Page 1

ARB TOYOTA 80 SERIES

REAR STEP TOW BAR

Product number: 5611210

Optional

Wheel

Optional

Jerry Can

Carrier

Carrier

Left Hand Side

of vehicle (LHS)

Rear Step Tow Bar

Right Hand Side

of vehicle (RHS)

READ FITTING INSTRUCTIONS

CAREFULLY BEFORE PROCEEDING

08-10-09 Page 1 of 19

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

3783146

Page 2

USE PART No QTY DESCRIPTION

FIT TAIL LIGHT ASSEMBLIES

TO REAR BAR

6821172L 1 Tail Light Assembly – Left Hand Side (LHS)

6821172R 1 Tail Light Assembly – RHS

6151017 12 Bolt M6 x 16

6151128 8 Nut M6 flange

6151300 4 Nut M6 cage

6151046 12 Washer 6mm flat

3756681 2 Light mount cover bracket

FIT CAGE NUTS TO REAR

BAR

6151300 16 Nut M6 cage

6151303 4 Nut M8 cage

3756701 2 Locking pin bracket

FIT LOCKING PIN BRACKETS

TO REAR BAR

6151022 4 Bolt M8 x 25

6151132 4 Nut M8 flange

4581044 4 Washer 8mm flat

FIT LOOM TO VEHICLE 6821163 1 Loom

6151096 2 Bolt M12 x 40 x 1.25

4581049 4 Washer 12mm flat

FIT BAR TO REAR CROSS

MEMBER

4581050 4 Washer 12mm spring

3199773 2 Cross member nut plate

6151306 2 Nut M12 cage

6151255 2 Bolt M12 x 40 x 1.75

6151097 4 Bolt M12 x 50 x 1.25

6151340 2 Bolt M12 x 50 x 1.75

4581007 6 Washer ½” flat heavy duty gold zinc

FIT BAR TO UNDERSIDE OF

CHASSIS

4581050 6 Washer 12mm spring

5848309 2 Chassis packer front

5848310 2 Chassis packer rear

3199772 1 Chassis lower nut plate

6151306 2 Nut M12 cage

6151255 4 Bolt M12 x 40 x 1.75

4581007 4 Washer ½” flat heavy duty gold zinc

FIT BAR TO CHASSIS SIDE

4581050 4 Washer 12mm spring

3199771 2 Chassis side nut plate

6151306 4 Nut M12 cage

6522646 1 Centre cover panel

6151300 2 Nut M6 cage

6151352 2 Socket head cap screw M6 x 25 stainless steel

FIT CENTRE COVER PANEL

6151207 2 Bolt M6 x 25

6151046 4 Washer 6mm flat

6151042 4 Washer 6mm spring

5848302 2 Packer black nylon

6250003 2 Spacer 8mm thick gold zinc

08-10-09 Page 2 of 19

3783146

Page 3

FIT END SURROUNDS TO

REAR BAR

FIT END SURROUND

BRACES

3131192L 1 End surround LHS

3131192R 1 End surround RHS

6151083 6 Bolt M8 x 35

6151132 6 Nut M8 flange

4581044 6 Washer 8mm flat

6250003 6 Spacer 8mm thick gold zinc

3756757L 1 End surround brace LHS

3756757R 1 End surround brace RHS

6151017 2 Bolt M6 x 20

6151046 2 Washer Flat M6

6151128 2 Nut Flange M6

6151083 4 Bolt M8 x 35

6151021 4 Bolt M8 x 20

6151132 4 Nut M8 flange

4581044 8 Washer 8mm flat

4581046 8 Washer 8mm spring

3199774 1 Wing brace nut plate

6151303 2 Nut M8 cage

3162478L 1 Vertical trim

3162478R 1 Vertical trim

3162482L 1 End surround trim

FIT URETHANE TRIMS

3162482R 1 End surround trim

6821166 2 Reflector

6151162 10 Nut M6 nyloc

4581082 10 Washer 6mm flat heavy duty black zinc

3199769 1 Top infill plate

FIT TOP INFILL PLATE

3199727 1 Aluminium step plate

4590019 1 Rubber extrusion seal

6151256 10 Button head cap screw M6 x 16 stainless steel

4761132 1 Gooseneck

FIT GOOSENECK

55010 1 Pull pin

55020 1 Spring Clip

FIT TRAILER PLUG 6151370 2 Screw M4 x 20 plastite pan head

PARTS SUPPLIED WITH THIS KIT TO BE USED WHEN FITTING WHEEL CARRIERS OR JERRY CAN CARRIERS

FITTING NUMBER PLATE

LIGHT

86060BL 1 Number plate light

6151281 2 Screw M5 pan head

6151282 2 Nut M5 flange

3756677 1 Centre locator bracket

6151255 2 Bolt M12 x 40 x 1.75

FIT CENTRE LOCATOR

4581049 4 Washer 12mm flat

4581050 2 Washer 12mm spring

6151189 2 Nut M12 x 1.75

TOOLS REQUIRED: Basic tool kit, 30mm socket, ¼” drive socket set, silicon.

TORQUE SETTINGS: 6mm – 9Nm, 8mm – 22Nm, 10mm – 44Nm, 12mm – 77Nm

08-10-09 Page 3 of 19

3783146

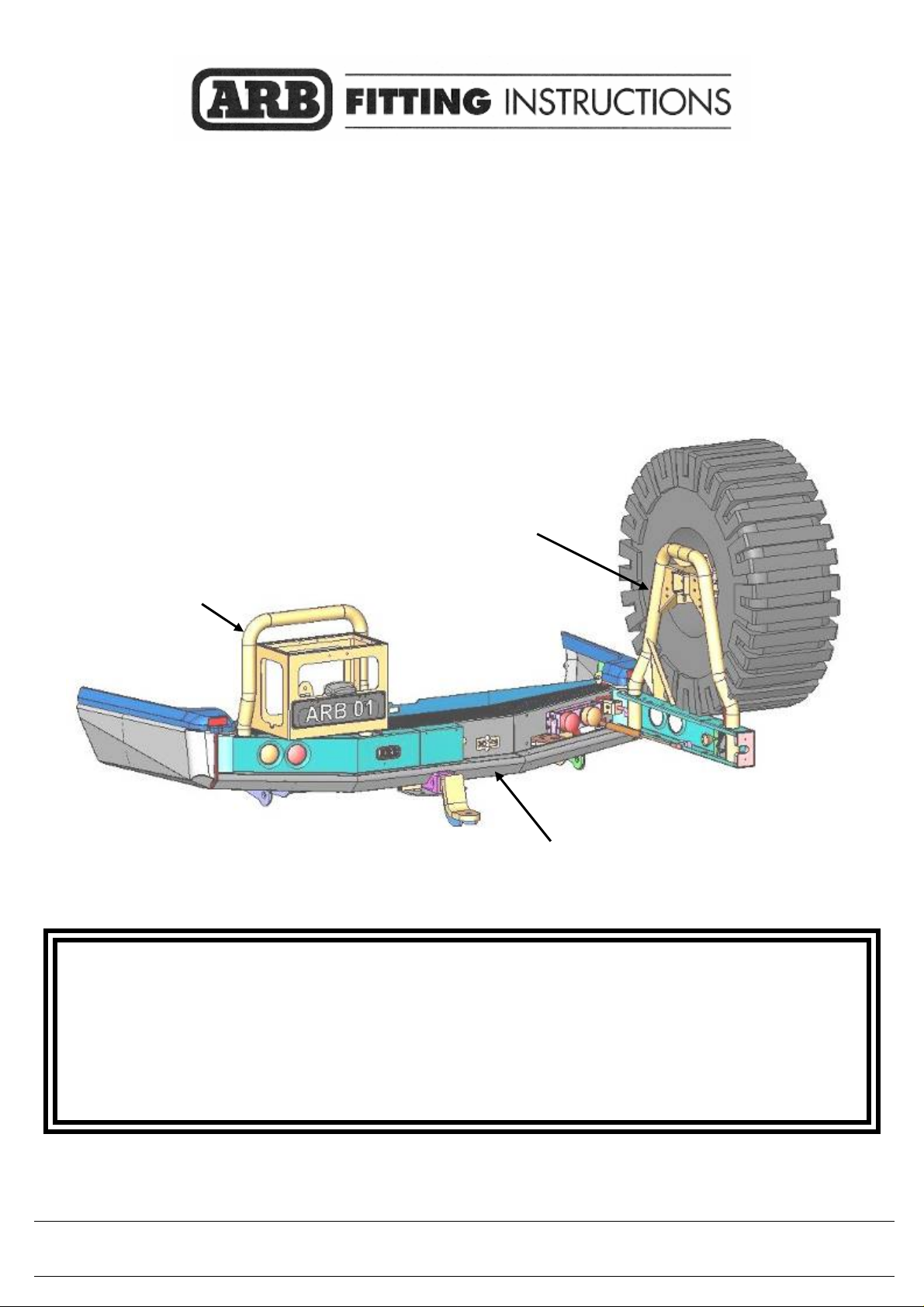

Page 4

FITTING TAIL LIGHTS TO BAR

1. Compile components as shown.

- Light assembly (LHS shown)

- Light cover

- 6 x M6 x 16mm bolts

- 6 x M6 flange nuts

- 2x M6 cage nuts

- 6 washers to suit M6

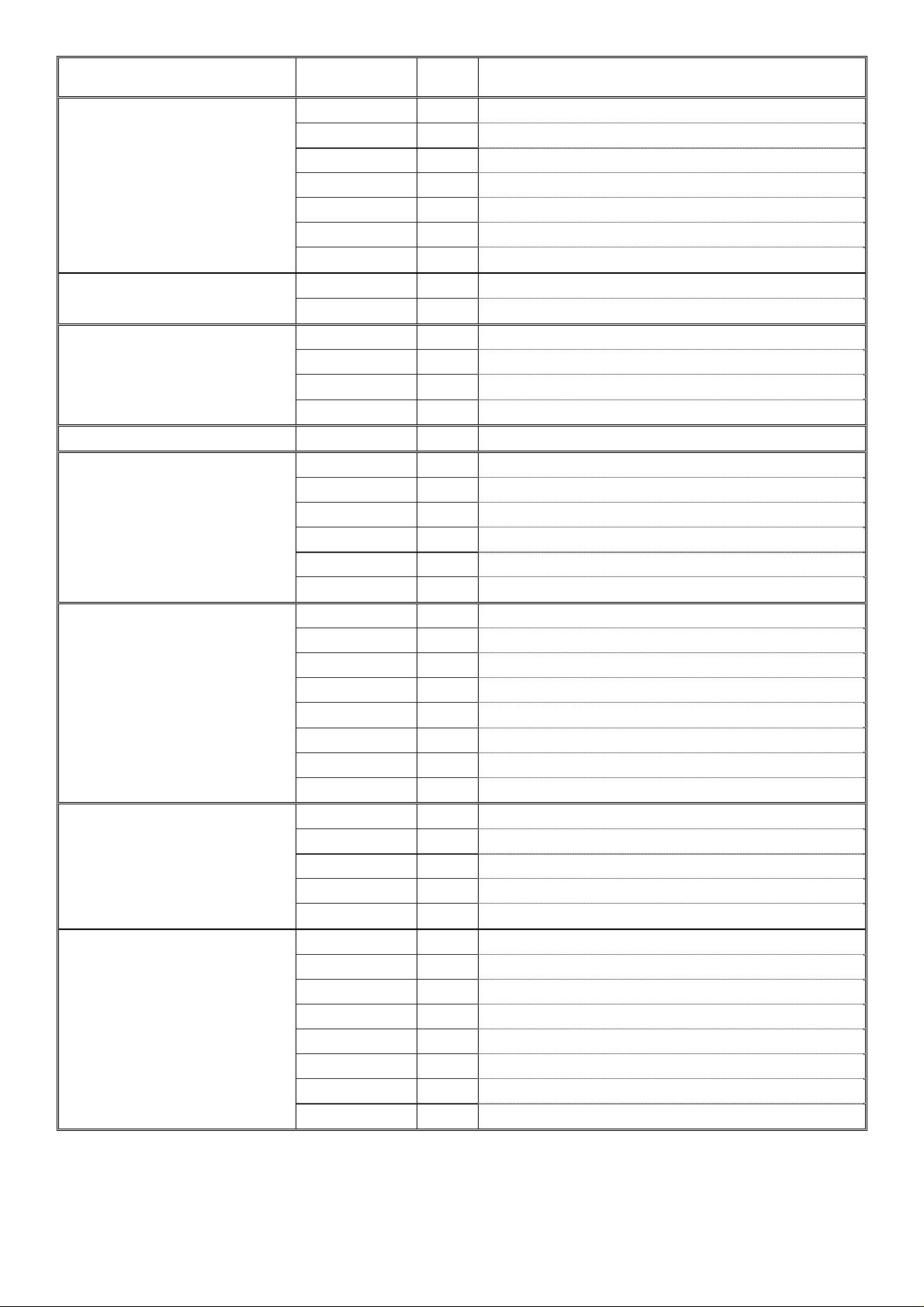

2. Fit cage nuts to light cover as shown.

Outside of car

When fitting light assemblies to bar,

orange (indicator) lights must be to

the outside as shown. The flange on

the bracket should also be at the top.

Orange light

3. Feed looms through large hole in bar.

4. Fit light assemblies using M6 hardware.

Finger tighten only.

5. Repeat steps 1 to 3 for RHS assembly.

08-10-09 Page 4 of 19

3783146

Page 5

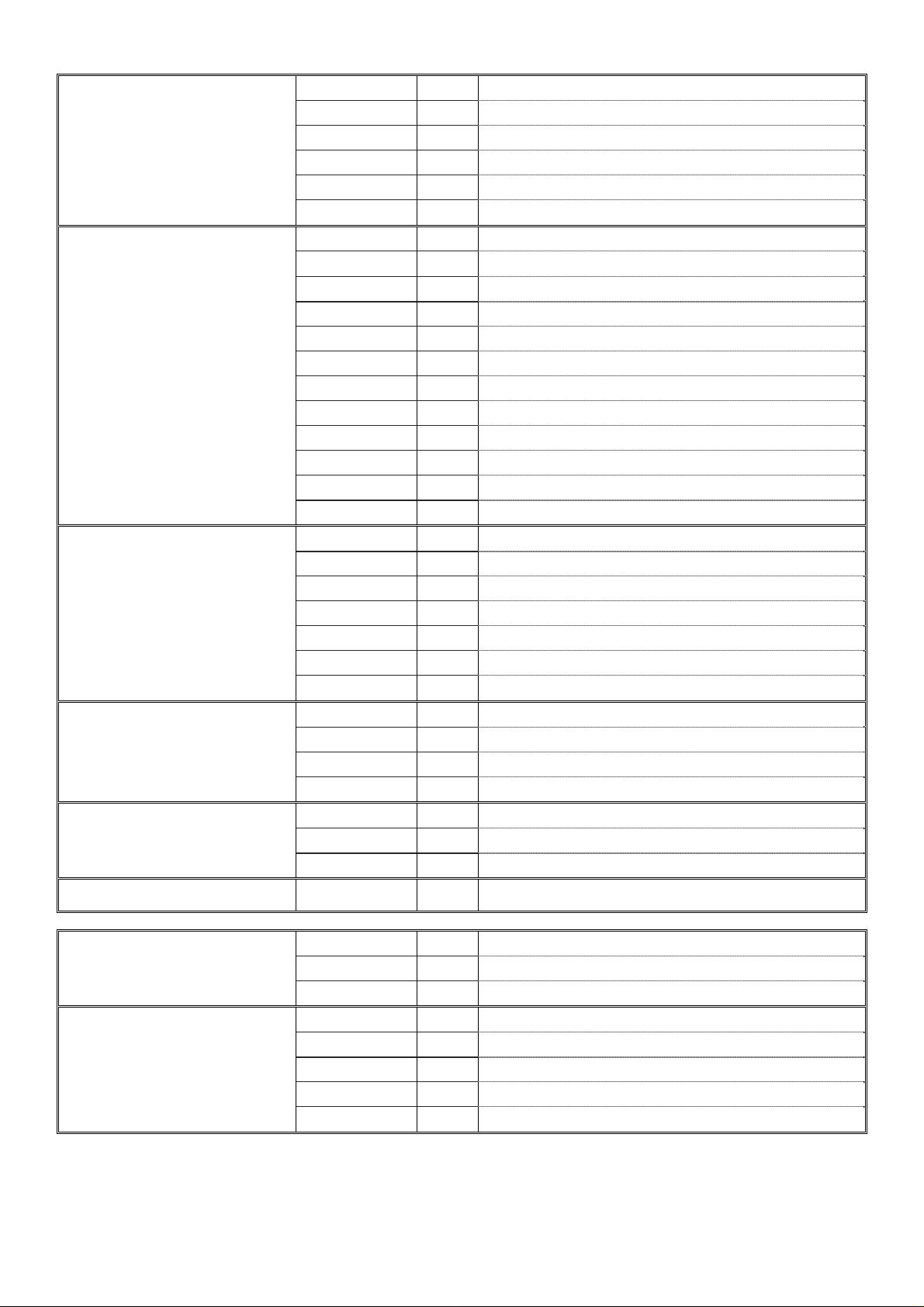

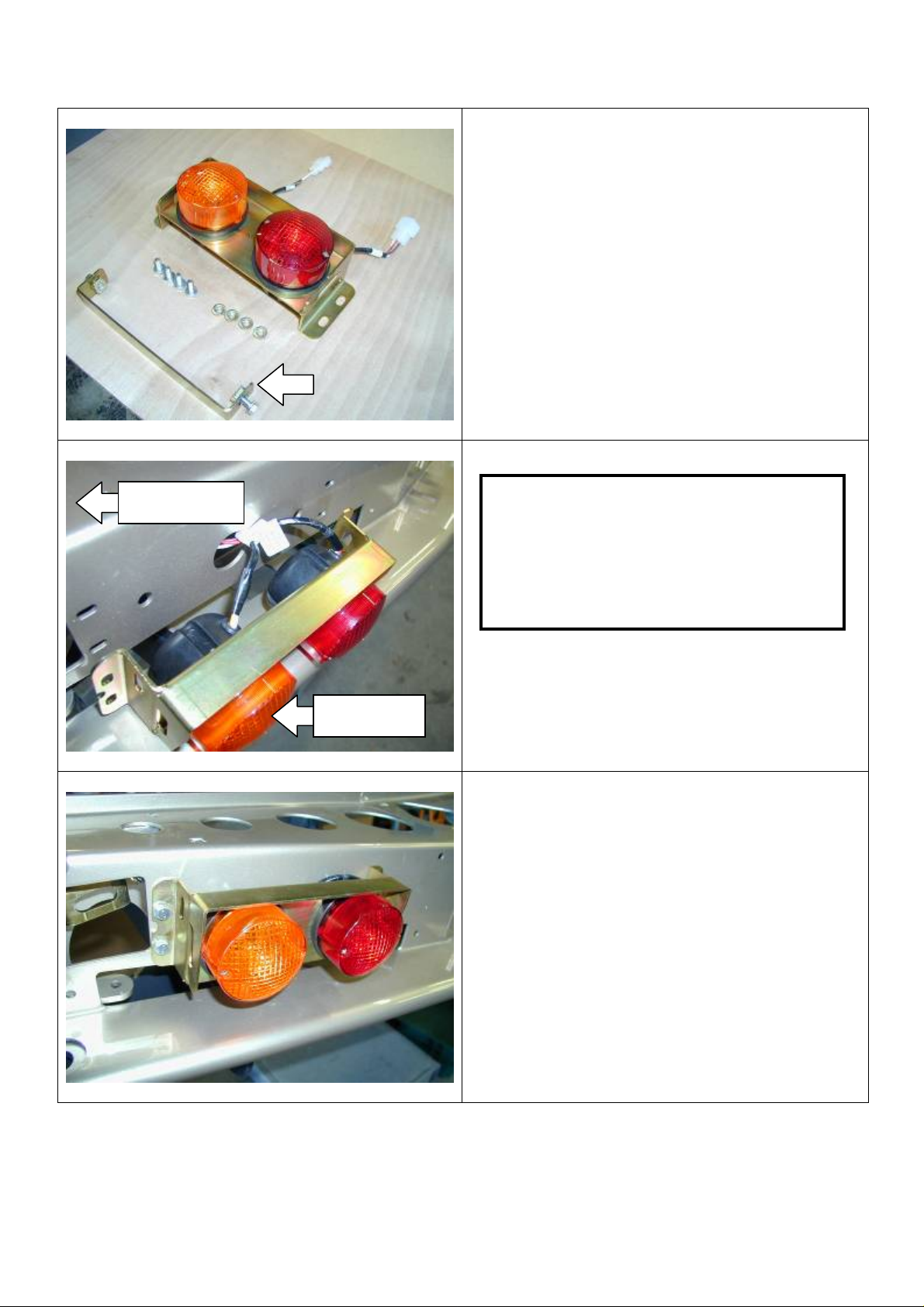

FITTING CAGE NUTS TO BAR

6. Fit M6 cage nuts

to light mount cover

bracket as shown.

7. Using M6 x 16 bolts and flat washers, fit

cover bracket to light mount.

8. Tighten only cover bracket bolts securely.

9. Fit M6 cage nuts (9 total) in square holes in

top of bar as shown.

M6

M6

10. Fit M6 cage nuts (6 total) and M8 cage nuts

M8

M6

08-10-09 Page 5 of 19

M8

(4 total) to front of bar. (RHS shown)

3783146

Page 6

FITTING LOCKING PIN BRACKETS TO BAR

Flange nuts this side

11. Fit locking pin brackets using two M8 x 25

bolts, flat washers and flange nuts. Finger

tighten only.

Fit bolts through from rear of rear bar so

that the flange nuts are on the same side

as the bracket as the photo shows.

(Viewed from front of bar LHS.)

REMOVING BUMPER

12. M8 bolts must fit in rear of bar for ease of

adjustment later on.

(Viewed from rear of bar LHS.)

13. To fit Rear Bar to vehicle, remove bumper

bar, mud flap and tow bar (if fitted) from

vehicle.

OPTIONAL

Paint lower rear quarter panel satin black.

08-10-09 Page 6 of 19

3783146

Page 7

FITTING LOOM TO VEHICLE

14. Fit loom inside rear cross member of

vehicle chassis.

The plug for connecting the loom to the

vehicle must be on the RHS of the

vehicle.

Trailer plug wires

LHS

Tail light

connector

with

yellow

RHS

Tail light

connector

with green

wire

15. Exit tail light wires and trailer plug wires as

shown.

The tail light connectors with the

GREEN wire must be on the RHS of the

vehicle.

The tail light connectors with the

YELLOW wire must be on the LHS of the

vehicle.

16. The loom is fitted with wiring for a number

plate light.

If a jerry can carrier is to be fitted the

number plate and light should be fitted to it.

The wire for the number plate light must be

on the same side of the vehicle as the jerry

can carrier.

Number plate

light wires

08-10-09 Page 7 of 19

If a wheel carrier is to be fitted without a

jerry can carrier the wire for the number

plate light should be on the same side of

the vehicle as the wheel carrier.

3783146

Page 8

17. Make sure when plug is connected to

vehicle that wire is cable tied well clear of

muffler and exhaust components that may

melt it.

FITTING REAR BAR TO VEHICLE

18. If a wheel carrier or jerry can carrier is not

to be fitted a cover panel must be fitted.

If cover panels are to be fitted

they must be fitted to the bar

before it is fitted to the vehicle.

Refer to fitting instructions supplied in

cover panel fitting kit for fitment of

cover panel.

19. Fit 8mm cage nuts to wing brace nut

plate and insert into LHS of vehicle and

align with rear holes in side of chassis

08-10-09 Page 8 of 19

3783146

Page 9

20. With the help of a friend to hold the

previously fitted nut plate in the correct

position, fit the LHS end surround brace to

the side of the chassis rail using M8 x

35mm bolts, spring washer and flat

washer., finger tighten only.

21. Whilst working on the LHS, fit M12 x 1.75

caged nuts into side plates, and fit plate

as to press wing brace nut plate arm

against the inside of the chassis rail to

stop any rattling when the rear bar is fitted

to vehicle.

NB FIT CAGE NUTS TO SIDE

PLATES SO PLATES ARE

HANDED.

22. Fit M12 x 1.75 cage nuts to chassis side

plates and insert into end of chassis rails.

NOTE:

After bar is fitted and bolts are tightened

in these chassis side plates, the handles

must be bend over so that struts are not

damaged when wheel carriers or jerry can

carriers are closed.

08-10-09 Page 9 of 19

3783146

Page 10

23.

Fit 2 x M12 x 1.75 cage nuts into plate and

insert into inside RHS chassis rail and

align with underside of chassis holes.

Bend rear handle of nut plate to enable

24.

plate to fit flat on the inside of chassis rail.

25. On RHS of vehicle remove exhaust

hanger bracket from vehicle and remove

rubber isolater body from muffler for ease

of fitment later.

26. Using M8 x 35mm bolts, spring washers

and flat washers, secure side surround

brace to rear holes in side of chassis

rails.

27. Refit rubber isolater body back to muffler

and to the side surround brace.

FINGER TIGHTEN ONLY

28. Fit M12 x 1.75 cage nut into rear cross

member nut plate and fit to both sides of

rear cross member.

08-10-09 Page 10 of 19

PHOTO IS LHS OF VEHICLE

3783146

Page 11

29. Slide bar onto rear of chassis leaving

enough room to plug main loom into tail

light assemblies on either side of vehicle.

30. When this is done push bar onto chassis

until centre mount of bar is flush up against

chassis cross member.

31. Fit two M12 x 40 x 1.25 bolts, spring

washers and flat washers as shown into

centre mounting bracket.

(Finger tighten only.)

32. Fit 3 x M12 x 40mm x 1.25 (fine thread)

bolts, spring washers and large gold

colored flat washers to underside of

chassis rails to LHS of vehicle

(Finger tighten only.)

08-10-09 Page 11 of 19

M12 X 1.25 X 50 BOLTS

( FINE THREAD )

3783146

Page 12

To the RHS of the vehicle, fit 2 x M12 x 1.75 x

50 ( coarse thread ) bolts, spring washer and

flat large gold coloured washer to the most

forward hole. To the rear hole, fit 1 x M12 x

1.25 x50 bolt, spring washer and flat large gold

coloured washer

M12 X 1.75 X 50 BOLTS

M12 X 50 X 1.25 BOLT

33. Fit two M12 x 40 x 1.75 bolts, large gold

coloured flat washers and spring washers

into captive nut plates (installed previously

step17) on each side of vehicle.

(Finger tighten only)

Align nut plates using handle that protrudes

through cut out in rear of bar.

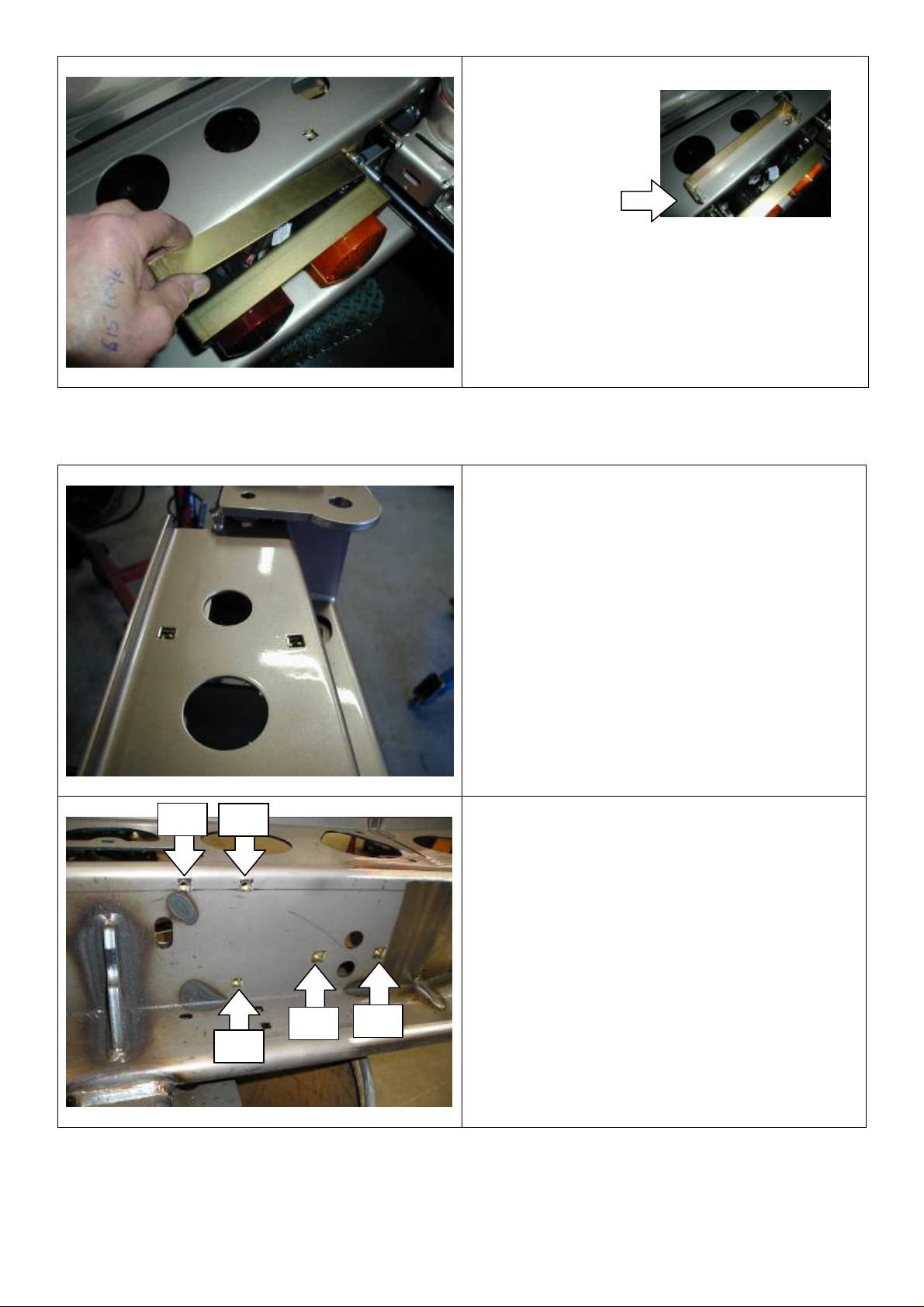

34. Before tightening any bolts you must fit the

8mm packers in between the rear bar and

the vehicle chassis. The double cut out

packers to the rear of the bar, and the

single cut out packers to the front of the

bar. When these packers are fitted, tighten

all bolts firmly.

ARROWS INDICATE WHERE

PACKERS ARE TO BE FITTED

08-10-09 Page 12 of 19

3783146

Page 13

35.

. The single cut out packers to the front of

the bar. (As viewed from front of vehicle )

When these packers are fitted, tighten all

bolts firmly.

Bend handle over

36.

Bend over handles of nut

plates so that struts are

not destroyed when wheel

carriers or jerry can carriers

are closed.

AT THIS STAGE JERRY CAN CARRIERS OR WHEEL CARRIERS MUST BE FITTED.

TO FIT JERRY CAN CARRIERS AND WHEEL CARRIERS, REFER TO FITTING

INSTRUCTIONS SUPPLIED IN FITTING KITS WITH JERRY CAN CARRIERS OR WHEEL

CARRIERS.

IF A JERRY CAN CARRIER OR WHEEL CARRIER IS NOT TO BE FITTED, THE COVER

PANEL SHOULD BE ALREADY FITTED. (REFER TO STEP 16.)

08-10-09 Page 13 of 19

3783146

Page 14

FITTING CENTRE COVER PANEL

Black nylon washer

37. Compile the components as shown

- Centre cover panel

- 2 x M6 cage nuts

- 2 x M6 x 25 socket head cap screw

stainless steel

- 2 x M6 x 25 bolts

- 4 x 6mm flat washers

- 2 x black nylon packers

- 2 x 8mm thick gold zinc spacers

- 4 x 6mm spring washers

38. Place M6 cage nuts into lower section of

centre cover panel.

39. Fit two M6 x 25 stainless steel socket

head cap screws, flat washers and spring

washers through top flange inside cover

panel as shown.

40. Place black nylon spacers on screws on

outside of centre cover panel flange and

attach to captive nuts in rear bar.

M6 cage nuts

(Finger tighten only.)

41. Place 8mm spacer between underside of

centre cover panel and rear bar.

08-10-09 Page 14 of 19

3783146

Page 15

42. From underneath rear bar pass two M6 x

25 bolts, flat washers and spring washers

through the aligned parts and finger

tighten.

M6 x 25 bolt and flat washer

FITTING END SURROUNDS TO REAR BAR

Top RHS

43.

Align faces of centre cover panel with

wheel carrier, jerry can carrier or cover

panel and tighten securely.

44. The surrounds are attached to rear bar

using three M8 x 35 bolts, flat washers

and flange nuts per side.

45. Place bolts and flat washers through the

top two holes of the rear bar end plate as

shown.

M8 flange nut

M8 x 35 bolt

and washer

46. Fit 8mm spacer to bolts, then fit end

surround and secure finger tight with M8

flange nuts.

8mm spacer

47. Fit the lower bolt with washer, spacer and

nut in the same sequence as the upper

two.

(Finger tighten only)

08-10-09 Page 15 of 19

3783146

Page 16

48. Using M8 x 20 bolts, flat washers and

flange nuts secure end surrounds to braces

finger tight. (RHS shown.)

VIEWED FROM RHS OF VEHICLE.

49. Before tightening bolts fit urethane vertical

trim between end plate and end surround.

50. Adjust trim to fit snugly around the rear bar

and the end surround.

51. Align top face of end surround parallel with

body of vehicle.

52. Starting in the top corner of the end

surround and working backwards tighten all

bolts.

A second person may be required to help

keep the vertical trim fitting snugly and to

ensure the end surround remains parallel

to the body.

08-10-09 Page 16 of 19

3783146

Page 17

53. Fit reflector to end of buffer.

54. Fit urethane buffer to top of end surround

using M6 nyloc nuts and large black flat

washers.

When fitting washers to studs under end

surround smear flat washers with grease to

hold them in place as shown below.

Reflector

FITTING TOP INFILL PLATE AND ALUMINIUM STEP PLATE

55. Using M6 button head cap screws fit top

infill plate.

56. To fit rubber sealing strip to underside of

aluminium step plate, lay strip on the

underside of step plate and place so over

hang is even on both ends. Using scissors,

cut darts up to the bulb end of the rubber

strip, so the strip can follow the front profile

of the aluminium step plate.

08-10-09 Page 17 of 19

3783146

Page 18

57. Carefully remove backing tape on the

rubber strip and fit to step plate working

from the centre outwards. Make sure

rubber strip hugs the front edge of the

aluminium step plate.

Using M6 button head cap screws fit

58.

aluminium step plate

08-10-09 Page 18 of 19

3783146

Page 19

FITTING TRAILER PLUG AND GOOSENECK

59. Fit trailer plug to recess using M5 pan head

screws as shown by arrows.

For aesthetics and protection of the plug it

is recommended that a flat type plug is

fitted.

To fit alternate plugs an adaptor bracket

(part number 5700090) is available. This is

not supplied as standard with the rear bar

kit.

60.

Fit gooseneck with pull pin and spring clip

as shown.

08-10-09 Page 19 of 19

3783146

Loading...

Loading...