX1-

53

53

TXGND

52

52

TX0+

51

51

TX0-

50

50

TXGND

49

49

TXC+

48

48

TXC-

47

47

TXGND

46

46

TXAVDD

45

45

TXDDC_SCL

44

44

TXDDC_SDA

43

43

TEST0

42

42

HP_TX

41

41

EXT_SWING

40

40

39

39

38

38

37

RXD_2+

TVDD

RXD_2-

37

363534333231302928272625242322212019181716151413121110987654321

TXPLVDD_1V8_3014

TXPVDD_1V8_3014

TVDD_3V3_3014

CVDD_1V8_3014

R865

DVDD_1V8_3014

TXAVDD_1V8_3014

1K(1%)

8.2K(1%)

R621

R607

TMDS Signal Amplitude Circuit

10K

_3V3_3014 DVDDIO_3V3_3014

DVDDIO

R617

10K_NC

10K

R602

10K

R616

R601

10K_NC

C

HDMI1_D2+

HDMI1_D2-

HDMI1_D1+

HDMI1_D1-

HDMI1_D0+