Page 1

SAFETY AND INSTALLATION MANUAL

ENERGY RECOVERY VENTILATORS

®

MODEL 8100

• Provides year-round fresh air

• Recovers 77% of the apparent heating or cooling energy from the exhausted air

See Warnings – Page 3

Page 2

Table of Contents

Safety Instructions ……………………………………………………3

®

Aprilaire

Specifications …………………………………………………………5

Components …………………………………………………………6

Operation ……………………………………………………………7

Procedure and Equipment Required …………………………………7

New Home Installation

A. Location ………………………………………………………8

B. General Mounting Information ………………………………8

C. Mounting the Unit …………………………………………8-12

Energy Recovery Ventilator System Diagram ………………4

D. Ductwork Specifications ……………………………………12

E. Grille and Hood Specifications ………………………………12

F. Ductwork Connection – Forced Air System …………………12

G. Electrical Connection ………………………………………13

Installation into Existing Home (Retrofitting) …………………………14

Installation into Homes Without Forced Air System …………………14

System Start Up ……………………………………………………14

Balancing the System ………………………………………………15

Balancing Diagram …………………………………………………16

© Research Products Corporation 2001

Page 3

SAFETY INSTRUCTIONS

Read the Safety and Installation Instructions carefully. They will help insure a correct and

®

SAFE installation of the Aprilaire

Energy Recovery Ventilator.

WARNINGS:

1. 120 Volts may cause serious injury from electrical shock. Sudden operation may cause serious injury

from moving parts. Leave power disconnected until installation is completed.

2. The fresh air intake

Examples of such sources, but not limited to these sources, include the exhausts from condensing

furnaces, condensing water heaters and vented space heaters. These exhausts contain toxic

substances that can be harmful to humans.

The fresh air

3. Connection with existing air exhaust sources may cause toxic conditions in the living area. The

Aprilaire ducting must be separate from sources such as dryer vents, water heater, furnace flues,

gas appliance flues or bathroom and kitchen exhausts.

4. Unit weight and dropping may cause personal injury or equipment damage. Handle with care and

follow installation instructions.

5. WARNING: To avoid serious injury, do not mount unit with access door facing down.

Unit must be mounted in an upright position.

6. Sharp edges may cause serious injury from cuts. Wear protective gloves and handle with care.

7. Excess negative or positive pressure may cause health problems or structural damage. Air flow

must

be balanced after installation.

must be

intake

should be installed a minimum of 10 feet from any exhaust vent.

mounted in a location removed from sources of dangerous toxic gases.

8. Insufficient combustion air may cause toxic conditions. The Energy Recovery Ventilator

exhaust air from an enclosed room with combustion appliances.

9. Installation

10. The fresh air duct from outside the Energy Recovery Ventilator and the stale air duct from the

Energy Recovery Ventilator to the outside

to the unit

the ductwork.

NOTE: This manual does not express or imply any warranty conditions. See Owner’s Manual for further information.

must

conform to all applicable codes.

must

be fully insulated. The fresh air duct connection

must

also be completely insulated. This is to prevent condensation from forming on

–3–

must not

Page 4

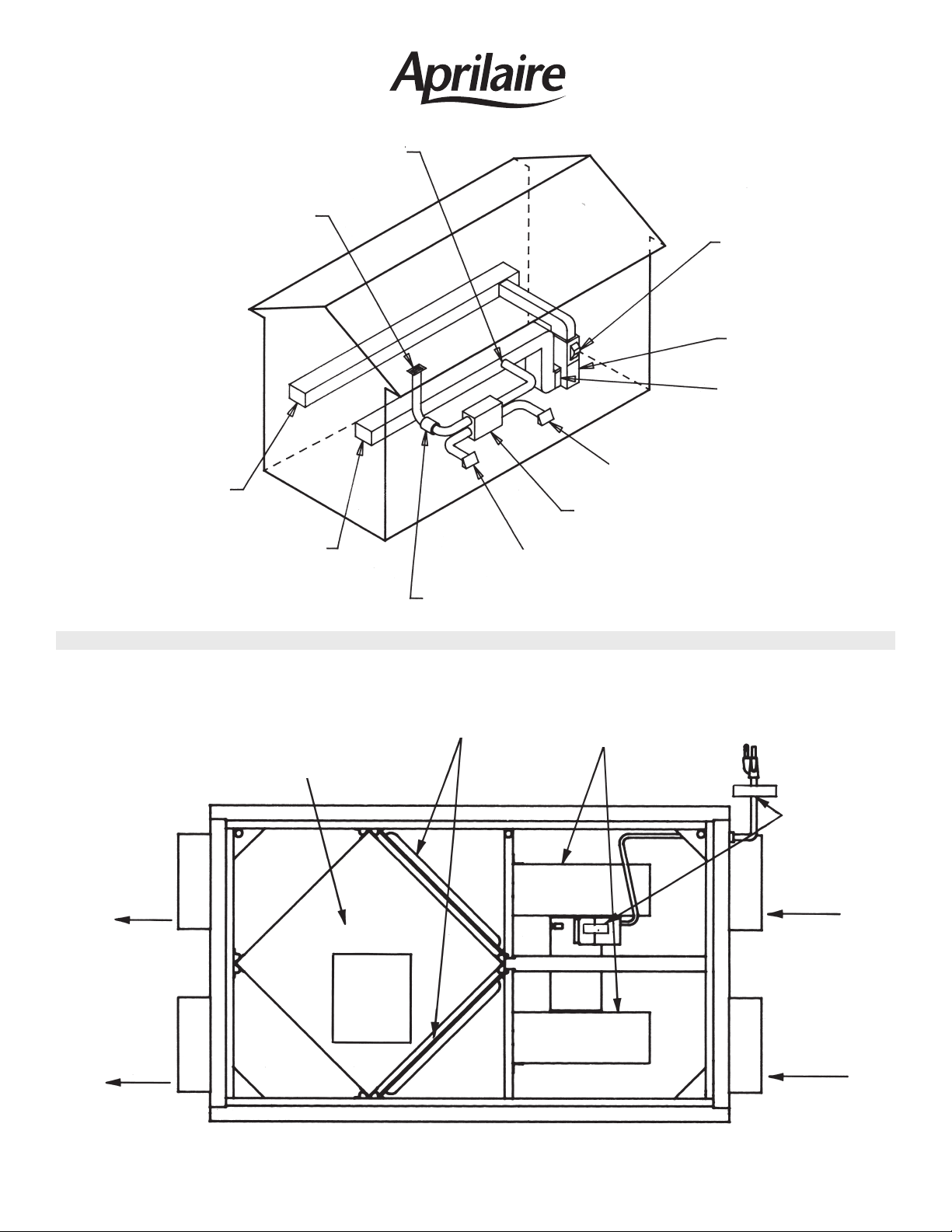

FRESH AIR TO HOUSE

STALE AIR FROM HOUSE

(Centrally Located such as

Hallway or Foyer)

SUPPLY AIR

®

THE BEST IN INDOOR AIR COMFORT

APRILAIRE® ENERGY

RECOVERY VENTILATOR

APRILAIRE

AUTOMATIC HUMIDIFIER

FURNACE

APRILAIRE® HIGH

EFFICIENCY AIR CLEANER

STALE AIR TO OUTSIDE

®

FIGURE 1

FRESH

AIR TO

HOUSE

(DAMPERED

DUCT)

STALE AIR

TO OUTSIDE

(INSULATED

DUCT)

RETURN AIR

ENERGYMAX

®

TRANSFER CORE

FRESH AIR FROM OUTSIDE

AIR MOVEMENT SOUND ABSORBER

E Z KLEEN

WASHABLE ALUMINUM

AIR FILTERS

INSTR.

LABEL

®

POWER

BLOWER

ASSEMBLY

CORD 120

VAC

WARNING

LABELS

STALE AIR

FROM

HOUSE

(DAMPERED

DUCT)

FRESH AIR

FROM

OUTSIDE

FIGURE 1A

(INSULATED

DUCT)

–4–

Page 5

SPECIFICATIONS

Model: The Aprilaire®Model 8100 Energy Recovery Ventilator is

an enthalpy (sensible and moisture transfer) type unit.

®

The unique paper/aluminum EnergyMax

exchanges energy between the fresh air supply and

exhaust air streams.

3

Unit Dimensions: Overall Unit – 37

EnergyMax

⁄8" W x 123⁄4" D x 209⁄16" H

®

Transfer Core – 121⁄8" x 121⁄8" x 103⁄4".

Air Flow Capacity: 120 cfm @ 0.30 in. w.g. external ductwork resistance, i.e.

240 equivalent feet for each of the “fresh” and “stale”

air streams.

Performance: Apparent Sensible Effectiveness (ASE) – 77% at rated

ventilation capacity with 72ºF indoor temperature and

32ºF outdoor temperature.

Transfer Core

Home Size: Up to 3600 sq. ft. home at rated air flow.

Power Requirements: 120 VAC, 1.4 ampere maximum. Unit equipped with a

3 ft. grounded power cord.

Interior Insulation: Entire interior surface is sealed with 1" single face insulation.

Filters: (2) – 10

13

⁄16" x 115⁄16" x 3⁄32" EZ Kleen®air filters coated with

Super Filter Coat adhesive for maximum performance.

Unit Weight and

Packaging: Total Shipping Weight with Mounting Hardware – 76 lbs.

–5–

Page 6

Energy Recovery Ventilator Components

MACHINE

SCREWS

OWNERS

MANUAL

HANGING HOOK

BRACKET

UNIT

HANGING PINS &

THREADED NUTS

ACCESS DOOR

MOUNTING BRACKET

WARRANTY

CARD

FIGURE 2

LAG BOLTS &

WASHERS

HANGING HINGE

BRACKET

–6– –11–

Page 7

GENERAL INFORMATION

OPERATION

The Aprilaire®Energy Recovery Ventilator is designed to

work in conjunction with the home’s forced air system, or

totally independent, incorporating its own duct system to

provide the homeowner with 1) a supply of fresh air

distributed into the living space and 2) to exhaust stale air

from the home to the outdoors through the EnergyMax

Transfer Core. It is designed to handle homes with up to

3,600 ft

2

living space.

During the winter season, the cross flow design of the

®

EnergyMax

Transfer Core allows the incoming cold fresh

outside air to be preheated by the warm stale air being

exhausted, reducing the energy required to heat the

incoming fresh air.

During the air conditioning season the Aprilaire Energy

Recovery Ventilator operates with a reverse effect. Cool

stale air, exhausted from the house, cools the incoming

warm fresh air. It also removes moisture from the incoming

fresh air to the home.

PROCEDURE AND EQUIPMENT REQUIRED

Read the installation instructions carefully to become

familiar with the requirements and refer to the proper

section of the instructions if any installation question

arises.

The Aprilaire Energy Recovery Ventilator is preassembled

and ready to install. See Figure 2 to become familiar with

all components and inspect unit and box containing all

mounting hardware to be sure all components are

included.

The following equipment will be needed and is detailed

throughout the manual.

Mounting – A mounting system is provided with the unit,

which requires 1/4" x 3" lag bolts (furnished) for

wood mounting and lag bolt anchors (not furnished)

for concrete mounting.

Ducting – All ducting must be 6" round or equivalent and

two balancing dampers must be installed. You must

also plan on temporarily

installing two air flow

measuring devices according to balancing instructions

found on Page 15. These measuring devices are

later removed after the system has been installed

®

and balanced. Use galvanized uninsulated ducting

(not furnished) between the Aprilaire Energy

Recovery Ventilator and home interior. Use insulated

ducting between the Aprilaire

®

and the outdoors or

duct runs through any unheated space. (Dampers

and air flow measuring devices not furnished.)

Duct Hanging – Duct tape, sheet metal screws, nylon

straps and duct hangers will also be needed to properly

hang, connect and seal ductwork (not furnished).

Balancing – Two balancing dampers designed to fit the

ductwork must be installed. See instructions page 15

(not furnished).

Collar – When connecting directly to furnace return duct-

work, a collar will be needed.

Return Grille – At least one return grille located in the

living space with a minimum of 75 square inches free

area will be required.

Hoods – Two outdoor hoods with cleanable screens and

caulk to seal them.

Sound Absorber – One 6' long sound absorber duct

section is required in the stale air return duct from

the house between the house and unit.

Supply Grilles – If the installation is in a home

forced air heating, it is recommended that

than 3 fresh air

supply ducts be used to assure

adequate air flow. The total free area should

less than 75 square inches. Use of less than the

minimum free area may result in greater than normal

air movement noise. Three supply ducts require a

minimum of 25 square inches of free area each; two

supply ducts 40 square inches and one supply duct

75 square inches of free area.

without

no more

not

be

Electrical – The Aprilaire Energy Recovery Ventilator is

pre-wired from the factory. The preferred installation

of the unit should be within 30" of an electrical outlet.

–7––10–

Page 8

INSTALLATION – NEW HOME

A. LOCATION

• It is recommended that the Model 8100 Aprilaire Energy

Recovery Ventilator be mounted in a conditioned

space. If the unit is mounted in an area where the temperature may drop below 32°F (0°C) or exceed 100°F

(38°C), ALL DUCTWORK in the unconditioned space

MUST BE INSULATED.

• The recommended mounting location is on the basement foundation wall, or a stud wall with easy access

to the furnace. This will minimize sound level and

shorten the length of duct runs and elbows required.

Unit may be mounted to basement ceiling joists if

desired.

NOTE: If the home has engineered ceiling "I" beam wood

trusses in the basement, the unit must be installed on the

wall. If that's not possible, the installation procedure must

be approved by a qualified builder before

• Mounting on a utility or laundry room wall, any heated

space or where the temperature is kept above 32°F

(0°C, i.e. in a closet) is also acceptable.

• If possible, do not locate the unit directly under bedrooms, This unit is designed for quiet operation, but with

any blower system there is some sound generated.

installation.

B. GENERAL MOUNTING

WARNING: To avoid serious injury, do not mount unit

with access door facing down. Unit must be mounted

in an upright position.

• The unit must be mounted with the mounting kit provided

on the wall or suspended from the ceiling joists.

• For scheduled maintenance or service, the unit must be

mounted in a position which allows easy access to all

duct connections, electrical components and all interior

components.

• A minimum of 36" opening clearance is recommended

to ensure that the access door can be safely removed

for easy access to all interior components for maintenance and service.

C. MOUNTING THE UNIT

To reduce the unit weight, remove the access door, filters

and EnergyMax Transfer Core. Lift only at the corners of

the core to avoid damage.

Determine whether unit is to be wall or ceiling mounted.

Brackets will be attached according to Figure 2A below.

WALL MOUNT

(NOT TO BE USED ON “I” BEAM WOOD TRUSSES)

CEILING MOUNT

LEFT END

FIGURE 2A

CEILING MOUNT

WALL MOUNT

RIGHT END

–8–

Page 9

FIGURE 3

SEQUENCE FOR MOUNTING THE APRILAIRE®ENERGY

RECOVERY VENTILATOR TO CONCRETE WALL

See Figures 3 through 6.

Fasten mounting bracket (furnished) to concrete wall

using lag bolts (furnished) and concrete anchors (not

CONCRETE WALL

furnished). Insert hanging pin in left hole of mounting

bracket and hand tighten with threaded nut.

NOTE: If mounting on a stud wall, mounting bracket is

pre-drilled for fastening to standard 16” O.C. or 24” O.C.

stud spacing using lag bolts (furnished).

FIGURE 4

For the wall installation (which is

preferred) pick the unit up from the back

side with your left hand in the upper duct

opening and right hand supporting the

lower right corner. Carefully lift unit up

and hook the hanging “hook” bracket

behind the hanging pin previously

installed on the left side of the mounting

bracket. Keep pressure against unit to

prevent it from swinging away from wall.

Fasten hanging “hook” bracket (furnished) securely to left

side of unit with 10-32 machine screws

3

⁄8" long (furnished)

using pre-tapped holes along side edge of unit. Fasten

hanging "hinge" bracket to right edge. Be sure both brackets

face outward from unit. Insert hanging pin (

5

⁄16" x 61⁄2" long

bolt furnished) in right hole of mounting bracket.

COLLAR

BROKEN OUT

TO SHOW HOOK

FIGURE 5

–9–

Page 10

FIGURE 6

While maintaining pressure, push unit up against bracket,

remove right side pin, align hanging "hinge" hook with

bracket and reinsert hanging pin. Tighten both threaded

nuts securely. Do not plug in unit until installation is

completed. Carefully reinstall EnergyMax Transfer Core,

air filters and access door.

SEQUENCE FOR MOUNTING THE APRILAIRE

®

ENERGY RECOVERY VENTILATOR TO CEILING

CAUTION: Do not mount the Energy Recovery Ventilator to ceiling "I" beam wood trusses.

To reduce the unit weight, remove the access door, filters and EnergyMax Transfer Core.

Lift only at the corners of the core to avoid damage.

For ceiling mounting, refer to the following Figures #7 through #10.

Mounting bracket (furnished) is pre-drilled for fastening to

standard 16" O.C. or 24" O.C. ceiling joists using lag bolts

(furnished).

FIGURE 7

Page 11

INSERT HANGING PIN

INTO MOUNTING CHANNEL

INSTALL HOOK ONTO

APRILAIRE®Energy

Recovery Ventilator

FIGURE 8

INSTALL HINGE ONTO

APRILAIRE®Energy

Recovery Ventilator

Fasten hanging “hook” bracket (furnished) securely to left end of unit with 10-32 machine screws 3⁄8" long

(furnished) using pre-tapped holes along top left edge of unit. Fasten hanging “hinge” bracket to right

edge. Be sure both brackets face outward from unit. Insert hanging pin in left hole of mounting bracket

and hand tightened with threaded nut.

For the ceiling installation lift

the unit with the blower end

against you. Left hand should

be under the top edge and

right hand should be under

the lower right corner as

shown in the drawing. Tilt the

far end up toward the mounting bracket and “hook” the

hanging “hook” bracket over

the hanging pin.

FIGURE 9

Page 12

FIGURE 10

SECOND HANGING PIN

INSTALLED

ENERGY RECOVERY VENTILATOR

CORE, FILTERS,

AND DOOR REPLACED

With second pin accessible, lift right side of unit up so

hanging “hinge” bracket is aligned with mounting bracket.

Insert second pin through hole and tighten both bolts with

®

threaded nuts. Carefully reinstall EnergyMax Transfer

Core, air filters and access door. Do not plug in unit until

entire installation is completed.

D. DUCTWORK SPECIFICATIONS

• You must plan on temporarily installing two air flow

measuring devices, according to Balancing Section

instructions. These measuring devices are later

removed after the system has been balanced. Please

refer to Figure 11, page 16.

• A sound absorber at least 6' long consisting of 1" thick

rigid fiberglass duct or insulated flexible duct (ATCO

series 70 or equivalent) is required for maximum

absorbing of air movement sounds between the unit

and the living space return grille.

• All flexible ducts used must

for Class 1 air ducts and connectors.

• All ducting must be installed according to locally

applicable HVAC codes and standards.

• Round 6" galvanized duct or equivalent should be used

for all duct runs that do not use insulated ducting.

• All ducting located in an unheated space must be

completely sealed and insulated.

• All ductwork runs should be kept as short, straight and

equal in length as possible to minimize system resistance for optimum performance and quiet operation.

meet U.L. safety standards

• Exterior intake and exhaust hoods must be weather

resistant. These hoods must also incorporate an easily

cleaned screen to help prevent unwanted debris,

animals and insects from entering the ductwork. This

screen should have no greater than

1

⁄4 inch openings.

F. DUCTWORK CONNECTIONS – FORCED AIR SYSTEM

• All duct collars are clearly labeled and must be

connected properly.

• Rigid ductwork should be connected to the collars with

sheet metal screws.

• Flexible ductwork must

be connected with clamps or

bands.

• All ductwork should be sealed with duct tape to prevent

leakage, and hung with straps where needed.

RETURN: From Living Space to Aprilaire®Energy

Recovery Ventilator

• Stale air from the house should be exhausted from one

exhaust grille centrally located; such as in a hallway.

For multi-floor homes, the exhaust grille should be

located on the same floor as the kitchen.

(Stale Air From House)

E. GRILLE AND HOOD SPECIFICATIONS

• Living space return grille should not be less than

75 square inches free area. Grille surfaces less than

this may produce excess air noise.

• Energy Recovery Ventilator ductwork must not

connected to a kitchen exhaust fan duct in order to

keep the core free of grease.

–12–

be

Page 13

• It is recommended that Aprilaire

®

Energy Recovery

Ventilator ductwork remains separate from bathroom

exhaust fan ducts.

• Galvanized ductwork (6" round) is recommended

between the living space return grille and return inlet.

If rectangular duct is used, be sure it has an equivalent

air flow rating. Undersized ducting can cause air flows

to be out of balance or air flow reductions in the system,

resulting in poor performance.

• With any blower system, some sound is transferred

along the ductwork. A sound absorber at least 6' long

consisting of 1" thick rigid fiberglass duct or insulated

flexible duct (ATCO series 70 or equivalent) is recommended for maximum absorbing of air movement sounds

between the unit and the living space return grille. A

balancing damper must be installed in this duct near the

Aprilaire

®

Energy Recovery Ventilator, see Figure 11,

page 16. Install an air flow measuring device at least 5'

from damper in straight section and then complete the

system installation before proceeding to the balancing

instructions found on page 15.

SUPPLY: Fresh Air From Unit to House

(Fresh Air To House)

• The supply duct should be connected directly to the

forced air system return duct a minimum of 10' from the

furnace blower. Avoid making this connection in the

area of any return grille.

Note: In climates where the outdoor temperature

drops below 10°F (-12°C), the fresh air inlet duct

insulation must extend all the way to the Aprilaire

Energy Recovery Ventilator housing. Extra

insulation may be needed at the fresh air inlet

duct connection to the unit.

• The fresh air intake hood and exhaust air outlet hood

must be located at least 10' apart to avoid cross contamination. Also, the fresh air intake should be a minimum of

10 feet from an appliance vent that exhausts toxic

gases. Using adjacent walls around an outside corner

will accomplish this easily. Both of these hoods should

be at least 18" above the ground or above the expected

snow line, whichever dimension is greater.

• The duct runs should be kept as straight, short and

equal as possible to minimize resistance and optimize

blower performance. Also, try to use as few bends and

restrictions as possible.

• DO NOT connect the exhaust outlet into an attic, storage

or garage space. This can cause excess moisture to

collect in these areas, causing possible damage to the

home from outdoors.

• The fresh air intake must be mounted in a location

removed from sources of pollution and extreme temperatures such as furnace exhaust, car exhaust, dryer

vents, central air condensing units, pet enclosures, etc.

NOTE: In some areas, local codes prohibit a direct

connection to the forced air system. In this case an

“INDIRECT” or “SOFT” CONNECTION must

be made.

• Use of a collar when connecting to the return duct is

recommended.

• 6" round galvanized ductwork is recommended.

• Be sure to install two balancing dampers, see Figure

11, page 16.

EXHAUST AND FRESH AIR OUTDOOR CONNECTIONS

(Stale Air To Outdoors and Fresh Air From Outdoors)

• Insulated duct (often flexible ducting) of at least R-4

insulating value with a continuous vapor barrier must

be used for both duct runs connecting the Energy

Recovery Ventilator to the outdoors. The vapor barrier

must be sealed at both ends and extend from the

Aprilaire Energy Recovery Ventilator Housing to the

header (outer wall).

• DO NOT connect the Aprilaire Energy Recovery

Ventilator exhaust to any gas appliance flue.

• Both intake and exhaust hoods must have a screen to

prevent small animals, insects, and large airborne

debris from entering the ductwork. This screen must be

accessible for easy cleaning. Both hoods must be

caulked to prevent water leakage.

WARNING: 120 Volts may cause serious injury from

electrical shock. Leave unit disconnected until

installation is complete.

G. ELECTRICAL CONNECTION

• The power cord can be plugged into any 120 VAC

grounded outlet preferably within 30" of unit.

–13–

Page 14

INSTALLATION INTO EXISTING HOME (RETROFITTING)

• All the same mounting, locating, ducting and electrical

hook-up guidelines apply for retrofitting as they do in

new home installations.

INSTALLATION IN HOMES WITHOUT FORCED AIR

(HYDRONIC OR ELECTRIC BASEBOARD)

All the same mounting, locating, ducting and electrical

connection procedures apply to this situation as they do

in new home construction, except for the following

changes:

• The Aprilaire Energy Recovery Ventilator can be properly

installed into a home with no forced air ducts by

installing fresh air supply ducts to various parts of the

house where fresh air is needed.

• It is recommended that no more than 3 fresh air supply

ducts be used to assure an adequate air flow.

The total free Area of supply grilles should not be less

than 75 square inches. Use of less than the minimum

free area may result in greater than the normal air

movement noise.

SYSTEM START-UP

• Three (3) supply ducts require a minimum of 25 square

inches free area each. Two (2) supply ducts require a

minimum of 40 square inches free area each. One (1)

supply duct requires a minimum of 75 square inches

free area.

• Do not place a supply outlet in the same room or in the

vicinity of the stale air return from the house.

• Try to place the supply of fresh air to the house outlet,

or outlets, in a hall or foyer to avoid drafts and possible

blower noise in occupied areas.

• Try to keep all supply duct runs short, straight and

equal in length.

1. Make sure the EnergyMax Transfer Core and filters

are installed correctly.

2. Double check all ductwork connections to be sure they

are installed and sealed properly.

3. Check to be sure all tools are removed from interior and

exterior of housing.

4. Make sure the blower motor and duct connections are

not obstructed.

5. Fasten door securely to housing.

6. Place all dampers in “full open” position.

7. Balance the system air flows per instructions on

page 15.

8. Give owner’s manual and warranty card to homeowner

after explaining operation of unit.

–14–

Page 15

BALANCING THE SYSTEM

In order for the Aprilaire®Energy Recovery Ventilator to

perform most effectively, the volume of fresh air supplied

to the house must match the volume of stale air

exhausted. Because the duct work in the two airstreams

will most likely be different, the system must be balanced.

Balancing is accomplished by installing dampers in both

airstreams, measuring the airflow, then dampering down

the airflow in the stream with the highest flow until the

airflow in both streams is the same.

The following balancing procedure is recommended by

Research Products Corporation. Other measuring instrumentation may be used if it is accurate enough to balance

the airflow in the supply and exhaust streams to within

10% of each other.

EQUIPMENT AND MATERIALS NEEDED

• Two (2) Dwyer Magnahelic®Differential Pressure Gauges;

Series 2000, 0-0.25 in. w.g. (or equal).

Do Not

reads above 0.25 w.g. because the reading will not be

accurate for the airflows required by the Aprilaire Energy

Recovery Ventilator.

• Two (2) Research Products’ airflow measuring devices.

• Flexible tubing,

• A 7/8" diameter hole is required to insert the airflow

use a standard differential pressure gauge that

Part No. 5158.

3

⁄16" inside diameter.

measuring devices. Part No. 5158.

3. Set up the pressure gauges so that they are VERTICAL

and LEVEL and adjust to zero. Failure to do so will

result in inaccurate gauge readings.

4. Connect the tubing from the airflow measuring

devices to the pressure gauges as shown in Figure

11. Be sure to connect high pressure tap on the airflow measuring device to the high pressure tap on

the pressure gauge. Likewise, connect low to low

pressure taps.

5. Make sure that the two dampers are in the full open

position.

6. If the unit is connected to a forced air system, be sure

that the furnace blower is OFF.

7. Plug in the unit.

8. Read the pressure gauges. (Gauges should read

approximately 0.065 in. w.c. when air flow is at 120

cfm in the system.) If the actual gauge readings are

the same, the unit is in balance and does not

require further adjustment. Skip Step 9 and proceed

to Step 10.

9. If the gauge readings are different, slowly close the

damper on the duct with the higher gauge reading

until the two readings are identical. The unit is now

in balance.

NOTE: The other damper should remain full open.

10. Secure the dampers to prevent the set positions

from changing.

PROCEDURE FOR BALANCING AIR FLOW DELIVERY

1. Be sure that the two dampers are installed correctly

as shown in Figure 11.

2. Install the two airflow measuring devices into the

duct as shown in Figure 11 and seal with tape. Be

sure the airflow arrows are pointed in direction of

airflow. To get an accurate airflow measurement, the

devices must be in the center of a five foot minimum

straight duct section.

11. Disconnect tubing and pressure gauges and remove

airflow measuring devices. Seal the duct openings

where the airflow measuring devices were located.

NOTE: Be sure the damper positions have not been affected.

–15–

Page 16

ENERGY RECOVERY VENTILATORS

®

DIAGRAM SHOWING POSITION OF AIR FLOW

MEASURING DEVICES AND BALANCING DAMPERS

AIR FLOW

MEASURING DEVICE

(RESEARCH PRODUCTS

#5158)

FRESH AIR

TO HOUSE

(DAMPERED

DUCT)

STALE AIR TO

OUTSIDE

(INSULATED DUCT)

AIR FLOW

MEASURING DEVICE

(RESEARCH PRODUCTS

5' MINIMUM

STRAIGHT

SECTION

#5158)

DAMPER

5' MINIMUM

STRAIGHT

SECTION

DAMPER

PRESSURE GAUGES

STALE AIR

FROM HOUSE

(DAMPERED

DUCT)

FRESH AIR

FROM

OUTSIDE

(INSULATED

DUCT)

A sound absorber at least 6' long consisting of 1" thick

*

rigid fiberglass duct or insulated flexible duct (ATCO

series 70 or equivalent) is recommended for maximum

absorbing of air movement sounds between the unit and

the living space return grille.

NOTE: Dampers, air flow measuring devices and pressure

gauges not included.

FIGURE 11

Airflow in a 6" duct as measured using

RP Airflow Measuring Device #5158

Gauge Gauge

Readings Airflow Readings Airflow

(in. w.g.) (cfm) (in. w.g.) (cfm)

0.005 30 0.065 119

0.010 44 0.070 124

0.015 55 0.075 128

0.020 64 0.080 132

0.025 72 0.085 137

0.030 80 0.090 141

0.035 86 0.095 145

0.040 93 0.100 149

0.045 98 0.105 152

0.050 104 0.110 156

0.055 109 0.115 160

0.060 114 0.120 163

P.O. BOX 1467 • MADISON, WI 53701-1467 • Phone 608/257-8801 • FAX 608/257-4357

Form No. 3028 2.5.08.01 Printed in U.S.A.

DP10002582

–16–

Loading...

Loading...