Page 1

TJ & TJ UNLIMITED JEEP REAR BAR & WHEEL CARRIER

• PART No 565 0010 REAR BAR.

• PART No 575 0012 WHEEL CARRIER.

• PART No 575 0020 TOW HITCH. (ACCESSORY)

• PART No 575 0030 HI-LIFT JACK ATTACHMENTS. (ACCESSORY)

• PART No 575 0040 WHEEL LOCKING NUTS – SET OF 4. (ACCESSORY)

•

PART No 575 0050 LICENCE PLATE LAMP RE-LOCATION KIT (ACCESSORY)

WARNING

NOTE THE FOLLOWING:

♦ This product must be installed exactly as per these instructions using only the hardware supplied.

♦ In the event of damage to any bull bar component, contact your nearest authorised ARB stockist.

Repairs or modifications to the impact absorption system must not be attempted.

♦ Do not use this product for any vehicle make or model, other than those specified by ARB.

♦ Do not remove labels from this bull bar.

♦ This product or its fixing must not be modified in any way.

♦ The installation of this product may require the use of specialized tools and/or techniques

♦ It is recommended that this product is only installed by trained personnel

♦ These instructions are correct as at the publication date. ARB Corporation Ltd. cannot be held

responsible for the impact of any changes subsequently made by the vehicle manufacturer

♦ During installation, it is the duty of the installer to check correct operation/clearances of all

components

♦ Work safely at all times

♦ Unless otherwise instructed, tighten fasteners to specified torque

ARB 4x4 ACCESSORIES

Corporate Head Office

42-44 Garden St Tel: +61 (3) 9761 6622

Kilsyth, Victoria Fax: +61 (3) 9761 6807

AUSTRALIA 3137

Australian enquiries sales@arb.com.au

North & South American enquiries sales@arbusa.com

Other international enquiries exports@arb.com.au

www.arb.com.au

Last Rev Date: 16/10/2006 Page 1 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 2

GENERAL CARE AND MAINTENANCE

By choosing an ARB Bar, you have bought a product that is one of the most sought after 4WD products

in the world. Your bar is a properly engineered, reliable, quality accessory that represents excellent

value. To keep your bar in original condition it is important to care and maintain it following these

recommendations:

Prior to exposure to the weather your bar should be treated to a Canuba based polish on all exposed

surfaces. It is recommended that this is performed on a six monthly basis or following exposure to

salt, mud, sand or other contaminants.

As part of any Pre Trip Preparation, or on an annual basis, it is recommended that a thorough visual

inspection of the bar is carried out, making sure that all bolts and other components are torqued to

the correct specification. Also check that all wiring sheaths, connectors, and fittings are free of

damage. Replace any components as necessary. This service can be performed by your local

authorised ARB Stockist.

REQUIRED TOOLS FOR FITMENT OF PRODUCT:

METRIC SOCKET SET, METRIC RING AND OPEN ENDED SPANNER SET, PHILLIPS AND FLAT SCREW

DRIVER SET, ELECTRIC DRILL AND METRIC DRILL BITS 6 mm, 13 mm AND 17 mm, LARGE HAMMER,

CENTRE PUNCH, HEX KEY SET, PIN PUNCH, GREASE, METAL SCRIBE .

WIRE CUTTERS , SOLDERING IRON & SOLDER, INSULATING TAPE AND ELECTRICAL TERMINAL CRIMPERS

( IF RE-CONNECTING THE FACTORY HI LEVEL STOP LAMP ).

NOTE :- The bearings & seals for the wheel carrier are available as spare parts.

PART No QTY DESCRIPTION

732 0003 2 SEAL

732 0002 2 BEARING

HAVE AVAILABLE THESE SAFETY ITEMS WHEN FITTING PRODUCT:

Protective eyewear

NOTE: ‘WARNING’ notes in the fitting procedure relate to OHS situations, where to avoid a potentially

hazardous situation it is suggested that protective safety gear be worn or a safe work procedure be

employed. If these notes and warnings are not heeded, injury may result.

FASTENER TORQUE SETTINGS:

SIZE Torque Nm Torque lbft

M6 9 Nm 4 lbft

Hearing protection

M8 22 Nm 16 lbft

M10 44 Nm 32 lbft

M12 77 Nm 57 lbft

Last Rev Date: 16/10/2006 Page 2 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 3

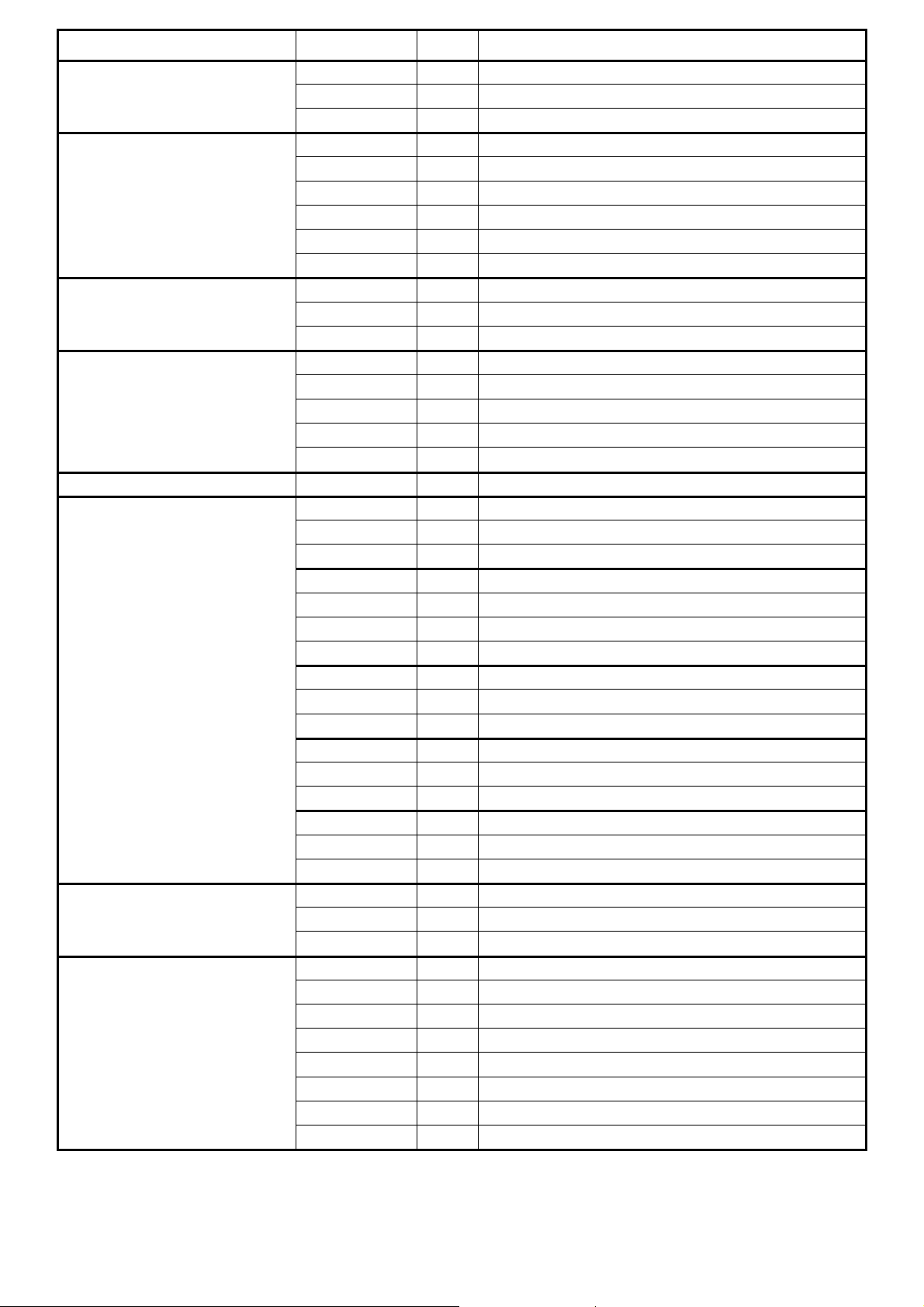

USE PART No QTY DESCRIPTION

)

FITTING SLIDER TO

REAR STEP.

FITTING CATCH HOOK TO

REAR BAR.

FITTING BUMP STOP TO

REAR BAR.

FITTING GRABBER TO

REAR BAR.

PIVOT LOCKING BOLT 615 1222 1 BOLT LOCKING M8 x 50 mm LONG (FINE PITCH

INSTALLATION OF

COMPONENTS TO WHEEL

CARRIER.

REINFORCING BRACKET

FITMENT TO CHASSIS.

REINFORCING BRACKET

FITMENT TO CHASSIS

CONTINUED.

566 5677 1 SLIDER

682 1116 2 SQUARE PLASTIC PLUG

615 1283 2 SELF TAPPING SCREWS

459 0007 1 CATCH HOOK

615 1303 2 CAGE NUT M8 SHORT LEG

615 1022 2 BOLT M8 x 25 mm LONG

458 1046 2 SPRING WASHER M8

458 1044 2 FLAT WASHER M8

3756746 2 PACKER CATCH HOOK

584 8322 1 BUMP STOP

615 1312 2 M6 BUTTON HEAD CAP SCREW x 25 mm

615 1162 2 M6 NUT NYLOC

375 6677 1 GRABBER

615 1303 2 CAGE NUT M8 SHORT LEG

615 1022 2 BOLT M8 x 25 mm LONG

458 1046 2 SPRING WASHER M8

458 1063 2 PANEL WASHER M8

459 0011 1 CATCH ASSEMBLY

615 1263 4 SOCKET HEAD CAP SCREWS M8 x 20 mm LONG

458 1046 4 SPRING WASHERS M8

626 0002 1 STOPPER

458 1046 1 SPRING WASHER M8

458 1044 1 FLAT WASHER M8

615 1028 1 NUT M8

626 0001 1 GRABBER BUFFER

615 1331 2 CAP SCREW COUNTERSUNK M6 x 30 mm LONG

615 1162 2 NUT NYLOC M6

459 0001 1 GAS STRUT ASSY (inc 1 strut, 2 clips, 2 spheres)

615 1132 2 NUT FLANGED M8

458 1044 2 FLAT WASHER M8

459 0008 1 LOCKING PIN

459 0009 1 LOCKING PIN SPRING

459 0010 1 ROLL PIN

375 6886 R 1 BRACKET RIGHT HAND

375 6886 L 1 BRACKET LEFT HAND

615 1291 6 TAB BOLT M12 x 40 mm LONG FINE PITCH

458 1049 22 FLAT WASHER M12

458 1050 14 SPRING WASHER M12

615 1135 6 NUT M12 FINE PITCH

615 1250 2 BOLT M12 x 90 mm LONG COARSE PITCH

472 1570 2 DIA 17 mm CRUSH TUBE x 60 LONG

615 1255 4 BOLT M12 x 40 mm LONG COARSE PITCH

615 1189 8 NUT M12 COARSE PITCH

615 1340 2 BOLT M12 x 50 mm COARSE PITCH

Last Rev Date: 16/10/2006 Page 3 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 4

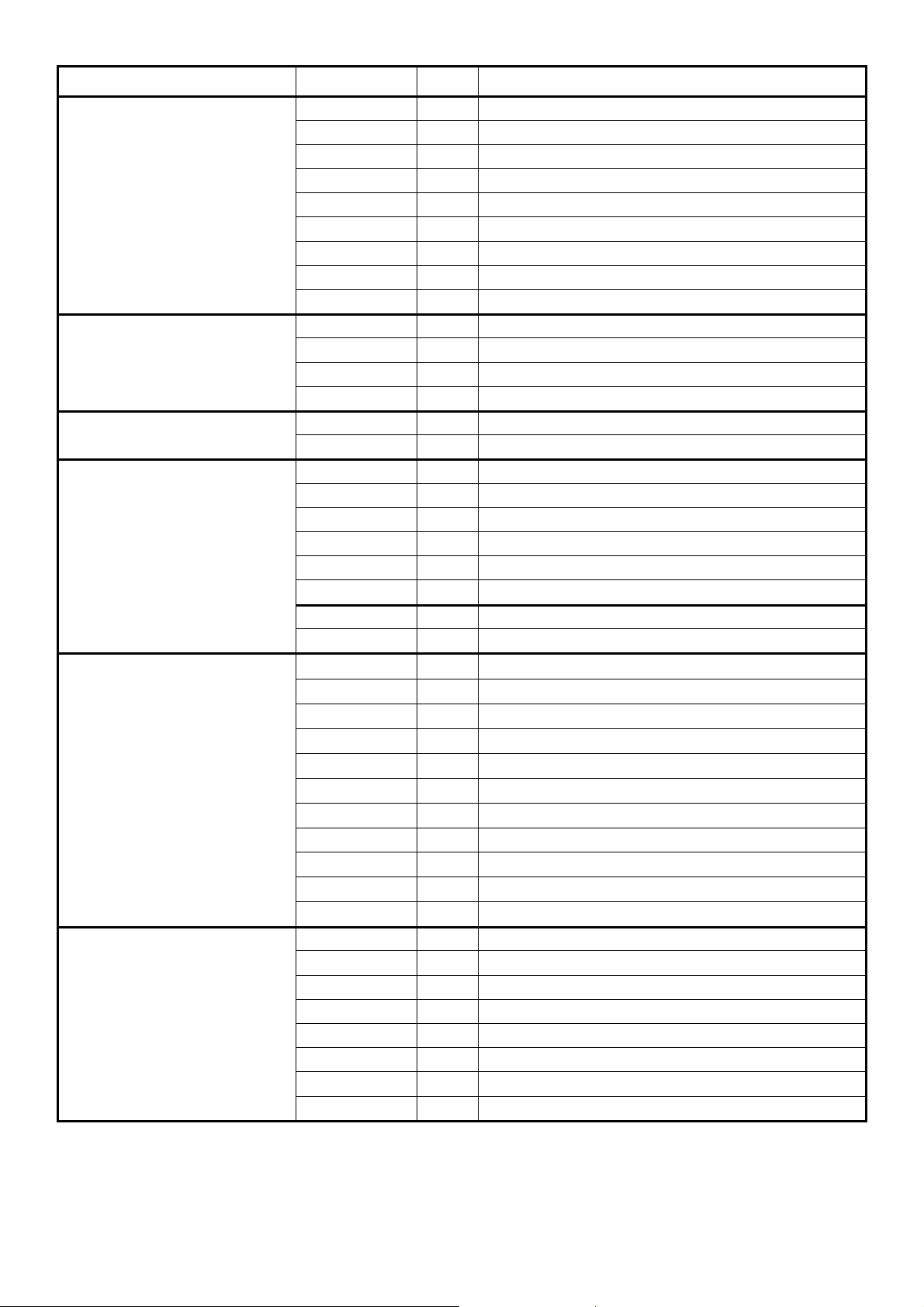

USE PART No QTY DESCRIPTION

BACKING PLATE TO

CHASSIS BEAM.

WHEEL CARRIER TO

REAR BAR.

MISC ITEMS TO REAR BAR

AND WHEEL CARRIER.

WHEEL MOUNTING PLATE

TO WHEEL CARRIER.

WHEEL MOUNTING PLATE

TO WHEEL CARRIER

PINNING BOLT .

HIGH LEVEL STOP LAMP TO

WHEEL CARRIER .

HIGH LEVEL STOP LAMP

WIRING LOOM EXTENSION

TO TAIL LAMP ON VEHICLE .

COVER PANEL FITMENT TO

REAR BAR.

319 9850 1 PLATE CHASSIS BEAM

615 1300 2 CAGE NUT M6

615 1017 2 BOLT M6 x 16 mm LONG

615 1046 2 FLAT WASHER M6

615 1042 2 SPRING WASHER M6

615 1306 2 CAGE NUT M12 SHORT LEG

615 1340 2 BOLT M12 x 50 mm

458 1049 2 FLAT WASHER M12

458 1050 2 SPRING WASHER M12

615 1330 1 NUT M20 NYLOC

615 1329 1 BOLT M20 x 190 mm LONG

636 4506 1 BUSH – ARM ASSY

625 0002 2 SPACER THIN – 9 mm THICK

180 302 4 CABLE TIES - BLACK

458 1299 5 WASHER FLAT NYLON

375 6909 1 WHEEL MOUNTING BRACKET

615 1382 3 WHEEL STUDS ½ “ WITH WHEEL NUT

615 1305 2 CAGE NUTS M12 LONG LEG

615 1355 2 BOLT M12 x 35 mm LONG

458 1007 2 PANEL WASHER M12 GOLD

458 1050 2 SPRING WASHER M12

615 1357 1 BOLT M10 x 30 mm LONG ( WITH WASHERS )

458 1063 1 FLANGE NUT M10

615 1301 4 CAGE NUTS M8 LONG LEG

615 1234 4 BOLT M8 x 25 mm LONG BLACK

458 1047 4 SPRING WASHER M8 BLACK

458 1045 4 FLAT WASHER M8 BLACK

682 1195 1 REAR DOOR BLANKING GROMMET

6821194 1 TWIN CORE CABLE - 750 mm LONG

CR 07 1 CONVOLUTE TUBING - 7 mm x 750 mm LONG

320 104N 1 TAIL LAMP HOUSING WIRING GROMMET

666 005 1 RING TERMINAL

180 701 1 SCOTCH LOCK CONNECTOR

180 302 6 CABLE TIES - BLACK

455 8424 1 COVER PANEL

615 1300 4 CAGE NUT M6

615 1312 2 SOCKET HEAD CAP SCREW M6 x 25 mm LONG

615 1270 2 BOLT M6 x 40 mm LONG

615 1046 4 FLAT WASHER M6

458 1036 4 SPRING WASHER M6

584 8302 2 PACKER BLACK NYLON

625 0003 2 SPACER 8 mm THICK

Last Rev Date: 16/10/2006 Page 4 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 5

K

PREPARATION OF THE VEHICLE

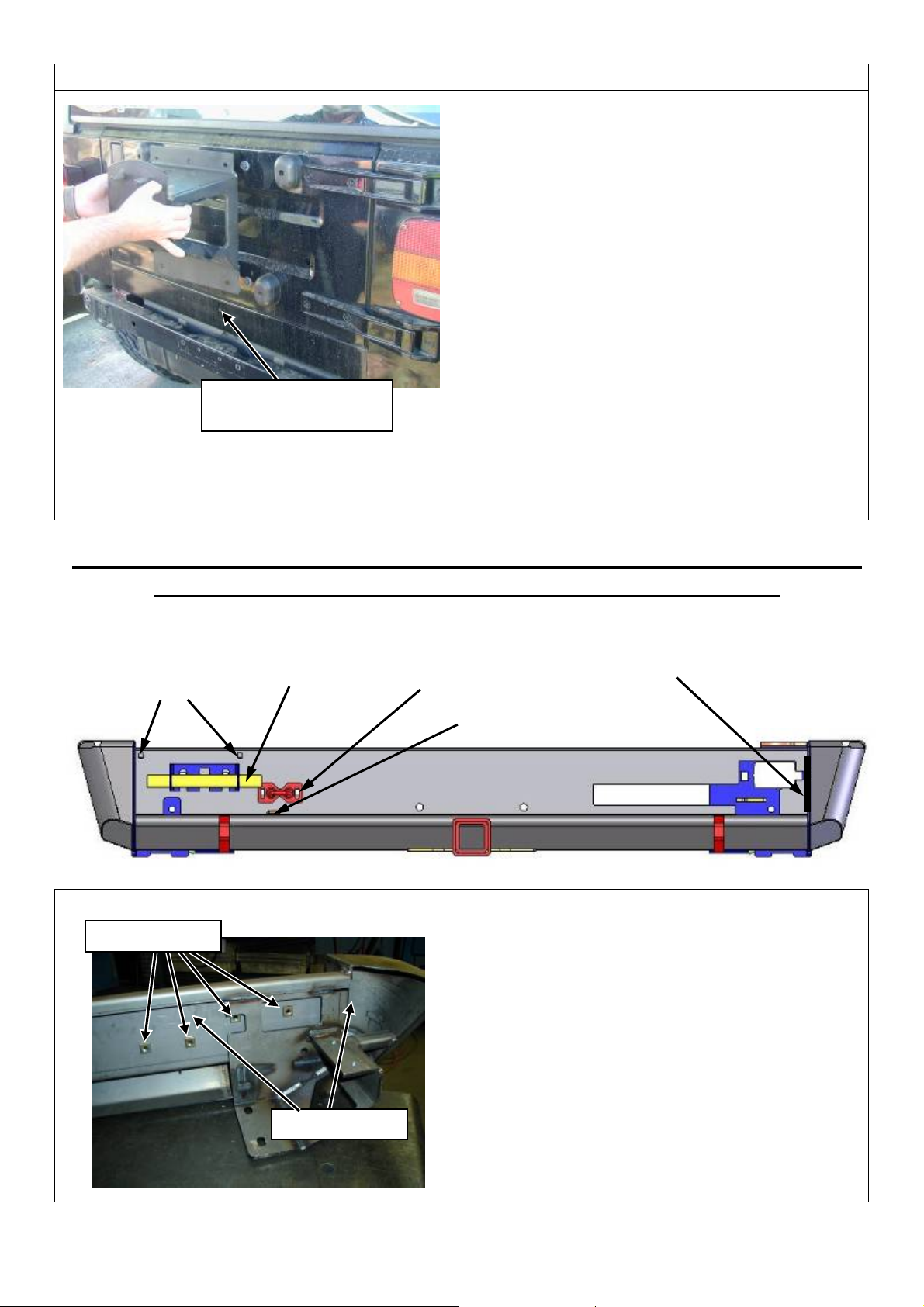

LOCATION OF LOWER

RUBBER STOPPER

1. REMOVAL OF THE FACTORY SPARE

WHEEL CARRIER.

Remove the spare wheel from the vehicle.

Unbolt the factory hi – level stop lamp and

disconnect the wiring loom.

Remove the five bolts that hold the carrier

to the rear door – remove the carrier and

replace the five bolts in their original

positions and tighten. Fit a nylon washer

under the head of each bolt.

Remove the rear bumper bar from the

vehicle ( On Australian vehicles keep the

licence plate lamp loom as it is re-used when

fitting the optional licence plate lamp kit ) .

Remove the lower rubber tire stopper.

THE FOLLOWING COMPONENTS CAN BE INSTALLED ONTO THE

REAR BAR BEFORE IT IS FITTED TO THE VEHICLE.

CAGED NUTS

FOR INFILL

PANEL

M8 cage nuts

GRABBER

BRACKET

CATCH

HOO

SLIDER

PRE - ASSEMBLY OF REAR BAR

M6 cage nuts

2. INSTALLATION OF THE CAGE NUTS

Install four M8 cage nuts (short leg) from

the back of the bar as shown. These cage

nuts will be used to fasten the grabber

bracket and the catch hook, as shown in the

diagram above.

Install two M6 caged nuts in from the back

of the bar as shown. These caged nuts will

be used to fasten the infill panel.

BUMP

STOP

Last Rev Date: 16/10/2006 Page 5 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 6

PRE - ASSEMBLY OF REAR BAR

3. INSTALLATION OF THE SLIDER

Insert two plastic square plugs into holes in

the rear bar. The plugs should snap into the

square holes as shown.

Fasten the slider to the rear bar using the

two black self-tapping screws provided.

NOTE: - Place the tapered face of the slider

towards the front face of the rear bar as

shown in the photo.

4. INSTALLATION OF THE CATCH HOOK

Fasten the catch hook to the rear bar as

shown.

Use the M8 x 25 mm bolts, spring washers

and panel washers supplied.

Make these bolts finger tight only at this

stage.

They will be tightened after the wheel

carrier has been adjusted.

Last Rev Date: 16/10/2006 Page 6 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 7

PRE - ASSEMBLY OF REAR BAR

Bump Stop

5. INSTALLATION OF THE BUMP STOP

Fasten the bump stop to the rear bar using

two M6 x 25 mm stainless steel button head

cap screws, flat washers and nyloc nuts.

Place the washers and nyloc nut inside the

right hand wing as shown.

NOTE: Do not over tighten.

M6 Lock Nuts

6. INSTALLATION OF THE GRABBER

BOLTS.

Fit the two M8 x 25 bolts with, spring

washers and flat washers to the bar as

shown engaging only a few threads.

7. INSTALLATION OF GRABBER

Slide the grabber bracket over the bolts as

shown in the photo.

Leave these bolts finger tight only at this

stage. The grabber will require adjustment

when the wheel carrier is fitted.

Last Rev Date: 16/10/2006 Page 7 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 8

PRE - ASSEMBLY OF REAR BAR

RH Wing Cavity

Adjusting Bolt

Pivot bracket

8. INSTALLATION OF PIVOT

ADJUSTING BOLT

Insert the M8 x 50 mm adjusting bolt (as

shown in the photo) through the hole in the

upright located in the right hand wing

cavity.

There is a corresponding tapped hole in the

pivot bracket that has been pre-drilled and

threaded. Wind the bolt in until a few

threads protrude through the bracket.

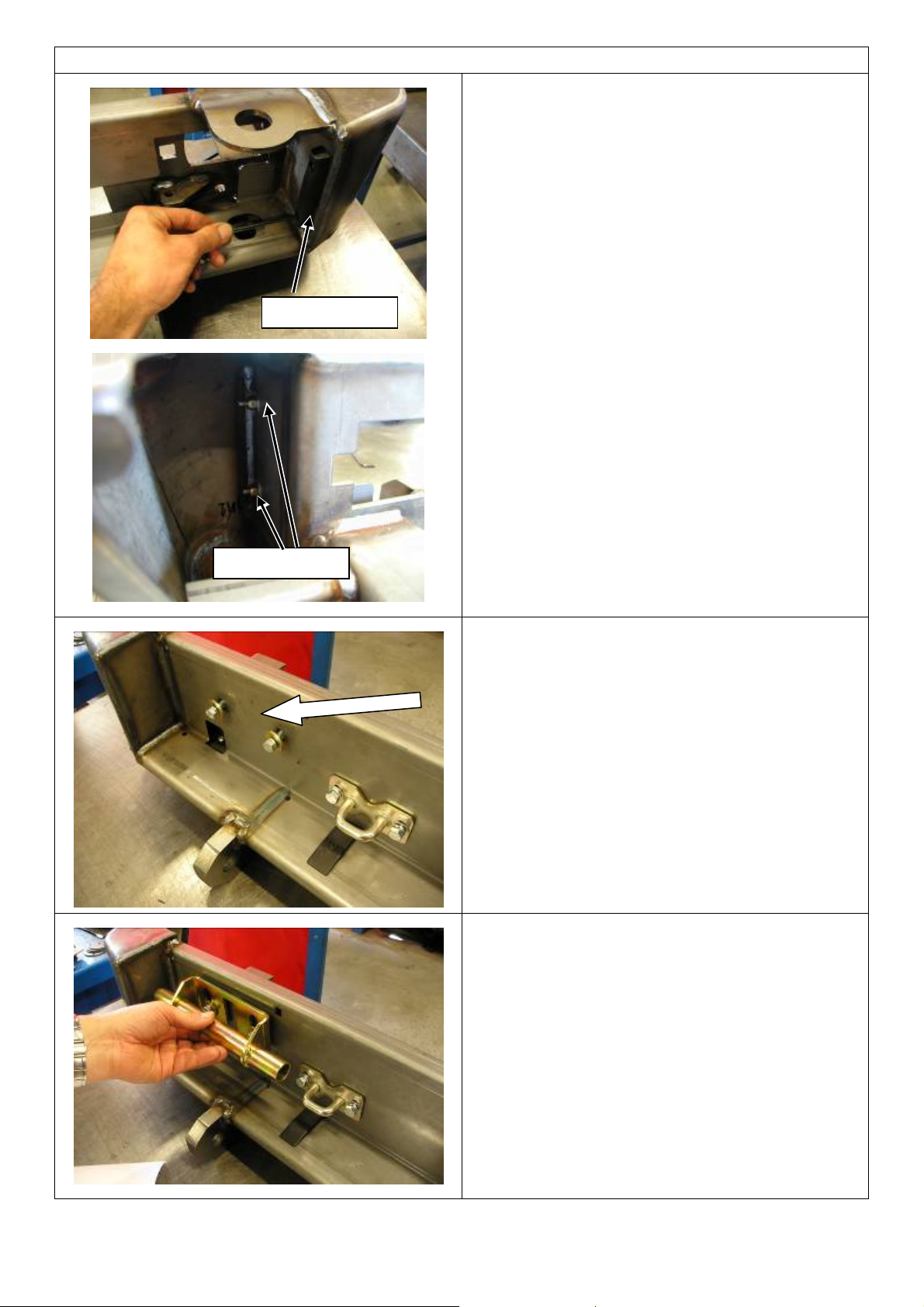

PRE - ASSEMBLY OF WHEEL CARRIER

THE FOLLOWING COMPONENTS CAN BE INSTALLED INTO THE WHEEL CARRIER BEFORE IT IS

FITTED TO THE REAR BAR .

NOTE :- THE BEARINGS AND SEALS ARE PRE - ASSEMBLED

ASSEMBLY , THESE PARTS ARE LISTED IN THE PARTS LIST .

INTO THE WHEEL CARRIER BUSH TO AID

STRUT SPHERE

LOCKING PIN

STOPPER

GRABBER

PRE - ASSEMBLY OF THE WHEEL CARRIER

1. INSTALLATION CATCH ASSEMBLY

Install the catch assembly using the four M8

x 20 mm socket head cap screws and spring

washers provided and fully tighten.

NOTE:- The mounting plate has been pre tapped to accept the socket head cap screws.

Last Rev Date: 16/10/2006 Page 8 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 9

PRE - ASSEMBLY OF THE WHEEL CARRIER

Insert Screws

From This Side

Mounting Plate

2. INSTALLATION OF THE STOPPER

Install one M8 nut, spring washer and flat

washer onto the threaded section of the

stopper.

Fit the stopper to the wheel carrier plate as

shown (the plate is pre – tapped). The

spring and flat washers should be placed

between the M8 nut and the treaded plate.

Do not tighten the nut at this stage. The

stopper will be adjusted after the wheel

carrier is fitted to the rear bar.

3. INSTALLATION OF GRABBER BUFFER

Install the grabber using the two M6

countersunk cap screws and lock nuts

provided. The grabber buffer should be

installed on the outer face of the mounting

plate as shown.

When tightening the bolts, start at the top

first. Pull the centre of the grabber towards

the top (stretching out the buffer) and

tighten the top bolt, repeat this for the

bottom of the arm as shown.

This will increase the grabber opening.

Ensure the buffer cut out is central to the

cut out in the mounting plate.

4. INSTALL STRUT PIVOT BALL

Install the gas strut pivot ball into the wheel

carrier as shown using the M8 flange nut

and flat washer provided.

Gas Strut Pivot Ball

Last Rev Date: 16/10/2006 Page 9 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 10

PRE - ASSEMBLY OF THE WHEEL CARRIER

Insert Pin Through Slot

Hole In Locking Pin

5. INSTALLATION OF THE LOCKING PIN

Place the spring inside the locking bracket

as shown in the photo.

Feed the locking pin through the bracket

and the spring as shown with the upturn of

the locking pin pointing upward.

Using a large flat bladed screwdriver, pull

back the spring as shown and insert the

dowel pin through the slot in the top of the

locking bracket.

Align the dowel pin with the hole in the

locking pin.

Ensure the pin is behind the spring.

Using a hammer, drive the dowel pin

through the hole until it sits flush with the

top surface of the bracket.

Last Rev Date: 16/10/2006 Page 10 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 11

REINFORCING BRACKET FITMENT TO VEHICLE

RIGHT HAND SIDE SHOWN

M12 x 90 MM BOLT

WITH CRUSH TUBE

Two Tab Bolts

Access Hole In Chassis

6. REINFORCING BRACKET FITMENT

TO CHASSIS. RIGHT HAND SIDE

SHOWN.

Insert an M12 x 90 mm bolt and flat

washer through the chassis reinforcing

bracket as shown. Place an M12 crush tube

over the bolt

Fit the reinforcing bracket against the side

of the chassis rail as shown. Pass the M12

bolt and crush tube through the chassis.

Fasten this bolt using a M12 flat washer,

spring washer and nut.

FOR JEEP UNLIMITED VEHICLES

The hole for the M12 X 90 mm bolt must

be drilled. Mark the position of the hole

using the bracket as a reference. Drill a 13

mm hole through the inner and outer

surfaces of the chassis. Enlarge the hole in

the outer surface of the chassis to 17 mm.

NOTE: Take care when drilling holes not

the damage the fuel tank.

WARNING: Wear eye and ear protection

when using drill.

Insert two M12 x 35 mm tab bolts up

through the access hole in the lower chassis

as shown. Guide the bolt up through the

chassis and through the side hole in the

chassis bracket (the tab on the bolt may

need to be bent to achieve this).

Fasten the bolts using a M12 flat washer,

spring washer and nut.

Make these bolts finger tight only at this

stage. They will be tightened after the rear

bar has been fitted to the vehicle.

REPEAT STEP 6 AS DESCRIBED ABOVE FOR THE LHS OF THE VEHICLE.

Last Rev Date: 16/10/2006 Page 11 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 12

Vehicle Cross Member

RIGHT HAND SIDE SHOWN

FITTING THE REAR BAR TO THE VEHICLE

Rear Bar

7. INSTALLATION OF THE REAR BAR

TO THE VEHICLES REAR

CROSS MEMBER.

With the assistance of another person lift

the rear bar into position and fit to the

back of the vehicle.

Slide the bar forward on the vehicle until

the uprights touch the rear cross member.

8. POSITIONING OF REAR BAR

ON VEHICLE.

Align the holes in the rear bar so that the

holes line up with the holes in the base of

the chassis.

There should be equal spacing between the

wing and quarter panel on both sides of

the vehicle.

9. ALIGN REAR BAR ON VEHICLE

Align the rear bar so that the gap between

the body and rear bar is parallel and level.

Insert two M12 x 40 mm bolts & flat

washer through the front of the bar as

shown.

Fasten these bolts with M12 flat washers,

spring washers and nuts.

NOTE: The bolts will pass through the

rear bar, the chassis cross member and the

chassis reinforcing bracket.

Do not tighten these bolts, as the rear bar

will be removed temporally after step 10.

LEFT HAND SIDE SHOWN

Last Rev Date: 16/10/2006 Page 12 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 13

FITTING THE REAR BAR TO THE VEHICLE

Mark these two holes

Narrow edge to top.

Mark & drill these two holes

WARNING: PLACE A BOARD BETWEEN THE

CHASSIS CROSS MEMBER AND THE FUEL TANK

WHEN DRILLING. THIS IS TO PREVENT DAMAGE

TO THE FUEL TANK.

M12 Caged Nuts

M6 Caged Nuts

10. MARKING THE REAR BAR POSITION

TO THE VEHICLE.

With the rear bar in position on the back of the

vehicle, mark the two holes in the centre of the

rear bar onto the rear cross member of the

vehicle. Use a metal scribe or felt tip marker to

do this.

Remove the bolts described in step 9 and

remove the rear bar to enable the holes to be

drilled (refer to step 11.)

11. POSITIONING THE BACKING PLATE

TO THE REAR CHASSIS BEAM.

Align the outer holes in the chassis beam plate

(supplied in the fitting kit) with the newly

marked holes on the cross member. Mark the

position of the two smaller holes.

NOTE: The smaller edge of the bracket is to

the top.

Centre punch the position of the four holes.

Drill the smaller holes using an 8 mm drill bit

and the two larger holes with a 13 mm drill bit.

WARNING: Wear eye and ear protection

when using drill.

12. INSTALLATION OF THE BACKING

PLATE TO THE CHASSIS BEAM

Insert an M12 (short leg) cage nut into the two

outer holes as shown. Insert an M6 cage nut

into the two inner holes as shown.

Place the assembled chassis beam plate in

behind the chassis cross member and align the

smaller inboard cage nuts with the drilled

holes. The position of the bracket is shown

dotted in the above photo.

Bolt the backing plate to the chassis beam

using the M6 bolts, flat washers and spring

washers. Tighten both bolts.

Reinstall the rear bar and hardware by

repeating steps 7 – 9.

Last Rev Date: 16/10/2006 Page 13 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 14

FITTING THE REAR BAR TO THE VEHICLE

M12 x 50 mm BOLTS

On some vehicles drill this hole in the

Existing Bolt

RIGHT HAND BRACKET SHOWN

Tab Bolt

Guide holes

13. INSTALLATION OF THE REAR BAR

With the rear bar back on the vehicle

insert two M12 x 50 mm bolts, spring

washers and flat washers through the rear

step and chassis rear cross member.

Thread and tighten these bolts into the

caged nuts in the chassis beam plate.

14. Bottom bolts on chassis bracket RHS.

Re-use one of the bolts from the factory

bumper bar as shown.

Insert another M12 x 35 MM tab bolt

(as previously described in step 6) through

the chassis ( existing hole ) and bracket as

shown. On some vehicles this Dia 13 mm

hole may need to be drilled in the chassis .

Fasten the bolt using an M12 spring

washer, flat washer and nut.

15. INSTALLATION OF THE REAR BAR

Drilling the pinning bolts.

With the rear bar and the chassis bracket

fully positioned the rear bar can now be

drilled and pinned.

Using the two small holes in the chassis

bracket as a guide, drill up through both

the chassis bracket & rear bar top plate

using an electric drill.

Use a 6 mm drill bit first as a pilot hole

and then a 13 mm as the final size.

WARNING: Wear eye and ear protection

when using drill

16. INSTALLATION OF THE REAR BAR

Fastening of the pinning bolts.

Insert two M12 x 40 mm bolts and flat

washers through the top of the bar as

shown. Fasten these bolts with M12 flat

washers, spring washers and nuts on the

chassis bracket side.

Do not fully tighten these bolts until the

left hand side has been fully bolted .

RIGHT HAND SIDE SHOWN

WITH THE RHS OF THE REAR BAR BOLTED AND PINNED IN POSITION, THE FASTENERS ON THE LHS

CAN BE SECURED. THIS IS DONE BY REPEATING STEPS 9 - 12

IMPORTANT: - ONCE COMPLETE, TIGHTEN ALL BOLTS BEFORE PROCEEDING.

Last Rev Date: 16/10/2006 Page 14 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 15

FITMENT OF WHEEL CARRIER TO REAR BAR

Housing retaining bolts

1. REMOVE RIGHT HAND TAIL LIGHT

The right hand tail light lens and housing

will need to be removed as shown , to allow

the pivot bolt (as per step 4 ) to be aligned

and fitted . Remove the lens from the

housing , remove the divider plate that

separates the two lower bulbs from the

housing to access the three housing

retaining bolts – remove as shown .

Tie or tape the housing out of the way to

prevent damage to the tail light housing or

the vehicle.

2. FIT PIVOT LOCK NUT

(fitted up from the underside )

Insert the M20 pivot lock nut below the

lower pivot plate as shown.

Position the nut so that it is central with

the hole on the lower pivot plate.

RIGHT HAND SIDE OF BAR

9 mm Spacers

3. INSERT PIVOT SPACER

Cover both the top and bottom seals and

bearing hubs with a liberal amount of

grease. This will help waterproof the hub

and aid with assembly. It will also hold the

spacer into the hub as covered in the next

step.

Insert a 9 mm spacer up into the underside

of the hub of the wheel carrier as shown in

the photo (the grease will hold it in

position). Push the spacer up through the

seal.

Place the other 9 mm spacer into the lower

hole of the rear bar shell as shown.

Last Rev Date: 16/10/2006 Page 15 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 16

FITMENT OF WHEEL CARRIER TO REAR BAR

20 mm Pivot Bolt

Bush

Wheel carrier pivot

Wheel carrier frame removed for clarity

Pivot plate

4. FIT WHEEL CARRIER

Assemble the 20 mm pivot bolt with the

bush . The bush when assembled fits into

the top bearing seal and will press against

the bearing.

With assistance, fit the wheel carrier pivot

between the upper and lower pivot plates.

Insert the M20 pivot bolt assembly

through the pivot plates and the top &

bottom bearings.

Align the bolt into the 20 mm lock nut

(installed previously) and - finger tight

only at this stage.

NOTE: - To Aid installation a

15mm – 18 mm rod or aligning pry bar

can be use to centralise the bearings,

spacers and nut so the pivot bolt assy will

pass through all components easily.

5. TIGHTEN PIVOT BOLT

Tighten of the pivot bolt to preload the

bearings.

Tighten the bolt until the free play has

been removed from the pivot assembly.

Back the bolt off by half a turn once this

has been achieved.

The wheel carrier should now swing freely.

Last Rev Date: 16/10/2006 Page 16 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

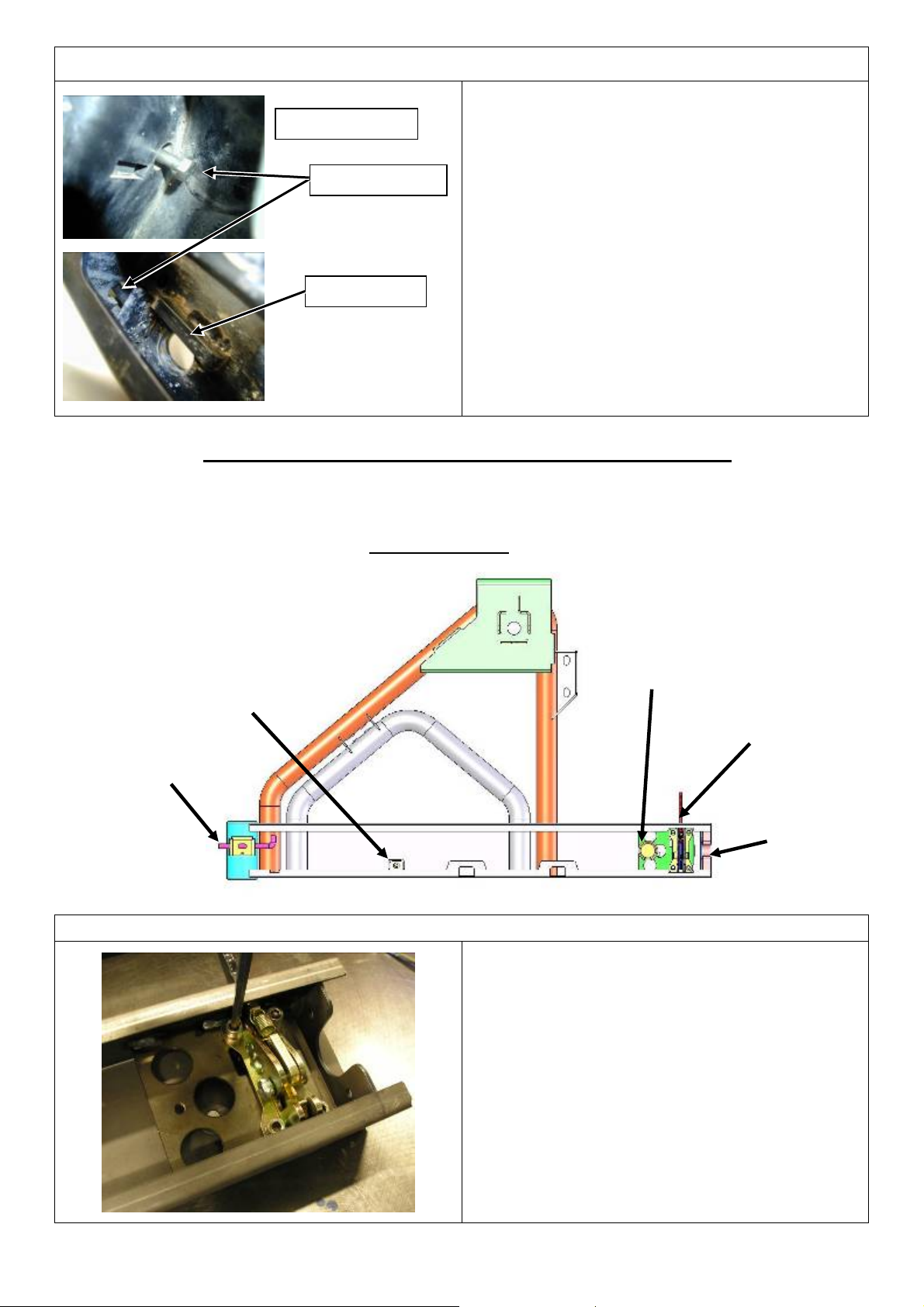

Page 17

(B)

BODY PIVOT

BALL (A)

FITTING OF THE GAS STRUT

DESCRIPTION OF STRUT

STRUT

MOUNTING TAB

STRUT ROD

ROD SOCKET

6. FITTING THE STRUT TO REAR BAR

Open wheel carrier to gain access to the strut

mounting tab (located on the carrier).

Insert the body pivot ball (A) - through the

strut mounting tab as shown.

Fasten the threaded section of the pivot ball

to the rear bar using the M8 flange nut.

INSERT FROM

THIS SIDE

PIVOT BALL

7. INSERT THE LOCKING CLIPS

Press the rod socket (B) over the pivot ball in

the wheel carrier as shown.

Insert the locking pin into the rod socket.

Place the straight piece of the clip through

the holes in the side of the sphere.

Roll the ‘C’ shaped clip over the shaft to lock

the pivot ball in place.

This needs to be done to both ends.

8. FITTING THE GAS STRUT TO THE

WHEEL CARRIER

Insert the pivot ball - through the strut

mounting bracket as shown.

Fasten the threaded section of the pivot ball

to the wheel carrier using the M8 flange nut.

NOTE: - The strut must be compressed

slightly to make the threaded section of the

pivot ball align with the gas strut bracket on

the wheel carrier.

Last Rev Date: 16/10/2006 Page 17 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 18

CATCH

OPENING

CENTRE

LINE

8 MM

ADJUSTMENT OF WHEEL CARRIER

9. ADJUSTING THE HEIGHT OF THE

WHEEL CARRIER

The wheel carrier should sit parallel with the

rear step when viewed horizontally.

The height of the wheel carrier arm can be

adjusted using the M8 bolt located inside the

right hand wing cavity.

M8 ADJUSTING

BOLT

10. ADJUST THE CATCH HOOK

Make sure that the bolts attaching the catch hook to the rear bar

are finger tight.

Slowly close the wheel carrier until the catch almost contacts the

catch hook. Check that the hook is positioned centrally about the

catch opening. If necessary, adjust the height of the catch hook.

When hook is in the correct position, tighten the bolts.

Shut the wheel carrier so that the catch engages. The catch

should make a crisp ‘click’ sound.

Standing behind the vehicle, pull the catch lever towards you.

The catch should make a crisp ‘click’ sound again and the wheel

carrier should be opened by the gas strut.

If the catch does not behave in this manner, the catch hook

requires further adjustment. If the top surface of the hook shows

evidence of scoring or is marked, the hook should be moved

lower down. If the bottom surface of the hook is scored, the hook

CATCH

HOOK

should be moved upward.

Continue adjusting the catch hook until the catch locks and

unlocks freely.

11. ADJUSTING THE STOPPER

Screw the stopper out until it protrudes 8 MM past the inside

edge of the wheel carrier.

Shut the wheel carrier so that the catch engages. If the catch will

not lock (‘click’) - screw the stopper in. If there is free play

between the wheel carrier and the rear bar - screw the stopper

out. Continue to screw the stopper out until the free play is

removed. When happy with the stopper position, tighten the M8

flange nut against the steel mounting plate.

Turning the bolt in raises the arm, raise until

the arm is parallel with the shell of the rear

bar.

Last Rev Date: 16/10/2006 Page 18 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 19

ADJUSTMENT OF THE REAR STEP COMPONENTS

12. ADJUSTING THE GRABBER BRACKET

With the bolts attaching the catch grabber bracket finger tight, shut the wheel carrier. This will

centralise the grabber bracket.

Taking care not to knock the grabber bracket, release the catch and swing the wheel carrier out into

the open position.

Tighten the bolts securing the grabber bracket to the rear bar.

FINAL CHECK AND ADJUSTMENT ON THE WHEEL CARRIER

With all of the bolts now tightened, shut the wheel carrier until the catch locks. The arm should

meet little resistance as it shuts and the catch should make a crisp ‘click’ sound as it closes.

At this point, it should not be possible to pull the wheel carrier open without releasing the catch.

There should be no free play between the wheel carrier and the rear bar.

Stand behind the vehicle and pull the catch lever. The catch should make a crisp ‘click’ sound and

the arm should open without further assistance.

IMPORTANT: - IF THE ARM DOES NOT OPERATE IN THIS

MANNER REPEAT STEPS 10 TO 13.

FITTING THE WHEEL MOUNTING BRACKET

Studs positioned in the 5 x 4 ½” pattern.

Vacant holes are used for 5 x 5 ½” pattern

1. STUD LOCATIONS ON THE

WHEEL MOUNT BRACKET

Studs can be fitted to the wheel mount

bracket in either a 5 x 4 ½” or 5 x 5 ½”

pattern.

The photo to the right shows the studs

in the 5 x 4 ½” pattern.

The studs are installed in the vacant

holes to achieve the 5 x 5 ½” pattern.

Installation of the studs is covered in

step 2.

Last Rev Date: 16/10/2006 Page 19 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 20

FITTING THE WHEEL MOUNTING BRACKET TO THE CARRIER

2. INSTALLATION OF THE STUDS

TO THE BRACKET

Using a steel vice or similar place the

stud through the appropriate holes.

NOTE: - 5 x 4½” has two studs at the

top and one in the bottom.

Using a large hammer hit the back of

the stud until it is fully bottomed out

as shown.

Top of bracket

Once all three studs are installed it will

look like the example shown above in

step 1 .

3. WHEEL MOUNTING BRACKET

COMPONENTS

Fit two M12 cage nuts (long leg) to the

wheel mount bracket as shown.

NOTE: The body of the cage nuts

should be on the inside of the channel

as shown.

M12 Caged

nuts

(long leg)

4. WHEEL MOUNTING BRACKET TO

CARRIER

Slide the wheel mount bracket into the

wheel carrier as shown in the photo.

Using the M12 bolts, spring washer

and body washer bolt the wheel mount

bracket to the wheel carrier both sides.

Do not fully tighten these bolts, as the

bracket must now be adjusted.

Last Rev Date: 16/10/2006 Page 20 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 21

FITTING THE WHEEL MOUNTING BRACKET TO THE CARRIER

Full contact required

Locking bolt

Drill up from underside

5. INSTALLATION OF THE SPARE

WHEEL TO THE BRACKET

Fit the spare wheel to the carrier and

ensure all three wheel nuts are fully

engaged. Slide the spare wheel and

carrier back towards the frames.

The tyre must have full contact with

the frames. Using a marker or scribe

mark the position of the bracket in

relation to the housing (in case it

moves when removing the spare

wheel). Remove the spare wheel.

To enable the tyre to be Pre -loaded on

the frame, push the bracket a further

5 mm inward. Tighten the two M12

side bolts.

6. WHEEL MOUNTING BRACKET

DRILL AND PINNING

From the underside of the wheel

carrier channel, there is a predrilled

pilot hole for the locking bolt.

Using a 10 mm drill bit in an electric

drill, drill through the lower wall of

the wheel mounting bracket . Ensure

eye protection is used.

Place the M10 bolt up through the

drilled hole and fasten on the inside

with the M10 flange nut .

Tighten the nut and bolt .

7. WHEEL MOUNTING BRACKET TO

WHEEL CARRIER

The wheel mounting bracket has been

designed to attach to the wheel carrier

and can slide forward and reward to

accommodate different size tyres and

wheel offsets .

The two components although bolted

together can be removed with the tyre

in place . It is recommended that a

padlock (not supplied) is used to

secure these items to the vehicle.

Last Rev Date: 16/10/2006 Page 21 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 22

RE-FITTING THE HI LEVEL BRAKE LAMP TO THE WHEEL CARRIER

g

M8 Cage nuts

(long leg)

Feed wiring through here

Grommet

Plu

Existing loom

New wiring

Cable tie as shown

8. INSTALLATION OF THE CAGE

NUTS INTO THE BRACKET

Fit the four M8 cage nuts (long leg) to

the top of the stop lamp bracket using

a small flat bladed screwdriver.

Note:- The body of the cage nut sits on

the underside of the bracket .

Refit the factory high level stop lamp

by aligning the holes in the base of the

lamp with the cage nuts.

Feed the wiring through the hole as

shown .

9. BOLTING THE HIGH LEVEL STOP

LAMP TO THE BRACKET

Use four black M8 bolts , spring

washers and flat washers fasten the

lamp to the bracket as shown .

Cut the wiring loom in between the

door grommet and the protective

tubing as shown .

The two brake lamp wires will need to

be extended . Solder the wires supplied

in the fitting kit to the factory loom .

Insulate the wires where they are

joined to the original loom .

10 . Partially cover the new wiring with

the convoluted tubing starting at the

new join in the loom .

Run the convoluted tube from the

existing loom along the new section of

cable and using the cable ties

provided , tie the wiring loom back to

the wheel carrier frame as shown .

Leave the ( lamp ) end of the wiring

uncovered ( no tubing ) at this stage .

Last Rev Date: 16/10/2006 Page 22 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 23

(

(

VEHICLE WIRING MODIFICATIONS FOR HI – LEVEL STOP LAMP

Feed wiring through grommet

Grommet

Housing

Ring terminal

Earth )

Scotch lock

Stop lamp

Positive ) wire

11. DRILLING THE TAIL LAMP

HOUSING

Turn the tail lamp housing upside

down as shown .

Using a 12 mm drill bit , drill a hole in

the bottom of the housing in the centre

on the faint mould line as shown .

Ensure the drill bit does not protrude

to far into the housing when drilling

causing damage to the housing or

wiring .

12. GROMMET AND WIRING TO TAIL

LAMP HOUSING

Push the grommet into the hole in the

tail lamp housing .

Re-fit the tail lamp housing to the

vehicle using the top bolt only at this

stage .

Split the twin core wire and push it

through the grommet into the housing

Allow approx 100mm of the wire

inside the housing .

13. WIRING THE LOOM TO THE TAIL

LAMP

Crimp the ring terminal to the earth

wire ( red with a black trace ) and

place the terminal under the head of

one of the two remaining bolts .

The two remaining bolts can now be

re-fitted to the tail lamp housing as

shown .

Attach the scotch lock to the ( white )

stop lamp positive wire and also secure

the red loom wire – crimp the scotch

lock together as shown .

Last Rev Date: 16/10/2006 Page 23 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 24

RE-FITTING THE TAIL LAMP TO VEHICLE

Cut out in divider

14. DIVIDER PLATE TO TAIL LAMP

HOSING

Re - fit the divider to the housing .

Ensure the wiring sits in the cut out

provided on each side at the back .

Note :- The folded edge of the divider

is on the lower side .

On the tail gate where the factory high

level stop lamp loom passes through

there is an exposed hole – Use the

blanking grommet supplied in the

fitting kit to cover it .

15. LENS TO TAIL LAMP

Re – fit the tail lamp lens to the

housing .

With the wheel carrier door open ,

trim the remaining end of the

convolute tubing to sit under the tail

lamp as shown .

Check that the high level brake lamp

is operational and the loom is tie to the

frame securely ( step 10 ) and does not

hang in the pivot area .

16. RE - FIT THE SPARE WHEEL

Re-fit the spare wheel using the wheel

nuts provided.

Locking wheel nuts are available as an

accessory from your ARB stockist .

( part number 575 0040 ) .

A Hi-Lift jack mounting bracket is

available as an accessory from your

ARB stockist ( part number 575 0030 ).

Last Rev Date: 16/10/2006 Page 24 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 25

Cover panel

M6 Cage nuts

M6 x 40 mm Bolt

FINAL - ASSEMBLY OF THE REAR BAR

M6 Cap

Nylon Spacer

Spacer

COVER PANEL ASSEMBLY

Now that all adjustments & operations

have been done and checked on the rear

bar and spare wheel carrier, the cover

panel can be fitted. Fit the two M6 cage

nuts to the cover as shown.

Fit the socket head cap screws into the

cover with the black nylon spacers on

the other side.

Place the bottom spacers over the

corresponding holes in the surface of

the rear bar.

INSTALLATION OF THE COVER TO

THE REAR BAR

To fix the cover to the rear bar, place a

hex key through the access hole in the

cover as shown. Thread the two M6

socket head cap screws into the caged

nuts installed at step 2.

The lower part of the cover is fixed by

inserting two M6 bolt from the

underside of the bar. These bolts pass

through the rear bar, through the

spacer and into the caged nut

( previously installed ) .

Tighten the four bolts.

RE - FIT THE LICENSE PLATE

Refit the license plate to the vehicle as

shown .

Note :- If the vehicle is not fitted with a

body lift / spacer kit , the license plate

will not fit as shown it will be necessary

to purchase the additional license plate

kit as listed below .

A licence plate relocation kit is available

as an accessory from your ARB stockist

( part number 575 0050 ).

Last Rev Date: 16/10/2006 Page 25 of 25 3783210 - rev 3

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Loading...

Loading...