SWAY BRACE – SEISMIC

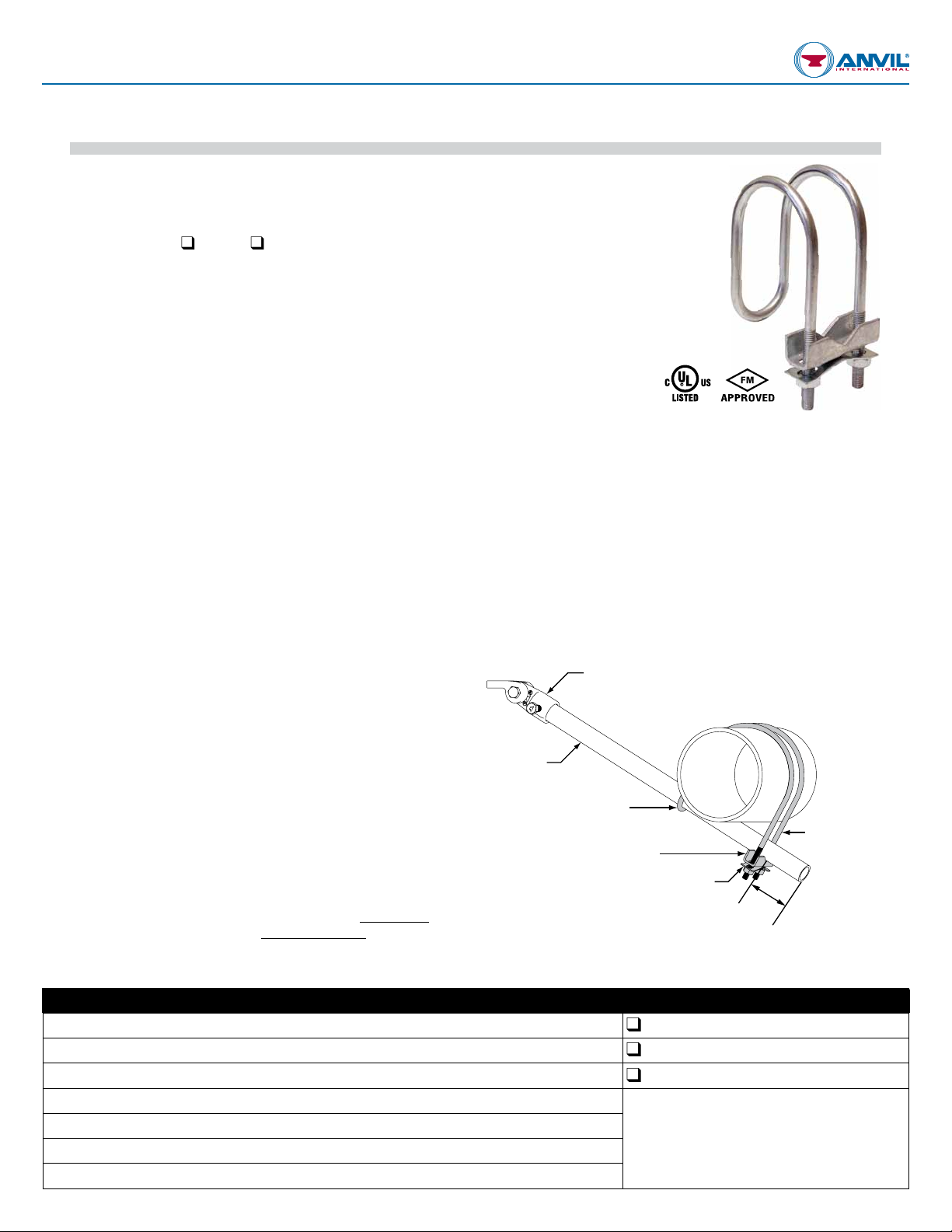

Fig. 771 Sway Brace Swivel Attachment

Fig. 770 Q Brace Clamp

Size Range: Service Pipe: 1" through 6" Sch. 10 and Sch. 40 IPS UL and FM Approved

Service Pipe: 1" through 6" Flow Pipe FM Approved

Brace Pipe: 1" or 11/4" Sch. 40 IPS

Material: Carbon steel

Finish: Brace Rod q Plain or q Galvanized, Channel bracket EG

Service: Used to rigidly brace piping systems subjected to sway and seismic disturbances. Pipe

clamp component of Anvil's 700 series sway brace assembly. Primarily a lateral brace clamp and

applicable as a riser/four way brace.

Approvals: UL and ULC Listed (UL 203A:2009), and FM Approved (FM 1950:2010). Complies

with seismic bracing requirements of NFPA-13. Office of Statewide Health Planning and

Development (OSHPD) State of California approved.

Features:

• Used to brace schedules 10 IPS, 40 IPS (UL and FM), and Sch. 7 IPS flow pipe (FM).

• Field adjustable design requires no threading of bracing pipe

• Can be used as a component of a four-way brace support

• Functions as a lateral brace application

Installation Instructions:

1. Minimum brace pipe extension 2" beyond channel bracket or brace clamp rod end. Note: 6" sizes are supplied with retaining

plate that assembles between sprinkler system pipe and brace pipe. Not required for FM applications.

2. The brace clamp channel bracket can be installed inside or outside the service pipe at the end of the brace pipe.

3. The Q brace clamp must be a minimum of 6" away from a pipe joint in order to not weaken the pipe joint.

4. Riser/4-way brace - The Q brace clamps must be installed within 6" of each other.

5. Adjust brace angle as necessary.

6. Tighten hex nuts until spring indicating clip is completely flattened and the required torque of 14 Ft-Lbs is achieved. For sizes

2" - 3", 4" x 1", 5" x 1", and 6" continue tightening to a torque of 16 Ft-Lbs.

Ordering: Specify service pipe diameter, brace pipe diameter, figure number, name and finish.

OPA-2804-10

Notes:

1. For fire protection installations - sway braces are intended to be

installed in accordance with NFPA-13 and Anvil's installations

instructions and local codes.

2. The required type, number and size of fasteners used for the

structural attachment fitting shall be in accordance with NFPA-13.

3. To assure proper performance, installer is responsible for:

a. Structural integrity of attachment member to safely handle

load requirements.

b. Securely tightening the component on the brace pipe.

4. Anvil International® brand bracing components are designed to be

compatible ONLY with other Anvil International® brand bracing

components, resulting in a Listed seismic bracing assembly.

5. Updated UL listing information may be viewed at www.ul.com and

FM approvals may be viewed at www.fmgobal.com

1" or 11/4"

Sch. 40 Brace Pipe

Rod End

Channel Bracket

(shown outside service pipe)

(Brace Pipe Below Service Pipe)

Indicator Clip

Typical Assembly

PROJECT INFORMATION APPROVAL STAMP

Project:

Address:

Contractor:

Engineer: Remarks:

Submittal Date:

Notes 1:

Notes 2:

Seismic-10.13

Approved

q

Approved as noted

q

Not approved

q

Fig. 770

Q Brace Clamp

2" Min.

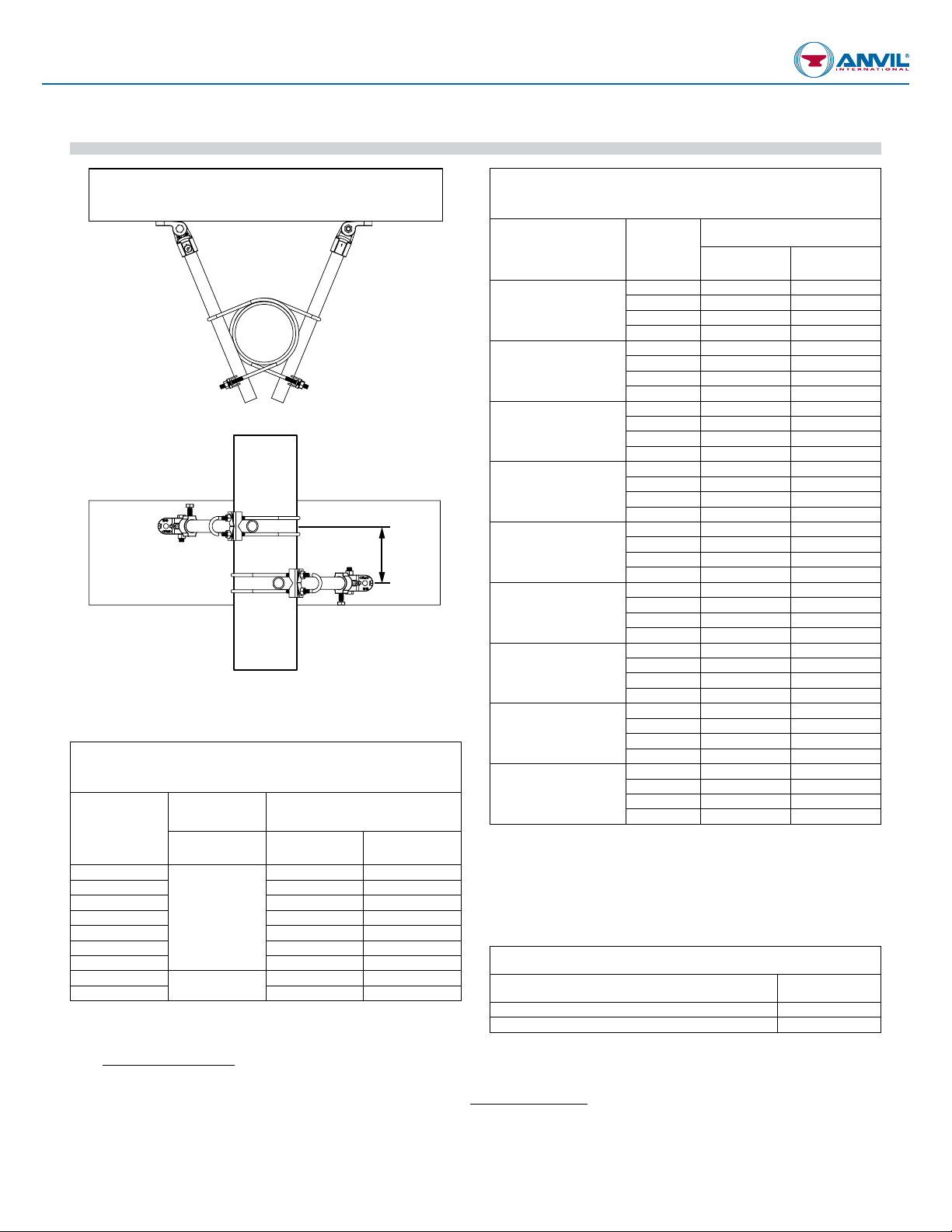

SWAY BRACE – SEISMIC

Fig. 770 Q Brace Clamp (cont.)

FIG. 770 FM MAX LOAD:

LOADS (LBS) • DIMENSIONS (IN) • ANGLES (DEGREES)

Plain View

Max. 6"

Elevated View

Riser/4-Way Brace Assembly

FIG. 770 UL MAX LOAD:

LOADS (LBS) • WEIGHT (LBS) • DIMENSIONS (IN)

UL

Service

Pipe Size

1 (A, B)

1

1

/4 (B) .86 .90

11/2 (B) .90 .95

2 (B) .96 1.00

21/2 1.02 1.06

3 1.09 1.13

4 1.23 1.26

5

6 1.49 1.53

A - Schedule 40 only.

B - UL Listed as a restraint and sway brace.

Max Load

Sch. 10

Sch. 40

1000

1600

Brace Pipe

Weight

1"

.82 .87

1.32 Not Listed

11/4"

Brace Pipe

Service Pipe Size

1

(1" or 1

/4" Brace Pipe)

1

1

1

/4

11/2

2

21/2

3

4

5

6

* See FM Approval guide for approved flow pipe.

** The allowable FM approved capacity of brace subassemblies have been determined

by resolving the load rating to the horizontal direction and dividing by a safety factor

of 1.5 to allow the values to be used directly for Allowable Stress Design.

For Load Resistance Factor Design (LRFD) capacities, the above values will need

to be multiplied by 1.5.

*** Brace Pipe Angles are determined from vertical.

Brace

Angle***

30-44 1110 250

45-59 1500 360

60-74 1900 440

75-90 2100 500

30-44 570 250

45-59 810 360

60-74 1000 440

75-90 1100 500

30-44 570 250

45-59 810 360

60-74 1000 440

75-90 1100 500

30-44 570 250

45-59 810 360

60-74 1000 440

75-90 1100 500

30-44 570 250

45-59 810 360

60-74 1000 440

75-90 1100 500

30-44 570 250

45-59 810 360

60-74 1000 440

75-90 1100 500

30-44 760 410

45-59 1070 590

60-74 1320 720

75-90 1470 800

30-44 760 410

45-59 1070 590

60-74 1320 720

75-90 1470 800

30-44 770 450

45-59 1090 630

60-74 1340 780

75-90 1490 870

FM Max Load** (Horizontal)

Sch. 10

Sch. 40

Flow Pipe

FIG. 770: TORQUE VALUE (FT-LBS)

Service Pipe Size Torque Value

1 thru 11/2, 4 x 11/4, 5 x 11/4 14

2 thru 3, 4 x 1, 5 x 1, 6 16

Go to www.anvilintl.com/OPA for State of California Office of Statewide Health Planning and Development (OSHPD) for design information

relating to OSHPD projects.

Seis Brace® Seismic Fire Protection Design Tool may be accessed at www.seisbrace.com

Disclaimer: Anvil International (“Anvil”) does not provide any warranties and specifically disclaims any liability whatsoever with respect to Anvil

bracing products and components that are used in combination with products, parts or systems not manufactured or sold by Anvil. In no event

shall Anvil be liable for any incidental, direct, consequential, special or indirect damages or lost profits where non-Anvil bracing components have

been, or are used.

Seismic-10.13

Loading...

Loading...