Anvil 212 User Manual

PIPE CLAMPS

D

H

C

G

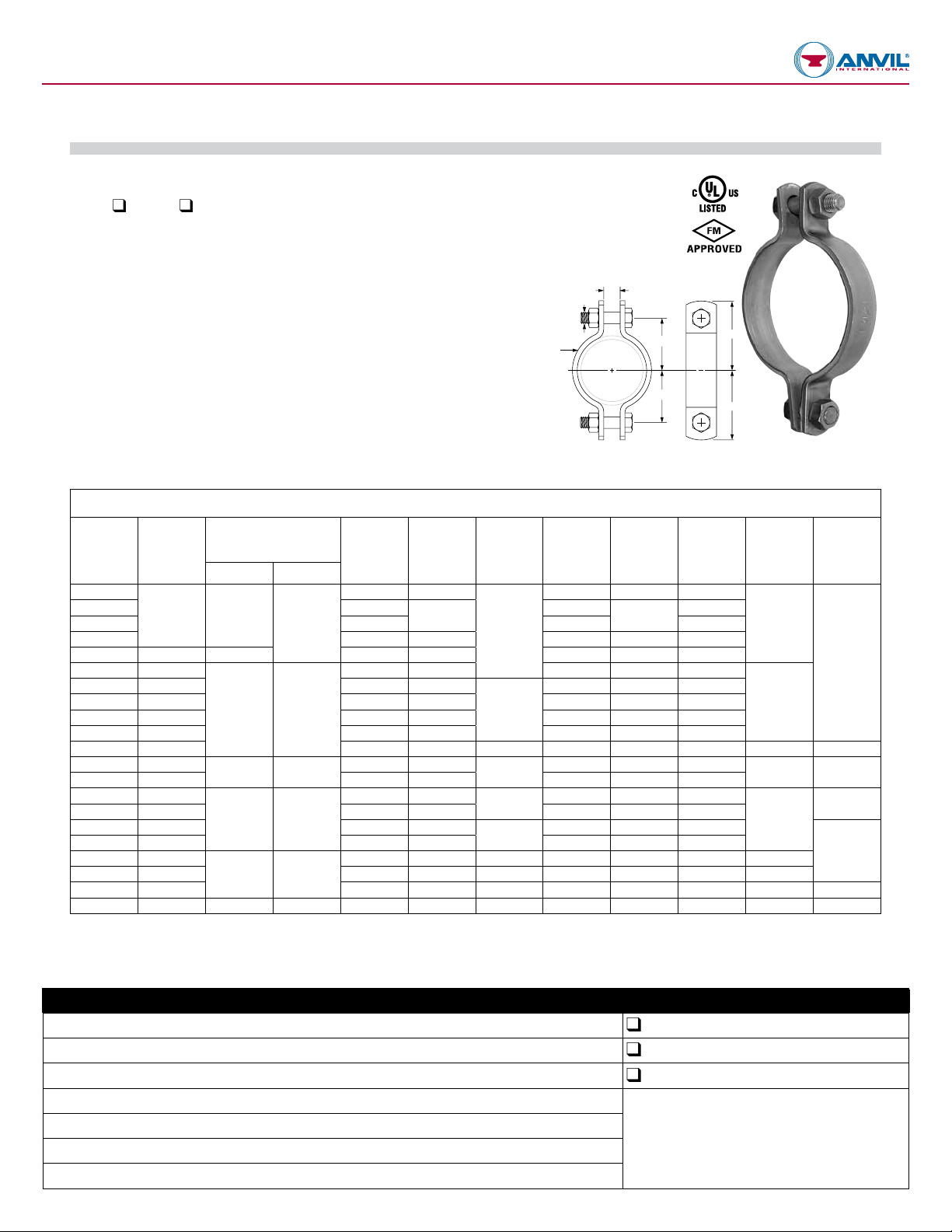

Fig. 212 (Formerly Afcon Fig. 415) Medium Pipe Clamp

Size Range: 1⁄2" through 30"

Material: Carbon steel

Finish:

Service: Recommended for suspension of cold pipe lines or hot lines where no insulation is required.

Maximum Temperature: Plain 750° F, Galvanized 450° F

Approvals: Complies with Federal Specification A-A-1192A (Type 4)

and MSS SP-58 (Type 4). UL, ULC Listed and FM Approved (Sizes

Installation: Normally used with weldless eye nut Fig. 290 or eye rod.

Features:

• Clamps tightly to pipe.

• Wide range of sizes.

• Equal gap design on many sizes.

Ordering: Specify pipe size, figure number, name and finish.

Note: The “C” gap dimension ensures adequate clearance at the top attachment

point for a weldless eye nut or other appropriate rod attachment. This gap may

or may not be present on the bottom portion of the clamp. If different loads or

dimensions are required, refer to Fig. 42 SD non-standard two bolt pipe clamp.

Plain or q Hot-Dip Galvanized (Hot Dip Galvanized comes with zinc plated hardware)

q

WW-H-171-E (Type 4),

3

⁄4" - 8").

ANSI/MSS SP-69

F

Note: This picture is representative of a typical Figure 212. Distance

between clamp ears beneath pipe may or may not be equal to upper gap.

FIG. 212: DIMENSIONS (IN) • LOADS (LBS) • WEIGHT (LBS)

E

C

L

B

Pipe

Size

Span

Ft.

Max Load

For Service Temp

Weight B C

650° F 750° F

1

⁄2

3

⁄4 0.33

1 0.35 13⁄8 129⁄32

7* 500

–

11⁄4 0.38 17⁄16 15⁄8 131⁄32 25⁄32

11⁄2 9* 800 0.43 19⁄16 111⁄16 23⁄32 27⁄32

2 10*

21⁄2 11* 1.20 25⁄8

3 12* 1.40 27⁄8 27⁄8 31⁄2 31⁄2

31⁄2 13* 1.50 33⁄16 33⁄16 313⁄16 313⁄16

1,040 930

4 14* 1.80 31⁄2 31⁄2 41⁄4 41⁄4

5 16* 2.60 43⁄16

6 17*

8 19* 6.50 6 6 67⁄8 67⁄8

1,615 1,440

10 22*

12 23* 15.20 87⁄16 87⁄16 99⁄16 99⁄16

14 20 20.50 91⁄4

2,490 2,220

16 15 22.30 101⁄4 101⁄4 115⁄8 115⁄8

18 15

20 12 35.80 123⁄4 13⁄8 123⁄4 141⁄8 141⁄8 11⁄8

3,060 2,730

0.29 1

11⁄8

1

⁄2

1.10 21⁄8 21⁄8 23⁄4 23⁄4

5

⁄8

3

⁄4 43⁄16 415⁄16 415⁄16

5.40 47⁄8

13.60 77⁄16

11⁄4

1

11⁄8

31.60 115⁄8 11⁄4 115⁄8 13 13 1

Rod

Take Out

H D F

E

13⁄16 117⁄32 123⁄32

11⁄4

25⁄8 31⁄4 31⁄4

47⁄8 53⁄4 53⁄4

77⁄16 89⁄16 89⁄16

91⁄4 105⁄8 105⁄8

121⁄32

125⁄32

Width

5

⁄16

1

⁄2

5

⁄8 11/4

3

⁄4 11/2

7

⁄8

G

1

2

21/2

24 12 53.10 151⁄4 15⁄8 151⁄4 167⁄8 167⁄8 11⁄4 3

30 9 3,500 3,360 113.90 19 2 19 211⁄8 211⁄8 13⁄4 4

Clamps may be furnished with square ends. “Span” represents the maximum recommended distance between hangers on a continuous & straight run of horizontal standard weight steel pipe filled with

water. In all cases, verify that chosen location of hangers does not subject hangers to a load greater than the maximum recommended load shown above. For vapor service, the presence of fittings or

insulation, and other weights and types of pipe, spans may either increase or decrease. In all cases, verify that chosen location of hanger does not subject hangers to a load greater than the maximum

recommended load shown. *Indicates that span represents the maximum span for water filled pipe.

PROJECT INFORMATION APPROVAL STAMP

Project:

Address:

Contractor:

Engineer: Remarks:

Submittal Date:

Notes 1:

Notes 2:

PH-1.18

Approved

q

Approved as noted

q

Not approved

q

Loading...

Loading...