Page 1

HP

HP_LCD_L1908W_SM070727V01

Service

Model ID: GA19WHBAS

GA19WHANS

Service Manual

Table of Contents

Important Safety Notice------------------------------------------------------------------------------------- 01

01. Circuit Description------------------------------------------------------------------------------------- 02

02. Packing Exploded Diagram---------------------------------------------------------------------------08

03. Product Exploded Diagram--------------------------------------------------------------------------- 09

04. ----------------------------------------------------------- 10

Assembly and Disassembly Procedures

05. Troubleshooting---------------------------------------------------------------------------------------- 18

06. Schematics and Layouts------------------------------------------------------------------------------ 30

AppendixI:UsersManual

Appendix II: Spare Parts List

Safety Notice

Any person attempting to service this chassis must familarize with the chassis and be aware of the

necessary safety precautions to be used when serving electronic equipment

containing high voltage.

Published by LITE-ON Service Printed in Taiwan © All rights reserved Subject to modification

27th-Jul.-2007

Page 2

Product Anouncement:

Important Safety Notice

HP L1908W

Go to cover page

1

This product is certificated to meet RoHS Directive and

Lead-Free produced definition. Using approved critical

components only is recommended when the situation

to replace defective parts. Vender assumes no liability

express or implied, arising out of any unauthorized

modification of design or replacing non-RoHS parts.

Service providers assume all liability.

Qualified Repairability:

Proper service and repair is important to the safe,

reliable operation of all series products. The service

providers recommended by vender should being

aware of notices listed in this service manual in order

to minimize the risk of personal injury when perform

service procedures. Furtermore, the possibile existed

improper repairing method may damage equipment or

Using Lead-Free solder to well mounted the parts.!

! The fusion point of Lead-Free solder requested in the

degree of 220 C.°

products. It is recommended that service engineers

should have repairing knowledge, experience, as well

as appropriate product training per new model before

performing the service procedures.

NOTICE:

To avoid electrical shocks, the products should be

!

connect to an authorized power cord, and turn off the

master power switch each time before removing the

AC power cord.

To prevent the product away from water or explosed

!

in extremely high humility environment.

To ensure the continued reliability of this product,

!

use only original manufacturer s specified parts.

To ensure following safty repairing behavior, put the

!

replaced part on the components side of PWBA, not

solder side.

To ensure using a proper screwdriver, follow the

!

torque and force listed in assembly and disassembly

procedures to screw/unscrew screws.

Page 3

2

HP L1908W

Go to cover page

1. Circuit Description

1.1 Power Board Operation Theory:

1.1.1 Line Filter:

It consists of C801, T801, C802, C803, C804,

C808, C809, C815, C819, C820, C825, and

eliminates the high frequency interference to

meet EMI's requirement.

1.1.2 Rec & Filter:

Bridge diodes D812, D813, D814, D815 convert

AC source into pulse DC. This pulse DC is

smoothed and filtered by C805 and R802 which is

an NTC (Negative Thermal Coefficient ) resistor,

and used to reduce inrush current within safe

range.

1.1.3 Power Transformer:

T802 converts energy into square wave given by

power source C805 as a filter on

the secondary winding of bridge rectifier to

generate +5V, +12V, and +22V.

1.1.4 Output:

The square wave from T802 is rectified by D808

D809, D810, then filtered by C817, C818, C824,

C823, C830, C833, C822 to generate +22.5V and

+12V, +5V respectively.

1.1.5 Driver:

Q803 drive T802 through PWM (Pulse-width

modulation) control of I801 for power converted.

1.1.6 FeedBack:

Negative feedback CKT consists of a photo

coupler I802 (LTV817) and an adjustable

regulator I803 (TEA1530). This circuitry can

maintain output voltages +22.5V, +12V, and +5V

at a stable level.

1.1.7 PWM :

(Pulse-width modulation)

1.1.7a Start:

When AC power switch is turned on. C807

is charged a 11V and an initial current

above 40uA flows to pin1 of I801. The I801

starts to oscillate and outputs a pulse train

through its pin6 to drive Q803.

1.1.7b OPP:

When Q803 turns on, C805 supplies a

linearly increasing triangle current

through the primary inductance of T802 to

the driver Q803, once the peak value of

this current multiplied by

0.52V, pulse train will be turn off 0.52V,

pulse train will be turn off immediately to

protect Q803, T802 from being blew out.

capacitor-input

R811 exceed

1.17c Regulation:

If output voltage +22V goes up, the R

terminal of I803 gets more bias,

accordingly photo transistor and photo

diode flow more current. The voltage of

pin2 goes up too, making the pulse width

of pin6 to become narrower. So the output

voltage +22V will be pulled down to a

stable value.

1.1.7d OVP:

If +22.5V goes up too much, the induced

voltage on pin4 of T802 becomes large

also. Suppose that voltage is over 20V,

the pulse train at pin6 goes down to zero,

shutting the Q803 off immediately.

1.1.7f SCP:

If output terminal is short to ground, photo

transistor does not conduct, hence I802

does not conduct either. Then oscillation

of I801 is stop, shutting Q803 off

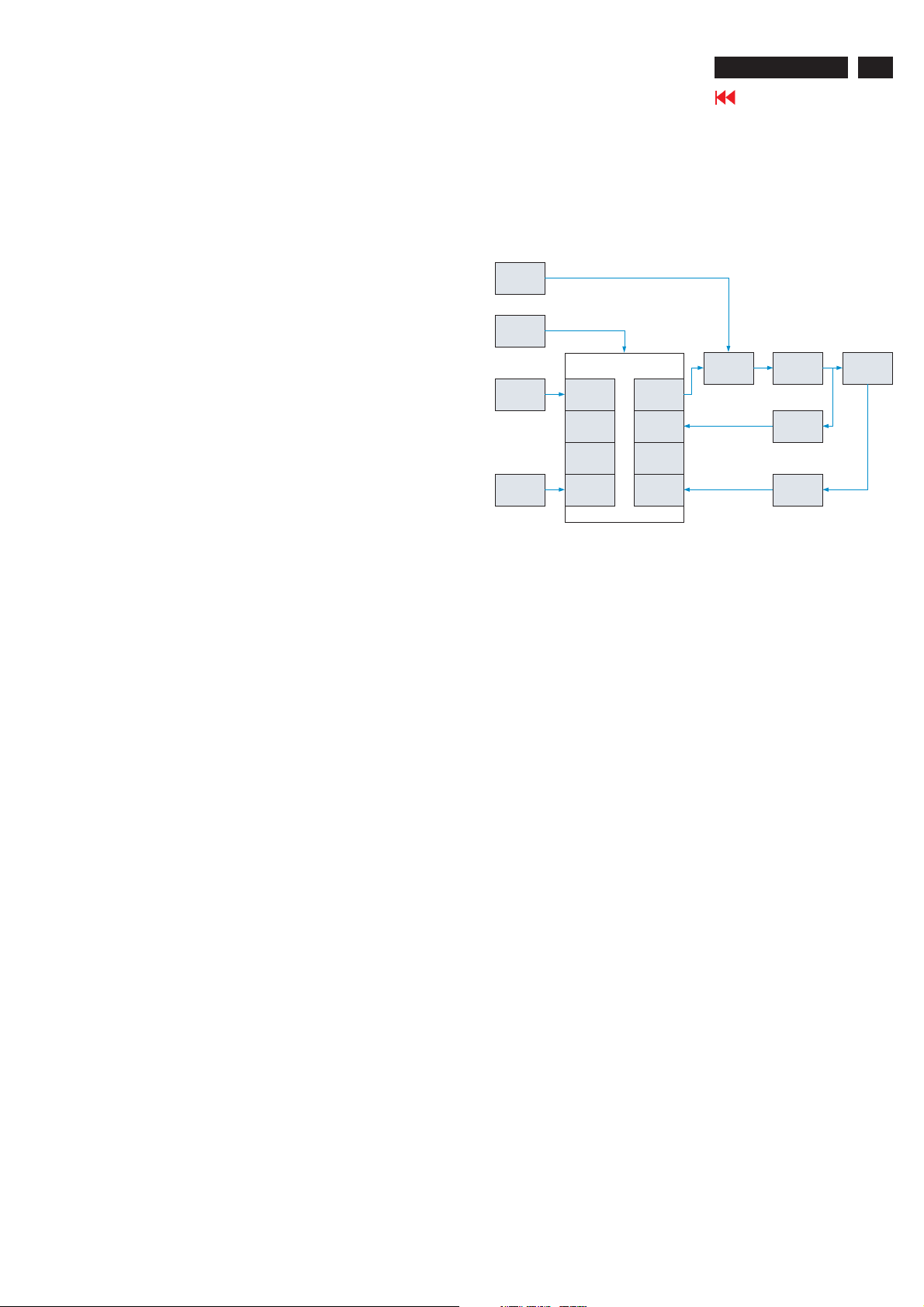

Power Board Block Diagram

Rec. & FilterLine Fil ter

PWM

Power

Transformer

Driver

Feedback

1.2 Inverter Circuit:

This unit operates on an output voltage of 22V given by

power source.

2.1 VDD:

1.

R105 gets a +5VDC for I101 power supply.

1.2.2 Control IC, I101 (OZ9938):

1.2.2a Enable:

When pin1 of I101 is over 2V, I101 is

initialized. If it is lower than 1V, the I101

turns off.

Output Rec. &

Filter

Page 4

1. Circuit Description (continued)

HP L1908W

Go to cover page

3

1.2.2b OSC:

When I101 enabled, C104, R118, R107 (pin13

of I101) determine the operating frequency.

1.2.2c SST:

C106 (pin12 of I101) provides soft start

function.

1.2.2d Ignition:

IC provides higher operating frequency

internally for more striking voltage until

regulation of feedback of lamp current. And it

provides 2 second striking time.

1.2.2e Dimming control:

The external PWM voltage of R136 and C111

control the duty pulse of burst-mode to drive

and perform a wide dimming control for the

CCFL. The burst-mode frequency is

determined by scaler IC.

1.2.2f Regulation:

Pin5 of I101 provides regulation of the CCFL

current from feedback. The non-inverting

reference is at 1.25V nominal.

1.2.2g Protection:

Open-lamp protection in the ignition period is

provided through pin6 of I101. Removal of the

CCFL during normal operation will trigger IC to

turn on and shut off the inverter. This is latch

function.

1.2.2h Output drivers:

The configuration prevents any shoot-through

issue associated with bridge-type power

conversion applications. Adjusting the overlap

conduction between Q104, Q105, the CCFL

current regulation is achieved.

1.2.3 Half-bridge Switching and Transformer:

Q104, Q105, C122, C123, C134 compose half-bridge

switching to convert DC into AC for driver the CCFL.

1.2.4 Detection:

C112, C114, C115, C116, C118, C119, R126, R116,

R115, R117, R119, R121, R122, R125 detect the

output voltage and ensure a rated voltage by pin6 of

I101 ensure not a open-lamp.

1.2.5 Feedback:

D116, D117, D120, D121, R111, R130 detect the

lamp current for negative feedback and

regulation.

Inverter Board Block Diagram

VCC

VDD

VDD

Half-bridge

Switching

ON/OFF

Brightness

Control

Control IC: OZ9938

Enable

OSC

SST

Dimming

Control

Output Driver

Protection

Ignition

Regulation

1.3 Interface Operation:

3.1 Top (Circuit diagrams sheet 2 of 8):

1.

This page is function block. (1)Power, (2)VGA &

DDC interface, (3)Scaler

GM5726H (GM5766H),

(5) Key & panel interface, (6) Audio.

1.3.2 Power (Circuit diagrams sheet 3 of 8):

1.3.2a P301 connector:

A 5V power supply for LCD module, also

it is main power of interface board. A VDD

(+5V) power supply for audio AMP. It is

generated from the P301 connector. And

adjust back light of LCD module from I306

scaler control.

GM5726H (GM5766H)

1.3.2b I302, 3-terminal regulator:

A 3.3V power supply for I306 scaler IC

GM5726H (GM5766H)

and I309 SPI flash ROM, it is generated

from the 5V source.

1.3.2c I303, 3-terminal regulator:

A 1.8V power supply for I306 scaler IC

GM5726H (GM5766H)

from the 3.3V source (I302).

Transformer Lamp

Detection

Feedback

and I308 EEPROM

, it is generated

Page 5

4

HP L1908W

Go to cover page

1. Circuit Description (continued)

1.3.2d Q302, I301:

The circuitry is functions of ON/OFF control

capable of initial the LCD module power on or

shut its power off (PANELVCC_EN) is

performed for power ON/OFF and also for the

power saving sequence. It supports 5V to

LCD module power. The PANELVCC_EN

signal is generated from I306 scaler IC

GM5726H (GM5766H)

1.3.2e R305:

ON/OFF control for LCD module back light

power ON/OFF control (BKLT_EN) is

performed for black light power ON/OFF and

also for the power saving sequence. The

BKLT_EN signal is generated from I306

scaler IC

3.2f Q301, R301, R302, R304:

1.

Adjusting backlight luminance of LCD

module, it s adjusted back light luminance

control (BKLT_ADJ) is performed for the back

light luminance. The BKLT_ADJ signal is

generated from I306 scaler IC

(GM5766H)

1.3.3 VGA & DDC interface (Circuit diagram sheet 4 of 8):

This sheet has RGB analog video and H/V sync

signals input from VGA connector.The RGB analog

video signals input through AC-coupled, analog

video signal is used to clamp the black level at 0V.

And H/V sync to scaler. Support EDID plug & play

function for analog video. It is to support VESA

DDC/CI interface for analog video.

1.3.3a P302 connector:

The RGB analog video and H/V sync input

signals to I306 scaler Gm5726H (Gm5766H).

The VESA DDC/CI function is through IIC bus

to I306 scaler IC .

1.3.3b I304, EDID EEPROM (24LC02B):

The I304 is support EDID information of the

VESA standard for VGA interface and support

plug and play for the PC host.

1.3.4 DVI & DDC interface (Circuit diagrams sheet 5 of 8):

The digital video signals (TMDS) input from P303

DVI-D connector. The digital video signal is TMDS

for DVI V1.0 standard. And support EDID plug&play

function for digital video. It supports VESA DDC/CI

interface, and support HDCP function.

.

.

.

GM5726H

GM5726H (GM5766H)

1.3.4a P303 connector:

P303 is DVI-D connector for DDWG standard,

it has digital video signals (TMDS) to I306

scaler IC . The VESA

DDC/CI function is through I2C bus to I306

GM5726H (GM5766H)

function is also through IIC bus to I306.

1.3.4b I305, EDID EEPROM (24LC02B):

The I305 is support EDID information of the

VESA standard for DVI interface, and support

plug & play for the PC host.

1.3.5 Scaler IC (Circuit diagram sheet 6 of 8):

The I306 is all-in-one LCD

monitor controller. It leverages Genesis patented

advanced image-processing technology as well as a

proven integrated ADC/PLL. Furthermore, it

integrates HDCP function, a micro-controller, an

OSD controller, and dual LVDS.

The RGB analog video signal from video input circuit

enter to incorporated A/D converted block (ADC) into

the digital data for analog video signal. The TMDS

digital signals input (with HDCP) entered from the

DVI-D connector is converted into the digital data.

Based on this conversion, this device performs

interpolation during pixel extension. These

interpolation digital data are transformed to LVDS

signal. The I306 source voltage is 3.3V and 1.8V, the

device clock source frequency is 14.318 MHz. And

support DDC/CI interface of VESAand function key

operation.

3.5a I308 EEPROM (24LC16B):

1.

1.3.5b I309 SPI Flash ROM:

1.3.5c I307 Microprocessor Supervisory Circuit:

GM5726H (GM5766H)

The control data and parameter, and OSD

related setting, and other service data, to be

stored in I308. The contents of which are

updated as required.

The firmware program running from I309

external SPI flash ROM, contains firmware

code and data for all firmware function. The

device is 2Mbits of flash ROM.

The function of this device is to assert a reset

to I306 scaler GM5726H (GM5766H), when

either the power supply dropped down.

GM5726H (GM5766H)

. And it supports HDCP

Page 6

1. Circuit Description (continued)

HP L1908W

Go to cover page

5

1.3.5d X301 14.318MHz:

It generates reference clock input for I306

scaler.

1.3.5e ISP and DDC/CI function:

The DDC/CI is VESA standard for the host PC

system, it can through I2C bus to control LCD

monitor. Enter I306 pin64 DDC_SCL_A and

pin65DDC_SDA_A of the VGA port. Enter I306

pin66 DDC_SCL_D pin67 DDC_SDA_D of the

DVI-D port. It use ISP function when change

new firmware to I309 SPI flash ROM, it used

IIC bus from VGA or DVI-D port through I306

to I309 SPI flash ROM.

1.3.5f The power save sequence function:

First I306 pin49 (BKLT_EN) set Low to disable

LCD module back light power, delay of some

time, then I306 pin127 (PANELVCC_EN) set

Low to disable LCD module power, then I306

enter to power down mode.

1.3.6 Key & Panel interface (Circuit diagrams sheet 7of 8):

1.3.6a P306 connector:

It is LVDS bus, it is from I306 scaler to LCD

panel module. The P306 output voltage is 5V.

1.3.6b P307 and P308 connector:

The P307/P308 has support keypad function.

Control is given effect for the push switch to be

used when the user changes the parameters,

in order to modify the respective setting

values. Whether the switch has been pressed

is identified with the switch input level change

of I306. Relate ports of I306 based on Table 1.

Each parameter is stored in the I308EEPROM,

the contents of which are updated as required.

The P307 have LED Blue and Amber light, the

LED Blue signal from I306 pin126, and the

LED Amber signal from I306 pin125.

Table 1 Related ports of I306

Pin No. I/O Signal name Function Remarks

Pin 113 I KEY_POWER Soft power s witch input Power k ey

Pin 115 I KEY_MENU Enter OSD s witc h input Enter O SD menu

Pin 114 I KEY_UP Switch input Up key or Viewing model selection

Pin 115 I KEY_DOWN Switch input Down key or Volume control of audio func tion

1.3.7 Audio (Circuit diagrams sheet 8of 8):

1.3.7a P309 connector:

The P309 is audio signal input from the audio

source.

1.3.7b P310 connector:

The P310 is audio output to speaker and

support 2Wx2speakers.

1.3.7c I310 TPA6021A4:

The I310 is 2x2W stereo audio amplifier, it is

an integrated class-AB dual output amplifier.

1.3.7d Q309:

Power down and mute control for Audio

ON/OFF control (AUDIO_EN) is performed for

standby mode and mute function. It supports

5V to audio IC power. The AUDIO_EN signal is

generated from I306.

1.3.7e R394, Q310, volume control for Audio:

Volume control (volume) is performed for

audio output signal power. The volume signal

is generated from I306.

1.3.8 Others:

1.3.8a Detection of POWER ON status:

The I306 is identified the ON status of two

modes for the power supplies. The

identification is made when the power supply

is turn off. For example, if the power supply is

turn off with the POWER key switch, the

POWER key switch must be turn on when

active the power supply again. If the power

supply turned off by the pulling out the power

cord, then this power supply can to be turned

on by connecting the power cord, without

pressing the POWER key switch.

1.3.8b Display mode identification:

(1) Display mode identification:

The display mode of input signal is

identified based on Table 2. When the

mode has been identified through the

measurement of horizontal and vertical

frequencies, the total number of lines is

determined with a formula of Horizontal

frequency and Vertical frequency=Total

number of number of lines . Final

identification can be made by examining

the coincidence of the obtained figure with

the number of lines for the mode identified

from the frequency.

Page 7

6

HP L1908W

1. Circuit Description (continued)

Go to cover page

The Distinction Hsync and Vsync of each mode is

shown in Table3. When the detected frequency if the

sync signal has changed, the total number of lines

should be counted even through it is range identified

frequency in the same mode.

(2) Out of range:

This out of range mode is assumed when the frequency

out of the horizontal/vertical signal is as specified

below.

Vertical frequency : 50 ~ 76 Hz.

Horizontal frequency : 24 ~ 83KHz.

(3) Power save mode:

The power save mode is assumed when the horizontal

and vertical signals are as specified below.

- If there is no horizontal sync signal input

- If there is no vertical sync signal input.

- If the horizontal sync signal is outside the measuring

range of I306.

- If the vertical sync signal is outside the measuring

range of I306.

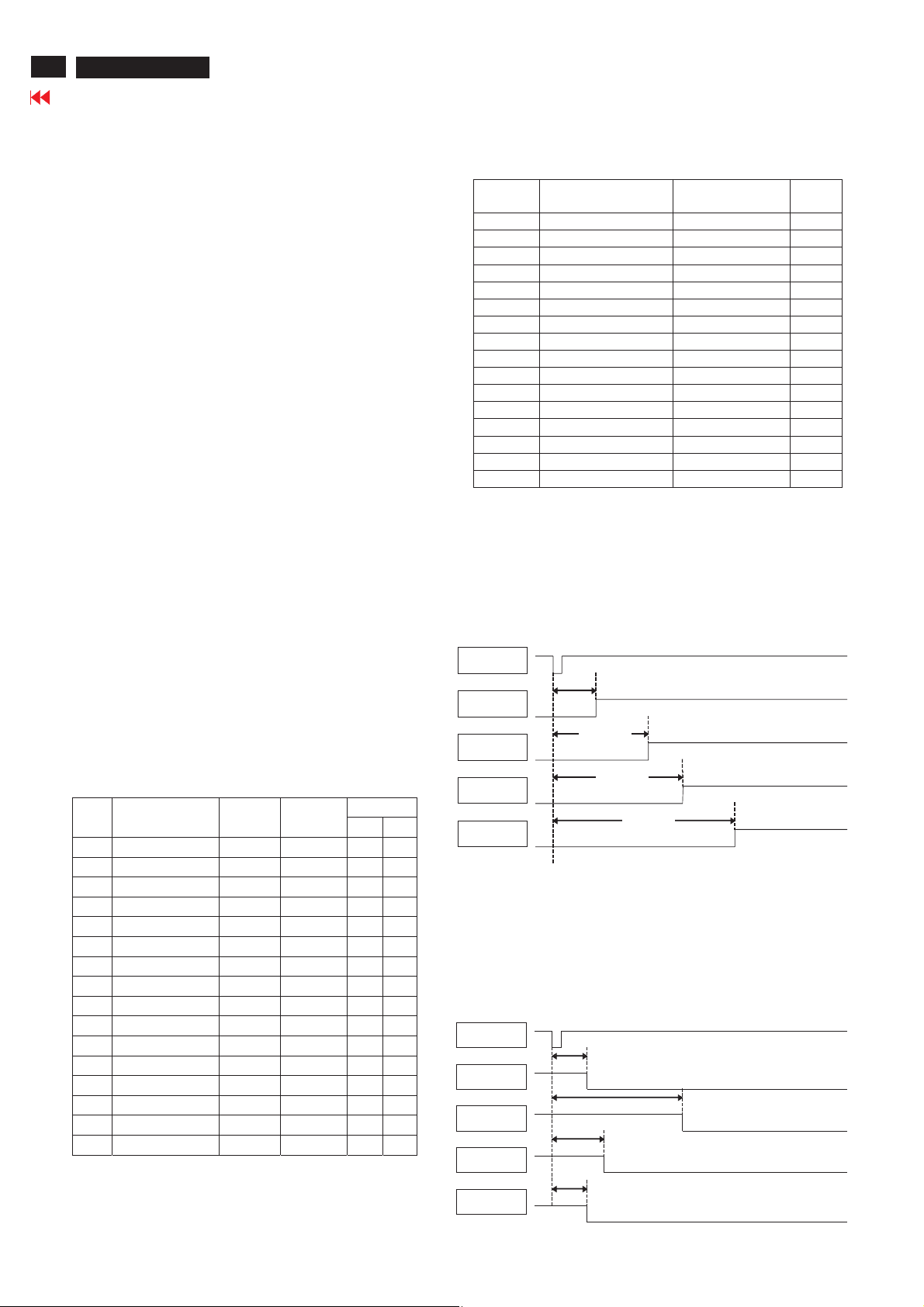

Table 3 the Hsync,Vsync distinction

Indication

resolution

640 x 480

640 x 480

720 x 400

800 x 600

800 x 600

832 x 624

1024 x 768

1024 x 768

1152x720

1152 x 870

1152 x 900

1280x768

1280x960

1280 x 1024

1280 x 1024

1440x900

Distinction Hsync Distinction Vsync The fixed

30.5KHz≦fH≦32.5KHz 59Hz≦fV≦61Hz

36.5KHz≦fH≦38.5KHz 74Hz≦fV≦76Hz

30.5KHz≦fH≦32.5KHz 69Hz≦fV≦71Hz

36.9KHz≦fH≦38.9KHz 59.3Hz≦fV≦61.3Hz

45.9KHz≦fH≦47.9KHz 74Hz≦fV≦76Hz

48.7KHz≦fH≦50.7KHz 73.5Hz≦fV≦75.5Hz

47.4KHz≦fH≦49.4KHz 59Hz≦fV≦61Hz

59KHz≦fH≦61KHz 74Hz≦fV≦76Hz

43.9KHz≦fH≦45.9KHz 59Hz≦fV≦61Hz

67.7KHz≦fH≦69.7KHz 74Hz≦fV≦76Hz

70.7KHz≦fH≦72.7KHz 75Hz≦fV≦77Hz

46.4KHz≦fH≦48.4KHz 59Hz≦fV≦61Hz

59KHz≦fH≦61KHz 59Hz≦fV≦61Hz

62.9KHz≦fH≦64.9KHz 59Hz≦fV≦61Hz

79KHz≦fH≦81KHz 74Hz≦fV≦76Hz

55KHz≦fH≦57KHz 59Hz≦fV≦61Hz

1.3.8c Power ON sequence

When the POWER key switch is pressed, the

POWER key switch signal is turned H . When this

H potential is detected, the CPU begins to

establish the respective power supplies according

to the sequence show below.

mode

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Table 2 video model

Band W idth

(KHz )

1 640x480 (59. 94Hz) 31.469 25.175 - -

2 640x480 (75Hz) 37.5 31.5 - -

3 720x400 (70Hz) 31.469 28.322 - +

4 800x600 (60Hz) 37.879 40 + +

5 800x600 (75Hz) 46.875 49.5 + +

6 832x624 (74. 55Hz) 49.722 57.284 +/- +/-

7 1024x768 (60Hz) 48.363 65 - -

8 1024x768 (75Hz) 60.023 78.75 - -

9 1152x864 (60Hz) 44.86 66.75 - +

10 1152x870 (75Hz) 68.68 100 +/- +/-

11 1152x900 (65Hz) 61.80 92.978 +/- +/-

12 1280x768 (60Hz) 47.396 68.25 + -

13 1280x960 (60Hz) 60.00 108.00 +/- +/-

14 1280x1024 (60Hz) 63.981 108 + +

15 1280x1024 (75Hz) 79.976 135 + +

16 1440x900 (60Hz) 55.94 106.5 - +

(M H z)

Po lar ityM o d e Reso lu tio n H-F r eq

HV

Power Key

296ms

LED Green

PANELVCC_EN

BKLT_EN

AUDIO_EN

516ms

825ms

3.68s

1.3.8d Power OFF sequence:

When the POWER key switch is pressed, while the

power supply is ON, the POWER key switch signal

is turned H . When this H potential is detected,

the CPU begins to turn off the respective power

supplies according to sequence show below.

Power Key

140ms

LED Green

460ms

PANELVCC_EN

157ms

BKLT_EN

AUDIO_EN

140ms

Page 8

1. Circuit Description (continued)

HP L1908W

Go to cover page

7

1. 3.8e List of I/O Pin Assignments of the I306:

Pin No. Port Signal Name

113 LBADC _IN3 PWR_KEYn H O N/OF F LCD monitor

126 GPIO14 LED_B L LED Blue enable when is H

125 GPIO13 LED_A L LED amber enable when is H

114 LBADC _IN2 KEY_UPn H OSD up/plus enable when is 2.46V

115 LBADC _IN1 KEY_MENUn H OSD enter enable when is 2.46V

115 LBADC _IN1 KEY_DO WNn H O SD down/ minus enable when is 2.0V

86 GPIO31 HDCP_HPDn L DVI HPD enable when is L

122 G PIO10 SC L H EEPR OM cloc k signal of IIC bus

123 G PIO11 SD A H EEPROM data signal of IIC bus

50 GPO4 BKLT_ADJ - Backlight br ightnes s control

124 G PIO12 D DC_WPn L DDC EEPROM write p rotect ion when is L

51 GPO0 AUDIO_EN L Audio enable when is H

56 GPO1 VOLUME L Audio v olume

121 GPIO9 VG A_DETn H VGA cable c onnected when is L

120 GPIO8 DVI_DETn H DVI cable connec ted when is L

58 GPO3 UART_DO H UART interface data O UT

57 GPO2 UART_DI H UART interface dat a IN

127 PPWR PANELVCC_EN L Panel power enable when is H

49 PBIAS BKLT_EN L Back light power enable when is H

64 GPIO16 DDC_SCL_VGA H DDC/CI interfac e for VGA

65 GPIO17 DDC_SDA_VGA H DDC/ CI interface for VG A

66 GPIO18 DDC_SCL_DVI H DDC /CI interface for D VI

67 GPIO19 DDC_SDA_DVI H DDC/CI interface for DVI

Initial

Setting

Function

1.3.9 Miscellaneous:

1.3.9a Connector Pin Assignments:

VGA Analog Connector Pinout

PIN MNEMONIC SIGNAL

1 RV Red Video

2 GV Green Video

3 BV Blue V ide o

4 NC None

5 GND Ground (DDC Return)

6RG RedGND

7 GG Green GND

8BG BlueGND

9 +3.3/+5 V +3.3/+5 V (from PC)

10 SG Sync Ground

11 NC None

12 SDA DDC Data

13 HS Horizontal Sync

14 VS Vertical Sync

15 SCL DDC Clock

1.3.9b LED Indicator:

Full Power - HP branded models Green

Sleep - all models Amber

Sleep Timer activated Sleep Mode Flashing Amber (0.5 Hz)

1.3.9c Factory Preset Display Modes:

V-

Pola rit y

Pix el Cl k

(MHz)

Source

CVT 0.83MA

DVT 16:10

Preset

NOTE: Modes 13 thru 15 are support ed with scaled down video pri mari ly t o support navigat ion

to a support ed ti ming mode.

Pix el

Format

1 640 x 480 31. 47 - 59.94 - 25.175 VGA

2 640 x 480 37. 5 - 75 - 31. 5 VGA

3 720 x 400 31. 47 - 70.08 + 28. 321 VGA

4 800 x 600 37. 88 + 60. 32 + 40 VESA

5 800 x 600 46. 88 + 75 + 49.5 VESA

6 832 x 624 49. 72 74.55 57.283 MAC

7 1024 x 768 48.36 - 60 - 65 VESA

8 1024 x 768 60.02 - 75. 03 - 78. 75 VESA

9 1152 x 720 44.86 - 60 + 66.75

10 1152 x 870 68.68 75.06 100 MAC

11 1152 x 900 61.8 65.96 92.978 SUN

12 1280 x 768 47.396 + 60 - 68.25 CVT 0.98M9-R

13 1280 x 960 60 60 108 VESA

14 1280 x 1024 63.98 + 60.02 + 108 VESA

15 1280 x 1024 79.98 + 75.02 + 135 VESA

16 1440 x 900 55.94 - 59. 89 + 106.5 CVT 1. 30MA

H-Fr eq

(kHz)H-Pola rit y

V-Fr eq

(Hz)

PI N 1

PI N 11

PI N 5

PI N 9

Page 9

8

HP L1908W

Go to cover page

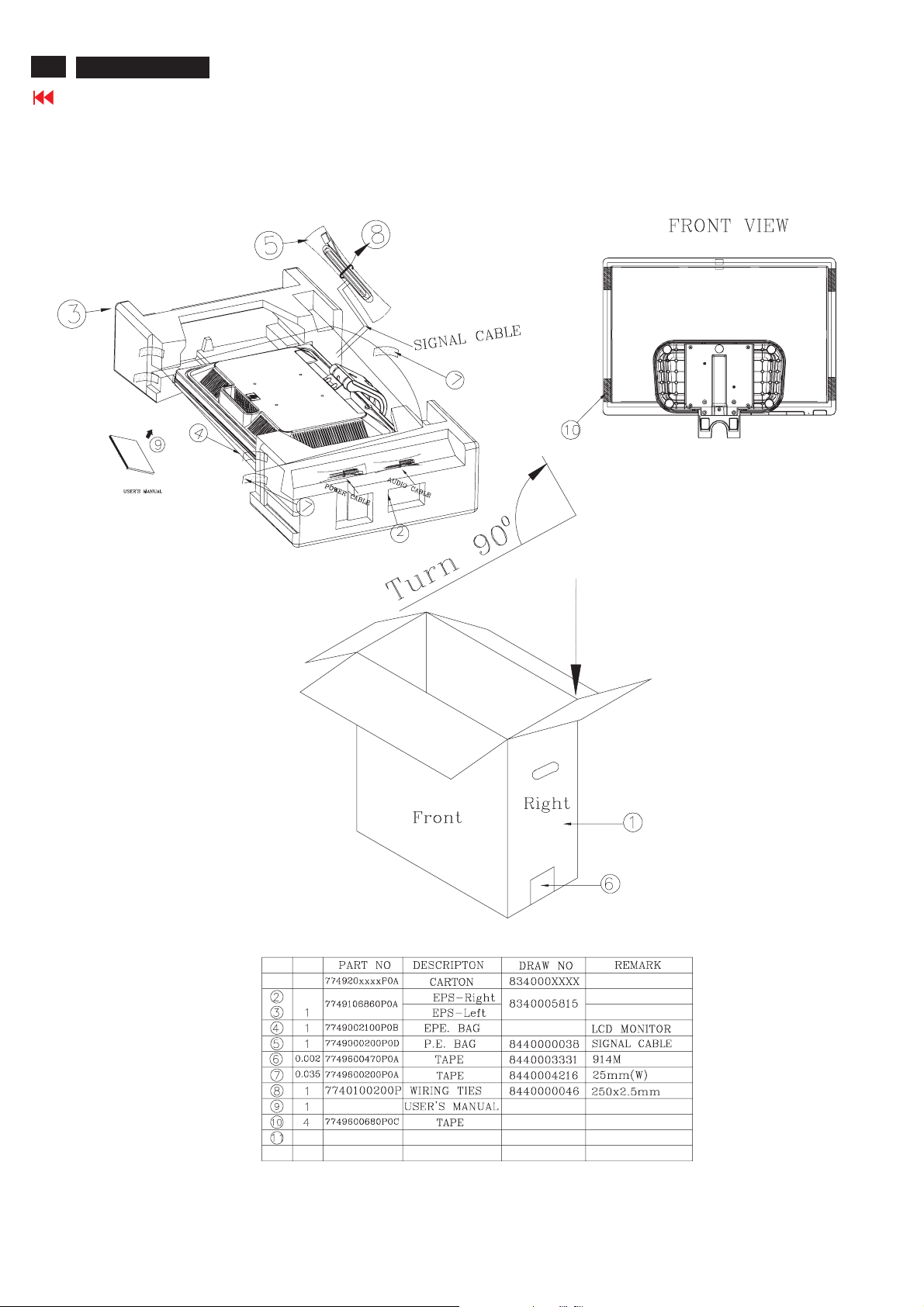

2. Packing Exploded Drawing

The Pape r m ust on top of USER'SMANUAL

in orde r to p ro t ect M ANU AL

.

Page 10

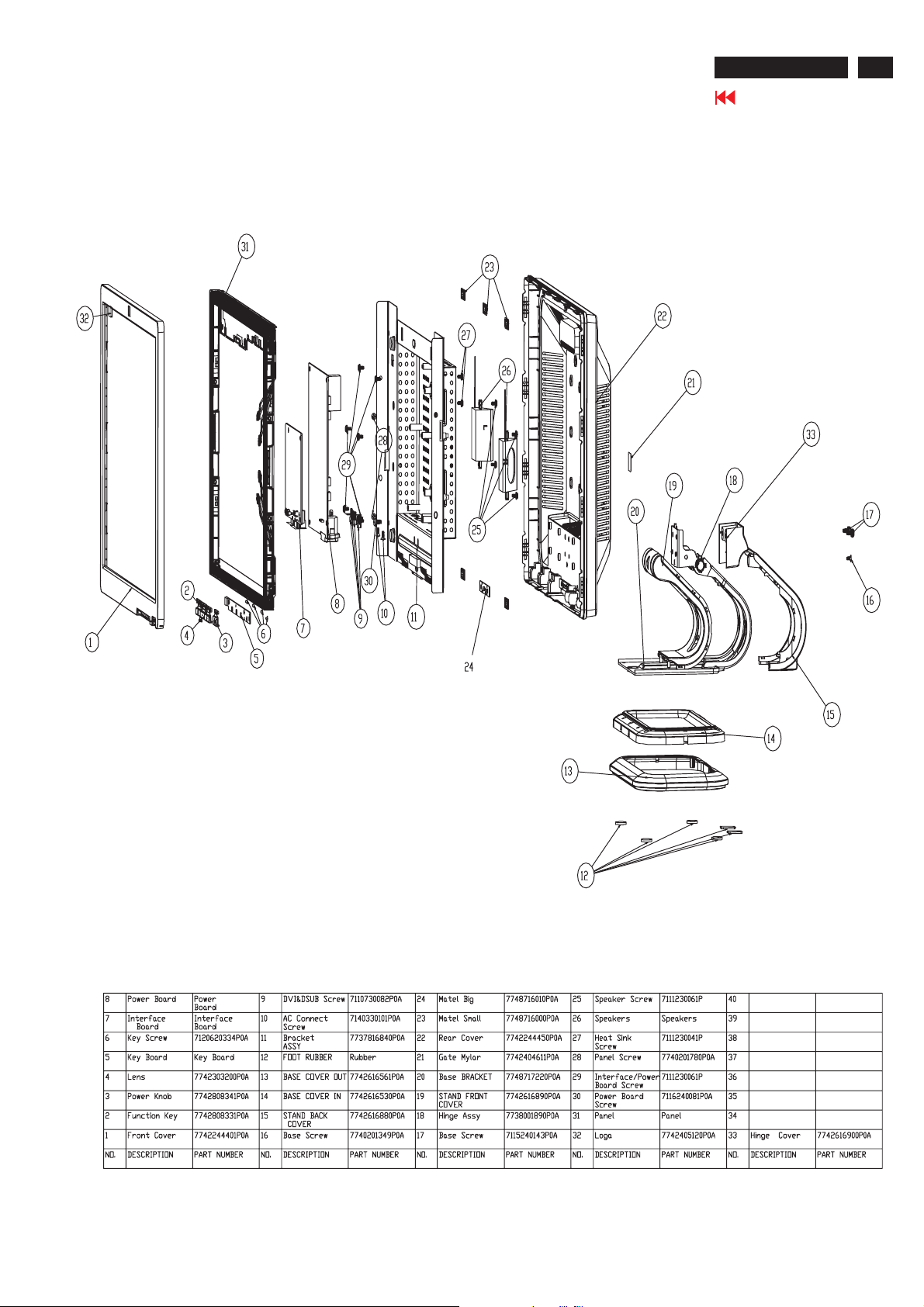

3. Product Exploded Drawing

HP L1908W

Go to cover page

9

Page 11

10

HP L1908W

Go to cover page

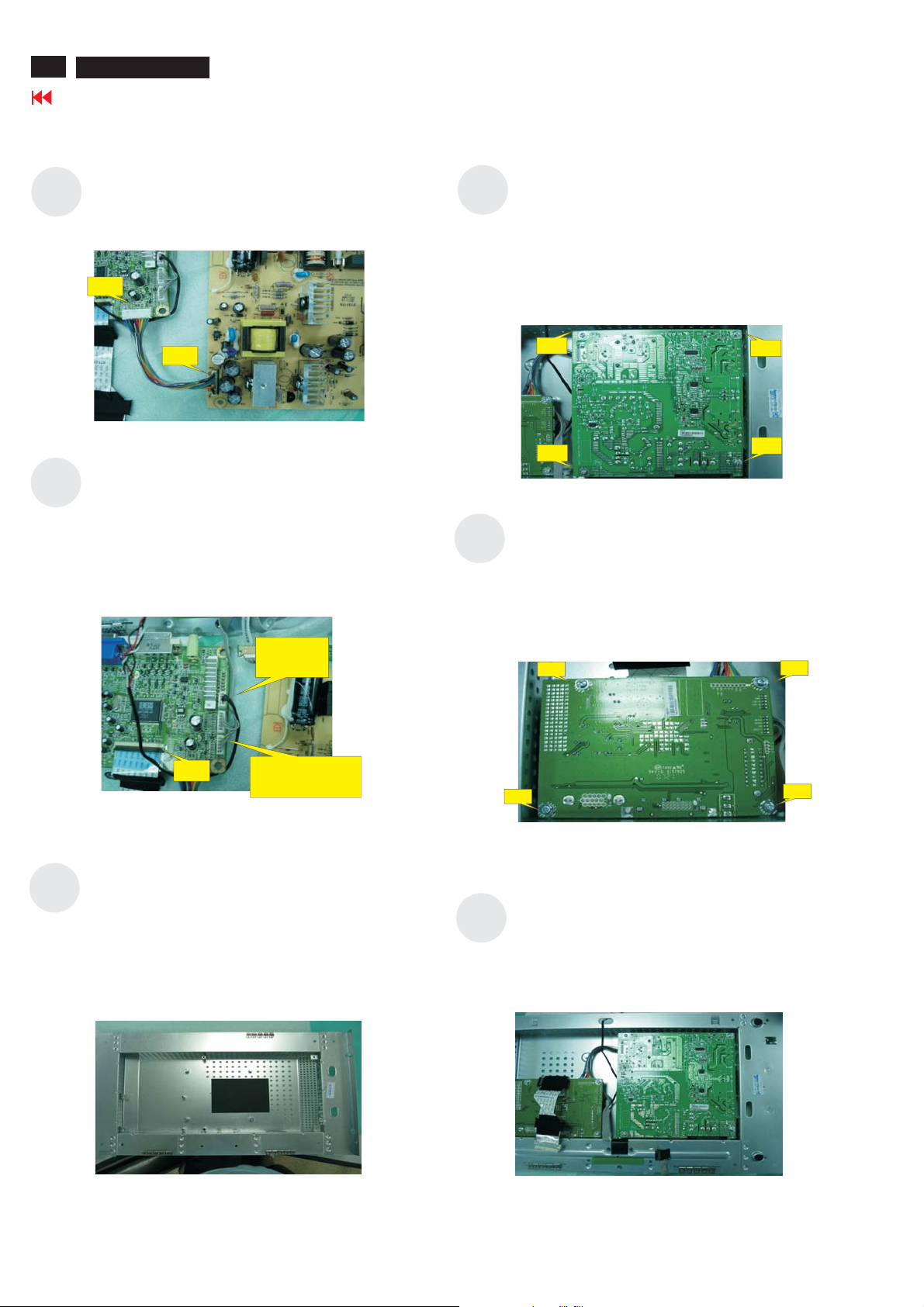

4.1 Assembly Procedures:

Connect the cable between power board(P802) and

S1

interface board (P301)

P301

4. Assembly and Disassembly Procedures

Use a Phillips-head screwdriver screwed the No.1~4

S4

screws till that power board and bracket chassis base

firmly attached.

(No1 screw size=M4x8; No2~4 screw size=M3x6;

Torque=8~10KGFxCM).

S2

P802

Connect FFC cable into interface board

Connect function key cable into interface

board(P307)

Connect speaker cable into interface board(P310)

SPEAKER

CABLE

FFC

FUNCTION KEY

CABLE

S5

3

1

Use a Phillips-head screwdriver screwed the

No.1~4 screws till that interface board and bracket

chassis base firmly attached.

(No1~4 screw size=M3x6; Torque=8~10KGFxCM).

3

4

4

2

1

2

S3

Take a bracket chassis base on a protective

cushion and stick an insulator on the specific

position, take a power board and turn it over. Then,

put it on the specific positions of bracket chassis

base.

Use PVC tape to stick the speaker cable

S6

Page 12

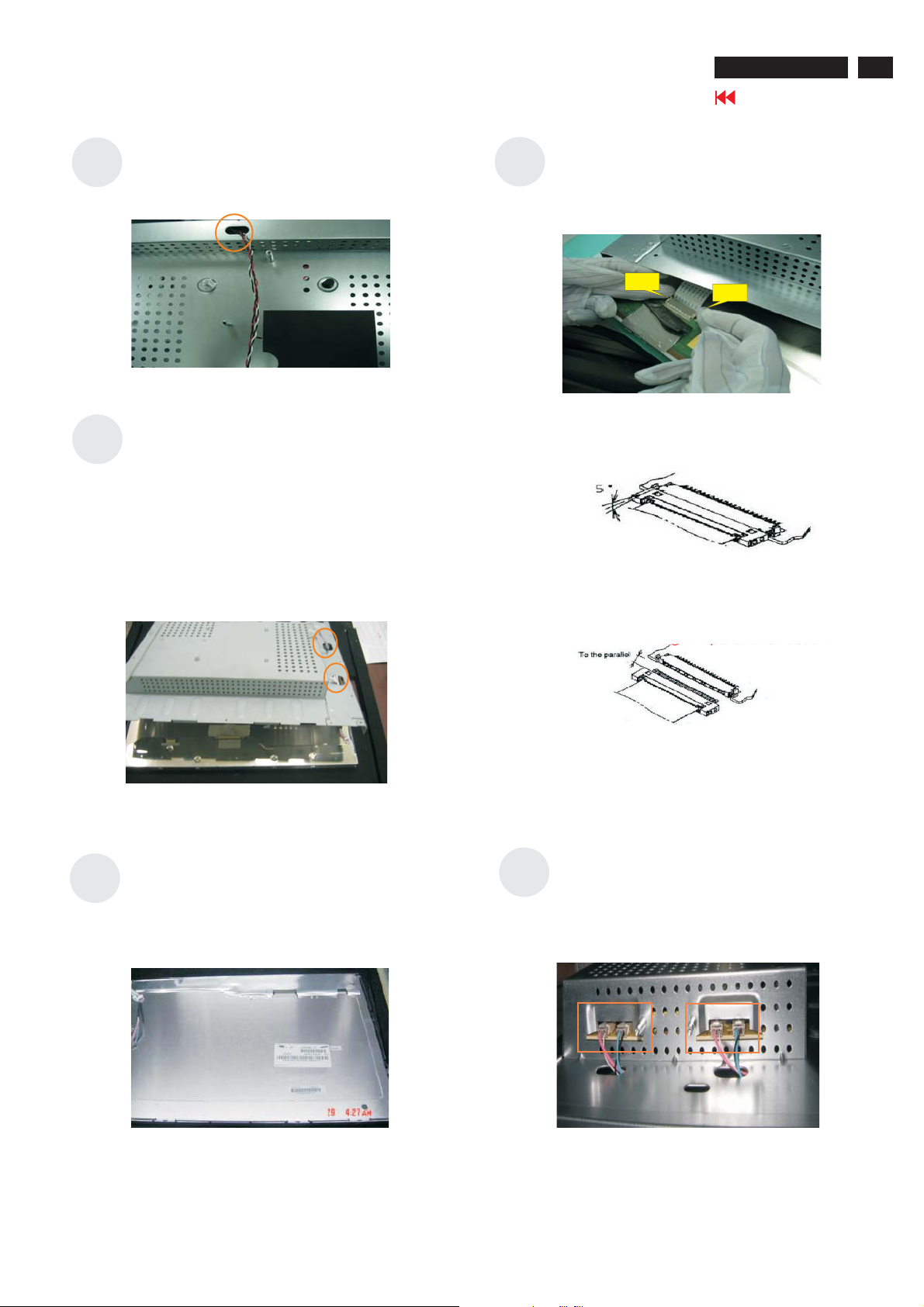

4. Assembly and Disassembly Procedures (continued)

HP L1908W

Go to cover page

11

Take the speaker cable out of the hole shown as

S7

photo

Turn the monitor faced down and put it on the

S8

Bracket Chassis module till both parts firmly

attached

Take lamp cables out from the holes shown as the

photo.

S10

Connect FFC cable to LCD panel. There are two

locks over here when plugging in should be

noticed

LOCK

LOCK

Plug in parallel direction

S9

Connect the FFC cable to the connector of the LCD

panel.

S11

Angel < 5 degrees

Plug 8 lamp cables to the connectors of power

board.(Both of right and left sides)

Page 13

12

HP L1908W

Go to cover page

4. Assembly and Disassembly Procedures (continued)

S12

S13

Use a Phillips-head screwdriver screwed the No.1~4

screws on both side and assemble the LCD panel

and bracket chassis module.

(No1~4 screw size=M3x5; Torque=2.5~3KGFxCM).

1

3

Use a Phillips-head screwdriver screwed the

No.1~2 screws.

(No1~2 screw size=M3x10; Torque=4~6KGFxCM).

1

2

4

2

S16

S17

Connect function key cable into key function cable

(P600)

Put the previous assembled module on the front bezel

Use a Phillips-head screwdriver screwed the

No.1~4 screws.

No1~4 screw size=M2x3.3Torque=0.8~1.2KGFxCM

34

2

1

S14

S15

Use a Hex-head screwdriver screwed the

bracket chassis

(No.1~4 Hex Nut screws

Size=M3x8;Torque=5~7KGFxCM).

12

4

Use a Phillips-head screwdriver screwed the bracket

chassis No.1 screw.

(No1 screw size=M3x4; Torque=4~6KGFxCM).

1

3

S18

S19

Use a Phillips-head screwdriver screwed the

No.1~4 screws.

(No1~4 screw size=M3x6; Torque=6~8KGFxCM).

2

3

Fix speaker line with hook shown as photo

1

4

Page 14

4. Assembly and Disassembly Procedures (continued)

HP L1908W

Go to cover page

13

S20

S21

Put a rear cover on the assembled unit and press

on force mechanisms locked and firmly attached.

4

3

2

1

4

3

2

1

Assemble the stand upper side to the rear cover

through the way of screwing 3 screws till both

units firmly attached.

(No1~2 screw size=M4x14; No3 screw

size=M4x10; Torque=11~13KGFxCM).

1

2

S24

S25

Take two cushion foams; one is held the right side

of LCD monitor, and another is held the left side.

Put accessories f VI able nd

pcos pb

ower able n pecific positions as hoto elow

o D c audio cable a

,

DVI CABLE

POWER

.

S22

S23

3

Stick a screen card on the front bezel with four

tapes.

3

4

1

2

Cover the finished good with an EPE bag. Stick

the EPE bag with one adhesive tape on the rear

side.

S26

AUDIO

CABLE

Move previous assembled parts into the carton

then packing the carton

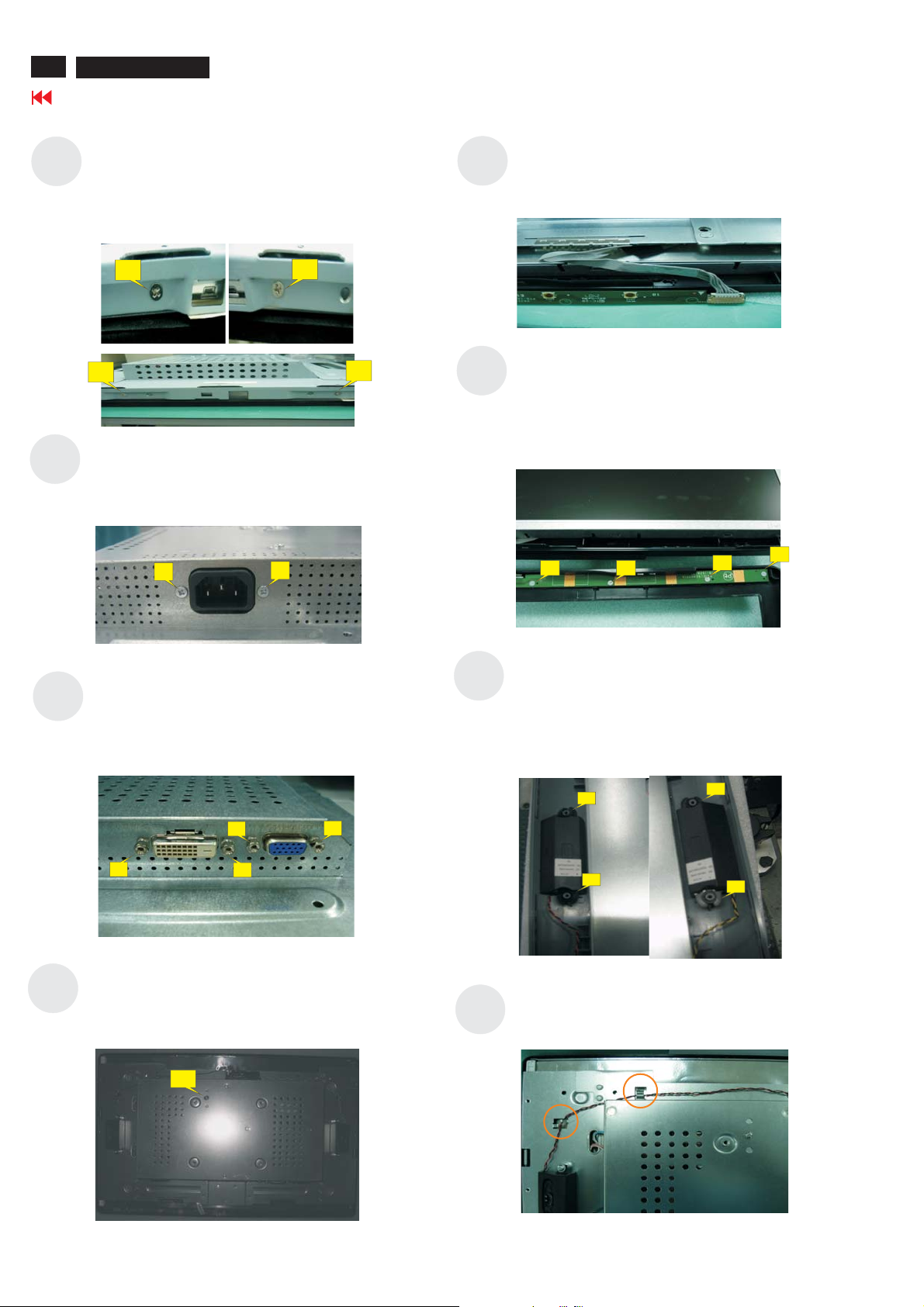

Page 15

14

HP L1908W

Go to cover page

4.2 Disassembly procedures

4. Assembly and Disassembly Procedures (continued)

S1

S2

Open the carton with a proper tool.

Take out all accessories including power cable, DVI

cables, audio cable and packing material from the

carton.

(Note: It depends on whether users returning the

accessories.)

DVI CABLE

POWER

S5

S6

Use a Phillips-head screwdriver unscrew 3 screws to

release the stand base.

(No1~2 screw size=M4x14; No3 screw size=M4x10;

Torque=11~13KGFxCM).

1

Turn over the LCD monitor (screen faced up).

2

3

S3

S4

AUDIO

CABLE

Take off two cushion foams

ut returned unit on a protective cushion,then

P

remove LDPE+EPE bag.

S7

Place cloth on the panel where you are working

on to protect the panel. Continuously, wedge

your finger between the front bezel and the panel,

then pry up on the front bezel to disengage the

locking mechanism.

Work your way along the front bezel to disengage

all the locking mechanism.

Page 16

4. Assembly and Disassembly Procedures (continued)

HP L1908W

Go to cover page

15

Turn over the LCD module(screen face down) then

S8

remove the rear cover

Use a Phillips-head screwdriver unscrewed

S9

number 1~4 screws to release the power key board

from the front bezel

No1~4 screwsize=M2x3.3 Torque=0.8~1.2KGFxCM

S11

S12

Use a Phillips-head screwdriver unscrewed number

1~2 screws to release the speaker from the front

bezel

(No1~4 screw size=M3x6; Torque=6~8KGFxCM).

2

3

1

4

Use a Hex-head screwdriver unscrewed 4 screws to

release the D-SUB and DVI connectors

(No.1~4 Hex Nut screws

Size=M3x8;Torque=5~7KGFxCM).

12

S10

34

2

1

Unconnect the function key cable then remove the

front bezel

S13

S14

4

3

Use a Phillips-head screwdriver unscrewed the

No.1~2 screws to lease power plug

(No1~2 screw size=M3x10; Torque=4~6KGFxCM).

1

2

Use a Phillips-head screwdriver unscrewed the

No.1~4 screws to disassemble the LCD panel and

bracket chassis module.

(No1~4 screw size=M3x5; Torque=2.5~3KGFxCM).

1

3

2

4

Page 17

16

HP L1908W

Go to cover page

4. Assembly and Disassembly Procedures (continued)

S15

S16

Use a Phillips-head screwdriver unscrewed the

No.1screws to lease power plug

(No1 screw size=M3x4; Torque=4~6KGFxCM).

1

Unplug 4 lamp cables (No. 1~4).

S18

S19

Disconnect the FFC cable to the connector of panel.

Use finger to push the lock according to arrow

direction then take out the FFC cable

LOCKLOCK

Examine the panel surface accoring to inspection

criteria. Put it aside.

S17

Take out lamp cables right through the No.1 and

2 square holes and separate the bracket chassis

module and LCD panel apart.

1

2

S20

Use a Phillips-head screwdriver unscrewed the

No.1~4 screws to release the interface board.

(No1~4 screw size=M3x6; Torque=8~10KGFxCM).

3

4

1

2

Page 18

S21

4. Assembly and Disassembly Procedures (continued)

Use a Phillips-head screwdriver unscrewed the

No.1~4 screws to disassemble the power board.

(No1 screw size=M4x8; No2~4 screw size=M3x6;

Torque=8~10KGFxCM).

HP L1908W

Go to cover page

17

S22

3

1

4

2

Disconnect FFC cable into interface board

Disconnect speaker cable into interface board

Disconnect function key cable into interface board

SPEAKER

CABLE

FFC

FUNCTION KEY

CABLE

S23

Disconnect the cable between power board(P802)

and interface board (P301)

P301

P802

Page 19

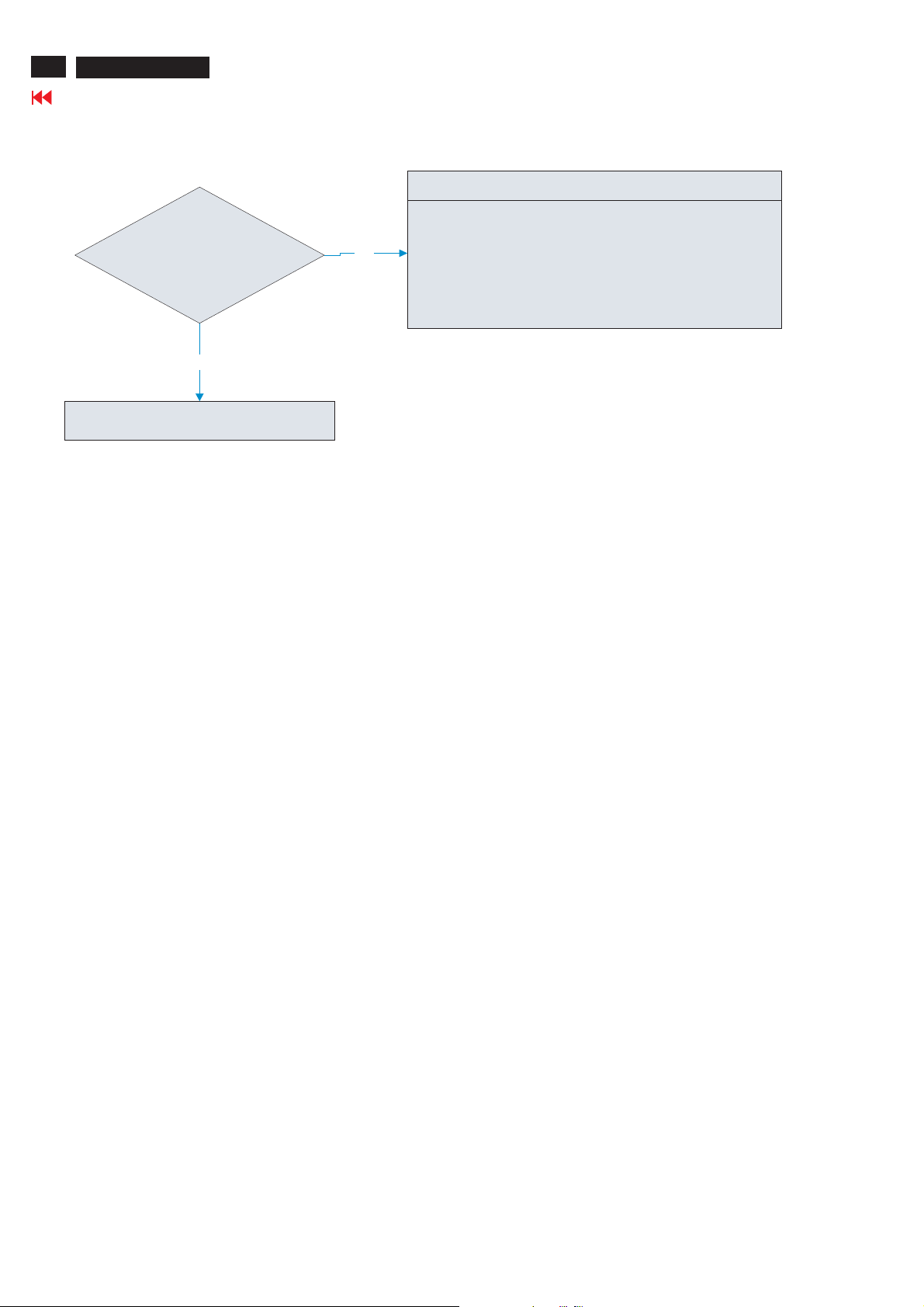

18

HP L1908W

5. Troubleshooting

Go to cover page

5.1 No display on the screen (screen is black, and colour of LED is amber.):

Does the OSD display

on the screen upon pressing

the ‘MENU’?

YES

Check if the sync

signal from computer is

output and if the video cable is

firmly connected.

OK

Proceed to ’5.4 Abnormal screen’

section.

Proceed to ’5.5 Abnormal OSM display’ section.

NG

Input the sync signal of computer or change to

NG

other workable cable for cross-test.

Page 20

5. Troubleshooting (continued)

5.2 Nothing displays on the screen (Screen is black, colour of LED is green.):

HP L1908W

Go to cover page

19

Is backlight lite? Proceed to ‘5.3 Checking the backlight unit’ section

OK

Does the connected

computer output RGB

video signals?

OK

Check the OSD

menu whether if be shown on

the screen upon pressing the

"MENU" key.

OK

Proceed to ‘5.4 Abnormal Screen’

section.

NG

NG

NG

1) Change pattern of video signal output on the host.

2) Reconnect the video cable.

3) Change the video cable.

Check if the LCD

video signal cable is connected

properly between the MAIN

PWB and LCD module.

The cable is disconnected.NG

Check if the 3.3V

power is supplied on I302, pin2

and the 1.8V power is supplied

on I303, pin2.

OK

Check all LVDS signal

pins, output from I306.

OK

Failure Point

1) The cable broke between P306

and LCD module.

2) LCD module failure.

OK

NG

NG

Failure Point

Printed wire broke or shorted

between I306 and P306.

on I302, pin3 that is high level

Check if the Vdc

DC at 5V.

OK

Failure Point

I302 is defected.

NG

Failure Point

1) Printed wire broke between

P301 pin1, pin2, pin3 and I302.

2) Check power board.

Page 21

20

HP L1908W

Go to cover page

5.3 Checking the backlight unit:

5. Troubleshooting (continued)

Check the BKLT_EN

signal of the rectangle input

P301 pin 2 at TTL

high level

OK

Check if the input

signal from the I306 pin50 is a

DC voltage.

OK

Failure Point

Inverter of power board is defected.

Proceed to ‘5.11 Checking the

backlight unit’ section

NG

NG

Is a "H" level been

output in the TTL level from I306

pin49? <or> Is a ‘BKLT_EN’ signal of

the rectangle been

output?

Failure Point

1) Printed wire broke between I306

pin50 and P301.

2) I306 failure.

NG

Failure Point

Printed wire is broken between

I306 pin49 and P301.

Page 22

5.4 Abnormal screen:

Check the R, G, B video

signal from computer input on DSub

R, G, B connector.

5. Troubleshooting (continued)

NG

1) No R, G and B video signal is output from the

connected computer. Contact your regional computer

supplier for technical support.

2) Video signal cable is disconnected.

Failure Point

HP L1908W

Go to cover page

21

OK

Check the R, G, B

input signals on I306 pin93, pin96,

pin99 respectively that their level is

0.7Vp-p maximum.

OK

Check all LVDS signal pins

which are output from I306.

OK

Process ‘5.8 Checking the resolution change

IC movement’ section.

NG

NG

Failure Point

Below results are based on the Red signal. (Green and

Blue signals are the same.)

1) Printed wire is broken between D-Sub(R) and I306

pin99.

2) R315 is short.

3) C317 is open.

4) R310 is open.

5) FB305 is open

6) FB306 is open

Failure Point

1) I306 failure.

2) Printed wire is broken between I306 and P306.

Page 23

22

HP L1908W

5. Troubleshooting (continued)

Go to cover page

5.5 Abnormal OSD screen, OSD adjustment problem:

Check the input TTL level

whether if it was changed upon

pressing function keys.

OK

Proceed ‘5.4 Abnormal Screen’ section.

NG

Failure Point

1) Printed wire broke between P308 pin 5 and I306 pin 113.

2) Printed wire broke between P308 pin 4 and I306 pin 113.

3) Printed wire broke between P308 pin 3 and I306 pin 113.

4) Printed wire broke between P308 pin 2 and I306 pin 113.

5) C389, C390, C391, C392, short.

6) R381, R382, R384, R385, R378, R379 short/open.

7) R380, R383 open.

8) I306 failure.

Page 24

5.6 Abnormal plug and play operation:

5.6.1 Abnormal DDC2 (D-SUB):

5. Troubleshooting (continued)

HP L1908W

Go to cover page

23

Confirm the output

of serial data on I304 pin 6

synchronize SCLK at

TTL level.

OK

Failure Point

1) The host machine isn't communicating in DDC2

mode.

2) The video cable may be defected or may be

disconnected to cause the DDC communication

failure.

3) Printed wire is broken between I304 pin6 and P302

pin15.

4) R328, R329 is open.

5) I304 pin5 or pin6 is short.

6) Video cable is defected.

5.6.2 Abnormal DDC2 (DVI):

Failure Point

NG

I304 is defected.

Confirm the output

of serial data on I305 pin6

synchronize SCLK

at TTL level.

OK

Failure Point

1) The host machine isn't communicating in DDC2

mode.

2) The video cable may be defected or may be

disconnected to cause DDC communication

failure.

3) Printed wire is broken between I305 pin6 and P303

pin6.

4) R346, R347 is open.

5) I305 pin5 or pin6 is short.

6) Video cable is defected.

Failure Point

NG

I305 is defected.

Page 25

24

HP L1908W

5. Troubleshooting (continued)

Go to cover page

5.7 Checking the interface circuit of sync signal:

5.7.1 Checking the control circuit of horizontal sync pulse:

Check the

Horizontal sync

signal on I306 pin89

TTL level.

OK

Proceed to ‘5.8 Checking the resolution

change IC movement’ section.

NG

Failure Point

1) Video cable may have failed.

2) Printed wire broke between P302 pin13 and I306

pin89.

3) FB311, R321 is open.

4) R324, C328 is short.

5) I306 is defected.

5.7.2 Checking the control circuit of vertical sync pulse:

Check the vertical

sync signal on I306

pin90 TTL level.

OK

Proceed to ‘5.8 Checking the resolution

NG

change IC movement’ section.

Failure Point

1) Video cable may be defected.

2) Printed wire is broken between P302

pin14 and I306 pin90.

3) FB312, R322 is open.

4) R323, C327 is short

5) I306 is defected.

Page 26

5.8 Checking the resolution changed IC movement:

5. Troubleshooting (continued)

HP L1908W

Go to cover page

25

on I306 pin2, pin25, pin47, pin53, pin74,

Is there +3.3V supply

pin82, pin91, pin92, pin101, pin110,

pin116?

OK

Is there +1.8V supply on I306

pin17, pin55, pin70, pin78, pin87,

pin104, pin106, pin118?

OK

Is 14.318MHz clock input

to I306 pin108 and pin109 at TTL

level during Power On?

OK

NG

NG

Proceed ‘5.9 Checking the DC/DC converter circuit’

section.

Proceed ‘5.9 Checking the DC/DC converter circuit’

section.

Is 14.318MHz clock

output from X301 pin1 at

NGNG

TTL level during Power

On?

Failure Point

OK

X301 failure

Failure Point

Is +5.0V supplied to I306 pin111 at

low level (Reset signal)?

OK

Failure Point

I306 is defected.

Print wire broke between X301

pin1 and I306 pin108.

NG

Check if the output of 5.0V

"L" pulse from I307 pin 2.

OK

Failure Point

Print wire broke between I307

pin2 and I306 pin111.

NG

Is 5.0V supplied to I307

pin3?

OK

Failure Point

I307 is defected.

Page 27

26

HP L1908W

Go to cover page

5.9 Checking the DC/DC converter circuit:

5. Troubleshooting (continued)

Check if the 5V is output

from P301 pin5, pin6 to I302 pin3.

Take off wire harness

connector of P301. Check if the

output of +5.15V between P802 +5.1V

(whichever pin 4,5,6,7) and ground (The

through hole of power board).

NG

Failure Point

Power board defect, proceed to

“5.10N0powerONcheck.”

NG

OK

Does +3.3V on I302 pin 2?OK Does +1.8V on I303 pin 2?OK

NG

Is the low resistance

(lower than 5? ) between I302

pin 2 and ground

(P301 pin 1 or pin 9) ?

Yes

Failure Point

1) I302 defected.

2) The +3.3V circuit been ground

connection.

* Might be I306 defected or by pass

capacitor of power pin of I306 3.3V

defect.

NG

Is the low resistance

(lower than 5? )

between I303 pin 2 and ground

(P301 pin 1 or pin 9) ?

Yes

Failure Point

1) I303 defected.

2) The +1.8V circuit been ground

connection.

* Might be I306 defected or by pass

capacitor of power pin of I306 1.8V

defect.

Is the low resistance

(lower than 5 ohm)

between I302 pin3 and ground

(P301pin1orpin9)?

No

Is the low resistance

(lower than 5 ohm) between

I302 pin2 and ground

(P301 pin1 or pin9)?

Yes

Failure Point

1) I302 defected.

2) The +3.3V circuit been ground

connection.

* Might be I306 defected or by pass

capacitor of power pin of I306 3.3V

defect.

Yes

Failure Point

1) C313 short.

2) I302 is defected.

No

Failure Point

1) I302 is defected.

2)Printed wire is broken between I302

pin3 and output of FB301,FB302.

Page 28

5.10 No power on:

Check if the output voltage

+5V is correctly

OK

6. Troubleshooting (continued)

Failure Point

OK

The functions of Power Board is working

successfully.

HP L1908W

Go to cover page

27

Check if AC power

cord P801 and signal cables

of P302, P802, P101, P102,

P103, P104 is connected

properly.

OK

Check if C801 has

charged DC140V-330V

OK

Check if C807 is over

16V or not.

OK

Check if I801 pin8

has same pulse

or not.

Failure Point

Reconnect the P801, P302, P802, P101, P102,

NG

P103, P104 cables and make sure they are firmly

connected.

Failure Point

NG

Check F801, D802, P801 and repair them if be

damaged

Failure Point

NG

Check D803, R807, I801, C807, ZD801 and repair

them if be damaged.

Failure Point

NG

Check peripheral components of I801 and repair

them if be damaged.

OK

CheckifT801pin1has

same pulse or not.

OK

Check if peak voltage

of R813 triangle pulse is up to

1.5V or not.

OK

Check T801,

D812, C825, C824 have

same short circuit, or the

output +5V is

over load

OK

Check feedback circuit around I803 and

the other component and repair them if be

damaged.

Failure Point

NG

Check Q801, R813 and repair them if be damaged.

Failure Point

NG

Check if peak voltage of R813 triangle pulse is up

to 0.85V or not.

Failure Point

OK

Repair T801, D812, C825, C824 if be damaged.

Page 29

28

HP L1908W

Go to cover page

5.11 Checking inverter board circuit:

5. Troubleshooting (continued)

Check 22V output

pin is around 20V; on/off

pin is over 3V; brightness pin is in the

range o f 0V and

3.2V.

OK

Check if I101 pin6 is 5V.

OK

Check if P101, P102, P103,

P104 is connected properly.

OK

Check if I101 pin4, pin5 has triangle

pulse.

Failure Point

OK

The functions of Inverter Board is working successfully.

Failure Point

NG

Check R105, C112 and repair them if be damaged.

Failure Point

NG

Check CCFL and repair them if be damaged.

Failure Point

NG

Check I101 and repair them if be damaged.

OK

Check if I101 pin1 has

soft start edge up to 2.4V.

OK

Check if T801 pin1 has

same pulse or not.

OK

Check if I101 pin8

haspulseupto1.2Vfromoutput

detection.

OK

Check if half bridge

circuit (Q104, Q105, Q106, Q107,

Q108) is

working fine .

Failure Point

NG

Repair I101.

Failure Point

NG

Check Q801, R813 and repair them if be damaged.

Failure Point

NG

Check D102, D103, D107, D108, D114, D115, D112,

D113 and repair them if be damaged.

Failure Point

OK

Repair Q104, Q105, Q106, Q107, Q108 if be damaged.

OK

Check if transformers of T101, T102 are

working fine .

Page 30

5.12. Abnormal Audio Output:

Check if the audio signal supplied

to I310 pin 4,5,7 and 8.

5. Troubleshooting (continued)

NG

HP L1908W

Go to cover page

Failure Point

1) Check if audio cable is connected to P309.

2) Check if FB318, R386 or C394 open/short.

3) Check if FB319, R387 or C398 open/short.

4) Check if C395, C396 open/short.

2) Check if printed wire is broken between P309

pin2 (pin3) and C398 (C394).

3) Check if I310 defect.

29

OK

Check if the +5.35V is

Supplied to I310 pin 3, pin 6

and pin 9.

OK

Check if the logic H level on the

I310 pin 14.

OK

I306 defected.

Check if the lower than 0.5V

on the I310 pin 18 while volume

at default setting.

Failure Point

1) Check if FB321 defect.

2) Check if printed wire is broken between P301

pin7 (pin8) and FB321.

NG

3) Check if I310 defect.

* The circuit been ground connection on

pin3, pin6, and pin9.

NG OK

Failure Point NG

Yes

Check if the logic High level

on I306 pin 51.

NG

Check if the PWM pulse on

I306 pin 56.

Failure Point

1) Check if R390, R391, R392 open.

2) Check if C400 short.

3) Check if Q309 defected.

4) Check if printed wire is broken between Q309

and I310 pin14.

5) Check if I310 defect.

* The circuit been ground connection on pin3

or pin 6 or pin 9.

Failure Point

1) Check if R393, R394, R395, R396, C405

open/short.

2) Check if Q310 defected.

Yes

3) Check if printed wire is broken between Q310

and I306 pin 56.

5) Check if I310 defect.

NG

1) Check if printed wire is broken between I310

pin2, pin20, pin10, pin12, and P310 pin4, pin3,

pin2, pin1.

2) Check if I310 defect.

3) Check if wire harness is broken.

4) Check if the speaker defected.

Page 31

1234567 8910111213

G

F

E

Speaker

2x2W

D

To Speaker

P310 Audio Output

C

B

A

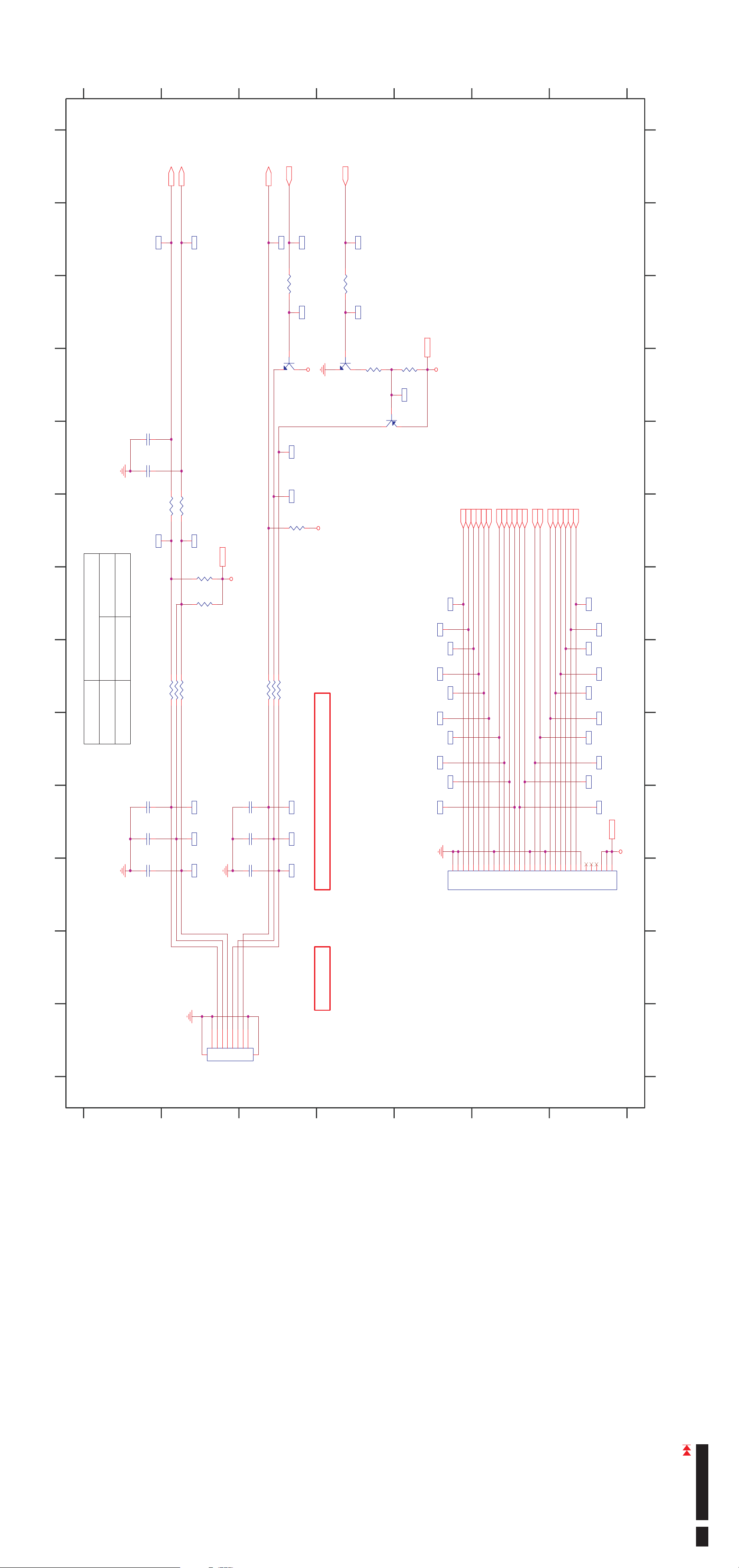

6. Schematics and Layouts:

.6 1 HP_L1908W_BLOCK DIAGRAM

AC IN-

1234567 8910111213

Audio

Source

P309 Audio Input

()AUDIO Source

DDC SCL DVI__

DDC SDA DVI__

()DVI EDID

I305 24LC02

I310 Audio AMP

()TDA6021A4

LDO

+.3 3V Main

Power

I303 I307 Reset IC

LDO

+5V DC power

I302

+5V DC power

for audio

Brightness Invter On Off,/

Power)

+5V DC Power

(Switch LCD

Panel

P301

()Connect to Power Board

Power Board

CCFL Wire

Video

Input

Video

Input

Digital

Analog

P303 DVI D-

P302 DSUB

TMDS

RGBHsVs,,, ,

()VGA EDID

DDC SCL VGA__,

DDC SDA VGA__

I304 24LC02

+.1 8V Main

Power

Power

Gm5726H

Scaler

I306

Serial Flash ROM

+.3 3V Main

I301

+5V Panel

Power

LVDS

P306 LVDS output

LCD Module

PCB No.

P307 P308&

Function Key Input

& LED output

Function

Key

Board

I309

EEPROM

24LC16B

I308

Interface Board

G

F

E

D

C

B

A

Go to cover page

HP L1908W

30

Page 32

G

F

E

D

C

B

A

._2 POWER BOARD6 _SCHEMATICSHP_L1908W

1234567 8910111213

R151 39K 75K:~

(. ~ . )7 5mA 6 5mA

VCC

GND 1-

P801

GND

R820

300K

0805

0 1U 275V./

C804

*

0 1U 275V./

C825

2200P 250V Y/-

GND 1-

0 01u 1KV./

2

D801

GBLA08

100U 450V/

GND

2

1

C809

N

0805

GND

15K

2

300K

+

1KV

R804

1

-

4

G

3

R821

300K

0805

C801

*

4

3

C819

C820

2200P 250V Y/-

+

C805

C815

0 01uF.

3 15AL250V.

R822

C803

ET 20-

3

L

1

T801

051.

F801

R802

SCK083

C808

0 01u 1KV./

R803

1234567 8910111213

GND 2-

R101

10K

C105

1000P

R135

1M

GND 2- GND 2-

1000P

C130

R151

39K

1000P

C131

GND 2-

GND 2-

GND 2-

1000P

GND 2-

2

2 2uF 50V./

30 1K.

R103

18K

GND 2-

876

NC

OVPT

VSEN

OZ9938

ENA

LCT

NC

9101112131415

C103

2 2uF 50V./

1

2

+

R106

150K 1%

C106

0 047uF.

C161

68P

C104

330P

C111

+

C110

R102

1

5

ISEN

DIM

SSTCMP

CT

R107

56K.

10K

4

GND 2-

R113

3

TIMER

GNDA

2

VDDA

DRV2

GND 2-

DRV1

PGND

GND

1

16

510K

56K

22uF 50V/

R104

R118

I101

10K

2

R136

0 1uF.

C101

C102

+

1

22

GND

R105

GND

GND

4 75K 1.%

23

R826

1K

R825

270

C827

GND 1-

R806

4

I802

1

R823

120K 0805/

R829

+5V

ON OFF-

BRI

R808

13K

GND 1-

33nF

C812

C826

10K

1uF 50V/

GND 1-

2 2uF 50V./

A

1

VR801

2

C828

I803

AP431

1

+

LTV817

+

C

2

1K

R

3

0 01uF.

R827

33K 1%

0

VCC

GND 1-

1uF 50V/

R816

0 22uF.

C813

R809

100K

1

2

+

C829

PRCT

CTRL

TEA1530

GDRV

IS

54

68K 0805/

R830

1K MOF/

R819

4 7K MOF./

R815

0 22uF.

C811

D807

18B

1

3

2

1

VCC

GND

I801

HV SPACE

DRAIN

8

7

6

82uF 35V/

GND 1-

C807

1

2

+

22 MOF/

R814

R813

100 MOF/

1N4148

D806

21

R807

39.

PCB No.

6832177300P01

GND

GND

2

2 1

0 022uF.

470 1%

D121

1N4148

D113

1N4148

C128

R130

1

GND

12K

21

21

1K 0805/

R128

D112 1N4148

21

GND

1N4148

R142

D120

D118

1N4148

GND

R122

15K 1%

100 0805/

1K 0805/

R126

33K1.%

470P

X7R

R140

R139

21

C119

2

2

1N4148

3M 1 4W/

R121

100K 1%

GND

D109

R125

MOF

100K 2W/

R818

C806

R805

1

C818

C817

0 1uF.

R840

D811

JUMPER WIRE

+

+

C814

1W

2 10

ER28

L804

3

2

1

+22V

T802

D809

STPF1020CT

1

1N4937

1

BEAD 6mm/

L803

SRF1045C

2

GND

GND

D804

21

7

3

D810

1K

1

2

3

7N65C

Q803

1KV X7R

R811

C832

3300P 250V/

0805

1000U 10V/

1000U 10V/

1000U 10V/

0 1uF.

+

C822

+

C824

+

C823

100P

100V X7R

C831

C810

3

C802

10U

1000P

C821

GND 1-

6

L802

+5V

R817

PR1007G

154

2

Q806

3904

D803

500V X7R

GND 2- GND

GND

1K

3

0 01uF 630V./

9

C816

1000P

470U 35V/

NC

0805

68K

0805

22B

R828

910 2W/

R824

R851

R852

100

GND

GND

8765432

1N4148

21

GND 1-

GND

ON OFF-

D812

1

0272W./

GND 1-

1000P 250V/

GND

GND

GND

BRI

P802

R853

Q102

+

+

C112

C114

2

15K.

33K 1%

47K1.%

3

1

1

+22V

GND

GND

9

10

1

1

2P

P101

R163

220K

2K 0805/

R134

2

Q103

R131

AOD413

Q104

3

C191

1N4148

21

3M 1 4W/

100K 1%

C115

2

2

2K 0805/

R132

2

1

1

3904

GND

2

C124

470uF 35V/

GND

2

470uF 35V/

C125

D106

R116

10P 3KV/

R117

5P 3KV/

1

1

2

2P

P102

GND

21

21

R120

D107 1N4148

D116

1K 0805/

3

GND

R141

21

1

2N7002

GND

2

D114

1N4148

GND

15K 1%

100 0805/

1K 0805/

2

Q101

3

33

SB140

0805

R115

33K1.%

R119

X7R

R138

R137

3906

1

D101

220P

470P

R133

33

1

D141

22B

GND

10P 3KV/

5P 3KV/

1

1

2P

P104

2

1206

1206

1206

C116

C118

2

3

10UF

10UF

10UF

C134

C123

C122

1

SB140

D102

0805

1

1

2P

AOD454

C192

220P

EEL22

P103

2

Q105

3

.

7

2

6

.

T101

.

.

514

8

12K

D108

2 1

1N4148

C109

0 022uF.

GND

470 1%

R111

1N4148

GND

2

1

D117

1N4148

GND

G

F

E

D

C

B

A

Go to cover page

HP L1908W

31

Page 33

G

F

E

D

C

B

A

._6 _SCHEMATICS3 INTERFACE BOARD TOPHP_L1908W

NC

1234567 8910111213

VOLUME

6 AUDIO.

VDD

6 AUDIO.

3 DVI DDC INTERFACE.&

VDD

DDC SDA DVI__

DDC SCL DVI__

AUDIO EN_

VOLUME VOLUME

AUDIO EN AUDIO EN__

DDC SDA DVI DDC SDA DVI__ __

DDC SCL DVI DDC SCL DVI__ __

NC

RXC+

RXC-

RXC RXC--

RX1+

RX0+

RX2-

RX1-

RX0-

RX1 RX1--

RXC RXC++

RX0 RX0++

RX1 RX1++

RX0 RX0--

VCC5V

3 DVI DDC INTERFACE.&

VCC5V

HDCP HPDn_

DDC WPn_

DVI DETn_

RX2+

RX2 RX2--

RX2 RX2++

DVI DETn DVI DETn__

DDC WPn_

HDCP HPDn HDCP HPDn__

2 VGA DDC INTERFACE.&

VGA DETn_

DDC WPn_

DDC WPn_

DDC SCL VGA__

DDC SDA VGA__

DDC SDA VGA DDC SDA VGA__ __

DDC SCL VGA DDC SCL VGA__ __

VCC5V

2 VGA DDC INTERFACE.&

VCC5V

HS IN_

VS IN_

VS IN VS IN__

GNDG

BIN

BIN BIN

GNDB GNDB

GNDR

GIN

GNDG GNDG

GIN GIN

RIN

GNDR GNDR

RIN RIN

GNDB

HS IN HS IN__

1234567 8910111213

VGA DETn_VGA DETn_

DDC WPn_

4 SCALER GM5726H.

AUDIO EN_

VOLUME

DDC SCL DVI__

DDC SDA DVI__

DDC SCL VGA__

DDC SDA VGA__

VGA DETn_

RXC-

DVI DETn_

HDCP HPDn_

RX2+

RX2-

RX1+

RX1-

RX0+

RX0-

RXC+

DDC WPn_

VS IN_

BIN

HS IN_

GNDB

GIN

GNDG

RIN

GNDR

4 SCALER GM5726H.

PANELVCC EN_

3V3 DVDD1_

VCC3V3

VCC1V8

VCC5V

CH0N LV O__

CH1N LV O__

CLKP LV O__

CH0P LV O__

PWR KEYn_

LBADC IN2_

BKLT ADJ_

BKLT EN_

LBADC IN1_

LED B_

LED A_

CLKN LV O__

CH2N LV O__

CH1P LV O__

CH2P LV O__

CH3N LV O__

CH3P LV O__

CLKN LV E__

CH0N LV E__

CLKP LV E__

CH0P LV E__

CH1P LV E__

CH1N LV E__

CH2P LV E__

CH3N LV E__

CH2N LV E__

CH3P LV E__

PCB No.

VCC5V

VCC3V3

VCC1V8

3V3 DVDD1_

VCC3V3

1 POWER.

VDD

VLCD

VCC1V8

VCC5V

BKLT ADJ BKLT ADJ__

BKLT EN BKLT EN__

PANELVCC EN PANELVCC EN__

1 POWER.

BKLT ADJ_

BKLT EN_

PANELVCC EN_

5 KEY PANEL INTERFACE.&

PWR KEYn PWR KEYn__

LBADC IN2_

PWR KEYn_

LED B LED B__

LED A LED A__

LBADC IN2 LBADC IN2__

LBADC IN1 LBADC IN1__

LED B_

LED A_

LBADC IN1_

3V3 DVDD1_

VLCD

CLKN LV O CLKN LV O__ __

CLKN LV O__

CLKP LV O__

VCC5V

CH0N LV O CH0N LV O__ __

CLKP LV O__CLKP LV O__

CH0P LV O__

CH0N LV O__

CH1P LV O CH1P LV O__ __

CH0P LV O CH0P LV O__ __

CH1N LV O CH1N LV O__ __

CH1N LV O__

CH1P LV O__

CH2N LV O CH2N LV O__ __

CH2P LV O CH2P LV O__ __

CH2N LV O__

CH2P LV O__

CH3N LV O__

CH3N LV O CH3N LV O__ __

CH3P LV O__

CH3P LV O__CH3P LV O__

CLKN LV E CLKN LV E__ __

CLKP LV E CLKP LV E__ __

CH0N LV E__

CLKP LV E__

CLKN LV E__

CH1N LV E CH1N LV E__ __

CH0N LV E CH0N LV E__ __

CH0P LV E CH0P LV E__ __

CH1N LV E__

CH0P LV E__

CH1P LV E CH1P LV E__ __

CH2N LV E CH2N LV E__ __

CH2P LV E__

CH2N LV E__

CH1P LV E__

CH3P LV E CH3P LV E__ __

CH2P LV E CH2P LV E__ __

CH3N LV E CH3N LV E__ __

CH3P LV E__

CH3N LV E__

5 KEY PANEL INTERFACE.&

6832176900P02

G

VDD

VLCD

F

VCC3V3

VCC1V8

VCC5V

E

D

VLCD

3V3 DVDD1_

C

VCC5V

B

A

Go to cover page

HP L1908W

32

Page 34

G

F

E

D

C

B

JWT A2001WR2 9P--

A

._6 4 _SCHEMATICS INTERFACE BD_POWERHP_L1908W

1234567 8910111213

10uF 16V/

C313

P301

1234567 8910111213

PANELVCC EN_

VCC5V

PANELVCC EN_

T16

R309

2K4

T10

PBY160808T 600Y S--

FB303

123456789

BACKLIGHT ADJ_

BACKLIGHT EN_

FB301 PBY160808T 600Y S--

FB302 PBY160808T 600Y S--

T2

T3

0 1uF.

0 1uF.

10uF 16V NC/()

C301

C302

C303

Note VDD for the audio power:

VDD

T1

VCC5V

C305

1

AIC1084 33CM-

ADJ

VOUTVIN

TAB

4

C314

100uF 16V/

I302

23

VCC3V3 VCC1V8

TO 263-

1

T18

C

EB

2

Q302

MMBT3904

T17

3

R307

10K

T14

R308

47K

C308

0 1uF.

C309

0 1uF.

T15

T11

R306

10K NC()

0 1uF.

VDD

C306

0 1uF.

VCC5V

C307

100uF 16V/

C304

0 1uF NC.()

T8

R303

18K NC()

T4

R302

VCC3V3 VCC1V8VCC5V VCC3V3

C315

10uF 16V/

1

TO 252-

ADJ

TAB

4

C316

I303

VOUTVIN

23

T19

AIC1117 18PE-

100uF 16V/

C310

10uF 16V/

2 3

AO3401

I301

D

SG

1

C311

0 1uF.

T12

PBY160808T 600Y S--

FB304

R305

100

10K

3

R304

T5

VCC5V

R301

1K

T6

MMBT3904

Q301

1

2

4K7

PCB No.

6832176900P02

G

F

E

T13

VLCD

C312

0 1uF.

VLCD

D

C

T9

BKLT EN_

BKLT EN_

T7

BKLT ADJ_

BKLT ADJ_

B

A

Go to cover page

HP L1908W

33

Page 35

G

F

E

D

C

CONNECTOR DB15

B

A

._56 _SCHEMATICS INTERFACE BD_HP_L1908W VGA DDC INTERFACE&

1234567 8910111213

MMSZ5232B

MMSZ5232B

T55

D309

D310

P302

16

815714613512411310291

VGA SCL_

VGA SCL_

VGA SDA_

VGA CONn_

T52

1

C321

0 1uF.

R329 47

R328 47

C330

0 1uF.

VGA 5V_

BAT54C

VCC5V

VCC5V

T50

D307

MMSZ5232B

T46

SBK160808T 451Y S--

D305

SBK160808T 451Y S--

FB312

T43

FB311

D304

MMSZ5232B

T41

R320 1K

T42

2

1

C322

0 1uF.

2

1

C323

0 1uF.

2

VGA VSYNC_

VGA HSYNC_

VCC5V VCC5V VCC5V

VGA SDA_

MMBD7000

MMBD7000

MMBD7000

D301

3

D302

3

D303

3

VGA BLUE_

FB309 0

17

VGA 5V_

VGA RED_

VGA GREEN_

VGA CONn_

T20

T21

FB305 0

T22 T27

FB307 0

1234567 8910111213

47pF

47pF

DDC SCL VGA__

DDC SDA VGA__

C331

C332

24C02

GNDSDA

DDC SCL VGA__

DDC SDA VGA__

678

SCLWPVCC

A0A1A2

123

45

I304

12K

12K

MMSZ5232B

0 1uF.

R326

R327

D308

C329

T51

R319

VCC5V

R313

75 1/%

R314

75 1/%

FB310 SBK160808T 600Y S--

R315

75 1/%

BLUE IN_

T38

T33

FB306 SBK160808T 600Y S--

FB308 SBK160808T 600Y S--

RED IN_

GREEN IN_

T23

T24

T25

T26

R323

2K4

C326

0 1uF.

D306

MMSZ5232B

R324

2K4

T47

T49

DDC5V A_

100pF

R322 100

C327

T44

R321 100

10K

PCB No.

6832176900P02

T57

T56

DDC SDA VGA__

DDC SCL VGA__

DDC SCL VGA__

DDC SDA VGA__

1

Q303

MMBT3904

2K4

R317 75 1/%

3

2

T53

R330

T54

DDC WPn_

DDC WPn_

R325

10K

100pF

C328

T48

VS IN

VS IN_

T45

VGA DETn_

HS IN

HS IN_

VGA DETn_

R318 100

C324 10nF

C325 10nF

T39

T40

GNDB

BIN

BIN

GNDB

R316 100

R312 75 1/%

T34

C319 10nF

C320 10nF

T35

T36

T37

GNDG

GIN

GIN

GNDG

R311 100

R310 75 1/%

T29

C318 10nF

GNDR

GNDR

C317 10nF

T28

RIN

RIN

T30

T31

T32

G

F

E

D

C

B

A

Go to cover page

HP L1908W

34

Page 36

G

F

E

D

C

B

A

._66 _SCHEMATICS INTERFACE BD_HP_L1908W SCALER GM5726H

1234567 8910111213

MMSZ5232B NC()

MMSZ5232B NC()

T83

D322

D323

DVI SCL_

DVI SDA_

R347 47 NC()

R346 47 NC()

28

1

Q305

MMBT3904 NC()

2

GND

C5

32

HS

RXC+

RX5+

GND

22

21

RX5-

T72

20

GND

19

RX0+

RX0-

17

18

DVI RX0_+

C4

BLU

C3

GRN

C2

T76

RED

C1

RXC-

23

24

DVI RXC_+

DVI RXC_- RXC-

3

GND

HP

5V

15

16

DVI HP_

DVI RX0_-

DVI CONn_

T69

T70 D319

RX3+

RX1+

RX3-

RX1-

GND

T67

T68

0 1uF NC.()

1K NC()

0 1uF NC.()

910111213

DVI RX1_-

DVI RX1_+

C343

R337

C344

14

DVI 5V_

VS

8

T66

DVI 5V_

SDA

DVI SDA_

SCL

DVI SCL_

RX4+

T65

DVI D NC-( )

T82

VCC5V

DVI 5V_

BAT54C NC()

VCC5V

D320

DDC5V D_

RX4-

GND

RX2+

27

293031

RX2-

1234567

DVI RX2_+

DVI RX2_-

T63

P303

T58

3

MMBD7000 NC()

3

MMBD7000 NC()

D311

D312

2

C333

0 1uF NC.()

1

2

0 1uF NC.()

VCC5V VCC5V VCC5V VCC5V

C334

1

1234567 8910111213

47pF NC()

47pF NC()

DDC SCL DVI__

DDC SDA DVI__

C346

C347

24C02 NC()

GNDSDA

45

DDC SDA DVI__

DDC SCL DVI__

678

SCLWPVCC

A0

A1

A2

123

I305

R342

12K NC()

R343

12K NC()

D321

MMSZ5232B NC()

C345

0 1uF NC.()

T79

3

MMBD7000 NC()

3

MMBD7000 NC()

D313

D314

R361 2K4 NC()

T176

3

MMBD7000 NC()

3

MMBD7000 NC()

D316

D317

2

C339

0 1uF NC.()

1

2

0 1uF NC.()

C340

VCC5V VCC5V VCC5V VCC5V

DVI CONn_

1

R336 1K NC()

3

D318

MMBD7000 NC()

T78

DDC5V D_

T101

3

DVI RXC_-

DVI RXC_+

MMBD7000 NC()

DVI RX0_-

DVI RX0_+

2

C341

0 1uF NC.()

1

DVI RX2_+

DVI RX2_-

10K NC()

2

C342

0 1uF NC.()

1

DVI RX1_-

DVI RX1_+

100uF 16V NC/()

C337

R331

2

1

2

1

0 1uF NC.()

0 1uF NC.()

VCC5V

C335

C336

PCB No.

6832176900P02

T85

T84

DDC SDA DVI__

DDC SCL DVI__

DDC SCL DVI__

DDC SDA DVI__

1

Q304

MMBT3904 NC()

2

R345 2K4 NC()

DDC WPn_

DDC WPn_

R341 10 1 NC/%( )

R340 10 1 NC/%( )

3

T80

T81

R344

10K NC()

T77

HDCP HPDn_

RXC+

RXC-

HDCP HPDn_

RXC+

R339 10 1 NC/%( )

R338 10 1 NC/%( )

T74

T75T73

T71

RX0-

RX0+

RX0-

RX0+

D315

MMSZ5232B NC()

C338

0 1uF NC.()

T64

DVI DETn_

RX1+

DVI DETn_

R332 10 1 NC/%( )

R333 10 1 NC/%( )

R334 10 1 NC/%( )

R335 10 1 NC/%( )

T59

T60

T61

T62

RX2-

RX2+

RX1-

RX1+

RX2+

RX2-

RX1-

G

F

E

D

C

B

A

Go to cover page

HP L1908W

35

Page 37

G

F

E

D

C

B

A

._6 _SCHEMATICS INTERFACE BD_SCALER7 HP_L1908W

1234567 8910111213

PIN 119 H UART on GPO L UART on DDC:,:.

PIN 58 Set to low.

PIN 51 H J TAG port disable L J TAG port enable:- ,:- .

PIN 56 H Use OSC L Use Xtal:,: .

PIN 57 H Internal ROMoff L Internal ROM on:,:.

PIN 50 H Use ATMELSPI ROM L Use Standard SPI ROM:,: .

4 5

24LC16B

GND SDA

T104

T105

R366 100

T106

T107

T103

4 5

SST25VF020A

GND SI

SCL

WP

678

R365 100

SDA

SCL

SPI WPn_

HOLD#

SCK

678

SPI DO_

SPI CLK IN__

DDC SCL DVI__

DDC SDA DVI__

123

I308

A0A1A2

VCC

VCC3V3

DDC SDA DVI__

DDC SCL DVI__

VCC3V3

C379

0 1uF.

R359

4K7

R360

4K7

R404 150 NC()

3

R403 150 NC()

3V3 DVDD_

1

CEN7002A

I313

2

3

R400 150 NC()

1

CEN7002A

I314

2

JWT A2001WV2 03 NC--()

P304

123

3V3 DVDD_

R364

10K

SPI CSn_

R363

2K4

SPI DI_

123

CE#SOWP#

VCC

SPI HOLDn_

0 1uF.

T100

C380

T99

VOLUME

AUDIO EN_

AUDIO EN AUDIO EN_ _

UART DI_

UART DO_

VOLUME

T98

BKLT ADJ_

BKLT ADJ_

T180

R401

4K7

R402

4K7

T179

RX2+

RX2-

RX1-

RX1+

RX0-

RX0+

RXC-

RXC+

DDC SDA VGA__

DDC SDA VGA__

R399 150 NC()

3

CEN7002A

I312

2

T178

SCL VGA_

SDA VGA_

T177

DDC SCL VGA__

DDC SCL VGA__

3

CEN7002A

I311

2

1

4K7

4K7

STL8110GNL463 FNLH()

1

R397

R398

GND

RST

123

VCC

VCC3V3 3V3 RPLL_

PBY160808T 301Y S--

FB316

C363

10uF 16V/

C364

3V3 DVDD_

VCC5V

I307

VCC5V

C374

0 1uF.

T94

VCC3V3

R348

2K4

T93

GNDR

GIN

GNDG

BIN

GNDB

HS IN_

VS IN_

0 1uF.

C365

0 1uF.

0 1uF.

0 1uF.

10uF 16V/

0 1uF.

0 1uF.

0 1uF.

0 1uF.

RIN

C366

C367

C368

C369

C370

C371

C372

T89

VCC1V8

VCC1V8VCC1V8 1V8 CVDD_

PBY160808T 301Y S--

FB317

1V8 AVDD_

T90

PBY160808T 301Y S--

FB314

C355

10uF 16V/

T87

C356

0 1uF.

PBY160808T 301Y S--

FB315

3V3 AVDD_VCC3V3

C357

10uF 16V/

C358

0 1uF.

T88

C359

0 1uF.

C360

0 1uF.

C361

0 1uF.

PBY160808T 301Y S--

FB313

C348

10uF 16V/

C349

0 1uF.

1234567 8910111213

3V3 DVDD_VCC3V3

820K

0 1uF.

R367

C381

2K4

2K4 NC()

T97

GPIO 26_

VCC3V3

R351

R352

0 1uF.

RX2 RX2++

RX2 RX2--

RX1 RX1++

RX1 RX1--

RX0 RX0++

RX0 RX0--

RXC RXC++

RXC RXC--

3V3 DVDD_

3V3 AVDD_

C377

R350

250 1/%

SCL VGA_

SDA VGA_

SDA DVI_SDA DVI_

SCL DVI_SCL DVI_

7372767581

RX2+

67

DDC SDA DVI GPIO 19__/ _

DDC SCL DVI GPIO 18__/ _

DDC SDA VGA GPIO 17__/_

646566

DDC SCL VGA GPIO 16__ /_

RVDD 33_

REXT

REXT

T96

80

848369

RX2-

RX1-

RX1+

RX0-

RX0+

RXC-

RXC+

IC RESETn_

GNDB GNDB

HS IN HS IN__

VS IN VS IN__

C375

100pF

3V3 DVDD_

C376

0 1uF.

IC RESETn_

111

89

RESETn

90

HSYNC

VSYNC

63

RIN RIN

BIN BIN

GIN GIN

GNDG GNDG

GNDR GNDR

3V3 RPLL_

C373 10pF

C362 10pF

T92

100

99

969793

94

RED+

RED-

GREEN+

GREEN-

BLUE+

BLUE-

TCLK

TCLK

109

XTAL

T91

X301

14 318MHZ.

XTAL

108

AVDD RPLL 33__

AVD D A DC 3 3__

AVD D A DC 3 3__

AVDD DVI 33__

AVDD DVI 33__

VDD OUT 33__

VDD OUT 33__

VDD OUT 33__

RVDD 33_

RVDD 33_

LBADC VDD 33__

CVDD 18_

CVDD 18_

CVDD 18_

CVDD 18_

AVDD DVI 18__

GPIO 15 VDATA 7_/ []

GPIO 12 VDATA 4_/ []

GPIO 13 VDATA 5_/ []

GPIO 14 VDATA 6_/ []

CH1N LV O DCLK__/

CH3N LV O PD21__/

CLKN LV O PD23__/

CH3P LV O PD20__/

CLKP LV O PD22__/

CH2N LV O DHS__/

CH2P LV O DEN__/

CH1P LV O DVS__/

PD16 GPO36/

PD19 GPO39/

PD18 GPO38/

PD17 GPO37/

PD14 GPO35/

PD12 GPO32/

PD14 GPO34/

CH0N LV O__

CH0P LV O__

GPIO 25_

GPIO 24_

PD13 GPO33/

CH0N LV E PD8__/

CH0N LV E PD9__/

CH2N LV E PD5__/

CH3N LV E PD1__/

CH1N LV E PD7__/

CH2P LV E PD4__/

CLKN LV E PD3__/

CH3P LV E PD0__/

CH1P LV E PD6__/

PD10 V FIELD/_

GPIO 31_

GPIO 30_

PD11

CLKP LV E PD2__/

VCLK IN_

VDE IN_

VHS IN_

VVS IN_

GPIO 10 VDATA 2_/ []

GPIO 11 DATA3_/ []

GPIO 8 VDATA 0_/ []

GPIO 9 VDATA 1_/ []

AVDD DVI 18__

AVD D A DC 1 8__

VDD RPLL 18__

0 1uF.

0 1uF.

0 1uF.

0 1uF.