Page 1

BRAVO 13X SERIES COMPUTERS

46713X01

Software rel. 2.1

USE AND MAINTENANCE

Page 2

•LEGENDSYMBOLS

= Generic danger

= Burn danger

= Warning

This manual is an integral part of the equipment to which it refers and must accompany the equipment in

case of sale or change of ownership. Keep it for future reference; ARAG reserves the right to modify the

specications and instructions regarding the product at any time and without prior notice.

2

Page 3

CONTENTS

• Legend symbols ............................................................................................................................ 2

1 Product description ...................................................................................................................... 5

1.1 Intended use ......................................................................................................................... 5

2 Contents of the packaging.......................................................................................................... 5

3 Control panel .................................................................................................................................. 6

3.1 Control panel ......................................................................................................................... 6

3.2 Display (in the example, the Spraying menu) ............................................................... 6

3.3 Control panel legend (Fig. 2) .............................................................................................. 7

3.4 Display legend (the example shows Spraying menu, Fig. 3) ..................................... 7

4 Product function ............................................................................................................................ 8

5 Installation ....................................................................................................................................... 8

5.1 Precautions ............................................................................................................................ 8

6 Start up ............................................................................................................................................. 8

7 Menus structure ............................................................................................................................. 9

8 Setting preliminary to use ......................................................................................................... 10

8.1 User menu ........................................................................................................................... 10

8.1.1 Wheel type ..........................................................................................................................11

8.1.2 Wheel Constant...................................................................................................................11

8.1.3 Product density ................................................................................................................. 13

8.1.4 Row distance ..................................................................................................................... 13

8.1.5 Canopy width ..................................................................................................................... 14

8.2 Treatment menu .................................................................................................................. 15

8.2.1 Tank filling ........................................................................................................................... 15

8.2.2 Setting the field number.................................................................................................... 16

8.2.3 Resetting the "field" counters .......................................................................................... 16

8.2.4 Row type ............................................................................................................................ 17

8.2.5 Canopy type ...................................................................................................................... 17

8.3 Spraying menu .................................................................................................................... 18

8.3.1 Speed ................................................................................................................................. 18

8.3.2 Pressure ............................................................................................................................. 18

8.3.3 Flow rate ............................................................................................................................ 19

8.3.4 Battery voltage ................................................................................................................... 19

8.3.5 Surface area ...................................................................................................................... 19

8.3.6 Liquid sprayed ................................................................................................................... 19

8.3.7 Tank level ............................................................................................................................ 19

8.3.8 Distance ............................................................................................................................. 19

8.3.9 Trees treated ...................................................................................................................... 20

8.3.10 Automatic ........................................................................................................................... 20

9 Use ................................................................................................................................................... 21

9.1 Automatic operating mode ................................................................................................ 22

9.1.1 Two-sensor configurations ................................................................................................ 23

9.1.2 Four-sensor configuration ................................................................................................. 24

9.2 Manual operating mode .................................................................................................... 25

9.3 Semi-automatic operating mode ..................................................................................... 25

9.4 Operating errors ................................................................................................................. 25

3

Page 4

10 Maintenance / diagnostics / repairs ....................................................................................... 26

10.1 Troubleshooting .................................................................................................................. 26

10.2 Check the parameter "1/0 Error" .....................................................................................27

10.2.1 Absence of errors (screen "a") ........................................................................................ 27

10.2.2 Programming error (screen "b") ...................................................................................... 27

11 Technical data .............................................................................................................................. 28

11.1 Units of measurement ....................................................................................................... 28

11.1.1 Spraying menu .................................................................................................................. 28

11.1.2 Treatment menu ................................................................................................................. 28

11.1.3 User menu .......................................................................................................................... 28

11.2 Technical characteristics ................................................................................................... 29

12 Index of functions ....................................................................................................................... 29

13 Disposal at the end of service ................................................................................................. 29

14 Guarantee terms ..........................................................................................................................30

4

Page 5

1 PRODUCT DESCRIPTION

Bravo 13X is an atomizer computer specically designed for treating leafy trees, equipped with

numerous control functions that can be activated from the driver’s cabin.

The computer controls the opening and closing of the section valves on a suitable control unit

(not supplied) in automatic, semi-automatic or manual mode, detecting the presence of a tree to

be treated by means of one or two pairs of ultrasound sensors: in this way, Bravo13X allows only

spraying in the presence of plants and not in the gaps.

1.1 Intended use

Device designed for installation on agricultural machinery used for weed-killing and

spraying.

The device is designed and carried out in conformity with directive 2004/108/CE and

subsequent modications, and the EN ISO 14982 standard.

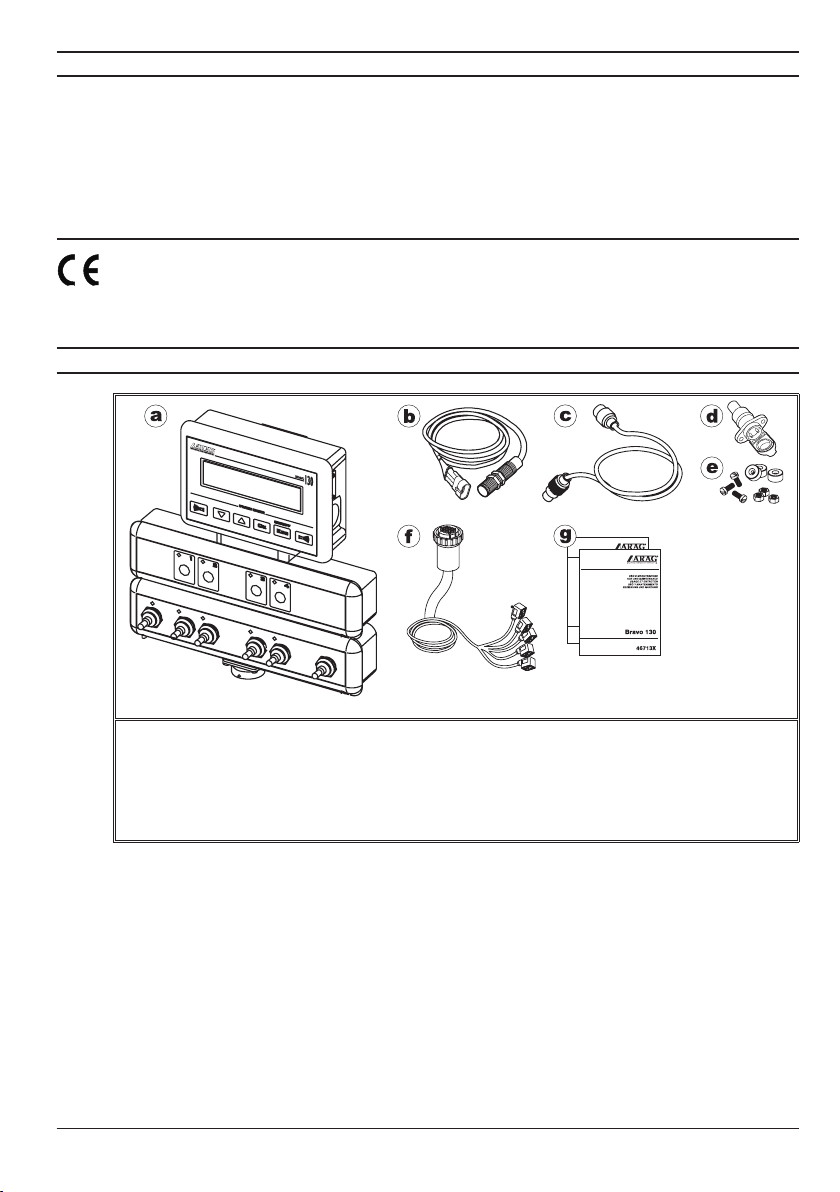

2 CONTENTS OF THE PACKAGING

Fi g. 1

a•Bravo13X

b•Speedsensor

c•Powersupplycable

d•Threepolesocketforpower

e•Magnetsandfasteningscrews

f •Cablingforconnectingtothevalves

g•InstructionManuals

5

Page 6

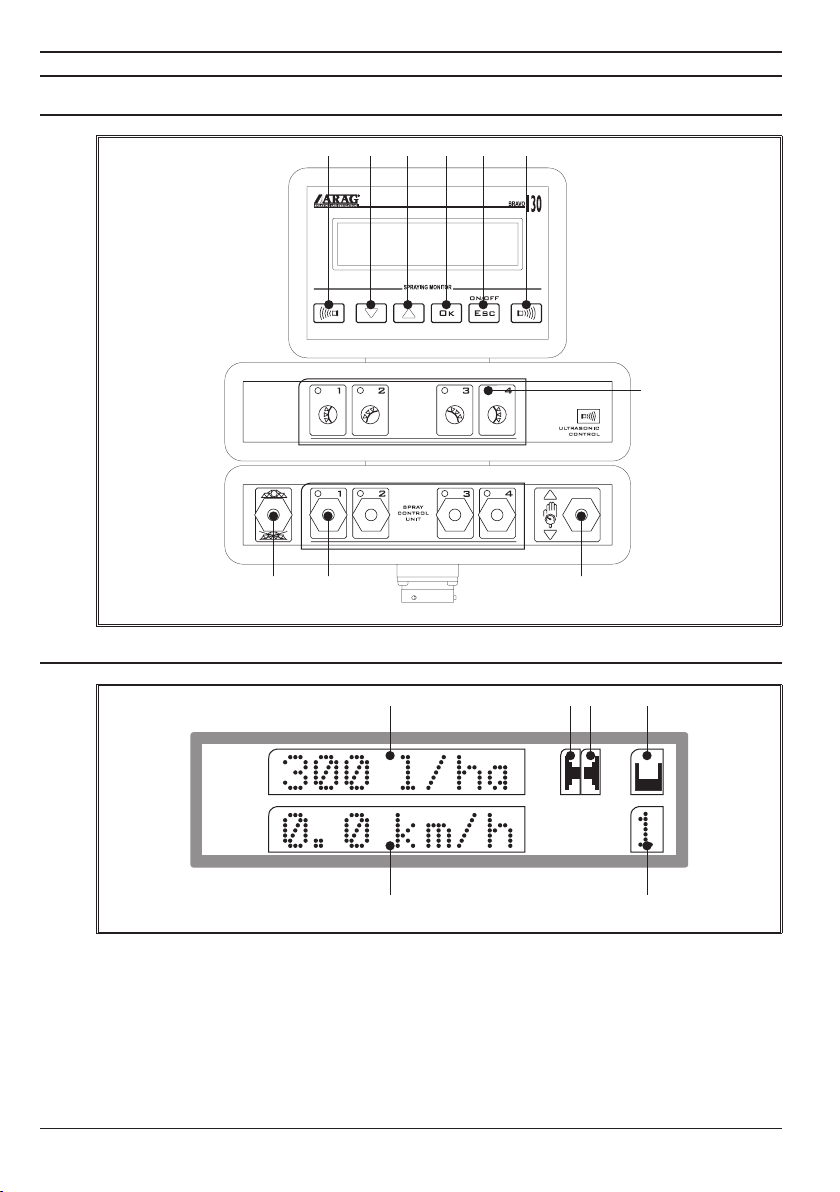

3 CONTROL PANEL

3.1 Control panel

Fi g. 2

I

L

BA C

H FG

E

D

3.2 Display (in the example, the Spraying menu)

R P OQ

Fi g. 3

M N

6

Page 7

3.3 Control panel legend (Fig. 2)

A = Control deviator for the drain valve

•Toopenthedrain valve, move the deviator downward (LED off).

•Toclosethedrain valve, move the deviator upward (LED on).

B = Control deviators for the section valves

(the number of deviators coincides with the number of section valves mounted on the system)

•Toopenthesectionvalve,movethecorrespondingdeviatorupward(LEDon).

•Toclosethedrain valve, move the corresponding deviator downward (LED off).

The section valve control varies depending on the type of function enabled in the computer.

Refer to paragraph 8.3.10 - Automatic and chapter 9 - Use.

C = Deviator for controlling the pressure control valve

•Toincreasethequantityofliquidtodistribute,pressthedeviatorupward.

•Todecreasethequantityofliquidtodistribute,pressthedeviatordownward.

When you release the deviator, the lever automatically returns to the center without making any

further changes to the quantity of liquid to be distributed.

D = The control status indicators of the section valves

(the number of LEDs coincides with the number of section valves mounted on the system)

•LEDon:thesectionvalveisopen.

•LEDoff:thesectionvalveisclosed.

E = Activation of sensors on the right side of the tractor.

F = ON/OFF button: turns the computer on/off.

ESC button: exits from the current menu during use of the Bravo 13X.

If the changed data has not been conrmed, pressing this key you exit the

current menu without making any changes.

G = Conrmation key

During the use of the Bravo 13X, this key conrms access to the selected menu or the value of the

parameter previously changed.

H = Data selection key: scrolls through the data, passing to the next eld.

Parameter change key: increases the value of a parameter.

I = Data selection key: scrolls through the data, passing to the previous eld.

Parameter change key: decreases the value of a parameter.

When changing parameters, pressing the or keys for more than three

seconds allows rapidly changing the values to be entered.

L = Activation of the sensors on the left side of the tractor

3.4 Display legend (the example shows Spraying menu, Fig. 3)

M = Second line value: the value selected is displayed (in the example, the tractor’s

instantaneous speed).

N = Number of the eld being treated

O = Tank: a ashing symbol means the reserve value has been reached.

P = Right sensor activated: indicates that the sensor, or sensors, on the right side

of the tractor have been activated; for the 4-sensor model, the symbol remains lit

independently of the number of sensors active.

Q = Left sensor activated: indicates that the sensor, or sensors, on the left side of

the tractor have been activated; for the 4-sensor model, the symbol remains lit independently of the number of sensors active.

R = First line value: the value pre-set during the installation of the computer (in the

example, instantaneous distribution).

7

Page 8

4 PRODUCT FUNCTION

Bravo 13X is an atomizer computer specically designed for treating leafy trees, equipped with

numerous control and display functions that can be activated from the driver’s cabin:

• Speed of the vehicle;

• Quantity of liquid distributed on the eld;

• Flow rate;

• Surface area treated (4 partials*);

• Distance traveled (4 partials*);

• Number of trees treated (4 partials*);

• Quantity of liquid sprayed (function equipped with 4 partials*, only enabled in the presence

of a owmeter in the system);

• Level of the tank (function only enabled in the presence of a owmeter in the system);

• Battery voltage;

• Pressure (function enabled only in the presence of a pressure transducer in the system).

The BRAVO 13X main operating principle that differentiates it from other BRAVO family computers

is the possibility of identifying the presence of plants on the sides of the tractor through the use of

ultrasound sensors and, thus, of only spraying plants and avoiding the waste of chemicals.

The BRAVO 132 must be equipped with two ultrasound sensors (mounted at the sides of the tractor)

to trip the control unit valves (t wo section valves, one pressure control valve and one drain valve)

and increase/decrease the sprayer delivery.

The model BRAVO 134 can be equipped with four sensors to detect trees of different heights and to

spray only where needed. BRAVO 134 can be connected to control units consisting of four section

valves, a pressure control valve and a drain valve.

* By partial we mean a memory area containing data relative to a parameter previously set and stored, which can be recalled at the time of use.

5 INSTALLATION

Installation, connection and start-up of the computer, unit and sensors connected to it must be

performed by specialized personnel.

All the information regarding installation and preliminary programming is described

in the installation manual provided to specialized installers.

ARAG is not responsible for damage to equipment, persons, animals or crops caused

by a faulty installation or one performed by non-specialized or unprepared personnel.

In the event of damage to the computer or the equipment and sensors connected to

it, caused by any of the above, the warranty will automatically be considered void.

5.1 Precautions

• Never expose the equipment to water jets.

• Never use solvents or petrol to clean the external parts of the container.

• Do NOT use direct jets of water for cleaning the display.

• Comply with the specic power supply voltage (12 Vdc).

• In case of electric arc welding, make sure that the power supply to the device is

disconnected; if necessary, disconnect the power supply cables.

• Use only original ARAG spare parts or accessories.

6 START UP

Before turning it on, make sure the drain valve is CLOSED.

To close the drain valve, push the deviator, A (Fig. 2) upwards.

To turn on the device, press the key.

When the device is turned on it rst performs a diagnostic test of the display.

Then it displays the version of the software and automatically goes to the Spraying menu

(Fig. 4), from which you can access all the functions provided by the computer.

8

Page 9

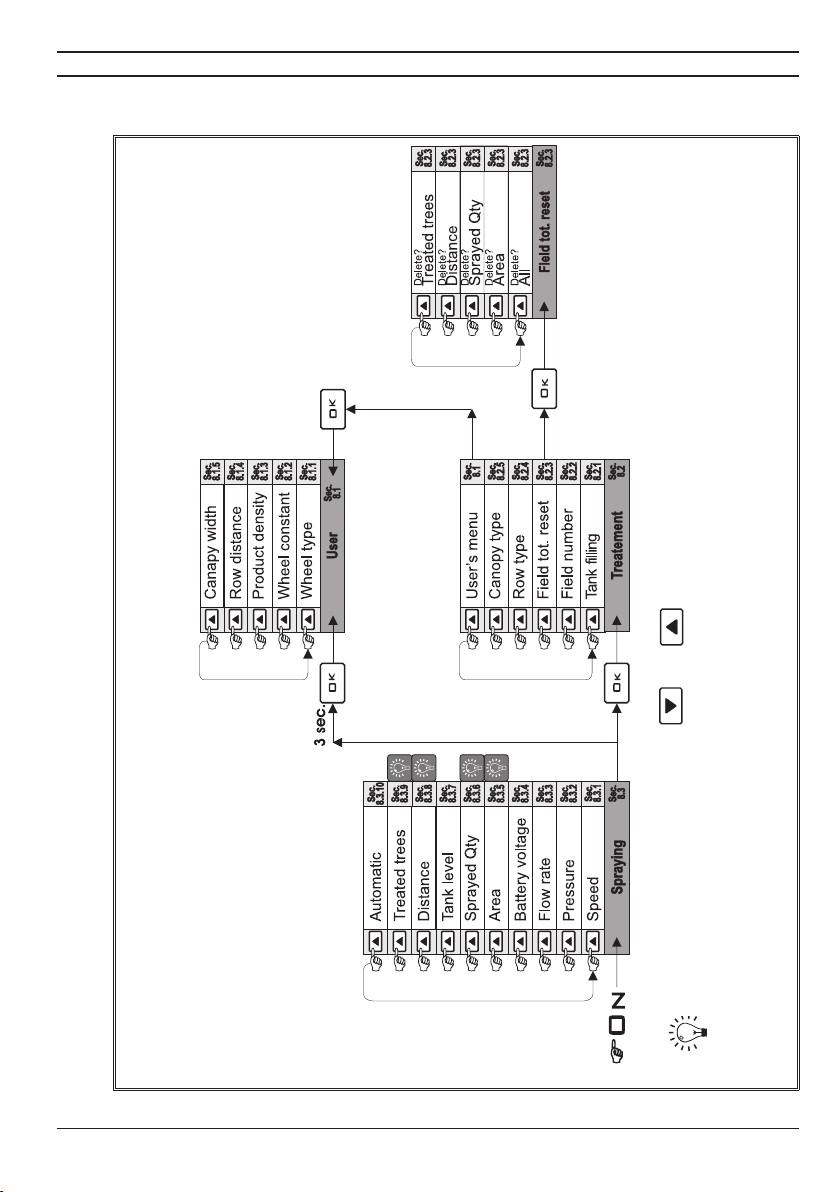

7 MENUS STRUCTURE

From the Spraying menu it is possible to access all the functions of the Bravo13X.

These functions are shown in Fig. 4, which illustrates the menu structure.

Fi g. 4

QUICK ACCESS: by pressing the and keys at the same time you can

reset the corresponding value.

9

Page 10

8 SETTING PRELIMINARY TO USE

It is necessary to set several parameters before beginning a treatment in order to

perform it correctly. Set all the functions on the following menus:

•User menu (par. 8.1)

•Treatment menu (par. 8.2)

For any questions regarding the conguration of these menus, consult sec.

7 - Menus structure.

8.1 User menu

To access the User menu, proceed as follows:

1) Turn on the device by pressing and holding the key; upon start-up, Bravo 13X performs the

self-diagnostics as indicated in sec. 6 - Start-up, then automatically enters the Spraying menu.

2) From any Spraying menu function, you can press the key to enter the

Treatment menu;

3) Now scroll through the functions of the Treatment menu:

3a) To go to the next function, press the key.

3b) To return to the previous function, press the key.

4) When the entry User menu appears, press the key;

Quick access: you can access the user menu directly from any function of the

spraying menu by pressing the key for at least three seconds.

Scroll through the entries by pressing the and keys and select the function you wish

to set by pressing the key.

The following functions will appear in succession:

•Wheel type (see sec. 8.1.1)

•Wheel constant (see sec. 8.1.2)

•Product density (see sec. 8.1.3)

•Row distance (see sec. 8.1.4)

• Canopy width (see sec. 8.1.5)

6) To exit from the User menu, press the key (return to the previous menu:

Spraying menu or Treatment menu depending on the selection method used).

For any questions regarding the method of selecting these functions, consult

sec. 7 - Menus structure.

10

Page 11

8.1.1 Wheel type

The “WHEEL TYPE” function allows programming and, thus, recalling with a single key, the parame-

ters relative to different types of wheels (such as: if they are replaced for different types of crops or if

the computer is moved from one agricultural machine to another). This function recalls a parameter, the

“WHEEL CONSTANT”, which must be entered as indicated in paragraph 8.1.2 - Wheel constant.

Up to 5 types of wheels can be programmed. These are recalled for use by the procedure described below.

1) Scroll through the functions on the User menu using the and keys and select the

entry “Wheel type”, followed by a number that indicates the active wheel.

2) Conrm the selection by pressing the key: the number that indicates the wheel type will

ash on the display.

3) Change the value using the and keys.

4) Conrm the value set by pressing the key.

8.1.2 Wheel Constant

As the tractor moves forward, the Bravo 13X computer receives signals from the speed sensor

installed on one of the wheels. This data is processed on the basis of a value called the “WHEEL

CONSTANT” that must be entered manually or through the automatic insertion function.

The wheel constant set represents the value of the constant relative to the wheel

type currently selected: for example, to change the wheel constant that corresponds

to wheel type 2, you must rst set the type for wheel 2 following the method shown

in paragraph 8.1.1 - Wheel type.

1) Scroll through the functions on the User menu using the and keys and select the

entry “WHEEL CONSTANT”, followed by the active value.

2) Conrm the selection by pressing the key: the active setting method appears on the display.

• MANUAL SETTING

To perform the setting using this method, you manually enter the value of the constant after having

previously calculated it.

The wheel constant can be calculated using the distance that the wheel on which the sensor

is installed travels in 10 revolutions (a value to be calculated with the tires inated to working

pressure).

The formula for calculating the wheel constant is:

Distance traveled (m) x 10

= ——————————————————

number of magnets

Example:

- Distance traveled in 10 revolutions of the wheel 25,4 m

- Number of magnets installed: 10

The wheel constant is:

25,4 x 10

= ————————————— = 25,4

10

1) Select the Manual setup mode by scrolling the Wheel Constant Menu with the and

keys;

2) Conrm the selection by pressing the key.

3) Change the value using the and keys.

4) Conrm the value set by pressing the key.

CONTINUES

11

Page 12

• AUTOMATIC CALCULATION

BRAVO 13X is able to calculate the wheel constant automatically by using the number of impulses

sent by the speed sensor in a straight line of:

- 100 m (EU)

- 300 yards (US)

1) Fill the tank 50% full.

2) Position the tractor at the beginning of the path.

3) Select Automatic calc. by scrolling the Wheel constant menu using the and

keys; Conrm the selection by pressing the key.

4) Start and follow the path.

5) At the end of the path, stop and press the key: BRAVO13X will automatically calculate the

wheel constant and display it.

- If the number of impulses received by the computer during automatic calibra-

tion is too low to calculate the wheel constant, the following message displays:

.

In this case, check the installation of the sensor and repeat the procedure.

An error can also occur if the wheel has been replaced incorrectly or if the sensor is

too far from the magnet.

If the problem persists after you have veried that everything is mounted correctly,

contact the installer.

- The test must be performed on medium hard ground.

If distribution is carried out on very soft or very hard ground, the difference in rolling

diameter could cause an error in the distribution calculation.

In this case, it is advisable to repeat the procedure.

End of the wheel constant setting procedure

12

Page 13

8.1.3 Product density

The quantity of the products sprayed can vary according to their density.

For this reason, the computer allows you to enter a density factor and, thus, to calculate the quantity

of liquid effectively sprayed.

This value is very important because, if mechanical palette or turbine owmeters are used, since

these are affected by variations in the density of the liquid, it could happen that the liquid will be

sprayed in a different quantity than that set and measured by the computer.

The preset density factor is “1” and it refers to water or, at any rate, a liquid having the same

density as water.

Since it would be impossible to provide a table with density data for all products that can be sprayed,

it is up to the user to evaluate any correction to the entered value that will allow the computer the

possibility to exactly indicate the quantity dispensed:

- if, at the end of spraying, the tank still contains liquid, the density factor must be decreased;

- if, on the other hand, the liquid is nished before the end of distribution, the factor must be increased.

An electromagnetic owmeter such as the ORION series 462XXX is not affected by

the difference in liquid density: for this reason, if this owmeter is present in your

system, set the density factor to 1,00.

1) Scroll through the functions on the User menu using the and keys and select the

entry “PRODUCT DENSITY”, followed by a number that indicates the value set.

2) Conrm the selection by pressing the key: in this way, the number that indicates the density

factor will ash on the display.

3) Change the value on the display by using the and keys.

4) Conrm the value set by pressing the key.

8.1.4 Row distance

The “ROW DISTANCE” function allows programming and recalling with a single key all the para-

meters relative to the distances between the rows of trees to be treated, so as to correctly calculate

the surface area treated and the volume of liquid sprayed in

liters/hectare.

Up to 5 types of rows can be programmed: to perform the setting, follow the procedure shown

below:

1) Scroll through the functions on the User menu using the and keys and select the

entry “ROW DISTANCE”.

2) Conrm the selection by pressing the key.

The following information will appear on the display:

AB

A•thetype of row active, indicated by a number

from 1 to 5;

B•thevalueofthedistance between rows.

Fi g. 5

3) Select the type of row you wish to set by scrolling to the A value using the and keys;

while scrolling, the display will show the distance between rows (B) corresponding to the type of

row activated.

4) Conrm the selection by pressing the key: in this way, the number that indicates the distance

between rows (B) will ash on the display.

5) Change the value B on the display by using the and keys.

6) Conrm the value set by pressing the key.

ARAG code 46713000.100 ultrasound sensors detect the presence of the plant up to

a distance of 6 m.

13

Page 14

8.1.5 Canopy width

Depending on how the ultrasound sensors are mounted to the tank or tractor, they will detect either the

trunk of the tree or its canopy.

The value to be entered in the computer is the

“CANOPY WIDTH”.

If the sensors are oriented towards the canopy,

set it to “0”;

if the sensors are oriented towards the trunk, the computer must be told how wide the canopy is to open the

valves at the correct point for effective spraying.

This is done with the following calculation:

width of the canopy in meters (CW) less the diameter of the trunk in meters (DT), divided by two:

Fi g. 6

LC – DT

—————

2

Therefore, in case of trees with an average width of 40 cm by the trunk and 3 m by the canopy, the

value to be entered is 1,3 m (Fig. 6):

3 - 0,4

= 1,3 m

2

If, on the other hand, the sensors are detecting the canopy and not the trunk, the value to enter will

be 0 so that when the canopy is detected, the computer will immediately begin treatment.

It is possible to program this function with up to 5 different types of canopy.

To enter the data, follow the procedure shown below:

1) Scroll through the functions on the User menu using the and keys and select the

entry “Canopy WIDTH”.

2) Conrm the selection by pressing the key.

The following information will appear on the display:

B A

Fi g. 7

A•thetype of canopy active, indicated by a

variable, progressive number up to 5;

B•thewidth value for the canopy.

Select the type of canopy you wish to set by scrolling the A value using the and keys;

while scrolling the A value, the display will show the width of the canopy (B) corresponding to the

type of canopy selected.

4) Conrm the selection by pressing the key: in this way, the number that indicates the width

of the canopy (B) will ash on the display.

5) Change the value B on the display by using the and keys .

6) Conrm the value set by pressing the key.

14

Page 15

8.2 Treatment menu

Before each new spraying, perform the preliminary operations gathered together in the Treatment

menu; to access the menu, proceed as follows:

1) Turn on the device by pressing and holding the key; upon start-up, Bravo 13X performs the

self-diagnostics as indicated in sec. 6 - Start up, then automatically enters the Spraying menu.

2) From any function of the Spraying menu, press the key;

3) Scroll through the entries in the Treatment menu by pressing the and keys and

select the function you wish to set by pressing the key.

The following functions will appear in succession:

• Tank lling (see sec. 8.2.1)

• Field Number (see sec. 8.2.2)

• Total Field Reset (see sec. 8.2.3)

• Row Type (see sec. 8.2.4)

• Canopy Type (see sec. 8.2.5)

• User menu (see sec. 8.1)

4) To exit from the Treatment menu, press the key (return to the Spraying menu).

For any questions regarding the method of selecting these functions, consult sec.

7 - Menus structure.

All the entries of the User menu are described in section 8.1 - User menu.

8.2.1 Tank lling

The "TANK FILLING" function allows setting the quantity of liquid in the tank and, thus, calculating

the liquid remaining at the end of treatment (starting from the ll value, BRAVO 13X takes away

the quantity of liquid sprayed).

The computer also signals when the reserve level is reached with a buzzer and ashing indicator

on the display.

The liquid loaded in the tank can be set by following the procedure described below:

1) Scroll through the functions on the Treatment menu using the and keys and select

the entry "TANK FILLING", followed by a number that indicates the quantity of liquid remaining in

the tank.

2) Conrm the selection by pressing : the display will ash the maximum tank lling quantity.

3) To modify this value, use the and keys.

4) Conrm the value set by pressing the key.

CONTINUES

15

Page 16

8.2.2 Setting the eld number

When a cultivation is being treated, BRAVO 13X keeps the following data in memory:

• Surface area treated

• Liquid distributed

• Distance traveled

• Number of trees treated

The four values grouped together relative to a specic treatment are called a "FIELD". It is possible

to store four different cultivations.

The "FIELD NUMBER" function allows choosing the number of the eld in which to store the data

relative to the cultivation that you are getting ready to treat, before the treatment.

To set the eld number, follow the procedure shown below:

1) Scroll through the functions on the Treatment menu using the and keys and select

the entry "FIELD NUMBER", followed by a number that indicates the active eld.

2) Conrm the selection by pressing the key: the number that indicates the eld will ash

on the display.

3) Change the value using the and keys.

4) Conrm the value set by pressing the key.

To read the cultivation data stored in a certain eld, consult the Spraying menu

(sec. 8.3 - Spraying menu).

8.2.3 Resetting the "eld" counters

Before beginning a new treatment, BRAVO 13X allows you to reset all, or only some, of the data

contained in the active "FIELD".

Before erasing the data, select the number of the eld in which you wish to record

the data relative to the new treatment. For any questions regarding the method of

eld selection refer to section 8.2.2 - Setting the eld number.

To reset the data, follow the procedure described below:

1) Scroll through the functions on the Treatment menu using the and keys and select

the entry "TOTAL FIELD RESET".

2) Conrm the selection by pressing the key.

3) Scroll through the "TOTAL FIELD RESET" function using the and keys and select

the parameter that you wish to reset; as you scroll through the display, the request to delete the

following data, will appear, in succession, as shown in F i g . 8 :

A

Fi g. 8

• All (allows resetting all the parameters at the

same time)

• Surface area

• Liquid sprayed

• Distance

• Trees treated

During this operation, the number of the active eld (A) appears on the display.

4) Conrm the deletion of the selected data by pressing the key.

End of the section on "Resetting the "eld" counters"

16

Page 17

8.2.4 Row type

The "ROW TYPE" function allows recalling, with a single key, all the parameters relative to the

distances between the rows of trees to be treated, that were previously programmed using the

"ROW DISTANCE" function (as described in section 8.1.4 - Row distance).

To select the type of row on which to perform the treatment, proceed as follows:

1) Scroll through the functions on the Treatment menu using the and keys and select

the entry "ROW TYPE", followed by a number that indicates the active row number.

The following information will appear on the display:

A B

Fi g. 9

A•thetype of row active, indicated by a progres-

sive number from 1 to 5;

B•thevalueofthedistance between rows,

relative to the row selected.

2) Conrm the selection by pressing the key: the number that indicates the row (A) will ash

on the display.

3) Change the value using the and keys.

4) Conrm the value by pressing the key.

8.2.5 Canopy type

The "CANOPY TYPE" function allows selecting and, thus, recalling, with a single key, all the pa-

rameters relative to the canopy of the trees to be treated, that were previously programmed using

the "CANOPY WIDTH" function (as described in section 8.1.5 - Canopy width).

To select the type of canopy on which to perform the treatment, proceed as follows:

1) Scroll through the functions on the Treatment menu using the and keys and select

the entry "CANOPY TYPE", followed by a number that indicates the active canopy number.

The following information will appear on the display:

A B

Fi g. 10

A•thetype of canopy active, indicated by a

progressive number from 1 to 5;

B•the width value for the selected canopy.

2) Conrm the selection by pressing the key: the number that indicates the type of canopy

(A) will ash on the display.

3) Change the value using the and keys.

4) Conrm the value by pressing the key.

17

Page 18

8.3 Spraying menu

During the treatment BRAVO 13X displays the value of the liquid that is being sprayed together with

other data, selectable using the functions of the Spraying menu, which are shown below:

•Speed(seesec.8.3.1)

•Pressure(seesec.8.3.2)

•Flowrate(seesec.8.3.3)

•Batteryvoltage(seesec.8.3.4)

•Surfacearea(seesec.8.3.5)

•Liquiddistributed(seesec.8.3.6)

•Tanklevel(seesec.8.3.7)

•Distance(seesec.8.3.8)

•Treestreated(seesec.8.3.9)

•Automatic(seesec.8.3.10)

1) Turn on the device by pressing the key.

Bravo 13X will perform the self-diagnostics as indicated in sec. 6 - Start-up, then automatically

enter the Spraying menu.

2) Now you can scroll through the functions using the and keys.

The following information will appear on the display:

CA B

Fi g. 11

A•thevalueofinstantaneous distribution;

B•thevaluerelativetothefunction selected

(in the example, the speed);

C•thenumber of the active eld.

Parameter “A” depends on the programming done at installation; Bravo 13X displays the volume

of liquid delivered per unit surface, the operating pressure, the treatment speed (updated every

ve seconds), or the volume of liquid delivered per tree (updated every ve trees).

For any questions regarding the conguration of these menus, consult

sec. 7 - Menus structure.

8.3.1 Speed

Through this function, BRAVO 13X displays the vehicle's instantaneous speed.

QUICK ACCESS: you can directly display the value for instantaneous speed from

any function on the Spraying menu by pressing the key for at least 3 seconds.

8.3.2 Pressure

This function displays the instantaneous pressure of the liquid during treatment, only if a pressure

transducer is installed in the control unit.

18

Page 19

8.3.3 Flow rate

Through this function, BRAVO 13X displays the system's instantaneous ow rate during the treatment, but only if there is a owmeter on the control unit.

8.3.4 Battery voltage

Through this function, BRAVO 13X displays the instantaneous voltage of the battery.

8.3.5 Surface area

Through this function, BRAVO 13X displays the value for the total surface area treated.

QUICK RESET: from this menu position, you can directly reset the value of total

surface area treated by simultaneously pressing the and keys for at least

3 seconds.

Press the key to conrm the resetting of the value.

8.3.6 Liquid sprayed

Through this function, BRAVO 13X displays the total value of the liquid sprayed during the treatment,

but only if there is a owmeter on the control unit.

QUICK RESET: from this menu position, you can directly reset the value of total

liquid sprayed by simultaneously pressing the and keys for at least 3

seconds.

Press the key to conrm the resetting of the value.

8.3.7 Tank level

Through this function, BRAVO 13X displays the total value of the quantity of liquid remaining during

the treatment, but only if there is a owmeter on the control unit.

This function is not a level indicator, but the liquid remaining in the tank will be calculated by subtracting the liquid used from that set according to the programming described in point

8.3.6 - Liquid sprayed.

QUICK ACCESS: from this menu position, you can directly pass to the tank lling

function by simultaneously pressing the and keys for at least 3 seconds

For any questions, consult the section 8.2.1 - Tank lling.

8.3.8 Distance

Through this function, BRAVO 13X displays the total distance traveled by the vehicle.

The value of distance traveled is only increased when the main valve is closed.

QUICK RESET: from this menu position, you can directly reset the distance traveled by simultaneously pressing the and keys for at least 3 seconds.

Press the key to conrm the resetting of the value.

19

Page 20

8.3.9 Trees treated

Through this function, BRAVO 13X displays the total number of trees treated.

QUICK RESET: from this menu position, you can directly reset the number of trees

treated by simultaneously pressing the and keys for at least 3 seconds.

Press the key to conrm the resetting of the value.

Fig. 12a Fig. 12b

The number of trees counted during the treatment will vary depending on whether you are at the

beginning or end of a row (Fig. 12a, trees only on one side of the tractor) or inside the rows (F i g .

12b) with trees on both sides of the tractor.

During the treatment, the Bravo 13X automatically counts the number of half units per tree treated:

for example, in Fig. 12a, when the tractor has treated the rst side of the row, Bravo 13X calculates

three trees (corresponding to half the trees effectively present in the row);

once it treats the second side, Bravo 13X completely counts the row, in other words, 6 trees.

In the event that several rows are treated (Fig. 12b), Bravo 13X counts half the trees in the rst and

last row (of six trees it will only count three in the rst row and three in the last), while it will count

the complete row when it is between two rows.

8.3.10 Automatic

Through this function, it is possible to display and set the device's operating mode.

The BRAVO 13X provides the following types of operation:

• Automatic: the opening and closing of the section valves is determined by ultrasound sensors

installed on the system that detect the presence or absence of the plant to be treated.

• Manual: the opening and closing of the section valves is manually controlled.

• Semi-automatic: the computer operates with some section valves controlled manually and

others controlled automatically through the ultrasound sensors activated.

For any questions regarding conguration of operating modes, consult sec. 9 - Use.

20

Page 21

9 USE

When the tractor is not being used for treatments, make sure that:

• the pump installed in the system is off

• the drain valve is open

Do not stop in front of the sensors, or in their immediate proximity, when they are

activated.

Use the Bravo 13X computer ONLY with ARAG units specically designed for this

computer: the use of control units, valves or parts connected to the computer other

than those mentioned above can cause damage to the device and injury to the user

for which ARAG will not be responsible. In the event of damage to the computer or

the equipment and sensors connected to it, caused by any of the above, the warranty will automatically be considered void.

Using the installed ultrasound sensors, the Bravo 13X computer recognizes the trees to be treated when the tractor moves forward, as a consequence, regulates the opening and closing of the

section valves at the right moment, allowing spraying only in the presence of plants and, thus,

avoiding product wastes.

Fig. 13

When the computer receives a signal indicating the presence of a tree, it calculates the exact moment to begin

treatment on the basis of the speed of the tractor, the distance between sensors and the spraying boom (DSR in

Fig.13), and the width of the tree's canopy (LFR in Fig.13).

The computer interrupts spraying by calculating the time necessary to treat the entire tree on the basis

of the tractor's speed, the distance between the sensors and the spraying boom (DSR), and the width of the

tree's canopy (LFR, set by the operator as indicated in section 8.1.5 - Canopy width).

Bravo 13X can control a minimum of two and a maximum of four section valves, depending on the

computer's conguration.

The BRAVO 13X provides the following congurations:

CONFIGURATION BRAVO ACCESSORIES UNIT TO CONNECT

Tab. 1

a

b

c

2 sensors and

2 section valves

2 sensors and

4 section valves

4 sensors and

4 section valves

132

134

134

Ultrasound sensor

code 46713000.100

Ultrasound sensor

code 46713000.100

Ultrasound sensor

code 46713000.100

463823400H

463823400CH

463843400H

463843400CH

463843400H

463843400CH

Each sensor can control the opening and closing of one or two section valves at the same time,

depending on the system conguration.

In the conguration b, the sensor installed on one side of the tractor simultaneously

controls the operation of both the section valves that allow spraying on that side of

the tractor.

21

Page 22

The ARAG code 46713000.100 sensors have a range of 6 m, but can be adjusted with

the buttons on the sensors themselves.

If the set distance between the sensors and the rows is too great, Bravo 13X may detect targets

beyond the trees to be treated and thus also spray when not desired (Fig. 14): to resolve this problem, reduce the sensitivity of the sensors (Fig. 15).

Fig. 14 Fig. 15

All adjustment instructions are given in the manual provided with the sensors themselves.

To perform the treatment, proceed as follows:

1) Go to the beginning of the eld to be treated.

2) Adjust the pressure on the control unit to the minimum by holding down deviator C (Fig. 2 - Control

Panel) for thirty seconds.

3) Correctly select all the values necessary for the treatment (refer to sec. 8.2 - Treatment menu).

4) Select the operating mode you wish to use.

The BRAVO 13X provides the following types of operation:

• Automatic (consult sec. 9.1 - Automatic operating mode)

• Manual (consult sec. 9.2 - Manual operating mode)

• Semi-automatic (consult sec. 9.3 - Semi-automatic operating mode)

5) Go to the beginning of the row to be treated and start the pump.

6) Close the drain valve by pushing control deviator A (Fig.2 - Control Panel) upwards, then keep

going with the tractor and begin treatment.

7) Regulate the pressure (and, then, the dosing) on the control unit to that selected for the treatment

by keeping deviator C up (Fig. 2 - Control Panel); check the value of the pressure or the dosing on

the display.

8) At the end of each row, open the drain valve by pushing control deviator A (Fig. 2 - Control Panel)

downward.

During and after the treatment, DO NOT TOUCH THE SOLENOID SECTION VALVES

installed on the system because there is a danger of burns.

Before performing any treatment make sure you have set the correct characteristics

indispensable for its correct performance: refer to sec. 8 - Setting preliminary to use.

9.1 Automatic operating mode

Before starting automatic mode operation, make sure that the drain valve is OPEN: push

control deviator A (Fig. 2 - Control Panel) downward; the display will show the entry

"MASTER OFF" (Fig.15-18). The Bravo 13X is set to ALWAYS start-up in manual mode.

In automatic operation, the opening and closing of the section valves is determined

by the ultrasound sensors installed on the system, which detect the presence or absence of the plant to be treated and enable treatment only if the tractor is in motion.

To set automatic operating mode, proceed as follows:

1) Turn on the device by pressing and holding the key. Bravo 13X will perform the self-dia-

gnostics as indicated in sec. 6 - Start-up, then automatically enter the Spraying menu.

2) Scroll through the functions using the and keys and select the entry "AUTOMATIC".

3) Put the ultrasound sensors into operation as described below.

22

Page 23

9.1.1 Two-sensor congurations

The following information will appear on the display:

DA B C

Fig. 16

2 SENSORS - 2 SPRAYING BOOMS

Fi g. 17

A•thedistributionvalue,theinstantaneous

speed or the pressure value measured by the

transducer; the value displayed will depend on how

the computer was programmed during installation.

B and C•datarelativetotheactivated sensors

(B for the left side and C for the right side of the

tractor).

D•thenumberoftheactive eld.

2 SENSORS - 4 SPRAYING BOOMS

Fig. 18

• The key activates the sensor installed on the left side of the tractor:

to activate sensor S1, which controls the opening and closing of R1 spraying boom, press the

key.

•The key activates the sensor installed on the right side of the tractor: to activate sensor S2,

which controls the opening and closing of R2 spraying boom, press the key.

The symbol displays when the LH sensor is active.

The symbol displays when the RH sensor is active.

When all the sensors are enabled, the display will show the following information:

DA B C

Fig. 19

A•thedistributionvalue,theinstantaneous

speed or the pressure value measured by the

transducer; the value displayed will depend on how

the computer was programmed during installation.

B and C•datarelativetotheactivated sensors

(B for the left side and C for the right side of the

tractor): the value between parentheses is the

number of the active sensor).

D•thenumberoftheactive eld.

When displays in place of the sensor number, this indicates that the sensor in

question has detected a tree: when one or more booms are in line with the plants, and

if the valves have been enabled (section valve switches up), treatment is initiated.

23

Page 24

9.1.2 Four-sensor conguration

The following information will appear on the display:

DA B C

Fig. 20

2 SENSORS - 4 SPRAYING BOOMS

Fig. 21

A•thedistributionvalue,theinstantaneous

speed or the pressure value measured by the

transducer; the value displayed will depend on how

the computer was programmed during installation.

B and C•datarelativetotheactivated sensors

(B for the left side and C for the right side of the

tractor).

D•thenumberoftheactive eld.

3a) To activate sensor S1, which controls the

opening and closing of R1 spraying boom, hold key

pressed and then press the key.

3b) To activate sensor S2, which controls the

opening and closing of R2 spraying boom, hold key

pressed and then press the key.

3c) To activate sensor S3, which controls the

opening and closing of R3 spraying boom, hold key

pressed and then press the key.

3d) To activate sensor S4, which controls the

opening and closing of R4 spraying boom, hold key

pressed and then press the key.

It is possible to enable automatic operation for only one sensor at a time.

The symbol appears on the display when at least one of the two sensors, on the

LEFT (S1-S2) is active.

The symbol appears on the display when at least one of the two sensors, on the

RIGHT (S3-S4) is active.

When all the sensors are enabled, the display will show the following information:

DA B C

Fig. 22

A•thedistributionvalue,theinstantaneous

speed or the pressure value measured by the

transducer; the value displayed will depend on how

the computer was programmed during installation.

B and C•datarelativetotheactivated sensors

(B for the left side and C for the right side of the

tractor): the value between parentheses is the

number of the active sensor).

D•thenumberoftheactive eld.

When displays in place of the sensor number, this indicates that the sensor in

question has detected a tree: when one or more booms are in line with the plants, and

if the valves have been enabled (section valve switches up), treatment is initiated.

If at least one of the sensor is disabled, automatic operating mode changes to semiautomatic mode (sec. 9.3).

24

Page 25

9.2 Manual operating mode

Before performing any operation, make sure that the drain valve is OPEN: position

control deviator A (Fig. 2 - Control Panel) downward; the display will show the entry

GEN OFF (Fig.15-18).

The Bravo 13X is set to ALWAYS start-up in manual mode.

By turning the BRAVO 13X off and on, you automatically change from any operating mode to

manual.

In this mode, the opening and closing of the section valves is manually controlled by

the section valve control deviators (B in Fig. 2 - Control Panel):

- to open the section valves, push the corresponding deviators upward;

- to close the section valves, push the corresponding deviators downward.

To enable the operation of the section valves and, thus, perform the treatment, you

must position control deviator A (Fig. 2 - Control Panel) upward, so that the drain

valve is CLOSED.

9.3 Semi-automatic operating mode

Using this mode, some section valves can be controlled manually through their deviators and others

will operate in automatic mode through their respective ultrasound sensors.

To use this mode, you need activate only some of the sensors installed on the system,

following the procedure shown below in section 9.1 Automatic operating mode.

To disable the operation of the sensors once they are enabled in automatic mode, just select the

sensor to be deactivated by following the same procedure used for putting them into operation.

Example: if you wish to deactivate the operation of sensor S1, for the 2-sensor congurations, press

the key;

if you wish to deactivate the operation of sensor S1 for the 4-sensor conguration, hold the

key and simultaneously press the key.

If all the sensors are disabled, the operating mode will change from semi-automatic

to manual mode.

9.4 Operating errors

ERROR MESSAGE CAUSE REMEDY

Tab. 2

The quantity of liquid in the

tank is less than the reserve

value

3 boom sections are open

(only for BRAVO code

467134 with the 2-sensor

conguration)

25

Fill the tank

The delivery calculation is not

correct: open the fourth section

or close one of the others

Page 26

10 MAINTENANCE / DIAGNOSTICS / REPAIRS

- Only use a soft damp cloth for cleaning.

- Do NOT use detergents or aggressive substances.

- Do NOT use direct jets of water for cleaning the display.

10.1 Troubleshooting

PROBLEM CAUSE REMEDY

The display does not display data No power

The valves are not connected Connect the connectors

Valves cannot be controlled during

manual operation

The section valves do not open corresponding to the plants in automatic

mode

The display does not display the

speed

The speed displayed is inaccurate Incorrect programming

The distribution volume displayed is

inaccurate

The count of the surface area

displayed on the computer is different

from that really treated

The count of liquid sprayed displayed

on the computer is different from the

value of liters/GPM really sprayed

The count of trees treated displayed

on the computer is different than the

number of trees really treated

Tab. 3

The computer is in automatic mode

The drain valve is open

The section valve control deviator is

in the "OFF" position

The valves are not connected Connect the connectors

The ultrasound sensors are not

connected

The drain valve is open

The section valve control deviator is

in the "OFF" position

Incorrect programming or installation

Target out of reach

The vehicle is stopped or the speed

signal is not arriving

Incorrect programming

The signal from the speed sensor is

not arriving

Incorrect programming

Incorrect programming

The counter was not reset Reset the counter (sec. 8.2.3)

Incorrect programming

The counter was not reset Reset the counter (sec. 8.2.3)

The counter was not reset Reset the counter (sec. 8.2.3)

Turn the start-up key to "Start"

Press the computer's start-up key

Verify that the power supply cable is

connected

Set the computer to manual operation

mode

Set the deviator for the drain valve to

the "ON" position

Set the deviator for the section valve

to the "ON" position

Connect the ultrasound sensors

Set the deviator for the drain valve to

the "ON" position

Set the deviator for the section valve

to the "ON" position

Check the parameter "1/0 Error" as

described in sec. 10.2

Verify that the sensors are detecting

the target: the symbol will appear

on the display (sec. 9.1-9.3)

Advance or check that the speed

signal is arriving

Check the programming of the wheel

constant (sec. 8.1.2)

Check the connections with the speed

sensor

Check the programming of the wheel

constant (sec. 8.1.2)

Check the programming of the wheel

constant (sec. 8.1.2)

Check the programming of the product density factor (sec. 8.1.3) and

the type of row (sec. 8.1.4 - 8.2.4)

Check the programming of the type of

row (sec. 8.1.4 - 8.2.4)

Check the programming of the product density factor (sec. 8.1.3)

26

Page 27

10.2 Check the parameter "1/0 Error"

If, during the use of the BRAVO 13X in automatic operating mode and with the tractor in motion,

you are not able to control the section valves, check the parameter "1/0 Error".

The check must be made with the tractor in motion and at the speed at which you

wish to perform the treatment.

To check the value, proceed as follows:

1) Turn on the device by pressing the key.

Bravo 13X will perform the self-diagnostics as indicated in sec. 6 - Start-up, then automatically

enter the Spraying menu.

2) Scroll through the functions using the and keys and select the entry "AUTOMATIC".

3) Press and hold the and keys until the error display screen appears.

According to the conditions that occur, the following screens can appear:

TYPE "a"

Fig. 23

TYPE "b"

A

Fig. 24

10.2.1 Absence of errors (screen "a")

The computer is able to correctly manage the opening and closing of the valves.

10.2.2 Programming error (screen "b")

If screen "b" appears, a wrong programming was performed.

Check that the parameter "CANOPY WIDTH" is set correctly (sec. 8.1.5).

If the problem persists, contact the nearest service center.

A

A is the line relative to

installation errors.

27

Page 28

11 TECHNICAL DATA

11.1 Units of measurement

11.1.1 Spraying menu

VALUE MIN. MAX. UM DESCRIPTION NOTES

Volume/

surface

area

Volume/

tree

Speed 0 199.9

Pressure 0 999,9

Flow rate 0 999,9

Battery

voltage

Surface

area

Liquid

distributed

Tank level 0 19999

Distance 0 99999

Trees

Tab. 4

treated

* alb = tree

11.1.2 Treatment menu

VALUE MIN. MAX. UM DESCRIPTION

Field

number

Row type 1 5 -- Type of row selected

Canopy

Tab. 5

type

11.1.3 User menu

VALUE MIN. MAX. UM DESCRIPTION

Type of

wheel

Wheel

Constant10,01

Product

density

Row

distance

Canopy

Tab. 6

width

0,0

0,0

0,0

0,0

9,0 19,5 V Battery voltage --

0 99999

0 99999

0 99999 Alberi

1 4 -- Number of the eld selected

1 5 -- Type of canopy selected

1 5 -- Type of wheel selected

0,01 99,99 -- Correction factor for liquid density

0,50

5,0

0,00

0,0

9999

9999

9999

9999

5

99,99

29,99

299,9

9,99

99,9

EU: lt/ha

US: gpa

EU: lt/alb*

US: gal/alb*

EU: Km/h

US: mph

EU: bar

US: psi

EU: lt/min

US: gpm

EU: ha

US: acres

EU: lt

US: gal

EU: lt

US: gal

EU: Km

US: miles

EU: cm/imp

US: inch/imp

EU: m

US:feet

EU: m

US:feet

Quantity of liquid

distributed per unit

of surface area

Quantity of liquid

distributed per each

tree treated

Speed of the vehicle Displayable on the rst line

Distribution pressure Displayable on the rst line

Instantaneous ow

rate (at the nozzles)

Surface area treated

Quantity of liquid

sprayed

Quantity of liquid in

the tank

Distance traveled

Number of trees

treated

Distance traveled by the wheel between one impulse

and the next

Distance between rows

Width of the canopy

Displayable on the rst line

From 0,0 to 999,9 resolution 0,1

From 1000 to 9999 resolution 1

Displayable on the rst line

From 0,0 to 999,9 resolution 0,1

From 1000 to 9999 resolution 1

--

Automatic decimal place

adjustment

Count with main valve ON

Count with main valve ON

The maximum value depends

on the parameter Tank volume

Automatic decimal place

adjustment

Count with main valve OFF

Count only active during automatic control of the section

valves

28

Page 29

11.2 Technical characteristics

Description BRAVO 13X

Alphanumeric LCD display

2 lines x 16 characters, backlit

0°C ÷ 60 °C

+32°F ÷ +140 °F

Tab. 7

Display:

Power supply: 11 ÷ 14 Vdc

Consumption (only computer): 150 mA

Working temperature:

Digital inputs: max. 2000 impulse/s

Analogue inputs: 4 ÷ 20 mA

Sensor power supply output: Bravo power supply

Solenoid valve control output gear motor: max. 2.5 A continuous

Drain valve control output gear motor: max. 1 A

Output for controlling the pressure control valve gear motor: max. 3 A

Weight: Bravo 132: 910 g - Bravo 134: 950 g

Protection against reversal of polarity: •

Protection against shor t circuit: •

12 INDEX OF FUNCTIONS

• Speed (par. 8.3.1) ........................................................................................................... 18

• Pressure (par. 8.3.2) ...................................................................................................... 18

• Flow rate (par. 8.3.3) ...................................................................................................... 19

• Battery voltage (par. 8.3.4) ............................................................................................ 19

• Surface area (par. 8.3.5) ................................................................................................ 19

• Liquid sprayed (par. 8.3.6) ............................................................................................ 19

• Tank level (par. 8.3.7) ..................................................................................................... 19

• Distance (par. 8.3.8) ....................................................................................................... 19

• Trees treated (par. 8.3.9) ................................................................................................ 20

• Automatic (par. 8.3.10) ................................................................................................... 20

• Wheel type (par. 8.1.1) ....................................................................................................11

• Wheel constant (par. 8.1.2) .............................................................................................11

• Product density (par. 8.1.3) ........................................................................................... 13

• Row distance (par. 8.1.4) ............................................................................................... 13

• Canopy width (par. 8.1.5) ............................................................................................... 14

• Tank lling (par. 8.2.1) ................................................................................................... 15

• Setting the led number (par. 8.2.2) ............................................................................. 16

• Resetting the "eld" counters (par. 8.2.3) ................................................................... 16

• Row type (par. 8.2.4) ...................................................................................................... 17

•Canopy type (par. 8.2.5) ................................................................................................ 17

13 DISPOSAL AT THE END OF SERVICE

Dispose of the system in compliance with the established legislation in the country of use.

29

Page 30

14 GUARANTEE TERMS

1. ARAG s.r.l. guarantees this apparatus for a period of 360 day (1 year) from the date of sale

to the client user (date of the goods delivery note). The components of the apparatus, that

in the unappealable opinion of ARAG are faulty due to an original defect in the material or

production process, will be repaired or replaced free of charge at the nearest Assistance

Centre operating at the moment the request for intervention is made.

The following costs are excluded:

- disassembly and reassembly of the apparatus from the original system;

- transport of the apparatus to the Assistance Centre.

2. The following are not covered by the guarantee:

- damage caused by transport (scratches, dints and similar);

- damage due to incorrect installation or to faults originating from insufficient or inadequate characteristics of the electrical system, or to alterations resulting from environmental,

climatic or other conditions;

- damage due to the use of unsuitable chemical products, for spraying, watering, weedkilling or any other crop treatment, that may damage the apparatus;

- malfunctioning caused by negligence, mishandling, lack of know how, repairs or modications carried out by unauthorised personnel;

- incorrect installation and regulation;

- damage or malfunction caused by the lack of ordinary maintenance, such as cleaning of

lters, nozzles, etc.;

- anything that can be considered to be normal wear and tear.

3. Repairing the apparatus will be carried out within time limits compatible with the organisational needs of the Assistance Centre.

No guarantee conditions will be recognised for those units or components that have not

been previously washed and cleaned to remove residue of the products used;

4. Repairs carried out under guarantee are guaranteed for one year (360 days) from the

replacement or repair date.

5. ARAG will not recognise any further expressed or intended guarantees, apart from those

listed here.

No representative or retailer is authorised to take on any other responsibility relative to

ARAG products.

The period of the guarantees recognised by law, including the commercial guarantees and

allowances for special purposes are limited, in length of time, to the validities given here. In

no case will ARAG recognise loss of prots, either direct, indirect, special or subsequent to

any damage.

6. The parts replaced under guarantee remain the property of ARAG.

7. All safety information present in the sales documents regarding limits in use, performance

and product characteristics must be transferred to the end user as a responsibility of the

purchaser.

8. Any controversy must be presented to the Reggio Emilia Law Court.

30

Page 31

CONFORMITYDECLARATION

s.r.l.

Via Palladio, 5/A

42048 Rubiera (RE) - Italy

P.IVA 01801480359

Dichiara

che il prodotto

descrizione: Computers

modello: Bravo130

serie: 46713xxx

risponde ai requisiti di conformità contemplati nelle seguenti

Direttive Europee:

2004/108/CEesuccessivemodicazioni

(Compatibilità Elettromagnetica)

Riferimenti alla Norma Applicata:

ENISO14982

(Macchine agricole e forestali - Compatibilità elettromagnetica

Metodi di prova e criteri di accettazione)

Rubiera, 3 settembre 2009

Giovanni Montorsi

(Presidente)

Page 32

Only use original ARAG accessories and spare parts, to maintain safety conditions foreseen by the constructor.

Always refer to the ARAG spare parts catalogue.

42048 RUBIERA (Reggio Emilia) ITALY

Via Palladio, 5/A

Tel. +39.0522.622011

Fax +39.0522.628944

info@aragnet.com

http://www.aragnet.com

D20093.GB-m02 02/2012

Loading...

Loading...