Aprilaire 800, 800LC Installation Manual

Series 800 Steam Humidifier

Installation & Maintenance Instructions

TABLE OF CONTENTS

Safety Cautions..........................................2

Materials List ...........................................3

Principles & Sequence of Operation.......................4

Specifications & Dimensions .............................5

Installation Instructions ..................................8

Choosing a Location .....................................8

- Dispersion Tube Location ..............................8

- Elevation ...........................................9

- Distance from Humidifier to Dispersion Tube/Fan Pack.....10

- Humidifier Location..................................11

Prepare Humidifier for Mounting ..........................12

Install Steam Dispersion Tube/Fan Pack ....................12

Mount Humidifier ......................................12

Install Steam Hose .....................................12

READ AND SAVE THESE INSTRUCTIONS

AprilairePartners.com

P.O. Box 1467

Madison, WI 53701-1467

800.334.6011 F: 608.257.4357

Printed in USA

©2018 Aprilaire – Division of Research Products Corporation

10010605 B2206277J 2.18

Supply Water..........................................12

Drain Line.............................................13

Electrical Power Wiring & Shut-off Switch ..................13

Automatic Digital Control & Accessory Wiring ...............18

Thermostat in a Zoned HVAC System ......................19

Manual Digital Humidistat & Fan Pack Wiring ...............20

Automatic Digital Modulating Control Wiring................21

Start-up Procedure .....................................23

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Shut Down Procedure...................................25

Display Panel ..........................................25

Maintenance...........................................26

Troubleshooting Guide ..................................27

Replacement Parts......................................29

SAFETY CAUTIONS

CAUTION

ATTENTION INSTALLER

Read this manual before installing. This product must be installed by qualified HVAC and electrical contractors and in

compliance with local, state, federal, and governing codes. Improper installation can cause property damage, severe personal

injury, or death as a result of electric shock, burns, or fire.

Read all cautions and instructions.

Read this manual before performing service or maintenance procedures on any part of the system. Failure to follow all cautions

and instructions could produce the hazardous situations described, resulting in property damage, personal injury, or death.

Failure to follow the instructions in this manual can cause moisture to accumulate, which can cause damage to structure and

furnishings.

HOT SURFACES AND HOT WATER

This steam humidification system has extremely hot surfaces. Water in steam canister, steam pipes, and dispersion tube can

be as hot as 212°F (100°C). Discharged steam is not visible. Contact with hot surfaces, discharged hot water, or air into which

steam has been discharged can cause severe personal injury. To avoid severe burns, follow procedures in this manual when

performing service or maintenance procedures on any part of the system.

DISCONNECT ELECTRICAL POWER

Disconnect electrical power before installing supply wiring or performing service or maintenance procedures on any part of

the humidification system. Failure to disconnect electrical power could result in fire, electrical shock, and other hazardous

conditions. These hazardous conditions could cause property damage, personal injury, or death.

Contact with energized circuits can cause property damage, severe personal injury, or death as a result of electrical shock or

fire. Do not remove access panels unless electrical power is disconnected.

Follow the shutdown procedure in this manual before performing service or maintenance procedures on any part of the system.

ELECTRICAL SHOCK HAZARD

If the humidifier starts up responding to a call for humidity during maintenance, severe injury or death from electrical shock could

occur. Follow the procedures in this manual before performing service or maintenance procedures on this humidifier.

EXCESSIVE SUPPLY WATER PRESSURE

Supply water pressure greater than 120 psi may cause the humidifier to overflow.

SHARP EDGES

Sharp edges may cause serious injury from cuts. Use care when cutting plenum openings and handling ductwork.

EXCESS HUMIDITY

Do not set humidity higher than recommended. Condensation may cause damage to structure and furnishings.

2

MATERIALS LIST

MODEL 800/800LC MODEL 801

MATERIALS FURNISHED

Humidifier

Model 62 Automatic Digital Humidifier Control

Dispersion tube

Steam hose (6 feet)

7/8” I.D. drain tubing (10 feet)

Hose clamps

Saddle valve

Mounting screws

NOT FURNISHED

Main power disconnect switch

Wiring

1/4” O.D. supply water tubing

Boards for mounting (if required)

MATERIALS FURNISHED

Humidifier

Dispersion tube

Steam hose (6 feet)

7/8” I.D. drain tubing (10 feet)

Hose clamps

Saddle Valve

Mounting Screws

NOT FURNISHED

Model 63 Automatic Digital Modulating Control

Main power disconnect switch

Wiring

1/4” O.D. supply water tubing

Boards for mounting (if required)

3

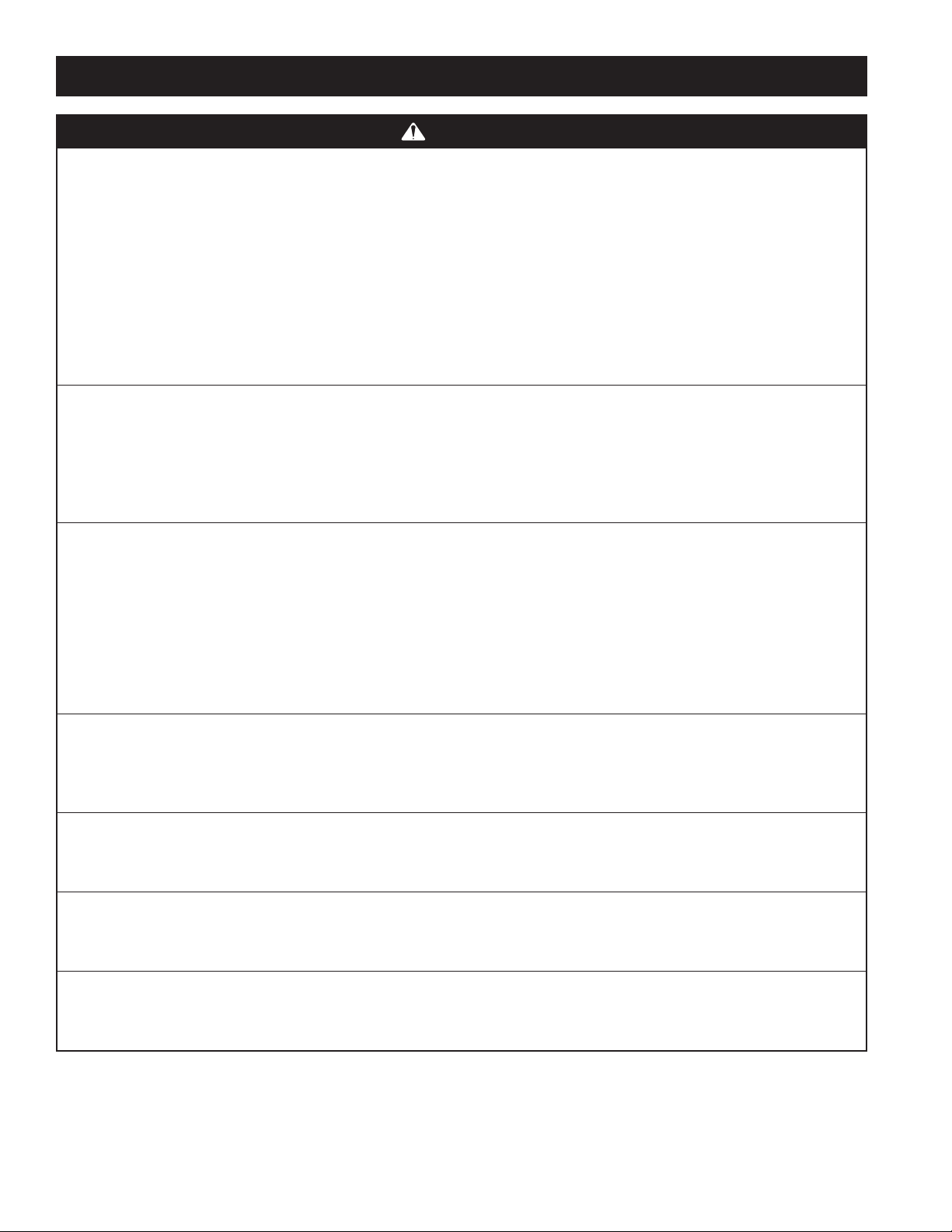

PRINCIPLES & SEQUENCE OF OPERATION

ube

Drain

Inlet

Fill V

2% PROPORTIONAL BAND SETTING

5% PROPORTIONAL BAND SETTING (DEF

10% PROPORTIONAL BAND SETTING

The Aprilaire® Steam Humidifier delivers humidity in the

form of steam to the conditioned space via the HVAC

system duct or the Fan Pack. The humidifier generates

steam by energizing two electrodes that extend into a

canister of water. Current flowing between the electrodes

causes the water to boil, creating steam. Water is

introduced to the humidifier through a fill valve to a fill

cup located in the top of the cabinet. The fill cup serves

as an overflow reservoir and provides an air gap between

the humidifier and water source. The steam canister is

filled from the bottom. The canister is seated in a drain

cup assembly which includes a drain valve. The drain and

fill valves work together to maintain water level in the

canister to deliver the rated steam capacity based on the

electrical conductivity of the water and to temper drain

water. See Figure 1 for representation of fill and drain

system and canister.

To control the Steam Humidifier as part of the HVAC

system, the Model 62 Automatic Digital Humidifier Control

(ADHC) is installed to detect the RH level in the duct.

When the ADHC detects RH below the set point, and the

humidifier and HVAC system blower are operating, the

humidifier energizes the electrodes to provide steam.

Steam is delivered into the duct work via the steam hose

and through the dispersion tube. The dispersion tube is

fitted with “Tubelets™.” The design of the dispersion tube and Tubelets distribute steam over a wide area in the duct and direct any condensed

moisture back into the steam hose. The blower activation function on the ADHC allows the control to turn on the HVAC system blower to

maintain the proper RH level even when the furnace or air handler is in stand-by mode. See ADHC installation manual.

FIGURE 1 – Fill and Drain System and Canister

Steam Hose

alve

Overflow

Fill

Supply

Water

Steam

Outlet

High Water Level Sensor

Electrodes

Canister

Drain Valve

Drain Cup

Tubelets

Dispersion T

in Duct

90-1522

Humidity can be distributed directly into the living space via the Fan Pack. When the Model 65 Manual Digital Humidistat detects RH below the

set point, the humidifier energizes the electrodes to provide steam via the steam manifold at the bottom of the Fan Pack. Steam is dispersed by

the fan located behind the grille above the steam manifold. The fan will operate for two minutes after the call for humidity ends, to disperse any

residual steam.

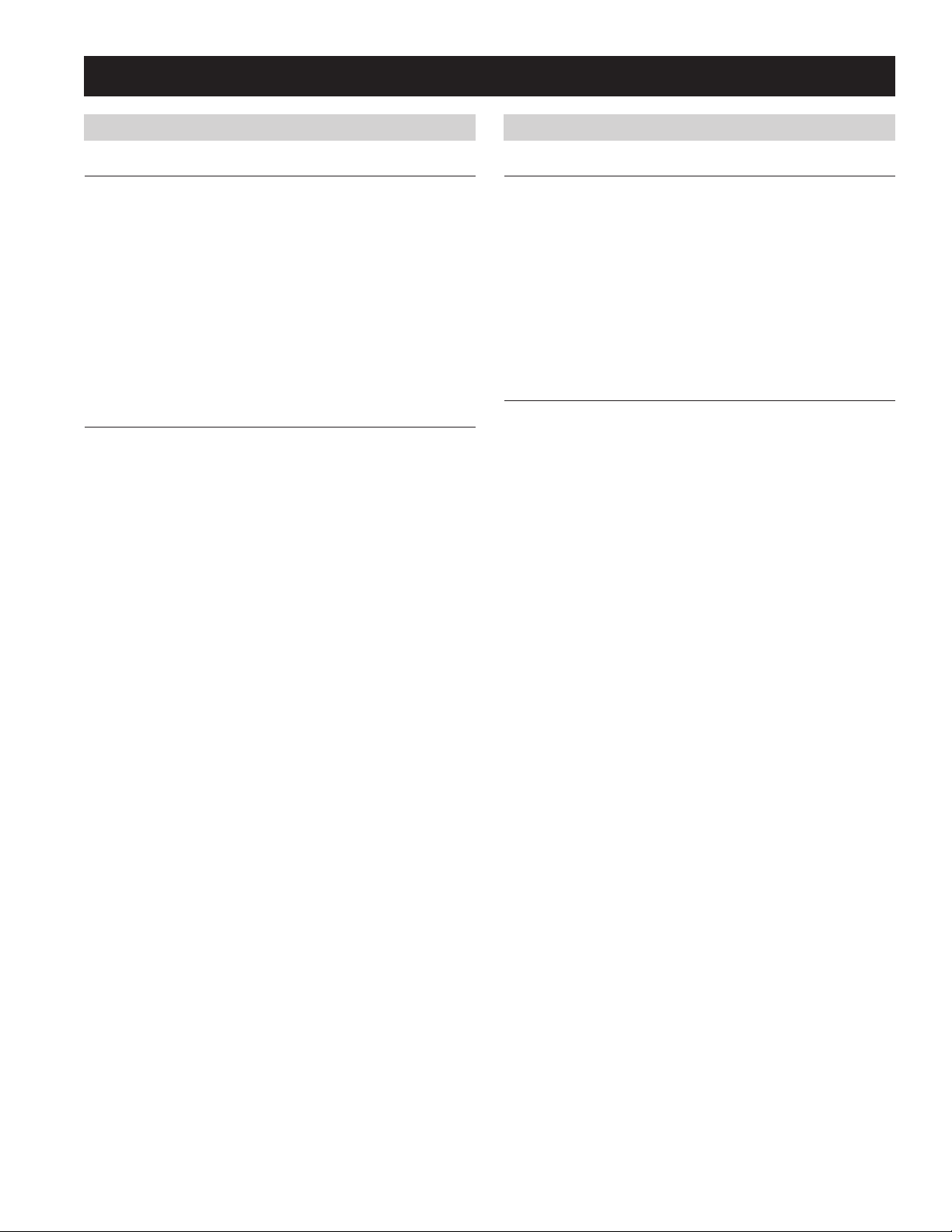

To provide precise control to the Modulating Steam

Humidifier, the Automatic Digital Modulating Control

FIGURE 2 – Humidifier Output for ADMC Signal

(ADMC) should be installed in the living space. The ADMC

will vary the Modulating Steam Humidifier output based

on the difference between set point and actual RH. The

ADMC sends a proportional signal to the Modulating

100%

PROPORTIONAL BAND

AULT)

Steam Humidifier providing precise control of living space

humidity. See Figure 2 for Steam Humidifier output vs RH

demand. The ADMC can be used in place of the ADHC

and Manual Digital Humidistat to provide On/Off control

to the Steam Humidifier not equipped with the modulating

feature. See the ADMC installation and operating manual

for details.

HUMIDIFIER OUTPUT (%)

20%

HUMIDIFIER OFF

-2% -5% -10%

RH DIFFERENCE FROM SETPOINT (%)

90-2008

4

SPECIFICATIONS & DIMENSIONS

This humidifier is able to produce steam at various capacities depending on the voltage and current applied. The unit can be wired to use an

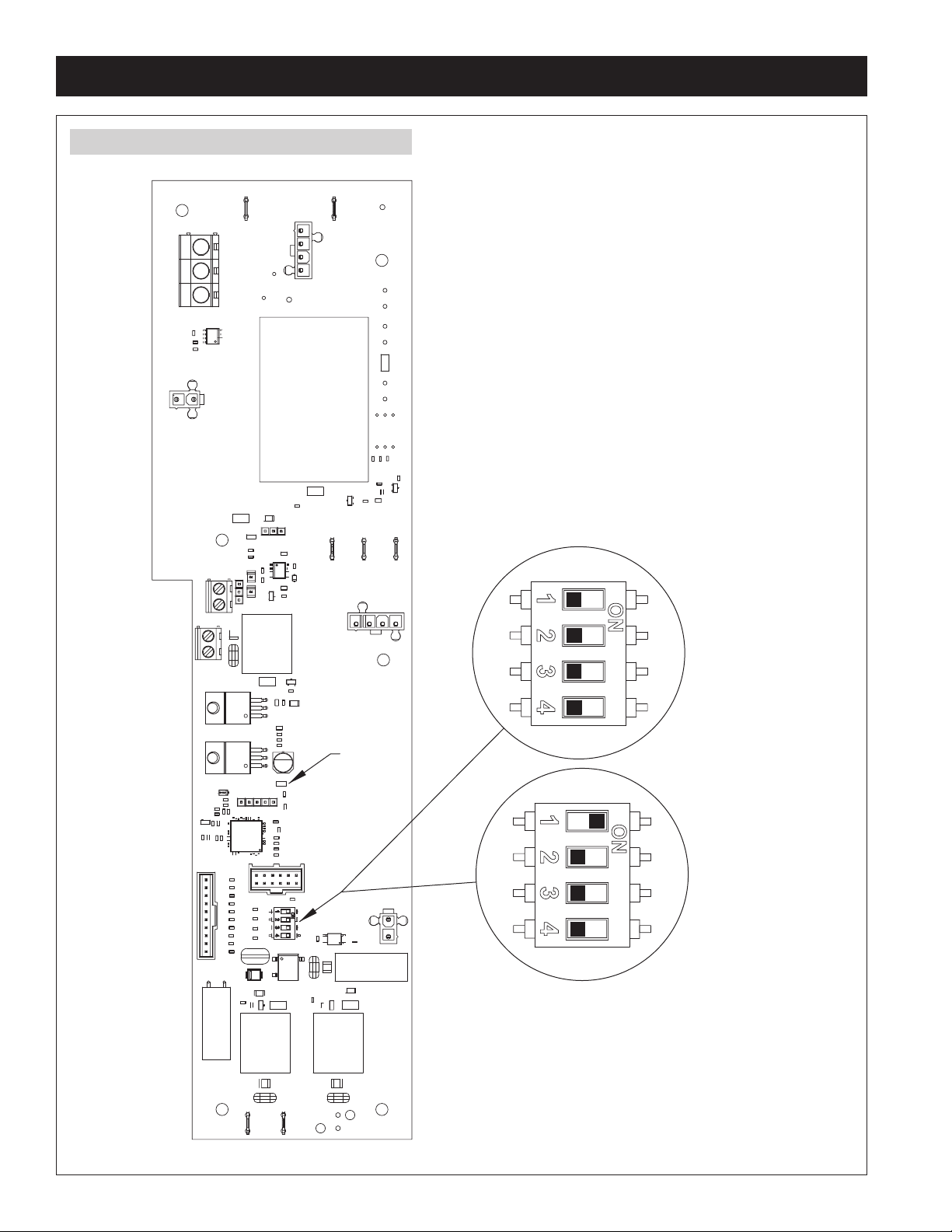

input voltage of 120, 208 or 240 Volts and input amperage can be set to 11.5 or 16.0 amps by changing a dip switch on the control circuit board

(see the Electrical Power Wiring & Shut Off Switch section on page 13). Configure the unit appropriately for the application (see Table 1 for

capacity specifications).

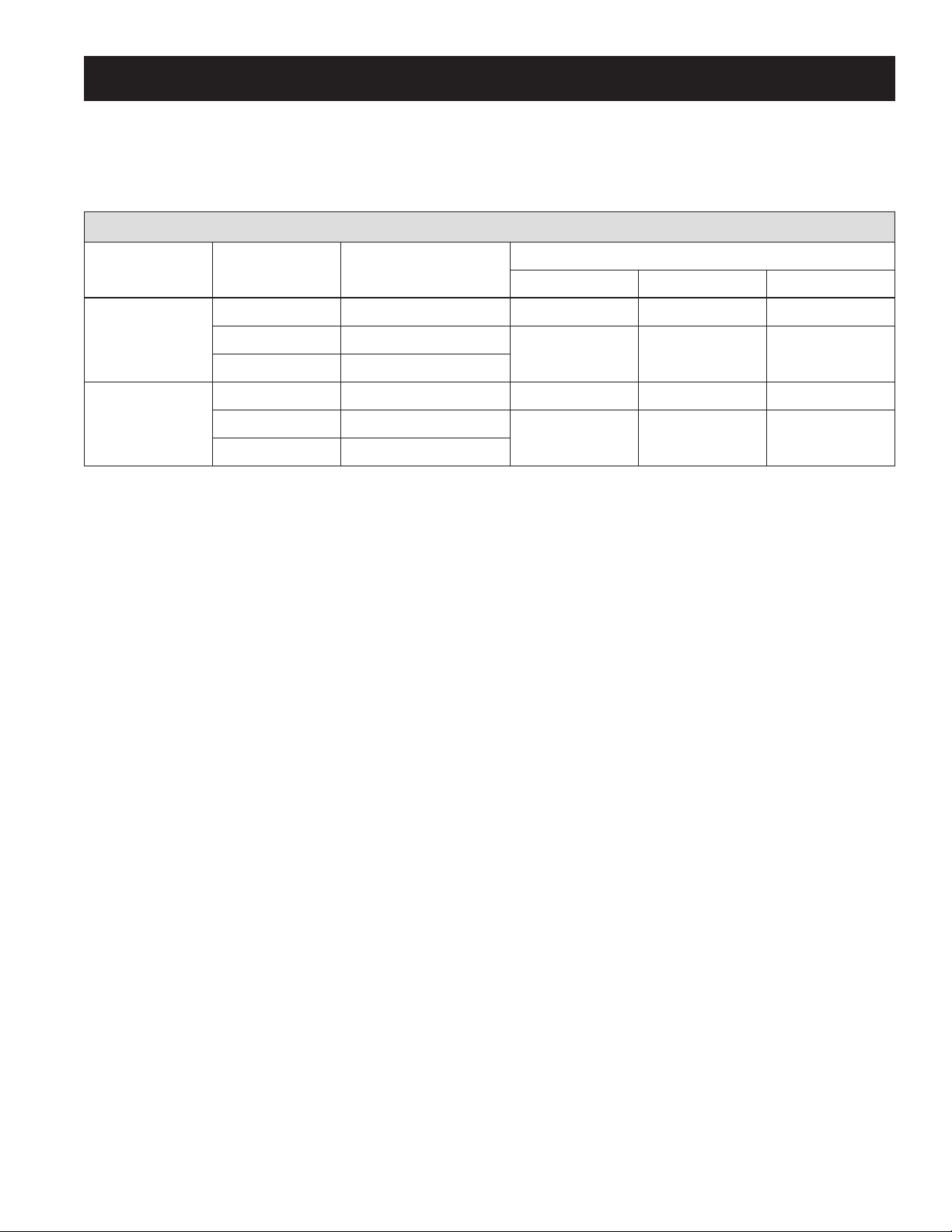

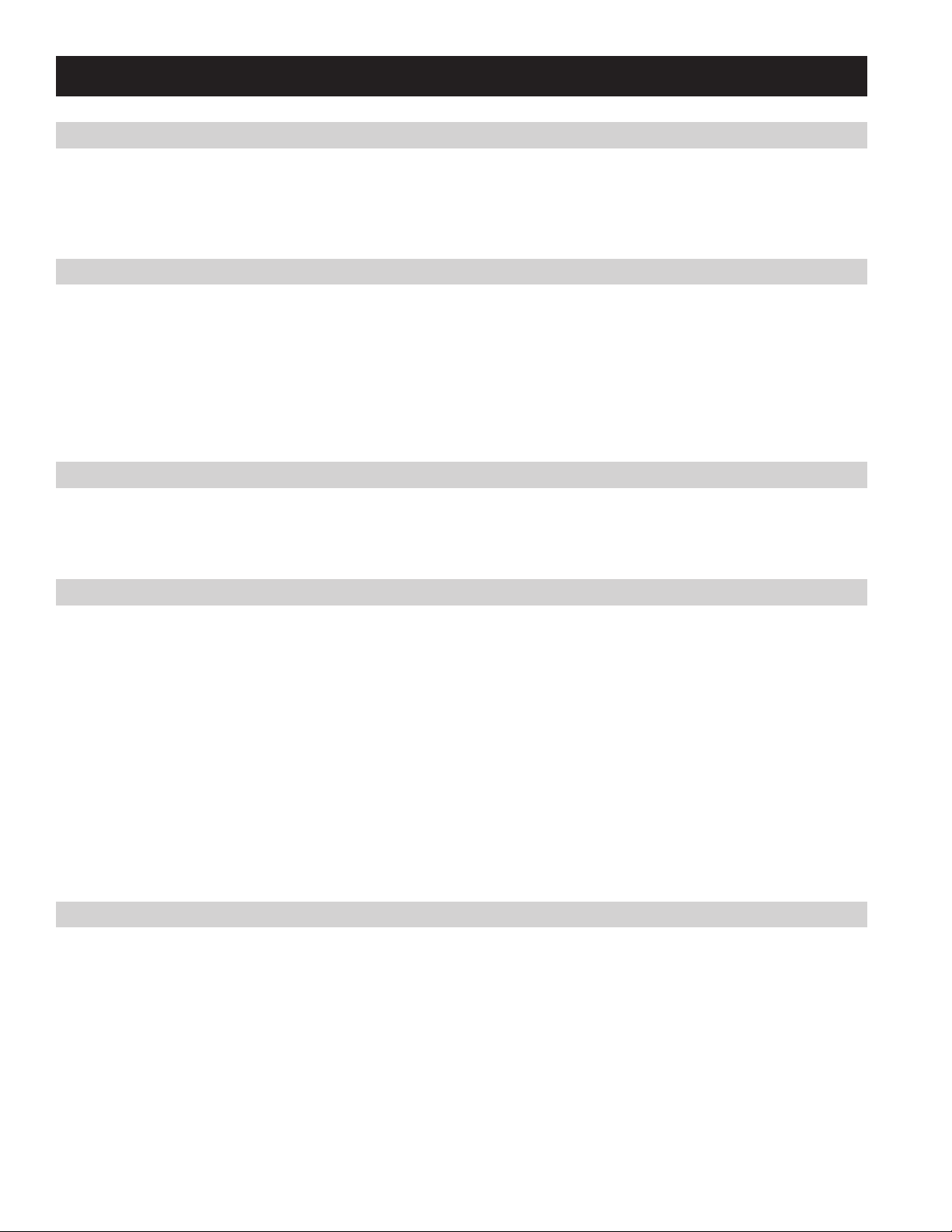

TABLE 1 – Humidifier Capacities and Recommended Home Sizes

2

*

Amperage Voltage

120V 11.5 2,500 sq ft 1,500 sq ft 1,000 sq ft

Maximum steam

capacity (gal/day)

Maximum recommended home size in ft

Tight Average Loose

11.5

208V 20.5

4,500 sq ft 2,500 sq ft 1,500 sq ft

240V 23.3

120V 16.0 3,500 sq ft 2,000 sq ft 1,500 sq ft

16.0

208V 30.0

6,000 sq ft 4,000 sq ft 2,500 sq ft

240V 34.6

* Assumes 8 ft ceiling height, adjust as necessary for higher ceilings. For homes with multiple furnaces/air handlers a humidifier should be installed on each.

Model 800 Series Shipping Weight: 28 lbs

Model 865 Shipping Weight: 39 lbs

Humidifier Operating Weight: 23 lbs**

** As minerals precipitate, unit weight can increase to approximately 30 lbs.

5

SPECIFICATIONS & DIMENSIONS (CONTINUED)

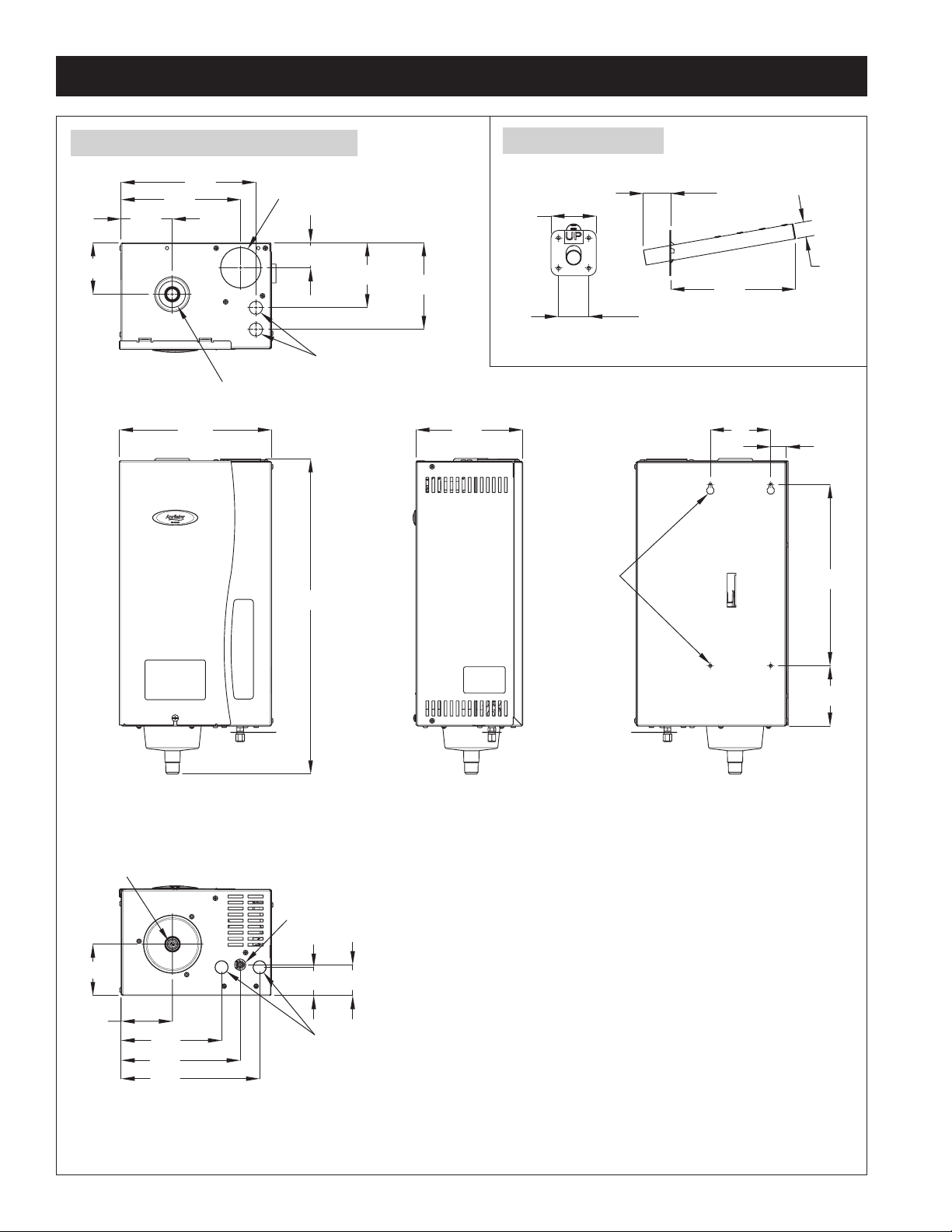

FIGURE 3 – Humidifier Dimensions (inches)

8-7/8

7-7/8

3-3/8

3-3/8

TOP VIEW

10-1/8

Fill Cup

1-5/8

Electrical Knockouts

Dispersion Outlet

20-7/8

4-1/4

5-3/4

7-1/8

Steam Dispersion Tube

3 sq

3 sq

90-1518

Mounting

Holes

2 sq

2 sq

1-3/4

8-1/4

8-1/4

1-3/4

1 dia

1 dia

4

1

12

3-3/8

3-3/8

FRONT VIEW

Drain

6-5/8

7-7/8

9-1/8

BOTTOM VIEW

Water

Fill Line

Connection

1-7/8

Electrical

Knockouts

4

SIDE VIEW

2

BACK VIEW

6

90-1518

SPECIFICATIONS & DIMENSIONS (CONTINUED)

WATER QUALITY

Minerals that are naturally found in water contribute to water’s electrical conductivity; water conductivity is measured in microsiemens per

centimeter (uS/cm). Mineral content, also described as “water hardness” is usually measured in grains per gallon. Variation is found among

water samples but generally the higher the mineral content, the higher the conductivity.

The Steam Humidifier is designed to operate on water with conductivity between 100 and 1,250 uS/cm. This correlates loosely with water

hardness between 3 and 36 grains/gallon. Water that is considered “hard” and softened water work well in the Steam Humidifier. The humidifier

makes steam when plumbed to low-conductivity water but it takes longer to reach nominal current.

Two canisters are available for use with the Steam Humidifier. The Model 80 canister is used in most installations and is optimized for “hard”

and softened water. The Model 80 typically works best when the Steam Humidifier is installed at 208 or 240 VAC. If the Steam Humidifier has

a yellow Steam light in the first two weeks of running with a new canister, the Steam Humidifier is taking a long time to reach its nominal

current; changing to the Model 80LC canister will prevent this from happening in the future.

The Model 80LC canister is optimized for use in areas where the water conductivity is less than 300 uS/cm or when the Steam Humidifier is

installed at 120VAC. The Model 80LC should not be used with softened water. If the Steam Humidifier is draining too frequently, the water

conductivity is too high; changing to the Model 80 canister will reduce the drain frequency.

As water in the canister boils and turns into steam, minerals are left behind. Minerals remaining in solution increase the conductivity of the

water. Minerals also deposit onto the submerged portions of the electrodes rendering those areas ineffective. As this occurs, the level of water

in the canister rises to expose uncoated electrode surface.

There are benefits and trade-offs to consider when the application allows a choice between hard and softened water:

Hard water: The benefit of hard water is less frequent draining and filling than with soft water, which results in better energy and water

efficiency and more consistent steam output. However, canister replacement could be more frequent with hard water, because mineral deposits

coat the electrodes. The harder the water, the more frequent the need for a new canister.

Softened water: The benefit of softened water is longer canister life (depending on water chemistry) than with hard water, because softened

water does not coat the electrodes nearly as much as hard water. However, softened water ions stay in solution to much higher concentrations

than hard water ions. This requires more frequent draining and filling, which results in lower energy efficiency, higher water consumption and

less consistent steam output.

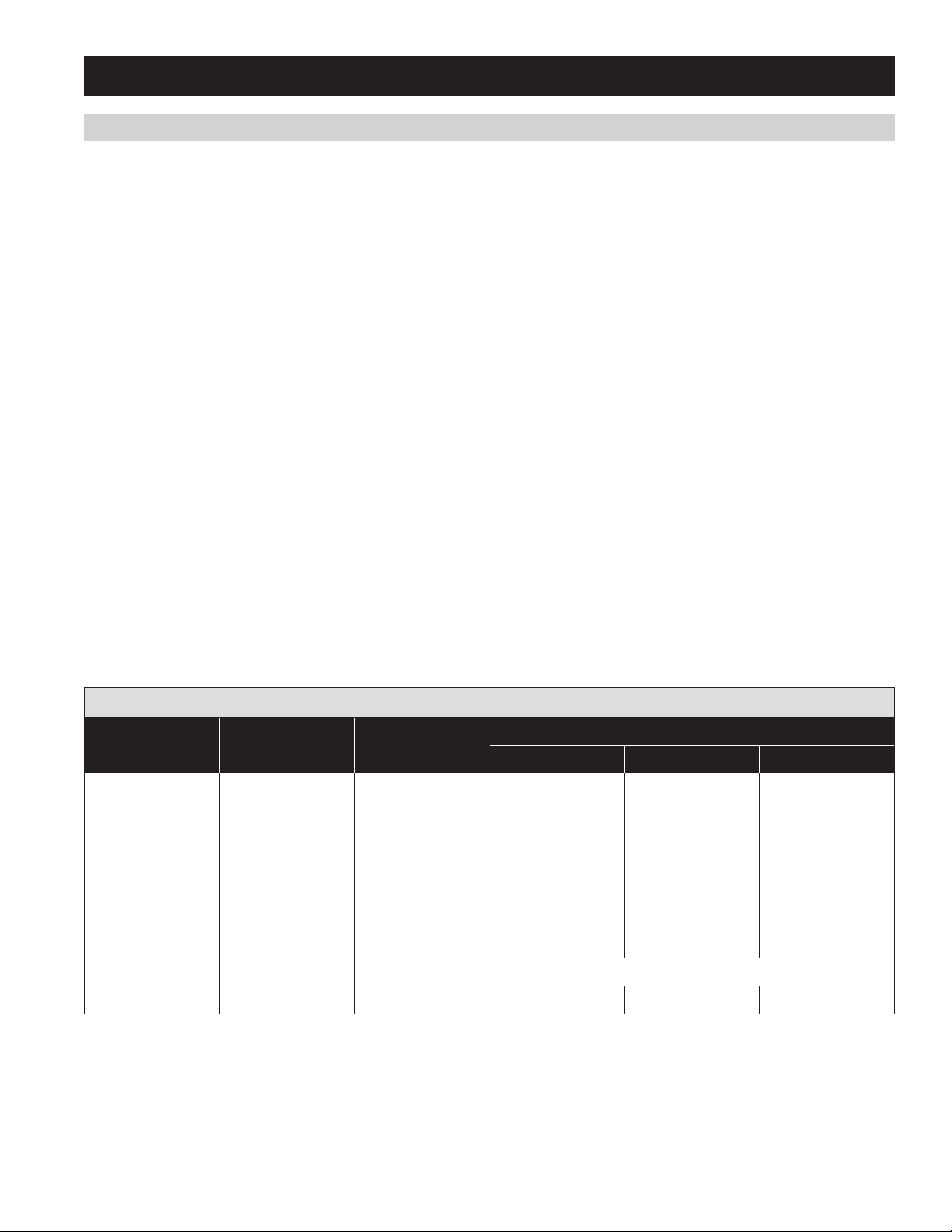

TABLE 2 – Water Quality Guidelines

Conductivity

(uS/cm)

75-100 0-3 Naturally Soft

100-300 3-9 Naturally Soft 80LC 80LC 80LC

300-500 9-15 Slightly Hard 80LC 80 80

500-650 15-20 Moderately Hard 80LC 80 80

650-850 20-25 Hard 80LC 80 80

850-1250 25-36 Very Hard 80LC 80 80

above 1250 above 36 Extremely Hard Installation Not Recommended

Grains/Gal Hardness

120VAC 208VAC 240VAC

Installation Not

Recommended

Recommended Canister by Voltage

80LC 80LC

Softened 80 80 80

7

INSTALLATION INSTRUCTIONS

CAUTION

Each humidifier requires its own steam hose and dispersion tube. Do not connect steam hoses from more than one humidifier

together. Back-pressure from one humidifier can lower the water level in the canister in the other humidifier and cause

operational problems.

Do not install the dispersion tube in a duct with greater than 2 in. wg static pressure. High duct pressure can cause backpressure in the canister which can result in unstable unit operation.

Do not mount humidifier in a location where operating ambient temperatures exceed 140°F or where freezing temperatures

may occur.

CHOOSING A LOCATION

DISPERSION TUBE LOCATION

When choosing a location for the dispersion tube three things must be considered: Location in duct, elevation with respect to the humidifier, and

distance from humidifier to dispersion tube.

Duct Location and Absorption Distance

Absorption distance, the unobstructed straight line distance needed for steam to be fully absorbed, is dependent on air velocity, air temperature

and relative humidity in the duct. Determine absorption distance based on the lowest duct temperature, lowest air velocity and

highest humidity that the system will see. The dispersion tube must be located in a straight section of duct far enough upstream of any

obstructions or bends in the duct. Use Table 3 to determine the appropriate absorption distance.

Operation during AC calls is not recommended because of the potential for condensation in the ductwork. Configure controls to lock out the

humidifier during AC calls and use the blower activation feature on the ADHC to allow the humidifier to run with the blower only. Call Aprilaire

Tech Support at 1-800-334-6011 for additional information on steam absorption.

The dispersion tube must be mounted with the plate on a vertical surface with the tube angled up as shown in Figure 4. The steam tubelets

must face up regardless of the airflow direction in the duct. The plate is labeled “UP”to indicate proper orientation. On horizontal duct runs

install the dispersion tube low in the duct, on vertical runs center the tube on the duct.

If the dispersion tube is mounted on insulated ductwork, make sure insulation is not more than 2” thick at tube location to prevent insulation

from blocking first steam outlet.

Note: If dispersion tubes for two humidifiers are installed in one duct, double the dispersion distances. If three dispersion tubes are installed,

triple the dispersion distance. Position dispersion tubes so one does not discharge directly onto another.

8

INSTALLATION INSTRUCTIONS (CONTINUED)

Steam hose or pipe.

Insulate pipe with 1” fiberglass

TABLE 3 – Absorption Distance (Minimum distance from dispersion tube downstream to any obstruction or bend in duct)

Humidifier

Output (gal/day)

Airflow Velocity*

70°F & 30% RH

Setpoint

70°F & 45% RH

Setpoint

65°F & 45% RH

300 fpm 13” 19” 23” 30”

Up to 16.0

600 fpm 6” 10” 12” 18”

1200 fpm 3” 5” 6” 13”

1800 fpm 2” 3” 4” 10”

300 fpm 15” 23” 28” 45”

20.5 – 25.0

600 fpm 6” 12” 13” 26”

1200 fpm 5” 6” 7” 19”

1800 fpm 3” 4” 5” 16”

300 fpm 24” 31” 36” 60”

25.0 – 35.0

600 fpm 17” 22” 26” 48”

1200 fpm 12” 15” 18” 25”

1800 fpm 10” 13” 15” 20”

*Velocity in feet per minute = Duct airflow volume in cubic feet per minute / duct area in square feet.

Example: 1,200 cfm through 16” x 12” duct = 1,200/(12 x 16/144 sq. in./sq ft.) = 1,200/1.333 = 900 fpm

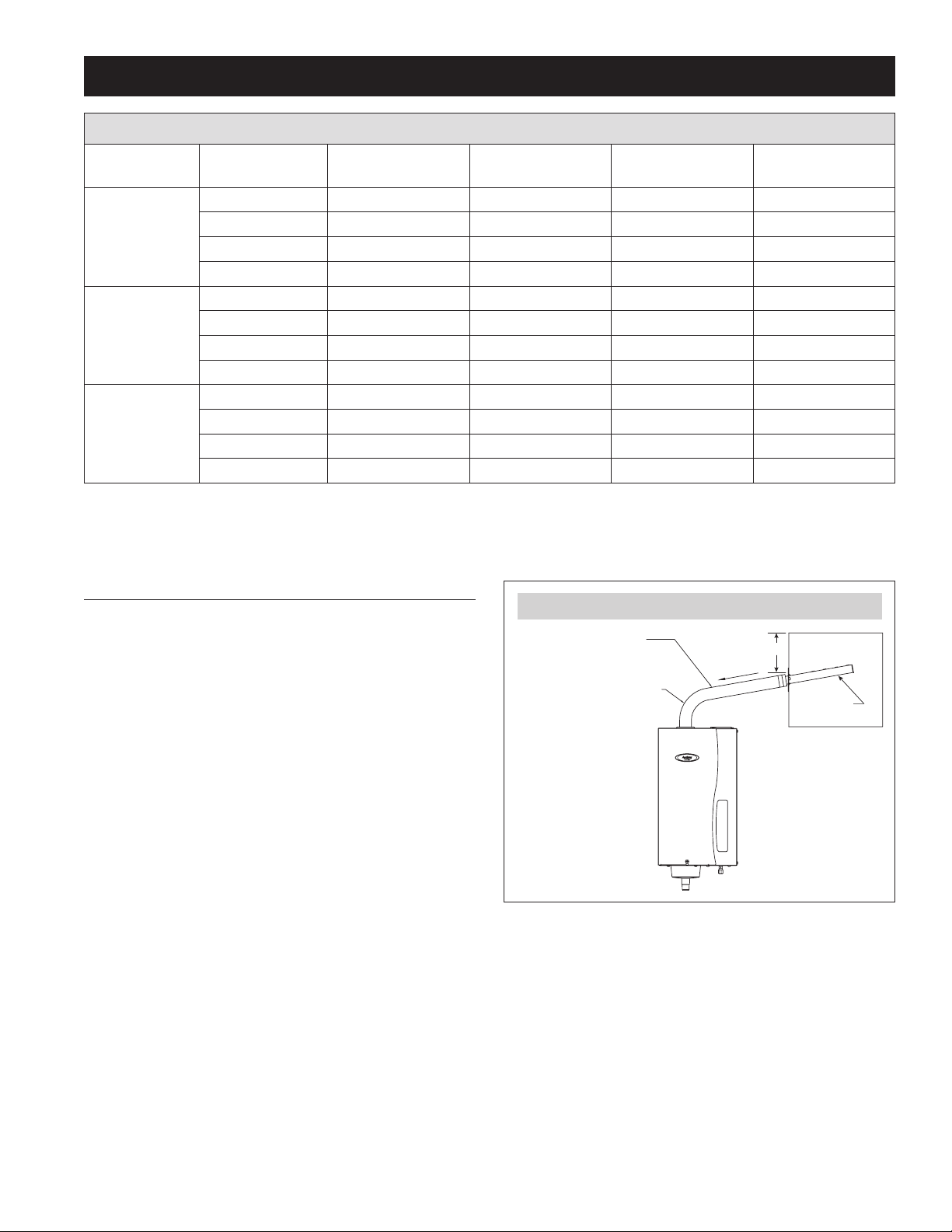

ELEVATION

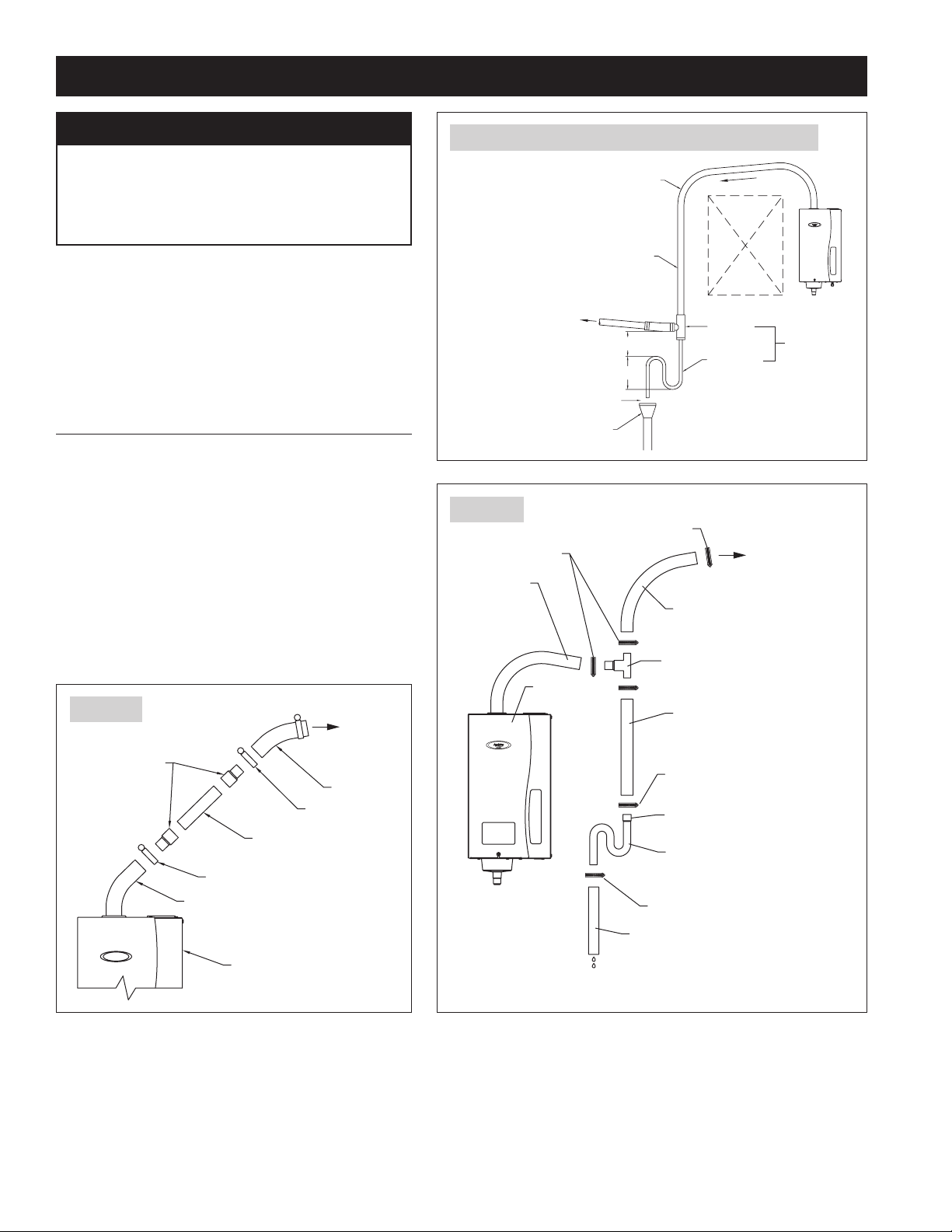

FIGURE 4 – Dispersion Tube Mounted Above Humidifier

The preferred location for the dispersion tube is higher than the

humidifier so that the steam hose has a constant downward slope of at

least 2” per foot from the dispersion tube to the humidifier. If hard pipe

is used, the slope can be 1/4” per foot. With the constant downward

slope, any condensation that forms in the steam hose will drain back

to reduce steam loss.

90° long sweep

or two 45° elbows

into the steam canister. See Figure 4.

Setpoint

5” minimum

Pitch*

45°F & 45% RH

Setpoint

Duct

Dispersion

tube

* Pitch steam hose down

from dispersion tube to

humidifier:

2”/ft (15%) minimum

when using steam hose.

1/4”/ft when using

hard pipe.

90-1521

9

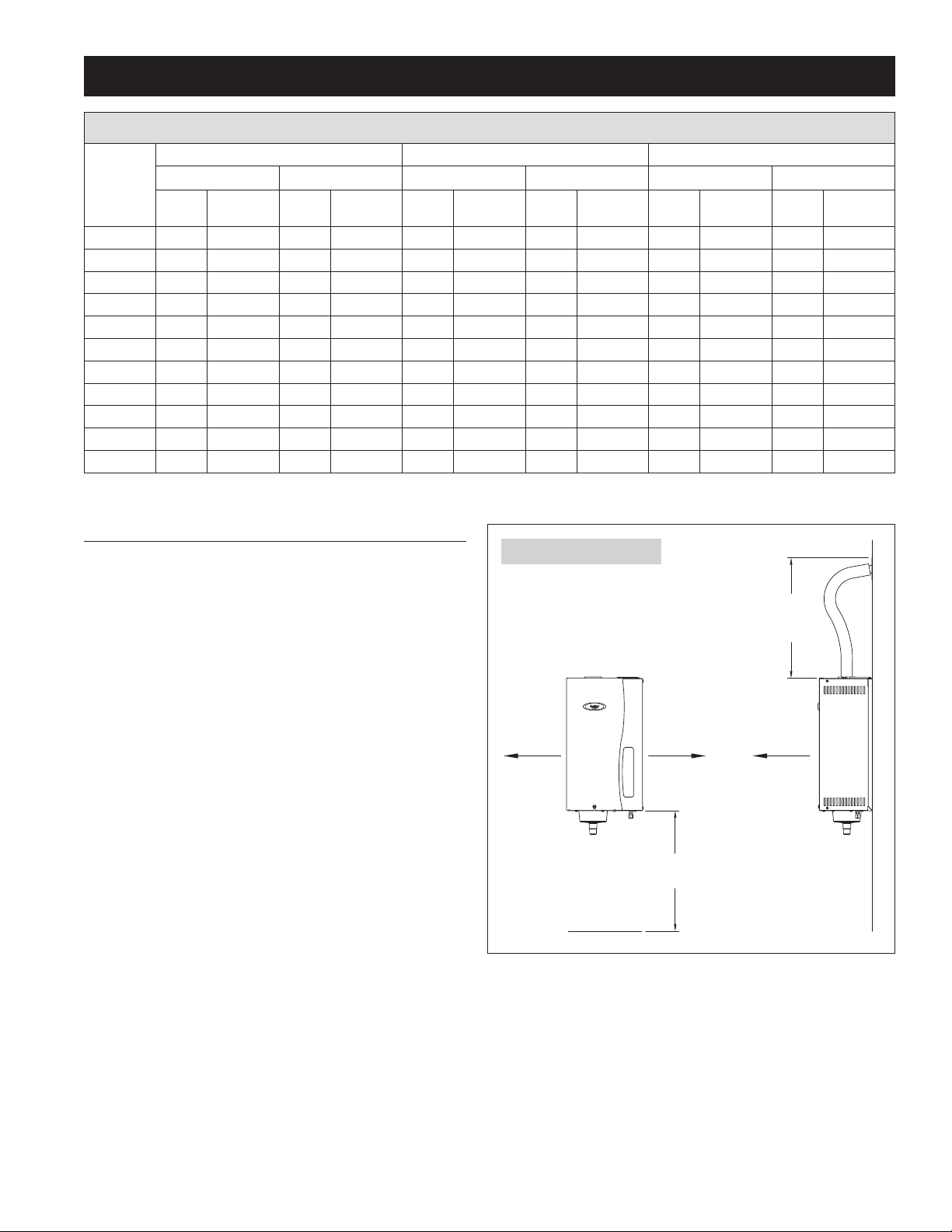

INSTALLATION INSTRUCTIONS (CONTINUED)

Drip tee installation for

piping over obstruction,

or if dispersion tube is

lower than humidifier

Reducing Coupling

To Steam

Dispersion

Hose Clamp

ube

NOTICE

CONTROL CONDENSATE FLOW AND COLLECTION.

Failure to follow steam hose recommendations in this

manual can result in reduced or erratic performance,

increased noise and condensate in the duct.

If the dispersion tube must be mounted below the humidifier

or if the steam hose needs to run up and over an obstruction, a

drip tee with drain trap, Part #4028, must be installed as shown

in Figure 5. When using the Fan Pack, install Part #4028 close

to the humidifier outlet to help prevent noise from gurgling as

shown in Figure 6.

DISTANCE FROM HUMIDIFIER TO

DISPERSION TUBE/FAN PACK

The capacity of the humidifier is reduced by the length of

the steam hose or pipe due to condensation. The maximum

recommended length of steam hose is 6 feet. Use hard pipe

insulated with 1” thick insulation rated for 212°F or higher

for lengths greater than 6 feet. Table 4 provides humidifier

capacity with various lengths of steam hose and pipe. If 6-foot

steam hose does not reach from humidifier to dispersion tube,

splice in 1” copper pipe using 3/4” x 1” reducing couplings as

shown in Figure 7.

FIGURE 7

Tube or

3/4" x 1"

1" Copper Pipe

1-1/2" Hose Clamp

Steam Hose

Fan Pack

Steam Hose

1-1/2" Hose Clamp

FIGURE 5 – Dispersion Tube Mounted Below Humidifier

90-1520

.

Insulate hard pipe to

reduce steam loss

To Dispersion

Tube/Fan Pack

1" air gap

Open drain required,

see note 1.

90° long

sweep or two

45° elbows

6" min

8" min

Pitch

Obstruction

Drip tee

Drain trap

NOTES:

1. Refer to governing codes for

drain pipe size and materials.

2. Support steam hose so there

are no sags or low spots.

FIGURE 6

Hose Clamp

Steam Hose

1" I.D.

(Downward

Slope from

Humidifier

to Tee)

Steam

Humidifier

Steam Hose, 1" I.D.

(Downward Slope to Tee)

Tee

Assembly

Steam

Hose

1" I.D.

Hose

Clamp

Flared

End

Trap

Note: Prime with water

before using humidifier

Hose Clamp

To Steam

Dispersion T

or Fan Pack

#4028 KIT

CONTENTS:

Hose Clamps (5)

Trap (1)

Tee Assembly (1)

Part #4028

10

Humidifier

Drain Hose

7/8" I.D.

90-1527 90-1844

INSTALLATION INSTRUCTIONS (CONTINUED)

TABLE 4 – Steam Humidifier Capacity in Gallons/Day

Steam

Hose or

Insulated

Pipe

Length

11.5 Amps 16.0 Amps 11.5 Amps 16.0 Amps 11.5 Amps 16.0 Amps

Steam

Hose

< 2 ft. 11.5 11.5 16.0 16.0 20.5 20.5 30.0 30.0 23.3 23.3 34.6 34.6

2 ft. 11 11 15.5 15.5 20 20 29 29.5 23 23 34 34

4 ft. 10 11 14.5 15.5 19 20 28 29.5 22 23 33 34

6 ft. 9 11 13.5 15 18 20 27 29 21 22 32 33

8 ft. 10 14 19 28 22 33

10 ft. 10 14 19 28 22 33

12 ft. 10 14 19 28 22 33

14 ft. 9 13 18 27 21 32

16 ft. 9 13 18 27 21 32

18 ft. 9 13 18 27 21 32

20 ft. 9 13 18 27 20 31

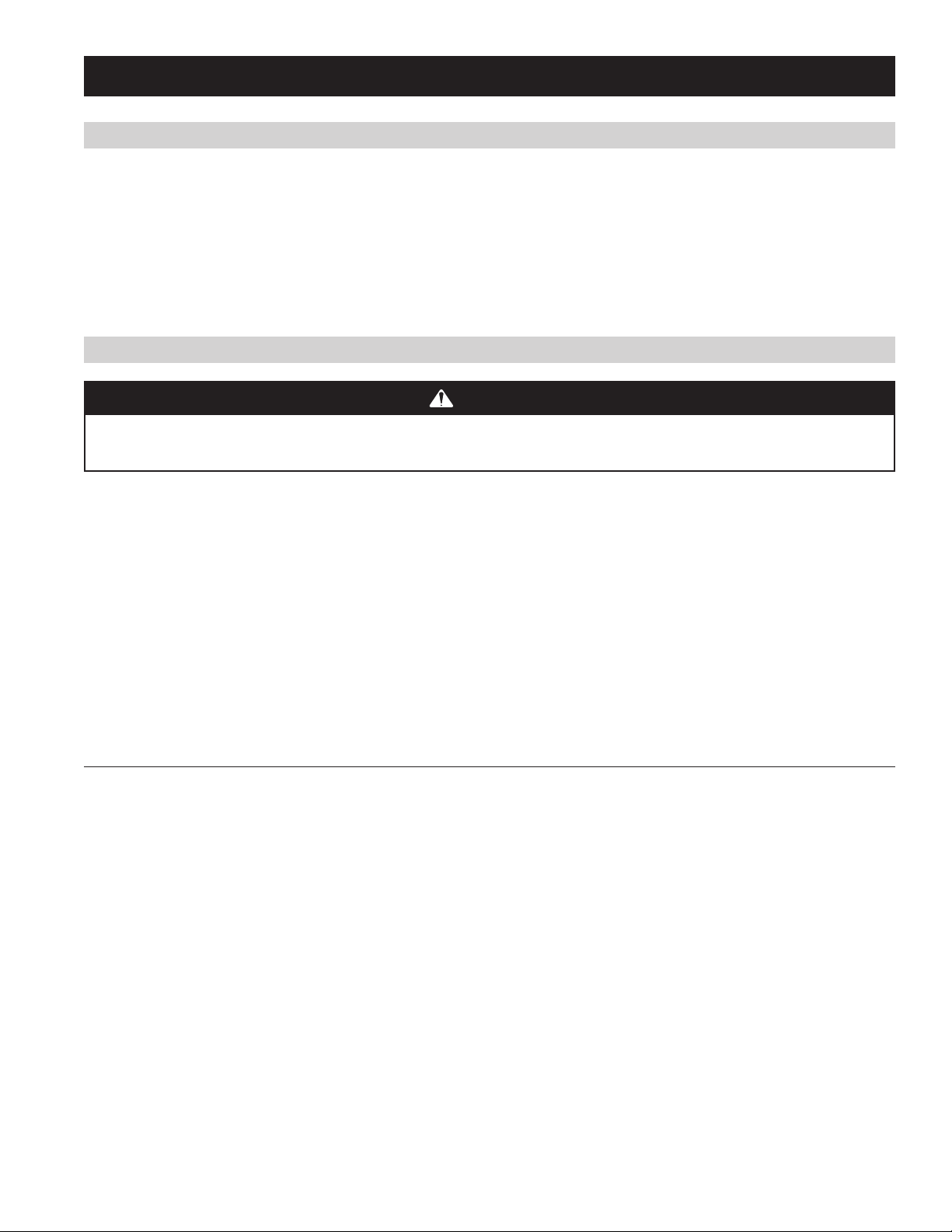

HUMIDIFIER LOCATION

Do not mount humidifier in a location where operating

ambient temperature exceeds 140°F or where freezing

temperatures may occur. Extreme temperatures may cause the

humidifier to leak which can damage furnishings or structure.

Mount humidifier in a location that allows access for servicing, and

clearance to remove front panel for replacing the canister and side

panel for access to the electrical components during installation.

See Figure 8 for minimum clearances around humidifier.

The humidifier should be mounted as close to the dispersion

tube as possible. Table 4 shows how capacity is reduced as the

distance between the humidifier and dispersion tube increases. If

the humidifier is mounted on the duct directly below the dispersion

tube, allow space for a bend in the steam hose. Allow a minimum

of 2” of steam hose to extend straight out of the humidifier before

beginning any bends; this will help ensure a tight connection with

the top of the canister.

The humidifier can be mounted to a wood surface, or to sheet metal

ductwork if it is structurally stable. Do not mount humidifier to fiber

duct board. Sound isolation may be desired when mounting to sheet

metal ductwork.

120 Volts 208 Volts 240 Volts

Insulated

Pipe

Steam

Hose

Insulated

Pipe

Steam

Hose

Insulated

Pipe

Steam

Hose

Insulated

Pipe

Steam

Hose

Insulated

FIGURE 8 – Clearances

FRONT VIEW

16" for

4"

90-1519

Electrical

Access

16"

for Drain

Pipe

Steam

Hose

16" for

Steam

Hose

30" for

Service

Access

SIDE VIEW

Insulated

Pipe

The humidifier must be mounted to a vertical surface and must be

mounted level in the upright position.

11

INSTALLATION INSTRUCTIONS (CONTINUED)

PREPARE HUMIDIFIER FOR MOUNTING

Unpack carton. Open front panel by removing screw and lifting panel up and away from humidifier. Disconnect three wires from top of canister

by pulling straight up. The two large wires are the electrode conductors. The smaller wire is connected to the high water level sensor. Remove

canister by pulling it up and out of drain assembly. Remove two screws on right side of humidifier and lift side panel off housing to expose

electrical compartment.

INSTALL STEAM DISPERSION TUBE

Make sure steam dispersion tube is mounted higher than the humidifier so that condensation that forms in the steam hose runs back into the

canister. If the dispersion tube cannot be mounted higher than the humidifier or if the steam hose must extend up from the humidifier then down

to the dispersion tube due to an obstruction, a drip tee and drain trap system (Part #4028) must be installed as shown in Figure 5.

Drill a 1-1/4” diameter hole in a vertical surface of the duct at the location chosen for the dispersion tube. Position the dispersion tube so it is

angled up, regardless of airflow direction. UP is stamped on the mounting bracket to aid in proper installation. Secure with four sheet metal

screws provided.

MOUNT HUMIDIFIER

Secure humidifier to a sturdy wall using screws provided, or to sheet metal duct. Humidifier initially weighs 23 lbs with a full canister, but will

increase in weight over time due to the precipitation of minerals inside the canister. Make sure mounting system will support weight. If mounting

to stud frame wall, install two spanner boards to studs and fasten humidifier to spanner boards. Make sure humidifier is mounted plumb.

INSTALL STEAM HOSE

Six feet of steam hose is provided with the humidifier. If the steam hose must be cut, use a hacksaw. If additional length is required, use

1” O.D. metal or copper pipe. Do not use PVC pipe for steam line. Insulate pipe with 1” thick insulation rated for 212°F or higher to reduce

steam loss. See Table 4 for humidifier capacity at various lengths of steam hose and pipe.

Use the steam hose provided. Other hoses may have impurities which can cause foaming in the canister. Foaming can cause water level

inaccuracies, reduced steam production and water sputtering into the duct. When using pipe, remove all traces of residual materials used to

connect the pipe to prevent foaming.

Verify that the O-ring is in place in the groove in the drain assembly. Dampen the O-ring with water (DO NOT use oil, grease,or any lubricant

besides water), then reinsert the canister with the caution label positioned toward the front of the unit.

Attach steam hose to dispersion tube and then to top of canister using hose clamps provided. Make sure steam hose has a constant slope of at

least 2” per foot between the dispersion tube and the humidifier. Any and every low spot in the steam hose or pipe must have a drip tee and drain

trap. Fill drain trap with water before making final connections. Support the steam hose in multiple locations over its span to prevent sagging.

Attach and fully seat the electrode conductors (interchangeable) and the high water level sensor wire to the top of the canister.

SUPPLY WATER

Plumb the humidifier to cold, hard or softened water. Do not use hot water because unheated supply water is used to cool water

draining from the humidifier. Do not use demineralized or reverse osmosis water. For proper operation, supply water pressure must be between

25 psi and 120 psi. Hard or softened water may be used provided it has conductivity between 125 microS/cm and 1250 microS/cm. See Table 2.

Supply water piping must be free of oils, lubricants, solder flux and other contaminants, which can cause foaming.

Follow local plumbing codes. An external backflow preventer may be needed.

Install the saddle valve according to the instructions printed on the bag. Run 1/4” copper tubing from the saddle valve to the humidifier. Connect

it to the fill valve. Double wrench to prevent leaking and damage to valve. Addition of a stainless steel braided water line can help reduce valve

noise.

Note: Adding an inline particulate filter can increase canister life in areas with high levels of suspended solids. DO NOT use filters that release

scale inhibitors, filters of this type can significantly decrease canister life.

12

INSTALLATION INSTRUCTIONS (CONTINUED)

DRAIN LINE

Attach the 7/8” I.D. drain tubing provided to the drain assembly at the bottom of the humidifier. Secure with the hose clamp provided. Do not

over tighten.

Make sure the drain line has a constant downward slope from the humidifier to the drain and is not kinked or blocked.

If floor drain is not available, use condensate pump (Part #4856) to route water to a suitable drain. Provide at least 16 inches for of drain line

between the Steam Humidifier and the condensate pump.

Note: The humidifier uses cold water to temper drain water to less than 140°F.

ELECTRICAL POWER WIRING & SHUT-OFF SWITCH

CAUTION

Only qualified electrical personnel should perform field wiring procedures. Improper wiring or contact with energized circuits

can cause property damage or severe personal injury.

All wiring must be installed in accordance with all governing electrical codes and with the wiring diagram provided inside the front panel.

Do not loop power wiring.

Do not use aluminum wire.

A safety grounding system that meets all governing electrical codes is required. The ground connection must be made with solid metal to metal

connections. Ground wire must be the same size as the power wiring.

With factory settings, the Steam Humidifier draws 11.5 amps +/- 10%. Use a minimum 20 amp dedicated circuit when installing to operate

at 11.5 amps. The Steam Humidifier can be set to draw 16.0 amps +/- 10% by repositioning dip switch #1 on the control circuit board (see

Figure 9). When set to 16 amps, use a minimum 25 amp dedicated circuit. For both applications, size wire according to local codes.

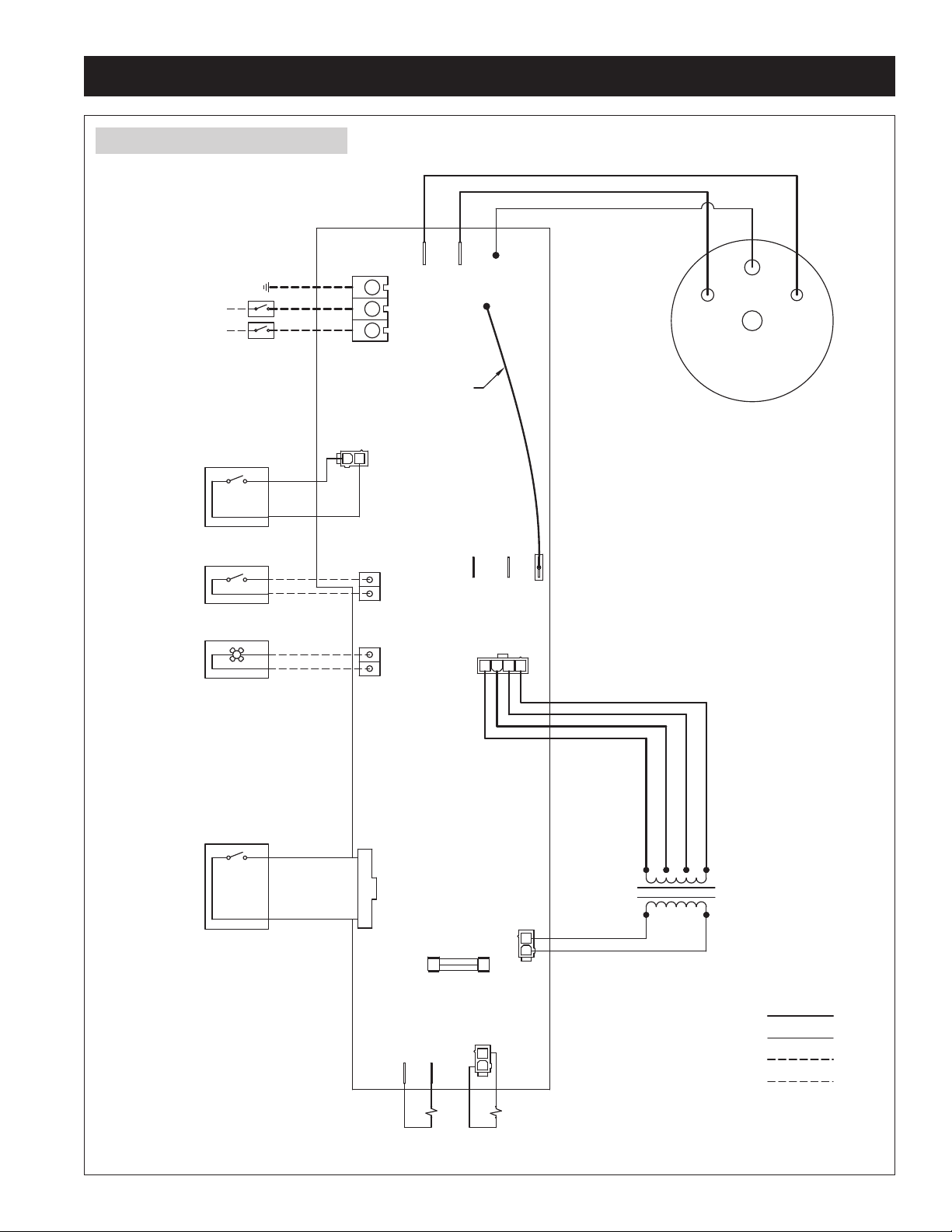

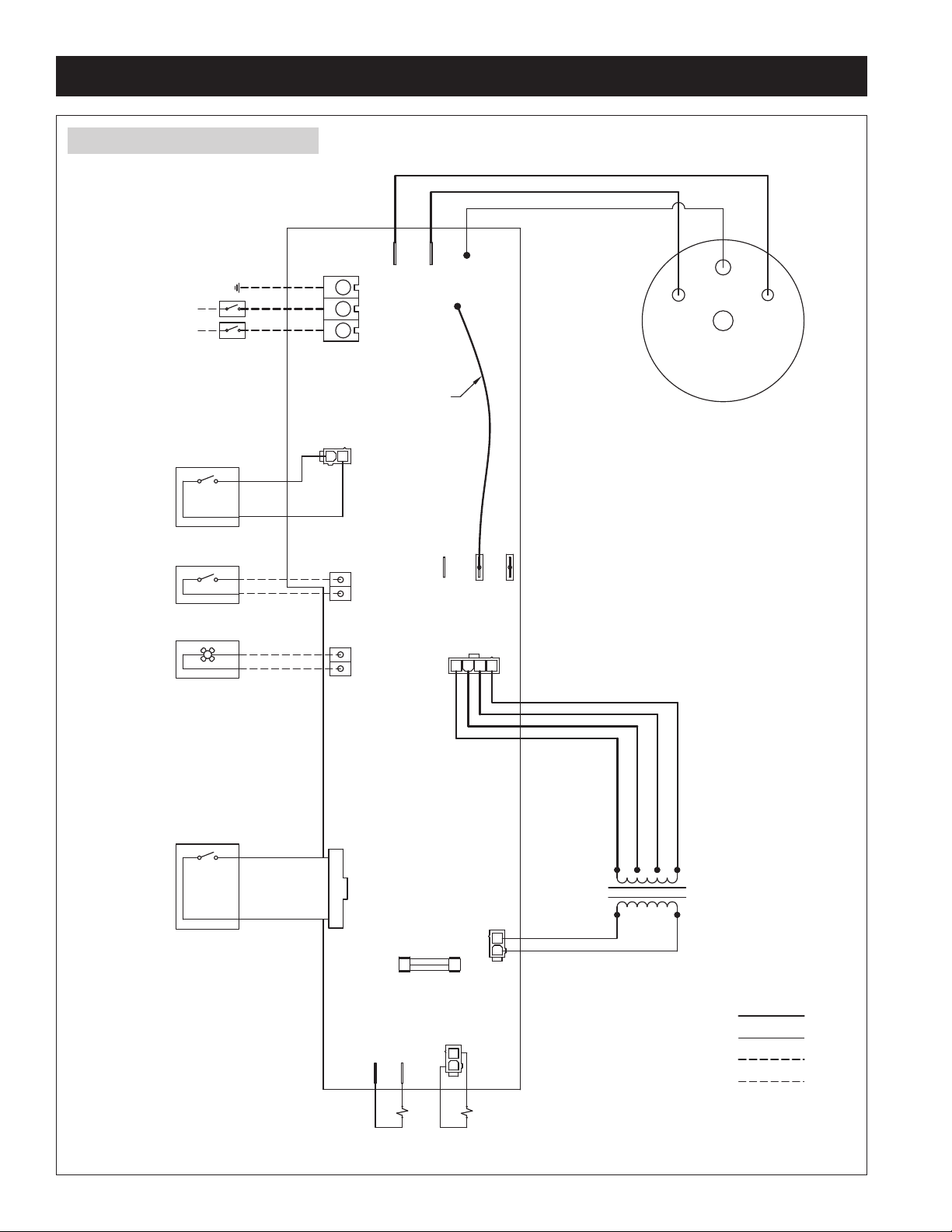

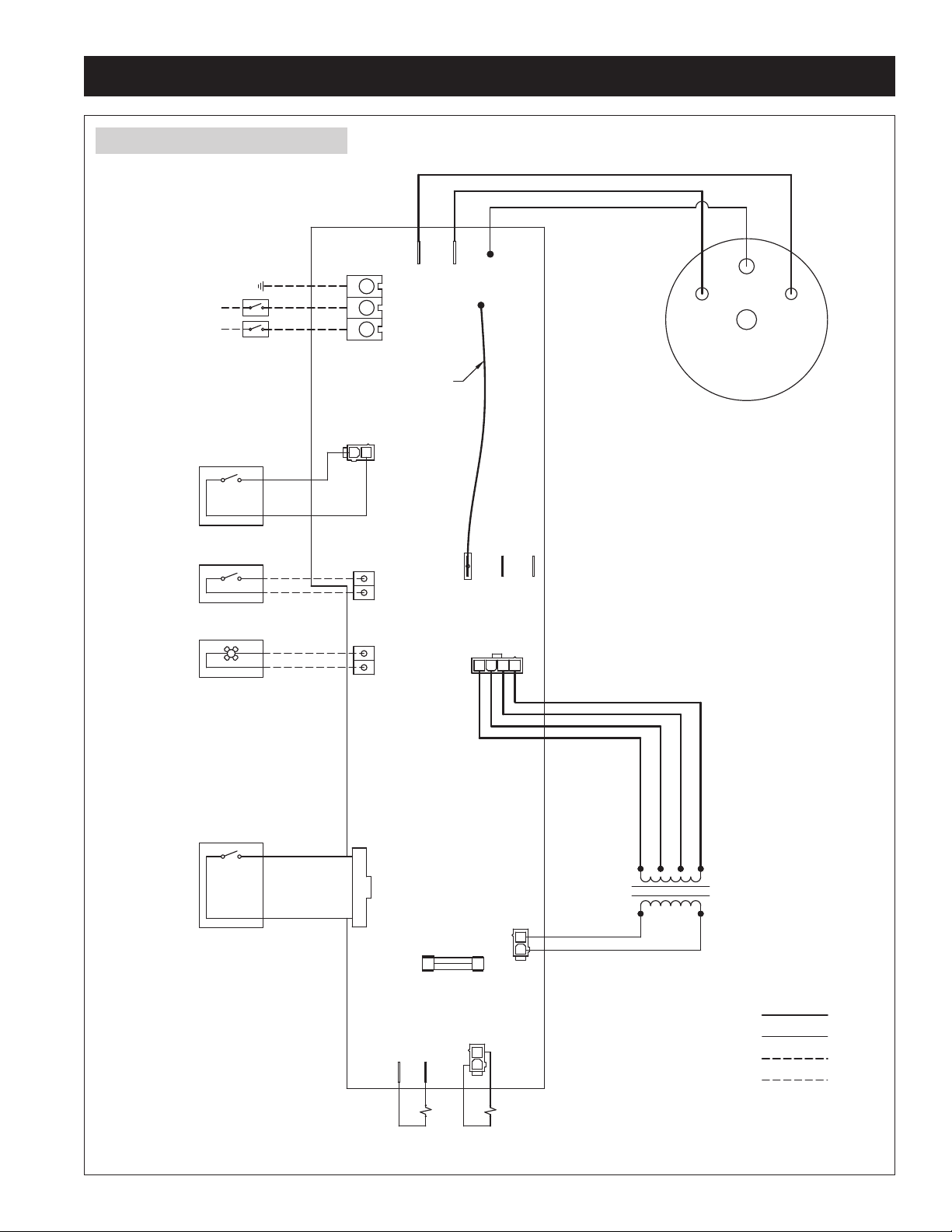

The Steam Humidifier is shipped from the factory wired for 240 VAC operation, but it can operate on 120, 208 or 240 VAC. If using 120V or

208V, move the black/white jumper wire to the proper tab on the control circuit board. See Figures 10, 11, 12.

WIRING INSTRUCTIONS

Install disconnect switch (not provided) between line power source and humidifier.

Knock-outs for power wiring and low voltage control circuit wiring are provided.

Connect power and ground wiring as shown in appropriate wiring diagram.

• 240 VAC – Figure 10

• 208 VAC – Figure 11

• 120 VAC – Figure 12

Do not run high voltage power lines over internal circuit boards.

13

INSTALLATION INSTRUCTIONS (CONTINUED)

FIGURE 9 – Control Circuit Board with Dip Switches

LED D8

Factory setting for

11.5 AMP nominal

operation.

Slide Dip Switch #1

to “ON” position

for 16.0 AMP

nominal operation.

90-1959

14

INSTALLATION INSTRUCTIONS (CONTINUED)

FIGURE 10 – 240 VAC Wiring Diagram

BLK

POWER

MAIN POWER BREAKER

(NOT PROVIDED)

GND

L2 / N

L1

DOOR SWITCH

ORANGE

TERMINAL

BLOCK

TRANSFORMER POWER

P7

J8

JUMPER WIRE

BLK/WHT

J10

BLK

J16

YEL

WATER LEVEL

PROBE

ELECTRODE

STEAM CANISTER

STEAM HUMIDIFIER IS SHIPPED FROM

THE FACTORY WIRED FOR 240 VOLTS.

ELECTRODE

HUMIDITY CONTROL

DRY

CONTACT

DISPLAY PANEL

(PROVIDED)

FAN PACK

(OPTIONAL)

RIBBON CABLE

HUMIDISTAT

1

2

FAN PACK

J2

10

1

J5 J6

J11

120

VAC

SLOW BLOW FUSE

(5X20mm 5A)

CON1

BLK

YEL

J13

208

VAC

ORG

RED

BLK

WHT

P4

J14

240

VAC

P3

TRANSFORMER

BLUE

YEL

HIGH VOLTAGE WIRING

CONTROL CIRCUIT WIRING

HIGH VOLTAGE FIELD WIRING

LOW VOLTAGE FIELD WIRING

90-1903

DRAIN

VALV E

FILL

VALV E

15

INSTALLATION INSTRUCTIONS (CONTINUED)

FIGURE 11 – 208 VAC Wiring Diagram

BLK

BLK

POWER

MAIN POWER BREAKER

(NOT PROVIDED)

GND

L2 / N

L1

DOOR SWITCH

ORANGE

TERMINAL

BLOCK

TRANSFORMER POWER

P7

J8

JUMPER WIRE

J10

BLK/WHT

J16

YEL

WATER LEVEL

PROBE

ELECTRODE

STEAM CANISTER

STEAM HUMIDIFIER IS SHIPPED FROM

THE FACTORY WIRED FOR 240 VOLTS.

MOVE THE JUMPER WIRE TO TERMINAL

J13 TO OPERATE AT 208VAC.

ELECTRODE

HUMIDITY CONTROL

DRY

CONTACT

DISPLAY PANEL

(PROVIDED)

FAN PACK

(OPTIONAL)

RIBBON CABLE

HUMIDISTAT

1

2

FAN PACK

J2

10

1

J5 J6

J11

120

VAC

SLOW BLOW FUSE

(5X20mm 5A)

CON1

BLK

YEL

YEL

J13

208

VAC

VAC

ORG

RED

BLK

WHT

P4

J14

240

P3

TRANSFORMER

BLUE

YEL

HIGH VOLTAGE WIRING

CONTROL CIRCUIT WIRING

HIGH VOLTAGE FIELD WIRING

LOW VOLTAGE FIELD WIRING

16

90-1904

DRAIN

VALV E

FILL

VALV E

INSTALLATION INSTRUCTIONS (CONTINUED)

FIGURE 12 – 120 VAC Wiring Diagram

BLK

BLK

POWER

MAIN POWER BREAKER

(NOT PROVIDED)

GND

L2 / N

L1

DOOR SWITCH

ORANGE

TERMINAL

BLOCK

TRANSFORMER POWER

P7

J8

JUMPER WIRE

BLK/WHT

J10

J16

YEL

WATER LEVEL

PROBE

ELECTRODE

STEAM CANISTER

STEAM HUMIDIFIER IS SHIPPED FROM

THE FACTORY WIRED FOR 240 VOLTS.

MOVE THE JUMPER WIRE TO TERMINAL

J11 TO OPERATE AT 120VAC.

ELECTRODE

HUMIDITY CONTROL

DRY

CONTACT

DISPLAY PANEL

(PROVIDED)

FAN PACK

(OPTIONAL)

RIBBON CABLE

HUMIDISTAT

1

2

FAN PACK

J2

10

1

J5 J6

J11

120

VAC

SLOW BLOW FUSE

(5X20mm 5A)

CON1

BLK

YEL

J13

208

VAC

WHT

P4

J14

240

VAC

P3

ORG

RED

BLK

TRANSFORMER

BLUE

YEL

HIGH VOLTAGE WIRING

CONTROL CIRCUIT WIRING

HIGH VOLTAGE FIELD WIRING

LOW VOLTAGE FIELD WIRING

90-1905

DRAIN

VALV E

FILL

VALV E

17

INSTALLATION INSTRUCTIONS (CONTINUED)

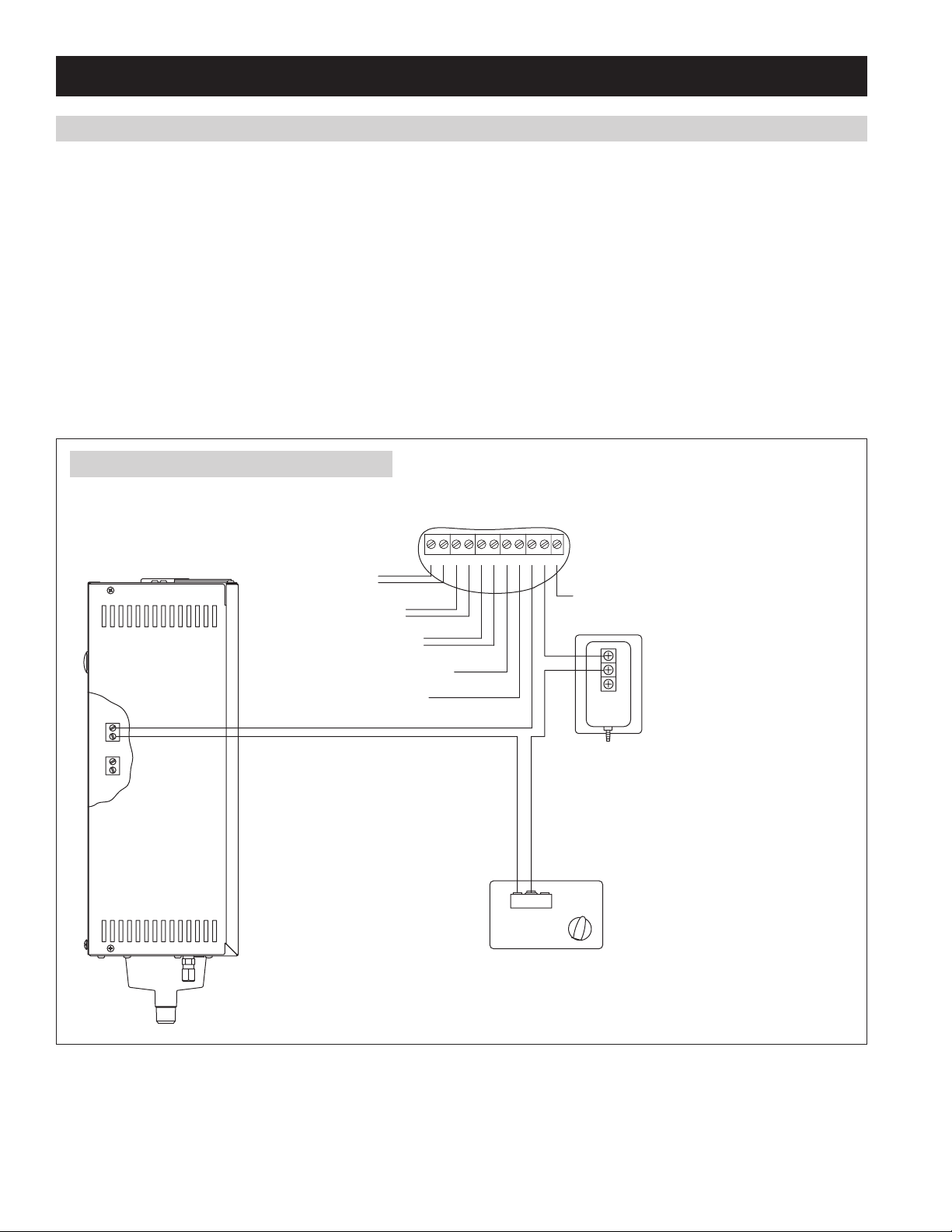

AUTOMATIC DIGITAL CONTROL & ACCESSORY WIRING (MODEL 800)

The control circuit operates on 24VAC.

The ADHC (Automatic Digital Humidifier Control) Model 62 must be mounted in the return air duct at least 6” upstream of any fresh air intake

ducts or sources of moisture and at least 12” upstream of the steam dispersion tube if it is mounted in the return. Follow instructions provided

with the control. Connect “H” terminals on ADHC to “HUMIDISTAT” terminals on humidifier circuit board. The “H” terminals on the Model 62

provide a dry contact switch to energize the humidifier.

If the application requires a wall-mounted humidistat in the conditioned space, use Manual Humidistat Part #4655, Digital Manual Humidistat

Part #65, Automatic Digital Modulating Humidistat Part #63 or any Aprilaire thermostat with integrated humidifier control functionality. Use

Blower Activation Relay Part #4851 with Aprilaire Manual and Digital Manual Humidistats in order to allow the humidifier to turn on the HVAC

system blower when humidity is required.

If protection from over-humidification is desired, install optional high humidity limit switch Part #4594 at least 4 feet downstream of the

dispersion tube. If airflow verification is desired, install optional airflow proving switch Part #4592 in duct. The high humidity limit switch and the

airflow proving switch are wired in series with the ADHC (humidistat) circuit. See Figure 13.

FIGURE 13 – Steam Humidifier Accessory Wiring

MODEL 62 DIGITAL HUMIDIFIER CONTROL

24V TERMINALS

24 VAC from HVAC

HGf RCAB ODT GWH

Equipment “R” & “C”

Communication with

Fan Signal to HVAC Equipment

Aprilaire 8570 Thermostat

Outdoor Temperature Sensor

C

Heat Signal from HVAC Equipment

NO

NC

Fan Signal from Thermostat or

Zone Panel Equipment Terminals

OPTIONAL:

FAN PACK HUMIDISTAT

AIR FLOW PROVING SWITCH #4592

Connect 1/4" plastic tubing from H (High) side

of proving switch to the airflow sensing probe

located 1.5 duct diameters downstream of

blower. Leave L (Low) side open to amosphere.

C

NC

NO

OPTIONAL:

HIGH HUMIDITY LIMIT SWITCH #4594

Switch breaks C to NO connection when

measured RH is above setpoint RH.

90-1544

18

Loading...

Loading...