Anvil 160, 163, 165A, 161, 164 User Manual

...

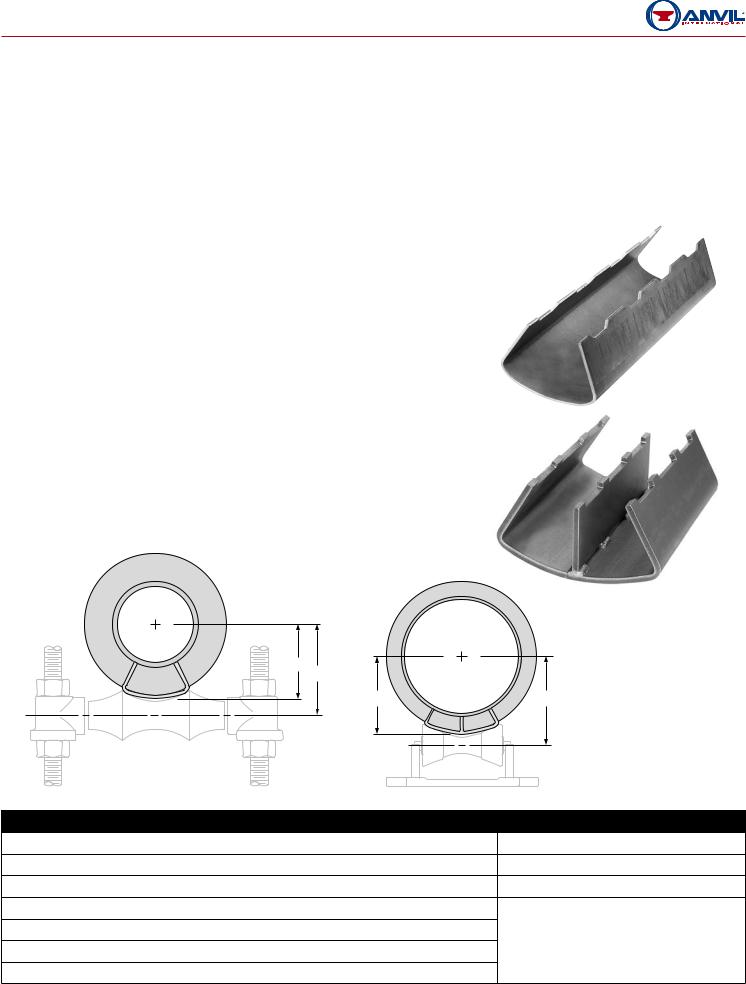

pipe shields & Saddles

Pipe Covering Protection Saddle

For Nominal Thickness of Covering Shown

Fig. 160: |

1" |

Fig. 161: 11⁄2" |

Fig. 162: 2" |

Fig. 163: |

21⁄2" |

Fig. 164: 3" |

Fig. 165: 4" |

Fig. 165A: 4" (Alloy) |

Fig. 166A: 51⁄2" (Alloy) |

||

|

|

|

|

Size Range: 3⁄4" through 36"

Material:

•Figs. 160, 161, 162, 163, 164, and 165 are curved carbon steel plate.

•Figs. 165A and 166A are alloy steel manufactured from ASTM A 387 Grade 22 Chrome Molybdenum steel plate.

•Figs. 165A and 166A have a welded-in center plate in all sizes.

•All other saddles have a welded-in center plate for pipe sizes 12" and larger.

•All saddles are 12" long with side edges turned up.

Finish: Plain

Service: Designed for use on insulated high temperature systems where heat losses are to be kept to a minimum and to protect insulation against damage.

Maximum Temperature: 650° F carbon steel, 950° F alloy steel.

Approvals: Complies with Federal Specification A-A-1192A (Type 39A & 39B), WW-H-171-E (Type 40A & 40B), ANSI/MSS SP-69 and MSS SP-58 (Type 39A & 39B).

Features: Permits finished, weather tight covering at all points of pipe support.

Ordering: Specify pipe size, figure number and name. Data for 42" size available on request. Installation: It is recommended that saddle be welded to the pipe.

C

L

C

L

C

D

C E

|

Continued on Following Page. |

Project information |

Approval Stamp |

Project: |

Approved |

Address: |

Approved as noted |

Contractor: |

Not approved |

Engineer: |

Remarks: |

Submittal Date: |

|

Notes 1: |

|

Notes 2: |

|

Catalog PH-2008

pipe shields & Saddles

Fig. 160 to Fig 166A |

Pipe Covering Protection Saddle (cont.) |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

Fig. 160, 161, 162, 163, 164, 165, 165A, 166A: Loads (lbs) • Weight (lbs) • Dimensions (in) |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Size of Pipe Roll |

Center Line |

Center Line of Pipe to |

||||||

|

|

|

|

|

Center Line of Roll |

||||||||

Pipe |

Fig. |

Max |

|

|

|

|

|

|

of Pipe to |

||||

Weight |

|

|

|

|

|

|

|

|

|

||||

Size |

No. |

Load n |

Figs. 171, |

|

Figs. |

|

Figs. 271, |

Outside of |

|

D |

E |

||

|

|

|

|

||||||||||

|

|

|

|

175, 177 |

|

174, 181 |

|

274, 277 |

Saddle C |

Figs. 171, |

|

Figs. |

Figs. 271, |

|

|

|

|

|

|

|

|

|

|

175, 177 |

|

174, 181 |

274, 277 |

|

160• |

|

1.4 |

2 |

|

21⁄2 |

|

|

15⁄8 |

21⁄16 |

|

21⁄8 |

21⁄4 |

3⁄4 |

161• |

1,200 |

2.1 |

3 |

|

31⁄2 |

|

2-31⁄2 |

23⁄16 |

23⁄4 |

|

23⁄4 |

27⁄8 |

|

162• |

|

2.8 |

4 |

|

5 |

|

|

211⁄16 |

35⁄16 |

|

35⁄16 |

33⁄8 |

|

160• |

|

1.4 |

21⁄2 |

|

3 |

|

|

113⁄16 |

25⁄16 |

|

21⁄4 |

27⁄16 |

1 |

161• |

1,200 |

2.1 |

3 |

|

4 |

|

2-31⁄2 |

25⁄16 |

27⁄8 |

|

27⁄8 |

3 |

|

162• |

|

2.8 |

4 |

|

5 |

|

|

27⁄8 |

31⁄2 |

|

31⁄2 |

31⁄2 |

|

160 |

|

1.4 |

21⁄2 |

|

3 |

|

|

115⁄16 |

21⁄2 |

|

27⁄16 |

29⁄16 |

11⁄4 |

161• |

1,200 |

2.1 |

31⁄2 |

|

5 |

|

2-31⁄2 |

29⁄16 |

31⁄16 |

|

31⁄16 |

33⁄16 |

162• |

2.8 |

4 |

|

|

|

3 |

35⁄8 |

|

35⁄8 |

311⁄16 |

|||

|

|

|

|

|

|

|

|||||||

|

163• |

|

3.6 |

5 |

|

6 |

|

4-6 |

33⁄4 |

43⁄8 |

|

43⁄8 |

43⁄8 |

|

160 |

|

1.5 |

3 |

|

31⁄2 |

|

2-31⁄2 |

21⁄8 |

25⁄8 |

|

25⁄8 |

211⁄16 |

11⁄2 |

161• |

1,200 |

2.1 |

31⁄2 |

|

5 |

|

25⁄8 |

31⁄4 |

|

31⁄4 |

35⁄16 |

|

|

|

|

|

||||||||||

162• |

3.2 |

5 |

|

6 |

|

4-6 |

35⁄16 |

4 |

|

4 |

37⁄8 |

||

|

|

|

|

|

|||||||||

|

163• |

|

3.6 |

6 |

|

8 |

|

37⁄8 |

41⁄2 |

|

45⁄8 |

41⁄2 |

|

|

|

|

|

|

|

||||||||

|

160 |

|

1.7 |

31⁄2 |

|

4 |

|

2-31⁄2 |

23⁄8 |

3 |

|

215⁄16 |

31⁄16 |

|

161• |

|

2.3 |

4 |

|

5 |

|

27⁄8 |

31⁄2 |

|

31⁄2 |

39⁄16 |

|

|

|

|

|

|

|

||||||||

2 |

162• |

1,200 |

3.2 |

5 |

|

6 |

|

|

39⁄16 |

41⁄4 |

|

41⁄4 |

43⁄16 |

|

163• |

|

3.6 |

6 |

|

8 |

|

4-6 |

41⁄16 |

43⁄4 |

|

413⁄16 |

43⁄4 |

|

164• |

|

4.5 |

8 |

|

|

|

49⁄16 |

53⁄8 |

|

53⁄8 |

51⁄4 |

|

|

|

|

|

|

|

|

|||||||

|

160 |

|

1.7 |

31⁄2 |

|

5 |

|

2-31⁄2 |

211⁄16 |

31⁄4 |

|

31⁄4 |

35⁄16 |

|

161 |

|

2.8 |

5 |

|

6 |

|

|

35⁄16 |

4 |

|

4 |

315⁄16 |

21⁄2 |

162 |

1,200 |

3.2 |

6 |

|

8 |

|

4-6 |

37⁄8 |

41⁄2 |

|

45⁄8 |

41⁄2 |

|

163 |

|

4.1 |

8 |

|

|

41⁄4 |

51⁄8 |

|

51⁄8 |

5 |

||

|

|

|

|

|

|

|

|||||||

|

164 |

|

4.5 |

|

10 |

|

|

47⁄8 |

55⁄8 |

|

53⁄4 |

51⁄2 |

|

|

|

|

|

|

|

|

|||||||

|

160 |

|

1.9 |

4 |

|

5 |

|

2-31⁄2 |

215⁄16 |

31⁄2 |

|

31⁄2 |

39⁄16 |

|

161 |

|

2.8 |

5 |

|

6 |

|

|

35⁄8 |

45⁄16 |

|

45⁄16 |

41⁄4 |

3 |

162 |

1,200 |

3.6 |

6 |

|

8 |

|

4-6 |

41⁄8 |

413⁄16 |

|

413⁄16 |

411⁄16 |

|

163 |

|

4.1 |

8 |

|

|

|

411⁄16 |

57⁄16 |

|

57⁄16 |

55⁄16 |

|

|

|

|

|

|

|

|

|||||||

|

164 |

|

4.9 |

|

10 |

|

8-10 |

51⁄16 |

6 |

|

6 |

61⁄16 |

|

|

|

|

|

|

|

||||||||

nMaximum recommended loads are applicable only when saddle is used on a flat bearing surface or roller hangers and tack welded to pipe. When saddle is used with a pipe roll, the maximum load for the assembly is the smaller of the two loads.

• Saddles may require notching when used with a U-bolt.

|

Continued on Following Page. |

|

|

Project information |

Approval Stamp |

|

|

Project: |

Approved |

Address: |

Approved as noted |

Contractor: |

Not approved |

Engineer: |

Remarks: |

|

|

Submittal Date: |

|

|

|

Notes 1: |

|

|

|

Notes 2: |

|

|

|

Catalog PH-2008

Loading...

Loading...