Page 1

Operation

InRow® SC

ACSC100

ACSC101

Page 2

This manual is available in English on the enclosed CD.

Dieses Handbuch ist in Deutsch auf der beiliegenden CD-ROM verfügbar.

Deze handleiding staat in het Nederlands op de bijgevoegde cd.

Este manual está disponible en español en el CD-ROM adjunto.

Ce manuel est disponible en français sur le CD-ROM ci-inclus.

Questo manuale è disponibile in italiano nel CD-ROM allegato.

本マニュアルの日本語版は同梱の CD-ROM からご覧になれます。

Instrukcja Obs

O manual em Português está disponível no CD-ROM em anexo.

Данное руководство на русском языке имеется на прилагаемом компакт-диске.

您可以从包含的 CD 上获得本手册的中文版本。

您可以从付属的CD上获得本手册的中文版本。

ługi w jezyku polskim jest dostepna na CD.

동봉된 CD 안에 한국어 매뉴얼이 있습니다 .

Page 3

Contents

General Information........................................................ 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Commissioning ............................................................... 3

Inspection Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Initial inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mechanical inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . . . 4

User interface inspection checklist . . . . . . . . . . . . . . . . . . . . . . . 5

Start-up inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Final inspection checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation ......................................................................... 6

Display Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Using the Display Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Scrolling status screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Main menu screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Navigating the main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Navigating the sub-menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using the Path statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Password entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Start the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Stop the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cooling Group Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Configure the cooling group . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Identify the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Configure Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

InRow SC Operation

i

Page 4

Control the Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Run hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Service intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Display Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Password & time-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Override the password time-out and

require password entry immediately.

Date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Configure display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Display units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

. . . . . . . . . . . . . . . . . . . . .18

Network Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

View Status Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Scrolling status screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Cooling unit status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Cooling group status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

About the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Respond to Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

View alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Clear active alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Alarm messages and suggested actions . . . . . . . . . . . . . . . . . .24

Network Management Card .......................................... 27

Quick Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

TCP/IP configuration methods . . . . . . . . . . . . . . . . . . . . . . . . . .27

APC Device IP Configuration Wizard . . . . . . . . . . . . . . . . . . . . .28

.ini file utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

BOOTP & DHCP configuration . . . . . . . . . . . . . . . . . . . . . . . . . .28

Local access to the control console . . . . . . . . . . . . . . . . . . . . . .30

Remote access to the control console . . . . . . . . . . . . . . . . . . . .30

Control console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

ii

InRow SC Operation

Page 5

Access a Configured Network Management Card . . . . . . . . . . . . . .32

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Web interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Telnet and SSH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Simple Network Management Protocol (SNMP) . . . . . . . . . . . . . 34

FTP/SCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Recover From a Lost Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Maintenance...................................................................36

Monthly Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Quarterly Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . .38

Semi-Annual Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . .39

Troubleshooting ............................................................40

Warranty .........................................................................42

InRow SC Operation

iii

Page 6

American Power Conversion Legal Disclaimer

The information presented in this manual is not warranted by the American Power Conversion Corporation to

be authoritative, error free, or complete. This publication is not meant to be a substitute for a detailed

operational and site specific development plan. Therefore, American Power Conversion Corporation assumes

no liability for damages, violations of codes, improper installation, system failures, or any other problems that

could arise based on the use of this Publication.

The information contained in this Publication is provided as is and has been prepared solely for the purpose of

evaluating data center design and construction. This Publication has been compiled in good faith by American

Power Conversion Corporation. However, no representation is made or warranty given, either express or

implied, as to the completeness or accuracy of the information this Publication contains.

IN NO EVENT SHALL AMERICAN POWER CONVERSION CORPORATION BE LIABLE FOR

ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL, OR INCIDENTAL

DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS,

CONTRACT, REVENUE, DATA, INFORMATION, OR BUSINESS INTERRUPTION) RESULTING

FROM, ARISING OUT, OR IN CONNECTION WITH THE USE OF, OR INABILITY TO USE THIS

PUBLICATION OR THE CONTENT, EVEN IF AMERICAN POWER CONVERSION

CORPORATION HAS BEEN EXPRESSLY ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. AMERICAN POWER CONVERSION CORPORATION RESERVES THE RIGHT TO

MAKE CHANGES OR UPDATES WITH RESPECT TO OR IN THE CONTENT OF THE

PUBLICATION OR THE FORMAT THEREOF AT ANY TIME WITHOUT NOTICE.

Copyright, intellectual, and all other proprietary rights in the content (including but not limited to software,

audio, video, text, and photographs) rests with American Power Conversion Corporation or its licensors. All

rights in the content not expressly granted herein are reserved. No rights of any kind are licensed or assigned or

shall otherwise pass to persons accessing this information.

iv

InRow SC Operation

Page 7

General Information

Overview

Note the definitions for the icons here and be observant for them throughout this manual. They are

intended to call attention to potential hazards and important information.

Symbols used in this manual

Electrical Hazard: Indicates an electrical hazard which, if not avoided, could result in

injury or death.

Danger:

death.

Warning: Indicates a hazard which, if not avoided, could result in personal injury or

damage to product or other property.

Heavy: Indicates a heavy load that should not be lifted without assistance.

Caution: Indicates a potential hazard which, if not avoided, could result in damage to the

equipment or other property.

Tip Hazard:

moving.

Note: Indicates important information.

Indicates that more information is available on the same subject.

Indicates a hazard which, if not avoided, could result in severe personal injury or

This equipment is easily tipped. Use extreme caution when unpacking or

Cross-reference symbol used in this manual

See another section of this document or another document for more information on this

subject.

1InRow SC Operation

Page 8

Safety

Read and adhere to the following important safety considerations when working with this cooling unit.

®

Note: All work must be performed by American Power Conversion (APC

personnel only.

Caution: Keep your hands, clothing, and jewelry away from moving parts. Check the

equipment for foreign objects before closing the doors and starting the equipment.

Heavy: The equipment is heavy. For safety purposes, at least two people must be present

when moving this equipment.

Tip Hazard: This equipment has a high center-of-gravity. Use extreme caution when

moving.

) authorized

Electrical Hazard:

Warning: Before performing any service, properly de-energize and remove access to

the equipment (Lockout). Physically label the equipment as intentionally out of service

(Tagout).

Do not wear jewelry when working near energized components.

InRow SC Operation2

Page 9

Commissioning

Warning: APC authorized personnel must perform the following procedures.

Electrical Hazard: Perform Lockout/Tagout procedures on the cooling unit before

servicing the cooling unit. Failure to remove power before servicing this equipment could

result in serious injury or death.

After installation is complete, verify that all components are working properly and that the cooling unit

is ready to begin operation.

Inspection Checklists

Initial inspection checklist

The initial inspection ensures that the cooling unit has been properly installed, the location of the cooling

unit has been properly prepared, and the cooling unit is free of damage.

Warning: The cooling unit operates under pressure. Take proper safety precautions

when connecting gauges or servicing piping.

Warning: Do not operate the cooling unit with any cover, guard, door, or panel removed

unless the instructions indicate otherwise. Then, proceed with extreme caution.

Warning: Do not run service utilities in front of the fan outlets.

unit is required for service access. To roll the cooling unit out of the row, there must be a

minimum of 1200 mm (48 in) of clear floor space in front of or behind the cooling unit.

Out-of-row service requires 760 mm (30 in) of side clearance in addition to the front and rear

clearance.

Ensure that:

The installation procedure is complete according to the installation manual.

The walls, floor, and ceiling of the room where the cooling unit is located are sealed with a vapor barrier.

There is no evidence of damage to the cooling unit.

The cooling unit is level and joined to the adjacent racks or secured to the floor.

The clearance around the cooling unit is in accordance with local and national codes and regulations as

well as the installation manual.

Caution: The vapor barrier minimizes moisture infiltration. Without a vapor barrier, it will

be difficult to maintain the humidity in the room.

Caution: Do not introduce unconditioned outside air into the space.

Note: A minimum of 900 mm (36 in) of clear floor space in front of and behind the cooling

3InRow SC Operation

Page 10

Electrical inspection checklist

The electrical inspection verifies that all electrical connections are secure and correct and that the

cooling unit is properly grounded.

Electrical Hazard: All electrical wiring must comply with local and national codes and

regulations.

Electrical Hazard: The equipment must be grounded (do not use a water-pipe ground).

Ensure that the:

Incoming voltages match the phase and voltage listed on the nameplate.

Electrical wiring complies with local and national codes and regulations.

Cooling unit is properly grounded.

Electrical connections are tight, including contactors, terminal blocks, controllers, switches, relays,

auxiliary devices, and field connections.

Mechanical inspection checklist

The mechanical inspection verifies that all mechanical components and connections are secure and tight

and ready for start-up and system charging. The inspection ensures that field piping is properly installed

to promote oil return to the compressor.

Caution: Improperly installed piping may result in improper operation and possible damage

to the cooling unit or surrounding equipment.

Ensure that the:

Fans are turning freely and that the blades are not distorted or bent.

Condensate drain line is at least the size of the drain connection.

Mechanical connections are tight, including compressor and receiver connections.

Ceiling tile adapter is secured to the building structure with properly-sized safety wire.

Covers and guards are in place.

InRow SC Operation4

Page 11

User interface inspection checklist

The user interface inspection verifies that the sensors and internal communications links of the cooling

unit are installed properly.

Ensure that:

An A-Link bus is connected to each cooling unit in the group and a terminator is plugged into all unused

A-Link connectors.

The input contacts and output relays are connected correctly.

The building management system (if used) is connected correctly.

The temperature sensor is properly routed and mounted on the front (entering air side) of the enclosure

immediately to the left or right of the equipment (if InRow or RACS operating mode will be selected).

The network port is connected correctly and an IP address has been assigned to the equipment.

Start-up inspection checklist

The start-up inspection ensures that the cooling unit is operating properly after the initial start-up. This

inspection verifies that all modes of operation are working correctly and that the cooling unit is ready for

normal operation.

While the cooling unit is operating, ensure that the:

Cooling unit is free from malfunctions, unusual vibrations, or other irregularities in each mode of

operation.

Cool cycles engage.

Cooling configuration matches the application of the cooling unit.

Air filters are clean and free of debris. Replace air filters with APC part number 875-2013.

Clogged filter alarm is operating properly:

Cover 1/3 of the filter area and monitor alarm performance.

Compressor suction and discharge pressures are recorded.

Final inspection checklist

The final inspection verifies that the system is clean and the start-up form has been sent to APC.

Ensure that:

The interior and exterior of the cooling unit is clean and free from debris.

Packaging materials have been disposed of properly.

The Start-up form was completed and sent to APC.

5InRow SC Operation

Page 12

Operation

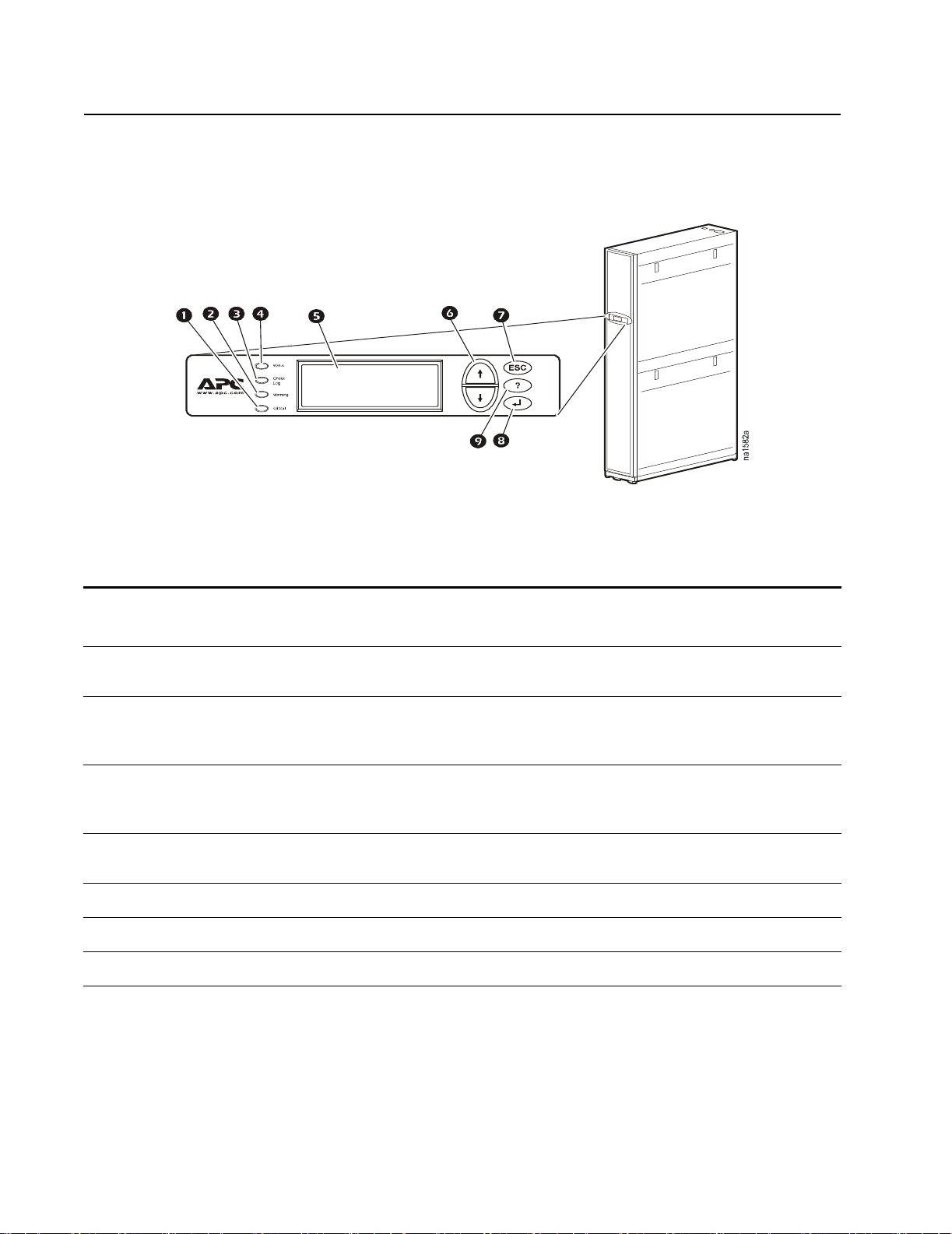

Display Interface

Item Function

Critical Alarm LED (red) When illuminated, a critical alarm condition exists that requires your

immediate attention.

Warning Alarm LED (yellow) When illuminated, a warning alarm condition exists. Failure to correct this

condition could cause a critical alarm.

Check Log LED (yellow) When illuminated, at least one new event has been logged since the last

Status LED (green) When illuminated, the cooling unit is receiving electrical power. When the

Liquid Crystal Display (LCD) View alarms, status data, context-sensitive help, and modify configurable

Up and down arrow keys Select menu items and access information.

ESC key Return to previous screen or cancel current operation.

Enter key Open menu items and input changes to the cooling unit settings.

Help key Display context-sensitive help. Press the help key for information about

time the log was checked. Only events that pertain to the operation of the

cooling unit will activate this LED.

LED is flashing, the cooling unit is downloading firmware for the

controller. This may take a few minutes.

items.

each option on the screen and for instructions on performing the tasks.

InRow SC Operation6

Page 13

Using the Display Interface

On/Standby

View Alarms

View Even t Log

na1636f

Set Date & Time

Set Password

Service Intervals

View Run Hou rs

Every time you apply power to the cooling unit, the display interface initializes, causing the LEDs to

cycle and the alarm tone to activate.

Scrolling status screens

After start-up, the interface displays the firmware revision number of the display interface. The display

interface then scrolls automatically and continuously through screens of status information.

Status Screen Name Status Information Displayed

APC InRow SC Status • On/Standby

• Cooling unit name

• Cooling unit location

Group • Alarms/No Alarms

• Cool Output kW

• Cool Setpoint °C (or °F)

• Max Rack (Maximum Rack Temperature) °C (or °F)

Unit • Alarms/No Alarms

• Cool Output kW

• Air Flow CFM (cubic feet per minute) or L/s (liters per second)

• Rack Inlet °C (or °F)

Main menu screens

Press the up or down arrow key to interrupt the automatic scrolling and view a specific status screen.

Screens automatically begin to scroll after five seconds of inactivity. Press the

ENTER or ESC key to return

to the main menu screen.

On any top-level status screen, press the ENTER or ESC key to open the

main menu screen.

Clear Alarms

Note: If the display interface is inactive for the time

configured for the password time-out, it returns to the

scrolling status screens.

For information on setting the password time-out, see

page 18.

Note: Pressing the up arrow key from the top line of the

top screen of the main menu will take you to the top line

of the bottom screen.

Clear Event Log

Configure Modbus

Set Display Units

Configure Display

Configure Network

About InRow SC

Set Identification

Configure Unit

Configure Group

Set Group Setpoi nts

Set Unit Th reshld s

View Group Status

View Unit Status

7InRow SC Operation

Page 14

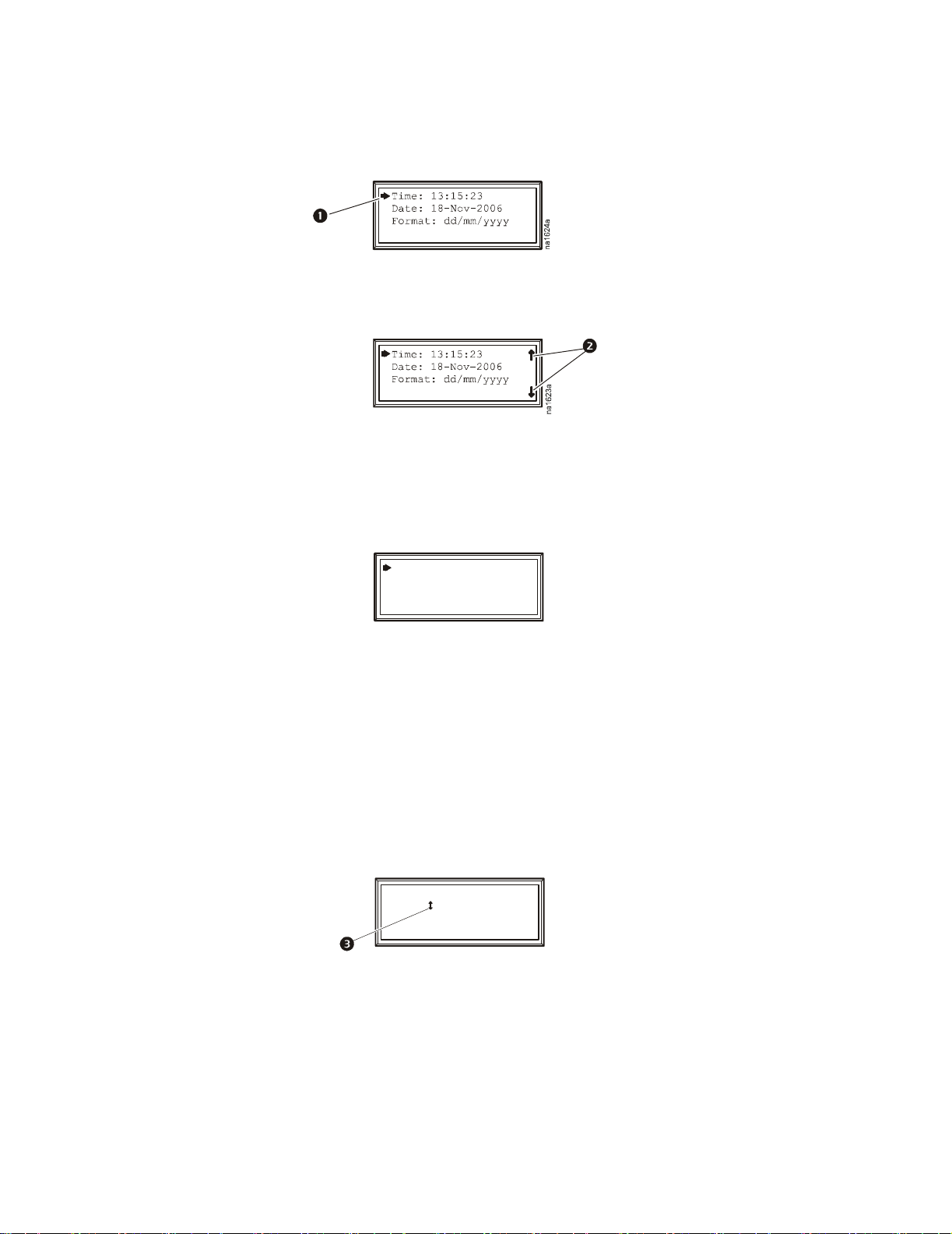

Navigating the main menu

Time: 13 :15:23

Time: 13 :15:23

Selector arrows. Press the up or down arrow key to move the selector arrow

setting. Press the

Continue arrows. Continue arrows

ENTER key to view the selected screen or modify the setting.

indicate that additional options or settings are available on a

to a menu option or

menu or status screen. Press the up or down arrow key to view the additional items.

Navigating the sub-menus

Selecting a main menu option displays the sub-menu screen for that option. Use the up or down arrow

key to move the selector arrow to the setting that you wish to change, and press the

ENTER key.

Date: 29 -Jan-0 9

Format : dd-mmm -yy

na1623e

• List of choices. If the setting is a list of choices, an input arrow is displayed next to the setting.

Press the up or down arrow key to select the choice you want, and then press the

the input mode and save the setting. Press the

ESC key to exit without saving.

ENTER key to exit

• Numbers or text fields. If the setting is a number or text field, use the arrow keys to select the

value of the first character, and press the

the last character is set to exit the input mode and save the setting. Press the

ENTER key to move to the next. Press the ENTER key after

ESC key to exit

without saving. If an invalid value is entered, the display beeps and restores the previous valid

value to the field.

• Input arrows next to a selected setting indicate that the setting can be modified by pressing the

up or down arrow key. Press the

ENTER key to save the change or the ESC key to cancel the change.

Date: 29 -Jan-0 9

Format: dd-mmm-yy

na162 2b

InRow SC Operation8

Page 15

Using the Path statement

Select the main- and sub-menu options specified in the path statement to view or configure a setting. The

path statement lists the main- and sub-menu items you select to navigate to the item to view or modify.

The parts of the path statement are defined below:

Path: Main > Set Password >Change Passwords

Main >

Set Password > Scroll to and select this option from the main menu.

Change Passwords > Scroll to and select this option from the sub-menu.

Your starting point is the main menu.

Subsequent options are listed and defined under the path statement.

Password entry

Path: Main Menu > Set Password > Change Passwords

The cooling unit has two levels of password protection:

• Device password for users who need to change basic and environmental settings.

• Admin password for users who need to modify settings that control the components in the

cooling unit or change advanced options.

When you try to change any of the settings, the local display prompts you to enter your Admin password.

The default value for both the Device and Admin passwords is apc (lower case). To enter your password,

use the up or down arrow keys to scroll through the available character set. Press the

ENTER key to select

the current letter and move the cursor to the next letter position. After selecting the last letter of your

password, press the

ENTER key once more to submit your password. If the Device and Admin passwords

have been configured to be unique, the Admin password can be entered for the Device password, and

Admin privileges will be granted.

Once the password is entered, it remains in effect until the period of inactivity exceeds the Password

Time-out setting.

See “Password & time-out” on page 18.

Note: Passwords are case-sensitive.

9InRow SC Operation

Page 16

Start the cooling unit

na296 9a

Limit Access: Yes

Path: Main Menu > On/Standby

Limiting access by requiring a password: Selecting On/

Standby will display the Operate: On/Standby screen. The second

line on the screen is Limit Access: Yes/No. Select Ye s to require a

password in order to stop or start the unit. When the curser is on

Operate: On/Standby and the

ENTER key is pressed, the screen will

display Enter Password. The password must then be entered in order

to continue. If Limit Access: No is selected, a password is not

required.

To start the cooling unit, change the setting to On by pressing the

ENTER key to toggle from Standby to On. At that point, the fans will

start or Unit startup in progress will appear if the Start-Up Delay

option is set to restart multiple cooling units sequentially.

The cooling unit will run according to the configured settings.

Note: On/Standby only affects the local cooling unit. You must set the On/Standby option

for each cooling unit in the cooling group.

Note: To toggle between On and Standby from the scrolling status screens, press the

key three times in rapid succession. This operation can only be done if Limit Access: Yes/No

is set to No.

Stop the cooling unit

On/Standby

View Alarms

Clear Alarms

View Event Log

Operate: On/Standby

Enter Password

********************

ENTER

Path: Main Menu > On/Standby

Note: The Limit Access: Yes/No information provided above is also applicable for shutting

down the unit.

Press the

ENTER key to change the setting to Standby. The cooling unit will enter the standby mode

Electrical Hazard: The Standby option does not remove power from the cooling unit. You

must disconnect power at the mains to remove power from the cooling unit.

InRow SC Operation10

Page 17

General Configuration

The cooling group configuration options are set during the commissioning of the cooling units in the

cooling group.

Caution: This procedure must be performed by APC authorized personnel only. Changing

the settings incorrectly can cause malfunctions to your cooling unit.

Cooling unit configuration

Path: Main > Configure Unit > General

Use the General menu to set the following:

Start-up Delay. The delay begins when the cooling unit is started and initialized. The cooling unit

cannot begin operation until this delay expires. Use the start-up delay to restart equipment sequentially in

your room after a scheduled downtime.

Idle On Leak. When set to Ye s, the cooling unit will enter idle mode if a Water Detection Fault

activates. Set to No to disable the cooling unit from entering idle mode if a leak is detected.

Note: The leak sensor (APC part number AP9325) is optional.

Note: There are three alarms that will cause the cooling unit to enter idle mode:

• Water Detection Fault (when Idle On Leak is set to Ye s )

• Condensate Pump Fault

• Cooling Failure

11InRow SC Operation

Page 18

Contacts

View the state of input and output contacts

Path: Main > Configure Unit > Discrete I/O

Each cooling unit supports a user-defined input contact and a user-defined output contact. Each contact

monitors a sensor and responds to changes in the state of the sensor (open or closed).

Input State. Indicates the actual state of the input contact (Open or Closed). A cooling unit is On when

the state is normal and in Standby when the state is not normal.

Output State. Indicates the actual state of the output contact (Open or Closed). An alarm will cause the

output contact to change from the normal state.

Edit the normal state of input and output contacts

Path: Main > Configure Unit > Discrete I/O > Normal State

Configure the input contacts to cause alarm conditions based on the user-defined normal state. Output

contacts can map internal alarms and events to outside devices.

Input Norm. Set the normal state of the contact (Open or Closed). The cooling unit changes its

operating mode to Closed when the actual state differs from the normal state.

Output Norm. Set the normal state of the contact (Open or Closed). If the state of an alarm or event

mapped to this contact changes from the normal state, the contact also changes state.

Outpt Src. Define the type of output source (alarm), either Any Alrm or Critical, that causes the output

to change from its normal state.

InRow SC Operation12

Page 19

Cooling Group Configuration

Use the cooling group configuration settings to add cooling units to the group and to define group

operation.

Caution: APC recommends that this procedure be performed by APC authorized personnel

only. The settings in the Configure Group menu are defined by APC authorized personnel

when the cooling group is commissioned.

Configure the cooling group

Path: Main > Configure Group

The Configure Group menu contains settings that identify the number of cooling units installed in this

cooling group and the physical arrangement of those cooling units.

Num Units. Enter the number of cooling units in this cooling group. Up to 12 cooling units can be

joined together to work as a single cooling group.

Type. Set the rack deployment strategy for the cooling units of this cooling group:

• Spot: The cooling unit is used as a stand-alone unit.

• In-Row: Air flow is not ducted. Hot-aisle air is cooled and the cooled-air supply is shared by all

loads in the row.

• RACS (Rack Air Containment System): Air flow in the enclosure is controlled by a ducting

system fitted to the enclosure.

Capacity Ctrl. Set the capacity control of the cooling unit:

• Disc (Discrete): The cooling unit operates as a room air conditioner. The evaporator fan speed will

remain constant at the user setting and the compressor will cycle on and off to maintain the cool

setpoint.

Note: The Disc mode is only available in a Spot cooling configuration.

• Prop (Proportional): The cooling unit matches the cooling output to the load demand. This is

accomplished using hot gas adjustment and fan speed control. Load demand is determined by the

cool setpoint and the temperature sensor at the rear of the cooling unit (in Spot configurations) or

the temperature sensor at the front of the load rack (in In-Row and RACS configurations).

Fan Cntrl. This selection allows air flow to be controlled automatically by the cooling unit or manually

by user-selected fan speed preference. This property only applies to Spot (Proportional), In-Row, and

RACS deployments.

• Auto: Air flow is automatically controlled by the unit.

• Manual: the air flow is fixed to the value of the Fan Speed Preference property. See page 19 for

more information.

Altitude. The height of the cooling unit above sea level. This number is used to estimate the density of

the air and is a factor in calculating the output power. Enter the altitude to the nearest meter or foot for

best results. Entries to the nearest 305 meters (1,000 feet) should be sufficient.

13InRow SC Operation

Page 20

Identify the cooling unit

Path: Main >Set Identification

The Set Identification menu contains settings that identify the name and location of the cooling unit.

Name. Assign a Name of up to 40 alpha-numeric characters to this cooling unit.

Location. Enter the Location, up to 40 alpha-numeric characters, of the cooling unit.

Note: Only the first 19 characters (of the 40 that are possible to enter) will display on the

display interface. You must use Telnet, the Control console or the Web to access all 40

characters. See page 33 for more information.

Configure Modbus

Path: Main > Configure Modbus

Use the Configure Modbus menu to set up communication between the cooling unit and the building

management system.

Modbus. Enable or Disable the Modbus communication protocol.

Target Id. Each Modbus device must have a unique target identification number. Enter a unique

number, from 1 to 247, for this cooling unit.

Baud Rate. Choose either 9600 bps or 19200 bps.

Fixed settings: 8 data bits, no parity, 1 stop bit. These settings cannot be modified.

To access the Modbus register map, go to the APC Web site, www.apc.com.To access the

Modbus register map, go to the APC Web site, www.apc.com.

InRow SC Operation14

Page 21

Control the Environment

The main function of the cooling unit is to remove waste heat and return treated air to the room at the

required temperature. The control strategies employed by the cooling unit depend upon the deployment

strategy of the cooling group.

In an In-row environment, the cooling unit supplies constant-temperature supply air to the common cold

aisle. The fan speed is modulated to ensure that the required volume of air reaches the IT equipment. The

fan speed is determined by the difference between the cooling setpoint and the maximum rack air inlet

temperature of the cooling group.

In a RACS environment, the front and rear of the IT equipment racks are fully enclosed. Waste heat is

funneled directly to the return air of the cooling unit so the heat cannot escape into the room. Cool air is

delivered directly from the cooling unit to the IT equipment racks.

In a Spot cooling environment, the cooling unit operates like traditional computer room air conditioning

(CRAC) equipment, providing a constant return air temperature. In Disc (Discrete) mode, the fans

operate at a user-selectable speed (Fan Control) and the compressor operates at maximum capacity. In

Prop (Proportional) mode, the fans are modulated to maintain the required return air temperature and the

compressor output is modulated to maintain the necessary supply air temperature.

Setpoints

Path: Main > Set Group Setpoint

A setpoint is the target value that a cooling group will maintain. The default setpoints are appropriate for

most cooling applications.

Default setpoints:

• Cool: 22.2°C (72.0°F)

• Deadband: 1.0°C (1.8°F)

• Supply Air:

15.0°C (57 – 59.0°F) Spot (Proportional) only

17.8°C (64.0°F) RACS or In-Row

Note: The Supply Air setting is defined by APC authorized personnel only when the

cooling group is commissioned.

Note: The Supply Air setpoint must never be set higher than the Cool setpoint.

• Fan Spd: When the unit is programmed for RACS mode, this property specifies the necessary

temperature difference (DT) across the IT equipment. When the cooling unit is programmed for

Spot (Proportional), In-Row, or RACS with the Fan Control property set to Manual, this

property defines the fan speed. When the cooling unit is programmed for Spot (Discrete), the fan

speeds are also selected from the following table but the Fan Control property is irrelevant.

– Low: 16.7°C (30°F) DT (60% of maximum fan speed)

– Med-Low: 13.9°C (25°F) DT (70% of maximum fan speed)

– Med: 11.1°C (20°F) DT (80% of maximum fan speed)

– Med-High: 6.3°C (15°F) DT (90% of maximum fan speed)

– High: 5.6°C (10°F) DT (100% of maximum fan speed)

15InRow SC Operation

Page 22

Run hours

Path: Main > View Run Hours

The cooling unit records the number of hours each of its components has operated. When a component is

replaced, use the Reset option to reset the run hours for the displayed component to zero.

Path: Main > View Run Hours > Air Filter

• Air Filter

• Reset Run Hours

Path: Main > View Run Hours > Fans > Condenser

• Fan n (n = 1, 2, or 3)

• Reset Run Hours

Path: Main > View Run Hours > Fans > Evaporator

• Fan n (n = 1, 2, or 3)

• Reset Run Hours

Path: Main > View Run Hours > Compressor

• Compressor

• Reset Run Hours

Path: Main > View Run Hours > Condensate Pump

• Conds Pump (Condensate Pump)

• Reset Run Hours

Path: Main > View Run Hours > Fan Power Supplies

• LT Fan PS (Left Fan Power Supply)

• RT Fan PS (Right Fan Power Supply)

• Reset LT PS Hours (Reset Left Fan Power Supply Hours)

• Reset RT PS Hours (Reset Right Fan Power Supply Hours)

Thresholds

Set alarms to alert you when components require service or there are high temperature violations.

Path: Main > Set Unit Thresholds

When the air temperature exceeds the temperature defined by the High Temperature Threshold, an

alarm will occur. Set High Temperature Thresholds for the following:

• Rack Inlet: An alarm condition exists when the temperature of the air entering the rack at the rack

inlet sensor exceeds the threshold.

• Supply Air: An alarm condition exists when the temperature of the air output from the cooling

unit exceeds the threshold.

• Return Air: An alarm condition exists when the temperature of the air entering the cooling unit at

the temperature sensor exceeds the threshold.

InRow SC Operation16

Page 23

Service intervals

Path: Main > Service Intervals

The air filters should be serviced regularly. The service interval depends on environmental cleanliness.

• Air Filter Interval: Set the number of weeks before service is required for the Air Filter

Interval. The default is 18 weeks.

• Alarm: The interval setting has an alarm (Enable or Disable). If enabled, an audible alarm

activates when the interval has elapsed. The alarm is cleared by selecting Clear Alarms in the

main menu.

Note: The Air Filter interval alarm is enabled by default.

17InRow SC Operation

Page 24

Display Settings

Set display settings, including the time and date, units, passwords, and time-out settings. You can also

adjust contrast, key click, beeper volume, and beep on alarm.

Password & time-out

Path: Main > Set Password

Note: The default user password is apc (lowercase).

Change passwords. Set the Admin and Device passwords.

1. Move the selector arrow next to the Change Passwords option and press the

ENTER key.

2. Select the password to change (either Admin or Device).

3. Enter a new password (up to 8 characters).

4. Press the

Time-out. Set the length of time which can elapse when no keys are pressed before the display interface

ENTER key to confirm.

returns to the scrolling screen status. The password must then be entered to regain access.

Invalidate Now. Override the password time-out and require password entry immediately.

Date and time

Path: Main > Set Date & Time

Set the time.

Enter the correct time, and press the ENTER key. The Time is displayed on some status

screens and is also used in the alarm/event log to time-stamp events.

Set the date. Enter the day, month, and year, and press the ENTER key. The Date is displayed on some

status screens and is also used in the alarm/event log to date-stamp events.

Set the format. Use the up or down arrow keys to select the date Format.

• mm/dd/yyyy (02/10/2009) (Default)

• yyyy-mm-dd (2009-02-10)

• dd-mmm-yy (10-Feb-09)

• mmm-dd-yy (Feb-10-009)

• dd.mm.yyyy (10.02.2009)

InRow SC Operation18

Page 25

Configure display

Path: Main > Configure Display

Contrast. Adjust the visibility of the screen text. Lower numbered settings provide darker text; higher

numbers provide lighter text. Settings range from 0 –7.

Key Click. Set to ON or OFF will enable or disable an audible tone that sounds every time a key is

pressed on the display interface.

Beeper Volume. Set the volume (Low, Medium, High or OFF) of the audible tone that sounds every

time a key is pressed on the display interface.

Beep on Alarm. Set to ON or OFF. When set to ON, the cooling unit will sound an audible tone every

30 seconds when a new alarm occurs. Silence the audible tone by pressing any key on the display

interface. When the alarm clears itself, the tone will stop on its own.

Display units

Path: Main > Set Display Units

Set the units of measure for the cooling unit to either US or Metric.

19InRow SC Operation

Page 26

Network Configuration

The cooling unit is shipped with a Network Management Card that enables the cooling unit to be

managed over a network. Configure the network settings for the Network Management Card for this

cooling unit from the display interface. The management card allows remote control and configuration

of the equipment.

Configure network

Path: Main > Configure Network

MAC Address.

Boot Mode. Set the method by which the cooling unit’s Network Management Card will acquire its

network settings.

• Manual: With Manual boot mode selected, enter the IP Address, Subnet Mask, and Default

Gateway using the IP Address menu shown below.

• BOOTP: Set the Network Management Card to obtain its network settings from a BOOTP server.

• DHCP: Set the Network Management Card to obtain its network settings from a DHCP server.

• BOOTPDHCP: Set the Network Management Card to search for its network settings from either

a BOOTP or a DHCP server.

IP Address. You will be prompted to enter the Admin password. Enter the password and press ENTER to

return to the IP screen. Press

• IP: Enter the IP address assigned to the Network Management Card of this cooling unit.

• SM: Enter the subnet mask for the Network Management Card of this cooling unit.

• GW: Enter the default gateway for the Network Management Card of this cooling unit.

Displays the unique network identifier assigned to each equipment at the factory.

By default, DHCP requires an APC cookie before it will accept an IP address. See

“DHCP” on page 29 for more information.

ENTER again to change the network settings for Manual boot mode only:

InRow SC Operation20

Page 27

View Status Readings

The display interface has several options for viewing the status of the cooling unit, the cooling group to

which the cooling unit belongs, and the environment being controlled. The status readings for the

cooling unit are available under the View Unit Status option in the main menu, and status readings for

the cooling group are available under the View Group Status option on the main menu or on the

scrolling status screens.

Scrolling status screens

When the display interface is idle, it scrolls through screens of status information. Press the up or down

arrow key to interrupt the automatic scrolling and view a specific status screen.

Cooling unit status

Path: Main > View Unit Status

Op Mode.

The cooling unit is in one of the following modes:

• On: The cooling unit is cooling.

• Standby: The cooling unit is receiving power but is not enabled for cooling.

• Idle: The cooling unit is on, but the compressor is not running because it has active alarms.

Cool Output. The actual cooling output of the cooling unit.

Cool Demand. The amount of cooling that the heat load currently requires.

Rack Inlet. The temperature of the air entering the rack at the remote temperature sensor.

Supply Air. The temperature of the air leaving the cooling unit.

Return Air. The temperature of the air entering the cooling unit.

Cond Outlet. The temperature of the air leaving the condenser.

Cond Inlet. The temperature of the air entering the condenser.

Suction Temp. The temperature of the low pressure refrigerant line.

Air Flow. The amount of air flowing through the evaporator required to maintain the setpoint

temperature.

Evap Fan Spd. The speed of the fans that regulate the air flow through the evaporator.

Cond Fan Spd. The speed of the fans that regulate air flow through the condenser.

Input State. The actual state of the input contact (open or closed).

Output State. The actual state of the output contact (open or closed).

Filter DP. The filter differential pressure.

Suction. The pressure at the compressor inlet.

Discharge. The pressure at the compressor outlet.

Superheat. The difference between the Suction Temp and the evaporator dew point temperature

Compressor. The state of the compressor, either on or off.

21InRow SC Operation

Page 28

Cooling group status

Path: Main > View Group Status

View information about the cooling group.

Cool Output. The combined output of the cooling group.

Cool Demand. The cooling output required to meet the current heat load of the conditioned space.

Cool Setpt. The temperature you set to maintain the room environment.

Air Flow. The combined airflow output of the cooling units in the cooling group.

Max Rack. The highest rack temperature reported by any cooling unit in the cooling group.

Min Rack. The lowest rack temperature reported by any cooling unit in the cooling group.

Max Return. The highest return temperature reported by any cooling unit in the cooling group.

Min Return. The lowest return temperature reported by any cooling unit in the cooling group.

About the cooling unit

Paths: Main > About InRow SC

View identifying information that is helpful when obtaining service:

• Model

• S/N Number (Serial Number)

• F/W (Firmware Version)

• H/W (Hardware Version)

• Made (Date of Manufacture)

• SC App (Application Version)

• AOS Ver (APC NMC Operating System Version)

InRow SC Operation22

Page 29

Event Log

The event log saves status information and a message each time a change in the cooling unit is detected.

Alarms events are recorded in the log and displayed on the active alarm screens. Status (informational)

events and system configuration changes are only displayed in the event log. The number of messages in

the event log is limited to 500. When the number of messages in the event log reaches 500, the oldest

message will be dropped from the list every time a new message is added to the log.

View event log

Path: Main > View Event Log

The event log keeps a record of all alarms and events. The screen displays the following:

• The name of the event

• The time and date the event occurred

Use the arrow keys to scroll through the list of events and display the date and time for each event.

Clear event log

Path: Main > Clear Event Log

A confirmation screen is displayed when you select this option. Enter the Admin password to erase the

log. Select YES to erase all of the events in the log. Select NO to return to the main screen.

Respond to Alarms

When an alarm is triggered, the cooling unit alerts you through the display by the following methods:

• Alarm screen entry on scrolling status screens

• LEDs on the front panel display

• An optional audible alarm every 30 seconds (if enabled)

View alarms

Path: Main > View Alarms

The View Alarms screen provides the number of alarms, the severity, and a brief description of the

alarm. Press the arrow keys to view the rest of the list.

Clear active alarms

Path: Main > Clear Alarms

A confirmation screen is displayed when you select this option. Enter the Admin password to clear the

alarm list. Select YES to clear all of the alarms in the list. Select NO to return to the main screen. If the

conditions that caused the alarm still exist, those conditions cause the alarm to be regenerated.

Note: A Critical fault prevents the system from performing its primary function. A primary

function is defined as any function that can effect the ability to deliver rated cooling

performance. A Warning fault is a fault that is not critical.

23InRow SC Operation

Page 30

Alarm messages and suggested actions

Displayed Alarm Message Severity Action Required

Air Filter Clogged Warning • Clean or replace the air filter.

• If the problem persists, refer to the back page of this manual for

contact information.

Air Filter Run Hours Violation Warning • Reset the Air Filter Run Hours after the air filter is cleaned or

replaced.

A-Link Isolation Relay Fault Critical • A hardware failure exists. For assistance, refer to the back page of

this manual for contact information.

Condensate Pan Full Fault Critical • Make sure the floats are operating correctly.

• Clear debris from the condensate pan and drain lines.

• If the problem persists, refer to the back page of this manual for

contact information.

Condensate Pump Fault Warning • Clear debris from the condensate pump reservoir and the condensate

removal lines.

• Make sure the condensate removal lines are free of obstructions and

the float switch moves freely.

• For assistance, refer to the back page of this manual for contact

information.

Condenser Fan #n Fault Warning • Make sure all air intakes are clear of any blockage.

Note: Fans are numbered sequentially, starting with Fan 1 at the

front of the cooling unit.

• If the problem persists, refer to the back page of this manual for

contact information.

Condenser Inlet Air Sensor

Fault

Condenser Outlet Air Sensor

Fault

Cooling Failure Critical • A hardware failure exists. For assistance, refer to the back page of

Discharge Pressure Sensor Fault Warning • A hardware failure exists. For assistance, refer to the back page of

Evaporator Fan #n Fault Warning • Make sure all air intakes are clear of any blockage.

External Communication Fault Critical • A hardware failure exists. For assistance, refer to the back page of

Warning • A hardware failure exists. For assistance, refer to the back page of

this manual for contact information.

Warning • A hardware failure exists. For assistance, refer to the back page of

this manual for contact information.

this manual for contact information.

this manual for contact information.

Note:Fans are numbered sequentially, starting with Fan 1 at the bot-

tom.

• If the problem persists, refer to the back page of this manual for

contact information.

this manual for contact information.

Fan Power Supply Left Fault Warning • Replace the power supply.

• For assistance, refer to the back page of this manual for contact

information.

Fan Power Supply Right Fault Warning • Replace the power supply.

• For assistance, refer to the back page of this manual for contact

information.

InRow SC Operation24

Page 31

Displayed Alarm Message Severity Action Required

Filter Sensor Fault Warning • A hardware failure exists. For assistance, refer to the back page of

this manual for contact information.

High Discharge Pressure Alarm Critical • For assistance, refer to the back page of this manual for contact

information.

Internal Communication Fault Critical • A hardware failure exists. For assistance, refer to the back page of

this manual for contact information.

Low Suction Pressure Alarm Warning • For assistance, refer to the back page of this manual for contact

information.

Rtn Air High Temp

(Return Air High Temperature

Violation)

Sply Air High Temp

(Supply air High Temperature

Violation)

Persistent High Discharge

Pressure Alarm

Persistent Low Suction Pressure

Alarm

Rack Inlet High Temperature

Violation

Rack Inlet Temperature Sensor

Fault

Warning • Make sure the Return Air threshold is set correctly in the Set Unit

Threshlds screen.

• If the problem persists, contact APC at a number on the back cover

of this manual.

Warning • Make sure the Supply Air threshold is set correctly in the Set Unit

Threshlds screen.

• If the problem persists, contact APC at a number on the back cover

of this manual.

Critical • For assistance, refer to the back page of this manual for contact

information.

Critical • Indicates there were 3 Low Suction Pressure shutdowns in 30

minutes. Alarms must be cleared manually.

• For assistance, refer to the back page of this manual for contact

information.

Critical • Make sure the Rack Inlet High Temperature Threshold is set

correctly in the "Thresholds" screen.

• Make sure remote temperature sensor is installed correctly in the

rack inlet air stream.

• If the problem persists, refer to the back page of this manual for

contact information.

Critical • For assistance, refer to the back page of this manual for contact

information.

Suction Pressure Sensor Fault Warning • A hardware failure exists. For assistance, refer to the back page of

this manual for contact information.

Suction Temperature Sensor

Fault

Water Detection Fault Warning • Identify the source of the leak.

Grp Comm Fault

(Group Communication Fault)

Warning • A hardware failure exists. For assistance, refer to the back page of

this manual for contact information.

• For assistance, refer to the back page of this manual for contact

information.

Critical • Make sure the number of cooling units in the group is configured

properly and the A-Link connections between cooling units are

correct.

• Make sure the system is receiving power and is connected properly.

• A hardware failure exists. For assistance, contact APC at a number

on the back cover of this manual.

25InRow SC Operation

Page 32

Displayed Alarm Message Severity Action Required

Input Contact Fault Warning • Make sure the Input Normal state is defined correctly in the

Configure Unit> Discrete I/O screen. See page 17 for more

information.

• Clear the problem that caused the input contact switch to change

from the normal state.

• If the problem persists, refer to the back page of this manual for

contact information.

Cannot Start Due to Low

Suction Pressure

Startup Line Pressure

Imbalance Alarm

Return Air Sensor Fault Critical • A hardware failure exists. For assistance,refer to the back page of

Supply Air Sensor Fault Critical • A hardware failure exists. For assistance,refer to the back page of

Critical • The unit cannot start because the suction (low side) refrigerant

pressure is too low.

• If the problem persists, refer to the back page of this manual for

contact information.

Critical • The unit cannot start because the line pressure is too low.

• If the problem persists, refer to the back page of this manual for

contact information.

this manual for contact information.

this manual for contact information.

InRow SC Operation26

Page 33

Network Management Card

Quick Configuration

The cooling unit is shipped with a Network Management Card that enables the cooling unit to be

managed over a network. Configure the Network Management Card to control this cooling unit through

a network.

Overview

You must configure the following TCP/IP settings before the Network Management Card can operate on

a network:

• IP address of the Network Management Card

• Subnet mask

• Default gateway

Caution: Never use the loopback address (127.0.0.1) as the default gateway address

for the Network Management Card. Doing so will disable the card and will require you

to reset TCP/IP settings to their defaults using a local serial login.

Note: If a default gateway is unavailable, use the IP address of a computer that is

located on the same subnet as the Network Management Card and that is usually

running. The Network Management Card uses the default gateway to test the network

when traffic is very light.

See “Watchdog Features” in the “Introduction” of the User’s Guide for more

information about the watchdog role of the default gateway.

TCP/IP configuration methods

Use one of the following methods to define the basic TCP/IP settings needed by the Network

Management Card:

• APC Device IP Configuration Wizard (See “APC Device IP Configuration Wizard” on this page.)

• BOOTP or DHCP server (See “BOOTP & DHCP configuration” on page 28.)

• Networked computer (See “Remote access to the control console” on page 30.)

27InRow SC Operation

Page 34

APC Device IP Configuration Wizard

You can use the APC Device IP Configuration Wizard at a computer running Microsoft® Windows 2000,

Windows Server 2003, or Windows XP to configure a Network Management Card.

Note: Most software firewalls must be temporarily disabled for the Wizard to discover

unconfigured Network Management Cards.

To configure one or more Network Management Cards from a user configuration file, see the

User’s Guide on the CD.

1. Insert the CD into a computer on your network.

2. If autorun is enabled, the user interface of the CD starts when you insert the CD. If autorun is not

enabled, open the file contents.htm on the CD.

3. When the Wizard discovers the unconfigured Network Management Card, follow the on-screen

instructions.

Note: If you leave the Start a Web browser when finished option enabled, you can

use apc for both the user name and password to access the Network Management Card

through your browser.

.ini file utility

You can use the .ini file export utility to export .ini file settings from configured Network Management

Cards to one or more unconfigured Network Management Cards. The utility and documentation are

included on the CD.

BOOTP & DHCP configuration

The default TCP/IP configuration setting, BOOTP & DHCP, assumes that a properly configured

BOOTP or DHCP server is available to provide TCP/IP settings to Network Management Cards. The

Network Management Card first attempts to discover a properly configured BOOTP server, and then a

DHCP server. It repeats this pattern until it discovers a BOOTP or DHCP server.

If neither of these servers is available, see “Local access to the control console” on page 30 or

“Remote access to the control console” on page 30 to configure the needed TCP/IP settings

A user configuration (.ini) file can function as a BOOTP or DHCP boot file. For more

information, see the TCP/IP configuration section of the User’s Guide, available from the

Utility CD or the APC Web site, www.apc.com.

.

InRow SC Operation28

Page 35

BOOTP. For the Network Management Card to use a BOOTP server to configure its TCP/IP settings, it

must find a properly configured RFC951-compliant BOOTP server.

1. In the BOOTPTAB file of the BOOTP server, enter the MAC address of the Network

Management Card, the IP address, the subnet mask, default gateway, and an optional bootup file

name. Look for the MAC address on the display interface (Path: Main > Configure Network)

or on the label on the back of the Network Management Card.

2. When the Network Management Card reboots, the BOOTP server provides it with the TCP/IP

settings.

– If you specified a bootup file name, the Network Management Card attempts to transfer that

file from the BOOTP server using TFTP or FTP. The Network Management Card assumes all

settings specified in the bootup file.

– If you did not specify a bootup file name, you can configure the other settings of the Network

Management Card remotely through its Web interface or control console; user name and

password are both apc, by default.

See your BOOTP server documentation to create a bootup file.

DHCP. You can use a RFC2131/RFC2132-compliant DHCP server to configure the TCP/IP settings for

the Network Management Card.

This section summarizes communication between the Network Management Card and a

DHCP server. For more detail about how a DHCP server can configure the network settings

for a Network Management Card, see “DHCP Configuration” in the User’s Guide.

1. A Network Management Card sends out a DHCP request that uses the following to identify itself:

– A Vendor Class Identifier (APC by default)

– A Client Identifier (by default, the MAC address value of the Network Management Card)

– A User Class Identifier (by default, the identification of the application firmware of the

Network Management Card)

2. A properly configured DHCP server responds with a DHCP offer that includes all of the settings

that the Network Management Card needs for network communication. The DHCP offer also

includes the Vendor Specific Information option (DHCP option 43). By default, the Network

Management Card will ignore DHCP offers that do not encapsulate the APC cookie in the Vendor

Specific Information option using the following hexadecimal format:

Option 43 = 01 04 31 41 50 43

where

– the first byte (

– the second byte (

– the remaining bytes (

01) is the code

04) is the length

31 41 50 43) are the APC cookie

See your DHCP server documentation to add code to the Vendor Specific

Information option.

To disable the requirement that a DHCP offer include the APC cookie, use the

DHCP Cookie Is setting in the control console:

Network>TCP/IP>Boot Mode>DHCP only>Advanced>DHCP Cookie Is.

29InRow SC Operation

Page 36

Local access to the control console

You can use a computer connected to the serial port on the main board holding the Network Management

Card to access the control console.

1. Select a serial port at the local computer, and disable any service that uses that port.

2. Use the provided configuration cable to connect the selected port to the serial port on the main

board holding the Network Management Card.

3. Run a terminal program (such as HyperTerminal) and configure the selected port for 9600 or

19200 bps, 8 data bits, no parity, 1 stop bit, and no flow control. Save the changes.

4. Press E

NTER to display the User Name prompt.

5. Use apc for the user name and password.

See “Control console” on page 31 to finish the configuration.

Remote access to the control console

From any computer on the same subnet as the Network Management Card, you can use ARP and Ping to

assign an IP address to a Network Management Card, and then use Telnet to access the control console of

that Network Management Card and configure the needed TCP/IP settings.

Note: After the IP address of the Network Management Card is configured, you can use

Telnet without first using ARP and Ping to access that Network Management Card.

1. Use the MAC address for the Network Management Card in the ARP command to define the IP

address. For example, to define an IP address of 156.205.14.141 for a Network Management

Card that has a MAC address of 00 c0 b7 63 9f 67, use one of the following commands:

– Windows command format:

arp -s 156.205.14.141 00-c0-b7-63-9f-67

– LINUX command format:

arp -s 156.205.14.141 00:c0:b7:63:9f:67

Note: The MAC address is available on the display interface at:

Path: Main > Configure Network or look at the label on the back of the Network

Management Card for the MAC address.

1. Use Ping with a size of 113 bytes to assign the IP address defined by the ARP command. For the

IP address defined in step 1, use one of the following Ping commands:

– Windows command format:

ping 156.205.14.141 -l 113

– LINUX command format:

ping 156.205.14.141 -s 113

2. Use Telnet to access the Network Management Card at its newly assigned IP address. For

example:

telnet 156.205.14.141

3. Use apc for both user name and password.

See “Control console” on page 31 to finish the configuration.

InRow SC Operation30

Page 37

Control console

After you log on at the control console, as described in “Local access to the control console” on page 30

or “Remote access to the control console” on page 30:

1. Choose Network from the Control Console menu.

2. Choose

3. If you are not using a

TCP/IP from the Network menu.

BOOTP or DHCP server to configure the TCP/IP settings, select the Boot

Mode menu and then select Manual boot mode.

4. Set the System

IP, Subnet Mask, and Default Gateway address values. (Changes will take effect

when you log out.)

5. Press

6. Press

ENTER to return to the TCP/IP menu.

CTRL+C to exit to the Control Console menu.

7. Log out (option 4 in the Control Console menu).

Note: If you disconnected a cable from the local computer during the procedure

described in “Local access to the control console” on page 30, reconnect that cable and

restart the associated service.

31InRow SC Operation

Page 38

Access a Configured Network Management Card

Overview

After the Network Management Card is running on your network, you can access the configured

Network Management Card through the following interfaces:

• Web interface (HTTP or HTTPS protocol)

• Telnet or Secure SHell (SSH)

• SNMP

• FTP or Secure CoPy (SCP) to upgrade firmware

• Modbus

For more information on the interfaces, see the User’s Guide.

Web interface

Use Microsoft Internet Explorer® (IE) 5.5 and higher (on Windows operating systems only), Mozillabased browsers that support Firefox 1.x (on all operating systems), or Netscape

operating systems) to access the Web interface of the cooling unit. Other commonly available browsers

may also work but have not been fully tested by APC.

You can use either of the following protocols when you use the Web interface:

• The HTTP protocol (enabled by default), which provides authentication by user name and

password but no encryption.

• The HTTPS protocol, which provides extra security through Secure Sockets Layer (SSL);

encrypts user names, passwords, and data being transmitted; and authenticates the Network

Management Card by means of digital certificates.

To access the Web interface and configure the security of your device on the network:

1. Address the Network Management Card by its IP address or DNS name (if configured).

2. Enter the user name and password (by default, apc and apc for an Administrator).

3. To enable or disable the HTTP or HTTPS protocols, use the Network menu on the

Administration tab, and select the Access option under the Web heading on the left navigation

menu.

For more information on selecting and configuring network security, see the Security

Handbook, available on the Utility CD or from the APC Web site, www.apc.com.

®

7.x and higher (on all

InRow SC Operation32

Page 39

Telnet and SSH

You can access the control console through Telnet or Secure SHell (SSH), depending on which is

enabled. Select the Administration tab, the Network option on the top menu bar, and then the Access

option under Console on the left navigation menu. By default, Telnet is enabled. Enabling SSH

automatically disables Telnet.

Telnet for basic access. Telnet provides the basic security of authentication by user name and

password, but not the high-security benefits of encryption. To use Telnet to access the control console of

the Network Management Card:

1. At a command prompt, use the following command line, and press

telnet address

ENTER:

As address, use the IP address of the Network Management Card (or DNS name if

configured).

2. Enter the user name and password (by default, apc and apc for an Administrator, or device and

apc for a Device User).

SSH for high-security access. If you use the high security of SSL for the Web interface, use Secure

SHell (SSH) for access to the control console. SSH encrypts user names, passwords, and transmitted

data.

The interface, user accounts, and user access rights are the same whether you access the control console

through SSH or Telnet, but to use SSH, you must first configure SSH and have an SSH client program

installed on your computer.

See the User’s Guide for more information on configuring and using SSH.

33InRow SC Operation

Page 40

Simple Network Management Protocol (SNMP)

SNMPv1 only. After you add the PowerNet

®

MIB to a standard SNMP MIB browser, you can use that

browser to access the Network Management Card. All user names, passwords, and community names for

SNMP are transferred over the network as plain text. The default read community name is public; the

default read/write community name is private.

SNMPv3 only. For SNMP GETs, SETs, and trap receivers, SNMPv3 uses a system of user profiles to

identify users. An SNMPv3 user must have a user profile assigned in the MIB software program to

perform GETs and SETs, browse the MIB, and receive traps. The default settings are no authentication

and no privacy.

Note: To use SNMPv3, you must have a MIB program that supports SNMPv3.

Note: The Network Management Card supports only MD5 authentication and DES

encryption.

SNMPv1 and SNMPv3. To use InfraStruXure Central or InfraStruXure Manager to manage the

Network Management Card, you must have SNMPv1 enabled in the interface of the cooling unit. Read

access allows InfraStruXure devices to receive traps from the cooling unit. Write access is required while

you set the InfraStruXure device as a trap receiver.

To enable or disable SNMP access, you must be an Administrator. Select the Administration tab, select

the Network menu on the top menu bar, and use the access option under SNMPv1 or SNMPv3 on the

left navigation menu.

FTP/SCP

You can use FTP (enabled by default) or Secure CoPy (SCP) to transfer downloaded firmware to the

Network Management Card, or to access a copy of the event or data logs of the cooling unit. SCP

provides the higher security of encrypted data transmission and is enabled automatically when you

enable SSH.

To use InfraStruXure Central or Manager to manage the Network Management Card, you must have

FTP Server enabled in the Network Management Card. To enable or disable FTP Server access, you

must be an Administrator. On the Administration tab, select the Network menu on the top menu bar,

and use the FTP server option on the left navigation menu.

In the User’s Guide, see the following sections:

• To transfer firmware, see “File Transfers.”

• To retrieve a copy of the event or data log, see “Use FTP or SCP to retrieve log files.”

Modbus

Use Modbus to view the Network Management Card through the interface of your building management

system. It is read-only.

The Modbus interface supports 2-wire RS-485, plus ground.

Note: Modbus can be configured to run at either 9600 or 19200 bps.

The Modbus register map is also available on the APC Web site, www.apc.com.

InRow SC Operation34

Page 41

Recover From a Lost Password

You can use a local computer (a computer that connects to the Network Management Card through the

serial port) to access the control console.

1. Select a serial port at the local computer, and disable any service that uses that port.

2. Connect the provided RS-232 configuration cable to the selected port on the computer and to the

RS-232 console port at the Network Management Card.

3. Run a terminal program (such as HyperTerminal) on your computer and configure the selected

port for 9600 or 19200 bps, 8 data bits, no parity, 1 stop bit, and no flow control.

1. Press E

display the User Name prompt, verify the following:

2. Press the Reset switch. The Status LED will flash alternately orange and green. Press the Reset

button a second time immediately while the LED is flashing to reset the user name and password

to their default values temporarily.

3. Press E

default, apc, for the user name and password. (If you take longer than 30 seconds to log on after

the User Name prompt is redisplayed, you must repeat step 5 and log on again.)

4. From the Control Console menu, select System, then User Manager.

5. Select Administrator, and change the User Name and Password settings, both of which are

now defined as apc.

6. Press C

disabled.

NTER, repeatedly if necessary, to display the User Name prompt. If you are unable to

– The serial port is not in use by another application.

– The correct cable is being used as specified in step 2.

– The terminal settings are correct as specified in step 3.

NTER as many times as necessary to redisplay the User Name prompt, then use the

TRL+C, log off, reconnect any serial cable you disconnected, and restart any service you

35InRow SC Operation

Page 42

Maintenance

Monthly Preventive Maintenance

The following pages can be photocopied and used during the maintenance procedures. After they have

been filled out, save them for future reference.

Prepared By: ________________________________

Model Number: ______________________________

Serial Number: ______________________________

Date: ______________________________________

Environment

In what type of room is the cooling unit located?

__________________________________________________

Is the cooling unit maintaining the temperature setpoint?

___________________________________________________

Temperature setpoint _________________________________

Is there visible damage to the cooling unit (dents, scratches)?

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________

Check for environmental damage (dirt, dust, debris, liquid stains) around the cooling unit installation area.

____________________________________________________________________________________

____________________________________________________________________

Record the room temperature/humidity near the return of the cooling unit.

Temperature ________________

Record last month’s alarm history.

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________

Cleanliness

Check the condition of return air filters. Change if necessary.

Check the condition of the drain pan and accumulation of debris in the pan. Clean as required.

InRow SC Operation36

Page 43

Mechanical

Electrical Hazard: Turn off the cooling unit and disconnect all power sources. Perform Lockout/

Tagout procedures before performing any electrical or mechanical service. Wear appropriate

personal protective equipment when checking hazardous voltages.

Check the fans. All components should be moving freely, with no signs of binding or damage.

Verify that the condensate line is flowing freely.

Electrical

Electrical Hazard: Turn off the cooling unit and disconnect all power sources. Perform Lockout/

Tagout procedures before performing any electrical or mechanical service. Wear appropriate

personal protective equipment when checking hazardous voltages.

Electrical Hazard: A Leakage Current Detector and Interrupter (LCDI) plug detects if there is

damage to the power cord that could cause arcing between wires, resulting in a fire. The LCDI shuts