Page 1

Addendum

Remote Air-Cooled

Condenser

Page 2

Contents

Overview.......................................................................... 1

Save these instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety symbols that may be used in this manual . . . . . . . . . . . 1

Cross-reference symbols used in this manual . . . . . . . . . . . . . 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Inspecting the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Filing a claim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Storing the Equipment Before Installation. . . . . . . . . . . . . . . . . . . . .3

Configuration and Integration........................................ 4

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Piping Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Flooded Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operational Temperature Controls . . . . . . . . . . . . . . . . . . . . 4

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Piping Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Installing the flooded receiver . . . . . . . . . . . . . . . . . . . . . . . 8

Refrigerant Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Recommended line sizes . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Fittings and valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Charging the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Piping Volume. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Piping Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Remote Air Cooled Condenser

i

Page 3

Temperature Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setpoint adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Differential adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjusting the A350A/B . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjusting the S350A/B . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Default jumper settings for “heating”, relay NC . . . . . . . . . . . 16

Adjustments to A350A/B . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Jumper setting: cooling with relay NO . . . . . . . . . . . . . . . . . 18

Jumper set as “cooling”, relay NO . . . . . . . . . . . . . . . . . . . 19

ii

Remote Air Cooled Condenser

Page 4

Overview

Save these instructions

This manual is an addendum to Larkin® installation manuals and contains technical information required

by American Power Conversion (APC

Safety symbols that may be used in this manual

Electrical Hazard: Indicates an electrical hazard, which, if not avoided, could result in

injury or death.

Danger:

substantial damage to product or other property.

Warning: Indicates a hazard, which, if not avoided, could result in personal injury or

damage to product or other property.

Heavy: Indicates a heavy load that should not be lifted without assistance.

Caution: Indicates a potential hazard, which, if not avoided, could result in personal injury

or damage to product or other property.

Tip Haza rd:

moving.

Indicates a hazard, which, if not avoided, could result in severe personal injury or

This equipment is easily tipped. Use extreme caution when unpacking or

®

) systems for proper condenser system installation and operation.

Note: Indicates important information.

Cross-reference symbols used in this manual

Indicates that more information is available on the same subject in a different section of this

manual.

Indicates that more information is available on the same subject in a different manual.

1Remote Air Cooled Condenser

Page 5

Safety

Note: All work should be performed by APC authorized personnel only.

Follow all local and national codes when installing this system.

Only a licensed plumber may connect the water lines.

Warning: A licensed plumber is required to connect all plumbing in compliance with all

local and national codes.

Caution: Keep your hands, clothing, and jewelry away from moving parts.

Check dry cooler fans for foreign objects before starting the unit.

Heavy: This equipment is heavy.

Rigging is required for moving and installing the dry cooler.

When using a forklift to move the pumping system, make sure to lift only from the bottom.

Electrical Hazard:

the equipment to the UPS.

Lock out power when shutting off the system for service.

Only a licensed electrician may connect the equipment to utility power.

Do not wear watches or jewelry when working near energized components.

Only a licensed electrician or APC Field Service Engineer may connect

Remote Air Cooled Condenser2

Page 6

Inspecting the Equipment

Your equipment has been tested and inspected for quality assurance prior to shipment from APC. To

ensure that the equipment has not been damaged during transit, carefully inspect both the exterior and

interior of the equipment immediately upon receipt.

Filing a claim

If damage is identified upon receipt of the equipment, note the damage on the bill of lading and file a

damage claim with the shipping company. Contact APC for information on filing a claim with the

shipping company. The shipping claim must be filed at the receiving end of the delivery.

Note: In case of shipping damage, do not operate the equipment. Keep all packaging for

inspection by the shipper and call APC at one of the numbers listed on the back cover of this

manual.

Storing the Equipment Before Installation

Caution: Leaving the equipment uncovered and exposed to the elements can cause damage

and will void the factory warranty.

3Remote Air Cooled Condenser

Page 7

Configuration and Integration

Introduction

The included electrical data, piping diagram, system installation information, and operational control

settings are required to properly connect and configure the Outdoor Heat Exchanger (OHE) to operate.

Warning: Failure to follow this information may result in poor performance or damage to air

conditioning products and/or the OHE.

Wiring Diagrams

See the wiring diagrams included with the OHE for proper electrical connection and jumper settings

required for each OHE model to operate properly. These wiring diagrams are also available at the Sales

Tool Portal for Wiring Diagrams on the APC web site at http://salestools.apc.com/.

Electrical Connections

See “Electrical Connections” on page 5, for OHE to NetworkAIR User Interface connection.

Electrical Data

See “Electrical Data” on page 6, for power requirements.

Piping Diagrams

See “Piping Diagrams” on page 7, for recommended piping and valve locations connecting the OHE to

the NetworkAIR equipment.

Flooded Receiver

See “System Installation” on page 8, for proper installation of the Flooded Receiver.

System Installation

See “Plumbing” on page 9, for piping sizes, piping insulation, and system charges.

Operational Temperature Controls

See “Temperature Controls” on page 13, for the correct settings used with NetworkAIR products.

Remote Air Cooled Condenser4

Page 8

Electrical Connections

REMOTE AIR COOLED CONDENSER

AFX FM

AFX FM

USER

INTERFACE

5Remote Air Cooled Condenser

Page 9

Electrical Data

Ambient Temperature Electrical Data

Larkin

OHE SKU

ACCD75018 FCB-8 208-230/1/60 AFX018 N/A N/A 3.9 15.0 15.0

ACCD75019 FCB-8 460/1/60 AFX018 N/A N/A 2.4 15.0 15.0

ACCD75028 FCB-14 208-230/1/60 FM35 AFX018 N/A 7.8 15.0 15.0

ACCD75322 FCB-14 460/1/60 FM35 AFX018 NA 4.8 15.0 15.0

ACCD75301 LNH-S01-A007 12FPI 208-230/3/60 AFX018/

ACCD75302 LNH-S01-A007 12FPI 460/3/60 AFX018/

ACCD75303 LNH-S01-A007 12FPI 575/3/60 AFX018/

ACCD75304 LNH-S02-A011 12FPI 208-230/3/60 FM40/50 FM35 AFX018 11.8 20.0 35.0

ACCD75305 LNH-S02-A011 12FPI 460/3/60 FM40/50 FM35 AFX018 5.9 15.0 15.0

ACCD75306 LNH-S02-A011 12FPI 575/3/60 FM40/50 FM35 AFX018 4.5 15.0 15.0

ACCD75307 LNH-S02-A017 12FPI 208-230/3/60 N/A FM40/50 FM35 11.8 20.0 35.0

ACCD75308 LNH-S02-A017 12FPI 460/3/60 N/A FM40/50 FM35 5.9 15.0 15.0

ACCD75309 LNH-S02-A017 12FPI 575/3/60 N/A FM40/50 FM35 4.5 15.0 15.0

ACCD75310 LNH-S03-A026 12FPI 208-230/3/60 N/A N/A FM40/50 18.8 22.8 40.0

ACCD75311 LNH-S03-A026 12FPI 460/3/60 N/A N/A FM40/50 9.4 15.0 20.0

ACCD75312 LNH-S03-A026 12FPI 575/3/60 N/A N/A FM40/50 7.3 15.0 15.0

P/N Voltage

95° F

(35° C)

FM35

FM35

FM35

105° F

(40.5° C)

AFX018 N/A 4.8 15.0 25.0

AFX018 N/A 2.4 15.0 15.0

AFX018 N/A 1.7 15.0 15.0

115° F

(46.1° C) FLA MCA MOP

ACCD75313 LNH-S02-A017 12FPI* 208-230/3/60 AFX065 N/A N/A 11.8 20.0 35.0

ACCD75314 LNH-S02-A017 12FPI* 460/3/60 AFX065 N/A N/A 5.9 15.0 15.0

ACCD75315 LNH-S02-A017 12FPI* 575/3/60 AFX065 N/A N/A 4.5 15.0 15.0

ACCD75316 LNH-S03-A026 12FPI* 208-230/3/60 N/A AFX065 N/A 18.8 22.8 40.0

ACCD75317 LNH-S03-A026 12FPI* 460/3/60 N/A AFX065 N/A 9.4 15.0 20.0

ACCD75318 LNH-S03-A026 12FPI* 575/3/60 N/A AFX065 N/A 7.3 15.0 15.0

ACCD75319 LNH-D06-A044* 208-230/3/60 N/A N/A AFX065 37.6 43.8 60.0

ACCD75320 LNH-D06-A044* 460/3/60 N/A N/A AFX065 18.8 21.9 30.0

ACCD75321 LNH-D06-A044* 575/3/60 N/A N/A AFX065 14.6 20.0 25.0

Note:* Dual circuited

FLA = Full Load Amps

MCA = Minimum Circuit Ampacity

MOP = Maximum Overcurrent Protection

Remote Air Cooled Condenser6

Page 10

Piping Diagrams

Head pressure control valve**

Flooded receiver**

Condenser

Inverted “P” trap

“S” trap

Note:*Items supplied by other

**Optional

Module

“P” trap

Pitch in direction of refrigerant flow, 1/2 in.

per 10 ft (4 mm per meter).

Control OHE interlock

7Remote Air Cooled Condenser

Page 11

System Installation

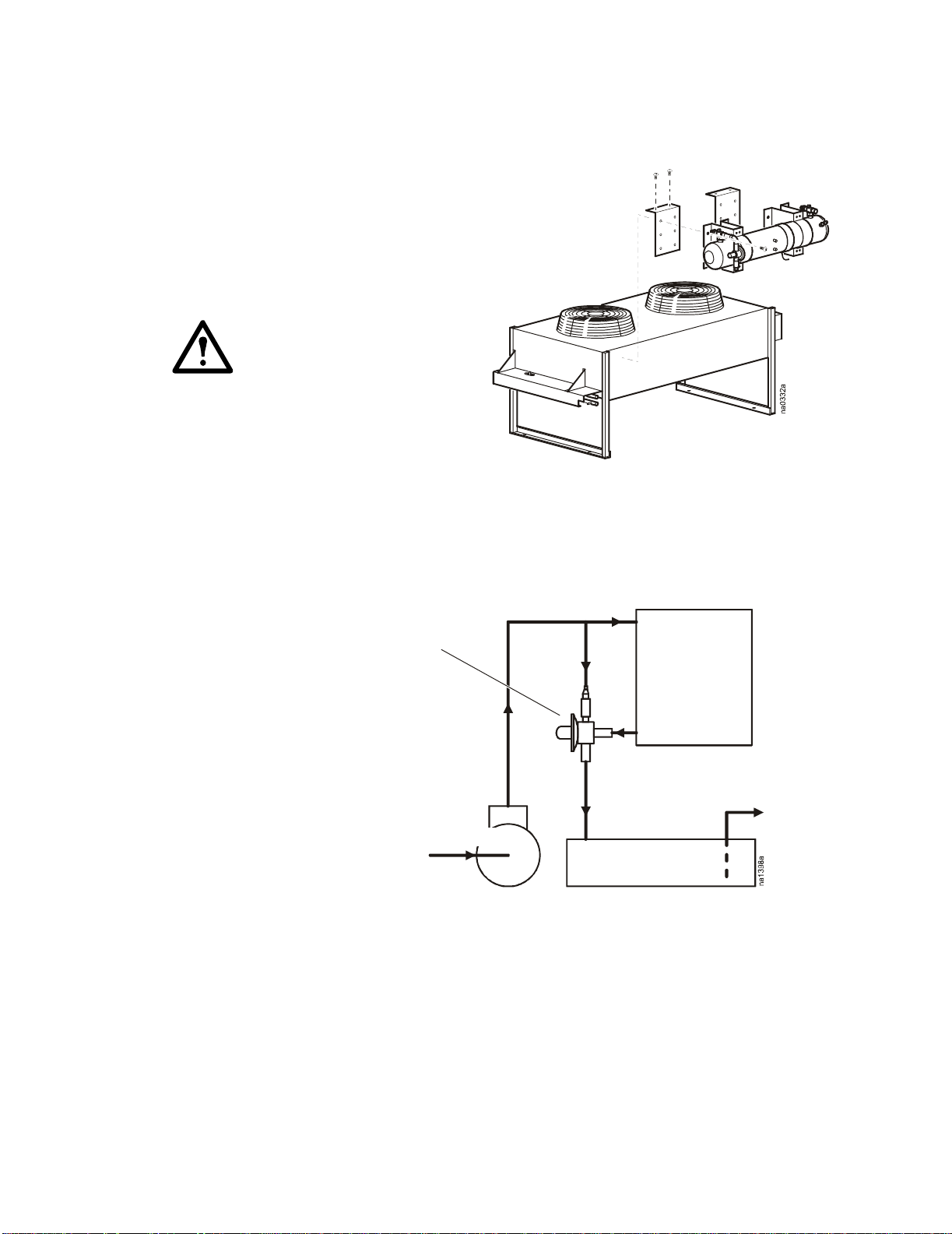

Installing the flooded receiver

Attach the flooded receiver to the side of the heat

exchanger.

1. Position the mounting brackets on the

desired side of the heat exchanger. Mount

each bracket to the heat exchanger using

two screws for each bracket, and using the

top holes in each bracket for placement.

Caution: Be careful to select a

mounting location that will

avoid hot gas inlet and liquid

outlet lines in the condenser.

2. Using the holes provided on the vertical

side of the mounting brackets as a

template, drill 3/16 in (5mm) pilot holes

for each remaining mounting hole (six per mounting bracket).

3. Attach the flooded receiver to the side of the heat exchanger, aligning the twelve holes of the

flooded receiver mounts to the corresponding holes in the mounting brackets, using twelve selftapping screws (provided).

tem Installation

4. Connect the flooded receiver as shown (all piping is field-supplied).

HEAD PRESSURE CONTROL

VALVE (MODEL OKEY)

CONDENSER

COMPRESSOR

FLOODED RECEIVER

Remote Air Cooled Condenser8

Page 12

Refrigerant Piping

Recommended line sizes

See the NetworkAIR FM Installation Manual for detailed installation information.

Equivalent

Length ft

(meters) Line type FM35 FM40 FM50

50 (15.25) Discharge line (horizontal) 1 1/8 1 1/8 1 3/8 7/8 1 3/8

Discharge line (vertical) 7/8 7/8 1 1/8 7/8 1 3/8

Liquid line 7/8 7/8 7/8 3/8 7/8

Flooded condenser to receiver 1 1/8 1 1/8 1 1/8 1 1/8 1 1/8

100 (31) Discharge line (horizontal) 1 1/8 1 3/8 1 3/8 7/8 1 3/8

Discharge line (vertical) 7/8 7/8 1 1/8 7/8 1 3/8

Liquid line 7/8 7/8 7/8 3/8 7/8

Flooded condenser to receiver 1 1/8 1 1/8 1 1/8 1 1/8 1 1/8

150 (46) Discharge line (horizontal) 1 1/8 1 3/8 1 5/8 1 1/8 1 5/8

Discharge line (vertical) 7/8 7/8 1 1/8 1 1/8 1 5/8

AFX

018

AFX

065

Liquid line 7/8 7/8 1 1/8 5/8 1 1/8

Flooded condenser to receiver 1 1/8 1 1/8 1 1/8 1 1/8 1 1/8

200 (61) Discharge line (horizontal) 1 1/8 1 3/8 1 5/8 1 1/8 1 5/8

Discharge line (vertical) 7/8 7/8 1 1/8 1 1/8 1 5/8

Liquid line 7/8 7/8 1 1/8 5/8 1 1/8

Flooded condenser to receiver 1 1/8 1 1/8 1 1/8 1 1/8 1 1/8

Follow ASHRAE and ARI guidelines for velocity and pressure drop in refrigerant piping design.

Vertical discharge lines shall have a loop down to the floor or a trap at a minimum of one (1) per vertical

run closest to the compressor, and additional traps at approximately every 20 feet to pr event oil return to

the compressor discharge.

T otal pressure drop in the gas and liqui d lines should not exceed 6 PSID for the AFX and FM series. The

installing contractor should verify their pressure drop based on type of pipe and fittings used. All piping

should be as clean as new, with a flush procedure and cleanliness testing for piping prior to being put into

service. In addition, pressure test lines with an inert gas (nitrogen) for leakage, prior to charging with

refrigerant.

Install piping in accordance with ASHRAE, ARI, and local and national codes. Piping shall be properly

supported throughout its entire length, with provisions for expansions due to temperature changes.

Insulate hot gas discharge sections and liquid return lines to prevent early condensation, maintain

required degrees of sub-cooling, and safeguard against personnel hazard from contact. All horizontal gas

discharge runs of piping should slope/pitch down and in the direction of flow away from the

compresor(s) at 1 inch over 10 feet. Return liquid lines should slope/pitch down and in the direction of

flow toward the compressor(s) at 1 inch over 10 feet.

9Remote Air Cooled Condenser

Page 13

Fittings and valves

See the NetworkAIR FM Installation Manual for detailed installation information.

ASHRAE refrigerant equivalent lengths for fittings and valve standards

Nominal Size

of Pipe (in

inches) Gate Valve

1/2 0.7 1.6 1.6 3.0 7.0

3/4 0.9 2.0 2.0 4.0 9.0

1 1.0 2.6 2.6 5.0 12.0

1 1/4 1.5 3.3 3.3 7.0 15.0

1 1/2 1.8 4.0 4.0 8.0 18.0

2 2.3 5.0 5.0 10.0 24.0

2 1/2 2.8 6.0 6 .0 12.0 29.0

3 3.2 7.5 7.5 15.0 35.0

Type of Fitting or Valve - Equivalent Length of Pipe in Feet

Std Elbow 90°

Reduced

Coupling

Side Outlet

“T” Angle Valve

Remote Air Cooled Condenser10

Page 14

Charging the system

35° C (95° F) Ambient Condenser Flooded Recievers

APC SKU Larkin Model

Charge needed

for Larkin

Condensers

filled 100% in

kg (lbs)

System charge -

CRAC Unit

Charge + Larkin

condenser

summer charge +

Liquid line

charge between

CRAC unit and

condenser +

optional flooded

receiver

Optional

Flooded

Charge

Receiver

Dimensions

Larkin

Condenser

Summer Charge

in kg (lbs)

ACCD75018

& 019

ACCD75028

& 322

ACCD75301,

302, & 303

ACCD75304,

305, & 306

ACCD75313,

314, & 315

* Dual Circuit = values shown are per circuit

NOTE: Two flooded receivers are needed for dual circuited condensers (one per circuit)

FCB-8 12.9 (28.3) 3.2 (9.5) 11.6 (25.5) 14 (31)

FCB-14 19.1 (42.0) 5.7 (12.5) 17.2 (37.8) 28 (62)

LNH-S01-A007

12FPI

LNH-S02-A011

12FPI

LNH-S02-A017

12FPI *

11.4 (25.0) 3.7 (8.0) 10.3 (22.5) 14 (31)

14.6 (32.0) 4.6 (10.0) 13.1 (28.8) 18 (39)

21.9 (48.0) 6.9 (15.0) 19.7 (43.2) 28 (62)

Flooded

Receiver

Options in

kg (lbs)

Weight - kg (lbs)

Diameter - mm

(in)

Length - mm (in)

152 (6)

914 (36)

219 (8 5/8)

914 (36)

152 (6)

914 (36)

168 (6 5/8)

965 (38)

219 (8 5/8)

914 (36)

11Remote Air Cooled Condenser

Page 15

40.5° C (105° F) Ambient Condenser Flooded Receivers

APC SKU Larkin Model

Charge needed

for Larkin

Condensers

filled 100% in

kg (lbs)

System charge -

CRAC Unit

Charge + Larkin

condenser

summer charge +

Liquid line

charge between

CRAC unit and

condenser +

optional flooded

receiver

Optional

Flooded

Charge

Receiver

Dimensions

Larkin

Condenser

Summer Charge

in kg (lbs)

ACCD75028

& 322

ACCD75301,

302, & 303

ACCD75304,

305, & 306

ACCD75307,

308, & 309

ACCD75316,

317, & 318

* Dual Circuit = values shown are per circuit

NOTE: Two flooded receivers are needed for dual circuited condensers (one per circuit)

FCB-14 19.1 (42.0) 12.5 (5.7) 17.2 (37.8) 28 (62)

LNH-S01-A007

12FPI

LNH-S02-A011

12FPI

LNH-S02-A017

12FPI

LNH-S02-A026

12FPI *

11.4 (25.0) 3.7 (8.0) 10.3 (22.5) 14 (31)

14.6 (32.0) 4.6 (10.0) 13.1 (28.8) 18 (39)

44.1 (97.0) 13.2 (29.0) 39.7 (87.3) 48 (106)

21.9 (48.0) 6.9 (15.0) 19.7 (43.2) 28 (62)

Flooded

Receiver

Options in

kg (lbs)

Weight - kg (lbs)

Diameter - mm

(in)

Length - mm (in)

219 (8 5/8)

914 (36)

152 (6)

914 (36)

168 (6 5/8)

965 (38)

219 (8 5/8)

1524 (60)

219 (8 5/8)

914 (36)

Remote Air Cooled Condenser12

Page 16

Piping Volume

Overall System Charge = CRAC Unit Charge* + Larkin Condenser Summer Charge +

Liquid line charge between CRAC unit and Condenser + Optional Flooded Charge.

Density of liquid R22 @ 105°F 260 psig = 70.3 lb/ft3 (40.5°C 1793 kPa = 95 N m)

Inside diameter for 7/8 in (22 mm) OD ACR copper tube is 0.785 in (20 mm)

Cross sectional area for 0.785 in (20 mm) ID pipe is 0.00336 ft

R22 in liquid line = area × Length in ft × density = 0.00336 ft

(312 mm

Liquid line charge for 7/8 in (22 mm) OD ACR copper tube is 2.36 lbs/10 ft R22

(1 kg/3 m)

2

× L m × 1126 kg/m3)

2

(312 mm2)

2

× L ft × 70.3 lb/ft3

Inside diameter for 1 1/8 in (28.6 mm) OD ACR copper tube is 1.025 in (26 mm)

Cross Sectional Area for 1.025 (26 mm) ID pipe is 0.00573 ft

R22 in Liquid line = area × Length in ft × density = 0.00573 ft

(532 mm2 × L ft × 1126 kg/m3)

Liquid line charge for 1 1/8 in (28.6 mm) OD ACR copper tube is 4.03 lbs/10 ft R22

(1.8 kg/3 m)

Note:*FM35 charge = 11.3 kg (25 lbs)

*FM50 charge = 1 1 .3 kg (25 lbs)

*AFX 018 charge = 6 kg (13 lbs)

*AFX 065 charge = 20 kg (44 lbs)

2

(532 mm2)

2

× L ft × 70.3 lb/ft

3

Piping Insulation

See “Piping Diagrams” on page 7 for details and locations of recommended valves.

To prevent condensation on piping, proper pipe insulation must be practiced. Insulate all piping that is

exposed to sunlight

Temperature Controls

Operation

The OHEs use A350A/B and S350A/B temperature controllers to regulate fan operation. These

controllers operate on 24 VAC, and each provides an SPDT relay output. Each controller has a front

panel LED that indicates when the relay is energized.

Adjustable features include:

• setpoint

• differential

• heating/cooling jumpers

Note: All System 350 controls are designed for use ONLY as operating controls.

Where an operating control failure would result in personal injury or loss of property , it

is the responsibility of the installer to add devices (safety, limit controls) that protect

against, or systems (alarm, supervisory systems) that warn of, control failure.

13Remote Air Cooled Condenser

Page 17

Setpoint adjustment

Setpoint adjustment is defined as the temperature at which the relay de-energizes. Use the setpoint dial

on the front of the controller to adjust the setpoint.

Differential adjustment

Differential adjustment is defined as the change in sensor temperature between energizing and deenergizing the relay. Use the potentiometer marked “DIFF” to adjust the temperature differential.

A350A/B Board Layout and Terminal

Locations

Setpoint Dial

24V

COM

VDC

SEN

DIFF

(Differential

Potentiometer)

Relay LED

Indicator

Cover

screw

NC

Relay

COM NO

Adjusting the A350A/B

Set the A350A/B for the desired operation:

1. Remove the A350A/B cover by loosening the four cover screws.

Module

Connector

Jumper

Block

Heat

Cool

Potentiometer

Module

Connector

Relay LED

Indicator

Cover

screw

S350A/B Board Layout and Terminal

Locations

Offset

NC

COM

DIFF (Differential

Relay

NO

Potentiometer)

Module

Connector

Heat

Cool

Jumper

Block

2. Set the heating/cooling jumper blocks to the desired mode of operation. Position the jumper

blocks vertically for heating or horizontal for cooling.

Note: Verify that the heating/cooling jumper blocks are in the proper position before

powering the System A350A/B modules. If the jumper blocks on the control or

staging modules are installed in the wrong position, the device will activate the relay

in response to the opposite signal. The heating or cooling equipment will remain

energized until the error is corrected.

Electrical Hazard:

Disconnect power to avoid possible electrical shock or

equipment damage. More than one disconnect may be required to completely deenergize the equipment.

Note: Make all wiring connections in accordance with all national and local codes.

Use copper conductors only. Do not exceed electrical ratings.

3.Adjust the differential potentiometer (DIFF) on the A350 to 3°F.

4. Replace the cover, and secure in place with the four captive screws. Move the setpoint dial to the

desired position.

Remote Air Cooled Condenser14

Page 18

Adjusting the S350A/B

Refer to the following steps for adjusting stage module settings.

Electrical Hazard:

Disconnect power supply to avoid possible electrical shock or

equipment damage. More than one disconnect may be required to completely de-energize

equipment.

1. Ensure all power to system is off. Each stage module may be receiving power from separate

sources. Make sure all power sources to each stage module are off.

2. Remove the stage module cover by loosening the four captive cover screws.

3. Set the heating/cooling jumper blocks to the desired mode of operation. Position the jumper

blocks vertically for heating or horizontal for cooling.

4. Adjust the differential using the potentiometer marked DIFF to the desired setting (the difference

in degrees [3°F] between energizing and de-energizing the stage module relay).

5. Use the potentiometer marked OFFSET to adjust the offset to the number of degrees from the

System 350 control setpoint at which the stage relay de-energizes.

6. Replace the cover on the stage module and fasten it in place with screws.

7. Restore power to system.

15Remote Air Cooled Condenser

Page 19

Default jumper settings for “heating”, relay NC

Fan

Mode

Heating NC to C Below

Heating NC to C Above

Connection

LNH 1140 rpm Larkin

Model

FM35 LNH-S01-A007 12FPI 1 × 1 x x x

FM40 LNH-S02-A011 12FPI 1 × 2 87 x x

Condensers

LNH-S01-A011 12FPI 1 × 2 90 x x

LNH-S02-A017 12FPI 1 × 2 100 x x

LNH-S02-A017 12FPI 1 × 2 95 x x

LNH-S02-A026 12FPI 1 × 3 110 12 x

Sensor

Reading Relay

Energized OFF Will drive

Setpoint

De-energized ON

Setpoint

Fan Config.

1×N or 2×N

Fan

Status

A350 Set

Point

S1 ºC (°F)

Standard

Operation

head pressure

toward

setpoint.

**

S350

OFFSET S2

(°F)

Control

Failure

May drive

head

pressure

below

desired

level.

OFFSET S3

S350

(°F)

**

FM50 LNH-S02-A011 12FPI 1 × 2 77 x x

LNH-S02-A017 12FPI 1 × 2 90 x x

LNH-S02-A026 12FPI 1 × 3 100 10 x

LNH-S01-A007 12FPI 1 × 1 x x x

AFX018

AFX065

Note:** Larkin wires A350A/B and S350A/B as NC, jumper positions in A350A/B and S350A/B as

LNH-S01-A007 12FPI 1 × 1 x x x

LNH-S02-A011 12FPI 1 × 2 95 x x

LNH-S02-A017 12FPI 1 × 2 70 x x

LNH-S03-A026 12FPI 1 × 3 96 20 x

LNH-D06-A044 2 × 3 100 10 x

heating.

Remote Air Cooled Condenser16

Page 20

Example of operation using an FM50 and LNH-S03A026 condenser:

The condenser has three fans. The first fan is located

closest to the header, is controlled by a P66 electronic

speed control, and is not discussed here. The second

fan (stage 1) is controlled by an A350A temperature

control module and the third fan (stage 2) is

controlled by an S350A temperature stag e mod ule .

Settings are as follows:

• A350A and S350A differential is 3°.

• A350A setpoint is 100°F ambient.

• S350A offset is 10°.

When the ambient temperature is above 90°F (100º

A350A setpoint minus 10º offset), the S350A is

deenergized and the third fan (stage 2) will run

(remember that the normally closed contacts are in

use).

When the ambient temperature falls below 87°F (90º

minus 3º S350A differential), the S350A is energized

and the third fan (stage 2) will stop (the stage 1 fan is still running).

When the ambient temperature goes above 100°F (A350A setpoint) the S350A is de-energized. The

stage 3 fan runs (the stage 1 and 2 fans remain running).

Note: In the case of A350A or S350 failure, the controls fail closed. The fan or fans will run

continuously. This may cause head pressure lower than required or wanted, but the fans will

stay on.

Adjustments to A350A/B

Electrical Hazard: Disconnect power supply to avoid possible electrical shock or

equipment damage. More than one disconnect may be required to completely de-energize

equipment.

1. Remove the stage module cover by loosening the four cover screws.

2. Using the potentiometer on the right, adjust the differential to 3°F.

3. Using the potentiometer on the left, adjust the offset to the desired setting (the difference in

degrees).

4. Replace the cover, fasten in place with screws, and restore power to the system.

17Remote Air Cooled Condenser

Page 21

Jumper setting: cooling with relay NO

Fan

Mode

Cooling NO to C Below

Cooling NO to C Above

Connection

Sensor

Reading Relay

De-energized OFF Will drive

Setpoint

Energized ON

Setpoint

Example of operation using an FM50 and LNH-S03A026 condenser:

The condenser has three fans. The first fan is located

closest to the header, is controlled by a P66 electronic

speed control, and is not discussed here. The second

fan (stage 1) is controlled by an A350A/B

temperature control module and the third fan (stage

2) is controlled by an S350A/B temperature stage

module.

Settings are as follows:

• A350A/B and S350A/B differential is 3°.

• A350A/B setpoint is 87°F ambient.

Fan

Status

Standard

Operation

head pressure

toward

setpoint.

Control

Failure

Unit will

trip on high

pressure

switch.

• S350A/B offset is 10°.

When the ambient temperature is above 90°F

(A350A/B setpoint plus 3º differential), the A350A/B

is energized, and the second fan (stage 1) will run

(remember that the normally open contacts are in

use).

When the ambient temperature is above 100° F

(A350A/B setpoint plus 10º offset, plus 3º S350A/B dif ferential), the S350A/B is ener gized and the third

fan (stage 2) will run (the stage 1 fan is still running at this temperature).

When the ambient temperature falls below 97°F (A350A/B setpoint plus 10° offset) the S350A/B is

de-energized. The stage 2 fan will stop, but the stage 1 fan remains running.

When the ambient temperature falls below 87°F (A350A/B setpoint), the A350A/B is de-energized and

the stage 1 fan will stop.

Note: In the case of a A350A/B and /or S350 failure, the controls fail open. Fan or fans will

stop, causing the computer room air conditioner (CRAC) to go high head pressure. The high

pressure cut switch in the CRAC will stop the compressors.

Remote Air Cooled Condenser18

Page 22

Jumper set as “cooling”, relay NO

A350 Set

Fan Config. 1

Model Condenser Model

LNH-S01-A007 12FPI 1 × 1 x x x

FM35

FM40

FM50

AFX018

AFX065

**

Larkin wires A350A/B and S350A/B as NO, jumper positions in A350A/B and S350A/B as cooling.

LNH-S01-A011 12FPI 1 × 2 87 x x

LNH-S01-A017 12FPH 1 × 2 97 x x

LNH-S02-A011 12FPI 1 × 2 84 x x

LNH-S02-A017 12FPI 1 × 2 92 x x

LNH-S03-A026 12FPI 1 × 3 95 12 x

LNH-S02-A011 12FPI 1 × 2 74 x x

LNH-S02-AP17 12FPI 1 × 2 87 x x

LNH-S03-A026 12FPI 1 × 3 87 10 x

LNH-S01-A007 12FPI 1 × 1 x x x

LNH-S01-A007 12FPI 1 × 1 x x x

LNH-S01-A011 12FPI 1 × 2 92 x x

LNH-S02-A017 12FPI 1 × 2 67 x x

LNH-S03-A026 12FPI 1 × 3 72 20 x

LNH-D06-A044 2 × 3 87 10 x

× N

Point

S1 (°F)

**

S350

OFFSET

S2 (°F)

OFFSET S3

S350

(°F)

**

Electrical Hazard: Ensure all power is off. It may be necessary to perform more than one

disconnect to de-energize the system.

1. Remove the stage module cover by loosening the four cover screws.

2. Using the potentiometer on the right, adjust the differential to 3°F.

3. Using the potentiometer on the left, adjust the offset to the desired setting (the difference in

degrees).

4. Replace the cover, fasten in place with screws, and restore power to the system.

19Remote Air Cooled Condenser

Page 23

APC Worldwide Customer Support

Customer support for this or any other APC product is available at no charge in any of the following ways:

• Visit the APC Web site to access documents in the APC Knowledge Base and to submit customer

support requests.

– www.apc.com (Corporate Headquarters)

Connect to localized APC Web sites for specific countries, each of which provides customer support

information.

– www.apc.com/support/

Global support searching APC Knowledge Base and using e-support.

• Contact an APC Customer Support center by telephone or e-mail.

– Regional centers

Direct InfraStruXure

Customer Support Line

APC headquarters U.S.,

Canada

Latin America

Europe, Middle East,

Africa

Japan

Australia, New Zealand,

South Pacific area

(1)(877)537-0607

(toll free)

(1)(800)800-4272

(toll free)

(1)(401)789-5735

(USA)

(353)(91)702000

(Ireland)

(0) 35434-2021

(61) (2) 9955 9366

(Australia)

– Local, country-specific centers: go to www.apc.com/support/contact for contact information.

Contact the

APC representative or other distributor from whom you purchased your APC product for

information on how to obtain local customer support.

Entire contents copyright 2006 American Power Conversion Corporation. All rights reserved. Reproduction

in whole or in part without permission is prohibited. APC, the APC logo, NetworkAIR, and InfraStruXure

are trademarks of American Power Conversion Corporation. All other trademarks, product names, and

corporate names are the property of their respective owners and are used for informational purposes only.

10/2006990-1904

*990-1904*

Loading...

Loading...