Anritsu 683XXB, 682XXB User Manual

SERIES

682XXB/683XXB

SYNTHESIZED SIGNAL GENERATORS

MAINTENANCE MANUAL

490 JARVIS DRIVE

MORGAN HILL, CA 95037-2809

P/N: 10370-10290

REVISION: H

PRINTED: AUGUST 2003

COPYRIGHT 2003 ANRITSU CO.

WARRANTY

The ANRITSU product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for one year from the date of shipment.

ANRITSU’s obligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyers shall prepay transportation charges for equipment returned to ANRITSU

for warranty repairs. Obligation is limited to the original purchaser.ANRITSU is not liable for con

sequential damages.

LIMITATION OF WARRANTY

The foregoing warrantydoes not apply to ANRITSU connectors that havefailed due to normal wear.

Also, the warranty does not apply to defects resulting from improper or inadequate maintenance by

the Buyer, unauthorized modification or misuse, or operation outside of the environmental specifications of the product. No other warranty is expressed or implied, and the remedies provided herein

are the Buyer’s sole and exclusive remedies.

TRADEMARK ACKNOWLEDGEMENTS

Adobe Acrobat is a registered trademark of Adobe Systems Incorporated.

NOTICE

ANRITSU Company has prepared this manual for use by ANRITSU Company personnel and cus

tomers as a guide for the proper installation, operation, and maintenance of ANRITSU Company

equipment and computor programs. Thedrawings, specifications, and information contained herein

are the property of ANRITSU Company, and any unauthorized use or disclosure of these drawings,

specifications, and information is prohibited; they shall not be reproduced, copied, or used in whole

or in part as the basis for manufacture or sale of the equipment or software programs without the

prior writtten consent of ANRITSU Company.

-

-

Table Of Contents

Chapter 1 - General Information

1-1 SCOPE OF MANUAL

1-2 INTRODUCTION

1-3 DESCRIPTION

1-4 IDENTIFICATION NUMBER

1-5 ELECTRONIC MANUAL

1-6 RELATED MANUALS

Operation Manual

GPIB Programming Manual

SCPI Programming Manual

1-7 OPTIONS .......................1-7

1-8 LEVEL OF MAINTENANCE .............1-8

Troubleshooting .................1-8

Repair......................1-8

Calibration ...................1-8

Preventive Maintenance .............1-8

1-9 PREVENTIVE MAINTENANCE...........1-9

1-10 STATIC-SENSITIVE COMPONENT HANDLING

PRECAUTIONS ...................1-9

....................

.................

...................

............

...............

................

................

...........

...........

1-3

1-3

1-3

1-5

1-6

1-6

1-6

1-6

1-6

1-11 STARTUPCONFIGURATIONS

1-12 RECOMMENDED TEST EQUIPMENT

1-13 EXCHANGE ASSEMBLY PROGRAM

1-14 REPLACEABLE SUBASSEMBLIES AND PARTS 1-14

...........

......

.......

1-11

1-12

1-14

Chapter 2 - Functional Description

2-1 INTRODUCTION

2-2 682XXB/683XXB MAJOR SUBSYSTEMS

Digital Control

Front Panel

Frequency Synthesis

Analog Instruction

YIG Driver

Function Generator

682XXB/683XXB MM i

...................

......

..................

...................

...............

................

...................

...............

2-3

2-3

2-3

2-4

2-4

2-5

2-5

2-5

Table of Contents (Continued)

ALC/AM/Pulse Modulation

RF Deck

Power Supply

Inputs/Outputs

Motherboard/Interconnections

2-3 FREQUENCY SYNTHESIS

Phase-Lock Loops

Overall Operation

RF Outputs 0.01 to 65 GHz

Frequency Modulation

Phase Modulation (Option 6)

Analog Sweep Mode (683XXB only)

Step Sweep Mode

2-4 ALC/AM/PULSE MODULATION ..........2-15

ALC Loop Operation ..............2-15

Pulse Generator Operation ...........2-18

2-5 RF DECK ASSEMBLIES ..............2-19

RF Deck Configurations ............2-20

YIG-tuned Oscillator ..............2-20

Power Level Control and Modulation ......2-23

RF Signal Filtering ...............2-23

0.01 to 2 GHz Down Converter .........2-24

0.5 to 2.2 GHz Digital Down Converter .....2-25

Switched Doubler Module

Source Quadrupler Module

Power Level Detection/ALC Loop

Step Attenuator

.....................

..................

.................

................

...............

................

................

............

..........

.............

...........

.............

..........

.......

............

...........

........

2-8

2-8

2-8

2-8

2-9

2-9

2-9

2-10

2-13

2-14

2-14

2-14

2-15

2-26

2-29

2-30

2-31

Chapter 3 - Performance Verification

3-1 INTRODUCTION

3-2 RECOMMENDED TEST EQUIPMENT

3-3 TEST RECORDS

3-4 CONNECTOR AND KEY LABEL NOTATION

3-5 682XXB/683XXB POWER LEVELS

3-6 INTERNAL TIME BASE AGING RATE TEST

Test Setup

Test Procedure

ii 682XXB/683XXB MM

....................

...................

.......

...................

...

.........

...

..................

3-3

3-3

3-3

3-3

3-6

3-8

3-8

3-9

Table of Contents (Continued)

3-7 FREQUENCY SYNTHESIS TESTS

Test Setup

Coarse Loop/YIG Loop Test Procedure

Fine Loop Test Procedure

3-8 SPURIOUS SIGNALS TEST: RF OUTPUT SIGNALS

£2 GHz (£2.2 GHz for 68XX5B MODELS)

Test Setup

0.01 - 2 GHz Test Procedure

0.5 - 2.2 GHz Test Procedure

3-9 HARMONIC TEST: RF OUTPUT SIGNALS

FROM2TO20GHz

Test Setup

Test Procedure (2 to 10 GHz)

Test Procedure (11 to 20 GHz)

3-10 SINGLE SIDEBAND PHASE NOISE TEST ....3-22

Test Setup ...................3-22

Test Procedure .................3-23

3-11 POWER LEVEL ACCURACY AND FLATNESS

TESTS........................3-26

...................

............

...................

..........

..........

................

...................

..........

........

......

.....

.........

3-11

3-11

3-12

3-13

3-14

3-14

3-14

3-17

3-18

3-18

3-19

3-20

Test Setup ...................3-26

Power Level Accuracy Test Procedure ......3-27

Power Level Flatness Test Procedure ......3-27

3-12 AMPLITUDE MODULATION TEST ........3-30

Test Setup

AM Input Sensitivity Procedure

3-13 FREQUENCY MODULATION TESTS

Test Setup

FM Input Sensitivity Procedure

3-14 PULSE MODULATION TESTS: RISE TIME,

FALL TIME, OVERSHOOT, AND LEVEL

Test Setup

Rise/Fall Time and Overshoot

Pulse Leveling Accuracy

3-15 PULSE MODULATION TEST: VIDEO

FEEDTHROUGH

Test Setup

Test Procedure

...................

.........

.......

...................

.........

....

...................

..........

............

..................

...................

.................

3-30

3-31

3-33

3-33

3-33

3-39

3-39

3-40

3-41

3-43

3-43

3-44

682XXB/683XXB MM iii

Table of Contents (Continued)

3-16 PULSE MODULATION TEST: RF ON/OFF RATIO 3-45

Test Setup

Test Procedure

3-17 PHASE MODULATION TESTS

Test Setup

FM Input Sensitivity Procedure

...................

.................

...................

...........

.........

3-45

3-45

3-48

3-48

3-48

Chapter 4 - Calibration

4-1 INTRODUCTION

4-2 RECOMMENDED TEST EQUIPMENT

4-3 TEST RECORDS

4-4 CALIBRATION FOLLOWING SUBASSEMBLY

REPLACEMENT...................4-4

4-5 CONNECTOR AND KEY LABEL NOTATION . . . 4-4

4-6 INITIAL SETUP....................4-7

Interconnection .................4-7

PC Setup — Windows 3.1 ............4-8

PC Setup — Windows 95 ............4-10

...................

.......

...................

4-3

4-3

4-3

4-7 PRELIMINARY CALIBRATION ..........4-13

Equipment Setup................4-13

Calibration Steps ................4-14

4-8 SWITCHED FILTER SHAPER CALIBRATION

Equipment Setup

Log Amplifier Zero Calibration

Limiter DAC Adjustment

Shaper DAC Adjustment

4-9 RF LEVEL CALIBRATION

4-10 ALC SLOPE CALIBRATION

Equipment Setup

ALC Slope DAC Adjustment

4-11 ALC BANDWIDTH CALIBRATION

Equipment Setup

Bandwidth Calibration

................

.........

............

............

.............

............

................

..........

........

................

.............

..

4-17

4-17

4-18

4-18

4-19

4-22

4-23

4-23

4-24

4-31

4-31

4-31

iv 682XXB/683XXB MM

Table of Contents (Continued)

4-12 AM CALIBRATION

Equipment Setup

AM Calibration Procedure

4-13 FM CALIBRATION

Equipment Setup

FM Calibration Procedure

4-14 PHASE MODULATION (FM) CALIBRATION

Equipment Setup

FM Calibration Procedure

.................

................

...........

.................

................

...........

................

...........

...

4-33

4-33

4-34

4-37

4-37

4-38

4-51

4-51

4-52

Chapter5-Troubleshooting

5-1 INTRODUCTION

5-2 RECOMMENDED TEST EQUIPMENT

5-3 ERROR AND WARNING/STATUS MESSAGES. . . 5-3

Self-Test Error Messages.............5-3

Normal Operation Error and Warning/

Status Messages ................5-7

...................

.......

5-3

5-3

5-4 MALFUNCTIONS NOT DISPLAYING AN ERROR

MESSAGE .....................5-10

5-5 TROUBLESHOOTING TABLES ..........5-10

Chapter 6 - Removal and Replacement Procedures

6-1 INTRODUCTION

6-2 REMOVING AND REPLACING THE CHASSIS

COVERS

Preliminary

Procedure

6-3 REMOVING AND REPLACING THE FRONT

PANEL ASSEMBLY

Preliminary

Procedure

6-4 REMOVING AND REPLACING THE A3, A4, A5,

OR A6 PCB

Preliminary

Procedure

.......................

....................

....................

....................

...................

...................

.................

...................

......................

...................

6-3

6-4

6-4

6-4

6-6

6-6

6-6

6-8

6-8

6-8

682XXB/683XXB MM v

Table of Contents (Continued)

6-5 REMOVING AND REPLACING THE A7 PCB

Preliminary

Procedure

6-6 REMOVING AND REPLACING THE A8, A9, A10,

A11, OR A12 PCB

Preliminary

Procedure

6-7 REMOVING AND REPLACING THE A13, A14,

OR A15 PCB

Preliminary

Procedure

6-8 REMOVING AND REPLACING THE A16

OR A17 PCB

Preliminary...................6-11

Procedure ...................6-11

6-9 REMOVING AND REPLACING THE A18

ORA19PCB....................6-12

Preliminary ..................6-12

Procedure ...................6-12

..................

...................

..................

..................

...................

....................

...................

...................

....................

...

6-10

6-10

6-10

6-10

6-10

6-10

6-11

6-11

6-11

6-11

6-10 REMOVING AND REPLACING THE REAR

PANEL ASSEMBLY ................6-13

Preliminary ..................6-13

Procedure

6-11 REMOVING AND REPLACING THE A21 PCB

Preliminary

Procedure

6-12 REMOVING AND REPLACING THE A21-1 PCB.6-17

Preliminary

Procedure

6-13 REMOVING AND REPLACING THE FAN

ASSEMBLY

Preliminary

Procedure

...................

..

..................

...................

..................

...................

.....................

..................

...................

6-13

6-16

6-16

6-16

6-17

6-17

6-18

6-18

6-18

Appendix A - Test Records

A-1 INTRODUCTION

...................

A-1

vi 682XXB/683XXB MM

Chapter 1

General Information

Table of Contents

1-1 SCOPE OF MANUAL

1-2 INTRODUCTION

1-3 DESCRIPTION

1-4 IDENTIFICATION NUMBER

1-5 ELECTRONIC MANUAL...............1-6

1-6 RELATED MANUALS ................1-6

Operation Manual ................1-6

GPIB Programming Manual ...........1-6

SCPI Programming Manual ...........1-6

1-7 OPTIONS .......................1-7

1-8 LEVEL OF MAINTENANCE .............1-8

Troubleshooting .................1-8

Repair

Calibration

Preventive Maintenance

1-9 PREVENTIVE MAINTENANCE

1-10 STATIC-SENSITIVE COMPONENT HANDLING

PRECAUTIONS

......................

....................

...................

.................

...................

............

.............

...........

...................

1-3

1-3

1-3

1-5

1-8

1-8

1-8

1-9

1-9

1-11 STARTUPCONFIGURATIONS

1-12 RECOMMENDED TEST EQUIPMENT

1-13 EXCHANGE ASSEMBLY PROGRAM

1-14 REPLACEABLE SUBASSEMBLIES AND PARTS 1-15

...........

......

.......

1-11

1-12

1-14

Figure 1-1. Typical Series 682XXB/683XXB Synthesized Signal Generator (Model 68369B Shown)

Chapter 1

General Information

1-1 SCOPE OF MANUAL This manual provides service information for all models of the Series

682XXB/683XXB Synthesized Signal Generators. The service informa

tion includes replaceable parts information, functional circuit descrip

tions, block diagrams, performance verification tests, and procedures

for calibration, troubleshooting, and assembly/subassembly removal

and replacement. (Throughout this manual, the terms 682XXB/

683XXB and signal generator will be used interchangeably to refer to

the instrument.) Manual organization is shown in the table of con

tents.

NOTE

Service information for the series 682XXB signal generators

and series 683XXB signal generators is combined into one

manual because identical model numbers of each series contain the same assemblies, subassemblies, and components.

Differences between the series are noted where applicable

throughout the manual.

-

-

-

1-2 INTRODUCTION This chapter provides a general description of the Series 682XXB/

683XXB Synthesized Signal Generators, identification numbers,

related manuals, and options. Information is included concerning level

of maintenance, replaceable subassemblies and RF components,

exchange assembly program, and preventive maintenance. Staticsensitive component handling precautions and lists of exchangeable

subassemblies and recommended test equipment are also provided.

1-3 DESCRIPTION The Series 682XXB Synthesized Signal Generator and the Series

683XXB Synthesized Signal Generator are microprocessor-based,

synthesized signal sources with high resolution phase-lock capability.

They generate both discrete CW frequencies and broad (full range)

and narrow band sweeps across the frequency range of 10 MHz to

65 GHz. All functions of the signal generators are fully controllable

locally from the front panel or remotely (except for power on/standby)

via the IEEE-488 General Purpose Interface Bus (GPIB).

The Series 682XXB Synthesized Signal Generator and the Series

683XXB Synthesized Signal Generator each presently consists of 15

models covering a variety of frequency ranges and power levels. Table

1-1, pages 1-4 and 1-5, lists models, frequency ranges, and maximum

leveled output.

682XXB/683XXB MM 1-3

GENERAL 682XXB/683XXB

INFORMATION MODELS

Table 1-1. Series 682XXB/683XXB Models (1 of 2)

68XXXB

Model

68X37B 2.0 – 20.0 GHz +13.0 dBm +11.0 dBm

68X45B 0.5 – 20.0 GHz +13.0 dBm +11.0 dBm

68X47B 0.01 – 20.0 GHz +13.0 dBm +11.0 dBm

68X53B

68X55B

68X59B

68X63B

68X65B

68X69B

68X75B

68X77B

68X85B

68X87B

68X95B

Frequency

(GHz)

2.0 – 20.0 GHz

20.0 – 26.5 GHz

0.5 – 2.2 GHz

2.2 – 20.0 GHz

20.0 – 26.5 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 26.5 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

0.5 – 2.2 GHz

2.2 – 20.0 GHz

20.0 – 40.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

0.5 – 2.2 GHz

2.2 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

0.5 – 2.2 GHz

2.2 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

50.0 – 60.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

50.0 – 60.0 GHz

0.5 – 2.2 GHz

2.2 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

50.0 – 65.0 GHz

Output Power

+9.0 dBm

+6.0 dBm

+13.0 dBm

+9.0 dBm

+6.0 dBm

+13.0 dBm

+9.0 dBm

+6.0 dBm

+9.0 dBm

+6.0 dBm

+13.0 dBm

+9.0 dBm

+6.0 dBm

+13.0 dBm

+9.0 dBm

+6.0 dBm

+11.0 dBm

+10.0 dBm

+2.5 dBm

+2.5 dBm

+12.0 dBm

+10.0 dBm

+2.5 dBm

+2.5 dBm

+11.0 dBm

+10.0 dBm

+2.5 dBm

+2.0 dBm

+2.0 dBm

+12.0 dBm

+10.0 dBm

+2.5 dBm

+2.0 dBm

+2.0 dBm

+11.0 dBm

+10.0 dBm

+2.5 dBm

0.0 dBm

–2.0 dBm

Output Power

w/Step Attenuator

+7.0 dBm

+3.5 dBm

+11.0 dBm

+7.0 dBm

+3.5 dBm

+11.0 dBm

+7.0 dBm

+3.5 dBm

+7.0 dBm

+3.0 dBm

+11.0 dBm

+7.0 dBm

+3.0 dBm

+11.0 dBm

+7.0 dBm

+3.0 dBm

+10.0 dBm

+8.5 dBm

0.0 dBm

–1.0 dBm

+10.0 dBm

+8.5 dBm

0.0 dBm

–1.0 dBm

+10.0 dBm

+8.5 dBm

0.0 dBm

–1.5 dBm

–2.0 dBm

+10.0 dBm

+8.5 dBm

0.0 dBm

–1.5 dBm

–2.0 dBm

Not Available

1-4 682XXB/683XXB MM

GENERAL IDENTIFICATION

INFORMATION NUMBER

Table 1-1. Series 682XXB/683XXB Models (2 of 2)

68XXXB

Model

68X97B

68X37B 2.0 – 20.0 GHz +17.0 dBm +15.0 dBm

68X45B

68X47B

68X53B

68X55B

68X59B

68X63B

68X65B

68X69B

68X75B 0.5 – 50.0 GHz Standard Standard

68X77B 0.01 – 50.0 GHz Standard Standard

68X85B 0.5 – 60.0 GHz Standard Standard

68X87B 0.01 – 60.0 GHz Standard Standard

68X95B 0.5 - 65.0 GHz Standard Not Available

68X97B 0.01 – 65.0 GHz Standard Not Available

Frequency

(GHz)

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

50.0 – 65.0 GHz

With Option 15B (High Power) Installed

0.5 – 2.2 GHz

2.2 – 20.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

2.0 – 20.0 GHz

20.0 – 26.5 GHz

0.5 – 2.2 GHz

2.2 – 20.0 GHz

20.0 – 26.5 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 26.5 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

0.5 – 2.2 GHz

2.2 – 20.0 GHz

20.0 – 40.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

Output Power

+12.0 dBm

+10.0 dBm

+2.5 dBm

0.0 dBm

–2.0 dBm

+13.0 dBm

+17.0 dBm

+13.0 dBm

+17.0 dBm

+13.0 dBm

+10.0 dBm

+13.0 dBm

+13.0 dBm

+10.0 dBm

+13.0 dBm

+13.0 dBm

+10.0 dBm

+13.0 dBm

+6.0 dBm

+13.0 dBm

+13.0 dBm

+6.0 dBm

+13.0 dBm

+13.0 dBm

+6.0 dBm

Output Power

w/Step Attenuator

Not Available

+11.0 dBm

+15.0 dBm

+11.0 dBm

+15.0 dBm

+11.0 dBm

+7.5 dBm

+11.0 dBm

+11.0 dBm

+7.5 dBm

+11.0 dBm

+11.0 dBm

+7.5 dBm

+11.0 dBm

+3.0 dBm

+11.0 dBm

+11.0 dBm

+3.0 dBm

+11.0 dBm

+11.0 dBm

+3.0 dBm

1-4 IDENTIFICATION

NUMBER

All ANRITSU instruments are assigned a unique six-digit ID number,

such as “403002.” The ID number is imprinted on a decal that is af

fixed to the rear panel of the unit. Special-order instrument configura

tions also have an additional special serial number tag attached to the

rear panel of the unit.

682XXB/683XXB MM 1-5

-

GENERAL ELECTRONIC

INFORMATION MANUAL

When ordering parts or corresponding with ANRITSU Customer Serv

ice, please use the correct serial number with reference to the specific

instrument’s model number (i.e., Model 68347B Synthesized Signal

Generator, Serial No. 403002).

1-5 ELECTRONIC MANUAL This manual is available on CD ROM as an Adobe Acrobat Portable

Document Format (*.pdf) file. The file can be viewed using Acrobat

Reader, a free program that is also included on the CD ROM. The file

is “linked” such that the viewer can choose a topic to view from the

displayed “bookmark” list and “jump” to the manual page on which the

topic resides. The text can also be word-searched. Contact ANRITSU

Customer Service for price and availability.

1-6 RELATED MANUALS This is one of a four manual set that consists of an Operation Manual,

a GPIB Programming Manual, a SCPI Programming Manual, and a

Maintenance Manual.

Operation

Manual

This manual provides information and instructions

for operation of the series 682XXB/683XXB signal

generators using the front panel controls. It also includes general information, performance specifications, installation instructions, and operation

verification procedures. The ANRITSU part number

for the Operation Manual is 10370-10284.

-

GPIB

Programming

Manual

SCPI

Programming

Manual

This manual provides information for remote operation of the series 682XXB/683XXB signal generators

using Product Specific commands sent from an ex

ternal controller via the IEEE 488 General Purpose

Interface Bus (GPIB). It contains a complete listing

and description of all 682XXB/683XXB GPIB Prod

uct Specific commands and several programming

examples. The ANRITSU part number for the GPIB

Programming Manual is 10370-10286.

This manual provides information for remote opera

tion of the series 682XXB/683XXB signal generators

using Standard Commands for Programmable In

struments (SCPI) commands sent from an external

controller via the IEEE 488 General Purpose Inter

face Bus (GPIB). It contains a complete listing and

description of each command in the 682XXB/

683XXB SCPI command set and examples of com

mand usage. The ANRITSU part number for the

SCPI Programming Manual is 10370-10288.

-

-

-

-

-

-

1-6 682XXB/683XXB MM

GENERAL OPTIONS

INFORMATION

1-7 OPTIONS The following instrument options are available.

Option 1, Rack Mounting. Rack mount kit containing a set of

q

track slides (90° tilt capability), mounting ears, and front panel

handles for mounting the instrument in a standard 19-inch

equipment rack.

Option 2A, 110 dB Step Attenuator. Adds a 10 dB per step

q

attenuator with a 110 dB range for models having a high-end

frequency of £26.5 GHz. Output power is selected directly in dBm

on the front panel (or via GPIB). Rated output power is reduced.

Option 2B, 110 dB Step Attenuator. Adds a 10 dB per step

q

attenuator with a 110 dB range for models having a high-end

frequency of £40 GHz. Output power is selected directly in dBm

on the front panel (or via GPIB). Rated output power is reduced.

Option 2C, 90 dB Step Attenuator. Adds a 10 dB per step

q

attenuator with a 90 dB range for models having a high-end

frequency of £50 GHz. Output power is selected directly in dBm

on the front panel (or via GPIB). Rated output power is reduced.

Option 2D, 90 dB Step Attenuator. Adds a 10 dB per step

q

attenuator with a 90 dB range for models having a high-end

frequency of £60 GHz. Output power is selected directly in dBm

on the front panel (or via GPIB). Rated output power is reduced.

q

Option 6, Phase Modulation (FM). Adds phase modulation capability. The internal FM generator becomes the FM/FM generator. (Not available in combination with Option 7.)

q

Option 7, Delete AM/FM Generator. Deletes the internal AM

and FM generators. External AM and FM capability remains un

changed. (Not available in combination with Option 8 or Option

20.)

q

Option 8, Internal Power Meter. Adds an internal power

meter that is compatible with ANRITSU 560-7, 5400-71, or 640071 series detectors. (Not available in combination with Option 7.)

q

Option 9, Rear Panel RF Output. Moves the RF output con

nector to the rear panel.

q

Option 11, 0.1 Hz Frequency Resolution. Provides frequency

resolution of 0.1 Hz.

q

Option 14, ANRITSU 360B VNA Compatibility. Modifies rack

mounting hardware to mate unit in a ANRITSU 360B VNA con

sole.

q

Option 15B, High Power Output. Adds high-power RF compo

nents to the instrument providing increased RF output power in

the 2–26.5 GHz frequency range. Option 15B is standard in mod

els having a high-end frequency that is >40 GHz.

q

Option 16, High-Stability Time Base. Adds an ovenized,

10 MHz crystal oscillator with <5 x 10

–10

/day frequency stability.

-

-

-

-

-

682XXB/683XXB MM 1-7

GENERAL LEVEL OF

INFORMATION MAINTENANCE

Option 17A, No Front Panel. Deletes the front panel for use in

q

remote control applications where a front panel display or key

board control are not needed.

Option 18, mmWave Module Bias Output. Provides bias out

q

put for 54000-xWRxx Millimeter Wave Source Modules. BNC

Twinax connector, rear panel.

Option 19, SCPI Programmability. Adds GPIB command

q

mnemonics complying with Standard Commands for Program

mable Instruments (SCPI), Version 1993. SCPI programming

complies with IEEE 488.2-1987.

Option 20, SCAN Modulator. Adds an internal SCAN modula

q

tor for simulating high-depth amplitude modulated signals in

models 68237B/68337B, 68245B/68345B, and 68247B/68347B

only. Requires an external modulating signal. (Not available in

combination with Option 7.)

-

-

-

-

1-8 LEVEL OF

MAINTENANCE

Maintenance of the 682XXB/683XXB consists of:

Troubleshooting the instrument to a replaceable subassembly or

q

RF component.

Repair by replacing the failed subassembly or RF component.

q

q

Calibration.

q

Preventive maintenance.

Troubleshooting

Repair Most instrument failures are field repairable by re

The 682XXB/683XXB firmware includes internal

diagnostics that self-test most of the internal assemblies of the instrument. When the signal generator

fails self-test, one or more error messages are dis

played to aid in troubleshooting the failure to a

replaceable subassembly or RF component. Chapter

5 lists and describes the self-test error messages

and provides procedures for isolating 682XXB/

683XXB failures to a replaceable subassembly or RF

component.

placing the failed subassembly or RF component.

Detailed instructions for removing and replacing

failed subassemblies and components are provided

in Chapter 6.

-

-

Calibration The signal generator may require calibration after

repair. Refer to Chapter 4 for a listing of calibration

requirements and calibration procedures.

Preventive

Maintenance

Preventive maintenance on the 682XXB/683XXB

consists of cleaning the fan honeycomb filter, de

scribed in paragraph 1-8.

-

1-8 682XXB/683XXB MM

GENERAL PREVENTIVE

INFORMATION MAINTENANCE

1-9 PREVENTIVE

MAINTENANCE

The 682XXB/683XXB must always receive adequate ventilation. A

blocked fan filter can cause the instrument to overheat and shut down.

Check and clean the rear panel fan honeycomb filter periodically.

Clean the fan honeycomb filter more frequently in dusty environ

ments. Clean the filter as follows.

Step 1 Remove the filter guard from the rear panel by pull

ing out on the four panel fasteners holding them in

place (Figure 1-2).

Step 2 Vacuum the honeycomb filter to clean it.

Step 3 Install the filter guard back on the rear panel.

Step 4 Press in on the panel fasteners to secure the filter

guard to the rear panel.

Filter

Guard

Panel

Fastener (4)

-

-

Figure 1-2. Removing/Replacing the Fan Filter Guard

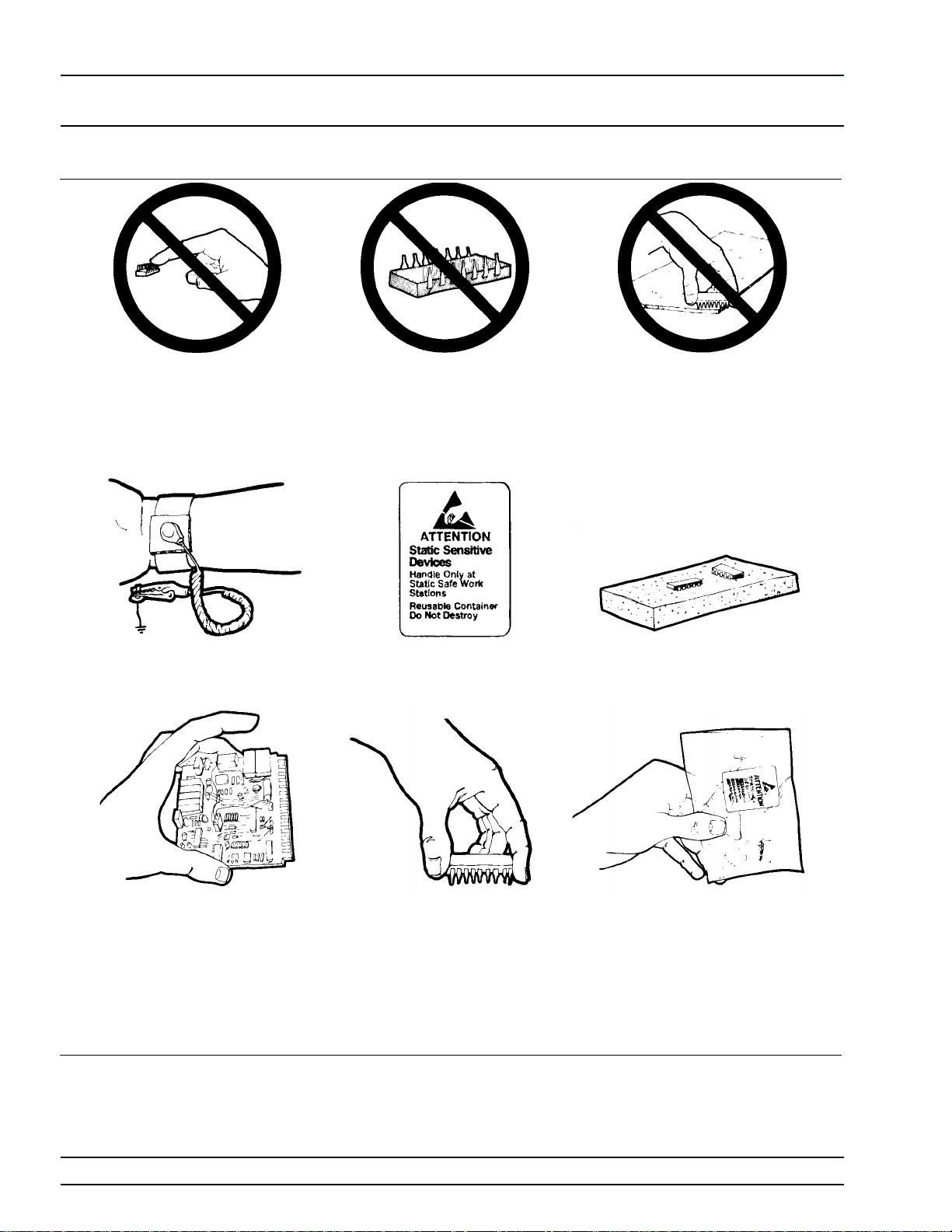

1-10 STATIC-SENSITIVE

COMPONENT

HANDLING

PRECAUTIONS

The 682XXB/683XXB contains components that can be damaged by

static electricity. Figure 1-3 illustrates the precautions that should be

followed when handling static-sensitive subassemblies and compo

nents. If followed, these precautions will minimize the possibilities of

static-shock damage to these items.

NOTE

Use of a grounded wrist strap when removing and/or replac

ing subassemblies or components is strongly recommended.

-

-

682XXB/683XXB MM 1-9

GENERAL STATIC-SENSITIVE COMPONENT

INFORMATION HANDLING PRECAUTIONS

1. Do not touch exposed contacts

on any static sensitive

component.

4. Wear a static-discharge wristband when working with static

sensitive components.

2. Do not slide static sensitive

component across any surface.

5. Label all static sensitive devices.

3. Do not handle static sensitive

components in areas where the

floor or work surface covering

is capable of generating a

static charge.

6. Keep component leads shorted

together whenever possible.

7. Handle PCBs only by their

edges. Do not handle by the

edge connectors.

10. ADDITIONAL PRECAUTIONS:

·

Keep workspaces clean and free of any objects capable of holding or storing a static charge.

·

Connect soldering tools to an earth ground.

·

Use only special anti-static suction or wick-type desoldering tools.

Figure 1-3. Static-Sensitive Component Handling Precautions

8. Lift & handle solid state de

vices by their bodies – never

by their leads.

-

9. Transport and store PCBs and

other static sensitive devices

in static-shielded containers.

1-10 682XXB/683XXB MM

GENERAL START UP

INFORMATION CONFIGURATION

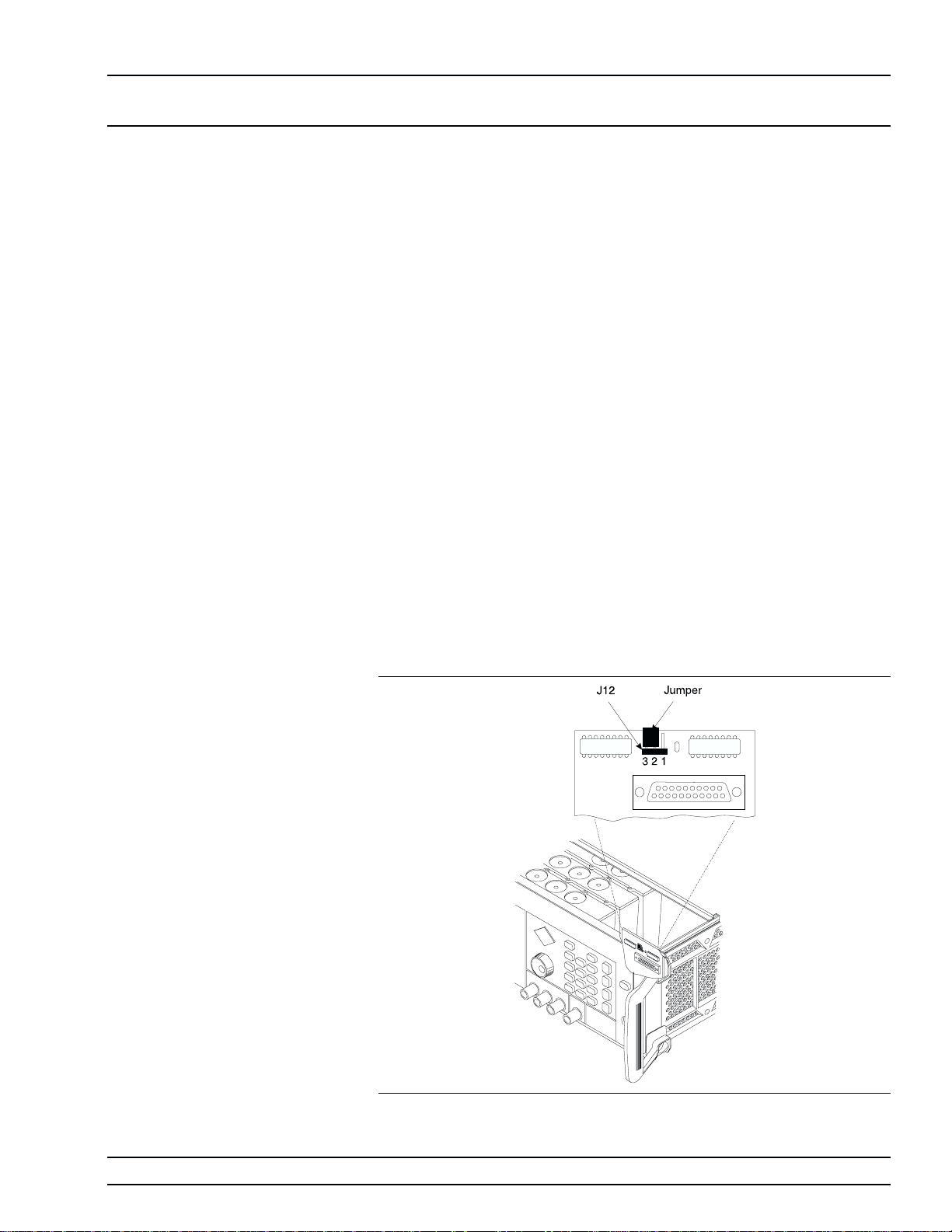

1-11 STARTUP

CONFIGURATIONS

The 682XXB/683XXB comes from the factory with a jumper across

pins 2 and 3 of front panel connector J12 (Figure 1-4). In this configu

ration, connecting the instrument to line power automatically places it

in operate mode (front panel OPERATE LED on).

The startup configuration can be changed so that the signal generator

comes up in standby mode (front panel STANDBYLED on) when it is

connected to line power. Change the startup configuration as follows:

Step 1 Disconnect the instrument from line power.

Step 2 Remove the top cover from the 682XXB/683XXB.

(Refer to Chapter 6 for instructions).

Step 3 Locate front panel connector J12 and remove the

jumper from across pins 2 and 3. It is located on the

A2A1 PCB which plugs into the Front Panel Assem

bly.

Step 4 Install the jumper across pins 1 and 2 of connector

J12.

Step 5 Install the top cover and connect the signal genera-

tor to line power. The instrument should come up in

standby mode.

-

-

Figure 1-4. Startup Configuration of Connector J12

682XXB/683XXB MM 1-11

GENERAL RECOMMENDED

INFORMATION TEST EQUIPMENT

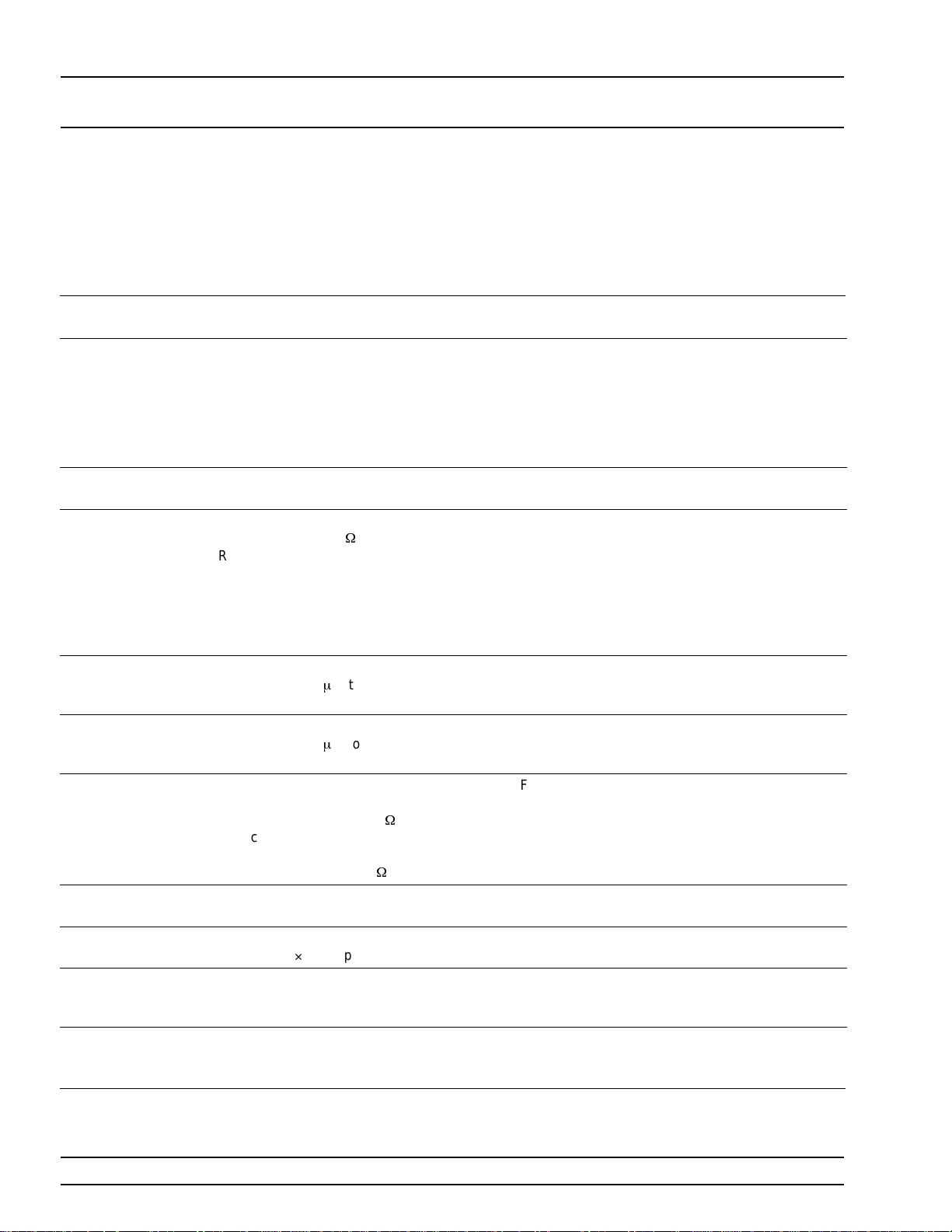

1-12 RECOMMENDED TEST

EQUIPMENT

Table 1-2 provides a list of recommended test equipment needed for

the performance verification, calibration, and troubleshooting proce

dures presented in this manual.

Table 1-2. Recommended Test Equipment (1 of 3)

INSTRUMENT

Spectrum Analyzer,

with

External Mixers

and

Diplexer Assy

Spectrum Analyzer Frequency Range: 20 Hz to 40 MHz

Frequency Counter

with

Cable Kit

and

External Mixer

Power Meter,

with Power Sensor

Power Meter,

with Power Sensor

Digital Multimeter Resolution: 4-1/2 digits (to 20V)

Frequency Reference Frequency: 10 MHz

Frequency Standard Frequency: 10 MHz

Function Generator Output Voltage: 2 volts peak-to-peak

Function Generator Output Voltage: 2 volts peak-to-peak

Frequency Range: 0.01 to 65 GHz

Resolution Bandwidth: 10 Hz

Resolution Bandwidth: 3Hz

Frequency Range: 0.01 to 65 GHz

Input Impedance: 50

Resolution: 1Hz

Other: External Time Base Input

Power Range: –30 to +20 dBm

Power Range: –30 to +20 dBm

DC Accuracy: 0.002% +2 counts

DC Input Impedance: 10 M

AC Accuracy: 0.07% +100 counts

AC Input Impedance: 1M

Accuracy: 5x10

Accuracy: 1´10

Functions: 0.1 Hz to 100 kHz sine and

square waveforms

Functions: 0.1 Hz to 100 kHz sine and

square waveforms

CRITICAL

SPECIFICATION

W

(1mW to 100mW)

(1mW to 100mW)

W

(to 20 kHz)

W

-12

parts/day

–10

parts/day

RECOMMENDED

MANUFACTURER/MODEL USAGE

Tektronix, Model 2794, with

External Mixers:

WM780K (18 to 26.5 GHz)

WM780A (26.5 to 40 GHz)

WM780U (40 to 60 GHz)

WM780E (60 to 90 GHz)

Diplexer Assy: 015-0385-00

Hewlett-Packard, Model 3585B P

EIP Microwave, Inc. Models 538B, 548B,

or 578B, with

Cable Kit: Option 590

and

External Mixer:

Option 91 (26.5 to 40 GHz)

Option 92 (40 to 60 GHz)

Option 93 (60 to 90 GHz)

Hewlett-Packard Model 437B, with

Power Sensor:

HP 8487A (0.01 to 50 GHz)

ANRITSU ML4803A, with

Power Sensor:

MP716A4 (50 to 75 GHz)

John Fluke, Inc., Model 8840A, with

Option 8840A-09K (True RMS AC)

Absolute Time Corp., Model 300 P

Spectracom Corp., Model 8161 C

Hewlett-Packard, Model 8116A C

Hewlett-Packard, Model 33120A C

C, P,T

C, P

C, P

C, P

C, T

-

(1)

1-12 682XXB/683XXB MM

GENERAL RECOMMENDED

INFORMATION TEST EQUIPMENT

Table 1-2. Recommended Test Equipment (2 of 3)

INSTRUMENT

Modulation Analyzer Frequency Input: 10 MHz

(or the IF of the Spectrum Analyzer)

AM Depth: 0% to 90%

AM Modulation Rates: DC to 100 kHz

Filters: 20 kHz lowpass, 300 Hz highpass

Oscilloscope Bandwidth: DC to 150 MHz

Vertical Sensitivity: 2mV/division

Horizontal Sensitivity: 50 ns/division

Mixer Frequency Range: 1 to 26 GHz Macom Micro Electronics Div.

Scalar Network

Analyzer, with

RF Detector

Adapter K (male) to 2.4 mm (female)

Adapter Adapts the MP716A4 Power Sensor to

Adapter WR15 to V (male)

Attenuator Frequency Range: DC to 40 GHz

Attenuator Frequency Range: DC to 40 GHz

Attenuator Frequency Range: DC to 60 GHz

Attenuator Frequency Range: DC to 60 GHz

RF Detector Frequency Range: 0.01 to 40 GHz

RF Detector Frequency Range: 0.01 to 50 GHz

Frequency Range: 0.01 to 50 GHz ANRITSU, Model 562, with

Adapts the Power Sensor, HP 8487A, to

the 682XXB/683XXB RF OUTPUT connector (£40 GHz models)

the ML4803A Power Meter

Adapts the MP716A4 Power Sensor to

the 682XXB/683XXB RF OUTPUT

connector (>40 GHz models)

Max Input Power: >+17 dBm

Attenuation: 10 dB

Max Input Power: >+17 dBm

Attenuation: 20 dB

Max Input Power: >+17 dBm

Attenuation: 10 dB

Max Input Power: >+17 dBm

Attenuation: 20 dB

Output Polarity: Negative

Output Polarity: Negative

CRITICAL

SPECIFICATION

Hewlett-Packard, Model 8901A P

Tektronix, Inc. Model TAS485 P, T

Model DMS1-26A

RF Detector:

560-7K50 (0.01 to 40 GHz)

560-7VA50(0.01 to 50 GHz)

SC5198 (40 to 60 GHz)

Hewlett-Packard

Part Number: HP 11904D

ANRITSU MA4002B C, P

ANRITSU, Model 35WR15V C, P

ANRITSU, Model 41KC-10 C, P

ANRITSU, Model 41KC-20 P

ANRITSU, Model 41V-10 C, P

ANRITSU, Model 41V-20 P

ANRITSU, Model 75KC50

(K input/BNC output connectors)

ANRITSU, Model 75VA50

(V input/BNC output connectors)

RECOMMENDED

MANUFACTURER/MODEL USAGE

(1)

P

C, T

C, P

T

T

682XXB/683XXB MM 1-13

GENERAL EXCHANGE

INFORMATION ASSEMBLY PROGRAM

Table 1-2. Recommended Test Equipment (3 of 3)

INSTRUMENT

Microwave (Pulse)

Detector

High Pass Filter 150 MHz High-Pass Filter (DC Block) Narda, Model 4564 P

Low Pass Filter 450 MHz Low-Pass Filter Mini-Circuits, Model SLP-450 P

Personal Computer PC Configuration: IBM AT or compatible

Serial Interface Assy Provides serial interface between the PC

Tee Connectors: 50WBNC Anycommon source C, P

Cables Connectors: 50WBNC Anycommon source C, P,T

NOTES: (1) P = Performance Verification Tests (Chapter 3); C = Calibration (Chapter 4); T = Troubleshooting (Chapter 5)

Output Polarity: Negative

Frequency Range: 0.01 to 40 GHz

Operating System: Windows 3.1

Accessories: Mouse

and the 682XXB/683XXB.

CRITICAL

SPECIFICATION

ANRITSU, Model SC3800

(K input/BNC output connectors)

Any common source C

ANRITSU P/N: T1678 C

RECOMMENDED

MANUFACTURER/MODEL USAGE

P

(1)

1-13 EXCHANGE

ASSEMBLY PROGRAM

1-14 REPLACEABLE

SUBASSEMBLIES

AND PARTS

ANRITSU maintains an exchange assembly program for selected

682XXB/683XXB subassemblies and RF components. If a malfunction

occurs in one of these subassemblies, the defective unit can be exchanged. Upon receiving your request, ANRITSU will ship the exchange subassembly or RF component to you, typically within 24

hours. You then have 45 days in which to return the defective item. All

exchange subassemblies or RF components are warranted for 90 days

from the date of shipment, or for the balance of the original equipment

warranty, whichever is longer.

Please have the exact model number and serial number of your unit

available when requesting this service, as the information about your

unit is filed according to the instrument’s model and serial number.

For more information about the program, contact your local sales rep

resentative or call your local ANRITSU service center. Refer to Table

1-5, on page 1-18, for a list of current ANRITSU service centers.

Table 1-3 lists those replaceable subassemblies and RF components of

the 682XXB/683XXB that are presently covered by the ANRITSU ex

change assembly program. Table 1-4, on page 1-16, lists common re

-

placeable parts for the 682XXB/683XXB that are not presently on the

exchange assembly program.

All parts listed in Tables 1-3 and 1-4 may be ordered from your local

ANRITSU service center.

-

1-14 682XXB/683XXB MM

GENERAL

INFORMATION PARTS LIST

Table 1-3. Replaceable Subassemblies and RF Components (1 of 2)

SUBASSEMBLY OR PART NAME ANRITSU PART NUMBER

Printed Circuit Board Assemblies

Front Panel Assy 683XXB ND40832

Front Panel Assy 682XXB ND40833

A3 Reference Loop PCB Assy D37436-3

A4 Coarse Loop PCB Assy D40604-3

A4 Coarse Loop PCB Assy D40634-3

A5 Fine Loop PCB Assy D37452-3

A5 Fine Loop PCB Assy D40605-3

A5 Fine Loop PCB Assy (w/Option 11) ND39917

A5 Fine Loop PCB Assy D40635-3

A5 Fine Loop PCB Assy (w/Option 11) D40635-7

A6 Pulse Generator PCB Assy D40606-3

A6 Pulse Generator PCB Assy D40626-3

A7 YIG Loop PCB Assy D40607-3

A7 YIG Loop PCB Assy D40637-3

A8 Function Generator PCB Assy D37408-3

A8 Function Generator PCB Assy D40608-3

A9 PIN Control PCB Assy D40609-3

A9 PIN Control PCB Assy D40629-3

A9 PIN Control PCB Assy D40639-3

A10 ALC PCB Assy D40610-3

A11FM PCB Assy D40611-3

A11FM PCB Assy D40641-3

A11FM PCB Assy (w/Option 6) D40641-4

A12 Analog Instruction PCB Assy D37448-3

A12 Analog Instruction PCB Assy (682XXB) D40612-3

A13 YIG Driver PCB Assy D40613-3

A14 SDM Driver PCB Assy, 26.5 GHz D40614-4

A14 SDM, SQM Driver PCB Assy D40614-3

A15 Regulator PCB Assy D40615-3

A16 CPU Interface PCB Assy D37416-3

A17 CPU PCB Assy D37444-3

A18 Power Supply PCB Assy D40618-3

A19 Line Conditioner PCB Assy D40619-3

A21 Line Filter/Rectifier PCB Assy ND39918

A21-1 BNC/AUX I/O Connector PCB Assy ND39919

10 MHz Crystal Oscillator Assy D37332

682XXB/683XXB MM 1-15

GENERAL

INFORMATION PARTS LIST

Table 1-3. Replaceable Subassemblies and RF Components (2 of 2)

SUBASSEMBLY OR PART NAME ANRITSU PART NUMBER

RF Components

YIG-Tuned Oscillator, 2 to 20 GHz C27327

Down Converter D27330

Pulsed Digital Down Converter D27370

Switched Doubler Module, 20 to 26.5 GHz ND40843

Switched Doubler Module, 20 to 40 GHz D28535

Source Quadrupler Module, 40 to 50 GHz D28185

Source Quadrupler Module, 40 to 60 GHz 60-141

Source Quadrupler Module, 40 to 65 GHz 60-142

Forward Coupler, 60 GHz and 65 GHz C27184

Coupler, 40 GHz D27115

Coupler, 60 GHz D27350

Pulsed Switched Filter D25015

Pulsed Switched Filter D29391

Pulsed Switched Filter (w/Option 15B) D26350

Pulsed Switched Filter (w/Option 15B) D29392

Output Connector Assy, K female ND39077

Output Connector Assy, V female ND40835

Step Attenuator, 110 dB, 26.5 GHz D27152

Step Attenuator, 110 dB, 40 GHz D25080

Step Attenuator, 90 dB, 50 GHz D27315

Step Attenuator, 90 dB, 60 GHz D28957

Table 1-4. Common Replaceable Subassemblies and Parts (1 of 2)

SUBASSEMBLY OR PART NAME ANRITSU PART NUMBER

Cap, Protective (for RF Output Connector) A20304

Cover, Top D37131

Cover, Bottom D37135

Cover, Side D37133

Cover, Side Handle 761-67

Cover, CPU Housing C37063

Cover, Main Card Cage D37064

Cover, Power Supply Housing C37062

EMI Gasket for side covers 790-437

EMI Gasket for side covers 790-390

EMI Gasket for Front Panel Assy 790-223

1-16 682XXB/683XXB MM

GENERAL

INFORMATION PARTS LIST

Table 1-4. Common Replaceable Subassemblies and Parts (2 of 2)

SUBASSEMBLY OR PART NAME ANRITSU PART NUMBER

Fan Assembly A40513

Fan Mount 790-425

Fan Membrane (Honey Comb Filter) C37137

Fan Grill 790-426

Fasteners (for Fan Grill) 790-433

Fuse, 5A, 3AG Slow Blow (110 Vac) 631-33

Fuse, 2.5A, 3AG Slow Blow (230 Vac) 631-14

Gasket, RFI (“O”rings for MCX connectors) 790-393

Handle, Side Carrying 783-830

Screw, Handle Side Carrying 900-714

Line Module 260-11

Shield Cover D37228

Shield D37229

Standoff 785-922

Tape 850-70

Foot, Rear Bottom Left 2000-548

Foot, Rear Bottom Right 2000-549

Foot, Rear Top Left 2000-552

Foot, Rear Top Right 2000-553

Screw, Green Head 2000-560

682XXB/683XXB without Front Handles Installed

Foot, Front Bottom Left 2000-546

Foot, Front Bottom Right 2000-547

Foot, Front Top Left 2000-550

Foot, Front Top Right 2000-551

682XXB/683XXB with Front Handles Installed

Upper Insert B37147

Foot, Bottom Left C37170

Foot,Bottom Right C37171

Handle, Left D37168-2

Handle, Right D37169-2

Tilt Bail 790-435

682XXB/683XXB MM 1-17

GENERAL ANRITSU

INFORMATION SERVICE CENTERS

Table 1-5. ANRITSU Service Centers

UNITED STATES

ANRITSU COMPANY

490 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300

1-800-ANRITSU

FAX: 408-776-1744

ANRITSU COMPANY

10 New Maple Ave., Unit 305

Pine Brook, NJ 07058

Telephone: (973) 227-8999

1-800-ANRITSU

FAX: 973-575-0092

ANRITSU COMPANY

1155 E. Collins Blvd

Richardson, TX 75081

Telephone: 1-800-ANRITSU

FAX: 972-671-1877

AUSTRALIA

ANRITSU PTY. LTD.

Unit 3, 170 Foster Road

Mt Waverley, VIC 3149

Australia

Telephone: 03-9558-8177

FAX: 03-9558-8255

BRAZIL

ANRITSU ELECTRONICA LTDA.

Praia de Botafogo, 440, Sala 2401

CEP22250-040, Rio de Janeiro, RJ, Brasil

Telephone: 021-527-6922

FAX: 021-53-71-456

CANADA

ANRITSU INSTRUMENTS LTD.

700 Silver Seven Road, Suite 120

Kanata, Ontario K2V 1C3

Telephone: (613) 591-2003

FAX: (613) 591-1006

CHINA

ANRITSU ELECTRONICS (SHANGHAI) CO. LTD.

2F, Rm B, 52 Section Factory Building

No. 516 Fu Te Rd (N)

Shanghai 200131 P.R. China

Telephone:21-58680226, 58680227, 58680228

FAX: 21-58680588

FRANCE

ANRITSU S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: 016-09-21-550

FAX: 016-44-61-065

GERMANY

ANRITSU GmbH

Grafenberger Allee 54-56

D-40237 Dusseldorf, Germany

Telephone: 0211-968550

FAX: 0211-9685555

INDIA

MEERA AGENCIES PVT. LTD.

23 Community Centre

Zamroodpur, Kailash Colony Extension,

New Delhi, India 110 048

Phone: 011-2-6442700/6442800

FAX : 011-2-644250023

ISRAEL

TECH-CENT, LTD.

4 Raul Valenberg St

Tel-Aviv 69719

Telephone: (03) 64-78-563

FAX: (03) 64-78-334

ITALY

ANRITSU Sp.A

Roma Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: (06) 50-99-711

FAX: (06) 50-22-4252

KOREA

ANRITSU CORPORATION LTD.

Head Office:

14F, Hyunjuk Building 832-41

Yeoksam-Dong, Kangnam-Ku

Seoul 135-080, South Korea

Telephone: 02-553-6603

FAX: 02-553-6604

Service Center:

8F Hyunjuk Building

832-41, Yeoksam Dong

Kangnam-Gu

Seoul, South Korea 135-080

Telephone: 82-2-553-6603

FAX: 82-2-553-6605

JAPAN

ANRITSU CUSTOMER SERVICE LTD.

1800 Onna Atsugi-shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-96-6688

FAX: 0462-25-8379

SINGAPORE

ANRITSU (SINGAPORE) PTE LTD.

10, Hoe Chiang Road

#07-01/02 Keppel Towers

Singapore 089315

Telephone: 282-2400

FAX: 282-2533

SOUTH AFRICA

ETECSA

12 Surrey Square Office Park

330 Surrey Avenue

Ferndale, Randburt, 2194

South Africa

Telephone: 011-27-11-787-7200

FAX: 011-27-11-787-0446

SWEDEN

ANRITSU AB

Botivid Center

Fittja Backe 13A

145 84 Stockholmn

Telephone: (08) 534-707-00

FAX: (08) 534-707-30

TAIWAN

ANRITSU CO., INC.

7F, No. 316, Section 1

NeiHu Road

Taipei, Taiwan, R.O.C.

Telephone: 886-2-8751-1816

FAX: 886-2-8751-2126

UNITED KINGDOM

ANRITSU LTD.

200 Capability Green

Luton, Bedfordshire

LU1 3LU, England

Telephone: 015-82-433200

FAX: 015-82-731303

1-18 682XXB/683XXB MM

Chapter 2

Functional Description

Table of Contents

2-1 INTRODUCTION

2-2 682XXB/683XXB MAJOR SUBSYSTEMS

Digital Control..................2-3

Front Panel ...................2-4

Frequency Synthesis...............2-4

Analog Instruction................2-5

YIG Driver ...................2-5

Function Generator ...............2-5

ALC/AM/Pulse Modulation............2-8

RF Deck.....................2-8

Power Supply ..................2-8

Inputs/Outputs .................2-8

Motherboard/Interconnections ..........2-9

2-3 FREQUENCY SYNTHESIS

Phase-Lock Loops

Overall Operation

RF Outputs 0.01 to 65 GHz

Frequency Modulation

Phase Modulation (Option 6)

Analog Sweep Mode (683XXB only)

Step Sweep Mode

...................

.............

................

...............

...........

.............

..........

.......

................

......

2-3

2-3

2-9

2-9

2-10

2-13

2-14

2-14

2-14

2-15

2-4 ALC/AM/PULSE MODULATION

ALC Loop Operation

Pulse Generator Operation

2-5 RF DECK ASSEMBLIES

RF Deck Configurations

YIG-tuned Oscillator

Power Level Control and Modulation

RF Signal Filtering

..............

...........

..............

............

..............

...............

..........

......

2-15

2-15

2-18

2-19

2-20

2-20

2-23

2-23

Table of Contents (Continued)

0.01 to 2 GHz Down Converter

0.5 to 2.2 GHz Digital Down Converter

Switched Doubler Module

Source Quadrupler Module

Power Level Detection/ALC Loop

Step Attenuator

................

............

.........

...........

........

.....

2-24

2-25

2-26

2-29

2-30

2-31

Loading...

Loading...