Anvil 137, 137S User Manual

U-BOLTS & STRAPS

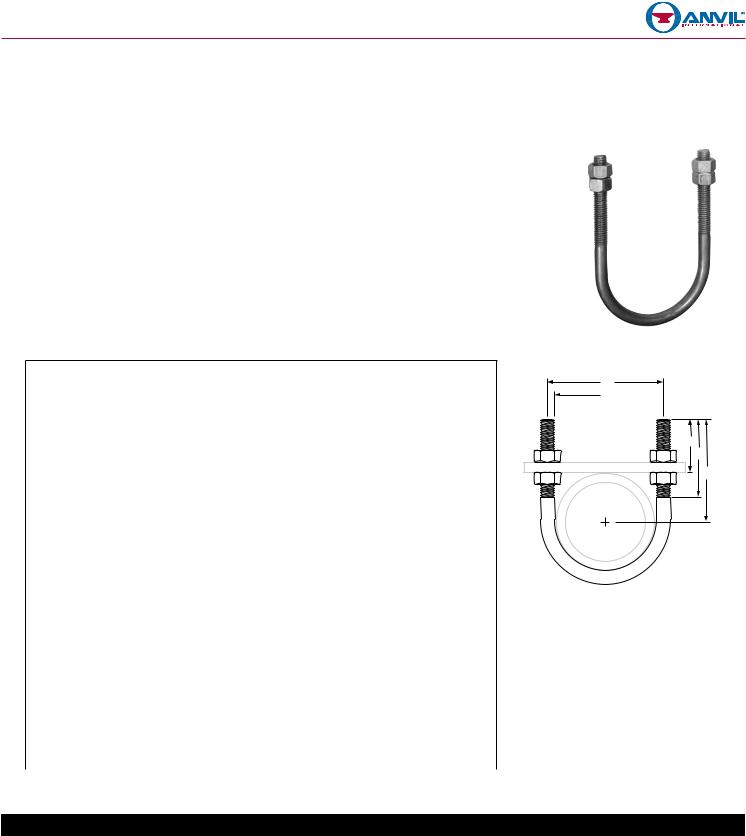

θ Fig. 137: Standard U-bolt |

U-Bolts |

θ Fig. 137S*: Special U-bolt (non-standard) |

|

|

|

|

|

Size Range: 1⁄2" through 36" |

|

Material: Carbon steel U-bolt and four finished hex nuts |

|

Finish: θ Plain or θ Fig. 137: Zinc Plated (Hot-Dip Galvanized optional) or θ Fig. 137S: Hot-Dip Galvanized |

|

(HDG not available for rod size 1/4". Stanless steel is offered as an alternative.) |

|

Service: Recommended for support, or guide of heavy loads; often employed in power, process plant and |

|

marine service. |

|

Approvals: Complies with Federal Specification A-A-1192A (Type 24), WW-H-171-E (Type 24), ANSI/MSS SP- |

|

69 and MSS SP-58 (Type 24). |

|

Ordering Fig. 137: Specify pipe size x rod size (e.g., 6 x 5⁄8), figure number, name. U-bolt will be furnished |

|

with longer tangents D or with longer threads E if so required and ordered. If hex nuts are not required, |

|

specify “without hex nuts”. |

|

Ordering Fig. 137S: Specify figure number, name, material specification, dimensions A, B, C, D, and E, and |

|

“with hex nuts” or “without hex nuts”. |

|

Note: The acceptability of galvanized coatings at temperatures above 450°F is at the discretion of the end user. |

|

FIG. 137: DIMENSIONS (IN) • LOADS (LBS) • WEIGHTS (LBS)n

Pipe |

Rod |

Max Normal |

650° F |

|

|

|

|

|

|

||

Size |

Load |

Max Side |

Wt. |

B |

C |

D |

E |

F |

|||

Size |

|||||||||||

|

|

||||||||||

A |

650˚ F |

750˚ F |

Load |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||

1⁄2 |

|

|

|

|

0.11 |

15⁄16 |

13⁄16 |

|

|

25⁄16 |

|

3⁄4 |

1⁄4 |

580 |

454 |

145 |

0.12 |

11⁄8 |

13⁄8 |

23⁄4 |

21⁄8 |

27⁄32 |

|

1 |

|

|

|

|

0.12 |

13⁄8 |

15⁄8 |

|

23⁄32 |

||

|

|

|

|

|

|

||||||

11⁄4 |

|

|

|

|

0.28 |

111⁄16 |

21⁄16 |

27⁄8 |

|

21⁄32 |

|

11⁄2 |

3⁄8 |

1,460 |

1,144 |

365 |

0.30 |

2 |

23⁄8 |

3 |

21⁄2 |

21⁄16 |

|

2 |

|

|

|

|

0.33 |

27⁄16 |

213⁄16 |

31⁄4 |

|||

|

|

|

|

|

|

||||||

21⁄2 |

|

|

|

|

0.73 |

215⁄16 |

37⁄16 |

33⁄4 |

|

25⁄16 |

|

3 |

|

|

|

|

0.78 |

39⁄16 |

41⁄16 |

4 |

|

|

|

31⁄2 |

1⁄2 |

2,700 |

2,114 |

675 |

0.84 |

41⁄16 |

49⁄16 |

41⁄4 |

3 |

21⁄4 |

|

4 |

|

|

|

|

0.90 |

49⁄16 |

51⁄16 |

41⁄2 |

|

|

|

5 |

|

|

|

|

1.0 |

55⁄8 |

61⁄8 |

5 |

|

27⁄32 |

|

6 |

5⁄8 |

4,320 |

3,382 |

1,080 |

2.0 |

63⁄4 |

73⁄8 |

61⁄8 |

31⁄2 |

213⁄16 |

|

8 |

2.3 |

83⁄4 |

93⁄8 |

71⁄8 |

|||||||

|

|

|

|

|

|

||||||

10 |

3⁄4 |

6,460 |

5,060 |

1,615 |

4.9 |

107⁄8 |

115⁄8 |

83⁄8 |

4 |

3 |

|

12 |

|

|

|

|

7.7 |

127⁄8 |

133⁄4 |

95⁄8 |

|

||

|

|

|

|

|

|

||||||

14 |

7⁄8 |

9,960 |

7,016 |

2,240 |

8.3 |

141⁄8 |

15 |

101⁄4 |

41⁄4 |

31⁄4 |

|

16 |

|

|

|

|

9.2 |

161⁄8 |

17 |

111⁄4 |

|

||

|

|

|

|

|

|

||||||

18 |

|

|

|

|

13.5 |

181⁄8 |

191⁄8 |

125⁄8 |

|

|

|

20 |

|

|

|

|

14.6 |

201⁄8 |

211⁄8 |

135⁄8 |

|

|

|

24 |

1 |

11,800 |

9,240 |

– |

16.9 |

241⁄8 |

251⁄8 |

155⁄8 |

43⁄4 |

35⁄8 |

|

30 |

|

|

|

|

19.1 |

301⁄8 |

311⁄8 |

185⁄8 |

|

|

|

36 |

|

|

|

|

23.2 |

361⁄8 |

371⁄8 |

215⁄8 |

|

|

|

nLoads, weights and dimensions shown do not apply for Fig. 137S. Max load rating for carbon steel is based on 2 x load rating for rod. Max load rating for stainless steel is 0.85 times the maximum stated load ratings listed above.

C

B

A

A

F

E

D

C

L

*When the combination of a normal load and a side load occurs, a straight line interaction

formula may be used to determine if the Fig. 137 is still within the allowable stress range:

Pn/Pna + Ps/Psa ≤ 1 Where:

Pn = actual applied normal load;

Pna = allowable normal load for the Fig. 137; Ps = actual applied side load;

Psa = allowable side load for the Fig. 137 Nuts must be snug tight in installation to achieve side loads shown.

PROJECT INFORMATION |

APPROVAL STAMP |

|

|

Project: |

θ Approved |

Address: |

θ Approved as noted |

Contractor: |

θ Not approved |

Engineer: |

Remarks: |

|

|

Submittal Date: |

|

|

|

Notes 1: |

|

|

|

Notes 2: |

|

|

|

PH-1.18

Loading...

Loading...