Page 1

02

ELECTROMAGNETIC FLOWMETER

4621BAXXXXX

4622BAXXXXX

Software rel. 1.x

INSTALLATION, USE AND MAINTENANCE

Page 2

•

LEGEND SYMBOLS

= Generic danger

= Warning

CONTENTS

•

Legend symbols...............................................................................................................2

1 Product description .........................................................................................................3

1.1 Intended use ............................................................................................................3

2 Installation ........................................................................................................................ 3

2.1 Electric connections ................................................................................................. 5

2.2 Hydraulic connections ..............................................................................................5

3 Switch on ..........................................................................................................................6

4 Preliminary setup for use ................................................................................................ 6

4.1 Notes on programming ............................................................................................6

4.2 "OPT" Advanced menu ............................................................................................ 6

4.3 "MODE" Operation mode ........................................................................................6

4.4 "UNIT" Unit of measure ...........................................................................................7

4.5 "VAL" Valve operation time ......................................................................................7

5 Use ....................................................................................................................................8

5.1 Mode 0 - Mode 2 Use ..............................................................................................8

5.1.1 Displaying data......................................................................................................8

5.1.2 Setting the amount of liquid to load into the tank ..................................................8

5.1.3 Mode 0 - Mode 2 Operation ..................................................................................9

5.1.4 Interrupting/Stopping before reaching the programmed amount .........................9

5.2 Mode 1 Operation .................................................................................................. 10

5.2.1 Displaying data.................................................................................................... 10

5.2.2 Resetting the liquid introduced into the tank counter .......................................... 10

5.3 Reaching the full scale ...........................................................................................10

6 Maintenance / Diagnostics / Repairs ............................................................................ 11

6.1 Troubleshooting ..................................................................................................... 11

7 Technical data ................................................................................................................12

8 Disposal at the end of service ...................................................................................... 12

9 Coding table ................................................................................................................... 13

10 Guarantee terms.............................................................................................................14

This manual is an integral part of the equipment to which it refers and must accompany the equipment in

case of sale or change of ownership. Keep it for future reference; ARAG reserves the right to modify the

specications and instructions regarding the product at any time and without prior notice.

Page 3

1 PRODUCT DESCRIPTION

The Orion Visual Flow electromagnetic owmeter is a device that permits measuring and reading

on the display the liquid quantity passing through it.

Using a principle of electromagnetic measuring (there are no internal moving mechanical parts)

the owmeter gives a signal in proportion to the ow of the liquid passing through it; Orion displays

the value of the owrate calculated according to the impulses generated and the value of the previously programmed owmeter constant.

Furthermore Orion can be used as a lling owmeter; this function enables the setting of the quantity

of liquid with which the tank is to be lled during loading and by using the Pump Stop Kit (optional)

enables loading to be stopped when the set value has been reached.

1.1 Intended use

This device is designed to work on agricultural machinery for crop spraying applications.

The machine is designed and built in compliance with EN ISO 14982 standard (Electromagnetic compatibility - Forestry and farming machines), harmonized with 2004/108/EC

Directive.

The owmeter must not be used to measure the passage of hydrocarbons, ammable,

explosive or toxic liquids. The owmeter is not suitable for contact with liquids for human

consumption. Use for sales transactions is not allowed.

2 INSTALLATION

Install the owmeter at least 20 cm from the elements that could cause turbulence inside the tubes

(valves, bends, constrictions, etc.).

The owmeter can be installed in a vertical or horizontal position.

CAUTION:

For proper sealing of the owmeter, use ARAG assembly kit ONLY (Ref. ARAG General Catalogue - Accessories for series 463/473 modular valves).

ARAG is not liable for damage to the system, persons, animals or things caused by

the use of material other than specied.

TOT

RESET

3

Fig. 1

CONTINUES

Page 4

- For proper operation, respect the mounting direction (Fig. 2a and 2b);

The cable must NEVER be placed facing upwards.

HORIZONTAL ASSEMBLY

OK

OK

VERTICAL ASSEMBLY

Fig. 2a

Fig. 2b

- Respect the correct direction of liquid inlet-outlet, as indicated by the arrow printed on the

owmeter body (Fig. 3).

INOUT IN OUT

Fig. 3

Use inlet and outlet pipes of the same diameter as the internal passages of the owmeter;

see table 4 (Chap. 7 - Technical data) for reference.

4

Page 5

2.1 Electric connections

The Orion Visual Flow owmeter has been designed to work as a separate device or to be connected

to ARAG appliances (computers, screens, displays) or to equipment by other manufacturers as

long as the latter is designed for use with owmeters of this kind.

When used as a lling owmeter, the owmeter should ONLY be connected to ARAG

appliances.

ARAG is not liable for damage to the system, persons, animals or things caused by

incorrect or inadequate installation of the owmeter.

In the event of damage to the owmeter, caused by incorrect or unsuitable assembly,

any form of guarantee is automatically rendered null and void.

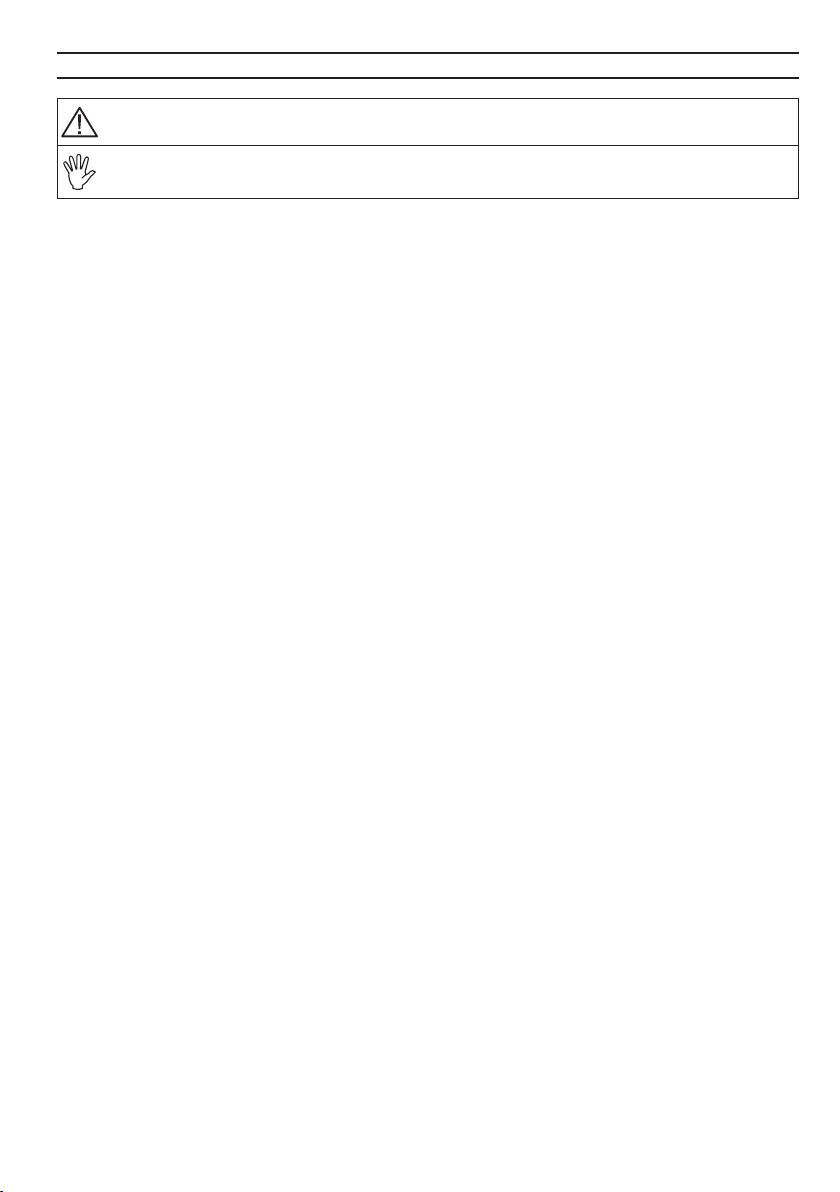

Connections of the owmeter to devices not produced by ARAG are shown in Table 1.

1

2

3

1

Fig. 4

2

3

4

4

Colour Position Connection

Black 1 GND

Red 2 +12 VDC

Green 3

Yellow 4 Pump control

Signal

(square wave)

It is possible to connect Orion Visual Flow to computers and screens in the Bravo series without the

"Pump Stop Kit" using the adapting cable (code 4622BA50000.110), which enables the connection

between the 4-pole connector on the owmeter and the 3-pole connector on the Bravo.

2.2 Hydraulic connections

For connection to the system, use appropriate ttings (Ref. ARAG General Catalogue).

Avoid bends and constrictions before connections and on tubes.

Regarding connections, use tubes and ttings properly sized for the operating pressure of the system.

The tightening of hose tails should be made with special metal clamps ensuring

perfect sealing even at high pressures.

The connection by means of threaded ttings should be done taking operating pressure into account.

CAUTION: For the implementation on already operating systems it is necessary to

follow all safety rules described herein.

System assembly and start-up must be carried out by expert personnel according to

the safety rules so as to ensure the same safety level of the system the owmeter is

going to be installed in.

Tab. 1

Tab. 1

5

Page 6

3 SWITCH ON

When the owmeter is turned on, after a diagnostic test, it displays the following information in

sequence:

• Software version;

• Unit of measurement;

• Indicator of data displayed.

4 PRELIMINARY SETUP FOR USE

4.1 Notes on programming

After having modied a parameter in the "OPT" Advanced menu, to return to the Main menu turn

the device off and then on again.

When you are modifying a parameter or are in a Menu other than the Main menu and you do not

press a key within 10 seconds, the display will automatically return to the Main menu.

When modifying a numerical value, keep the key pressed to enable quick modication.

4.2 "OPT" Advanced menu

Upon installation of the owmeter in the lling system some settings are

needed to properly display the lling data:

• Operation mode

• Unit of measure

• Valve operation time

To access the Advanced menu, keep the key pressed while switching ON

Fig. 6

4.3 "MODE" Operation mode

It is possible to set three different operating modes:

MODE 0 = Tank lling count with pump stop control (0000 ÷ 9999 EU: l [predened setting] - US: Gal).

MODE 1 = Flowrate display.

MODE 2 = Tank lling count with pump stop control (0 ÷ 999,9 EU: l - US: Gal).

the device until the "OPT" screen appears.

1

Access the "OPT" Advanced menu as shown in Par. 4.2.

1) Press in succession to display the enabled operation mode; the value alternates with the message

"MODE".

2) To modify the value, keep the keys pressed simultaneously until "SET" screen appears.

3) Press in succession to select the mode you wish to use.

4) To conrm the setting, keep the keys pressed simultaneously until "SAVE" screen appears.

The display alternatively ashes the set operation mode and "MODE" screen.

2 3 4

6

Fig. 7

Page 7

4.4 "UNIT" Unit of measure

It is possible to choose the units of measure for displaying data:

EU = Europa (l - l/min) [predened setting].

US = USA (Gal - Gpm).

1

Access the "OPT" Advanced menu as shown in Par. 4.2.

1) Press in sequence to display the type of current unit of measure; the value alternates with the message

"UNIT".

2) To modify the value, keep the keys pressed simultaneously until "SET" screen appears.

3) Press to select the unit of measure you wish to use.

4) To conrm the setting, keep the keys pressed simultaneously until "SAVE" screen appears.

The display alternatively ashes the set unit of measure and the "UNIT" screen.

2

3 4

4.5 "VAL" Valve operation time

This parameter lets you set the time it takes the valve installed on the system to complete its closing

operation; setting this value the owmeter enables to anticipate the exact moment in which

closing begins, thus avoiding the introduction of a greater amount of product when the set value

is reached.

VAL = 0 ÷ 20 sec.

1

2 3 4

+

Access the "OPT" Advanced menu as shown in Par. 4.2.

1) Press in succession to display the "VAL" valve operation time.

2) To modify the value, keep the keys pressed simultaneously until "SET" screen appears.

3) Press to enter the operation time value using TOT key (increase) and RESET key (decrease); keep the

keys pressed to enable quick modication.

4) To conrm the setting, keep the keys pressed simultaneously until "SAVE" screen appears.

The display alternately ashes the set operation time and "VAL" screen.

Fig. 8

Fig. 9

7

Page 8

5 USE

When using the system the owmeter sends pulses to the computer which will indicate instantaneous

owrate based on the constant value previously set.

The owmeter can only detect the passage of conductive liquids having conductivity greater

than or equal to 300 µS/cm (Ref. Table 3, Chap. 7).

- Do not subject the equipment to jets of water under pressure.

- Respect the required power supply voltage (12 Vdc).

- If arc welding is needed, make sure that the power supply to the owmeter is disconnected; if necessary disconnect power cables.

- Use the owmeter only within stated owrate limits (Ref. Table 4, Chap. 7). Outside these

limits, the owmeter may provide incorrect data, thus misleading the operator or the automatic system.

ARAG cannot be held responsible for damage caused to persons, animals or things due to

incorrect or inadequate use of the owmeter or its parts.

5.1 Mode 0 - Mode 2 Use

5.1.1 Displaying data

The following parameters can be displayed during operation:

Total liquid introduced into the tank

Instantaneous rate 0 ÷ 999,9 (EU: l/min - US: Gpm)

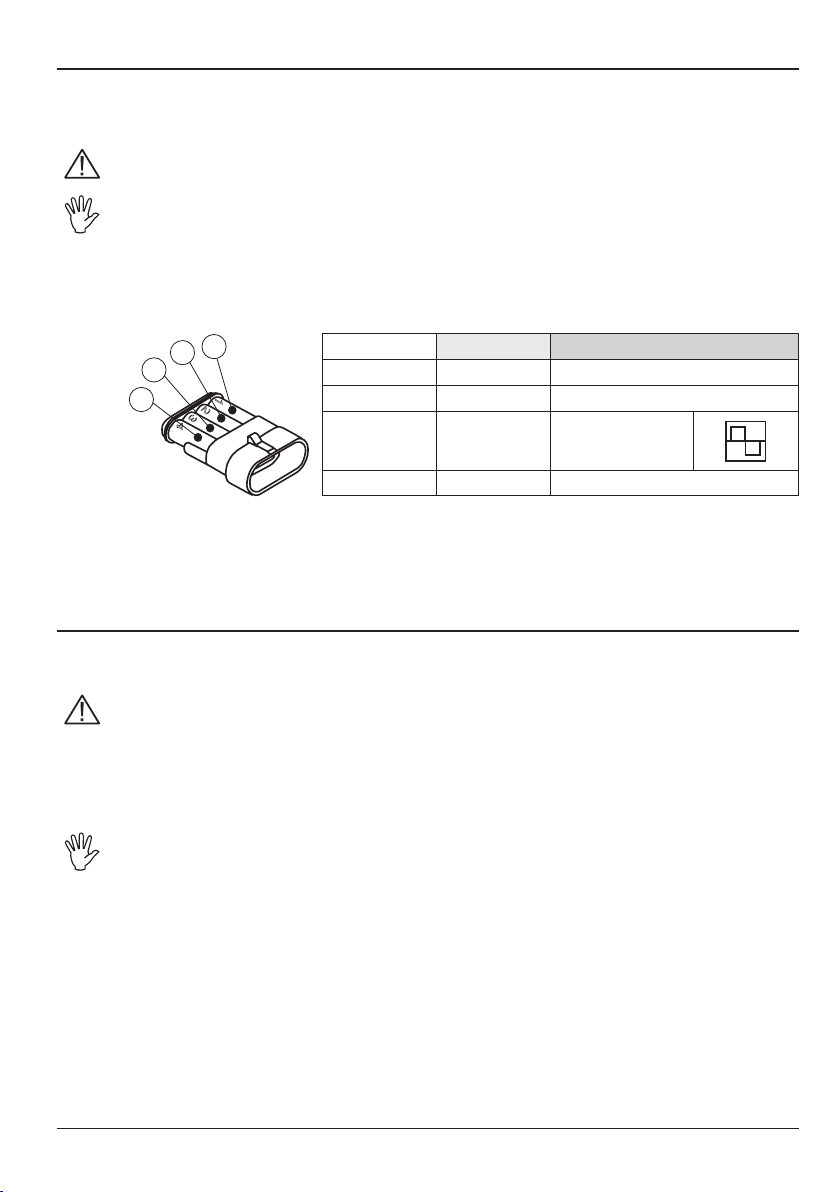

5.1.2 Setting the amount of liquid to load into the tank

In this operation mode the owmeter displays the total amount of liquid to load into the tank:

0 ÷ 9999 (EU: l - US: Gal) - "Mode 0"

0 ÷ 999,9 (EU: l - US: Gal) - "Mode 2"

1

2 3 4

+

Fig. 10

After having been turned on, the display shows the amount of liquid to load into the tank; to modify it,

proceed as follows:

1) Press RESET key until "FILL" screen appears.

2) Set the amount of liquid to load into the tank using TOT key (increase) and RESET key (decrease); keep

the keys pressed to enable quick modication.

3) To conrm the setting, keep the keys pressed simultaneously until "SAVE" screen appears.

4) The set amount of liquid to load into the tank is displayed preceded by "TOT" screen.

8

Page 9

5.1.3 Mode 0 - Mode 2 Operation

1

3

1) After having been turned on, the display shows the amount of liquid to load into the tank.

2) To start the loading procedure, keep TOT key pressed until "STRT" screen appears; the amount of total

liquid loaded into the tank is displayed in real time.

3) Press TOT key to display the instantaneous rate of the liquid loaded into the tank, preceded by "LIT"

screen. Press the key again to display the amount of liquid introduced into the tank.

4) When the set value has been reached, the display alternately ashes "END" screen and the total

amount of liquid loaded into the tank.

If the Pump Stop Module is present, the lling device will automatically stop; otherwise, it should be

stopped manually.

5) To complete tank lling, press RESET key: the display will go back to the beginning of the lling procedure, showing an amount of liquid to load into the tank preceded by "TOT" screen.

4 5

2

5.1.4 Interrupting/Stopping before reaching the programmed amount

1

2 3 4

Fig. 11

Fig. 12

1) During the lling process, you can temporarily stop the pump (*) by pressing RESET key; "STRT" screen

appears.

If the instantaneous quantity is displayed, "STRT" screen does not appear: in this case, press TOT key to

display it.

2) To resume loading, press RESET key again.

3) To complete loading before reaching the set value, press the keys simultaneously until "END" screen

appears.

4) The count will end and the display will show the programmed amount of liquid.

(*) The loading can be automatically started/stopped only if owmeter is connected to ARAG Pump Stop

Module (code 4622BA50000.200). If not, the owmeter will not be able to start or stop the pump on its own

and will work as a display only.

9

Page 10

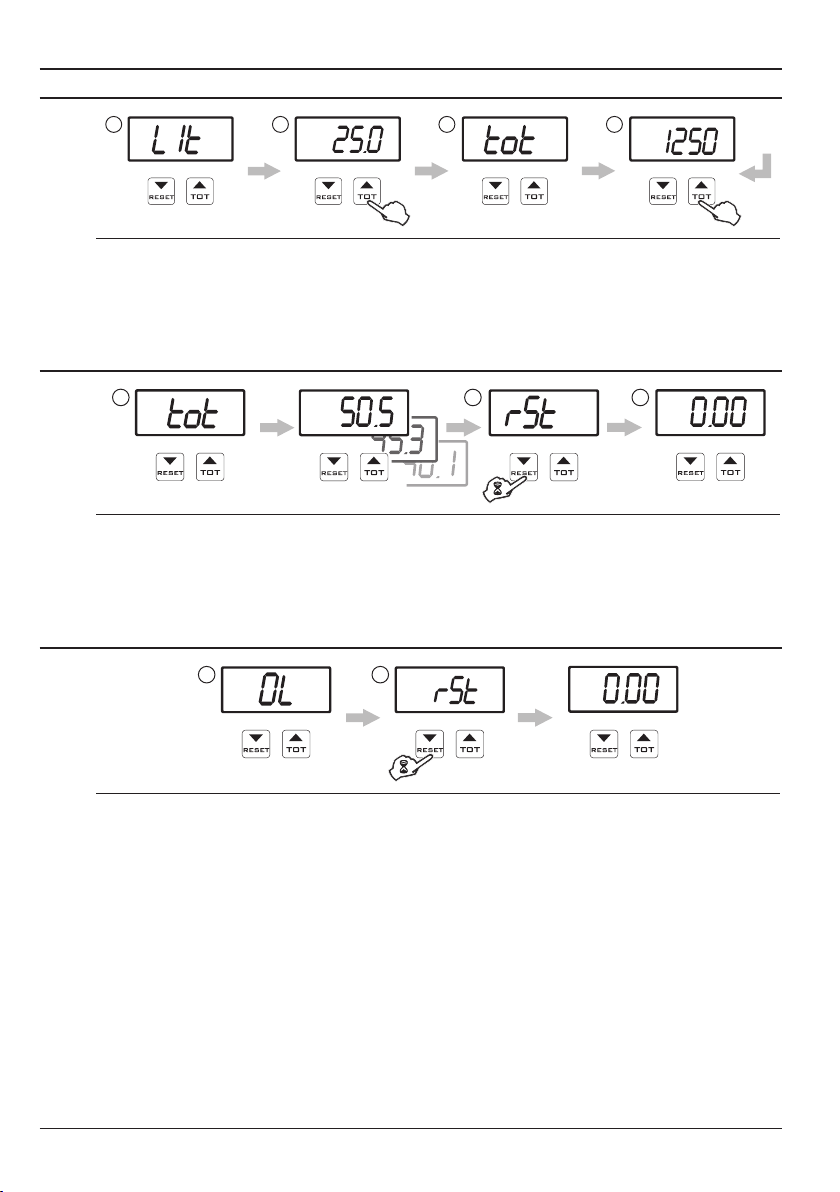

5.2 Mode 1 Operation

5.2.1 Displaying data

1

After having been turned on, the display shows the parameters read for Total liquid introduced into the

tank and Instantaneous rate using the previously set unit of measure (EU / US):

• Total liquid introduced into the tank = 0,00 ÷ 9999 (EU: l - US: Gal).

• Instantaneous rate = 0,0 ÷ 999,9 (EU: l/min - US: Gpm).

2 3 4

5.2.2 Resetting the liquid introduced into the tank counter

1

1) Access the total amount of liquid introduced into the tank display (Par. 4.2.1).

2) To reset the total amount of liquid introduced into the tank, keep RESET key pressed until "RST" screeen

appears.

3) At this point the display will show "TOT" screen followed by the reset total quantity counter.

5.3 Reaching the full scale

1

2

Fig. 13

2 3

Fig. 14

Fig. 15

1) The counter displays this screen when the full-scale value (9999 liters - Gal) is reached, and it therefore

becomes necessary to reset the counter.

2) To reset the count of the total amount of liquid introduced into the tank, keep RESET key pressed until

"RST" screen appears.

10

Page 11

6 MAINTENANCE / DIAGNOSTICS / REPAIRS

- At the end of each treatment, run clean water through the duct.

- At the end of each season or in the event of a malfunction, clean the owmeter duct using a

specic detergent.

- Do not use metal or abrasive objects for cleaning the duct.

- Do not use solvents or petrol for cleaning the external parts of the container.

6.1 Troubleshooting

FAULT CAUSE REMEDY

The owmeter does not read any

value

The value read by the owmeter is

not linear or stable

The owmeter shows incorrect data

The owmeter shows the message

No power supply • Check the owmeter wiring.

Presence of turbulence or air in the

circuit

Incorrect programming

Problems with the sensors

Problems with the owmeter

Endscale value has been

reached

• Check the circuit.

• Check programming concerning the

displayed data.

• Contact the nearest Assistance Centre.

• Reset the display following the

procedure described in the section on

the displayed value.

Tab. 2

11

Page 12

7 TECHNICAL DATA

Description Orion Visual Flow

Power supply 11 ÷ 14,5 Vdc

Max. absorption 300 mA

Minimum conductivity of liquid 300 µScm

Working temperature

Storage temperature

Dimensions 100x200x126 mm

Weight 886 ÷ 1650 g (depending on the type)

0 °C ÷ 60 °C

+32 °F ÷ +140 °F

-20 °C ÷ 60 °C

-4 °F ÷ +140 °F

Tab. 3

Flowrate

l/min US GPM pls/l pls/GAL

1 ÷ 20 0,3 ÷ 5 7 3000 11355

2,5 ÷ 50 0,6 ÷ 13 10 1200 4542

5 ÷ 100 1,3 ÷ 26 14 600 2271

10 ÷ 200 2,6 ÷ 53 18,5 300 1135

20 ÷ 400 5 ÷ 106 28 150 568

30 ÷ 600 8 ÷ 158 28 100 378

Models (*)

4621BAx1x1x 20 N + P + A

4622BAx1x1x 20 N + P + A

4622BAx7x1x 20 N + P + A

4621BAx3x3x 40 N + P + A + O

Typical error ± 0,5% of maximum value

Maximum error ± 1% of maximum value

(*) = 'x' stays for all possible variations of that position.

Internal passages

(Ø mm)

Max pressure

(bar)

Pulses/liter

Materials Legend:

Tab. 6

8 DISPOSAL AT THE END OF SERVICE

Dispose of the system in compliance with the established legislation in the country of use.

Tab. 4

N = Nylon

P = Polypropylene

A = Inox stainless steel

O = Brass

Tab. 5

12

Page 13

9 CODING TABLE

462 Single root for all subgroups

1 Body flange 463

2 Body flange 473

A Without display display 20/40 Bar

B With display display 20/40 Bar

A 316 STAINLESS STEEL electrodes

1 Flowrate 1/20 L/min

2 Flowrate 2,5/50 L/min

3 Flowrate 5/100 L/min

4 Flowrate 10/200 L/min

5 Flowrate 20/400 L/min

6 Flowrate 30/600 L/min

BODY 463

BODY 473

0 Without connection

1 Flange w/male thread

2 Flange w/female thread

3 Flange w/brass male thread

4 Flange w/brass female thread

5 Flange w/NPT male thread

6 Flange w/NPT female thread

7 Cam-Lock adapter

8 "Banjo" flange

9 ISO flange Inlet connection to Flowmeter

A Fork connection MALE flange

B

Fork connection FEMALE flange

0 See body flange

3 3/4" DN20 T3

4 1" DN25 T4

5 1"1/4 DN32 T5

6 1"1/2 DN40 / 2"STD PORTT6

7 2" DN50 / 2"FULL PORTT7

0 Without connection

1 Flange w/male thread

2 Flange w/female thread

3 Flange w/brass male thread

4 Flange w/brass female thread

5 Flange w/NPT male thread

6 Flange w/NPT female thread

7 Cam-Lock adapter

8 "Banjo" flange

9 ISO flange Outlet connection from Flowmeter

A Fork connection MALE flange

B Fork connection FEMALE flange

See body flange

0

0

3 3/4" DN20 T3

4 1" DN25 T4

5 1"1/4 DN32 T5

6 1"1/2 DN40 / 2"STD PORTT6

7 2" DN50 / 2"FULL PORTT7

462 1A A 30000

462 2B A 57616

13

Flowmeter with flange 463 for control unit, 5/100 l/min,

standard electrodes.

Flowmeter body/flange 473, 20/400 l/min, standard electrodes,

1"½ CAM-LOCK inlet connection, 1" 1/2 gas Male thread outlet.

Page 14

10 GUARANTEE TERMS

1. ARAG s.r.l. guarantees this apparatus for a period of 360 day (1 year) from the date of sale

to the client user (date of the goods delivery note). The components of the apparatus, that

in the unappealable opinion of ARAG are faulty due to an original defect in the material or

production process, will be repaired or replaced free of charge at the nearest Assistance

Centre operating at the moment the request for intervention is made.

The following costs are excluded:

- disassembly and reassembly of the apparatus from the original system;

- transport of the apparatus to the Assistance Centre.

2. The following are not covered by the guarantee:

- damage caused by transport (scratches, dints and similar);

- damage due to incorrect installation or to faults originating from insufficient or inadequate

characteristics of the electrical system, or to alterations resulting from environmental, climatic or other conditions;

- damage due to the use of unsuitable chemical products, for spraying, watering, weedkilling or any other crop treatment, that may damage the apparatus;

- malfunctioning caused by negligence, mishandling, lack of know how, repairs or modications carried out by unauthorised personnel;

- incorrect installation and regulation;

- damage or malfunction caused by the lack of ordinary maintenance, such as cleaning of

lters, nozzles, etc.;

- anything that can be considered to be normal wear and tear.

3. Repairing the apparatus will be carried out within time limits compatible with the organisational needs of the Assistance Centre.

No guarantee conditions will be recognised for those units or components that have not

been previously washed and cleaned to remove residue of the products used.

4. Repairs carried out under guarantee are guaranteed for one year (360 days) from the

replacement or repair date.

5. ARAG will not recognise any further expressed or intended guarantees, apart from those

listed here.

No representative or retailer is authorised to take on any other responsibility relative to

ARAG products.

The period of the guarantees recognised by law, including the commercial guarantees and

allowances for special purposes are limited, in length of time, to the validities given here. In

no case will ARAG recognise loss of prots, either direct, indirect, special or subsequent to

any damage.

6. The parts replaced under guarantee remain the property of ARAG.

7. All safety information present in the sales documents regarding limits in use, performance

and product characteristics must be transferred to the end user as a responsibility of the

purchaser.

8. Any controversy must be presented to the Reggio Emilia Law Court.

14

Page 15

Conformity Declaration

ARAG s.r.l.

Via Palladio, 5/A

42048 Rubiera (RE) - Italy

P.IVA 01801480359

Dichiara

che il prodotto

descrizione: Flussometro elettromagnetico

modello: Orion Visual Flow

codice: 4621BAXXXXX e 4622BAXXXXX, 4621CXXXX

risponde ai requisiti di conformità contemplati nelle seguente Direttiva Europea:

2004/108/CE e successive modificazioni

(Compatibilità elettromagnetica)

Riferimenti alle Norme Applicate:

EN ISO 14982

(Compatibilità elettromagnetica - Macchine agricole e forestali)

Rubiera, 25 Settembre 2012

Giovanni Montorsi

(Presidente)

Page 16

Only use original ARAG accessories and spare parts, to maintain safety conditions foreseen by the constructor.

Always refer to the ARAG spare parts catalogue.

42048 RUBIERA (Reggio Emilia) - ITALY

Via Palladio, 5/A

Tel. +39 0522 622011

Fax +39 0522 628944

www.aragnet.com

info@aragnet.com

D20067_GB-m05 10/2012

Loading...

Loading...