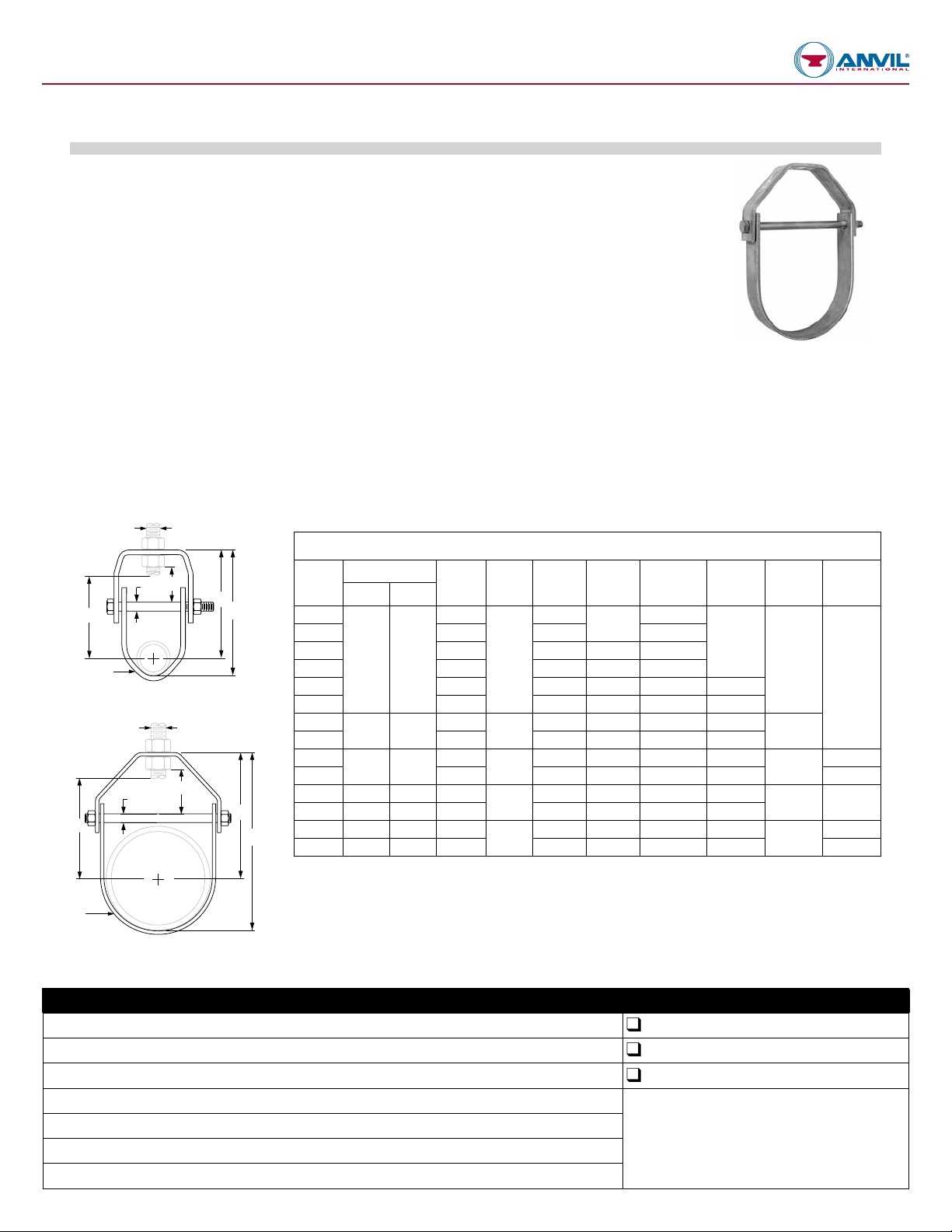

CLEVIS HANGERS AND SHIELDS

A

C

A

C

Fig. 260SS Adjustable Clevis Hanger

Size Range: 1⁄2" through 12"

Material: 304 stainless steel

Service: Recommended for the suspension of stationary pipe lines.

Maximum Temperature: 650° F

Approvals: Complies with Federal Specification A-A-1192A (Type 1),

ANSI/MSS SP-69 and MSS SP-58 (Type 1).

Installation: Hanger load nut

above

clevis must be tightened securely to assure proper hanger performance.

Adjustment: Vertical adjustment without removing pipe may be made from 3⁄8" through 5 1⁄8",

varying with the size of clevis. Tighten upper nut after adjustment.

Features:

• Design has yoke on outside of lower U-strap so yoke cannot slide toward center of bolt, thus bending of bolt is minimized.

• Sizes 5" and up have rod and two nuts instead of bolt and nut; thread length on clevis rod is such that the thread locks the

nuts in place, and threads are not in shear plane.

Ordering: Specify pipe size, figure number and name.

Notes: Punched forming holes may be present on certain sizes of this clevis hanger. These holes are solely for the purpose of man-

ufacturing, and do not effect the structural integrity or load carrying capacities of these hangers. For insulated line options without

shields, see Figures 260 ISS and Figure 300. For ductile iron pipe sizes, see Figure 590SS.

Caution: When an oversize clevis is used, a pipe spacer or multispacer should be placed over clevis bolt to ensure that the lower

U-strap will not move in on the bolt.

WW-H-171-E (Type 1)

,

F

G

E

C

L

H

Pipe Size 1/2" to 3/4"

G

E

C

L

H

Pipe Sizes 1" and Larger

FIG. 260SS: DIMENSIONS (IN) • LOADS (LBS) • WEIGHTS (LBS)

Pipe

B

F

B

Size

11⁄4 0.40 23⁄8 31⁄4 111⁄16

11⁄2 0.45 213⁄16 313⁄16 21⁄8

21⁄2

10 1,750 1,575 8.60

12 1,850 1,665 11.20 119⁄16 1715⁄16 101⁄8 213⁄16 2

“Span” represents the maximum recommended distance between hangers on a continuous and straight run of horizontal

standard weight steel pipe filled with water. In all cases, verify that chosen location of hangers does not subject hangers to a

load greater than the maximum recommended load shown above. *Indicates that span represents the maximum span for water

filled pipe.

Max Load

450˚ F 650˚ F

1

⁄2

3

⁄4 0.34 2 15⁄16

1 0.35 25⁄16 3 15⁄8

520 470

Weight

0.34

Rod

Size A

3

⁄8

B C

23⁄16

211⁄16

Rod Take

Out E

11⁄2

Adjust.

F

5

⁄8

7

⁄8

G

1

⁄4

H Width

Lower

2 0.50 35⁄16 41⁄2 25⁄8 11⁄8

960 865

3 0.85 43⁄4 61⁄2 41⁄16 15⁄8

4

1,215 1,095

5 1.70 69⁄16 815⁄16 51⁄2 115⁄16 13/16

0.65

1.51

6 1,650 1,485 3.10

8 1,700 1,530 4.75 83⁄8 1211⁄16 73⁄16 2

41⁄16 51⁄2 33⁄16 15⁄16

1

⁄2

59⁄16 713⁄16 41⁄2 111⁄16

5

⁄8

615⁄16 101⁄4 53⁄4 111⁄16

3

⁄4

97⁄8 151⁄4 87⁄16 21⁄8

7

⁄8

3

⁄8

3

⁄8

1

⁄2 17/16

5

⁄8

13/4

1

PROJECT INFORMATION APPROVAL STAMP

Project:

Address:

Contractor:

Engineer: Remarks:

Submittal Date:

Notes 1:

Notes 2:

PH-1.15

Approved

q

Approved as noted

q

Not approved

q

Loading...

Loading...