PIPE ROLLS & SADDLES

C

H

G

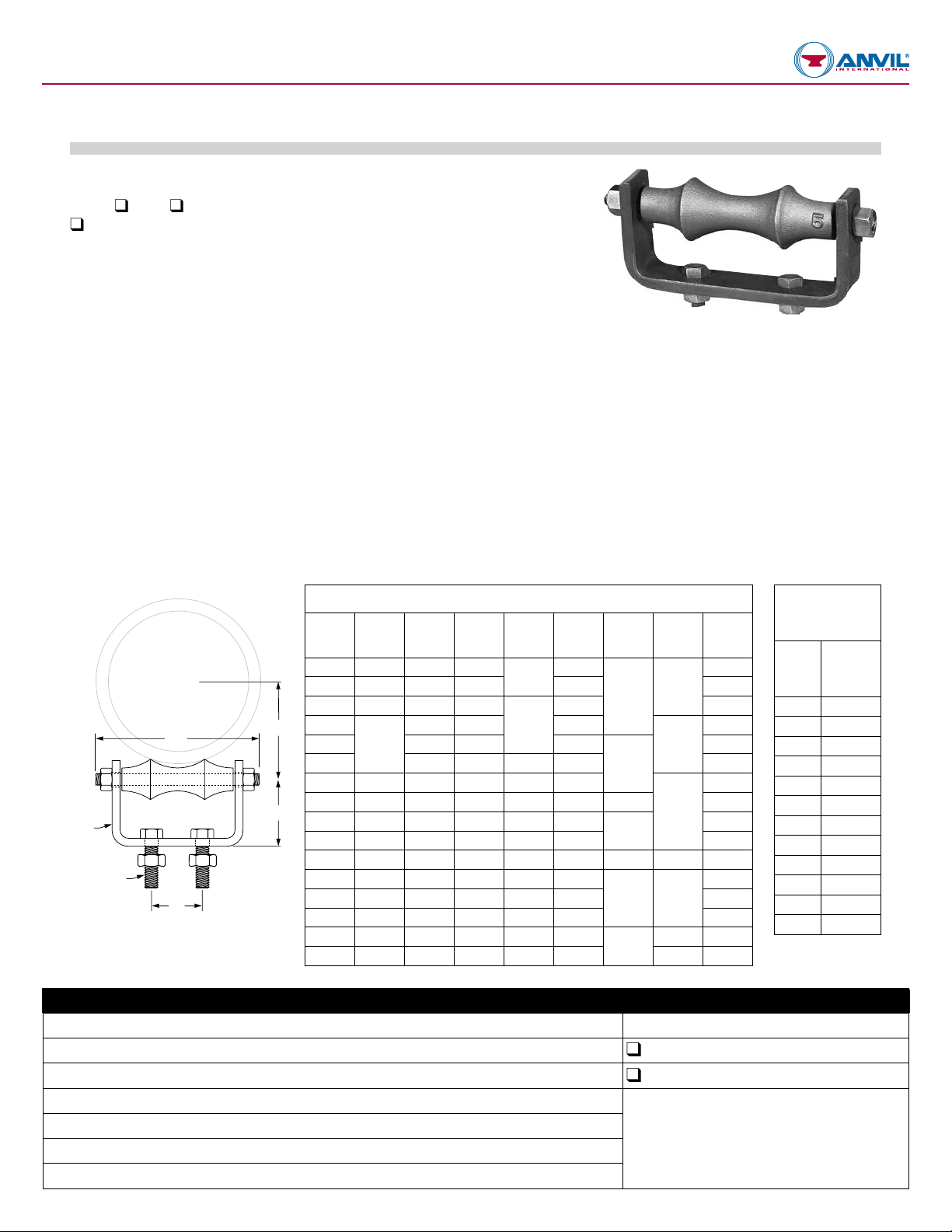

Fig. 175 Roller Chair

Size Range: 2" through 30" pipe

Material: Cast iron roll, steel chair, roll rod, bolts and hex nuts

Finish: q Plain, q Hot-Dip Galvanized Chair with Zinc Plated Parts or

Resilient Coated

q

Maximum Temperature: 400° F at roller, 300˚ F at resilient coated roller.

Service: For support of pipe where longitudinal movement due to expansion and

contraction may occur, but where no vertical adjustment is required.

Approvals: Complies with Federal Specification A-A-1192A (Type 44),

ANSI/MSS SP-69 and MSS SP-58 (Type 44).

Installation: Two bolts and nuts provide anchorage to floor or top of steel beam or bracket or chair may be welded to supporting steel.

Features: Advantages of pipe rollers with a protective resilient coated covering.

• Non conductive pipe rollers - prevent the passing of current from pipeline to structure.

• Corrosion resistant - for protection against severe weather conditions, moderate corrosive conditions such as marine

atmospheres and weather resistant to ultra-violet radiation.

• Low coefficient of friction between pipe and resilient coated pipe roller.

How to size:

(1) If roll is to support bare pipe, select the size directly from nominal pipe size (see below).

(2) If used with pipe covering protection saddle, see Figure 160 to Figure 166A for size of pipe roll.

(3) If roll is to support covered pipe, the O.D. of the covering should not be greater than the O.D. of the pipe for which the roll

was designed.

Ordering: Specify size of roll, figure number, name and finish. Be certain to order oversized rolls when insulation and protection

saddles are required.

WW-H-171-E (Type 45)

,

FIG. 175: DIMENSIONS (IN) • LOADS (LBS) • WEIGHT (LBS)

Pipe

Size

C

L

W

F

B

Max

Load

2 600 1.1 4

21⁄2 660 1.4 47⁄8 15⁄8 115⁄16

3 700 1.6 53⁄8

31⁄2

4 2.9 65⁄8 25⁄16

5 3.7 77⁄8 3 21⁄2 37⁄16

6 1,070 5.9 91⁄4 31⁄8 23⁄4

8 1,350 9.0 115⁄8 33⁄8 35⁄8 x 11⁄2 51⁄8

10 1,730 13.8 143⁄8 51⁄4 35⁄8

12 2,400 18.9 161⁄8 51⁄2 41⁄8 77⁄16

14 3,130 28.07 183⁄4 61⁄2 411⁄163⁄4 x 2 21/2 83⁄8

16 3,970 34.93 21 81⁄4 53⁄8

18 4,200 44.35 231⁄8 91⁄4 6 107⁄16

20 4,550 56.34 245⁄8 101⁄4 61⁄2 115⁄8

24 6,160 87.52 293⁄8 121⁄4 77⁄8

30 7,290 151.25 3413⁄16 153⁄8 83⁄4 6 177⁄16

Wgt. W B C F

1

1

2.6 61⁄8 21⁄16

750

2

11⁄2

⁄4

3

⁄8 x 11⁄2

13⁄4 21⁄4

1

⁄2 x 11⁄2

5

⁄8 x 2

3

⁄4 x 21⁄2 3

7

⁄8 x 31⁄2

G

Width

11/4

11/2

2

4 14

H

15⁄8

29⁄16

213⁄16

4

63⁄8

93⁄8

DI/CI

ROLL SIZING

DI/CI

Fig. 175

Pipe

Size

Roller

Size

3 4

4 5

6 6

8 8

10 10

12 14

14 16

16 18

18 20

20 24

24 30

30 No Recom.

PROJECT INFORMATION APPROVAL STAMP

Project:

Address:

Contractor:

Engineer: Remarks:

Submittal Date:

Notes 1:

Notes 2:

PH-8.16

Approved

q

Approved as noted

q

Not approved

q

Loading...

Loading...