Anvil 92 User Manual

BEAM CLAMPS

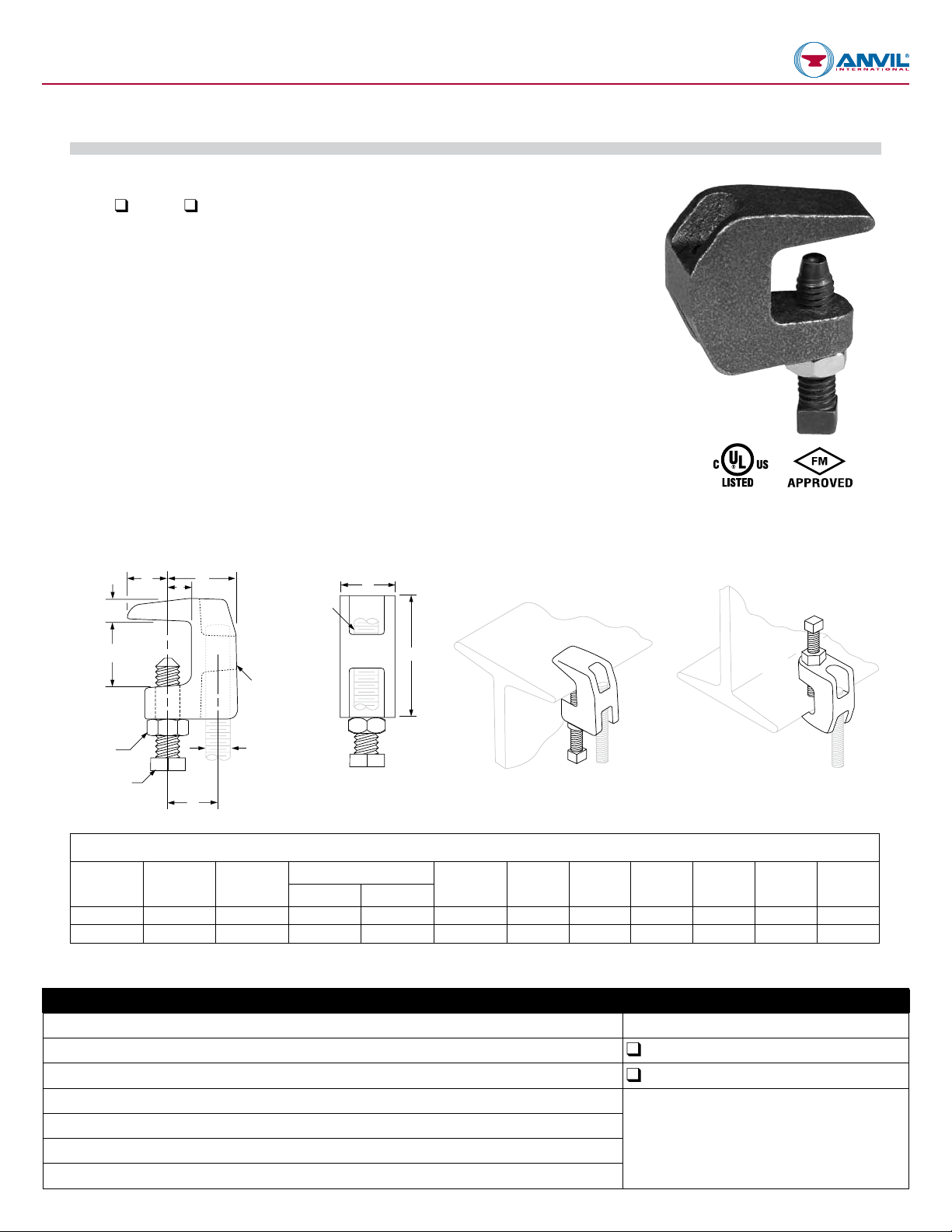

Fig. 92 Universal C-type Clamp (Standard Throat)

Size Range: 3⁄8" and 1⁄2"

Material: Ductile iron, hardened steel cup point set screw and locknut.

Finish: q Plain or q Galvanized

Service: Recommended for use under roof installations with bar joist type construction,

or for attachment to the top or bottom flange of structural shapes where the

vertical hanger rod is required to be offset from the edge of the flange and where

the thickness of joist or flange does not exceed 3⁄4".

Approvals: Complies with Federal Specification A-A-1192A (Type 19 & 23)

WW-H-171-E (Type 23)

UL, ULC Listed and FM Approved.

How to size: Size of clamp is determined by size of rod to be used.

Installation: Follow recommended set screw torque values per MSS-SP-69

(See table on page 233)

Features:

• They may be attached to horizontal flanges of structural members in either the top beam or

bottom beam positions.

• Secured in place by a cup-pointed Set Screw tightened against the flange.

A Jam Nut is provided for tightening the Set Screw against the Body Casting.

• Thru tapping of the body casting permits extended adjustment of the threaded rod.

• Can be used with Fig 89X retaining clip for seismic applications.

Ordering: Specify rod size, figure number, name of clamp and finish.

, ANSI/MSS SP-69 and MSS SP-58 (Type 19 & 23).

JAM - NUT

SET SCREW

H

G

3

⁄4"

C

E

1"

BODY

CASTING

A

AT LEAST ONE

FULL THREAD

OF ROD MUST

BE EXPOSED

F

D

FIG. 92: LOAD (LBS) • WEIGHT (LBS) • DIMENSIONS (IN) • TORQUE (IN-LBS)

Rod Size ASet Screw

Size

3

⁄8

1

⁄2

n

Maximum temperature of 450° F

3

⁄8 60 500 250 0.34 15⁄16 19⁄16

1

⁄2 125 950 760 0.63 13⁄8 113⁄16

Torque

Value

Max Loads

Top Bottom

PROJECT INFORMATION APPROVAL STAMP

Project:

Address:

Contractor:

Engineer: Remarks:

Submittal Date:

Notes 1:

Notes 2:

PH-11.11

n

Weight C D E F G H

Approved

q

Approved as noted

q

Not approved

q

9

⁄16

1

⁄2 11⁄16

13

⁄16

3

⁄8

7

⁄16

1

⁄2

23

⁄32

Loading...

Loading...