Page 1

Model 8800 Universal

Communicating Thermostat

Safety &

Installation

Instructions

READ AND SAVE THESE INSTRUCTIONS

TABLE OF CONTENTS

INSTALLATION

Installation location recommendations.............2

Thermostat mounting...........................2

Outdoor temperature sensor (optional) .............2

Remote temperature sensor (optional) .............3

Power & reset options..........................3

Wiring terminal ...............................4

Wiring diagrams ............................5-7

SETUP & TESTING

Equipment type selection switch (SW1) ............8

Installer setup menu ...........................8

Installer system settings table ................9-11

System test menu ............................12

System test tables............................13

REFERENCES

Quick reference to controls & display..........14-15

Thermostat features ..........................16

Troubleshooting ..............................17

Error codes ..................................18

Specifications................................19

Page 2

INSTALLATION

CR

CR

INSTALLATION

INSTALLATION LOCATION RECOMMENDATIONS

Thermostat should be mounted:

• On an interior wall, in a frequently occupied space.

• Approximately 5‘ above floor.

• At least 18” from outside wall.

• Thermostat can be mounted to a vertical junction box.

Do not mount thermostat:

• Behind doors, in corners or other dead air spaces.

• In direct sunlight, near lighting fixtures, or other

appliances that give off heat.

• On an outside or unconditioned area wall.

• In the flow of a supply register, in stairwells, or near

outside doors.

• On a wall with concealed pipes or ductwork.

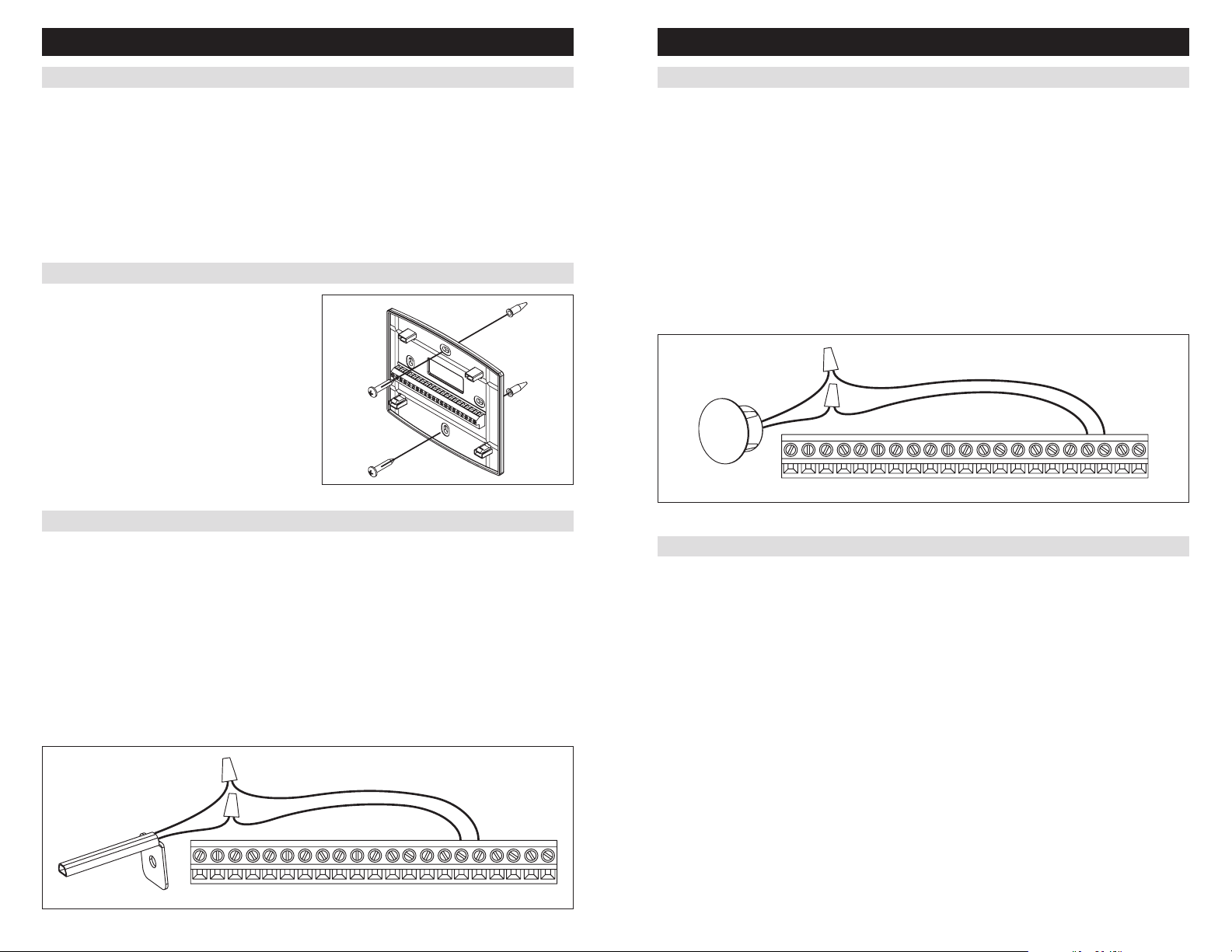

THERMOSTAT MOUNTING

1. Remove the rear mounting plate from the thermostat.

2. Pull wires through the opening on the back of the

thermostat.

3. Position and level the mounting plate of the thermostat

on wall and mark the hole locations with a pencil.

4. Drill 1/4” holes and insert supplied anchors

(drywall only).

5. Place mounting plate over anchors, insert and tighten

screws.

6. Seal wire entry holes to prevent drafts affecting

temperature readings.

OUTDOOR TEMPERATURE SENSOR (OPTIONAL)

Outdoor temperature can be measured by attaching an 8052 sensor to the S1 and S2 terminals. The outdoor sensor

must be enabled in the installer setup menu.

In heat pump mode the outdoor temperature

sensor can be used to efficiently utilize an air

source heat pump:

• When the outdoor temperature is less than the Low

Balance Point, the heat pump will be locked out and

only auxiliary heating will be used.

• When the outdoor temperature is higher than the

High Balance Point, the auxiliary heating will be

locked out and only the heat pump will be used to

Outdoor temperature sensor should be mounted:

• On side of building out of direct sunlight (north side

recommended).

• Above snow line.

• At least 3’ away from exhaust vents and condensing

lines.

• Using less than 300’ of wire.

• Do not route wires along 120 VAC lines.

provide heating.

REMOTE TEMPERATURE SENSOR (OPTIONAL)

A remote temperature sensor can be used if the thermostat is to be mounted in a concealed location. A 8051 flush

mount or 8053 surface mount remote temperature sensor can be attached to the T1 and T2 terminals and mounted

in a recommended area. The remote sensor must be enabled in the installer set-up menu, and once enabled will

override the thermostat’s internal temperature sensor.

Remote temperature sensor should be mounted:

• On an interior wall, in a frequently occupied space.

• Approximately 5‘ above floor.

• At least 18” from outside wall.

• Using less than 300’ of wire.

Do not mount remote sensor:

• Behind doors, in corners or other dead air spaces.

• In direct sunlight, near lighting fixtures, or other

appliances that give off heat.

• On an outside or unconditioned area wall.

• In the flow of a supply register, in stairwells, or near

outside doors.

• On a wall with concealed pipes or ductwork.

• Near 120 VAC lines.

B+ A+ B- A-

W2RH

RC WBOYY2G

S2

T2T1S1

RSARSB

POWER & RESET OPTIONS

The thermostat is a 24VAC powered device with a battery back-up for the clock.

The thermostat has a memory backup that saves the thermostat settings in case of a power interruption. The system

settings will be retained but the clock will reset after 90 seconds with no battery or AC power.

The reset button located under the battery cover can be used to reset the thermostat to factory defaults. The system

settings will also be reset to default.

W2RH

B+ A+ B- A-

2 3

RC WBOYY2G

S2

T2T1S1

RSARSB

Page 3

INSTALLATION

BW

CS

BW

CS

THERMOSTAT IS POWERED

INSTALLATION

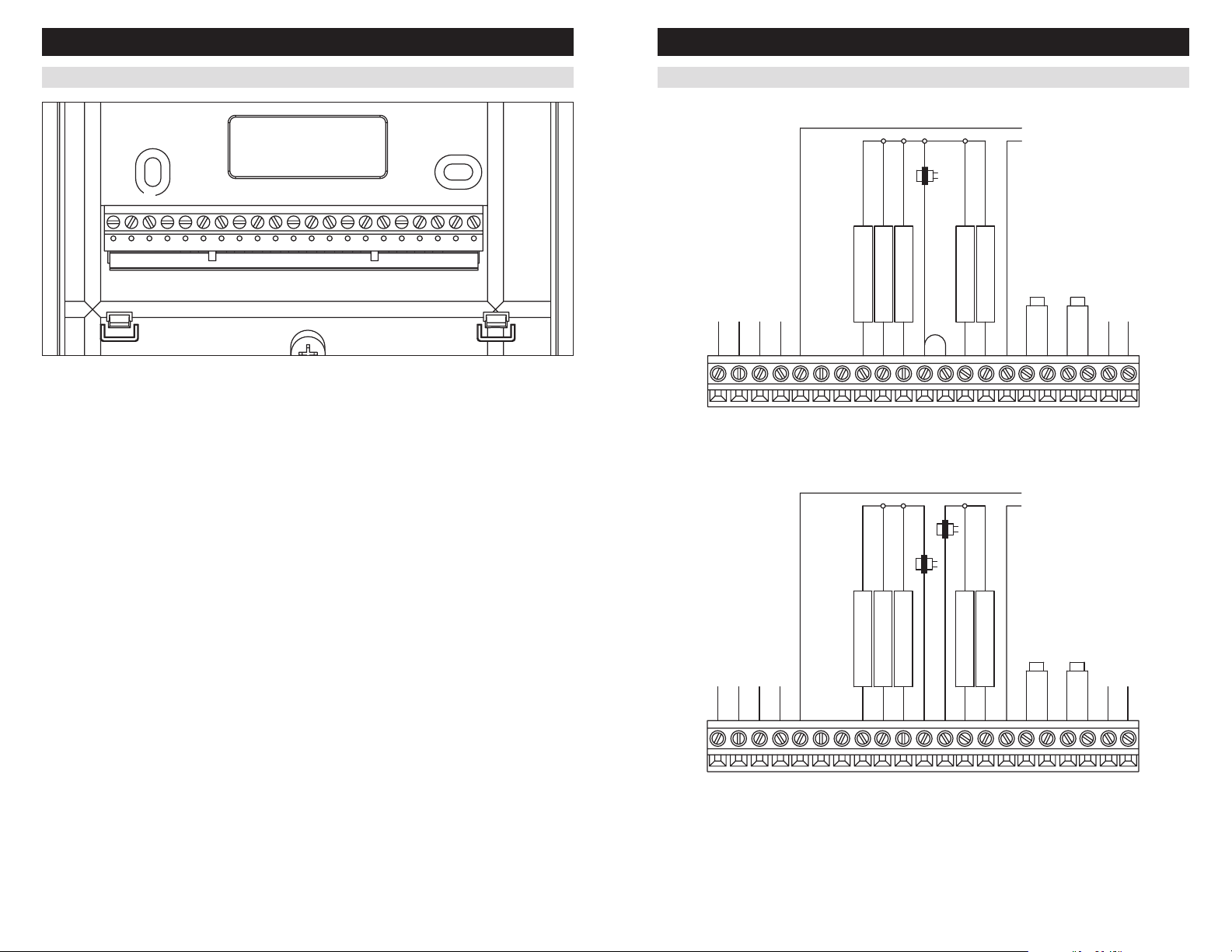

WIRING TERMINAL

B+

A+ A-

B-

BYORC RH

Y2

G

C

Wire specifications:

18-24 gauge thermostat wire

CAT-5 or equivalent for communication terminals

Installation notes:

• Ensure power at the HVAC equipment is off.

• Loosen screw terminals, insert stripped wire and

re-tighten.

• Push the excess wire back into the opening and plug

the wall opening to prevent drafts.

Note: If the HVAC system was installed before the

automation system, the HVAC installer may have

powered the thermostat connecting a wire to the

C terminal and installing a jumper wire from the R

terminal to RH or RC. When used with an automation

system, the R and C terminals on the Model 8800

thermostat should only be connected to the same

terminals on the 8819 or a dedicated 24VAC transformer.

There should be no connection to the R or C terminals

coming from the HVAC equipment.

W2

RT2

W

B+ / B- – Receive communication terminal

(reference automation system)

A+ / A- – Transmit communication terminal

(reference automation system)

S2

S1

T1

RSARSB

1

1

C – 24VAC Thermostat power (common) from 8819

R – 24VAC Thermostat power (hot) from 8819

B – Reversing valve for heat

O – Reversing valve for cool

2

2

Y – 1st stage cooling / compressor or dehumidifier3

Y2 – 2nd stage cooling / compressor

G – Fan

RC – 24VAC supply cooling

RH – 24VAC supply heating

4

4

W2 – 2nd stage heat / auxiliary / E-Heat

W – 1st stage heat / auxiliary / E-Heat / humidifier

S1 & S2 – outdoor temperature sensor (optional)

T1 & T2 – remote temperature sensor (optional)

RSA & RSB – 8081 or 8082 Support Module

communication (half duplex)

1

Refer to Aprilaire HVAC Automation System Installation Manual

for communication wiring details.

2

O and B terminals are both de-energized when system mode is

OFF or in AUTO when the heating and cooling equipment is idle.

3

When the unit is configured for humidistat mode.

4

Jumper between RC & RH is used in single transformer systems

(see wiring diagrams).

5

Refer to Support Module literature for wiring details.

5

CONVENTIONAL HEAT/COOL

SINGLE TRANSFORMER (USE JUMPER WIRE)

THERMOSTAT IS POWERED

FROM 8819 OR 24VAC

TRANSFORMER

TRANSFORMER

COMMUNICATION

TERMINALS

NOT USED

NOT USED

FAN

1st COOLING

2nd COOLING

GY2YO

JUMPER

RC RH W2

2nd HEATING

1st HEATING

SENSOR

OUTDOOR TEMP

S2R

SENSOR

REMOTE TEMP

SUPPORT

MODULE

1T1T2A-B-A+B+

RSB RSA

TWO TRANSFORMERS (REMOVE JUMPER WIRE)

FROM 8819 OR 24VAC

TRANSFORMER

HEATING

TRANSFORMER

COOLING

TRANSFORMER

3

COMMUNICATION

TERMINALS

NOT USED

NOT USED

FAN

1st COOLING

2nd COOLING

GY2YO

RC RH W2

2nd HEATING

1st HEATING

SENSOR

OUTDOOR TEMP

S2R

SENSOR

REMOTE TEMP

SUPPORT

MODULE

1T1T2A-B-A+B+

RSB RSA

4 5

Page 4

INSTALLATION

BW

CS

THERMOSTAT IS POWERED

BW

CS

THERMOSTAT IS POWERED

BW

CS

THERMOSTAT IS POWERED

BW

CS

INSTALLATION

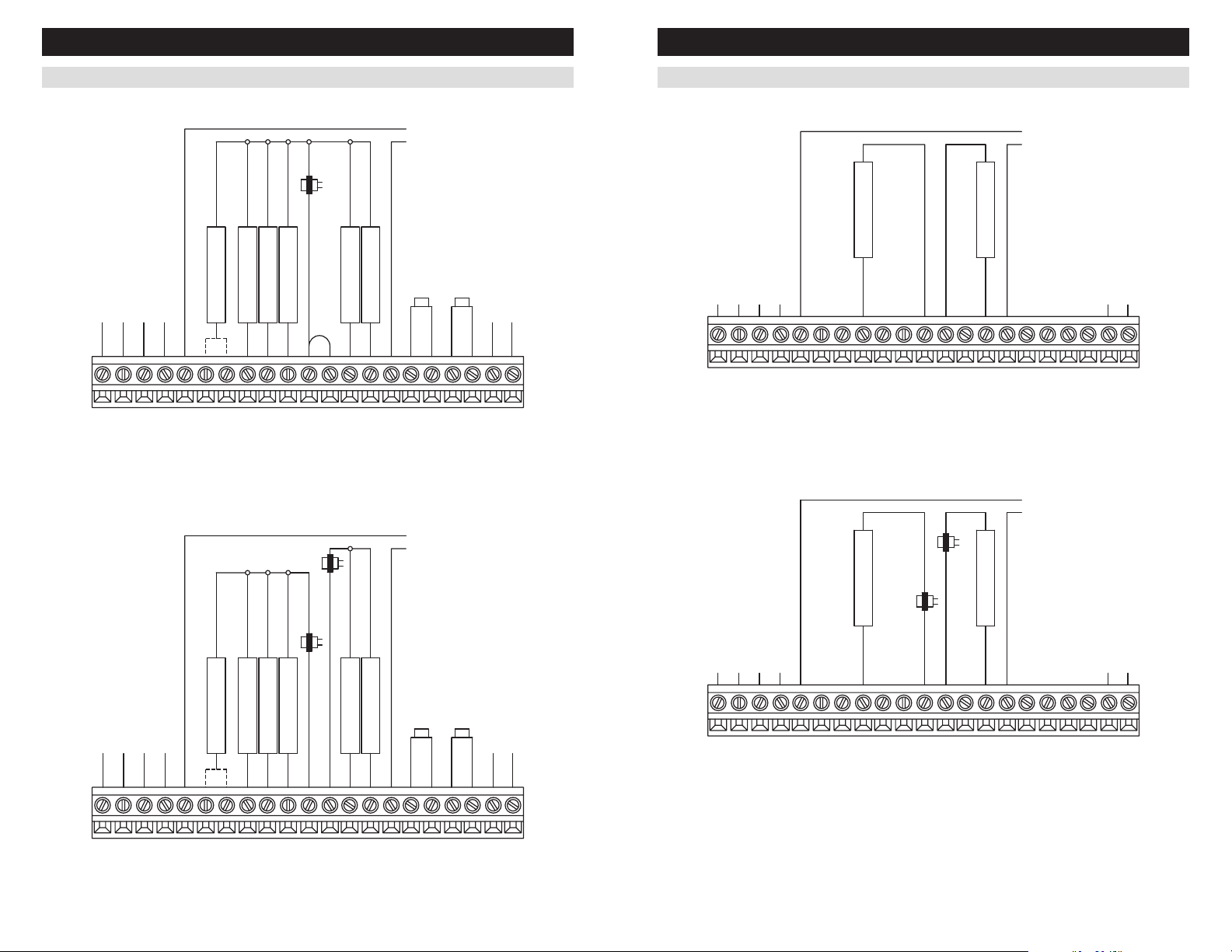

HEAT PUMP

COMMUNICATION

COMMUNICATION

TERMINALS

TERMINALS

SINGLE TRANSFORMER (USE JUMPER WIRE)

FROM 8819 OR 24VAC

TRANSFORMER

HEAT PUMP

TRANSFORMER

1st COMPRESSOR

REVERSING VALVE

FAN

2nd COMPRESSOR

JUMPER

2nd AUX HEATING

OUTDOOR TEMP

1st AUX HEATING

OR

GY2YO

RC RH W2

S2R

NOTE: “O” is active in cooling and “B” is active in heating.

TWO TRANSFORMERS (REMOVE JUMPER WIRE)

FROM 8819 OR 24VAC

TRANSFORMER

HEATING

TRANSFORMER

HEAT PUMP

TRANSFORMER

1st COMPRESSOR

REVERSING VALVE

FAN

2nd COMPRESSOR

2nd AUX HEATING

OUTDOOR TEMP

1st AUX HEATING

SENSOR

1T1T2A-B-A+B+

SENSOR

SENSOR

REMOTE TEMP

SUPPORT

MODULE

RSB RSA

SENSOR

REMOTE TEMP

SUPPORT

MODULE

HUMIDISTAT

COMMUNICATION

COMMUNICATION

TERMINALS

TERMINALS

DRY CONTACT

DEHUMIDIFIER

GY2YO

RC RH W2

POWERED CONTACT

HUMIDIFIER

DEHUMIDIFIER

DEHUMIDIFIER

TRANSFORMER

GY2YO

RC RH W2

TRANSFORMER

FROM 8819 OR 24VAC

TRANSFORMER

HUMIDIFIER

S2R

1T1T2A-B-A+B+

THERMOSTAT IS POWERED

FROM 8819 OR 24VAC

TRANSFORMER

HUMIDIFIER

S2R

1T1T2A-B-A+B+

SUPPORT

MODULE

RSB RSA

SUPPORT

MODULE

RSB RSA

OR

GY2YO

RC RH W2

S2R

1T1T2A-B-A+B+

RSB RSA

NOTE: “O” is active in cooling and “B” is active in heating.

6 7

Page 5

SETUP & TESTING

HC

HP

SETUP & TESTING

EQUIPMENT TYPE SELECTION SWITCH (SW1)

This thermostat has the option of being used in heat

pump or heat/cool systems. Switch SW1 located on the

back of the thermostat’s face is used to select this option.

This setting can also be checked in the Installer System

Settings under Equipment Type.

Note: Thermostat reboots within 10 seconds after switch

position is changed.

HC

HP

INSTALLER SETUP MENU

HOW TO ENTER THE INSTALLER SETUP MENU TO CHANGE SYSTEM SETTINGS:

Press [MODE] to set system to OFF.

Press [MENU] to enter main menu.

Press and hold [SETUP] for seven seconds, [INSTALL

SETUP] appears.

Press [INSTALL SETUP] to enter installer setup menu.

Press [NEXT] or [BACK] to page through the settings.

Press

or to adjust the setting.

Press [DONE] to save and exit, or [CANCEL] to exit

without saving.

The thermostat will discard changes and exit if nothing

is pressed within 60 seconds.

SETTING

NUMBER

To reset the installer settings to the default, reset the

thermostat by pressing the [RESET] button inside the

battery cover.

SETTING

OPTIONS

SETTING

DESCRIPTION

SW1

HEAT/COOL

HEAT PUMP

INSTALLER SYSTEM SETTINGS TABLE

The following table is the list of the settings and their details. Default settings are shown in bold. Some settings are

only available to thermostats set to heat pump or humidistat mode.

Factory default setting (bold)

System setting Description

00. NETWORK ADDRESS Network communication address.

01. NUMBER OF NODES Total number of thermostats on the network.

02. BAUD RATE Communication baud rate.

03. CONTROLLER TYPE Sets controller to Thermostat or Humidistat.

04. EQUIPMENT TYPE Equipment type is set by SW1.

05. CONTROL SETUP Used to lockout heating or cooling outputs

06. AUTO CHANGEOVER Enable or disable Auto changeover mode.

07. NUMBER OF STAGES Number of stages of equipment.

08. AUX HEAT STAGES Number of stages of auxiliary heat equipment.

09. Heat/Cool: FAN

CONTROL IN HEATING

Heat Pump: AUXILIARY

EQUIPMENT TYPE

10. Thermostat:

COMPRESSOR MIN OFF

TIME

10. Humidistat:

DEHUMIDIFIER MIN

ON/OFF TIME

11. Thermostat: HEATING

MIN OFF TIME

11. Humidistat: HUMIDIFIER

MIN ON/OFF TIME

12. EQUIPMENT MIN ON

TIME

13. AUTO CHANGEOVER

TIME

14. REMOTE SENSOR Select if remote sensor is attached at T1 and T2.

15. OUTDOOR SENSOR Select if outdoor sensor is attached at S1 and S2.

16. CONTROL SENSOR

BACKUP

17. FIRST STAGE

DIFFERENTIAL

18. SECOND STAGE

DIFFERENTIAL

1

If utilizing a fossil fuel auxiliary heat system, set to Gas or Oil Furnace. In this setting, the heat pump will lock out before the fossil fuel auxiliary

heat comes on; eliminating the need for a dual fuel kit. If utilizing electric auxiliary heat, set to Electric. In this setting, the heat pump and

electric auxiliary heat are allowed to run simultaneously.

(only available in Heat/Cool mode).

Heat/Cool: Determines if the thermostat or

equipment controls the fan in heating.

Heat Pump: Auxiliary Equipment type.

Thermostat: Minimum off time for compressor

protection.

Humidistat: Minimum on/off time for dehumidifier

protection.

Thermostat: Minimum off time for heating.

Humidistat: Minimum on/off time for humidifier.

Minimum on time for heating and cooling.

Minimum time between heating and cooling calls.

Control sensor failure response. STOP CONTROL (enter Error Mode)

1st stage differential.

2nd stage differential.

1

and setting range

1

Address selection of 1 to 64 in steps of 1

64

Selection of 1 to 64 in steps of 1

9600

19200

THERMOSTAT

HUMIDISTAT

HEAT/COOL

HEAT PUMP

HEAT AND COOL

HEAT ONLY

COOL ONLY

DISABLE

ENABLE

SINGLE

MULTI

ONE

TWO

GAS/OIL HEAT (equipment controls fan)

ELECTRIC HEAT (thermostat controls fan)

5 MINUTES

1 to 5 MINUTES

2 MINUTES

1 to 5 MINUTES

2 MINUTES

1 to 5 MINUTES

4 MINUTES

1 to 5 MINUTES

NO

YES

NO

YES

USE BUILT-IN

1°F (0.5°C)

1°F to 9°F (0.5°C to 4.5°C)

1°F (0.5°C)

1°F to 9°F (0.5°C to 4.5°C)

8 9

Page 6

SETUP & TESTING

SETUP & TESTING

INSTALLER SYSTEM SETTINGS TABLE (CONTINUED)

Factory default setting (bold)

System setting Description

19. THIRD STAGE

DIFFERENTIAL

20. FOURTH STAGE

DIFFERENTIAL

21. INTEGRAL FACTOR

PERIOD

22. LOW BALANCE POINT Outdoor temperature low balance point

23. HIGH BALANCE POINT Outdoor temperature high balance point

24. EXTENDED FAN – HEAT Extends fan operation after heat call ends.

25. EXTENDED FAN – COOL Extends fan operation after cool call ends.

26. PROGRESSIVE

RECOVERY

27. DEADBAND Auto changeover mode dead band.

28. HUMIDISTAT MODE Sets humidity control mode. HUMIDIFY

29. TEMPERATURE SCALE Set the thermostat to Fahrenheit or Celsius

30. AUTO DAYLIGHT

SAVINGS

32. CONSTANT BACKLIGHT Enable constant, low intensity, backlight when

33. BACKLIGHT INTENSITY Backlight intensity as a percentage of full on.

34. SENSOR OFFSET Field adjustment of the controlling temperature

35. PROGRAM FORMAT Select weekly program format.

36. EVENT CONFIGURATION Setting for event naming.

37. EVENTS PER DAY Number of program events per day.

38. USER SECURITY SETUP Enable or disable security setup system

39. SECURITY Enable or disable security.

40. SECURITY PIN Security pin code. ####

3rd stage differential.

4th stage differential.

Short period = more cycles per hour (comfort)

Long period = less cycles per hour (economical).

(This option is only displayed if the outdoor

temperature sensor is enabled).

(This option is only displayed if the outdoor

temperature sensor is enabled).

Enable or disable Progressive recovery. DISABLE

mode.

Enable or disable auto daylight savings. OFF

24VAC is present.

sensor.

variables in the User Setup Screens.

and setting range

1°F (0.5°C)

1°F to 9°F (0.5°C to 4.5°C)

1°F (0.5°C)

1°F to 9°F (0.5°C to 4.5°C)

2 MINUTES

1 to 5 minutes or “OFF” for proportional

control only

20°F (–6°C)

10°F to 50°F (-12°C to 9°C) or OFF to ignore

65°F (18°C)

40°F to 85°F (3°C to 30°C) or OFF to ignore

DISABLE

ENABLE (90 second extension)

DISABLE

ENABLE (90 second extension)

ENABLE

3°F (2°C)

2°F to 9°F (1°C to 5°C)

DEHUMIDIFY

AUTO

OFF

FAHRENHEIT

CELSIUS

MARCH (second Sunday in March to the

first Sunday in November)

APRIL (first Sunday in April to the last Sunday

in October)

DISABLE

ENABLE

100 PERCENT

0 – 100%

0°: No offset applied

–8°F to +8°F (-4°C to +4°C)

7-DAY (Mon, Tue, Wed, Thu, Fri, Sat, Sun)

5/1/1 (weekdays, Saturday and Sunday)

5/2 WEEKDAYS (weekdays and weekends)

NON-PROG

RESIDENTIAL

COMMERCIAL

FOUR

TWO

DISABLE

ENABLE

DISABLE

ENABLE

4-digit numeric pin

INSTALLER SYSTEM SETTINGS TABLE (CONTINUED)

Factory default setting (bold)

System setting Description

41. LOCKOUT TYPE Screen lockout level. (Override lockout by

42. MODE LOCKOUT System mode lockout setting.

43. FAN LOCKOUT Fan Mode lockout setting.

44. SETPOINT LOCKOUT

TYPE

45. MAX SETPOINT

CHANGE IN LOCKOUT

46. TEMPORARY CHANGE

PERIOD

47. NETWORK OVERRIDE Network override feature setting. ENABLE

48. DISPLAY REMOTE

SENSORS

49. AIR FILTER ALARM

PERIOD

50. WATER PANEL ALARM

PERIOD

51. HUMIDIFIER TYPE Select humidifier type. Flow through type

52. DEHUMIDIFIER ALARM

PERIOD

53. HVAC ALARM PERIOD The period for displaying the “Service HVAC”

holding [MENU] for 7 seconds).

Setpoint lockout setting.

Select setpoint limits (only available when

lockout is set to partial lockout).

Time-limited lockout temporary change period.

Enable or disable display of support module

monitor (remote) sensor readings.

The period for displaying the “Change Air

Filter” message.

Set number of months until the first reminder

is required. The following reminders will occur

every 12 months for a flow through humidifier,

and 3/9 months for a drainless humidifier.

gives a 12 month reminder, and drainless

gives a 3/9 month reminder.

The period for displaying the “Service

Dehumidifier” message.

message.

and setting range

OFF

PARTIAL

FULL

DISABLE

ENABLE

OFF

TIMED

FULL

OFF

TIME-LIMITED

RANGE-LIMITED

TIME AND RANGE

FULL

+/-5 DEGREES (from current setpoint)

±1° to 20° OFF indicates no setpoint changes

or

+/-5% RH (from current setpoint)

±1% to 20% OFF indicates no setpoint changes

60 MINUTES

Selection of 0 to 255 minutes in 5 minute step;

0 indicates no temporary change period.

DISABLE

ENABLE

DISABLE

OFF

1, 3, 6, 12 MONTHS or “OFF” to disable

OFF

1 to 12 MONTHS or “OFF” to disable

FLOW THROUGH (1 reminder per season)

DRAINLESS (2 reminders per season)

OFF

1 to 12 MONTHS or “OFF” to disable

OFF

1 to 12 MONTHS or “OFF” to disable

10 11

Page 7

SETUP & TESTING

SETUP & TESTING

SYSTEM TEST MENU

The system test menu is used to test a system after installation. The outputs of the thermostat or humidistat can be

manually activated to test their function. The instructions below show how to enter the test mode and turn outputs

on and off.

HOW TO ENTER THE SYSTEM TEST MENU:

Press [MODE] to set system to off.

Press and hold [FAN] and [MODE] for three seconds

to enter system test mode. Note: Buttons will not be

shown in humidistat mode. Press in the same area that

the button would be displayed.

The screen of the first test step is displayed:

TEST NUMBER MODEL

OUTPUT

STATE

(SW1 SETTING)

STAGE

FLASHES

IF 24VAC

IS NOT

PRESENT

The test number is displayed on the upper left, and the

output state is displayed in the message center.

Press

output, press

Press

to turn on the output (01). For multi stage

again to turn on the 2nd stage (02).

to turn off all the outputs (00).

Press [BACK] or [NEXT] to change to the next test

step.

When the last step is done, press [NEXT]. The

message “installer test complete“ will display.

All minimum on and off timers will be reset after

returning from system test mode.

Note: Second stage will only be displayed when the

thermostat is set to multi-stage mode.

Test Number Thermostat System Test

60 Heating equipment test

61 Cooling equipment test

62 Auxiliary equipment test (HP only)

63 Fan equipment test

Test Number Humidistat System Test

70 Humidification equipment test

71 Dehumidification equipment test

SYSTEM TEST TABLES

Test 60: Heating Equipment Test

Button

Press

1st UP

press

2nd UP

press

Equipment

Type

Heat Cool

Heat Pump ON ON ON

Heat Cool

Heat Pump

Stages

Heat

Type

Gas ON ON

Electric ON ON ON

1

Gas ON ON ON

2

Electric ON ON ON ON

1

2 ON ON ON ON

Test 61: Cooling Equipment Test

Button

1st UP

2nd UP

Press

press

press

Equipment

Type

Heat Cool ON ON ON

Heat Pump ON ON ON

Heat Cool

Heat Pump

Stages W W2 Y Y2 G O B

1

2 ON ON ON ON

1

2 ON ON ON ON

Test 62: Auxiliary Equipment Test (HP only)

Button

1st UP

2nd UP

Press

press

press

Equipment

Type

Heat Pump

Heat Pump

Heat

Type

Gas ON ON

Electric ON ON ON

Gas ON ON ON

Electric ON ON ON ON

Test 63: Fan Equipment Test

Button

Press

1st UP

press

W W2 Y Y2 G O B

W W2 Y Y2 G O B

W W2 Y Y2 G O B

ON

Test 70: Humidifier Equipment Test

Button

Press

1st UP

press

W W2 Y Y2 G O B

ON ON ON

Test 71: Dehumidifier Equipment Test

Button

Press

1st UP

press

12 13

W W2 Y Y2 G O B

ON ON ON

Page 8

QUICK REFERENCE TO CONTROLS & DISPLAY

QUICK REFERENCE TO CONTROLS & DISPLAY

HOME SCREEN

FAN MODE

BUTTON

FAN MODE

SETTING

SYSTEM MODE

BUTTON

SYSTEM MODE

SETTING

EQUIPMENT

STATUS

MESSAGE

CENTER

(SCROLLING TEXT)

LOW BATTERY

INDICATOR

MAIN MENU

CURRENT DAY

NOTE: BACKLIGHT IS ACTIVATED WITH FIRST BUTTON PRESS AND AUTOMATICALLY TURNS OFF.

OUTDOOR TEMPERATUREROOM TEMPERATURE

CURRENT TIME & DATE MAIN MENU BUTTON

ROOM RELATIVE HUMIDITY

TEMPERATURE SETTING

TEMPERATURE

ADJUSTMENT

HOLD BUTTON

(IN PROGRAMMABLE MODE

SETS OR CLEARS HOLD)

NETWORK OVERRIDE

(IN NON-PROGRAMMABLE MODE)

HEAT PUMP MODE ONLY

EMERGENCY/AUXILIARY

HEAT (RED)

INDICATOR SHOWS THROUGH HOUSING

HUMIDISTAT

The Model 8800 has the option of being configured as a humidistat that can control a humidifier and dehumidifier.

Note: The 8800 is set to operate as a humidistat through the installer setup menu.

ROOM RELATIVE HUMIDITY

MESSAGE

CENTER

(SCROLLING TEXT)

CURRENT TIME

& DATE

ROOM RELATIVE HUMIDITY SETPOINT CURRENT DAY

HUMIDIFIER ADJUSTMENT

OUTDOOR TEMPERATURE

DEHUMIDIFIER ADJUSTMENT

NETWORK OVERRIDE

(IF ENABLED)

MAIN MENU BUTTON

CLEAN SCREEN

(LOCKOUT TOUCH SCREEN

FOR 30 SECONDS)

SET VACATION HOLD

(HOLD–TO TIME AND DATE)

SET SCHEDULE

BUTTON

USER SYSTEM SETTINGS

SET CURRENT TIME

SET CURRENT DATE

DONE BUTTON

(EXIT MENU)

14 15

Page 9

THERMOSTAT FEATURES

TROUBLESHOOTING

• Large touch screen with adjustable backlight.

• Message center provides feedback and instructions.

• 7 day programmability or separately programmable

weekday/weekend schedules.

• Thermostat can be removed from the wall for easy

programming (batteries must be installed).

• Front battery door access for fast, easy replacement.

• Displays room temperature, room humidity,

temperature setting, and optional outdoor temperature.

• Air filter, humidifier, dehumidifier, and HVAC service

indicators.

• Programmable fan control with fan circulation mode.

• Easy to use temperature control can override program

schedule at any time.

• Progressive recovery ensures proper temperature at

the start of a program event.

• Built in compressor protection prevents damage to

your equipment.

• Battery back-up.

• System test mode.

• RS485 communications ready.

• Universal system compatibility.

• Configurable to control a humidifier or dehumidifier.

DISPLAY IS BLANK

• Check circuit breaker and reset if necessary.

• Make sure power switch at heating & cooling

system is on.

• Make sure furnace door is closed securely.

TEMPERATURE SETTINGS DO NOT CHANGE

Make sure heating and cooling temperatures are set to

acceptable ranges:

• Heat: 40° to 90°F (4° to 32°C).

• Cool: 50° to 99°F (10° to 37°C).

HEATING SYSTEM DOES NOT RESPOND

(“HEATING” APPEARS ON SCREEN)

• Check for 24VAC at the equipment on the secondary

side of the transformer between power and

common. If voltage is not present, check the heating

equipment to find the cause of the problem.

• Check for 24VAC between the heat terminal (W)

and the transformer common. If 24VAC is present,

the thermostat is functional. Check the heating

equipment to find the cause of the problem.

• Check for loose or broken wires between the

thermostat and the heating equipment.

FAN DOES NOT TURN ON IN A CALL FOR HEAT

• Check System Setting 09 (Fan Control), to make sure

the fan control is properly set to match the type of

system (see page 9).

HEAT PUMP ISSUES COOL AIR IN HEAT MODE,

OR WARM AIR IN COOL MODE

• Check wiring at the terminal block to confirm the

reversing valve is connected to the proper terminal.

O is active in cooling and B is active in heating.

HEAT/COOL BOTH ON AT SAME TIME

• Check SW1 (Equipment Type), to make sure it is set

to match the installed heating/cooling equipment

(see page 8).

• Check to make sure heating and cooling wires are

not shorted together.

HEATING EQUIPMENT IS RUNNING IN

COOL MODE

• Check SW1 (Equipment Type), to make sure it is set

to match the installed heating/cooling equipment

(see page 8).

COOLING SYSTEM DOES NOT RESPOND

(“COOLING” APPEARS ON SCREEN)

• Check for 24VAC at the equipment on the secondary

side of the transformer between power and

common. If voltage is not present, check the cooling

equipment to find the cause of the problem

• Check for 24VAC between the cooling terminal (Y)

and the transformer common. If 24VAC is present,

the thermostat is functional. Check the cooling

system to find the cause of the problem.

• Check for loose or broken wires between the

thermostat and the cooling equipment.

16 17

“HEATING” IS NOT DISPLAYED

• Check Installer System Setting number 05

(Control Setup) is set correctly.

• Change the System Mode to Heat, and set

the temperature level above the current room

temperature.

“COOLING” IS NOT DISPLAYED

• Check Installer System Setting number 05

(Control Setup) is set correctly.

• Change the System Mode to Cool, and set

the temperature level below the current room

temperature.

Page 10

ERROR CODES

SPECIFICATIONS

If the thermostat enters an error mode, all outputs are turned off. The thermostat attempts to recover every 10 minutes.

If the error does not clear, use the reset button. This will return all settings back to factory default.

Error code Message Error Description

01

02 Shorted temperature sensor circuit

03 “RH SENSOR ERROR” Invalid response from the RH sensor

04 “EEPROM ERROR” Error in permanent memory

05 “SENSOR ERROR”

“SENSOR ERROR”

All controlling support modules are unresponsive and

Open temperature sensor circuit

the built-in sensor is not used as a backup option

Environment

Temperature

Relative humidity Operating: 5% to 90% R.H. (non-condensing)

Operating voltage 24VAC (18 – 30VAC)

Current

Battery back-up AA size alkaline battery x 2

Outdoor & Remote temperature sensor Maximum distance: 300 feet

Room temperature measurement Display range: 32° to 99°F (0° to 40°C)

Outdoor temperature measurement Display range: -20° to 130°F (-30° to 55°C)

Setpoint temperature range

Setpoint humidity range

Operating: 32° to 120°F (0° to 48.9°C)

Shipping: -30° to 150°F (-34.4° to 65.5°C)

Electrical

Maximum: 2.5A (total), 1.0A (single output)

Maximum surge current: 5A

Thermal

Heat: 40° to 90°F (4° to 32°C)

Cool: 50° to 99°F (10° to 37°C)

Humidification: 10% to 90% R.H.

Dehumidification: 10% to 90% R.H.

18 19

Page 11

P.O. Box 1467 • Madison, WI 53701-1467 • Phone: 800/334-6011 • Fax: 608/257-4357

www.aprilairepartners.com

61000761 1.12

B2205382C © 2012 Aprilaire – A division of Research Products Corporation

Loading...

Loading...