Aprilaire 8120, 8126 Installation Manual

STEP 9: SET THE SAMPLING TIME INTERVAL

10005991

WIRING AND

JUMPER

CONFIGURATION

CYCLE TIME

1 HR 3 HR

2 HR 4 HR

TO STAT

TO HVAC

TO HVAC

GS

W

G

H

CRDDTT

TO HVAC

DAMPER

TEMP

SENSOR

OUTDOOR

TEMPERATURE

SENSOR

24VAC

A

/

A

CYCLE TIME

1 HR 3 HR

2 HR 4 HR

A. The Cycle Time Interval is the time period over which ventilation

will occur. This is variable from 1 to 4 hours depending on

customer preference. Keep in mind, once the Ventilation

requirement is met the Vent Control won’t run again until the

start of the next cycle. The Cycle Time is the length of the

sampling period, while the Ventilation time as set is the actual

operating time.

B. The device is factory set to a 1 hour sample time. This is

recommended for a quicker reaction to conditions. Also the

longer Cycle Intervals are more likely to require more than the

60 minutes available on the dial.

C. Remove knob by carefully pulling it out from the case. Snap the

cover off and refer to Figure 7 to locate the cycle time setting

tab and pins.

D. The jumper tab on the 5 pin array determines the sampling time

interval. Per diagram this can be 1,2,3 or 4 hours. The jumper

tab is removed by pulling it straight out from the pins. Take care

in replacing, do not bend.

STEP 10: DETERMINE THE VENT CONTROL KNOB SETTING

FIGURE 7 – Cycle Time

90-698

Step 7C

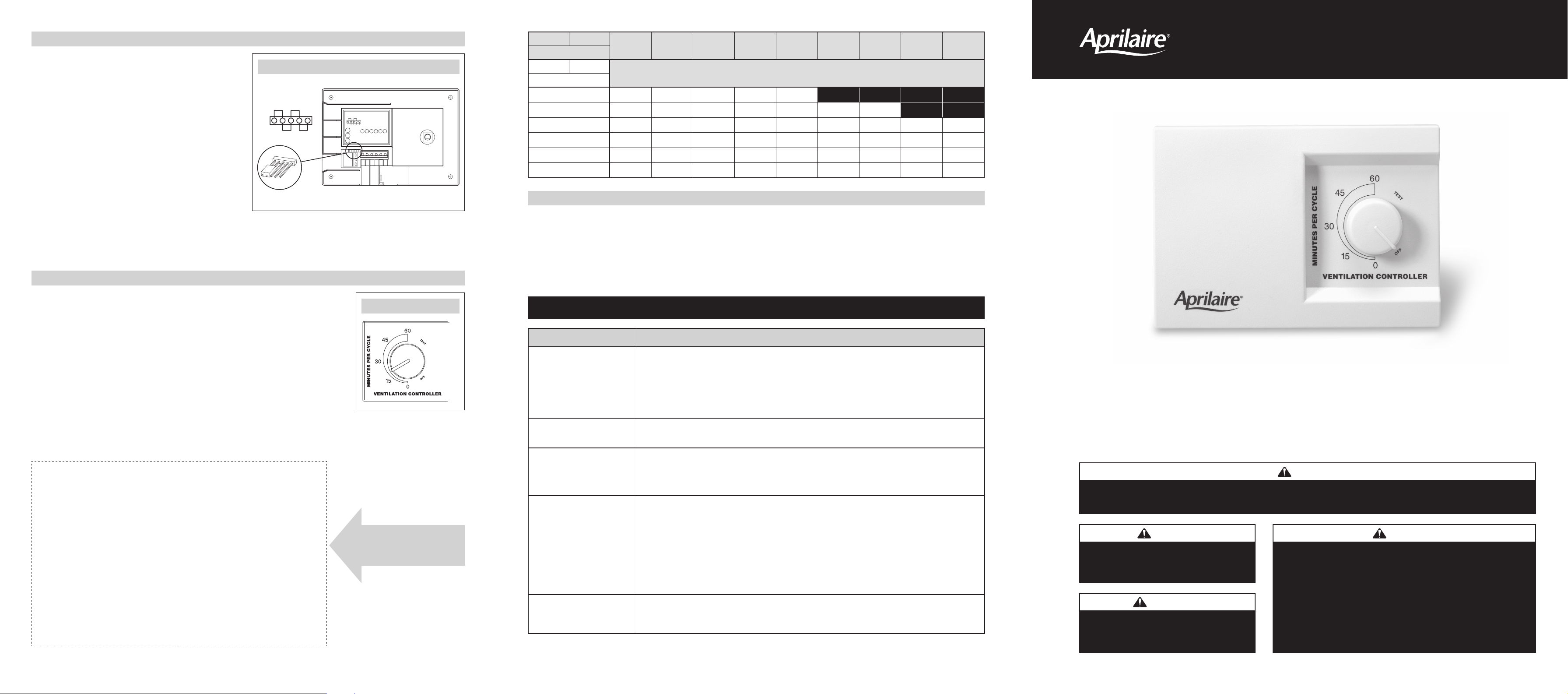

CFM Required >>

Step 8C

CFM Delivered

60

80

100

120

140

160

20 30 40 50 60 70 80 90 100

KNOB SETTINGS (in minutes) FOR AIRFLOW DELIVERED vs AIRFLOW REQUIRED (1 HR CYCLE)

20 30 40 50 60

15 25 30 40 45 55 60

15 20 25 30 35 40 50 55 60

10 15 20 25 30 35 40 45 50

10 15 15 20 25 30 35 40 45

10 10 15 20 25 25 30 35 40

70 80 90 100

70 75

STEP 11: SYSTEM CHECK OUT

A. For system test be sure that 24 VAC is applied in series with the 6506 damper (normally closed) and the A/A terminals on the Vent Control.

Check the wiring as described in Step 6.

B. Turn knob on Control dial to TEST position. If the installation is correct the blower will turn on (independent of heat or cooling operation)

and the damper will open. The vent system will operate for 1 minute unless the knob is turned off of TEST. If system does not operate in the

TEST Mode check the Troubleshooting Guide.

C. Return knob to the calculated setting. Do not leave in TEST, the Vent Control won’t operate normally.

Ventilation Controller

A. The run time in minutes is set with the knob. The Time 0 setting keeps the circuit live but the

vent won’t operate. OFF deactivates it completely. Any setting made is the total running

time per 1, 2, 3 or 4 hour cycle.

B. Record your entries from Steps 7C and 8C in the Table on page 6. From this you can determine

the correct knob setting. For example, if 80 CFM is required but the Vent delivers 120 CFM set

the knob to 40 minutes. The knob settings as listed are for a 1 hour cycle time.

C. All values can be set except those in the black area. If the Vent Control is clocked out (black

area) and if the cycle is set to 2, 3 or 4 hours, reset the pin jumper to get a settable time. For

example, if 80 minutes is required at 2 hours, at 1 hour this would be a settable 40 minutes. If

you’re still clocked out or are already set to a 1 hour cycle consult with the homeowner about

installing a second device.

FIGURE 8 – Set Vent Time

INSTALLATION TEMPLATE

4-11/16” x 2-15/16” cutout

90-702

TROUBLESHOOTING

PROBLEM TROUBLESHOOTING PROCEDURE

HVAC Blower doesn’t turn on

in Test Mode.

Damper does not open

in Test.

The Vent Control doesn’t

turn off after the knob is

turned off Test.

The damper does not open

with the blower operating.

Blower turns on unexpectedly.

P.O. BOX 1467 • Madison, WI 53701-1467 • Phone: 800/334-6011 • Fax: 608/257-4357 • www.aprilairecontractor.com

1. Make sure you turned the power back on to the HVAC equipment.

2. Check the wiring diagram for the R, C, W and GSTAT and GHVAC at both the HVAC equipment and the Vent Control.

3. Make sure the Outdoor Sensor Terminals on the Control are connected with either the Temperature Sensor, the Time

Only Insert or a jumper wire. If nothing is connected here the Control will not function.

4. Check voltage across the Vent Control R&C terminals. Voltage should be in the 22 VAC to 30 VAC range.

5. Remember, once the Test minute is up the system won’t operate.

1. Follow above procedure.

2. Check wiring diagram to make sure the damper is wired in series with the circuit board and transformer.

1. This might be okay, the thermostat might have activated. Also the blower might be set up for continuous operation.

The Vent Control should deactivate once the time setting is reached.

2. If the pins are set to 1 hour and the knob is turned to 60 minutes the Vent Control will not turn off. But for a 2 hour

pin setting, if the knob is at 60 minutes, at the end of that 60 minutes the Vent will turn off.

1. The damper will not operate once the time interval has been met. If the knob is turned to 5 minutes and 5 minutes

has elapsed, the damper will close and it will stay closed until the pin setting interval is met.

2. If the Indoor RH is above 55% and the outdoor temperature is above 50° the damper will not open because of the

potential for excess humidity.

3. If the outdoor temperature is below 0° or above 100° the vent stays off.

4. Verify that the outdoor temperature sensor is located within 3 feet of the vent inlet, or if located outside that it’s not

in direct sunlight at any time.

5. Turbulence in the return duct, plenum or mixing box can give false readings. Make sure the Vent Control is at least

6 inches upstream of the fresh air intake port in the return to minimize this effect.

1. The Vent Control will activate the blower whether or not heat or A/C is on call. This ensures ventilation even if the

thermostat is lowered.

2. To verify proper operation see if the blower turns off by turning down the knob. Return to its original setting.

RESEARCH PRODUCTS CORPORATION

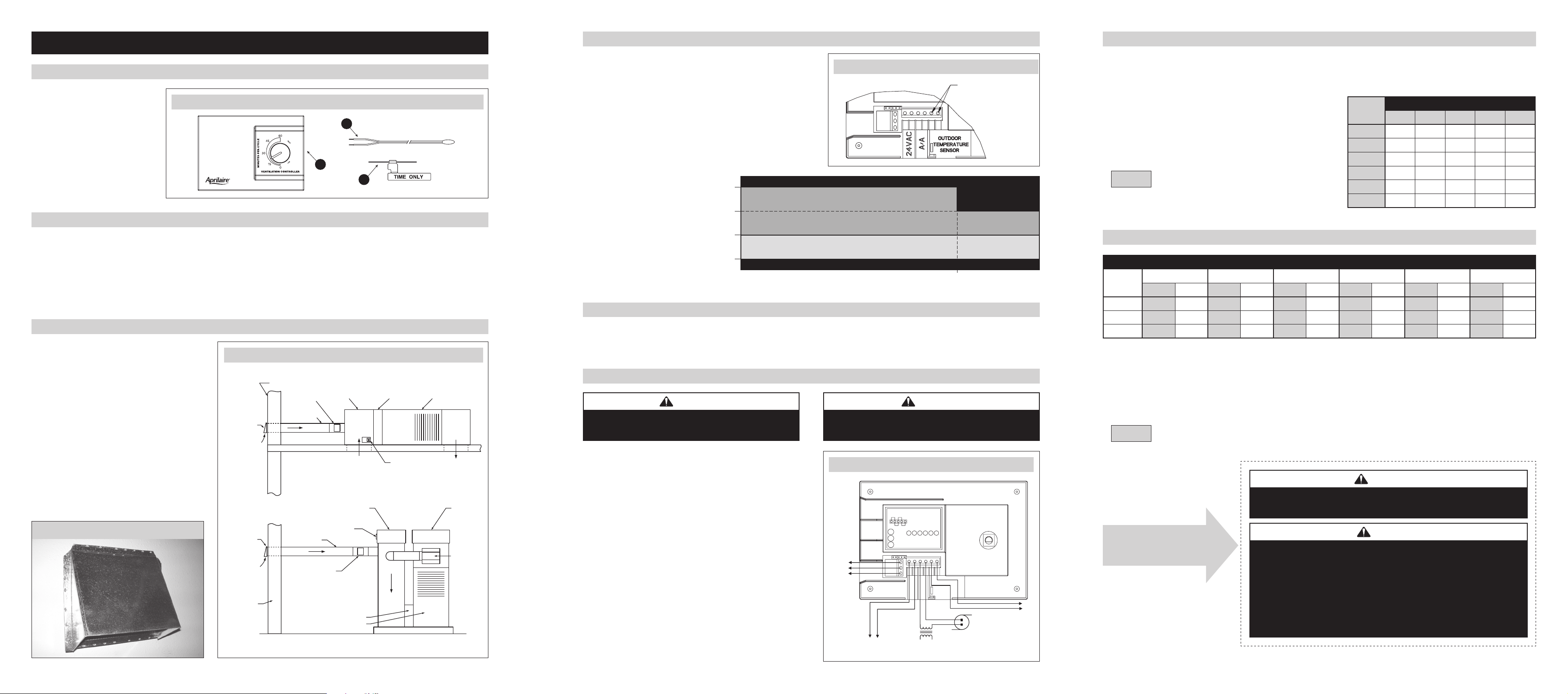

Model 8120 and 8126

Safety & Installation Instructions

FAMILIARIZE YOURSELF WITH THE INSTALLATION INSTRUCTIONS BEFORE STARTING

DANGER

ATTENTION INSTALLER:

To prevent serious injury from electrical shock this product must be installed by a qualified HVAC contractor.

DANGER

120 volts can cause serious injury from

electric shock. Disconnect electrical power

to the HVAC system before proceeding.

WARNING

Sharp metal edges can cause serious injury

from cuts. Use gloves when cutting plenum

openings and handling ductwork.

10007162 2.09

B2204388B

65

Do not mount the Vent Control on the supply plenum or duct. The unit

will malfunction at heated temperatures and lose its calibration.

When installing the Vent Control on downflow furnaces, ensure that

the blower continues to run after the heat call is satisfied to prevent

high temperatures from damaging the Control circuit board.

Do not mount the Vent downstream from any fresh air intake port,

humidifier or bypass outlet. False humidity conditions will cause the

Vent Control to operate incorrectly.

CAUTION

TYPICAL BASEMENT INSTALLATION

Outside

Wall

Fresh Air

Fresh Air

Intake Duct

Motorized

Damper

Ventilation

Controller

Air

Flow

Furnace/Air Handler

Filter

TYPICAL ATTIC INSTALLATION

Ventilation Controller

Air Flow

(Return)

Filter

Furnace/Air Handler

Return Mixing Box

Fresh Air

Intake Hood

w/screen

Fresh Air

Intake Duct

Motorized

Damper

Fresh Air

Gable End Wall,

Band Joist, or Porch Soffit

Fresh Air

Intake Hood

w/screen

Supply

Plenum

Return Duct

Supply

Duct

Humidifier

INSTALLATION

A

B

C

INSERT ONLY ONE OF THE

FOLLOWING: “OUTDOOR

TEMPERAT URE SENSOR”

OR “WIRE JUMPER” OR

“TIME ONLY RESISTOR”

SECTION A

SECTION B

SECTION C

100°

20°

0°

55%

INDOOR RELATIVE HUMIDITY

OUTDOOR TEMPERATURE (F)

50°

SECTION A

15% 25% 35% 45% 65%

10005991

WIRING AND

JUMPER

CONFIGURATION

CYCLE TIME

1 HR 3 HR

2 HR 4 HR

TO STAT

TO HVAC

TO HVAC

GS

W

G

H

CRDDTT

TO HVAC

DAMPER

TEMP

SENSOR

OUTDOOR

TEMPERATURE

SENSOR

24VAC

A

/

A

CRDDTT

Ts

G

HVAC

W

Ts

C R

TO HVAC

G

STAT

APRILAIRE

®

MODEL 4010

24 V TRANSFORMER

APRILAIRE

®

MODEL 6506

NC DAMPER

STEP 1: REMOVE ITEMS FROM BOX

See Figure 1.

A. MODEL 8120 VENT CONTROL

B. OUTDOOR TEMPERATURE SENSOR

C. TIME ONLY RESISTOR INSERT

FIGURE 1 – Carton Contents

90-697

STEP 4: CHOOSE MODE OF OPERATION (W/OUTDOOR TEMP SENSOR, W/O TEMP SENSOR, OR TIME ONLY)

A. By connecting the outdoor temperature sensor the Vent Control will

run according to the timer settings, the indoor RH and the outdoor

FIGURE 4 – Insert Temp Sensor

temperature. See Chart below and Figure 4.

B. The outdoor temperature can be bypassed by jumpering the outdoor

temp terminals with a wire. The Control will operate on the timer

settings and the indoor RH only.

C. Connecting the Time Only insert to the outdoor temp terminals will let

the Vent run on Time Only. In this mode the Control’s operation is not

limited by the temperature and humidity limits as shown in Chart below.

SECTION A: Ventilation prevented

due to temperature extremes and/or

high indoor humidity.

90-700

STEP 7: CALCULATE THE VENTILATION REQUIREMENT

A. The MINIMUM ventilation requirement is calculated using ASHRAE 62.2-2007.

ASHRAE Airflow In CFM = [House Area in Sq Ft x 0.01] + [No. Bedrooms +1 x 7.5]

Use the Number of Bedrooms (Plus 1) or the Number of Occupants, Whichever Is Larger

Additional ventilation may be required for pets, hobbies,

fireplaces and attached garage, etc. Use your judgement.

HOUSE

B. This Table shows calculated airflow values at the nearest 5 CFM.

If more outdoor air is required than the Vent Control can deliver,

a 2nd device is advised. Consult with the homeowner.

C. Indicate the required CFM below.

SQ FT

1000

1500

2000

2500

3000

3500

Minimum CFM Per Number Bedrooms

2 3 4 5 6

35 40 50 - - - - - -

40 45 55 60 70

45 50 60 65 75

50 55 65 70 80

55 60 70 75 85

- - - - - - 75 80 90

STEP 2: DETERMINE VENT CONTROL LOCATION AND INSTALL

A. The Control must be installed in the return duct, at least 6 inches upstream of the fresh air intake opening, the humidifier if present, and/or

the humidifier bypass duct opening. See Figure 2.

B. For systems using flexible duct for return chases a mixing box might be necessary to locate the control. The mixing box can make it difficult

to get the Control away from the fresh air duct port. Get it as close to the main return as possible, or located remotely from the fresh air

opening.

C. Then use the template (page 4) to cut the opening and mount the Control.

STEP 3: INSTALL INLET VENT, DUCTING (FLEX OR RIGID) AND DAMPER (INCLUDED WITH MODEL 8126)

A. All duct work must be insulated. The damper

assembly is heavy and requires support. Install the

FIGURE 2 – Typical Installations

damper with the crimped end downstream. Insulate

the damper assembly but leave the motor cover

exposed to open air for adjustment access (see

Damper Instruction sheet and Figure 2).

B. If working with sharp metal edges wear gloves. For

metal or flexible duct, seal joints with UL181 foil tape.

C. Keep the inlet away from dryer or furnace vents,

driveways, trash containers and swimming pools.

Also the inlet vent should be above expected snow

accumulation. Local codes might apply.

D. The inlet vent should be a metal open hood model,

plastic louvers will greatly cut airflow. Make sure the

inlet hood has a screen. See Figure 3.

FIGURE 3 – Recommended Inlet Vent

2 3 4

90-948

SECTION B: Ventilation per the

timer settings (Time Only).

SECTION C: Ventilation only with

heat, per the timer settings.

STEP 5: INSTALLING THE OUTDOOR TEMPERATURE SENSOR (IF OPTION A USED IN STEP 4)

The outdoor temperature sensor can be located in the fresh air duct or the vent inlet. The sensor cannot be exposed to the heat of direct

sunlight. The lead lengths won’t affect operation but don’t route alongside 120 volt wires. Insert the stripped lead ends into the Outdoor

Temperature Sensor terminals (see Figures 4 and 5).

STEP 6: WIRE THE VENT CONTROL TO THE HVAC SYSTEM

CAUTION

Improper wiring to the HVAC equipment can damage it or

the Vent Control!

120 Volts can cause serious injury. Disconnect electrical

power before proceeding!

DANGER

A. When installing the Vent Control in a system with a Power

Stealing thermostat, it is recommended that you set load resistors

FIGURE 5 – Wiring Connection Diagram

(300 ohm, 5 watt) across the Y & C terminals and the W & C

terminals.

B. Disconnect the thermostat lead from the HVAC terminal G and

connect to the Vent Control G

S TO STAT terminal. Connect a lead from

the Vent Control terminal GH TO HVAC to the HVAC terminal G.

The only wire connected to HVAC G will be from the Vent Control

GH TO HVAC terminal.

C. Route leads from the R, C and W terminals on the Vent Control

to the corresponding terminals on the HVAC control board

(see Figure 5). Leave any existing R, C and W leads in place.

D. Install the 24 volt transformer (provided with Model 8126 only).

The transformer should be continuously energized, do not wire to

the HVAC blower circuit. The transformer, damper and the Vent

Control DD terminals will be wired in series. Refer to Figure 5

and the 6506 damper instructions for additional information.

90-713

90-701

STEP 8: DETERMINE THE VENT CONTROL’S FRESH AIR DELIVERY RATE

AIRFLOW DELIVERY VS NEGATIVE STATIC PRESSURE AS MEASURED FOR RETURN DUCT OR PLENUM (IN WC)

DUCT

LENGTH

10 FT

20 FT

30 FT

0.05 0.10 0.15 0.20 0.25 0.30

FLEX PIPE FLEX PIPE FLEX PIPE FLEX PIPE FLEX PIPE FLEX PIPE

60 65 85 90 105 110 120 125 135 140 150 160

55 60 80 85 100 105 115 120 130 135 140 150

50 55 75 80 95 100 110 115 125 130 130 140

A. Measure the negative static pressure of the return system and consult table above for approximate inlet airflow. But these values are

not absolute. An airflow measuring device (Nailor-Hart, etc.) will give the Vent Control’s airflow exactly.

B. For the Table above the flex duct is laid loose with 2 wide 90° bends, and the damper is full open. For the rigid pipe the values are

based on two 90° elbows, and the damper is open. For both cases the air intake is through a metal vent hood with a bird screen.

Adjust airflow up or down for variations, including one elbow or bend, or the length of duct you’re using isn’t listed, etc.

C. Measure the delivered airflow or determine from above chart and record below.

WARNING

Sharp edges can cause injury from cuts. Use gloves when cutting plenum

openings or handling ductwork.

INSTALLATION TEMPLATE

4-11/16” x 2-15/16” cutout

1. Do not mount Vent Control on supply side. The unit will malfunction at

heated temperatures.

2. When installing the Vent Control on downflow furnaces make sure

blower continues to run after burner shuts off to prevent high heat

damage to the Control

3. Do not mount the Vent Control downstream of the fresh air intake, or a

humidifier or bypass outlet. False humidity levels can cause the Control

to malfunction.

CAUTION

Loading...

Loading...