Page 1

SERIES

690XXB/691XXB

SYNTHESIZED CW/SIGNAL GENERATORS

MAINTENANCE MANUAL

490 JARVIS DRIVE

MORGAN HILL, CA 95037-2809

P/N: 10370-10347

REVISION: C

PRINTED: AUGUST 2003

COPYRIGHT 2003 ANRITSU CO.

Page 2

WARRANTY

The Anritsu product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for one year from the date of shipment.

Anritsu's obligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyers shall prepay transportation charges for equipment returned to Anritsu for

warranty repairs. Obligation is limited to the original purchaser.Anritsu is not liable for consequen

tial damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to Anritsu connectors that have failed due to normal wear.

Also, the warranty does not apply to defects resulting from improper or inadequate maintenance by

the Buyer, unauthorized modification or misuse, or operation outside of the environmental specifications of the product. No other warranty is expressed or implied, and the remedies provided herein

are the Buyer's sole and exclusive remedies.

TRADEMARK ACKNOWLEDGEMENTS

Adobe Acrobat is a registered trademark of Adobe Systems Incorporated.

NOTICE

Anritsu Company has prepared this manual for use by Anritsu Company personnel and customers

as a guide for the proper installation, operation, and maintenance of Anritsu Company equipment

and computor programs. The drawings, specifications, and information contained herein are the

property of Anritsu Company, and any unauthorized use or disclosure of these drawings, specifica

tions, and information is prohibited; they shall not be reproduced, copied, or used in whole or in part

as the basis for manufacture or sale of the equipment or software programs without the prior writt

ten consent of Anritsu Company.

-

-

-

Page 3

Page 4

Page 5

Table of Contents

Chapter 1 - General Information

1-1 SCOPE OF MANUAL

1-2 INTRODUCTION

1-3 DESCRIPTION

1-4 IDENTIFICATION NUMBER

1-5 ELECTRONIC MANUAL

1-6 RELATED MANUALS

Operation Manual

GPIB Programming Manual

SCPI Programming Manual

1-7 OPTIONS .......................1-6

1-8 LEVEL OF MAINTENANCE.............1-8

Troubleshooting .................1-8

Repair......................1-8

Calibration ...................1-8

Preventive Maintenance .............1-8

1-9 STATIC-SENSITIVE COMPONENT HANDLING

PRECAUTIONS ...................1-8

....................

.................

...................

............

...............

................

................

...........

...........

1-3

1-3

1-3

1-5

1-5

1-5

1-5

1-5

1-5

1-10 PREVENTIVE MAINTENANCE ..........1-10

1-11 STARTUPCONFIGURATIONS

1-12 RECOMMENDED TEST EQUIPMENT

1-13 EXCHANGE ASSEMBLY PROGRAM

1-14 REPLACEABLE SUBASSEMBLIES AND PARTS 1-14

...........

......

.......

1-11

1-12

1-14

Chapter 2 - Functional Description

2-1 INTRODUCTION

2-2 690XXB/691XXB MAJOR SUBSYSTEMS

Digital Control

Front Panel

Frequency Synthesis

Analog Instruction

YIG, SDM, SQM Driver

ALC/Modulation

690XXB/691XXB MM i

...................

......

..................

...................

...............

................

.............

.................

2-3

2-3

2-3

2-4

2-4

2-5

2-5

2-8

Page 6

Table of Contents (Continued)

RF Deck

Power Supply

Inputs/Outputs

Motherboard/Interconnections

2-3 FREQUENCY SYNTHESIS

Phase Lock Loops

Overall Operation

RF Outputs 0.00001 to 65 GHz

Frequency Modulation (691XXB only)

Analog Sweep Mode (691XXB only)

Step Sweep Mode

2-4 ALC AND MODULATION

ALC Loop Operation

Amplitude Modulation (691XXB only) ......2-18

Square Wave Modulation (691XXB only) ....2-18

2-5 RF DECK ASSEMBLIES ..............2-19

RF Deck Configurations ............2-19

YIG-tuned Oscillator ..............2-20

Power Level Control and Modulation ......2-20

RF Signal Filtering ...............2-25

0.01 to 2 GHz Down Converter .........2-26

0.01 to 2.2 GHz Digital Down Converter ....2-27

Switched Doubler Module............2-28

Source Quadrupler Module

Power Level Detection/ALC Loop

Step Attenuators

.....................

..................

.................

..........

.............

................

...............

.........

......

.......

................

..............

..............

...........

........

................

2-8

2-8

2-8

2-9

2-9

2-9

2-10

2-13

2-14

2-14

2-15

2-15

2-15

2-29

2-30

2-31

Chapter 3 - Performance Verification

3-1 INTRODUCTION

3-2 RECOMMENDED TEST EQUIPMENT

3-3 TEST RECORDS

3-4 CONNECTOR AND KEY LABEL NOTATION

3-5 690XXB/691XXB POWER LEVELS

3-6 INTERNAL TIME BASE AGING RATE TEST

Test Setup

Test Procedure

ii 690XXB/691XXB MM

....................

...................

.......

...................

...

.........

...

..................

3-3

3-3

3-3

3-3

3-6

3-7

3-7

3-8

Page 7

Table of Contents (Continued)

3-7 FREQUENCY SYNTHESIS TESTS

Test Setup

Coarse Loop/ YIG Loop Test Procedure

Fine Loop Test Procedure

3-8 SPURIOUS SIGNALS TEST: RF OUTPUT

SIGNALS £2 GHz (£2.2 GHz UNITS

W/OPTION 21A)

Test Setup

0.01 - 2 GHz Test Procedure

0.01 - 2.2 GHz Test Procedure

3-9 HARMONIC TEST: RF OUTPUT SIGNALS

FROM2TO20GHz

Test Setup

2 - 10 GHz Test Procedure

11 - 20 GHz Test Procedure ..........3-18

3-10 SINGLE SIDEBAND PHASE NOISE TEST ....3-20

Test Setup ...................3-20

Test Procedure .................3-21

...................

............

..................

...................

..........

..........

................

...................

...........

........

.....

3-10

3-10

3-10

3-11

3-12

3-12

3-12

3-15

3-16

3-16

3-17

3-11 POWER LEVELACCURACY AND FLATNESS

TESTS........................3-24

Test Setup ...................3-24

Power Level Accuracy Test Procedure ......3-25

Power Level Flatness Test Procedure ......3-26

3-12 AMPLITUDE MODULATION TEST

Test Setup

AM Input Sensitivity Procedure

3-13 FREQUENCY MODULATION TESTS

Test Setup

FM Input Sensitivity Procedure

...................

...................

........

.........

.......

.........

Chapter 4 - Calibration

4-1 INTRODUCTION

4-2 RECOMMENDED TEST EQUIPMENT

4-3 TEST RECORDS

4-4 CALIBRATION FOLLOWING SUBASSEMBLY

REPLACEMENT

...................

.......

...................

...................

3-28

3-28

3-29

3-31

3-31

3-32

4-3

4-3

4-3

4-4

4-5 CONNECTOR AND KEY LABEL NOTATION

690XXB/691XXB MM iii

...

4-4

Page 8

Table of Contents (Continued)

4-6 INITIAL SETUP

Interconnection

PC Setup — Windows 3.1

PC Setup — Windows 95/Windows 98

4-7 PRELIMINARY CALIBRATION

Equipment Setup

Calibration Steps

Alternate Reference Oscillator Calibration

4-8 SWITCHED FILTER SHAPER CALIBRATION

Equipment Setup

Log Amplifier Zero Calibration

Limiter DAC Adjustment

Shaper DAC Adjustment

4-9 RF LEVELCALIBRATION .............4-23

4-10 ALC SLOPE CALIBRATION (691XXB ONLY). . . 4-24

Equipment Setup................4-24

ALC Slope DAC Adjustment ..........4-25

4-11 ALC BANDWIDTH CALIBRATION ........4-28

....................

.................

............

......

..........

................

................

...

................

.........

............

............

..

4-7

4-7

4-8

4-10

4-13

4-13

4-14

4-17

4-19

4-19

4-20

4-20

4-22

Equipment Setup................4-28

Bandwidth Calibration .............4-28

4-12 AM CALIBRATION (691XXB ONLY)........4-30

Equipment Setup

AM Calibration Procedure

4-13 FM CALIBRATION (691XXB ONLY)

Equipment Setup

FM Calibration Procedure

................

...........

........

................

...........

4-30

4-31

4-34

4-34

4-35

Chapter5-Troubleshooting

5-1 INTRODUCTION

5-2 RECOMMENDED TEST EQUIPMENT

5-3 ERROR AND WARNING/STATUS MESSAGES

Self-Test Error Messages

Normal Operation Error and Warning/

Status Messages

5-4 MALFUNCTIONS NOT DISPLAYING AN ERROR

MESSAGE

...................

.......

...

.............

................

.....................

5-3

5-3

5-3

5-3

5-7

5-10

iv 690XXB/691XXB MM

Page 9

Table of Contents (Continued)

5-5 TROUBLESHOOTING TABLES

..........

5-10

Chapter 6 - Removal and Replacement Procedures

6-1 INTRODUCTION

6-2 REMOVING AND REPLACING THE CHASSIS

COVERS

Preliminary

Procedure

6-3 REMOVING AND REPLACING THE FRONT

PANEL ASSEMBLY

Preliminary

Procedure

6-4 REMOVING AND REPLACING THE A3, A5,

ORA6PCB......................6-8

Preliminary ...................6-8

Procedure ....................6-8

6-5 REMOVING AND REPLACING THE A4 PCB . . . 6-8

Preliminary ...................6-8

Procedure ....................6-8

.......................

....................

....................

...................

...................

.................

...................

6-3

6-4

6-4

6-4

6-6

6-6

6-6

6-6 REMOVING AND REPLACING THE A7 PCB. . . 6-10

Preliminary ..................6-10

Procedure ...................6-10

6-7 REMOVING AND REPLACING THE A9, A10,

A11, OR A12 PCB

Preliminary

Procedure

6-8 REMOVING AND REPLACING THE A13

OR A15 PCB

Preliminary

Procedure

6-9 REMOVING AND REPLACING THE A14 PCB

Preliminary

Procedure

6-10 REMOVING AND REPLACING THE A16

OR A17 PCB

Preliminary

Procedure

...................

...................

...................

...................

...................

...................

..................

..................

....................

..

....................

..................

6-10

6-10

6-10

6-11

6-11

6-11

6-11

6-11

6-11

6-13

6-13

6-13

690XXB/691XXB MM v

Page 10

Table of Contents (Continued)

6-11 REMOVING AND REPLACING THE A18

OR A19 PCB

Preliminary

Procedure

6-12 REMOVING AND REPLACING THE REAR

PANEL ASSEMBLY

Preliminary

Procedure

....................

..................

...................

.................

..................

...................

6-13

6-13

6-13

6-14

6-14

6-14

6-13 REMOVING AND REPLACING THE A21 PCB

Preliminary

Procedure

6-14 REMOVING AND REPLACING THE

A21-1/A21-2 PCB

Preliminary ..................6-18

Procedure ...................6-18

6-15 REMOVING AND REPLACING THE FAN

ASSEMBLY .....................6-19

Preliminary ..................6-19

Procedure ...................6-19

..................

...................

..................

..

6-17

6-17

6-17

6-18

Appendix A - Test Records

A-1 INTRODUCTION...................A-1

vi 690XXB/691XXB MM

Page 11

Chapter 1

General Information

Table of Contents

1-1 SCOPE OF MANUAL

1-2 INTRODUCTION

1-3 DESCRIPTION

1-4 IDENTIFICATION NUMBER

1-5 ELECTRONIC MANUAL...............1-5

1-6 RELATED MANUALS ................1-5

Operation Manual ................1-5

GPIB Programming Manual ...........1-5

SCPI Programming Manual ...........1-5

1-7 OPTIONS .......................1-6

1-8 LEVEL OF MAINTENANCE.............1-8

Troubleshooting .................1-8

Repair

Calibration

Preventive Maintenance

1-9 STATIC-SENSITIVE COMPONENT

HANDLING PRECAUTIONS

......................

....................

...................

.................

...................

............

.............

............

1-3

1-3

1-3

1-5

1-8

1-8

1-8

1-8

1-10 PREVENTIVE MAINTENANCE

1-11 STARTUPCONFIGURATIONS

1-12 RECOMMENDED TEST EQUIPMENT

1-13 EXCHANGE ASSEMBLY PROGRAM

1-14 REPLACEABLE SUBASSEMBLIES AND PARTS 1-14

..........

...........

......

.......

1-10

1-11

1-12

1-14

Page 12

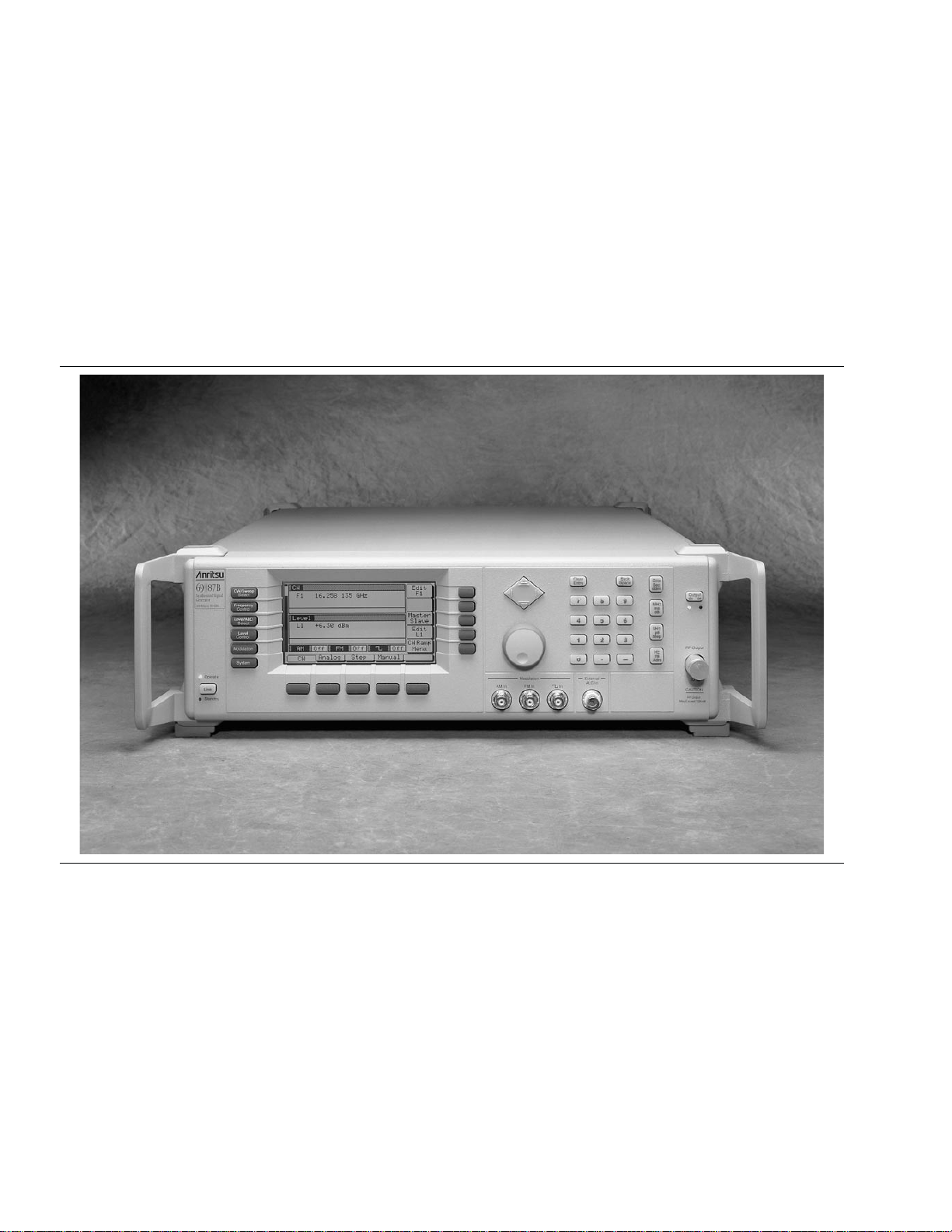

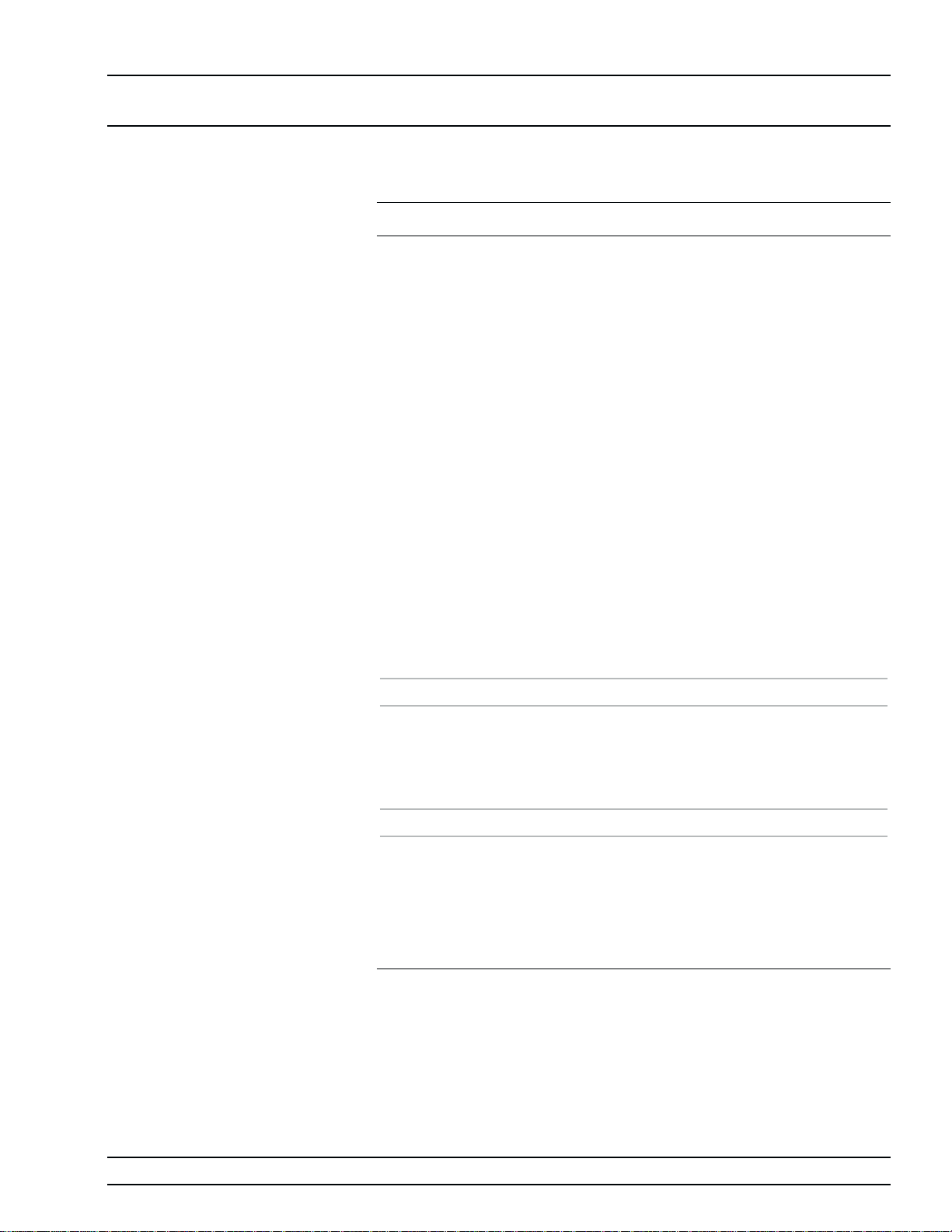

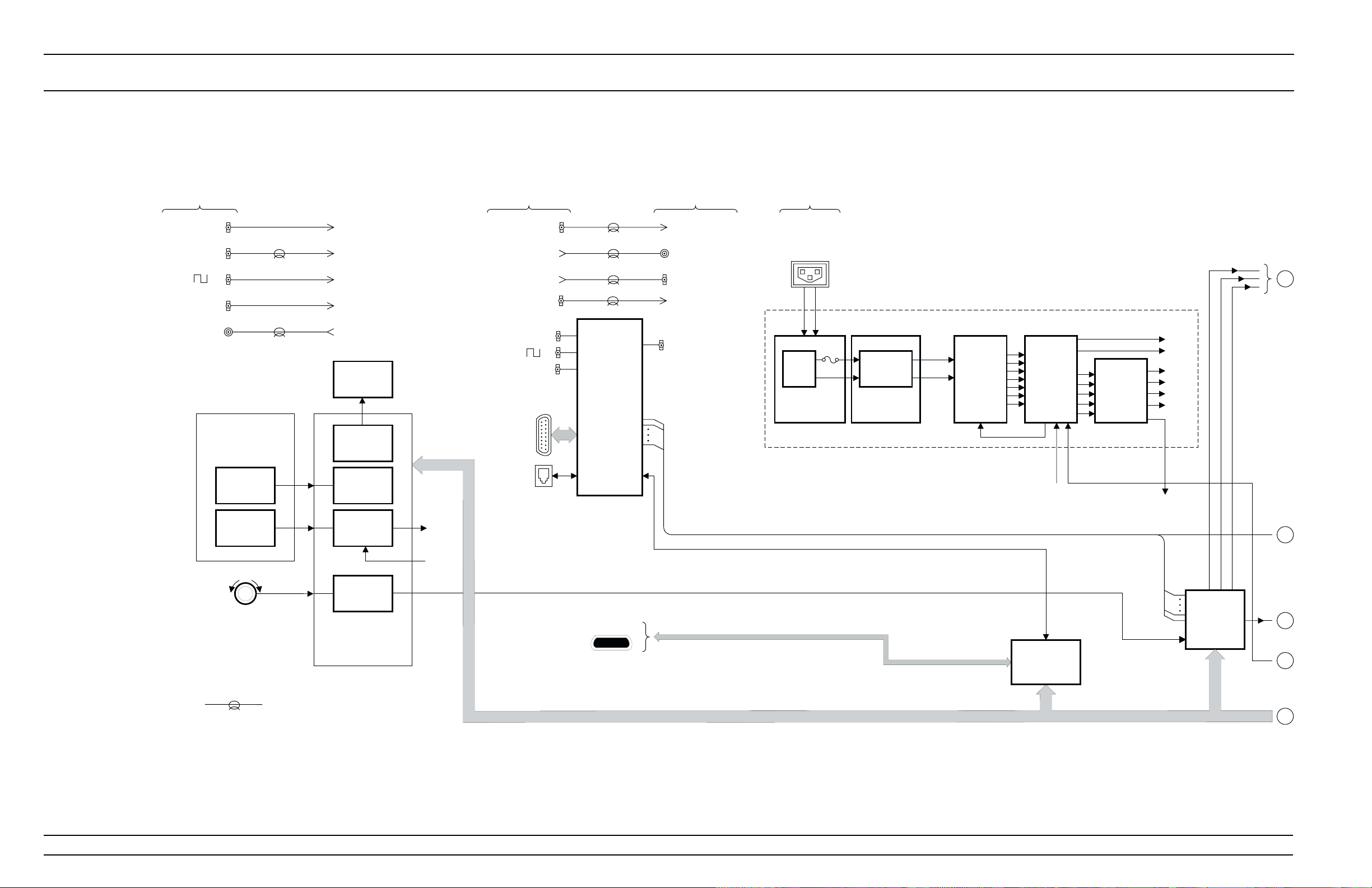

Figure 1-1. Typical Series 690XXB/691XXB Synthesized CW/Signal Generator (Model 69187B Shown)

Page 13

Chapter 1

General Information

1-1 SCOPE OF MANUAL This manual provides service information for all models of the Series

690XXB Synthesized CW Generator and the Series 691XXB Synthe

sized Signal Generator. The service information includes replaceable

parts information, functional circuit descriptions, block diagrams, per

formance verification tests, and procedures for calibration, trouble

shooting, and assembly/subassembly removal and replacement.

(Throughout this manual, the term 690XXB/691XXB is used to refer

to the instrument.) Manual organization is shown in the table of con

tents.

NOTE

Service information for the series 690XXB CW generators

and series 691XXB signal generators is combined into one

manual because identical model numbers of each series contain the same assemblies, subassemblies, and components.

Differences between the series are noted where applicable

throughout the manual.

-

-

-

-

1-2 INTRODUCTION This chapter provides a general description of the Series 690XXB/

691XXB Synthesized CW/Signal Generators, identification numbers,

related manuals, and options. Information is included concerning level

of maintenance, replaceable subassemblies and RF components, ex

change assembly program, and preventive maintenance. Staticsensitive component handling precautions and lists of exchangeable

subassemblies and recommended test equipment are also provided.

1-3 DESCRIPTION The Series 690XXB Synthesized CW Generator and the Series

691XXB Synthesized Signal Generator are microprocessor-based, syn

thesized signal sources with high resolution phase-lock capability.

They generate both discrete CW frequencies and broad (full range)

and narrow band sweeps across the frequency range of 10 MHz to

65 GHz. All functions of the 690XXB/691XXB are fully controllable lo

cally from the front panel or remotely (except for power on/standby)

via the IEEE-488 General Purpose Interface Bus (GPIB).

The Series 690XXB Synthesized CW Generator and the Series

691XXB Synthesized Signal Generator each presently consists of

seven models covering a variety of frequency ranges and power levels.

Table 1-1, on page 1-4, lists models, frequency ranges, and maximum

leveled output.

-

-

-

690XXB/691XXB MM 1-3

Page 14

GENERAL 690XXB/691XXB

INFORMATION MODELS

Table 1-1. Series 690XXB/691XXB Models

69XXXB

Model

69X17B 0.01 – 8.4 GHz +13.0 dBm +11.0 dBm +9.0 dBm

69X37B 2.0 – 20.0 GHz +13.0 dBm +11.0 dBm +3.0 dBm

69X47B 0.01 – 20.0 GHz +13.0 dBm +11.0 dBm +3.0 dBm

69X67B

69X77B

69X87B

69X97B

Frequency

(GHz)

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

50.0 – 60.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

50.0 – 65.0 GHz

Output Power

+13.0 dBm

+9.0 dBm

+6.0 dBm

+12.0 dBm

+10.0 dBm

+2.5 dBm

+2.5 dBm

+12.0 dBm

+10.0 dBm

+2.5 dBm

+2.0 dBm

+2.0 dBm

+12.0 dBm

+10.0 dBm

+2.5 dBm

0.0 dBm

–2.0 dBm

With Option 15A (High Power) Installed

Output Power

w/Step Attenuator

+11.0 dBm

+7.0 dBm

+3.0 dBm

+10.0 dBm

+8.5 dBm

0.0 dBm

–1.0 dBm

+10.0 dBm

+8.5 dBm

0.0 dBm

–1.5 dBm

–2.0 dBm

Not Available Not Available

Output Power

w/Electronic

Step Attenuator

Not Available

Not Available

Not Available

69X17B

69X37B 2.0 – 20.0 GHz +17.0 dBm +15.0 dBm +7.0 dBm

69X47B

69X67B

69X77B 0.01 – 50.0 GHz Standard Standard Not Available

69X87B 0.01 – 60.0 GHz Standard Standard Not Available

69X97B 0.01 – 65.0 GHz Standard Not Available Not Available

Note: In models with Option 22 that have a high-end frequency of£20 GHz, rated output power is reduced by 1 dB.

In models with Option 22 that have a high-end frequency of >20 GHz, rated output power is reduced by 2 dB.

0.01 – 2.0 Ghz

2.0 – 8.4 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

+13.0 dBm

+17.0 dBm

+13.0 dBm

+17.0 dBm

+13.0 dBm

+13.0 dBm

+6.0 dBm

+11.0 dBm

+15.0 dBm

+11.0 dBm

+15.0 dBm

+11.0 dBm

+11.0 dBm

+3.0 dBm

+11.0 dBm

+11.0 dBm

+11.0 dBm

+7.0 dBm

Not Available

1-4 690XXB/691XXB MM

Page 15

GENERAL IDENTIFICATION

INFORMATION NUMBER

1-4 IDENTIFICATION NUMBER All Anritsu instruments are assigned a unique six-digit ID number,

such as “875012”. The ID number is imprinted on a decal that is af

fixed to the rear panel of the unit. Special-order instrument configura

tions also have an additional special serial number tag attached to the

rear panel of the unit.

When ordering parts or corresponding with Anritsu Customer Service,

please use the correct serial number with reference to the specific in

strument's model number (i.e., Model 69147B Synthesized Signal Gen

erator, Serial No. 875012).

-

-

1-5 ELECTRONIC MANUAL This manual is available on CD ROM as an Adobe Acrobat Portable

Document Format (*.pdf) file. The file can be viewed using Acrobat

Reader, a free program that is also included on the CD ROM. The file

is "linked” such that the viewer can choose a topic to view from the

displayed "bookmark” list and "jump” to the manual page on which the

topic resides. The text can also be word-searched. Contact Anritsu

Customer Service for price and availablility.

-

-

1-6 RELATED MANUALS This is one of a four manual set that consists of an Operation Manual,

a GPIB Programming Manual, a SCPI Programming Manual, and a

Maintenance Manual.

Operation

Manual

GPIB

Programming

Manual

This manual provides instructions for operation of

the 690XXB/691XXB using the front panel controls.

It also includes general information, performance

specifications, installation instructions, and opera

tion verification procedures. The Anritsu part

number for the Series 690XXB Operation Manual is

10370-10341; the part number for the Series

691XXB Operation Manual is 10370-10344.

This manual provides information for remote opera

tion of the 690XXB/691XXB using Product Specific

commands sent from an external controller via the

IEEE 488 General Purpose Interface Bus (GPIB). It

contains a complete listing and description of all

690XXB/691XXB GPIB Product Specific commands

and several programming examples. The Anritsu

part number for the Series 690XXB GPIB Program

ming Manual is 10370-10342; the part number for

the Series 691XXB GPIB Programming Manual is

10370-10345.

-

-

-

SCPI

Programming

Manual

This manual provides information for remote opera

tion of the 690XXB/691XXB using Standard Com

mands for Programmable Instruments (SCPI)

commands sent from an external controller via the

-

690XXB/691XXB MM 1-5

-

Page 16

GENERAL

INFORMATION OPTIONS

IEEE 488 General Purpose Interface Bus (GPIB). It

contains a complete listing and description of each

command in the 690XXB/691XXB SCPI command

set and examples of command usage. The Anritsu

part number for the Series 690XXB SCPI Program

ming Manual is 10370-10343; the part number for

the Series 691XXB SCPI Programming Manual is

10370-10346.

1-7 OPTIONS The following instrument options are available.

Option 1, Rack Mounting. Rack mount kit containing a set of

q

track slides (90° tilt capability), mounting ears, and front panel

handles for mounting the instrument in a standard 19-inch

equipment rack.

Option 2A, 110 dB Step Attenuator. Adds a 10 dB per step

q

attenuator with a 110 dB range for models having a high-end frequency of £20 GHz. Output power is selected directly in dBm on

the front panel (or via GPIB). Rated output power is reduced.

-

Option 2B, 110 dB Step Attenuator. Adds a 10 dB per step

q

attenuator with a 110 dB range for models having a high-end frequency of £40 GHz. Output power is selected directly in dBm on

the front panel (or via GPIB). Rated output power is reduced.

q

Option 2C, 90 dB Step Attenuator. Adds a 10 dB per step

attenuator with a 90 dB range for models having a high-end frequency of £50 GHz. Output power is selected directly in dBm on

the front panel (or via GPIB). Rated output power is reduced.

q

Option 2D, 90 dB Step Attenuator. Adds a 10 dB per step

attenuator with a 90 dB range for models having a high-end fre

quency of £60 GHz. Output power is selected directly in dBm on

the front panel (or via GPIB). Rated output power is reduced.

q

Option 2E, 120 dB Electronic Step Attenuator. Addsa10dB

per step electonic attenuator with a 120 dB range for models hav

ing a high end frequency of £8.4 Ghz. Output power is selected

directly in dBm on the front panel (or via GPIB). Rated output

power is reduced.

q

Option 2F, 120 dB Electronic Step Attenuator. Addsa10dB

per step electonic attenuator with a 120 dB range for models hav

ing a high end frequency of £20 Ghz. Output power is selected di

rectly in dBm on the front panel (or via GPIB). Rated output

power is reduced.

-

-

-

-

q

Option 9, Rear Panel RF Output. Moves the RF output con

nector to the rear panel.

q

Option 11, 0.1 Hz Frequency Resolution. Provides frequency

resolution of 0.1 Hz.

-

1-6 690XXB/691XXB MM

Page 17

GENERAL

INFORMATION OPTIONS

Option 14, Rack Mounting without Chassis Slides. Modifies

q

rack mounting hardware to install unit in console that has

mounting shelves. Includes mounting ears and front panel han

dles.

-

Option 15A, High Power Output. Adds high-power RF compo

q

nents to the instrument in the 2–20 GHz frequency range. Op

tion 15A is standard in models having a high-end frequency that

is >40 GHz.

Option 16, High-Stability Time Base. Adds an ovenized,

q

10 MHz crystal oscillator with <5 x 10

Options 17A & 17B, No Front Panel. Deletes the front panel

q

–10

/day frequency stability.

for use in remote control applications where a front panel display

or keyboard control are not needed. Option 17A deletes the front

panel from 691XXB models; Option 17B deletes the front panel

from 690XXB models.

Option 18, mmWave Module Bias Output. Provides bias out

q

put for 54000-xWRxx Millimeter Wave Source Modules. BNC

Twinax connector, rear panel.

Option 19, SCPI Programmability. Adds GPIB command

q

mnemonics complying with Standard Commands for Programmable Instruments (SCPI), Version 1993. SCPI programming

complies with IEEE 488.2-1987.

q

Option 21A, Digital Down Converter. Replaces the standard

Analog Down Converter (0.01 to 2.0 GHz) with a Digital Down

Converter (0.01 to 2.2 GHz).

q

Option 22, 0.1 Hz to 10 MHz Audio Frequency. Adds fre

quency coverage below 10 Mhz. In models having a high-end fre

quency of £20 GHz, rated output power is reduced by 1 dB; in

models having a high-end frequency of >20 GHz, rated output

power is reduced by 2 dB.

-

-

-

-

-

690XXB/691XXB MM 1-7

Page 18

GENERAL LEVEL OF

INFORMATION MAINTENANCE

1-8 LEVEL OF MAINTENANCE Maintenance of the 690XXB/691XXB consists of:

Troubleshooting the instrument to a replaceable subassembly or

q

RF component.

Repair by replacing the failed subassembly or RF component.

q

Calibration.

q

Preventive maintenance.

q

Troubleshoot

ing

Repair Most instrument failures are field repairable by

Calibration The 690XXB/691XXB may require calibration after

Preventive

Maintenance

The 690XXB/691XXB firmware includes internal

-

diagnostics that self-test most of the internal assem

blies of the instrument. When the 690XXB/691XXB

fails self-test, one or more error messages are dis

played to aid in troubleshooting the failure to a

replaceable subassembly or RF component. Chapter

5–Troubleshooting lists and describes the self-test

error messages and provides procedures for isolat

ing 690XXB/691XXB failures to a replaceable subas

sembly or RF component.

replacing the failed subassembly or RF component.

Detailed instructions for removing and replacing

failed subassemblies and components are provided

in Chapter 6–Removal and Replacement Procedures.

repair. Refer to Chapter 4–Calibration for a listing

of calibration requirements and calibration proce

dures.

Preventive maintenance on the 690XXB/691XXB

consists of cleaning the fan honeycomb filter, de

scribed in paragraph 1-10.

-

-

-

-

-

-

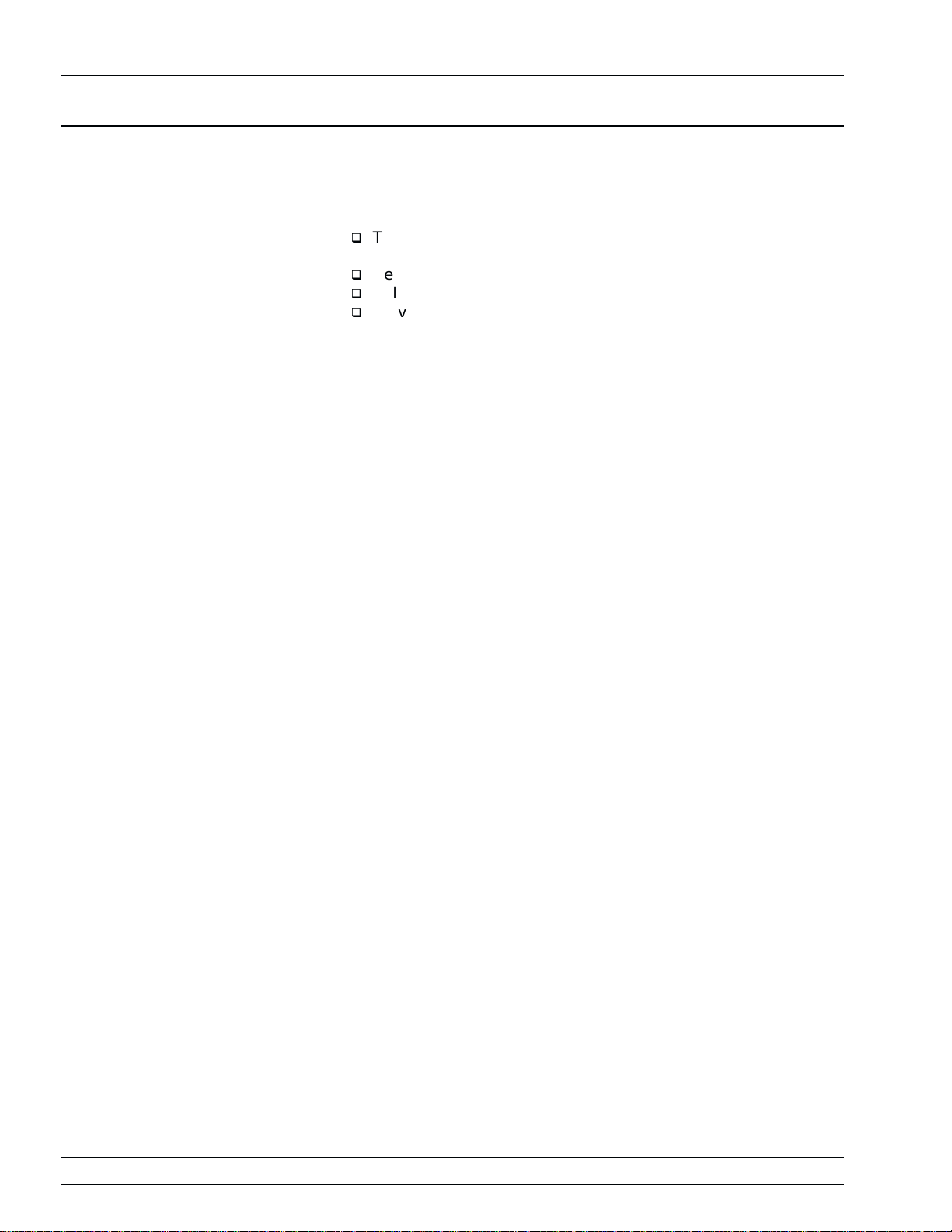

1-9 STATIC-SENSITIVE

COMPONENT HANDLING

PRECAUTIONS

The 690XXB/691XXB contains components that can be damaged by

static electricity. Figure 1-2 illustrates the precautions that should be

followed when handling static-sensitive subassemblies and compo

nents. If followed, these precautions will minimize the possibilities of

static-shock damage to these items.

NOTE

Use of a grounded wrist strap when removing and/or replac

ing subassemblies or components is strongly recommended.

-

-

1-8 690XXB/691XXB MM

Page 19

GENERAL STATIC-SENSITIVE COMPONENT

INFORMATION HANDLING PRECAUTIONS

1. Do not touch exposed contacts

on any static sensitive compo

nent.

4. Wear a static-discharge wristband when working with static

sensitive components.

2 Do not slide static sensitive

-

component across any surface.

5. Label all static sensitive

devices.

3. Do not handle static sensitive

components in areas where the

floor or work surface covering

is capable of generating a

static charge.

6. Keep component leads shorted

together whenever possible.

7. Handle PCBs only by their

edges. Do not handle by the

edge connectors.

10. ADDITIONAL PRECAUTIONS:

·

Keep workspaces clean and free of any objects capable of holding or storing a static charge.

·

Connect soldering tools to an earth ground.

·

Use only special anti-static suction or wick-type desoldering tools.

Figure 1-2. Static-Sensitive Compontent Handling Precautions

8. Lift & handle solid state de

vices by their bodies – never

by their leads.

-

9. Transport and store PCBs and

other static sensitive devices

in static-shielded containers.

690XXB/691XXB MM 1-9

Page 20

GENERAL PREVENTIVE

INFORMATION MAINTENANCE

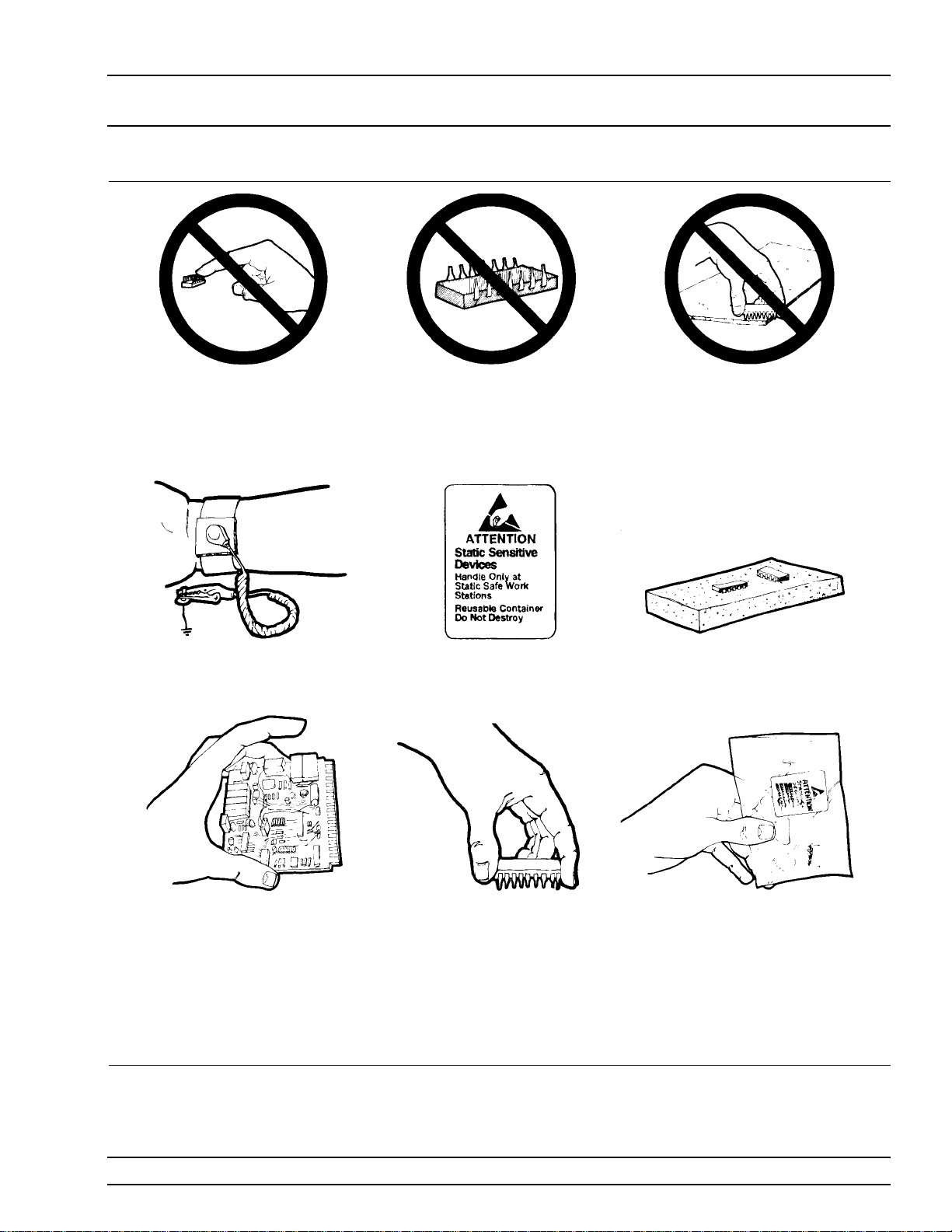

1-10 PREVENTIVE

MAINTENANCE

The 690XXB/691XXB must always receive adequate ventilation. A

blocked fan filter can cause the instrument to overheat and shut down.

Check and clean the rear panel fan honeycomb filter periodically.

Clean the fan honeycomb filter more frequently in dusty environ

ments. Clean the filter as follows.

Step 1 Remove the filter guard from the rear panel by pull

ing out on the four panel fasteners holding them in

place (Figure 1-3).

Step 2 Vacuum the honeycomb filter to clean it.

Step 3 Install the filter guard back on the rear panel.

Step 4 Press in on the panel fasteners to secure the filter

guard to the rear panel.

-

-

Figure 1-3. Removing/Replacing the Fan Filter Guard

1-10 690XXB/691XXB MM

Page 21

GENERAL START UP

INFORMATION CONFIGURATION

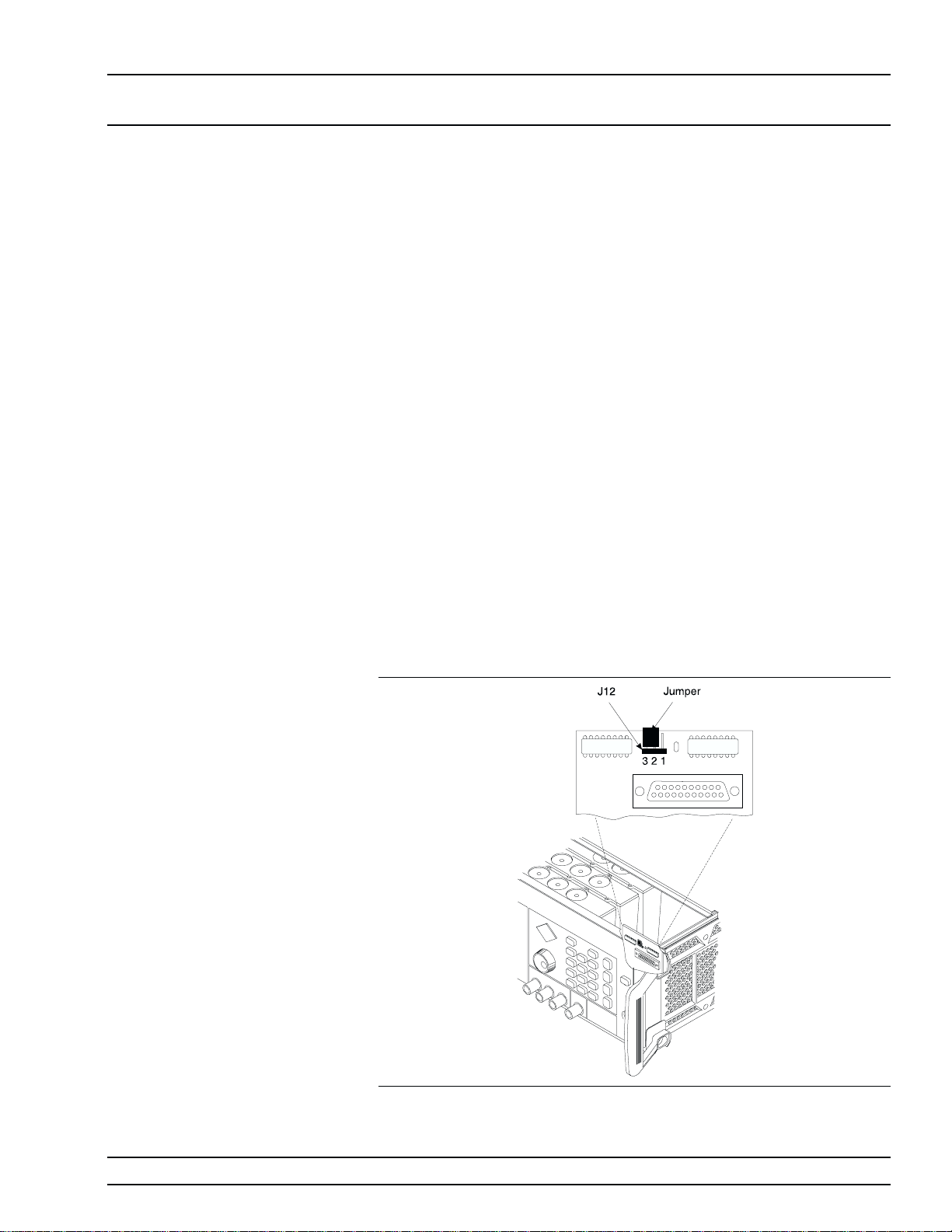

1-11 STARTUP

CONFIGURATIONS

The 690XXB/691XXB comes from the factory with a jumper across

pins 2 and 3 of front panel connector J12 (Figure 1-4). In this configu

ration, connecting the instrument to line power automatically places it

in operate mode (front panel OPERATE LED on).

The startup configuration can be changed so that the 690XXB/691XXB

comes up in standby mode (front panel STANDBY LED on) when it is

connected to line power. Change the startup configuration as follows:

Step 1 Disconnect the instrument from line power.

Step 2 Remove the top cover from the 690XXB/691XXB.

(Refer to Chapter 6 for instructions).

Step 3 Locate front panel connector J12 and remove the

jumper from across pins 2 and 3. It is located on the

A2A1 PCB which plugs into the Front Panel Assem

bly.

Step 4 Install the jumper across pins 1 and 2 of connector

J12.

Step 5 Install the top cover and connect the 690XXB/

691XXB to line power. The instrument should come

up in standby mode.

-

-

Figure 1-4. Startup Configuration of Connector J12

690XXB/691XXB MM 1-11

Page 22

GENERAL RECOMMENDED

INFORMATION TEST EQUIPMENT

1-12 RECOMMENDED TEST

EQUIPMENT

Table 1-2 provides a list of recommended test equipment needed for

the performance verification, calibration, and troubleshooting proce

dures presented in this manual.

Table 1-2. Recommended Test Equipment (1 of 2)

INSTRUMENT

Spectrum Analyzer,

with

External Mixers

and

Diplexer Assy

Phase Noise

Measurement

System

Frequency Counter Frequency Range: 0.01 to 40 GHz

Power Meter,

with

Power

Sensors

Digital Multimeter Resolution: 4-1/2 digits (to 20V)

Frequency Reference Frequency: 10 MHz

Function Generator Output Voltage: 2 volts peak-to-peak

Modulation Analyzer Frequency Input: 10 MHz

Frequency Range: 0.01 to 65 GHz

Resolution Bandwidth: 10 Hz

Frequency Range: 5 MHz to 26.5 GHz Aeroflex/Comstron PN9000

Input Impedance: 50

Resolution: 1Hz

Other: External Time Base Input

Power Range: –30 to +20 dBm

DC Accuracy: 0.002% +2 counts

DC Input Impedance: 10 M

AC Accuracy: 0.07% +100 counts

AC Input Impedance: 1M

Accuracy: 5x10

Functions: 0.4 Hz to 100 kHz sine and

square waveforms

(of the IF of the spectrum analyzer)

AM Depth: 0% to 90%

AM Modulation Rates: DC to 100 kHz

Filters: 20 kHz lowpass, 300 Hz highpass

CRITICAL

SPECIFICATION

W

(1mW to 100mW)

W

(to 20 kHz)

W

-12

parts/day

RECOMMENDED

MANUFACTURER/MODEL USAGE

Tektronix, Model 2794, with

External Mixers:

WM780K (18 to 26.5 GHz)

WM780A (26.5 to 40 GHz)

WM780U (40 to 60 GHz)

WM780E (60 to 90 GHz)

Diplexer Assy: 015-0385-00

with

PN9060-00 Status Module

PN9470-00 Noise Output Module

PN9450-00 Lock Control Module

PN9342-01 Phase Detector Module

PN9530-00 Crystal Oscillator Module

Anritsu Model MF2414A C, P

Anritsu Model ML2437A or ML2438A,

with

Power Sensors:

MA2474A (0.01 to 40 GHz)

MA2475A (0.01 to 50 GHz)

John Fluke, Inc., Model 8840A, with

Option 8840A-09K (True RMS AC)

Absolute Time Corp., Model 300 P

Hewlett-Packard, Model 33120A C, P

Hewlett-Packard, Model 8901A P

C, P,T

P

C, P

C, T

-

(1)

1-12 690XXB/691XXB MM

Page 23

GENERAL RECOMMENDED

INFORMATION TEST EQUIPMENT

Table 1-2. Recommended Test Equipment (2 of 2)

INSTRUMENT

Oscilloscope Bandwidth: DC to 150 MHz

Vertical Sensitivity: 2mV/division

Horizontal Sensitivity: 50 ns/division

Scalar Network

Analyzer, with

RF Detector

Attenuator Frequency Range: DC to 40 GHz

Attenuator Frequency Range: DC to 40 GHz

Attenuator Frequency Range: DC to 60 GHz

Attenuator Frequency Range: DC to 60 GHz

RF Detector Frequency Range: 0.01 to 40 GHz

RF Detector Frequency Range: 0.01 to 50 GHz

Personal Computer PC Configuration: IBM ATor compatible

Serial Interface Assy Provides serial interface between the PC

Special AUX I/O

Cable Assy

Tee Connectors: 50WBNC Any common source C, P

Cables Connectors: 50WBNC Any common source C, P,T

Frequency Range: 0.01 to 60 GHz Anritsu, Model 56100A, with

Max Input Power: >+17 dBm

Attenuation: 10 dB

Max Input Power: >+17 dBm

Attenuation: 20 dB

Max Input Power: >+17 dBm

Attenuation: 10 dB

Max Input Power: >+17 dBm

Attenuation: 20 dB

Output Polarity: Negative

Output Polarity: Negative

Operating System: Windows 3.1, 95, or

98

Accessories: Mouse

and the 690XXB/691XXB.

Provides interface between the 690XXB/

691XXB and the Power Meter

CRITICAL

SPECIFICATION

Tektronix, Inc. Model TAS485 P, T

RF Detector:

560-7K50 (0.01 to 40 GHz)

560-7VA50(0.01 to 50 GHz)

SC5198 (40 to 60 GHz)

Anritsu, Model 41KC-10 C, P

Anritsu, Model 41KC-20 P

Anritsu, Model 41V-10 C, P

Anritsu, Model 41V-20 P

Anritsu, Model 75KC50

(K input/BNC output connectors)

Anritsu, Model 75VA50

(V input/BNC output connectors)

Any common source C

Anritsu P/N: T1678 C

Anritsu P/N: 806-90 P

RECOMMENDED

MANUFACTURER/MODEL USAGE

C, T

T

T

(1)

NOTES: (1) P = Performance Verification Tests (Chapter 3); C = Calibration (Chapter 4); T = Troubleshooting (Chapter 5)

690XXB/691XXB MM 1-13

Page 24

GENERAL EXCHANGE

INFORMATION ASSEMBLY PROGRAM

1-13 EXCHANGE ASSEMBLY

PROGRAM

1-14 REPLACEABLE

SUBASSEMBLIES AND

PARTS

Anritsu maintains an exchange assembly program for selected

690XXB/691XXB subassemblies and RF components. If a malfunction

occurs in one of these subassemblies, the defective unit can be

exchanged. Upon receiving your request, Anritsu will ship the

exchange subassembly or RF component to you, typically within 24

hours. You then have 45 days in which to return the defective item. All

exchange subassemblies or RF components are warranted for 90 days

from the date of shipment, or for the balance of the original equipment

warranty, whichever is longer.

Please have the exact model number and serial number of your unit

available when requesting this service, as the information about your

unit is filed according to the instrument's model and serial number.

For more information about the program, contact your local sales rep

resentative or call your local Anritsu service center. Refer to Table 1-5,

on page 1-18, for a list of current Anritsu service centers.

Table 1-3, on page 1-15, lists those replaceable subassemblies and RF

components of the 690XXB/691XXB that are presently covered by the

Anritsu exchange assembly program. Table 1-4, on page 1-16, lists

common replaceable parts for the 690XXB/691XXB that are not presently on the exchange assembly program.

All parts listed in Tables 1-3 and 1-4 may be ordered from your local

Anritsu service center.

-

1-14 690XXB/691XXB MM

Page 25

GENERAL

INFORMATION PARTS LIST

Table 1-3. Replaceable Subassemblies and RF Components (1 of 2)

SUBASSEMBLY OR PART NAME ANRITSU PART NUMBER

Printed Circuit Board Assemblies

Front Panel Assy 691XXB ND40832

Front Panel Assy 690XXB ND40514

A3 Reference Loop PCB Assy D40603-4

A4 Coarse Loop PCB Assy D40624-3

A5 Fine Loop PCB Assy D40625-3

A6 Square Wave Generator PCB Assy D37406-3

A7 YIG Loop PCB Assy D40627-3

A9 PIN Control PCB Assy D40659-3

A10 ALC PCB Assy (691XXB) D40610-3

A10 ALC PCB Assy (690XXB) D40610-4

A11FM PCB Assy (All 691XXBs except 69117B) D40651-3

A11FM PCB Assy (69117B only) D40651-4

A11FM PCB Assy (All 690XXBs except 690117B) D40651-5

A11FM PCB Assy (69017B only) D40651-6

A12 Analog Instruction PCB Assy (691XXB) D37448-3

A12 Analog Instruction PCB Assy (690XXB) D40612-3

A13 10 MHz DDS PCB Assy D40653-3

A14 YIG, SDM Driver PCB Assy

(£40 GHz models)

A14 YIG, SDM, SQM Driver PCB Assy

(>40 GHz models)

A15 Regulator PCB Assy D40655-3

A16 CPU Interface PCB Assy D37416-3

A17 CPU PCB Assy D37444-3

A18 Power Supply PCB Assy D40638-3

A19 Power Conditioner PCB Assy D40649-3

A21 Line Filter/Rectifier PCB Assy ND49529

A21-1 BNC/AUX I/O Connector PCB Assy

690XXB

A21-2 BNC/AUX I/O Connector PCB Assy

691XXB

10 MHz Crystal Oscillator Assy D37332

40654-3

40654-4

ND49525

ND40526

RF Components

YIG-Tuned Oscillator, 2 to 20 GHz 48514

YIG-Tuned Oscillator, 2 to 8.4 GHz 37266

Down Converter D27330

Digital Down Converter 50722-1

Switched Doubler Module, 20 to 40 GHz D28540

Source Quadrupler Module, 40 to 50 GHz D28185

Source Quadrupler Module, 40 to 60 GHz 60-141

690XXB/691XXB MM 1-15

Page 26

GENERAL

INFORMATION PARTS LIST

Table 1-3. Replaceable Subassemblies and RF Components (2 of 2)

SUBASSEMBLY OR PART NAME ANRITSU PART NUMBER

RF Components (Continued)

Source Quadrupler Module, 40 to 65 GHz 60-142

Coupler, 40 GHz D27115

Coupler, 60 GHz D27350

Forward Coupler, 60 GHz C27184

Switched Filter D45194

Switched Filter (w/Option 15A) D45198

Output Connector Assy “K” ND39077

Output Connector Assy “V” ND40835

Step Attenuator, 110 dB, 20 GHz D27152

Step Attenuator, 110 dB, 40 GHz D25080

Step Attenuator, 90 dB, 50 GHz D27315

Step Attenuator, 90 dB, 60 GHz D28957

Electronic Step Attenuator, 120 dB, 20 GHz 45720

Diplexer, 10 MHz 46504

Diplexer, <20 GHz 29860

Diplexer, >20 GHz 28850

Table 1-4. Common Replaceable Subassemblies and Parts (1 of 2)

SUBASSEMBLY OR PART NAME ANRITSU PART NUMBER

Cap, Protective (for RF Output K-Connector) A20304

Cap, Protective (for RF Output V-Connector) B37220

Cover, Top D37131

Cover, Bottom D37135

Cover, Side D37133

Cover, Side Handle 761-67

Cover, CPU Housing C37063

Cover, Main Card Cage D37064

Cover, Power Supply Housing C37062

EMI Gasket for side covers 790-437

EMI Gasket for side covers 790-390

EMI Gasket for Front Panel Assy 790-223

1-16 690XXB/691XXB MM

Page 27

GENERAL

INFORMATION PARTS LIST

Table 1-4. Common Replaceable Subassemblies and Parts (2 of 2)

SUBASSEMBLY OR PART NAME ANRITSU PART NUMBER

Fan Assembly A40513

Fan Mount 790-425

Fan Membrane (Honey Comb Filter) C37137

Fan Grill 790-426

Fasteners (for Fan Grill) 790-433

Fuse, 5A, 3AG Slow Blow (110Vac) 631-33

Fuse, 2.5A, 3AG Slow Blow (230 Vac) 631-14

Gasket, RFI (“O”rings for MCX connectors) 790-393

Handle, Side Carrying 783-830

Screw, Handle Side Carrying 900-714

Line Module 260-11

Shield Cover D37228

Shield D37229

Standoff 785-922

Tape 850-70

Foot, Rear Bottom Left 2000-548

Foot, Rear Bottom Right 2000-549

Foot, Rear TopLeft 2000-552

Foot, Rear TopRight 2000-553

Screw, Green Head 2000-560

690XXB/691XXB without Front Handles Installed

Foot, Front Bottom Left 2000-546

Foot, Front Bottom Right 2000-547

Foot, Front TopLeft 2000-550

Foot, Front TopRight 2000-551

690XXB/691XXB with Front Handles Installed

Upper Insert B37147

Foot, Bottom Left C37170

Foot, Bottom Right C37171

Handle, Left D37168-2

Handle, Right D37169-2

Tilt Bail 790-435

690XXB/691XXB MM 1-17

Page 28

GENERAL ANRITSU

INFORMATION SERVICE CENTERS

Table 1-5. Anritsu Service Centers

UNITED STATES

ANRITSU COMPANY

490 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300

1-800-ANRITSU

FAX: 408-776-1744

ANRITSU COMPANY

10 New Maple Ave., Unit 305

Pine Brook, NJ 07058

Telephone: (973) 227-8999

1-800-ANRITSU

FAX: 973-575-0092

ANRITSU COMPANY

1155 E. Collins Blvd

Richardson, TX 75081

Telephone: 1-800-ANRITSU

FAX: 972-671-1877

AUSTRALIA

ANRITSU PTY. LTD.

Unit 3, 170 Foster Road

Mt Waverley, VIC 3149

Australia

Telephone: 03-9558-8177

FAX: 03-9558-8255

BRAZIL

ANRITSU ELECTRONICA LTDA.

Praia de Botafogo, 440, Sala 2401

CEP22250-040, Rio de Janeiro, RJ, Brasil

Telephone: 021-527-6922

FAX: 021-53-71-456

CANADA

ANRITSU INSTRUMENTS LTD.

700 Silver Seven Road, Suite 120

Kanata, Ontario K2V 1C3

Telephone: (613) 591-2003

FAX: (613) 591-1006

CHINA

ANRITSU ELECTRONICS (SHANGHAI) CO. LTD.

2F, Rm B, 52 Section Factory Building

No. 516 Fu Te Rd (N)

Shanghai 200131 P.R. China

Telephone:21-58680226, 58680227, 58680228

FAX: 21-58680588

FRANCE

ANRITSU S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: 016-09-21-550

FAX: 016-44-61-065

GERMANY

ANRITSU GmbH

Grafenberger Allee 54-56

D-40237 Dusseldorf, Germany

Telephone: 0211-968550

FAX: 0211-9685555

INDIA

MEERA AGENCIES PVT. LTD.

23 Community Centre

Zamroodpur, Kailash Colony Extension,

New Delhi, India 110 048

Phone: 011-2-6442700/6442800

FAX : 011-2-644250023

ISRAEL

TECH-CENT, LTD.

4 Raul Valenberg St

Tel-Aviv 69719

Telephone: (03) 64-78-563

FAX: (03) 64-78-334

ITALY

ANRITSU Sp.A

Roma Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: (06) 50-99-711

FAX: (06) 50-22-4252

KOREA

ANRITSU CORPORATION LTD.

Head Office:

14F, Hyunjuk Building 832-41

Yeoksam-Dong, Kangnam-Ku

Seoul 135-080, South Korea

Telephone: 02-553-6603

FAX: 02-553-6604

Service Center:

8F Hyunjuk Building

832-41, Yeoksam Dong

Kangnam-Gu

Seoul, South Korea 135-080

Telephone: 82-2-553-6603

FAX: 82-2-553-6605

JAPAN

ANRITSU CUSTOMER SERVICE LTD.

1800 Onna Atsugi-shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-96-6688

FAX: 0462-25-8379

SINGAPORE

ANRITSU (SINGAPORE) PTE LTD.

10, Hoe Chiang Road

#07-01/02 Keppel Towers

Singapore 089315

Telephone: 282-2400

FAX: 282-2533

SOUTH AFRICA

ETECSA

12 Surrey Square Office Park

330 Surrey Avenue

Ferndale, Randburt, 2194

South Africa

Telephone: 011-27-11-787-7200

FAX: 011-27-11-787-0446

SWEDEN

ANRITSU AB

Botivid Center

Fittja Backe 13A

145 84 Stockholmn

Telephone: (08) 534-707-00

FAX: (08) 534-707-30

TAIWAN

ANRITSU CO., INC.

7F, No. 316, Section 1

NeiHu Road

Taipei, Taiwan, R.O.C.

Telephone: 886-2-8751-1816

FAX: 886-2-8751-2126

UNITED KINGDOM

ANRITSU LTD.

200 Capability Green

Luton, Bedfordshire

LU1 3LU, England

Telephone: 015-82-433200

FAX: 015-82-731303

1-18 690XXB/691XXB MM

Page 29

Chapter 2

Functional Description

Table of Contents

2-1 INTRODUCTION

2-2 690XXB/691XXB MAJOR SUBSYSTEMS

Digital Control

Front Panel

Frequency Synthesis...............2-4

Analog Instruction................2-5

YIG, SDM, SQM Driver .............2-5

ALC/Modulation .................2-8

RF Deck.....................2-8

Power Supply ..................2-8

Inputs/Outputs .................2-8

Motherboard/Interconnections ..........2-9

2-3 FREQUENCY SYNTHESIS .............2-9

Phase Lock Loops ................2-9

Overall Operation

RF Outputs 0.00001 to 65 GHz

Frequency Modulation (691XXB only)

Analog Sweep Mode (691XXB only)

Step Sweep Mode

...................

......

..................

...................

...............

.........

......

.......

................

2-3

2-3

2-3

2-4

2-10

2-13

2-14

2-14

2-15

2-4 ALC AND MODULATION

ALC Loop Operation

Amplitude Modulation (691XXB only)

Square Wave Modulation (691XXB only)

2-5 RF DECK ASSEMBLIES

RF Deck Configurations

YIG-tuned Oscillator

Power Level Control and Modulation

RF Signal Filtering

0.01 to 2 GHz Down Converter

0.01 to 2.2 GHz Digital Down Converter

..............

..............

...............

..............

......

....

..............

............

......

.........

....

2-15

2-15

2-18

2-18

2-19

2-19

2-20

2-20

2-25

2-26

2-27

Page 30

Table of Contents (Continued)

Switched Doubler Module

Source Quadrupler Module

Power Level Detection/ALC Loop

Step Attenuators

................

............

...........

........

2-28

2-29

2-30

2-31

Page 31

Chapter 2

Functional Description

2-1 INTRODUCTION This chapter provides brief functional descriptions of the major sub

systems that are contained in each model of the Series 690XXB/

691XXB Synthesized CW/Signal Generators. In addition, the opera

tion of the frequency synthesis, automatic level control (ALC), and RF

deck subsystems is described so that the reader may better under

stand the overall operation of the instrument. Block diagrams are in

cluded to supplement the written descriptions.

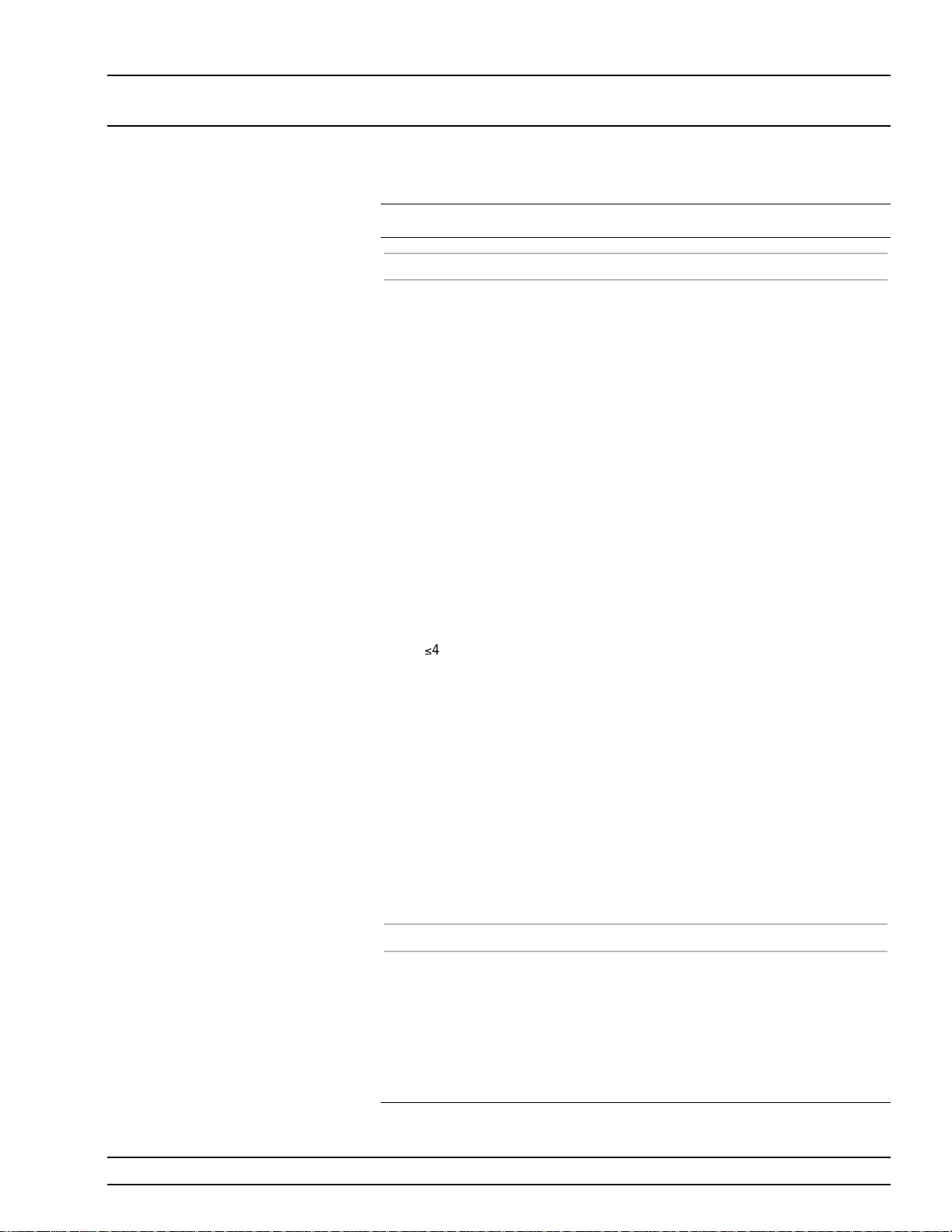

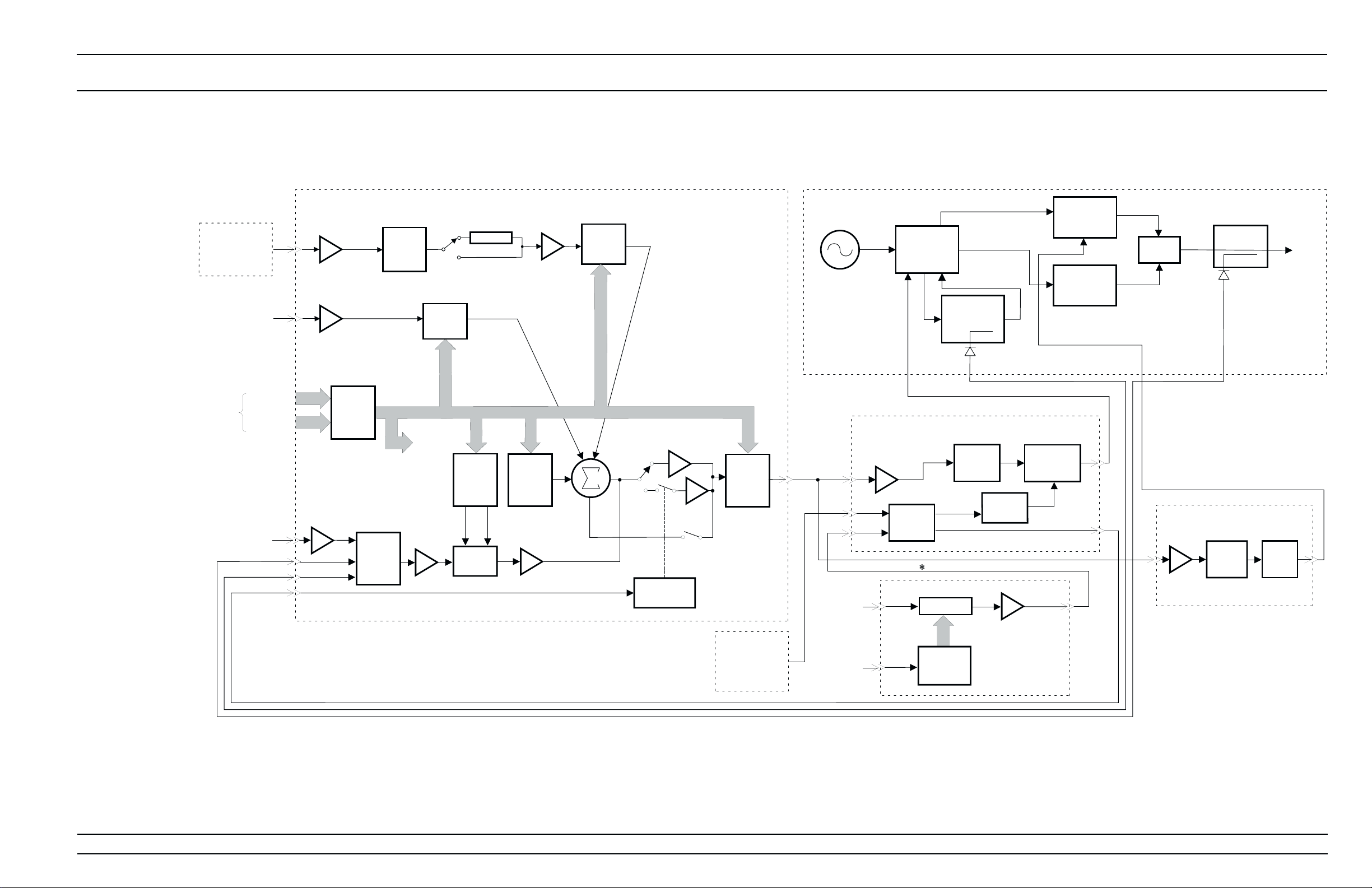

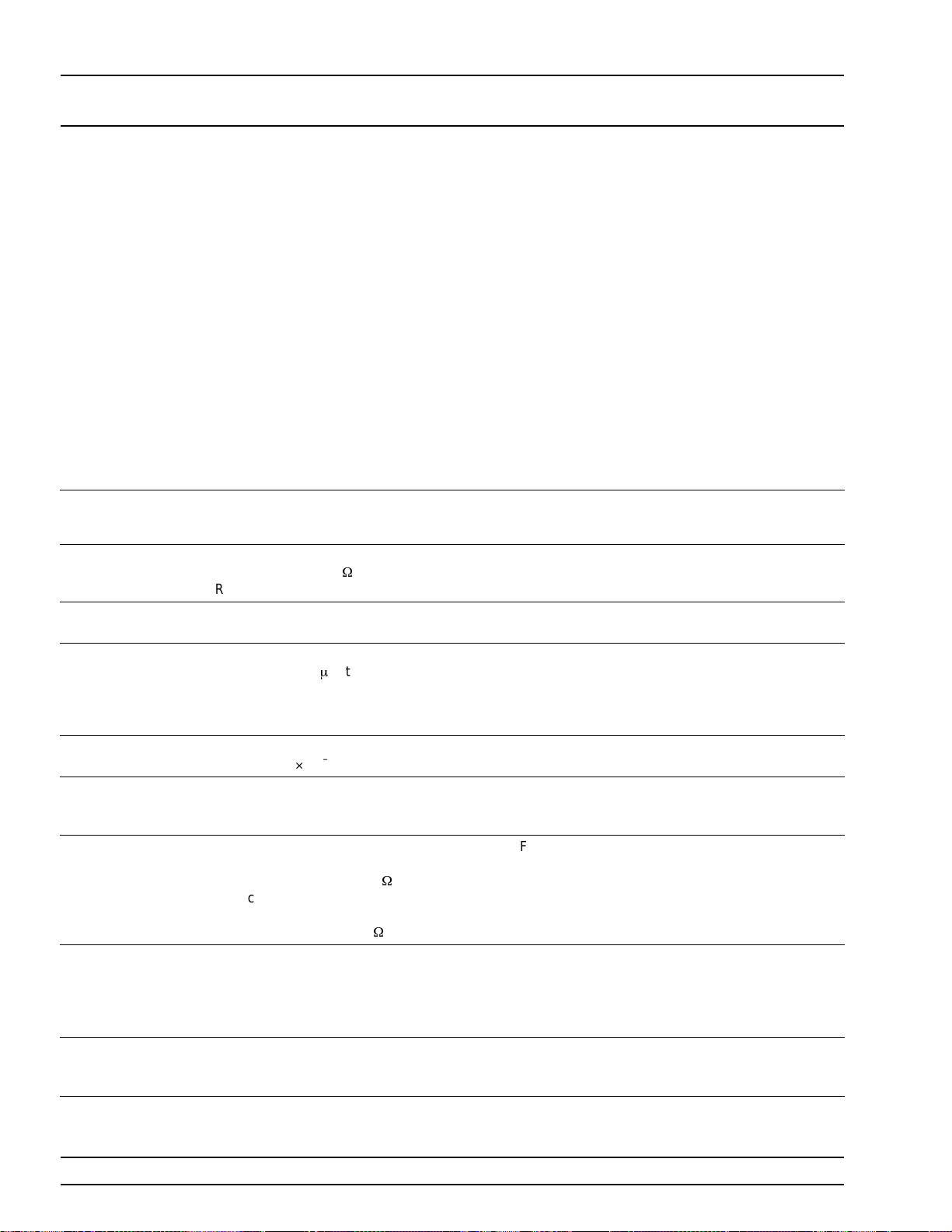

2-2 690XXB/691XXB MAJOR

SUBSYSTEMS

The 690XXB/691XXB circuitry consists of various distinct subsystems

that are contained on one or more printed circuit board (PCB) assemblies or in microwave components located on the RF deck. The following paragraphs identify the subsystems that make up the instrument

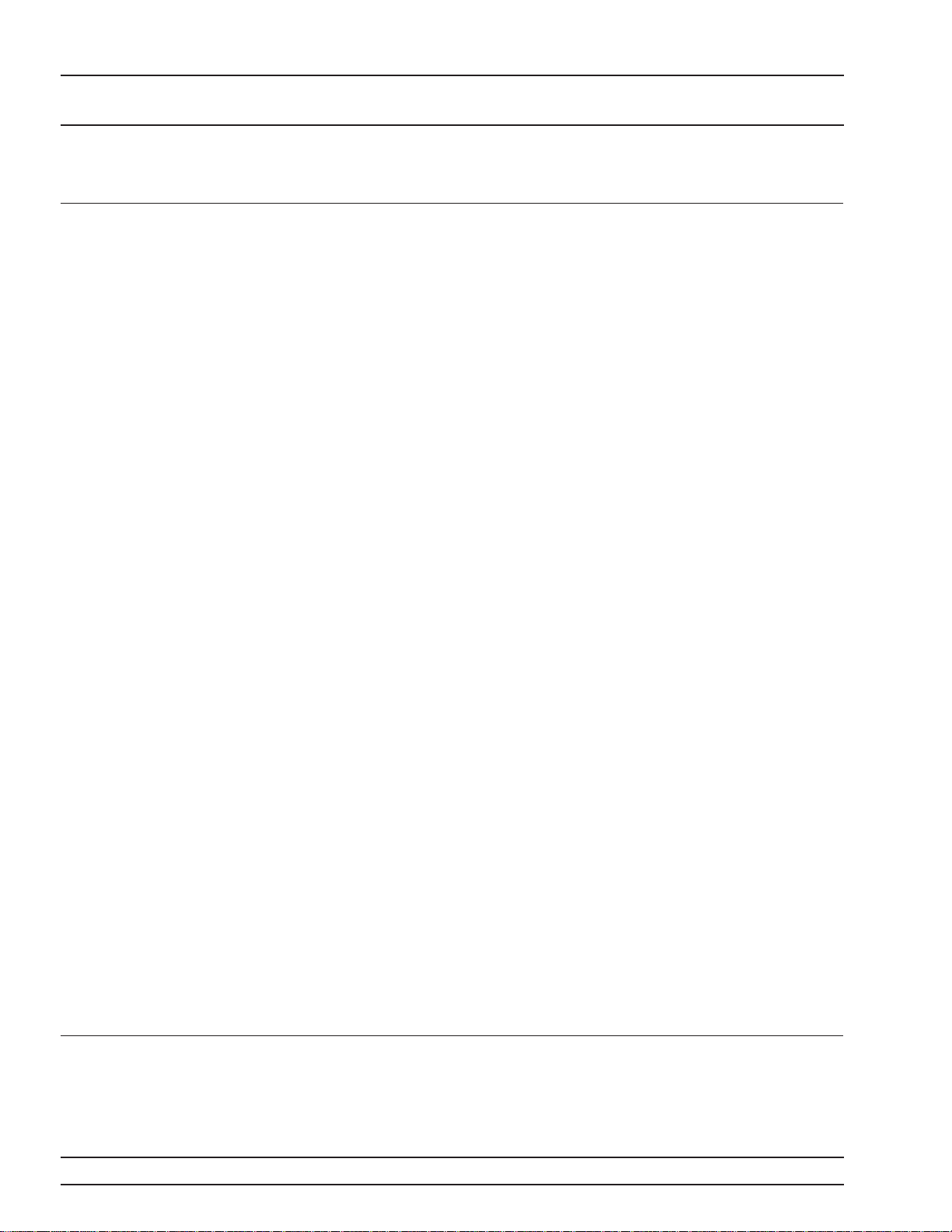

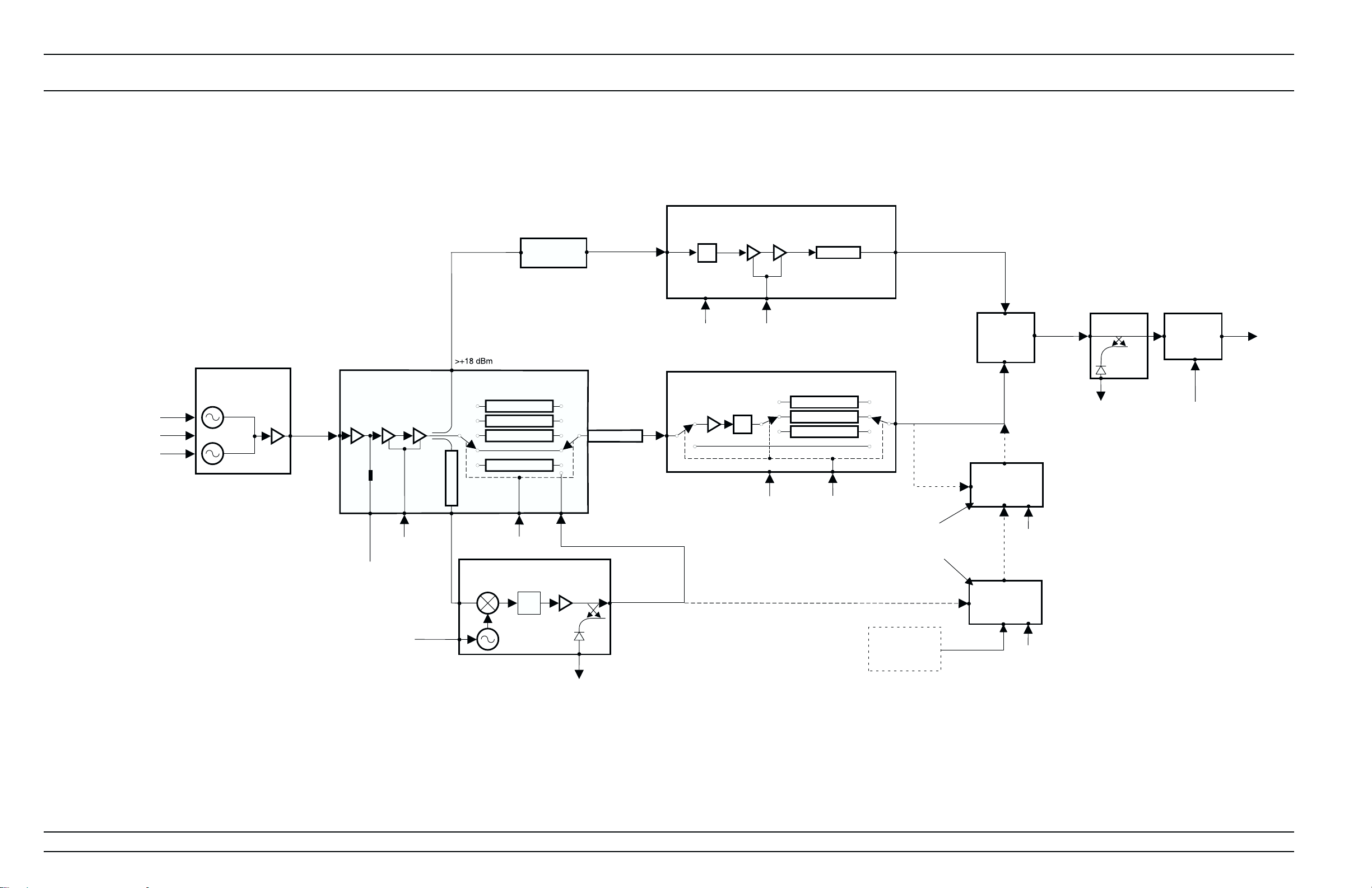

and provide a brief description of each. Figure 2-1 (page 2-6) is an

overall block diagram of a typical 690XXB/691XXB.

NOTE

Although identical model numbers of the series 690XXB CW

generators and series 691XXB signal generators contain the

same major subsystems, there are some functional differences between them. These functional differences result

fromthe series 691XXB having the additional capability of

producing analog frequency sweeps and AM, FM, and

square wave modulation of the RF output signal. Functional

differences between the series are noted in the following de

scriptions where applicable.

-

-

-

-

-

Digital

Control

This circuit subsystem consists of the A17 CPU and

A16 CPU Interface PCBs. The central processor unit

(CPU) is the main controller for the 690XXB/

691XXB. This controller directly or indirectly con

trols all functions of the instrument. The CPU con

tains memory that stores the main operating system

components and instrument firmware, instrument

calibration data, and front panel setups in the

power-off condition. It has a GPIB interface that

allows it to communicate with external devices over

the GPIB and a serial interface to a serial terminal

port on the rear panel. The CPU is directly linked

via a dedicated data and address bus to the A2

Front Panel PCB, the A9 PIN Control PCB, the A10

ALC PCB, the A11 FM PCB, the A12 Analog

Instruction PCB, the A14 YIG, SDM, SQM Driver

-

-

690XXB/691XXB MM 2-3

Page 32

FUNCTIONAL 690XXB/691XXB

DESCRIPTION MAJOR SUBSYSTEMS

PCB, the A16 CPU Interface PCB, and the optional

A13 10 MHz DDS PCB.

The CPU is indirectly linked via the A16 CPU Inter

face PCB to the A3 Reference Loop PCB, the A4

Coarse Loop PCB, the A5 Fine Loop PCB, and the

A6 Square Wave Generator PCB. The A16 PCB

contains circuitry to perform parallel-to-serial and

serial-to-parallel data conversion. It also contains

circuitry for many of the rear panel signals, a 13-bit

resolution DVM, and decoder circuitry for the front

panel rotary data knob optical encoder.

Front Panel This circuit subsystem consists of the the A1 Front

Panel PCB, the A2 Front Panel Control PCB, and

the Liquid Crystal Display (LCD). This subsystem

interfaces the front panel LCD, LEDs, and keys to

the CPU via the dedicated data and address bus.

The front panel rotary data knob is indirectly linked

to the CPU via the A16 CPU Interface PCB.

The A1 Front Panel PCB contains the keyboard

matrix of conductive rubber switches. The A2 Front

Panel Control PCB has circuits to control the LCD

dot-matrix display, turn the front panel LEDs on

and off, and convert keyboard switch matrix signals

to parallel keycode. It also contains the standby/

operate line switch logic circuit and the optical encoder for the rotary data knob.

-

Frequency

Synthesis

The frequency synthesis subsystem consists of the

A3 Reference Loop PCB, the A4 Coarse Loop PCB,

the A5 Fine Loop PCB, the A7 YIG Loop PCB, and

the A11 FM PCB. It provides the reference frequen

cies and phase lock circuits for precise control of the

YIG-tuned oscillator frequencies, as follows:

q

The A3 Reference Loop PCB supplies the sta

ble 10 MHz, 100 MHz, and 500 MHz reference

frequency signals for the rest of the frequency

synthesis system.

q

The A4 Coarse Loop PCB generates coarse

tuning frequencies of 202.5 to 990 MHz for use

by the YIG Loop.

q

The A5 Fine Loop PCB provides fine tuning

frequencies of 30 to 40 MHz for use by the YIG

Loop.

-

2-4 690XXB/691XXB MM

-

Page 33

FUNCTIONAL 690XXB/691XXB

DESCRIPTION MAJOR SUBSYSTEMS

Analog

Instruction

The A7 YIG Loop PCB performs phase detec

q

tion of the YIG-tuned oscillator's output fre

quency and provides a YIG loop error voltage

to the A11 PCB.

The A11 FM PCB conditions the YIG loop error

q

voltage, producing a correction signal that is

used to fine tune and phase lock the YIG-tuned

oscillator. In the 691XXB, the A11 PCB also

contains circuitry for frequency modulation of

the YIG-tuned oscillator RF output.

The CPU sends control data to the A3 Reference

Loop PCB, the A4 Coarse Loop PCB, and the A5

Fine Loop PCB via the A16 PCB as serial data

words. The CPU controls the A11 FM PCB via the

dedicated data and address bus. Refer to paragraph

2-3 for a functional overview of the frequency syn

thesis subsystem.

The A12 Analog Instruction PCB provides the frequency tuning voltages to the A14 YIG, SDM, SQM

Driver PCB. In addition, it provides a 0V to +10V

ramp signal to the rear panel HORIZ OUT connector,

a V/GHz signal to the rear panel AUX I/O connector,

and a SLOPE signal to the A10 ALC PCB for slopevs-frequency correction of the RF output power. The

A17 CPU controls the A12 Analog Instruction PCB

via the dedicated data and address bus.

-

-

-

YIG, SDM,

SQM Driver

The A14 YIG, SDM, SQM Driver PCB supplies the

tuning current and bias voltages for the YIG-tuned

oscillator. It also provides bias voltages for the

Down Converter assembly and the Switched Filter

assembly. For models with a frequency range

greater than 20 GHz, the A14 PCB supplies bias

voltages for the Switched Doubler Module (SDM)

and the Source Quadrupler Module (SQM). In addi

tion, it provides modulator drive signals for the

SQM.

The A12 Analog Instruction PCB provides frequency

tuning voltages for the main tuning coil driver of the

YIG-tuned oscillator. Thw A17 CPU controls the

A14 YIG, SDM, SQM Driver PCB via the dedicated

data and address bus.

690XXB/691XXB MM 2-5

-

Page 34

FUNCTIONAL 690XXB/691XXB

DESCRIPTION MAJOR SUBSYSTEMS

C o n n e c t o r s

A M I N

*

F M I N

*

*

E X T A L C I N

R F O U T P U T

I N

A 1

F r o n t

P a n e l

K e y b o a r d

M a t r i x

L i n e

S w i t c h

R o t a r y

D a t a

K n o b

C o a x i a l C a b l e s

F r o n t P a n e l

T o A 1 0 A L C P C B

( V i a A 2 0 M o t h e r b o a r d )

T o A 1 1 F M P C B

T o A 9 P I N C o n t r o l P C B

( V i a A 2 0 M o t h e r b o a r d )

T o A 1 0 A L C P C B

( V i a A 2 0 M o t h e r b o a r d )

F r o m R F D e c k

L C D

L C D

C o n t r o l

K e y b o a r d

E n c o d e r

L i n e

S w i t c h

L o g i c

O p t i c a l

E n c o d e r

A 2

F r o n t P a n e l

C o n t r o l

+ 2 4 V

( T o A 1 8

P C B )

+ 2 4 V

( F r o m

A 1 5 P C B )

I n p u t s

1 0 M H z R E F I N

F r o m R F D e c k

( O p t i o n 9 )

F r o m A 3

R e f e r e n c e L o o p

F M I N

*

A M I N

*

I N

*

E X T A L C I N

A U X

I / O

S E R I A L

I / O

P h a s e A / P h a s e B D a t a

A 2 1 - 1 / A 2 1 - 2

B N C / A U X

I / O C o n n e c t o r

P C B

I E E E - 4 8 8

R e a r P a n e l

O u t p u t s

T o A 3

R e f e r e n c e L o o p

R F O U T P U T

1 0 M H Z R E F O U T

T o A 1 1 F M P C B

H O R I Z O U T

P o w e r I n p u t

L i n e

F i l t e r

P / O R e a r

C a s t i n g A s s y

G P I B B u s

1 1 0 / 2 2 0 V A C

F u s e

R e a r P a n e l S i g n a l s

B r i d g e

R e c t i f i e r /

D o u b l e r

P / 0 A 2 1

R e a r

P a n e l P C B

P o w e r S u p p l y

+ 1 6 5 V

- 1 6 5 V

S e r i a l I / O

A 1 9

L i n e

C o n d i t i o n e r

A 1 8

P o w e r

S u p p l y

C o n t r o l 4 0 0 k H z

+ 2 4 V

( F r o m A 2 P C B )

A 1 7

C P U

A 1 5

R e g u l a t o r

+ 2 4 V

( T o A 2 P C B )

D i g i t a l

C o n t r o l

D a t a a n d A d d r e s s B u s

+ 5 V

+ 9 V

+ 1 5 V

- 1 5 V

+ 2 4 V

- 2 8 V

A 1 6

C P U

I n t e r f a c e

( C o n t i n u e d o n S h e e t 2 )

A

E

B

C

D

Figure 2-1. Block Diagram of a Typical 690XXB/691XXB

Synthesized CW/Signal Generator (Sheet 1 of 2)

2-6 690XXB/691XXB MM

Page 35

FUNCTIONAL 690XXB/691XXB

(

)

DESCRIPTION MAJOR SUBSYSTEMS

S e r i a l D a t a

S e r i a l D a t a

S e r i a l D a t a

1 0 M H z R E F I N

R e a r P a n e l B N C

A

1 0 M H z

H I - S T A B

X T A L O S C

( O p t i o n )

A 3

R e f e r e n c e

L o o p

1 0 M H z R E F O U T

R e a l P a n e l B N C

1 0 M H z

1 0 0 M H z

5 0 0 M H z

( T o D o w n

C o n v e r t e r )

F r e q u e n c y

S y n t h e s i s

Y I G L o o p E r r o r

A 4

C o a r s e

L o o p

2 0 2 . 5 - 9 9 0 M H z

A 7

Y I G

L o o p

S a m p l e d

2 - 2 0 G H z

R F

1 0 M H z

3 0 - 4 0 M H z

F i n e

L o o p

A 5

1 0 M H z ( T o A 6 )

2 6 . 8 4 3 5 4 5 6 M H z

( T o A 1 3 - O p t i o n 2 2 )

A 1 1

F M

W i d e

F M

A 1 4

Y I G , S D M

A L C

( F r o m A 1 0 )

E

1 0 M H z

( F r o m A 5 )

B

C

D

S e r i a l D a t a

4 0 0 k H z

C o n t i n u e d F r o m S h e e t 1

D r i v e r

F r e q

F r e q

B a n d

T u n i n g

S e l e c t

A 1 2

A n a l o g

I n s t r u c t i o n

R e a r P a n e l S i g n a l s

A 6

S q u a r e

W a v e

G e n e r a t o r

F r o n t P a n e l F M I N

R e a r P a n e l F M I N

F M

M a i n

B i a s

2 - 2 0 G H z

O s c i l l a t o r

B i a s ( t o S D M )

A n a l o g

I n s t r u c t i o n

D a t a A n d A d d r e s s B u s

Y I G

S q u a r e W a v e

A L C / A M / S q u a r e W a v e

M o d u l a t i o n

F r o n t P a n e l E X T A L C I N

M o d u l a t o r

C o n t r o l

S w i t c h e d F i l t e r

8 . 5 G H z L P F

6 . 5 1 - 8 . 5 G H z

5 0 0 M H z

( F r o m A 3 )

R e a r P a n e l

F r o n t P a n e l

R e a r P a n e l A M I N

F r o n t P a n e l A M I N

3 . 3 G H z L P F

5 . 5 G H z L P F

8 . 4 G H z L P F

1 3 . 5 G H z L P F

D o w n C o n v e r t e r

0 . 0 1 - 2 G H z R F

R e a r P a n e l E X T A L C I N

D e t e c t e d

2 0 G H z L P F

S w i t c h C o n t r o l

0 . 0 1 - 2 G H z

0 . 0 1 - 2 0 G H z

A L C

( T o A 1 4 )

R F D e c k

S w i t c h e d D o u b l e r M o d u l e

2 0 - 2 5 G H z

x 2

B i a s

( F r o m A 1 4 )

A 9

P I N

C o n t r o l

S a m p l e /

A L C

H o l d

A 1 0

A L C

2 5 - 3 2 G H z

3 2 - 4 0 G H z

S w i t c h

C o n t r o l

D e t e c t e d

2 - 4 0 G H z R F

0 . 0 1 -

4 0 G H z

0 . 0 1 - 1 0 M H z

( T o R F D e c k

v i a D i p l e x e r s )

A 1 3

1 0 M H z

D D S

( O p t i o n 2 2 )

D i r e c t i o n a l

C o u p l e r

6 9 1 X X B M o d e l s O n l y

2 6 . 8 4 3 5 4 5 6 M H z

( F r o m A 5 )

A t t e n u a t o r

S t e p

A t t e n u a t o r

C o n t r o l

1 1 0 d B

S t e p

( O p t i o n )

R F O u t p u t

0 . 0 1 - 4 0 G H z

Figure 2-1. Block Diagram of a Typical 690XXB/691XXB

Synthesized CW/Signal Generator (Sheet 2 of 2)

690XXB/691XXB MM 2-7

Page 36

FUNCTIONAL 690XXB/691XXB

DESCRIPTION MAJOR SUBSYSTEMS

ALC/

Modulation

RF Deck This subsystem contains those elements related to

This circuit subsystem consists of the A6 Square

Wave Generator PCB, the A9 PIN Control PCB, the

A10 ALC PCB, and part of the A14 YIG, SDM, SQM

Driver PCB. It provides the following:

Level control of the RF output power.

q

In the 691XXB, AM modulation and square

q

wave modulation.

Current drive signals to the PIN switches

q

located in the Switched Filter assembly and

Switched Doubler Module (SDM).

Drive signals for the Step Attenuator (Option

q

2) and the Diplexers (used with Option 22).

The A17 CPU controls the A9 Pin Control PCB, the

A10 ALC PCB, and the A14 YIG, SDM, SQM Driver

PCB via the dedicated data and address bus. It

sends control data to the A6 Square Wave Generator

PCB via the A16 PCB as serial data words. Refer to

paragraph 2-4 for a functional overview of the ALC

and modulation subsystem.

the generation, modulation, and control of the

sweep- and CW-frequency RF signals. These elements include; the YIG-tuned oscillator, the 0.01 to

2 GHz Down Converter assembly, the optional 0.01

to 2.2 GHz Digital Down Converter assembly, the

Switched Filter assembly, the Switched Doubler

Module (SDM), the Source Quadrupler Module

(SQM), the Diplexer, the Directional Coupler/Level

Detector, and the optional Step Attenuator. Refer to

paragraph 2-5 for a functional overview of the RF

deck subsystem.

Power Supply The power supply subsystem consists of the A15

Regulator PCB, the A18 Power Supply PCB, the

A19 Line Conditioner PCB, and part of the A21

Rear Panel PCB and Rear Casting Assembly. It

supplies all the regulated DC voltages used by the

690XXB/691XXB circuits. The voltages are routed

-

Inputs/

Outputs

throughout the instrument via the A20 Mother

board PCB.

The A21-1/A21-2 BNC/AUX I/O Connector PCB and

the A16 CPU Interface PCB contain the interface

circuits for the majority of the rear panel input and

output connectors, including the AUX I/O connector.

2-8 690XXB/691XXB MM

Page 37

FUNCTIONAL FREQUENCY

DESCRIPTION SYNTHESIS

The front panel external ALC input goes via the A20

Motherboard PCB to the A10 ALC PCB; the rear

panel external ALC input goes by way of the A21-1/

A21-2 PCB and the A20 PCB to the A10 PCB. The

rear panel connectors, 10 MHz REF OUT and

10 MHz REF IN, are coupled directly to the A3 Refer

ence Loop PCB via coaxial cables. The rear panel

IEEE-488 GPIB and SERIAL I/O connectors are

connected to the A17 CPU PCB by way of the Moth

erboard PCB.

In 691XXB models, the front panel AM and Square

Wave inputs go by way of the Motherboard PCB to

the internal PCBs—the AM input to the A10 ALC

PCB and the Square Wave input to the A9 PIN Con

trol PCB. The rear panel AM and Square Wave

inputs route via the A21-2 PCB and the Mother

board PCB to their respective internal PCBs. The

front panel and rear panel FM inputs are coupled

directly via coaxial cable to the A11 FM PCB.

-

-

-

-

Motherboard/

Interconnections

The A20 Motherboard PCB and associated cables

provide the interconnections for the flow of data,

signals, and DC voltages between all internal components and assemblies throughout the 690XXB/

691XXB.

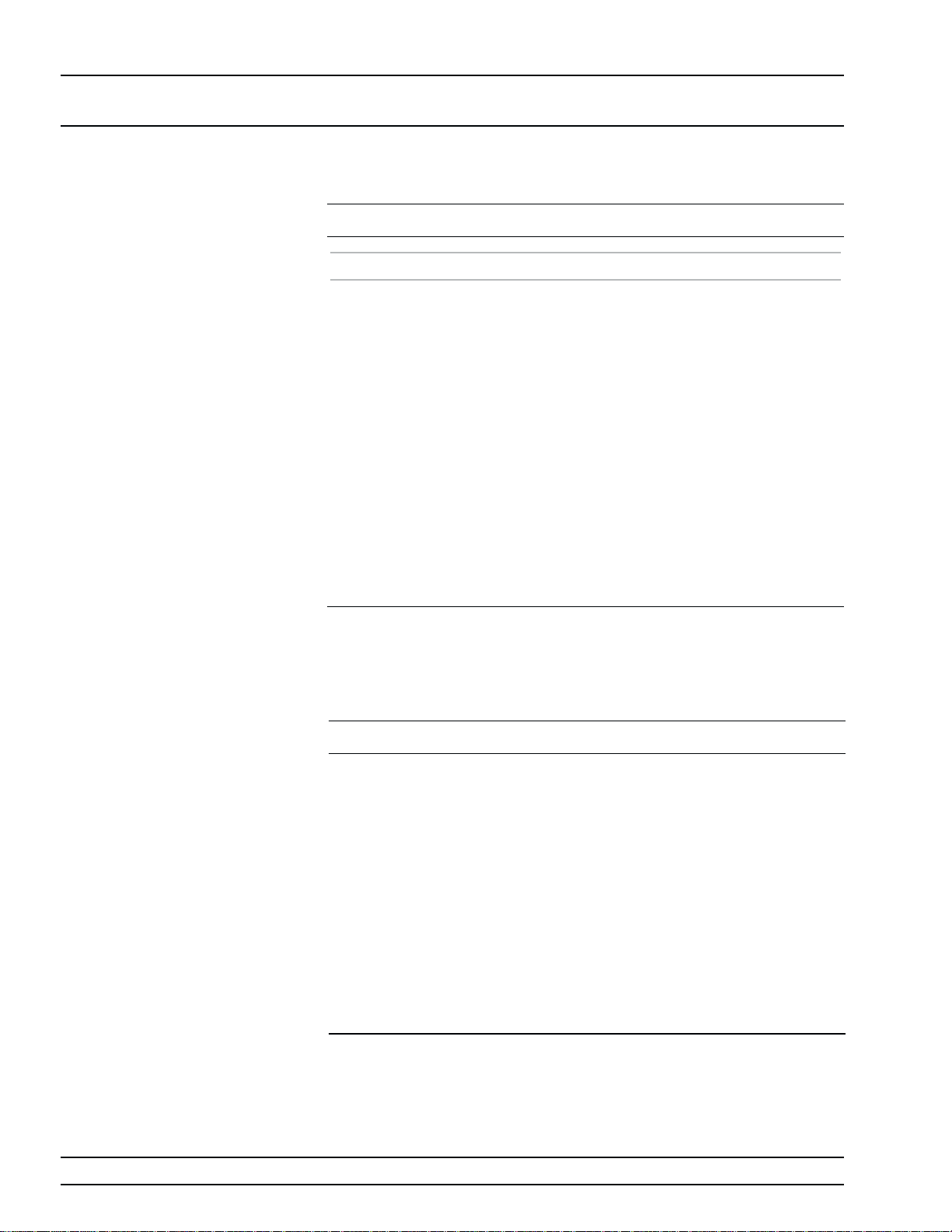

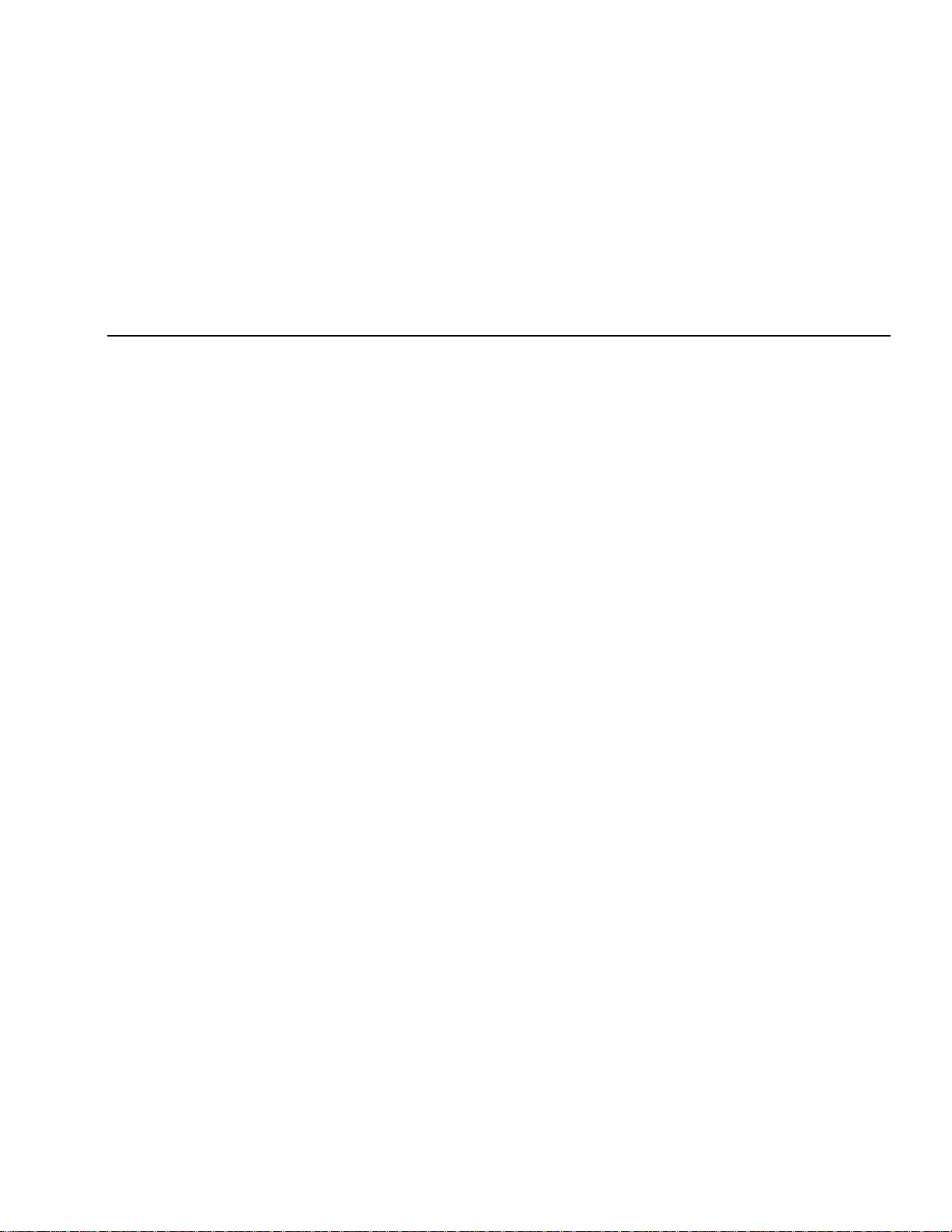

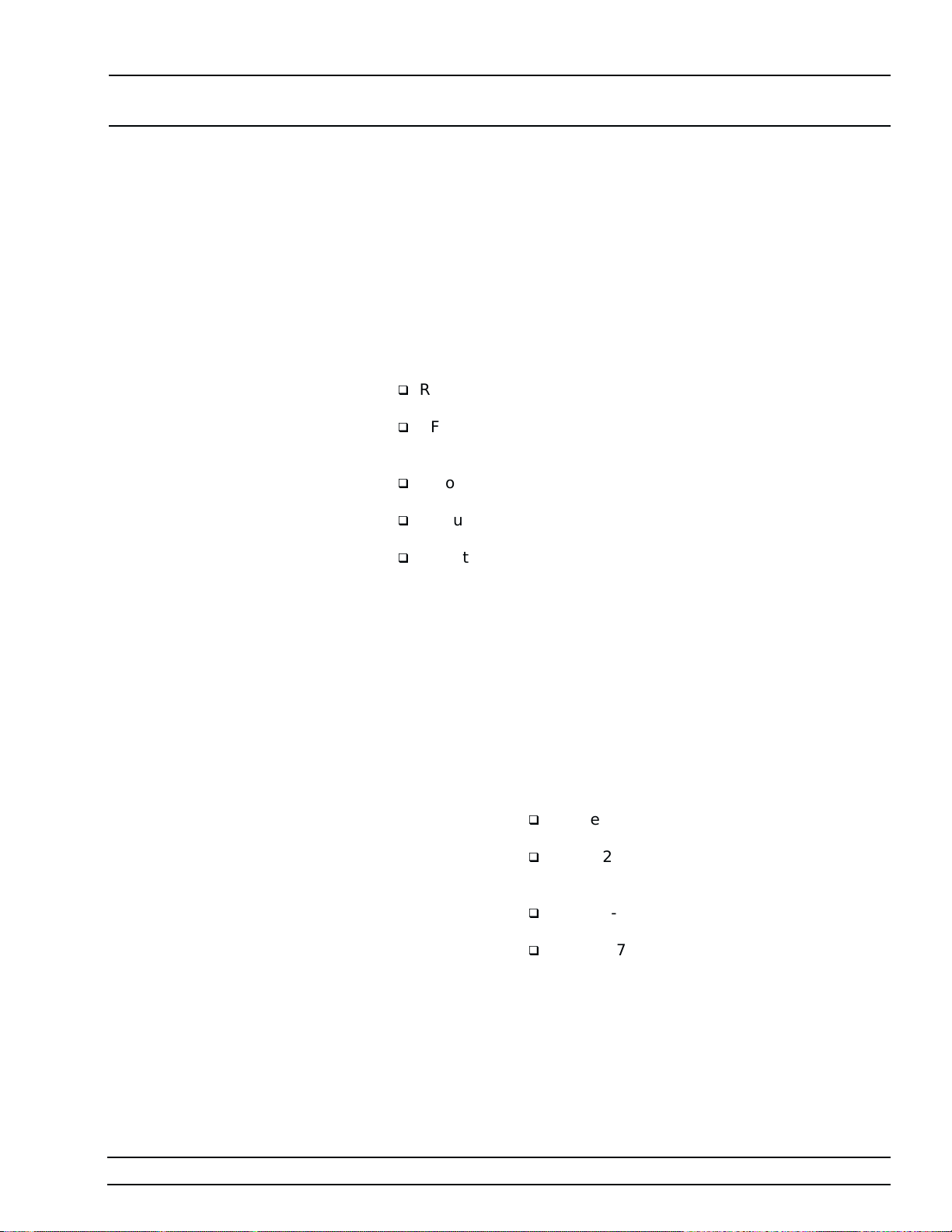

2-3 FREQUENCY SYNTHESIS The frequency synthesis subsystem provides phase-lock control of the

690XXB/691XXB output frequency. It consists of four phase-lock loops,

the Reference Loop, the Coarse Loop, the Fine Loop, and the YIG

Loop. The four phase-lock loops, operating together, produce an accu

rately synthesized, low-noise RF output signal. Figure 2-2 (page 2-11)

is an overall block diagram of the frequency synthesis subsystem. The

following paragraphs describe phase-lock loops and the overall opera

tion of the frequency synthesis subsystem.

Phase Lock

Loops

The purpose of a phase-lock loop is to control the

frequency of a variable oscillator in order to give it

the same accuracy and stability as a fixed reference

oscillator. It works by comparing two frequency in

puts, one fixed and one variable, and supplying a

correction signal to the variable oscillator to reduce

the difference between the two inputs. For example,

suppose we have a 10 MHz reference oscillator with

a stability of1x10

that stability to a voltage controlled oscillator

(VCO). The 10 MHz reference signal is applied to

the reference input of a phase-lock loop circuit. The

signal from the VCO is applied to the variable input.

-7

/day, and we wish to transfer

-

-

-

690XXB/691XXB MM 2-9

Page 38

FUNCTIONAL FREQUENCY

DESCRIPTION SYNTHESIS

A phase detector in the phase-lock loop circuit com

pares the two inputs and determines whether the

variable input waveform is leading or lagging the

reference. The phase detector generates a correction

signal that (depending on polarity) causes the VCO

frequency to increase or decrease to reduce any

phase difference. When the two inputs match, the

loop is said to be locked. The variable input from the

VCO then equals the reference input in phase, fre

quency, accuracy, and stability.

In practical applications a frequency divider is

placed between the output of the variable oscillator

and the variable input to the phase-lock loop. The

circuit can then be used to control a frequency that

is an exact multiple of the reference frequency. In

this way, the variable oscillator acquires the stabil

ity of the reference without equaling its frequency.

In the A3 Reference Loop, the 100 MHz ovencontrolled crystal oscillator (OCXO) can be controlled by the phase-lock loop using a 10 MHz reference. This is because a divide-by-ten circuit is

between the OCXO's output and the variable input

to the phase-lock loop. Both inputs to the phase detector will be 10 MHz when the loop is locked.

-

-

-

Overall

Operation

If a programmable frequency divider is used, a

number of frequencies can be phase-locked to the

same reference. The limitation is that all must be

exact multiples of the reference. The A4 Coarse

Loop and A5 Fine Loop both use programmable fre

quency dividers.

The YIG-tuned oscillator generates a high-power RF

output signal that has low broadband noise and low

spurious content. The frequency of the YIG-tuned

oscillator is controlled by means of (1) its main tun

ing coil and (2) its FM (fine tuning) coil. Main tun

ing coil current from the YIG Driver PCB coarsely

tunes the YIG-tuned oscillator to within a few

megahertz of the final output frequency. The YIG

phase-lock loop is then used to fine tune the YIGtuned oscillator to the exact output frequency and to

reduce FM noise close to the carrier.

-

-

-

2-10 690XXB/691XXB MM

Page 39

FUNCTIONAL FREQUENCY

DESCRIPTION SYNTHESIS

1 0 M H z R E F I n

1 0 M H z

H i - S t a b i l i t y

X T A L O s c i l l a t o r

( O p t i o n a l )

A 3 R e f e r e n c e L o o p

P h a s e /

F r e q u e n c y

D e t e c t o r

1 0 0 M H z

R e f e r e n c e

O s c i l l a t o r

P h a s e

E r r o r

1 0 M H z

1 0 0 M H z

÷ 1 0

P o w e r

S p l i t t e r

F M S w e e p

*

( F r o m A 1 2 P C B )

F M I n

*

( F r o n t P a n e l o r

R e a r P a n e l )

F M

1 0 M H z

1 0 0 M H z

D i v i d e r

C o n t r o l

F M

C o i l

D r i v e r

R F

S p l i t t e r

÷ 1 0

B L o o p

F r e q u e n c y

S y n t h e s i z e r

C L o o p

F r e q u e n c y

S y n t h e s i z e r

A 1 1 F M

x 9

P h a s e

E r r o r

P h a s e

E r r o r

9 0 0 M H z

A 4 C o a r s e L o o p

8 0 9 - 9 9 1 M H z

V C O

5 0 0 - 1 0 0 0 M H z

V C O

1 0 M H z

2 0 . 9 -

9 0 M H z

S a m p l e r

÷ 4

÷ 2

S a m p l e r

2 0 2 . 5 -

9 9 0 M H z

1 0 0 k H z

P h a s e E r r o r

( L o o p O s c . # 3 )

P h a s e /

F r e q u e n c y

D e t e c t o r

2 6 . 8 4 M H z

V C X O

÷ 1 0 0

1 0 M H z

1 0 0 k H z

D i g i t a l

S y n t h e s i z e r

2 . 5 - 5 M H z

F r e q u e n c y

S y n t h e s i z e r

P h a s e /

F r e q u e n c y

D e t e c t o r

P h a s e

E r r o r

2 . 5 - 5 M H z

P h a s e

E r r o r

A 5 F i n e L o o p

1 1 9 0 - 1 5 9 0 M H z

V C O

( L o o p O s c . # 1 )

F i n e

L o o p

O s c i l l a t o r # 2

÷ 4

2 9 7 . 5 - 3 9 7 . 5 M H z

÷ 1 0

3 0 0 -

4 0 0 M H z

3 0 - 4 0 M H z

A 7 Y I G L o o p

1 . 9 6 2 5 t o 2 0 . 0 4 G H z

2 0 2 . 5 - 9 9 0 M H z

F M

F M

L P F

S w e e p

Y I G L o o p E r r o r

P h a s e /

F r e q u e n c y

D e t e c t o r

S R D

÷ 1 2 8

÷ 1 2 8

H a r m o n i c s

S a m p l e r

3 0 - 4 0 M H z

3 0 - 4 0 M H z I F

3 0 - 4 0 M H z

S a m p l e d 2 - 2 0 G H z R F

P / O S w i t c h e d F i l t e r

T u n e

( F r o m A 1 2 P C B )

+ 1 8 V G

A 1 4 Y I G , S D M D r i v e r

B i a s

R e g u l a t o r s

M a i n

C o i l

D r i v e r s

M a i n

B i a s

Y I G - T u n e d

O s c i l l a t o r

F M

2 - 2 0 G H z

M o d u l a t o r

C o n t o l

P u l s e

R F O u t

*

6 9 1 X X B M o d e l s O n l y

Figure 2-2. Block Diagram of the Frequency

Synthesis Subsystem

690XXB/691XXB MM 2-11

Page 40

FUNCTIONAL FREQUENCY

DESCRIPTION SYNTHESIS

One input to the YIG Loop is the 202.5 to 990 MHz

signal from the Coarse Loop. This signal is ampli

fied to drive the step-recovery diode. The steprecovery diode produces harmonics of the coarse

loop signal (³1.9625 to 20.04 GHz). These harmonics

are used by the sampler.

-

Table 2-1. RF Output and Loop Frequencies

RF OUTPUT/LOOP FREQUENCIES

(in MHz)

RF OUT COARSE LOOP FINE LOOP

2000 218.055 37.5

3000 217.143 40.0

4000 212.631 40.0

5000 402.000 40.0

6000 464.615 40.0

7000 469.333 40.0

8000 472.941 40.0

9000 821.818 40.0

10000 836.667 40.0

11000 849.231 40.0

12000 926.154 40.0

The other input to the sampler is the RF output sig

nal from the YIG-tuned oscillator. Mixing this RF

output signal sample with the adjacent coarse-loop

harmonic produces a low frequency difference signal

that is the YIG IF signal (30 to 40 MHz).

The 690XXB/691XXB CPU programs the coarse-loop

oscillator's output frequency so that one of its har

monics will be within 30 to 40 MHz of the desired

YIG-tuned oscillator's output frequency. The YIG

Loop phase detector compares the YIG IF signal to

the 30 to 40 MHz reference signal from the Fine

Loop. If there is a difference, the YIG phase detector

fine tunes the YIG-tuned oscillator (via the FM

circuitry and the FM coil drivers) to eliminate any

frequency difference between the two signals.

Phase locking the instrument's output frequency

over a broad frequency range is accomplished by

programming the coarse-loop oscillator's output to

various frequencies that have harmonics close to the

desired operating frequencies. Exact frequency tun

ing for each desired operating frequency is accom

plished by programming the fine-loop oscillator. (In

each case, the YIG-tuned oscillator is first tuned via

the main tuning coil to the approximate desired

operating frequency.) Table 2-1 shows the coarseloop and fine-loop frequencies for some specific RF

output frequencies.

The coarse-loop oscillator has a programming (tun

ing) range of 202.5 to 990 MHz. This provides har

-

monics from ³1.9625 GHz to 20.04 GHz. This allows

any YIG-tuned oscillator output frequency to be

down converted to a YIG IF signal of 30 to 40 MHz.

-

-

The YIG Loop is fine tuned by varying the 30 to

40MHz reference signal applied to the YIG loop

phase detector. By programming the fine-loop oscil

lator, this signal can be adjusted in 1 kHz incre

ments over the 30 to 40 GHz range. The resolution

of the fine-loop oscillator (hence the resolution of the

RF output signal) is 1 kHz, which is much finer

2-12 690XXB/691XXB MM

-

Page 41

FUNCTIONAL FREQUENCY

DESCRIPTION SYNTHESIS

RF Outputs

0.00001 to

65 GHz

than is available from the coarse loop alone. For ap

plications requiring a resolution finer than 1 kHz,

an optional tuning resolution of 0.1 Hz is available.

The Coarse Loop and Fine Loop outputs are derived

from high-stability 10 MHz and 100 MHz signals

generated by the Reference Loop. For applications

requiring even greater stability, the 100 MHz refer

ence oscillator can be phase locked to an optional

10 MHz reference (internal or external).

Refer to the block diagram of the RF Deck shown in

Figure 2-1 (page 2-7) for the following description.

The 690XXB/691XXB uses one YIG-tuned oscillator.

All other frequencies output by the instrument, ex

cept for 0.01 to 10 MHz, are derived from the funda

mental frequencies generated by this YIG-tuned

oscillator.

0.01 to 2 GHz

RF output frequencies of 0.01 to 2 GHz are developed by down converting the fundamental frequencies of 6.51 to 8.5 GHz. This is achieved using a

6.5 GHz local oscillator signal that is phase locked

to the 500 MHz output of the Reference Loop. Precise control of the 0.01 to 2 GHz frequencies to

1 kHz (0.1 Hz with Option 11) resolution is accomplished by phase-lock control of the 6.51 to 8.5 GHz

fundamental frequencies prior to down conversion.

-

-

-

-

20 to 40 GHz

RF output frequencies of 20 to 40 GHz are produced

by doubling the 10 to 20 GHz fundamental frequen

cies. Phase-lock control of the 10 to 20 GHz funda

mental frequencies, accomplished prior to doubling,

ensures precise control of the 20 to 40 GHz frequen

cies to 1 kHz (0.1 Hz with Option 11) resolution.

40 to 65 GHz

RF output frequencies of 40 to 65 GHz are devel

oped by quadrupling of the 10 to 16.25 GHz funda

mental frequencies (refer to Figure 2-7, page 2-24).

Precise control of the 40 to 65 GHz to 1 kHz (0.1 Hz

with Option 11) resolution is accomplished by

phase-lock control of the 10 to 16.25 GHz fundamen

tal frequencies prior to quadrupling.

0.01 to 2.2 GHz (Option 21A)

RF output frequencies of 0.01 to 2.2 GHz are devel

oped by down converting the fundamental frequen

-

-

-

-

-

690XXB/691XXB MM 2-13

-

-

-

Page 42

FUNCTIONAL FREQUENCY

DESCRIPTION SYNTHESIS