APL5605

600mA Linear Regulator for DC Fan Speed Control

Features

• Low Dropout Voltage: 220mV (typical) @ 600mA

• Low Quiescent Current: 140µA

• Enable/Shutdown function

• Output Voltage / VSET Voltage: 1.6 times

• Stable with Low ESR Ceramic Capacitors

• Over-Temperature Protection

• Current Limit Protection with Foldback Current

• Internal Soft-start

• SOP-8 Package

• Lead Free Available (RoHS Compliant)

Applications

• Notebook Fan Driver

• Motherboards

• PC Peripherals

• Battery-Powered System

General Description

The APL5605 is a low quiescent current and low dropout

linear regulator whic h is designed to power a DC fan

and delivers up to 600mA output current. The output

voltage follows the 1.6 times of VSET voltage and typical dropout voltage is only 220mV (typical) at 600mA

output current. The APL5605 with low 140µA quiescent

current is ideal for battery-powered sys tem appliances

and stable with a 2.2µF ceramic output c apacitor. The

features of current limit (with foldback current) and overtemperature protection protect the device against current over-loads and over temperature. The APL5605 is

available in a SOP-8 package.

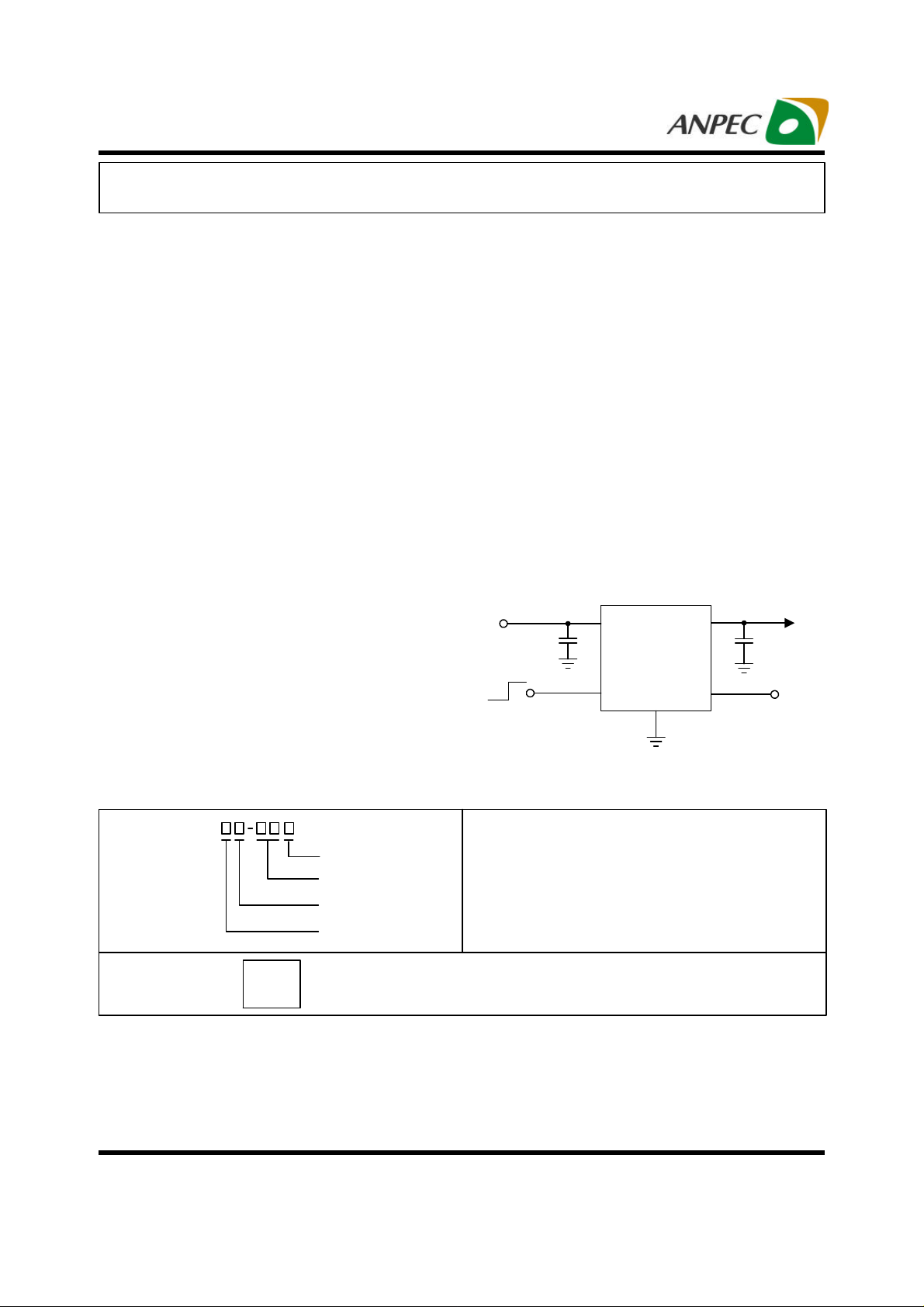

Simplified Application Circuit

V

C2

2.2µF

V

OUT

SET

OFF

V

IN

C1

1µF

ON

VIN

APL5605

EN

GND

VOUT

VSET

Ordering and Marking Information

APL5605

Lead Free Code

Handling Code

Temperature Range

Package Code

APL5605 K :

Note: ANPEC lead-free products contain molding compounds/die attach materials and 100% matte tin plate termination finish; which are fully

compliant with RoHS and compatible with both SnPb and lead-free soldering operations. ANPEC lead-free products meet or exceed the leadfree requirements of IPC/JEDEC J STD-020C for MSL classification at lead-free peak reflow temperature.

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and

advise customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

APL5605

XXXXX

Package Code

K : SOP-8

Operating Ambient Temperature Range

I : -40 to 85 C

Handling Code

TR : Tape & Reel

Lead Free Code

L : Lead Free Device

XXXXX - Date Code

°

www.anpec.com.tw1

APL5605

Pin Configuration

SOP-8 Top View

EN 1

VIN 2

VOUT 3

VSET 4

APL5605

Absolute Maximum Ratings (Note 1)

Symbol Parameter Rating Unit

VIN

VEN EN to GND -0.3 ~ VIN+0.3 V

V

VOUT to GND -0.3 ~ VIN+0.3 V

OUT

T

J

PD Power Dissipation Internally Limited

T

STG

T

SDR

Note 1: Stresses beyond the absolute maximum rating may damage the device and exposure to absolute maximum rating conditions for extended

periods may affect device reliability.

VIN to GND

Maximum Junction Temperature

Storage Temperature Range

Maximum Lead Temperature (Soldering, 10 sec)

8 GND

7 GND

6 GND

5 GND

-0.3 ~ 6.5 V

150

-65 ~ 150

260

o

o

o

C

C

C

Thermal Characteristics

Symbol Parameter Rating Unit

Note 2:

θ

JA

θ

is measured with the component mounted on a high effective thermal conductivity test board in free air.

JA

Junction to Ambient Thermal Resistance

SOP-8

80

Recommended Operating Conditions

Symbol Parameter Range Unit

VIN VIN to GND 4.5 ~ 6 V

VEN EN to GND 0 ~ VIN V

V

VOUT to GND 0 ~ VIN-V

OUT

V

VSET to GND 0 ~ 3.3 V

SET

I

Output Current 0 ~ 0.6 A

OUT

CIN Input Capacitor 0.82 ~ 470

C

Output Capacitor 1 ~ 330

OUT

TJ Junction Temperature -40 ~ 125

TA Ambient Temperature -40 ~ 85

V

DROP

°

C/W

µ

°C

°C

F

Copyright ANPEC Electronics Corp.

www.anpec.com.tw2

Rev. A.1 - Jan., 2008

APL5605

Electrical Characteristics

Refer to the typical application circuit. VIN = 5V, VEN = VIN, I

unless otherwise specified. Typical values are at TA = 25 °C.

OUT

= 1mA~600mA, TJ = -40 to 125 °C, TA = -40 to 85°C

,

Symbol

Parameter Test Conditions Min Typ Max Unit

SUPPLY CURRENT

IQ Quiescent Current

VEN = 0V - - 1

VEN = 5V, I

= 0A - 140 200

OUT

UNDER-VOLTAGE-LOCKOUT (UVLO)

VIN UVLO Threshold VIN rising 2.1 2.5 2.9 V

VIN UVLO Hysteresis - 0.15 - V

OUTPUT VOLTAGE

VOUT Voltage / VSET Voltage

VOUT Voltage / VSET Voltage

VSET pin Current

Load Regulation I

V

DROP

Dropout Voltage

TJ = 25°C, VIN=5.5V, I

V

=3.3V

SET

TJ = 40 ~ 125°C, VIN=5.5V, I

V

=1 ~ 3.3V

SET

V

=5V

SET

= 1mA to 600mA - 60 100 mV

OUT

I

=600mA, V

OUT

I

=600mA, V

OUT

I

=600mA, V

OUT

OUT

OUT

OUT

OUT

=2.5V

=3.3V

=5V

=1mA,

OUT

=1mA,

1.552 1.6 1.648 V/V

1.504 1.6 1.696 V/V

- 0.05 1

- 250 400 mV

- 220 350 mV

- 200 320 mV

PROTECTION AND SOFT-START

Output Current Limit 700 - - mA

Thermal Shutdown Temperature - 150 Thermal Shutdown Hysteresis - 40 Foldback Current Limit

V

OUT

< 0.6V

- 250 - mA

TSS Soft-Start Time - 130 300

VOUT Pull Low Resistance VEN=0V, V

=0.5V - 60 -

OUT

LOGIC INPUT

EN Logic Input-High Level 1.6 - - V

EN Logic Input-Low Level - - 0.4 V

EN Pull-Low Resistance VEN<3V - 2 -

µ

A

µ

A

µ

A

°

C

°

C

µ

s

Ω

MΩ

Copyright ANPEC Electronics Corp.

www.anpec.com.tw3

Rev. A.1 - Jan., 2008

APL5605

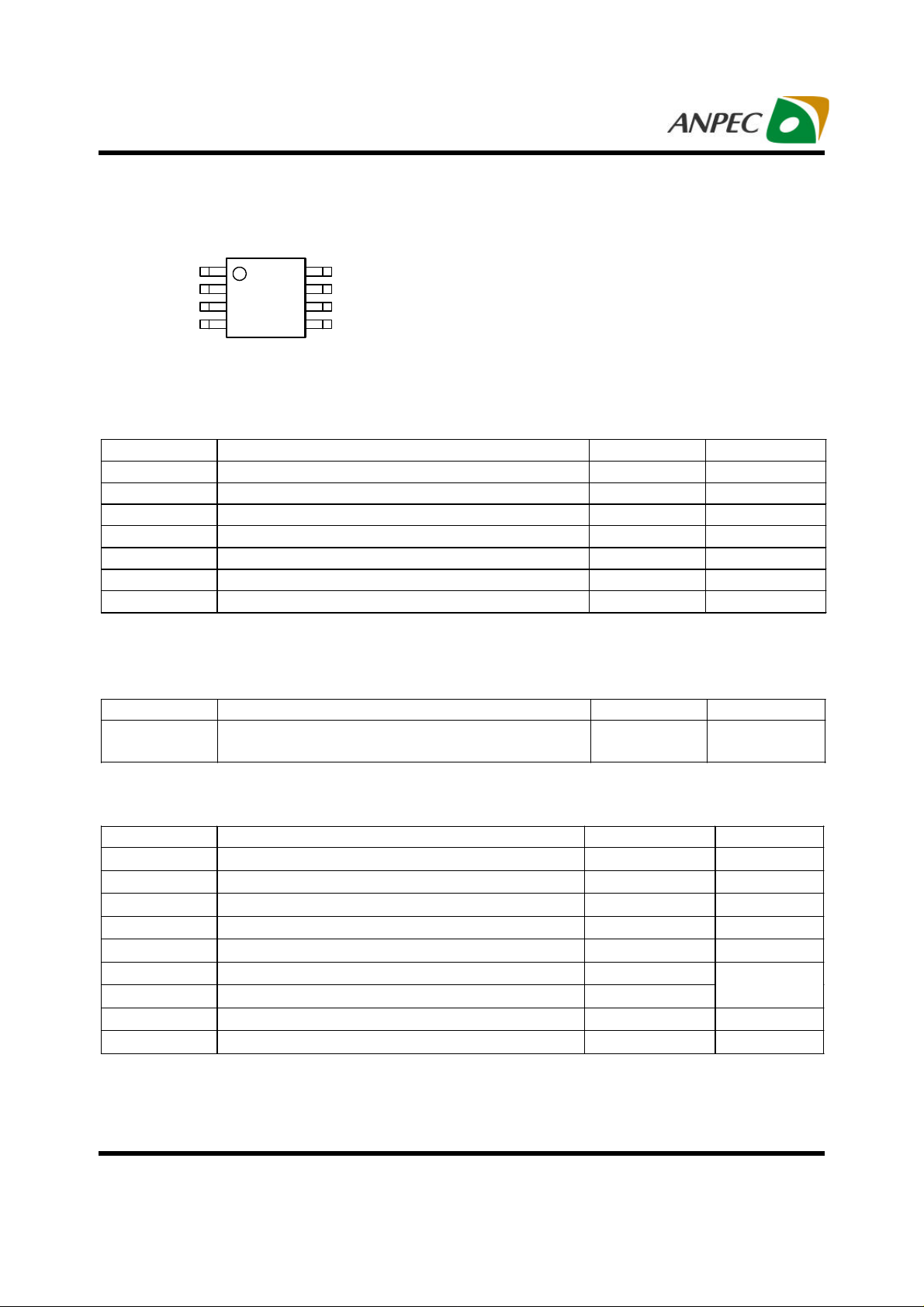

Typical Operating Characteristics

VIN=5V, V

SET

=2V, V

=3.2V, CIN=1µF, C

OUT

=2.2µF, unless otherwise specified.

OUT

EN Voltage threshold vs.

1.6

1.5

1.4

1.3

1.2

1.1

1

EN Voltage Threshold (V)

0.9

0.8

3 3.5 4 4.5 5 5.5 6 6.5

Input Voltage

Input Voltage (V)

VSET Voltage vs. Output Voltage

6

I

5

4

3

OUT

=10mA

Quiescent Current vs. VSET Voltage

180

160

140

(μA)

120

Q

100

Quiescent Current, I

I

=0mA

OUT

80

60

40

20

0

0 0.5 1 1.5 2 2.5 3

VSET Voltage (V)

Dropout vs. Junction Temperature

300

V

=5V

OUT

250

200

150

I

OUT

=600mA

I

OUT

=400mA

2

Output Voltage (V)

1

0

0 0.5 1 1.5 2 2.5 3 3.5

VSET Voltage (V)

Dropout vs. Junction Temperature

350

V

=3.3V

OUT

300

I

=600mA

OUT

250

200

150

100

Dropout Voltage (mV)

50

0

-50 0 50 100 150

I

=400mA

OUT

I

=200mA

OUT

Junction Temperature, T

(°C)

J

I

=200mA

100

Dropout Voltage (mV)

50

0

-50 0 50 100 150

OUT

Junction Temperature, T

J

(°C)

Power Supply Rejection Ratio

=3.2V

OUT

=500mA

OUT

Frequency (Hz)

(PSRR)

=2.2µF,

OUT

I

OUT

=400mA

0

VIN=5, CIN=1µF, C

-5

V

=2V, V

SET

-10

-15

-20

-25

-30

PSRR (dB)

-35

-40

-45

-50

1000 10000 100000 1000000

I

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

www.anpec.com.tw4

APL5605

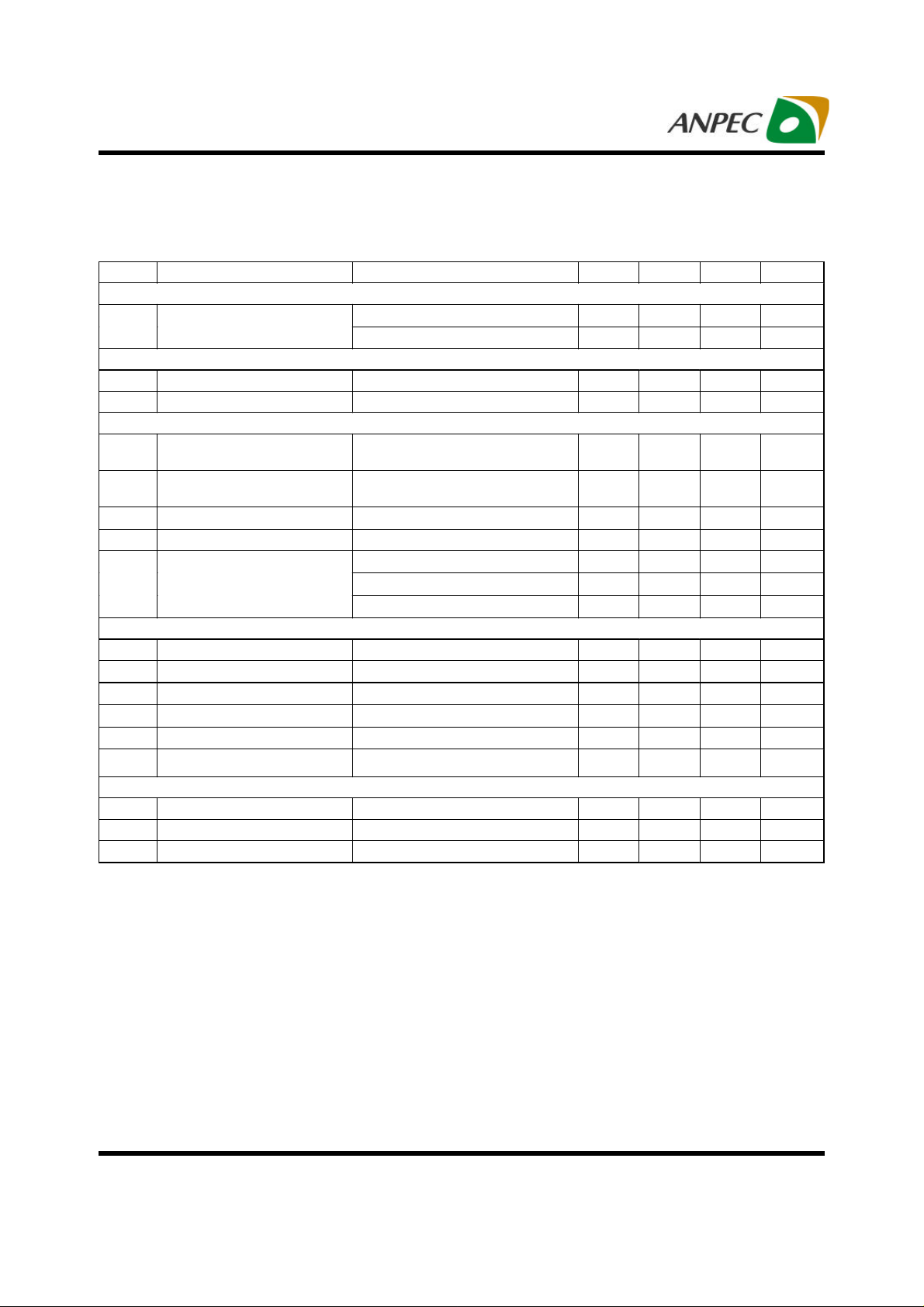

Typical Operating Characteristics (Cont.)

VIN=5V, V

SET

=2V, V

=3.2V, CIN=1µF, C

OUT

Quiescent Current vs. Input Voltage

200

I

=0mA

OUT

0 1 2 3 4 5 6

Quiescent Current (µA)

160

120

80

40

0

Input Voltage, VIN (V)

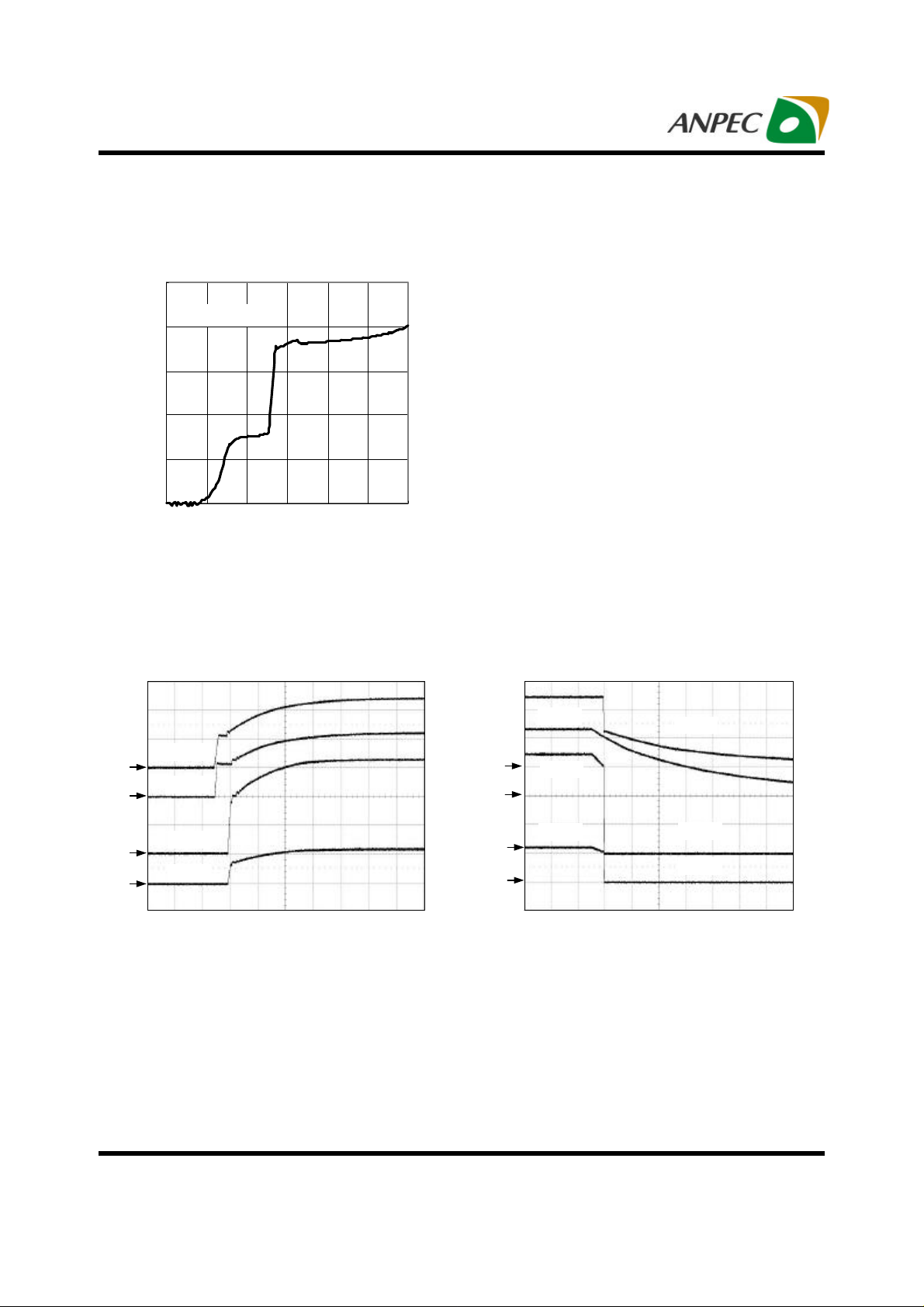

Operating Waveforms

VIN=5V, V

SET

=2V, V

=3.2V, CIN=1µF, C

OUT

Power On

=2.2µF, unless otherwise specified.

OUT

=2.2µF, unless otherwise specified.

OUT

Power Off

1

2

3

4

CH1 : VIN , 2V/div

CH2 : V

CH3 : V

CH4 : I

Time : 1ms/div

V

V

V

I

IN

SET

OUT

OUT

OUT

, 1V/div

SET

, 1V/div

OUT

, 500mA/div

V

SET

1

V

OUT

V

IN

2

I

OUT

V

OUT

3

I

OUT

4

CH1 : VIN , 2V/div

CH2 : V

CH3 : V

CH4 : I

Time : 200ms/div

, 1V/div

SET

, 1V/div

OUT

, 500mA/div

OUT

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

www.anpec.com.tw5

APL5605

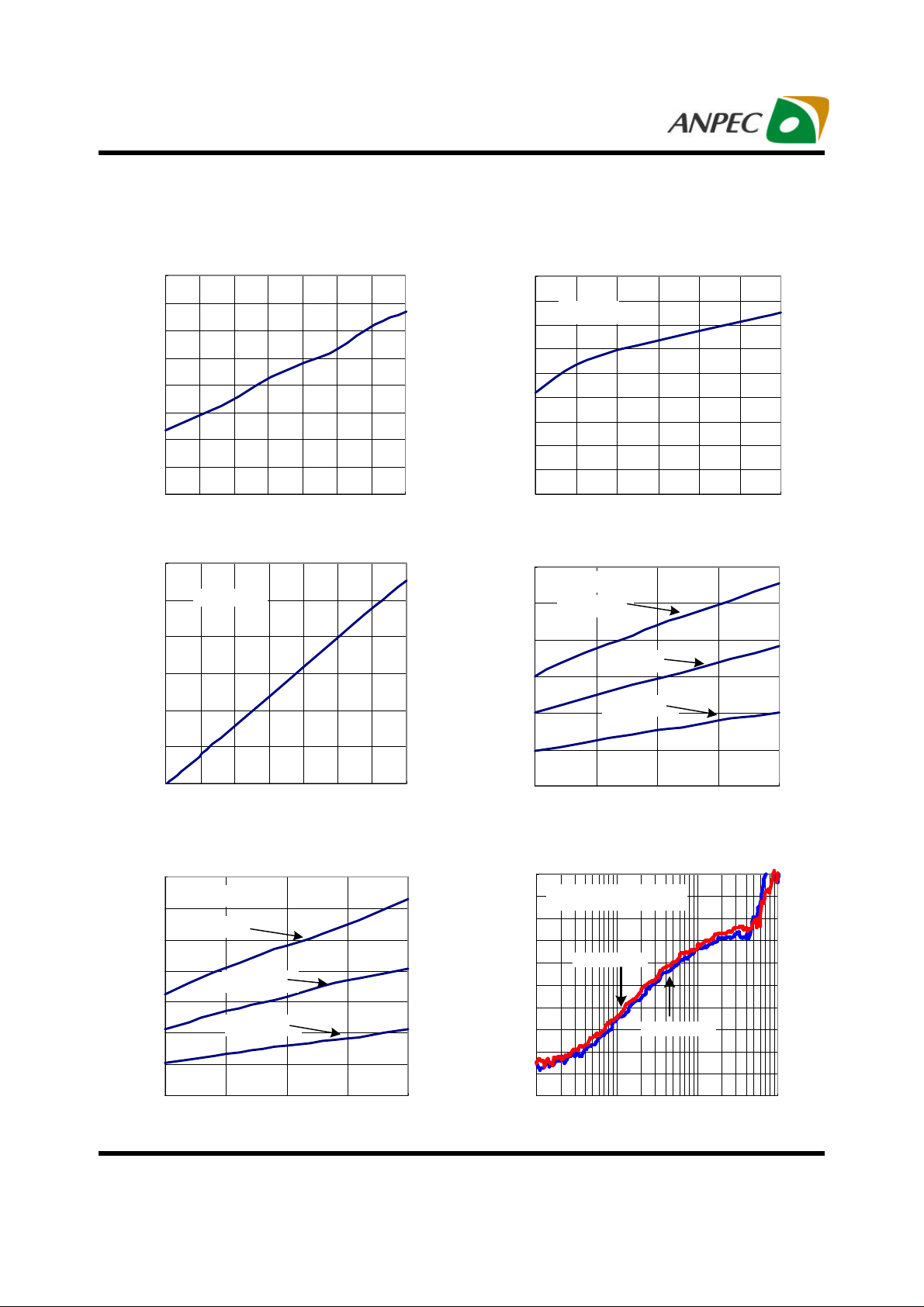

Operating Waveforms (Cont.)

VIN=5V, V

SET

=2V, V

=3.2V, CIN=1µF, C

OUT

=2.2µF, unless otherwise specified.

OUT

VIN=5V, V

CIN=1µF, C

1

2

Load transient

=2V , V

SET

=2.2µF

OUT

CH1 : V

CH2 : I

Time : 200µs/div

, 100mV/div

OUT

, 200mV/div

OUT

=3.2V

OUT

Enable

Line transient

VIN=5V, V

CIN=1µF, C

V

OUT

I

OUT

2

1

CH1 : VIN , 1V/div

CH2 : V

Time : 1ms/div

=2V , V

SET

=2.2µF

OUT

, 100mV/div

OUT

OUT

=3.2V

V

IN

V

OUT

Shutdown

V

SET

V

1

EN

2

V

3

4

OUT

I

OUT

CH1 : VEN , 2V/div

CH2 : V

CH3 : V

CH4 : I

Time : 200µs/div

, 1V/div

SET

, 1V/div

OUT

, 500mA/div

OUT

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

1

2

3

4

CH1 : VEN , 2V/div

CH2 : V

CH3 : V

CH4 : I

Time : 10µs/div

, 1V/div

SET

, 1V/div

OUT

, 500mA/div

OUT

V

SET

V

EN

V

OUT

I

OUT

www.anpec.com.tw6

APL5605

Operating Waveforms (Cont.)

VIN=5V, V

SET

=2V, V

=3.2V, CIN=1µF, C

OUT

Thermal Shutdown

=2.2µF, unless otherwise specified.

OUT

Current Limit and Foldback

Current Limit

V

IN

1

V

OUT

V

IN

1

V

2

OUT

2

I

3

CH1 : VIN, 5V/div

CH2 : V

CH3 : I

Time : 500ms/div

, 2V/div

OUT

, 500mA/div

OUT

OUT

3

Time : 2ms/div

CH1 : VIN, 5V/div

CH2 : V

CH3 : I

OUT

OUT

, 2V/div

, 1A/div

I

OUT

Pin Descriptions

Pin

No. Name

1 EN

2 VIN

3 VOUT

Enable Control Input. Driving the EN high turns on the regulator. Pulling the EN low turns the

regulator into shutdown mode. The EN is pulled low by an internal resistor.

Supply Voltage Input Pin. Supply voltage can range from 4.5V to 6V. Bypass with a 1µF (typical)

capacitor to GND

Regulator Output. Sources up to 600mA. A small capacitor is needed from this pin to ground to

assure stability.

4 VSET Output Voltage-Set Input. The output voltage follows the 1.6 times of the VSET voltage.

5,6,7,8 GND

Ground. These pins are internally connected with the internal leadframe. Connect these pins to a

wide ground plane for good heat dissipation.

Function Descriptions

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

www.anpec.com.tw7

APL5605

Block Diagram

VIN

EN

VSET

UVLO and

Soft-Start

Thermal

Shutdown

Current Limit

and Foldback

0.6R

R

V

= V

SET

x 1.6

OUT

VOUT

GND

Typical Application Circuit

V

IN

C

IN

1µF

ON

V

EN

OFF

VIN

EN

APL5605

GND

V1.6 V ⋅=

VSET

VOUT

SETOUT

V

V

C

OUT

2.2µF

SET

OUT

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

www.anpec.com.tw8

APL5605

Function Descriptions

Under-Voltage Lock-Out (UVLO)

The APL5605 has a built-in under-voltage lock-out circuit

to keep the output off until the internal circuitry is operating properly. The UVLO function initiates a soft start process after input voltage exceeds its rising UVLO threshold during power on. Typical UVLO threshold is 2.5V

with 0.15V hysteresis.

Soft-Start

The APL5605 provides an internal soft-start circuitry to

control rise rate of the output voltage and limit the current surge during start-up. Approximate 20µs delay time

after the VIN is over the UVLO threshold, the IC starts a

soft-start. The typical soft-start interval is about 130µs.

Enable/Shutdown

Driving the EN high turns on the regulator, driving the EN

low puts the regulator into shutdown mode. A logic low

also causes the output voltage to discharge to GND. The

EN is pulled low by an internal resistor.

Current Limit

The APL5605 provides a current limit circuitry, which

monitors the output current and controls P-MOS’s gate

voltage to limit the output current at 700mA.

Thermal Shutdown

A thermal shutdown circuit limits the junction temperature

of APL5605. When the junction temperature exceeds

+150οC, the thermal shutdown circuitry disables the

output, allowing the device to cool down. The output

circuitry is enabled again after the junction temperature cools down by 40οC, resulting in a pulsed output

during continuous thermal overload conditions.

Foldback Current Limit

When the output voltage drops below 0.6V (typical),which

is caused by over load or short circuit, the foldback current limit circuitry limits the output current to 250mA. The

foldback current limit is used to ruduce the power dissipation during short circuit condition. The foldback current

limits is disabled for 0.8ms(typical) after UVLO threshold

is reached, so that the IC has normal 700mA (typical)

current limit level during start-up.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

www.anpec.com.tw9

APL5605

Application Information

Input Capacitor

The APL5605 requires proper input capacitors to supply

surge current during stepping load transients to prevent

the input rail from dropping. Because the parasitic inductor from the voltage sources or other bulk capacitors to

the VIN limits the slew rate of the surge current, place the

Input capacitors near VIN as close as possible. Input

capacitors should be larger than 0.82µF.

Output Capacitor

The APL5605 needs a proper output capacitor to maintain circuit stability and to improve transient response

over temperature and current. In order to insure the circuit stability, the proper output capacitor value should be

larger than 1µF. With X5R and X7R dielectrics, 2.2µF is

sufficient at all operating temperatures. Maximum output

capacitor should be less than 330µF to insure the system can be powered on effectively.

Operation Region and Power Dissipation

The APL5605 maximum power dissipation depends on

the thermal resistance and temperature difference between the die junction and ambient air. The power dissipation PD across the device is:

AJ

)TT(

−

D

P

=

JA

θ

where (TJ-TA) is the temperature difference between the

junction and ambient air. θJA is the thermal resistance

between Junction and ambient air. Assuming the TA=25οC

and maximum TJ=150οC (typical thermal limit threshold),

the maximum power dis sipation is calculated as:

P

=(150-25)/80

D(max)

= 1.56(W)

For normal operation, do not exceed the maximum junction temperature rating of TJ = 125οC. The calculated

power dis sipation should less than:

PD =(125-25)/80

= 1.25(W)

The GND provides an electrical connection to ground and

channels heat away. Connect the GND to ground by us ing a large pad or ground plane.

PCB Layout Considerations

Figure 1 illustrates the layout. Below is a checklist for

your layout:

1. Please place the input capacitors close to the VIN

2. Ceramic capacitors for load must be placed near the

load as close as poss ible

3. To place APL5605 and output capacitors near the load

is good for performance.

4. Large current paths, the bold lines in figure 1, must

have wide tracks.

V

IN

C

IN

V

EN

APL5605

VIN

EN

GND

VSET

VOUT

V

SET

V

OUT

C

OUT

Figure 1

Optimum performance can only be achieved when the

device is mounted on a PC board according to the SOP-8

Board Layout diagram.

For dissipating heat

GND

C

GND

OUT

V

OUT

SOP-8

V

IN

C

IN

Figure 2

Recommanded Minimum Footprint

0.024

8 7 6 5

0.072

0.212

1 2 3 4

0.050

Unit : Inch

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

www.anpec.com.tw10

APL5605

Pack age Information

SOP-8

A

A1

A2

b

c

D

E

E1

e

h

L

0

D

SEE VIEW A

E

E1

h X 45

e

A2

A

A1

VIEW A

S

Y

M

B

O

L

MILLIMETERS

MIN. MAX.

SOP-8

1.75

0.10

0.25

1.25

0.31 0.51

0.17 0.25

4.80

5.80

3.80

5.00

6.20

4.00

cb

0.25

GAUGE PLANE

L

INCHES

MIN. MAX.

SEATING PLANE

0.069

0.004

0.010

0.049

0.012 0.020

0.007 0.010

0.189 0.197

0.228 0.244

0.150 0.157

1.27 BSC 0.050 BSC

0.25 0.50

0.40 1.27

0

8

0.010 0.020

0.016 0.050

0

8

Note: 1. Follow JEDEC MS-012 AA.

2. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion or gate burrs shall not exceed 6 mil per side.

3. Dimension “E” does not include inter-lead flash or protrusions.

Inter-lead flash and protrusions shall not exceed 10 mil per side.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

www.anpec.com.tw11

APL5605

Carrier Tape & R eel Dimensions

OD0

B0

P0

P2

P1

A

E1

F

W

A0

SECTION B-B

13.0+0.50

-0.20

1.5+0.10

-0.00

OD1

B

T

1.5 MIN. 20.2 MIN.

1.5 MIN.

0.6+0.00

-0.40

A

d

12.0±0.30 1.75±0.10 5.5±0.05

6.40±0.20 5.20±0.20 2.10±0.20

Application

SOP-8

K0

SECTION A-A

T1

B

A

H

A H T1 C d D W E1 F

330.0±2.00

50 MIN.

12.4+2.00

-0.00

P0 P1 P2 D0 D1 T A0 B0 K0

4.0±0.10 8.0±0.10 2.0±0.05

(mm)

Devices Per Unit

Package Type Unit Quantity

SOP-8 Tape & Reel 2500

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

www.anpec.com.tw12

APL5605

Reflow Condition (IR/Convection or VPR Reflow)

T

P

Ramp-up

T

L

Tsmax

Tsmin

Temperature

ts

Preheat

25

°

t 25 C to Peak

tp

t

L

Ramp-down

Critical Zone

TL to T

Time

Reliability Test Program

Test item Method Description

SOLDERABILITY MIL-STD-883D-2003

HOLT MIL-STD-883D-1005.7

PCT JESD-22-B, A102

TST MIL-STD-883D-1011.9

245°C, 5 sec

1000 Hrs Bias @125°C

168 Hrs, 100%RH, 121°C

-65°C~150°C, 200 Cycles

ESD MIL-STD-883D-3015.7 VHBM > 2KV, VMM > 200V

Latch-Up JESD 78 10ms, 1tr > 100mA

Classification Reflow Profiles

P

Profile Feature Sn-Pb Eutectic Assembly Pb-Free Assembly

Average ramp-up rate

(TL to TP)

Preheat

Temperature Min (Tsmin)

-

- Temperature Max (Tsmax)

- Time (min to max) (ts)

Time maintained above:

- Temperature (TL)

- Time (tL)

3°C/second max. 3°C/second max.

100°C

150°C

60-120 seconds

183°C

60-150 seconds

150°C

200°C

60-180 seconds

217°C

60-150 seconds

Peak/Classification Temperature (Tp) See table 1 See table 2

Time within 5°C of actual

Peak Temperature (tp)

Ramp-down Rate

Time 25°C to Peak Temperature

10-30 seconds 20-40 seconds

6°C/second max. 6°C/second max.

6 minutes max. 8 minutes max.

Note: All temperatures refer to topside of the package. Measured on the body surface.

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

www.anpec.com.tw13

APL5605

Classification Reflow Profiles (Cont.)

Table 1. SnPb Eutectic Process – Package Peak Reflow Temperatures

Package Thickness

<2.5 mm

≥2.5 mm 225 +0/-5°C 225 +0/-5°C

Table 2. Pb-free Process – Package Classification Reflow Temperatures

Volume mm

<350

240 +0/-5°C 225 +0/-5°C

3

Volume mm

≥350

3

Package Thickness

<1.6 mm

1.6 mm – 2.5 mm

≥2.5 mm 250 +0°C* 245 +0°C* 245 +0°C*

* Tolerance: The device manufacturer/supplier shall assure process compatibility up to and including the stated

classification temperature (this means Peak reflow temperature +0°C. For example 260°C+0°C) at the rated MSL

level.

Volume mm3

<350

260 +0°C* 260 +0°C* 260 +0°C*

260 +0°C* 250 +0°C* 245 +0°C*

Volume mm3

350-2000

Volume mm3

>2000

Customer Service

Anpec Electronics Corp.

Head Office :

No.6, Dusing 1st Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

2F, No. 11, Lane 218, Sec 2 Jhongsing Rd.,

Sindian City, Taipei County 23146, Taiwan

Tel : 886-2-2910-3838

Fax : 886-2-2917-3838

Copyright ANPEC Electronics Corp.

Rev. A.1 - Jan., 2008

www.anpec.com.tw14

Loading...

Loading...