Page 1

02

Tank Filling sysTem

462F4501

Software rel. 1.x

insTallaTiOn, Use anD mainTenanCe

Page 2

LEGEND SYMBOL

= Generic danger

= Warning

This manual is an integral part of the equipment to which it refers and must accompany the equipment in

case of sale or change of ownership. Keep it for future reference; ARAG reserves the right to modify the

specications and instructions regarding the product at any time and without prior notice.

2

Page 3

SUMMARY

1 SAFETY GUIDELINES....................................................................................................................................4

2 PRODUCT DESCRIPTION ............................................................................................................................4

2.1 Intended use ......................................................................................................................... 4

3 INSTALLATION .................................................................................................................................................. 5

3.1 Electric connections ............................................................................................................. 6

3.2 Hydraulic connections ......................................................................................................... 7

3.2.1 General warnings ................................................................................................................7

3.2.2 Hydraulic connections ........................................................................................................ 7

3.3 Connections - general diagram .......................................................................................... 7

3.4 Monitor rotation ..................................................................................................................... 8

4 CONTROLS IN THE MENU...........................................................................................................................9

4.1 First switch on ....................................................................................................................... 9

5 MENU STRUCTURE ...................................................................................................................................... 10

6 PRELIMINARY SETUP FOR USE ........................................................................................................... 11

6.1 Operating mode selection (FILLING / FLOWRATE) .....................................................11

7 USE IN FILLING MODE ............................................................................................................................... 11

7.1 Preliminary setup .................................................................................................................11

7.1.1 Valve activation time ...........................................................................................................11

7.2 Flowmeter use (FILLING mode) ...................................................................................... 12

8 USE IN FLOWRATE MODE ........................................................................................................................ 13

8.1 Flowmeter use (FLOWRATE mode) ............................................................................... 13

8.2 Partial totalizer reset .......................................................................................................... 13

9 OTHER SETTINGS .........................................................................................................................................14

9.1 Calibration............................................................................................................................ 14

9.1.1 Automatic calibration ........................................................................................................ 14

9.1.2 Manual calibration ............................................................................................................. 15

9.2 Flowrate alarms .................................................................................................................. 15

9.3 Display .................................................................................................................................. 16

9.4 Options ................................................................................................................................. 16

9.4.1 Language ........................................................................................................................... 16

9.4.2 Units of measurement ....................................................................................................... 17

9.4.2.1 Rate units of measurement ............................................................................................... 17

9.4.2.2 Volume units of measurement .......................................................................................... 17

9.5 Test ....................................................................................................................................... 18

9.5.1 Display test......................................................................................................................... 18

9.5.2 Keys test ............................................................................................................................. 18

10 MAINTENANCE ...............................................................................................................................................19

10.1 Notes on maintenance ...................................................................................................... 19

10.2 Paddle cleaning and replacement ................................................................................... 19

10.3 OR replacement ................................................................................................................. 20

10.4 Troubleshooting .................................................................................................................. 21

11 TECHNICAL DATA .......................................................................................................................................... 22

12 DISPOSAL AT THE END OF SERVICE ................................................................................................. 23

13 GUARANTEE TERMS ...................................................................................................................................26

3

Page 4

INTRODUCTION

1 SAFETY GUIDELINES

CARRYING OUT INSTALLATION AND MAINTENANCE OPERATIONS WITHOUT DISCONNECTING THE VALVE FROM ITS POWER SUPPLY MAY CAUSE SEVERE INJURY.

Do not operate the valve with no load for long periods of time, as this might damage the

components inside the valve.

ARAG can not be held responsible for direct or indirect damage caused by the type of uids

used for spraying and crop spraying applications.

These products are used under the exclusive responsibility of the operator, who must make

sure that all safety prescriptions indicated on the product label are complied with and that

suitable personal protective equipment (such as gloves, overalls, boots, helmet, etc.) is worn

at all times in compliance with the applicable legal requirements.

The tank lling system can detect the passage of conductive uids with a conductivity equal

to or higher than 300 μS/cm.

- Do not place the equipment under pressurized water.

- Comply with the specied power voltage (12 Vdc).

- If arc welding is needed, make sure that the power supply to the tank lling system is

disconnected; if necessary disconnect power cables.

- Use the tank lling system only within recommended rate range (Tab. 1, Pag. 13). Outside

this range, the tank lling system may provide incorrect data, thus misleading the operator

or the automatic system.

ARAG can not be held responsible for damage caused to persons, animals or things from

the incorrect or unintended use of the tank lling system or its parts.

2 PRODUCT DESCRIPTION

The movable tank lling system measures and displays on its screen a pre-established quantity of

uid and stops tank lling when the set quantity is reached. Through electromagnetic measurement,

the tank lling system (which features no moving mechanical parts) emits a signal that is proportional

to the ow of uid passing through it. The

owmeter displays the relevant owrate, which is calculated according to the impulses generated

and the value of the owmeter constant previously set.

2.1 Intended use

This device is designed for agricultural use. The machine is designed and built in compliance with EN ISO 14982 standard (Electromagnetic compatibility - Forestry and farming

machines), harmonized with 2004/108/EC Directive and in compliance with 2006/42/EC

Directive.

The tank lling system must not be used to measure the passage of hydrocarbons, ammable, explosive or toxic liquids. The tank lling system is not suitable for contact with

liquids for human consumption. Use for sales transactions is not allowed.

4

Page 5

INSTALLATION

3 INSTALLATION

The tank lling system must be connected by means of suitable ttings (With female fork coupling)

to a pump, which will supply the liquid to be poured into the tank.

Install the tank lling system at least 20 cm from the elements that could cause turbulence inside

the tubes (valves, bends, constrictions, etc.).

WARNING:

- Rest the tank lling system on a horizontal surface

- The system to which it is connected must have a ltering element with a lter of at

least 50 mesh, together with a safety valve to limit use pressure at the specied max.

value (12 bar).

CAUTION:

ARAG is not liable for damage to the system, persons, animals or things caused by

the use of material other than specied.

Failure to observe the above instructions automatically voids the warranty.

5

Page 6

INSTALLATION

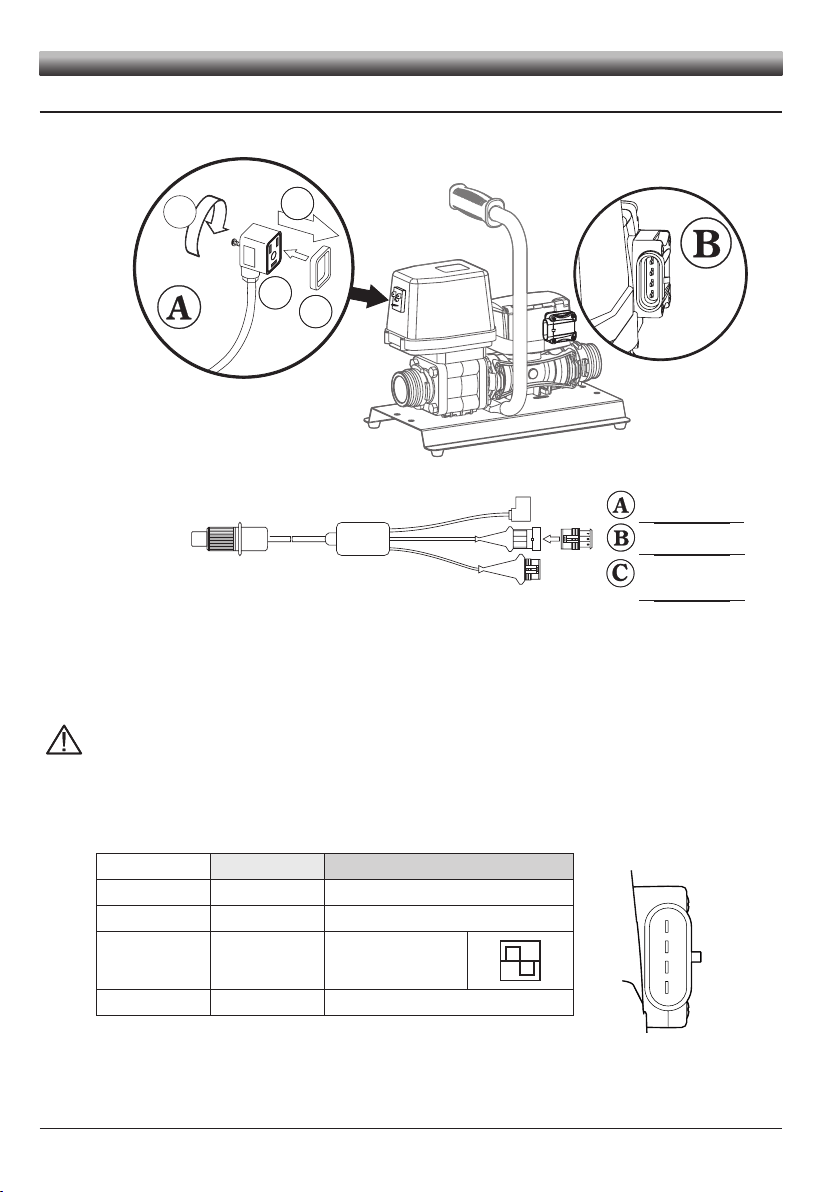

3.1 Electric connections

The tank lling system must be connected using the supplied cables.

4

3

2

1

valve cable

12 Vdc

- Remove the protection cap from the valve

- Position seal (1 in Fig. A) onto connector (2 in Fig. A), then connect the latter pressing it fully home

(3 in Fig. A). During this operation, take special care not to bend valve electric contacts.

- Fasten screw (4 in Fig. A) until it is tightened.

CAUTION: If the gasket is not positioned correctly, there may be inltrations of water

in the connector and in the valve, with the consequent risk of damage to the device.

to flowmeter

to computer

(e.g., Bravo 400s,

Bravo 300s)

DO NOT CONNECT THE POWER SUPPLY USING DIRECT FASTON CONNECTORS.

Bravo connector (C) - Connections:

Cable colour Position Connection

Grey 1 GND

Brown 2 +12 VDC

Yellow/Green 3

Black 4 Pump control

Signal

(square wave)

6

Tab. 1

4

3

2

1

Page 7

SPRAYINGCOMPUTER

A

B

C

D

E

Computer(e.g., Bravo 400s)

INSTALLATION

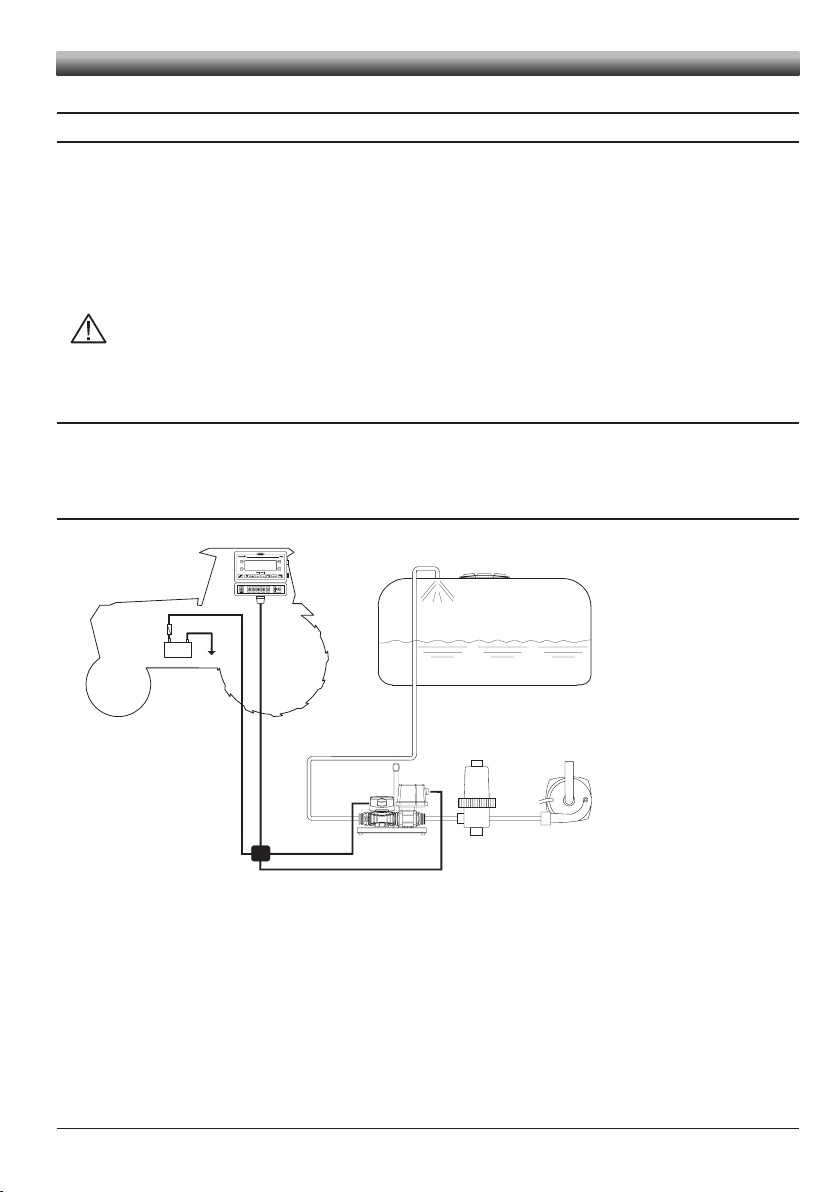

3.2 Hydraulic connections

3.2.1 General warnings

Avoid bends and constrictions before connections and on tubes.

Do not use the tank lling system with pressure values over 12 bar.

Regarding connections, use tubes and ttings properly sized for the operating pressure of the system.

Use Arag T6 ttings (see general catalogue) with female fork coupling. Do not use

elbow ttings.

WARNING: For the implementation on already operating systems it is necessary to

follow all safety rules described herein. System assembly and start-up must be carried out by expert personnel according to the safety rules so as to ensure the same

safety level of the system.

3.2.2 Hydraulic connections

Connect inlet pipes to the valve and outlet pipes from the owmeter, using suitable connectors.

Take special care, where requested, to insert the O-ring correctly. If, for any reason, the pipes leak

at connection points, apply unsintered PTFE tape to improve sealing.

3.3 Connections - general diagram

2 43 5

1

+-

12Vdc

Legend:

A Tank filling system

B Filter

C Tank filling pump

D Battery

E

7

Page 8

INSTALLATION

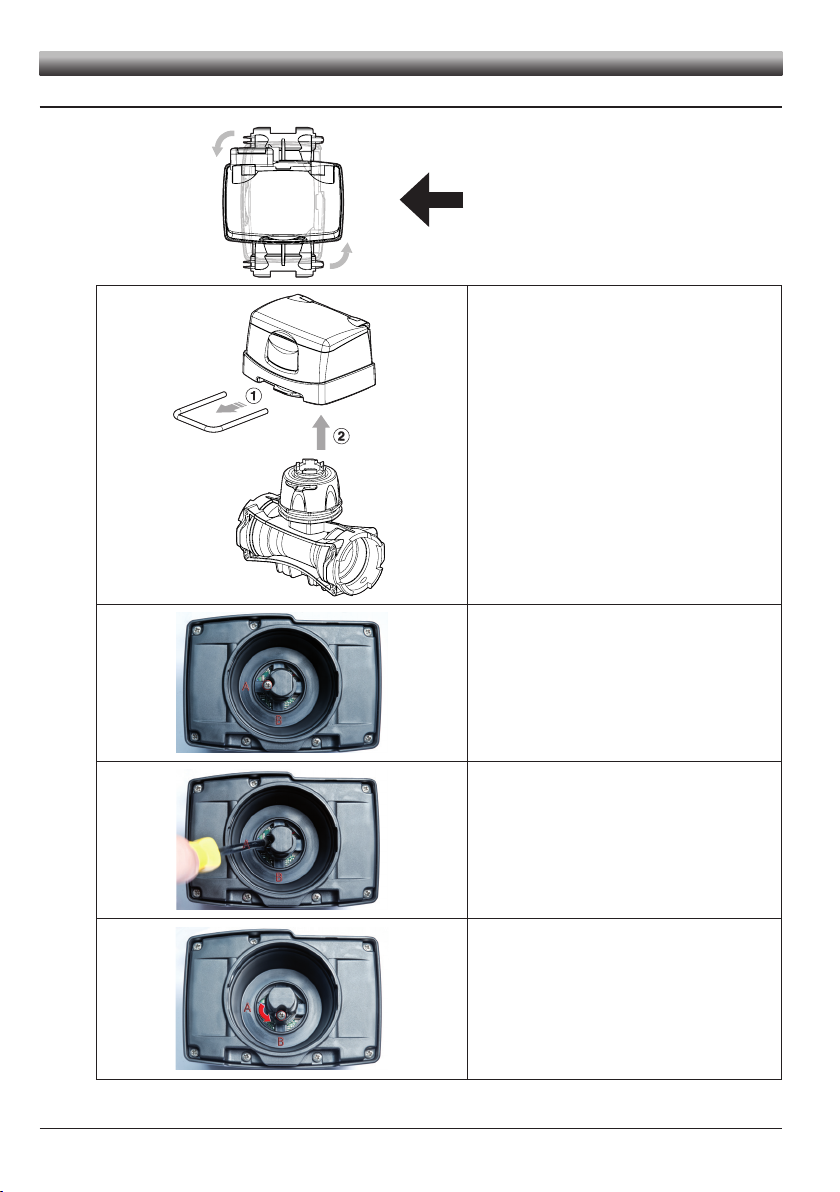

3.4 Monitor rotation

In case of vertical assembly, to simplify

the use of the DigiWolf it is possible to

rotate the monitor by 90° with respect to

the body.

1) Remove the fork from the monitor using a screwdriver.

2) Remove the monitor from the owmeter body.

If the monitor is turned upside down, the letters A and

B can be seen: these correspond to the two possible

monitor positions (parallel and perpendicular to the

body).

DigiWolf is supplied with the sensor in position A (paral-

lel to the body).

With the aid of a screwdriver, loosen the screw locking

the sensor without removing it.

Rotate the sensor anti-clockwise until reaching B stop

position.

Tighten back the screw without forcing it. The monitor

is ready to be tted in perpendicular position to the body.

Fit the monitor back on the owmeter body.

8

Page 9

4 CONTROLS IN THE MENU

0.0 l

2

1

0.0 l/min

0.0 l

2

1

0.0 l/min

Setup menu

Calibration

Flowrate alarms

Display

A

B

Flowrate constant

Min value

Max value

C

1

50000

01230

B

D

A

CONTROLS

SWITCH ON

The owmeter is turned on when powered.

Press the key to see the succession of different values written in

full (central part of the display).

Whenever the device is switched on, it will briey display its

name and software version.

ACCESS TO SETUP MENU

Press the keys for 2 seconds at the same time to access setup

menu.

SELECTION AND ACCESS TO MENU ITEMS

A Press in succession to move through items (the selected item

is highlighted with a black band)

B Press to access the selected item

Three dots under an item show the presence of

another setup menu.

MODIFYING DATA

A Press to toggle from one digit to another

B Press in succession to modify the value of the digit highlighted

by the cursor

C Press to conrm the change. The display goes back to the

previous screen.

D Press to exit current page without conrming changes.

4.1 First switch on

At rst switch on, DigiWolf will run a guided procedure to set the language, two units

of measurement (owrate and volume), and the operating mode (lling or owrate).

Press key to move between items, OK to save and move to the next setting, or ESC return

to the previous setting.

9

Page 10

Setup menu

Flowrate alarms

Calibration

Flowrate alarms

Min flow alarm

Max flow alarm

Display

Setup menu

Display

Display

Brightness

Contrast

Calibration

Flowrate alarms

OFF

50%

Setup menu

Options

Options

Language

Units of measurem.

Operating mode

Flowrate alarms

Display

English

0.0 l

2

1

0.0 l/min

Setup menu

Calibration

Flowrate alarms

Display

Calibration

Auto calibration

Man. calibration

Calibration

Man. calibration

600

Auto calibration

Par. 9.1.1

Flowrate alarms

Min flow alarm

Max flow alarm

OFF

Par. 9.2

Par. 9.2

Display

Contrast

Brightness

50%

Par. 9.3

Par. 9.3

Options

Units of measurem.

Language

Units of measurem.

Flowrate

Volume

l/min

Units of measurem.

Volume

Flowrate

l

Switch on

2s.

Setup menu

Test

Test

Firmware version

Sensor frequency

Battery voltage

Display

Options

1.00

Par. 9.5

Par. 9.5

Test

Sensor frequency

Firmware version

0.0Hz

Battery voltage

Par. 9.5

Test

Battery voltage

Firmware version

Sensor frequency

Par. 9.5.1

Test

Display test

Sensor frequency

Battery voltage

Par. 9.5.2

Test

Keys test

Battery voltage

Display test

Operating mode

Par.7

Options

Operating mode

Language

Operating mode

Filling

Flowrate

Operating mode

Flowrate

Filling

Units of measurem.

Filling

Par.8

13.4V

Setup menu

Valve activ. time

Flowrate alarms

Display

0.0s

‘FILLING’ mode only

MENU

5 MENU STRUCTURE

Par. 9.4.1

Par. 9.4.2

Par. 6.1

10

Par. 9.1.2

Par. 9.4.2.1

Par. 9.4.2.2

Page 11

6 PRELIMINARY SETUP FOR USE

Options

Operating mode

Language

Units of measurem.

Filling

Operating mode

Filling

Flowrate

Setup menu

Valve activ. time

Flowrate alarms

Display

0.0s

Valve activ. time

Min value

Max value

C

0.0

9.9

.00

B

D

A

s

For a correct display of data regarding treatment, some preliminary set ups are necessary when

installing DigiWolf on farming machines.

6.1 Operating mode selection (FILLING / FLOWRATE)

DigiWolf can be used to measure the owrate of a uid in a hydraulic circuit ("Flowrate" mode), or

to control the lling of a tank by stopping the introduction of liquid once the set quantity has been

reached ("Filling" mode).

Some menu items will be available or not according to the set mode.

1) Go to the operating mode selection menu (Setup menu > Options

> Operating mode).

Under the selected item, the currently set mode will be displayed.

SETUP

2

2

7 USE IN FILLING MODE

7.1 Preliminary setup

7.1.1 Valve activation time

It is possible to set the lling valve activation time, i.e. the time interval between the sending of

valve closure signal and the ow actual interruption, so that DigiWolf can calculate the exact time

of operation and therefore the quantity introduced.

The value to be entered is indicated in the technical sheet of the lling valve installed in the system.

1) Select the desired operating mode with the key.

1

2) Press OK to save, or ESC to exit without saving.

1) Access the valve activation time menu (Setup menu > Valve activ.

time).

Under the selected item, the currently set value will be dis-

played.

2) Use the relevant keys to set the valve activation time:

A) Press to toggle from one digit to another

B) Press in succession to modify the value of the digit highlighted by

the cursor

C) Press to save changes or D) Press to exit current page without

conrming changes.

11

Page 12

Start

¬

¬

Quantity

¬

¬

o

3000.0

o

Start

¬

¬

Quantity

¬

¬

o

3000.0

Quantity

Min

Max Value

ValueC0.1

99999.9

B

D

A

3000.00

l

Start

¬

¬

Quantity

¬

¬

o

5000.0

5000.0 l

o

6.23

21.84 l/min

5000.0 l

o

15.98

Pause

5000.0 l

o

5000.0

Complété

USE (FILLING MODE)

7.2 Flowmeter use (FILLING mode)

The main screen shows the display divided into three horizontal sectors:

- upper sector:

The Start item refers to the key on the side, which allows starting the procedure

(OK key);

- central sector:

the value represents the set lling quantity (in liters).

Next to it appears the symbol

- lower sector:

The Quantity item refers to the key on the side, which allows setting the value

of tank lling (ESC key).

1) Keep ESC key pressed for two seconds to access the lling quantity set up

menu.

2) Using the suitable keys, set the lling quantity value:

A) Press to toggle from one digit to another

B) Press in succession to modify the value of the digit highlighted by the cursor

C) Press to save changes or D) Press to exit current page without conrming

changes.

3) Keep OK key pressed for two seconds. The lling process starts.

;

The display shows the following data:

- upper sector: set lling quantity;

- central sector: partial totalizer;

- lower sector: instant rate.

To see a datum in full, press the button several times until the desired value is in

the central sector of the display.

Displayed data can not be edited.

The tank lling can be interrupted at any time by pressing ESC key. The

Pause message will appear in the lower part of the display.

Press OK key to restart the lling process;

Press ESC key to denitively stop the lling; the display will go back to the main

page.

The lling stops automatically once the set quantity is reached.

The Completed message will appear in the lower part of the display.

12

Page 13

8 USE IN FLOWRATE MODE

1

0.0 l

2

1

0.0 l/min

6.23 l

2

1

21.84 l/min

6.23

6.23 l

2

1

21.84 l/min

6.23

6.23 l

2

1

21.84 l/min

0.00

50.00 l

2

1

21.84 l/min

999.99

1050.0 l

2

1

21.84 l/min

1000.0

10049 l

2

1

21.84 l/min

9999.9

10050 l

2

1

21.84 l/min

10000

...

8.1 Flowmeter use (FLOWRATE mode)

The main screen shows the display divided into three horizontal sectors.

The sectors showing the symbols

The third data represents instant rate value.

8.2 Partial totalizer reset

and 2 represent the partial totalizers, individually resettable.

Partial totalizers

Instantaneous rate

Feed some liquid to the system. The display will start to show the

increasing value of the measured quantity of liquid, and the instant

rate value.

To reset a totalizer, it is necessary to visualize it in full.

To do this, press the button several times until the value to zero is in

the central area of the display.

USE (FLOWRATE MODE)

Press ESC key for two seconds. The totalizer will zero.

- Do not place DigiWolf under pressurized water.

- Use the owmeter only within recommended rate range (Tab. 2 - Pag. 22). Beyond these

limits, the ow-meter may give out incorrect data.

- To avoid damaging the owmeter, do not exceed the maximum rate except for short periods.

ARAG can not be held responsible for damage caused to persons, animals or things from

the incorrect or unintended use of Digiwolf or its parts.

- Do not exceed the max. operation pressure (12 bar).

Display of the symbol ------ shows that the rate or the totalizer are over the max. displayable value.

Totalizers have oating points and display a max. of 5 gures. Up to 999.99 two decimals

are shown, it then drops to 1 and 0 with the transition to thousands and tens of thousands

(See g. below).

13

Page 14

End reading

0.0 l/min

¬

¬

Calibration

67.58 l

¬

¬

C

D

067.580

o

1

2

B

A

1

2

SETUP

9 OTHER SETTINGS

What follows applies to both operating modes of the owmeter.

9.1 Calibration

Rate reading may not be correct due to different system congurations (tubes,

valve, etc.). Therefore, we recommend to make a spray test; in case the measured

value is different from the real one, perform an automatic calibration procedure or

manually calculate owrate constant.

9.1.1 Automatic calibration

Make a quantity of liquid previously measured or that can be measured with another system

go through the owmeter. The greater the amount of liquid used to perform the calibration

procedure, the more accurate the calibration.

1) Access Automatic calibration menu (Setup menu > Calibration >

Auto calibration). Once inside the menu, the device is ready to

start measuring without any further controls.

2) Make the liquid go through the system. The display will start to

show the increasing value of the measured quantity of liquid. Once

liquid passage has nished, the value on the display will not change

any more.

At this point, press OK. In the lower part of the display, the message Stabilization will come up and the device will show

the screen on the side.

Setting of liquid amount actually passed through the owmeter during calibration procedure.

Display of liquid amount read by the owmeter during calibration procedure.

3) Using the keys, enter the values of the liquid quantity previously measured:

A) Press to toggle from one digit to another

B) Press in succession to modify the value of the digit highlighted by the cursor

C) Press to complete calibration procedure, or D) Press for 1 sec. to cancel calibration procedure.

If, after starting calibration, the device does not sense any ow passage (and the display

remains in 0), press OK to exit the calibration procedure without saving.

If the device continues to sense the liquid ow after pressing OK, after a few seconds

the error message Stop flow!will be displayed.

Once the ow has been interrupted, the reading will stabilize as by standard procedure.

14

Page 15

9.1.2 Manual calibration

Calibration

Man. calibration

Auto calibration

600

Flowrate constant

Min value

Max value

C

1

50000

B

D

A

06000

APPROXIMA

TE CONST

ANT

XXX

Flowrate alarms

Min flow alarm

Max flow alarm

6.00/min

Min flow alarm

Min value

Max value

0.1

99999.9

OFF

o

Min flow alarm

Min value

Max value

C

0.1

99999.9

B

D

A

0040.00

l/min

o

To set the owrate constant manually, calculate and set the correct constant using the following

formula:

SETUP

[amount measured by device]

[actually delivered quantity]

x [constant indicated on flowmeter body]

1) Access Manual calibration menu (Setup menu > Calibration > Man. calibration).

In Calibration menu, selecting Manual calibration, under the item the cur-

rently set constant will be displayed.

Press OK key to access value modication.

2) Using the suitable keys, set the value of the owmeter constant:

A) Press to toggle from one digit to another

B) Press in succession to modify the value of the digit highlighted by the cursor

C) Press to save changes or D) Press to exit current page without conrming

changes. Refer to the label on the body

The owmeter body must be assembled with the arrow on the

label facing the ow direction.

APPROXIMATE CONSTANT

XXX

CODE Approximate constant

4627405A 250

4627506A 132

4627707A 64

9.2 Flowrate alarms

Set the minimum and maximum values beyond which the display must show an alarm message.

1) Access Flowrate alarms menu (Setup menu > Flowrate alarms).

Min. and max. owrate alarms setting is done in the same way.

Under the selected item, the currently set value will be displayed.

Press OK key to access modication of the selected item.

and

2) To activate the alarm, press

message OFF disappears and owrate alarm value is displayed.

keys at the same time until the

Carry out the same procedure to deactivate owrate alarm again.

3) Set owrate alarm value:

A) Press to toggle from one digit to another

B) Press in succession to modify the value of the digit highlighted by the cursor

C) Press to save changes of D) Press to exit current page without conrming

changes.

15

Page 16

SETUP

Display

Brightness

Contrast

50%

Brightness

50%

1

2

2

Options

Language

Units of measurem.

English

Language

Italiano

English

Español

Português

9.3 Display

Adjust display brightness and contrast.

9.4 Options

9.4.1 Language

Set desired language and units of measurement.

Access display menu (Setup menu > Display).

Brightness and contrast adjustment is done in the same way.

Under the selected item, the currently set value will be displayed.

Press OK key to access modication of the selected item.

1) Set the value using the key. Each time it is pressed, the value will increase

by 10% until reaching 100% and then starts back from 0.

2) Press the OK key to save, or ESC to exit without saving.

Access language setup menu (Setup menu > Options > Language).

Under the selected item, the currently set value will be displayed.

Press OK key to access language selection.

2

2

1) Select language using the key.

1

2) Press the OK key to save, or ESC to exit without saving

16

.

Page 17

9.4.2 Units of measurement

Units of measurem.

Flowrate

Volume

l/min

Flowrate

l/min.

GPM

m/h

3

Units of measurem.

Volume

Flowrate

l

Volume

l

gal

m

3

Set units of measurement for owrate values and volume read by the device.

9.4.2.1 Rate units of measurement

Access instant rate units of measurement menu (Setup menu > Options > Units

of measurem. > Flowrate).

Under the selected item, the currently set value will be displayed.

Press OK key to access owrate units of measurement selection.

SETUP

2

2

9.4.2.2 Volume units of measurement

2

2

1) Select measurement unit using key.

1

2) Press OK key to save, or ESC to exit without saving.

Access volume units of measurement menu (Setup menu > Options > Units of

measurem. > Volume).

Under the selected item, the currently set value will be displayed.

Press OK key to access volume units of measurement selection.

1) Select measurement unit using key.

1

2) Press OK key to save, or ESC to exit without saving.

17

Page 18

Test

Display test

Sensor frequency

Battery voltage

Test

Keys test

Battery voltage

Display test

1

2

1

1

SETUP

9.5 Test

In this menu is it possible to see some information and run a device operation test:

- Firmware version:

The display shows the rmware version installed on the device.

- Sensor frequency:

In the presence of ow passage, the display shows in real time the frequency of the signal from the

sensor reading the owrate.

- Battery voltage:

the display shows the device supply voltage level.

9.5.1 Display test

Display test checks the correct operation of the display on the device.

Access display test menu (Setup menu > Test > Display test).

Press OK key to access the test.

The display shows all pixels on.

Press ESC key to return to the previous screen.

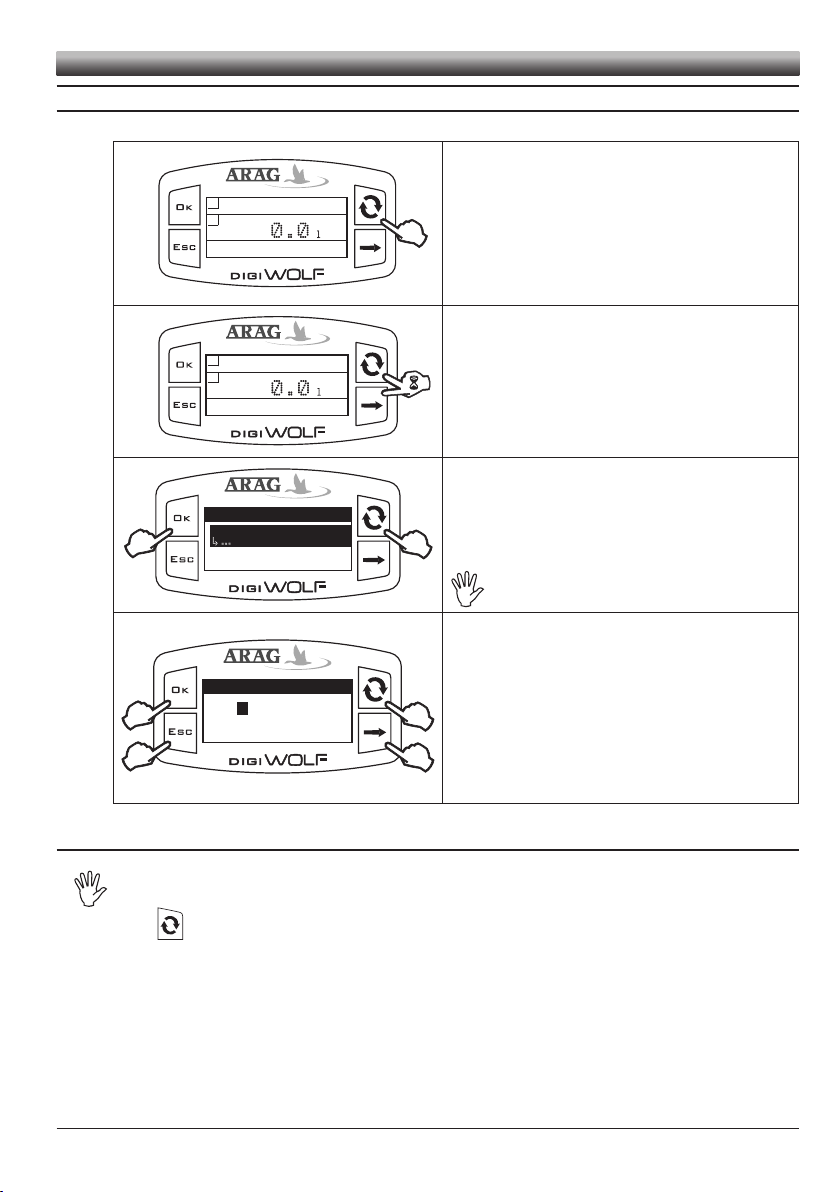

9.5.2 Keys test

Keys test checks the correct operation of the keys on the device.

Access keys test menu (Setup menu > Test > Keys test).

Press OK key to access the test.

1) Pressing one key, the corresponding portion of the display will light up.

2) To exit, press ESC key: after lighting up the corresponding portion of the

display, it will return to the previous screen.

18

Page 19

MAINTENANCE

10 MAINTENANCE

10.1 Notes on maintenance

- At the end of each treatment, run clean water through the tubes.

- Clean the tank lling system pipe with a special detergent on a regular basis.

- Clean (and if necessary, replace) the owmeter paddle on a regular basis (page 19, chap 10.2)

- Do not use metal or abrasive objects to clean the paddle.

- Do not use solvents or fuel to clean the case outer surface.

10.2 Paddle cleaning and replacement

4

sblocca

2

4

1) Remove the fork from the monitor using a screwdriver.

2) Remove the monitor from the owmeter body.

3) Unscrew the ring nut in a counter clockwise direction and remove the sensor housing block from

the owmeter body.

4) With half a rotation, remove the paddle group from the sensor housing block in a counter clockwise

direction.

5) Immerse the paddle group in detergent liquid for several hours.

6) Wash the paddle group thoroughly with running water and check its correct operation. If necessary,

replace the complete paddle group with its suitable spare part (code 4626000.500).

7) Ret the paddle group on the electronic sensor with a clockwise rotation until it clicks in place.

blocca

7

CONTINUES

19

Page 20

APPROXIMA

TE CONST

ANT

XXX

MAINTENANCE

2

1

Arrows direction on the body must

correspond to the one on the label

8) Ret the sensor housing block on the owmeter body tightening the ring nut in a clockwise

direction until it stops paying attention to keep the arrow on the coupling facing the ow

direction.

10.3 OR replacement

With the removed sensor housing block (see Par. 10.2) proceed as follows:

1) Remove the fork from the ring nut using a screwdriver.

2) Remove the ring nut.

- OR replacement:

Replace the ORs (Code G10051V - ARAG spare parts catalogue).

3) Ret the sensor housing block ensuring that the fork is correctly

inserted in the ring nut.

20

Page 21

10.4 Troubleshooting

FAULT CAUSE REMEDY

The valve leaks or the seal of the

ball is not enough

The valve is not working and the

display is off

The valve does not work Geared motor broken

The valve does not stop at the

preset point

Totalizers do not progress during the

passage of liquid.

Displayed owrate is not stable

Presence of foreign bodies

Worn seals • Contact your nearest assistance centre.

Lack of power

Malfunction of the microswitches

in the geared motor

Rate is beyond operation limits of

the owmeter

The paddle-wheel is locked

Presence of turbulence or air in

the circuit

Worn paddle • Replace the paddle.

MAINTENANCE

• Make sure there are no foreign bodies;

if so, remove them.

• Check the connections, the cables, and

the controls. Replace the cable.

If the problem persists, contact your

nearest service centre.

• Replace the geared motor. The

instructions can be found on our Website

www.aragnet.com - ADDIN D30025.

• Contact your nearest assistance centre.

• The model of the owmeter is not ad-

equate for the owrate to be measured.

Replace the owmeter.

• Clean or replace the paddle-wheel group

if necessary.

• Check the circuit.

21

Page 22

TECHNICAL DATA

11 TECHNICAL DATA

Data Min. Max. Default UoM Notes

Calibration Manual calibration 1 50,000 600 -- --

The alarm can be deactivated

setting the value "OFF"

The alarm can be deactivated

setting the value "OFF"

Language settings: Italiano,

English, Español,

Português, Français, Deutsch,

Cesky, Polski,

, Русский, Magyar.

ニホン

Units of measurement settings: l/min, GPM, m

Units of measurement settings: l, gal, m

Flowrate alarms

Display

Filling

Options

Min. owrate alarm 0.1 99999.9 OFF l/min.

Max. owrate alarm 0.1 999999.9 OFF l/min.

Brightness 0% 100% 50% % --

Contrast 0% 100% 50% % --

Valve activation time 0.0 9.9 0.0 sec.

Filling quantity 0.1 99999.9 3000.0 litres

Language - - English -

Rate units of

measurement

Volume units of

measurement

- - l/min. -

- - litres -

Description Tank lling system

Power supply 12 Vdc ± 10%

Short circuit protection •

Flowrate signal square wave (0 ÷ V suppl.)

Max. frequency 1,2 KHz

Max. absorption 3 A

Working temperature

0 °C ÷ 60 °C

+32 °F ÷ +140 °F

Storage temperature -30 °C ÷ 80 °C / -22 °F ÷ +176 °F

Dimensions 330x200x346 mm

Weight 3500 g

3

/h

3

Tab 2

22

Page 23

12 DISPOSAL AT THE END OF SERVICE

Dispose of the system in compliance with the established legislation in the country of use.

INFORMATION TO USERS – PROFESSIONAL WEEE RECYCLING

This product complies with European Directive 2002/96/EC and subsequent modifications. At end-of-life and for disposal, the device must be taken to a waste recycling centre for electrical and electronic waste, or returned to the seller when buying a new equivalent device.

The user is responsible for its transfer to the appropriate collection facilities. For more detailed information concerning the collection systems available contact your local waste disposal service.

23

Page 24

Notes

24

Page 25

Notes

25

Page 26

GUARANTEE

13 GUARANTEE TERMS

1. ARAG s.r.l. guarantees this apparatus for a period of 360 day (1 year) from the date of sale to

the client user (date of the goods delivery note).

The components of the apparatus, that in the unappealable opinion of ARAG are faulty

due to an original defect in the material or production process, will be repaired or replaced

free of charge at the nearest Assistance Centre operating at the moment the request for

intervention is made. The following costs are excluded:

- disassembly and reassembly of the apparatus from the original system;

- transport of the apparatus to the Assistance Centre.

2. The following are not covered by the guarantee:

- damage caused by transport (scratches, dints and similar);

- damage due to incorrect installation or to faults originating from insufficient or inadequate

characteristics of the electrical system, or to alterations resulting from environmental, climatic or other conditions;

- damage due to the use of unsuitable chemical products, for spraying, watering, weedkilling

or any other crop treatment, that may damage the apparatus;

- malfunctioning caused by negligence, mishandling, lack of know how, repairs or modications carried out by unauthorised personnel;

- incorrect installation and regulation;

- damage or malfunction caused by the lack of ordinary maintenance, such as cleaning of

lters, nozzles, etc.;

- anything that can be considered to be normal wear and tear.

3. Repairing the apparatus will be carried out within time limits compatible with the organisational needs of the Assistance Centre.

No guarantee conditions will be recognised for those units or components that have not

been previously washed and cleaned to remove residue of the products used.

4. Repairs carried out under guarantee are guaranteed for one year (360 days) from the replacement or repair date.

5. ARAG will not recognise any further expressed or intended guarantees, apart from those

listed here.

No representative or retailer is authorised to take on any other responsibility relative to

ARAG products.

The period of the guarantees recognised by law, including the commercial guarantees and

allowances for special purposes are limited, in length of time, to the validities given here. In

no case will ARAG recognise loss of prots, either direct, indirect, special or subsequent to

any damage.

6. The parts replaced under guarantee remain the property of ARAG.

7. All safety information present in the sales documents regarding limits in use, performance

and product characteristics must be transferred to the end user as a responsibility of the

purchaser.

8. Any controversy must be presented to the Reggio Emilia Law Court.

26

Page 27

declaration of conformity and of

incorporation of partly completed machinery

ARAG s.r.l.

Via Palladio, 5/A

42048 Rubiera (RE) - Italy

P.IVA 01801480359

Dichiara

che il prodotto

descrizione: Sistema di caricamento cisterna

modello: codice: 462FXXXX

risponde ai requisiti di conformità contemplati nelle seguenti Direttive Europee:

2004/108/CE e successive modificazioni

(Compatibilità elettromagnetica)

2006/42/CE e successive modificazioni (*)

(Macchine)

Riferimenti alle Norme Applicate:

EN ISO 14982:1998

(Macchine agricole e forestali - Compatibilità elettromagnetica Metodi di prova e

criteri di accettazione)

(*) Dichiarazione ai sensi All. II B Dir. 2006/42/CE

• la documentazione tecnica pertinente è custodita da Arag, nella persona del suo legale rappresentante, sig. Giovanni Montorsi;

• ci si impegna a trasmettere, in risposta ad una richiesta adeguatamente motivata delle Autorità Nazionali, informazioni pertinenti sulle

quasi-macchine. Tale impegno comprende le modalità di trasmissione e lascia impregiudicati i diritti di proprietà intellettuale del fabbricante

della quasi-macchina;

• la conformità alla Direttiva Macchina, è applicata nei seguenti requisiti essenziali: 1.1.2, 1.1.3, 1.1.5, 1.1.6, 1.2.1, 1.2.2, 1.2.3, 1.2.4.1,

1.2.4.2, 1.2.6, 1.3.1, 1.3.2, 1.3.4, 1.3.7, 1.3.8.1, 1.4.1, 1.4.2.1, 1.5.4, 1.6.1, 1.6.5, 1.7.4, 1.7.4.1, 1.7.4.2, 1.7.4.3.

• la presente quasi-macchina non deve essere messa in servizio finchè la macchina finale in cui deve essere incorporata non sia stata

dichiarata conforme alle prescrizioni di cui Direttiva Macchine 2006/42/CE.

Rubiera, 12 Marzo 2012

Giovanni Montorsi

(Presidente e Legale Rappresentante)

Page 28

Only use original ARAG accessories and spare parts, to maintain safety conditions foreseen by the constructor.

Always refer to the ARAG spare parts catalogue.

42048 RUBIERA (Reggio Emilia) - ITALY

Via Palladio, 5/A

Tel. +39 0522 622011

Fax +39 0522 628944

http://www.aragnet.com

info@aragnet.com

D20261-m00 09/2012

Loading...

Loading...