PDM Digital Input, Mono

V

Data Sheet

FEATURES

Filterless digital Class-D amplifier

Pulse density modulation (PDM) digital input interface

2.4 W into 4 Ω load and 1.38 W into 8 Ω load at 5.0 V supply

with <1% total harmonic distortion plus noise (THD + N)

Available in 9-ball, 1.5 mm × 1.5 mm, 0.5 mm pitch WLCSP

92% efficiency into 8 Ω at full scale

Output noise: 43 μV rms at 3.6 V, A-weighted

THD + N: 0.035% at 1 kHz, 100 mW output power

PSRR: 85 dB at 217 Hz, input referred with dither input

Quiescent power consumption: 10.4 mW

(VDD = 1.8 V, PVDD = 3.6 V, 8 Ω + 33 μH load)

Pop-and-click suppression

Configurable with PDM pattern inputs

Short-circuit and thermal protection with autorecovery

Smart power-down when PDM stop condition

or no clock input detected

64 × f

or 128 × fS operation supporting 3 MHz and 6 MHz clocks

S

DC blocking high-pass filter and static input dc protection

User-selectable ultralow EMI emissions mode

Power-on reset (POR)

Minimal external passive components

APPLICATIONS

Mobile handsets

GENERAL DESCRIPTION

The SSM2517 is a PDM digital input Class-D power amplifier

that offers higher performance than existing DAC plus Class-D

solutions. The SSM2517 is ideal for power sensitive applications,

such as mobile phones and portable media players, where system

noise can corrupt the small analog signal sent to the amplifier.

The SSM2517 combines an audio digital-to-analog converter

(DAC), a power amplifier, and a PDM digital interface on a single

chip. The integrated DAC plus analog Σ-Δ modulator architecture

2.4 W Class-D Audio Amplifier

SSM2517

enables extremely low real-world power consumption from

digital audio sources with excellent audio performance. Using

the SSM2517, audio can be transmitted digitally to the audio

amplifier, significantly reducing the effect of noise sources such as

GSM interference or other digital signals on the transmitted audio.

The SSM2517 is capable of delivering 2.4 W of continuous output

power with <1% THD + N driving a 4 Ω load from a 5.0 V supply.

The SSM2517 features a high efficiency, low noise modulation

scheme that requires no external LC output filters. The closed-loop,

three-level modulator design retains the benefits of an all-digital

amplifier, yet enables very good PSRR and audio performance. The

modulation continues to provide high efficiency even at low output

power and has an SNR of 96 dB. Spread-spectrum pulse density

modulation is used to provide lower EMI-radiated emissions

compared with other Class-D architectures.

The SSM2517 has a four-state gain and sample frequency selection

pin that can select two different gain settings, optimized for 3.6 V

and 5 V operation. This same pin also controls the internal digital

filtering and clocking, which can be set for 64 × f

sample rates to support both 3 MHz and 6 MHz PDM clock rates.

The SSM2517 has a micropower shutdown mode with a typical

shutdown current of 1 μA for both power supplies. Shutdown is

enabled automatically by gating input clock and data signals. A

standby mode can be entered by applying a designated PDM stop

condition sequence. The device also includes pop-and-click suppression circuitry. This suppression circuitry minimizes voltage

glitches at the output when entering or leaving the low power

state, reducing audible noises on activation and deactivation.

The SSM2517 is specified over the industrial temperature range

of −40°C to +85°C. It has built-in thermal shutdown and output

short-circuit protection. It is available in a 9-ball, 1.5 mm × 1.5 mm

wafer level chip scale package (WLCSP).

or 128 × fS input

S

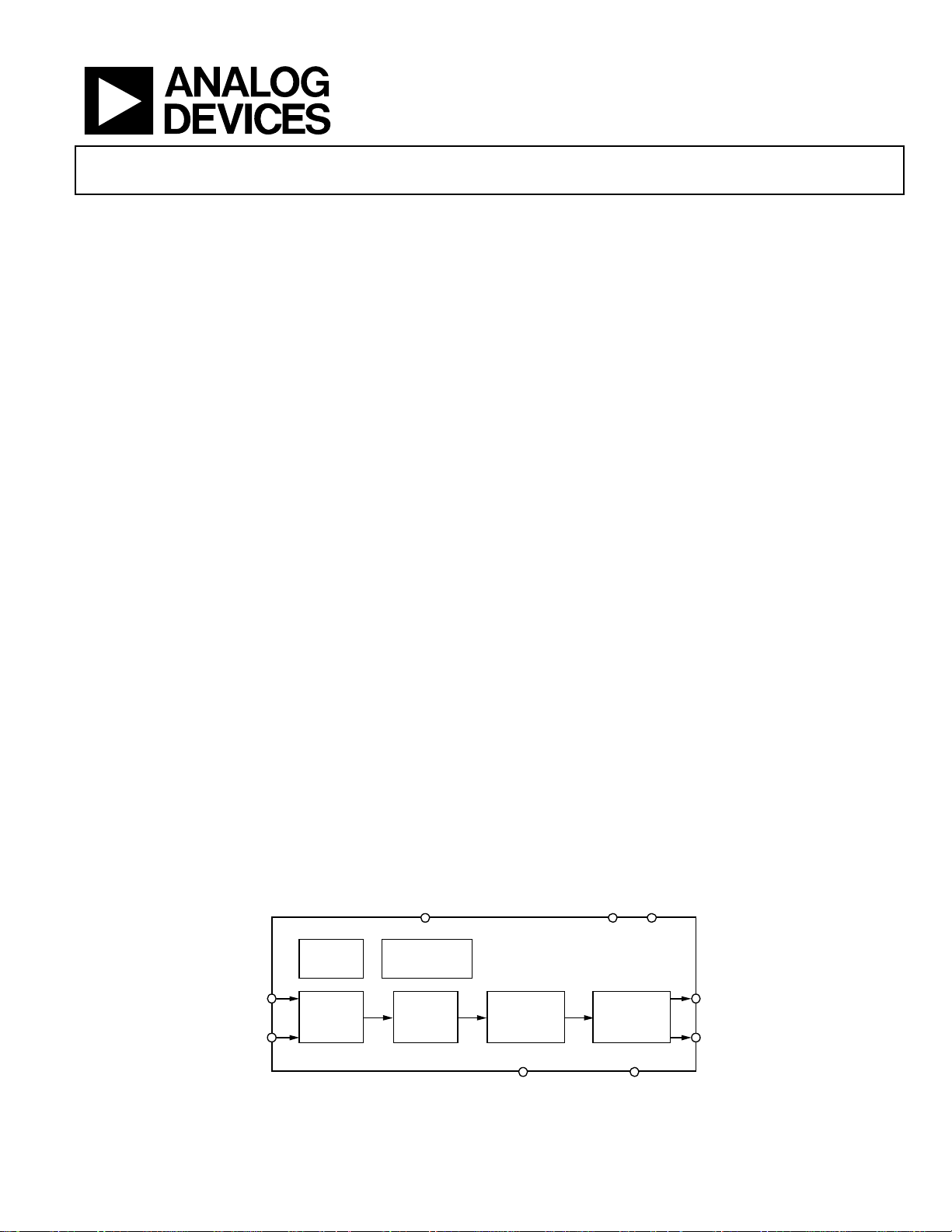

FUNCTIONAL BLOCK DIAGRAM

DD

POWER-ON

RESET

PDAT

PCLK

Rev. B

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

INPUT

INTERFACE

CLOCKING P OWER

CONTROL

FILTERING/

DAC

Σ-∆

CLASS-D

MODULATO R

GAIN_FS LRSEL

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010-2011 Analog Devices, Inc. All rights reserved.

PVDD PGND

SSM2517

FULL-BRI DGE

POWER STAGE

OUT+

OUT–

09211-001

SSM2517 Data Sheet

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Digital Input Specifications......................................................... 4

PDM Interface Digital Timing Specifications .......................... 5

Absolute Maximum Ratings............................................................ 6

Thermal Resistance ...................................................................... 6

ESD Caution.................................................................................. 6

Pin Configuration and Function Descriptions............................. 7

Typical Performance Characteristics ............................................. 8

Theory of Operation ...................................................................... 13

Master Clock............................................................................... 13

Power Supplies............................................................................ 13

Power Control............................................................................. 13

Power-On Reset/Voltage Supervisor ....................................... 13

System Gain/Input Frequency.................................................. 13

PDM Pattern Control ................................................................ 14

EMI Noise.................................................................................... 14

Output Modulation Description .............................................. 14

Applications Information.............................................................. 15

Layout .......................................................................................... 15

Power Supply Decoupling......................................................... 15

Outline Dimensions....................................................................... 16

Ordering Guide .......................................................................... 16

REVISION HISTORY

9/11—Rev. A to Rev. B

Changes to Table 3, Endnote 1, and Figure 2................................ 5

5/11—Rev. 0 to Rev. A

Changes to Table 6, LRSEL Pin Description................................. 7

10/10—Revision 0: Initial Version

Rev. B | Page 2 of 16

Data Sheet SSM2517

SPECIFICATIONS

PVDD = 5.0 V, VDD = 1.8 V, fS = 128×, TA = 25°C, RL = 8 Ω + 33 μH, unless otherwise noted. When fS = 128×, PDM clock = 6.144 MHz;

when f

= 64×, PDM clock = 3.072 MHz.

S

Table 1.

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

DEVICE CHARACTERISTICS

Output Power P

O

R

R

R

R

R

Total Harmonic Distortion Plus Noise THD + N f = 1 kHz, BW = 20 kHz

P

P

P

R

R

R

R

Efficiency η PO = 2.4 W into 4 Ω, PVDD = 5.0 V 86 %

P

Average Switching Frequency fSW No input 290 kHz

Closed-Loop Gain Gain

PVDD = 3.6 V 3.5 VP

PVDD = 5.0 V 4.78 VP

Differential Output Offset Voltage V

Low Power Mode Wake Time t

OOS

WAKE

Input Sampling Frequency fS f

f

POWER SUPPLY

Supply Voltage Range

Amplifier Power Supply PVDD 2.5 3.6 5.5 V

Digital Power Supply VDD 1.62 1.8 3.6 V

Power Supply Rejection Ratio PSRR

Supply Current, H-Bridge I

PVDD

PVDD = 5.0 V, fS = 64× 3.1 mA

PVDD = 5.0 V, fS = 128× 3.2 mA

PVDD = 3.6 V, fS = 64× 2.6 mA

PVDD = 3.6 V, fS = 128× 2.7 mA

PVDD = 2.5 V, fS = 64× 2.2 mA

PVDD = 2.5 V, fS = 128× 2.3 mA

Standby Current PVDD = 5.0 V 0.0 mA

Power-Down Current 100 nA

Supply Current, Modulator I

VDD

VDD = 3.3 V, fS = 64× 1.3 mA

VDD = 3.3 V, fS = 128× 2.4 mA

VDD = 1.8 V, fS = 64× 0.6 mA

VDD = 1.8 V, fS = 128× 1.2 mA

f = 1 kHz, BW = 20 kHz

RL = 4 Ω, THD = 1%, PVDD = 5.0 V 2.4 W

= 8 Ω, THD = 1%, PVDD = 5.0 V 1.38 W

L

= 4 Ω, THD = 1%, PVDD = 3.6 V 1.2 W

L

= 8 Ω, THD = 1%, PVDD = 3.6 V 0.7 W

L

= 4 Ω, THD = 10%, PVDD = 3.6 V 1.5 W

L

= 8 Ω, THD = 10%, PVDD = 3.6 V 0.9 W

L

= 100 mW into 8 Ω, PVDD = 3.6 V 0.035 %

O

= 500 mW into 8 Ω, PVDD = 3.6 V 0.1 %

O

= 1 W into 8 Ω, PVDD = 5.0 V 0.12 %

O

= 4 Ω, −6 dBFS input, PVDD = 5.0 V 3.6 %

L

= 8 Ω, −6 dBFS input, PVDD = 5.0 V 1.0 %

L

= 4 Ω, −6 dBFS input, PVDD = 3.6 V 5.2 %

L

= 8 Ω, −6 dBFS input, PVDD = 3.6 V 2.3 %

L

= 1.38 W into 8 Ω, PVDD = 5.0 V 92 %

O

−6 dBFS PDM input, BTL output,

f = 1 kHz

Gain = 6 dB 0.5 mV

0.5 ms

= 64× 1.84 3.072 3.23 MHz

S

= 128× 3.68 6.144 6.46 MHz

S

GSM VRIPPLE

= 100 mV at 217 Hz 85 dB

Dither input, 8 Ω + 33 μH load

Dither input, 8 Ω + 33 μH load

Rev. B | Page 3 of 16

SSM2517 Data Sheet

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

Standby Current VDD = 1.8 V, fS = 64× 57 μA

VDD = 1.8 V, fS = 128× 114 μA

Shutdown Current VDD = 3.3 V 3.0 μA

VDD = 1.8 V 0.9 μA

NOISE PERFORMANCE

Output Voltage Noise en Dithered input, A-weighted

PVDD = 3.6 V, fS = 64× 43 μV

PVDD = 3.6 V, fS = 128× 52 μV

PVDD = 5.0 V, fS = 64× 52 μV

PVDD = 5.0 V, fS = 128× 60 μV

Signal-to-Noise Ratio SNR

f

f

= 1.38 W, PVDD = 5.0 V, RL = 8 Ω,

P

O

A-weighted

= 64× 96 dB

S

= 128× 95 dB

S

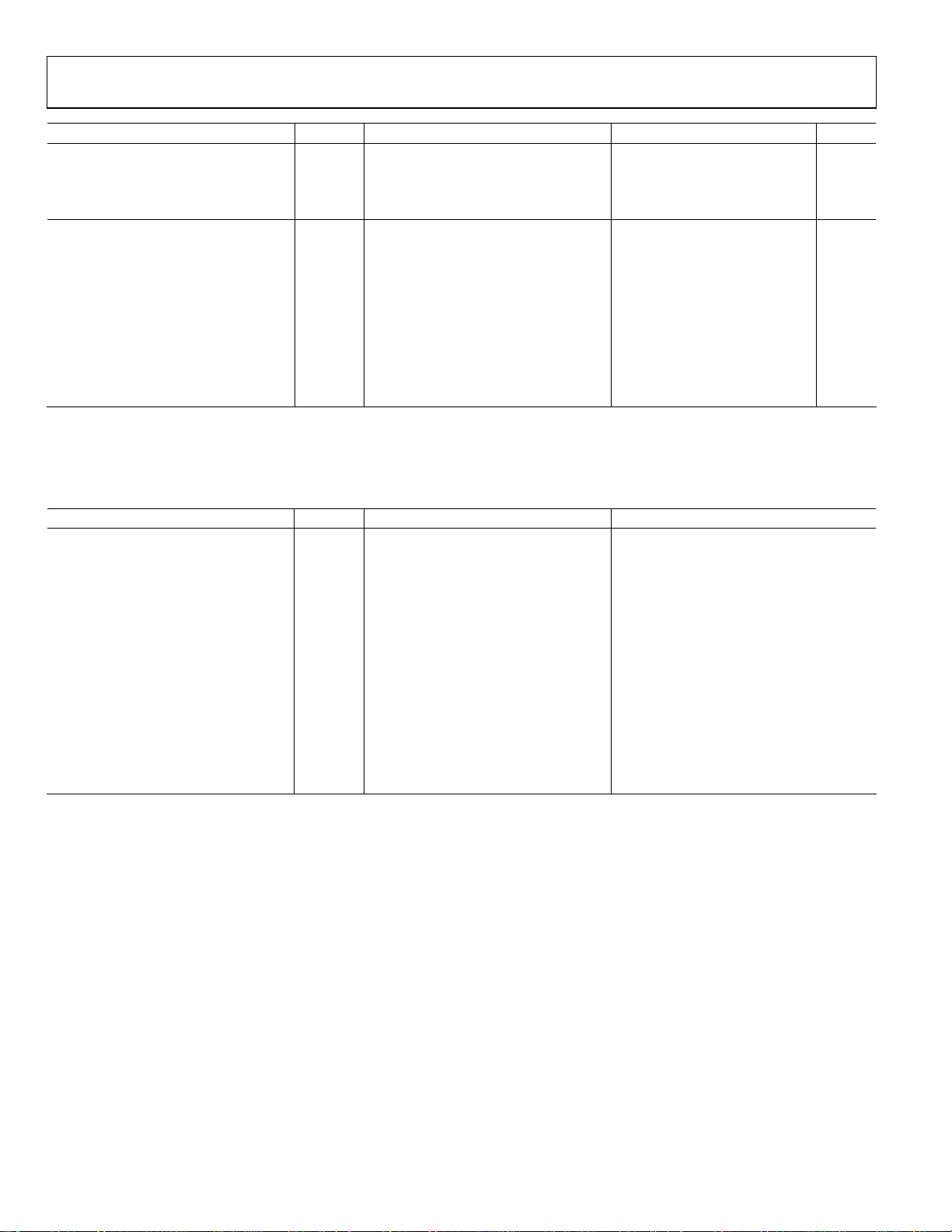

DIGITAL INPUT SPECIFICATIONS

Table 2.

Parameter Symbol Min Typ Max Unit

INPUT SPECIFICATIONS

Input Voltage High VIH

PCLK, PDAT, LRSEL Pins 0.7 × VDD 3.6 V

GAIN_FS Pin 1.35 5.5 V

Input Voltage Low VIL V

PCLK, PDAT, LRSEL Pins −0.3 0.3 × VDD V

GAIN_FS Pin −0.3 +0.35 V

Input Leakage High IIH

PDAT, LRSEL, GAIN_FS Pins 1 μA

PCLK Pin 3 μA

Input Leakage Low IIL

PDAT, LRSEL, GAIN_FS Pins 1 μA

PCLK Pin 3 μA

Input Capacitance 5 pF

Rev. B | Page 4 of 16

Data Sheet SSM2517

PDM INTERFACE DIGITAL TIMING SPECIFICATIONS

Table 3.

Limit

Parameter

t

t

MIN

MAX

tDS 44 ns Valid data start time1

tDE 7 ns Valid data end time1

1

The SSM2517 was designed so that the data line can transition coincident with or close to a clock edge. It is not necessary to delay the data line transition until after the

clock edge because the SSM2517 does this internally to ensure good timing margins. The data line should remain constant during the valid sample period illustrated

in Figure 2; it may transition at any other time. Timing is measured from 70% of VDD on the rising edge or 30% VDD on the falling edge.

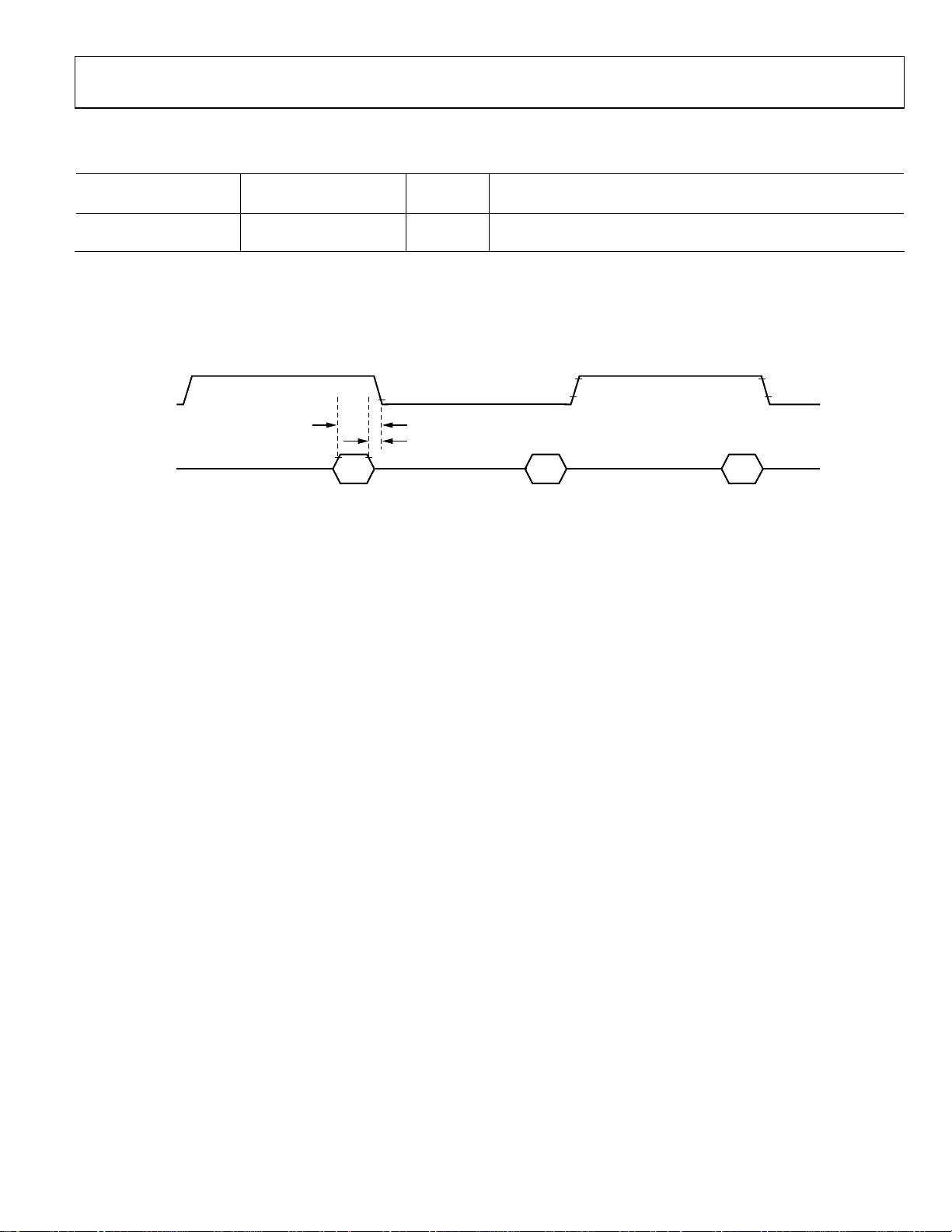

Timing Diagram

PCLK

t

DS

PDAT

Unit Description

t

DE

VALID LEFT SAMPLE VALID LEFT SAMPLEVALID RIGHT SAMPLE

09211-002

Figure 2. PDM Interface Timing

Rev. B | Page 5 of 16

SSM2517 Data Sheet

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings apply at 25°C, unless otherwise noted.

Table 4.

Parameter Rating

PVDD Supply Voltage −0.3 V to +6 V

VDD Supply Voltage −0.3 V to +3.6 V

Input Voltage (Signal Source) −0.3 V to +3.6 V

ESD Susceptibility 4 kV

OUT− and OUT+ Pins 8 kV

Storage Temperature Range −65°C to +150°C

Operating Temperature Range −40°C to +85°C

Junction Temperature Range −65°C to +165°C

Lead Temperature (Soldering, 60 sec) 300°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

Junction-to-air thermal resistance (θJA) is specified for the worstcase conditions, that is, a device soldered in a printed circuit board

(PCB) for surface-mount packages. θ

thermal resistance) are determined according to JEDEC JESD51-9

on a 4-layer PCB with natural convection cooling.

Table 5. Thermal Resistance

Package Type PCB θJA θJB Unit

9-Ball, 1.5 mm × 1.5 mm WLCSP 1S0P 162 39 °C/W

2S0P 76 21 °C/W

and θJB (junction-to-board

JA

ESD CAUTION

Rev. B | Page 6 of 16

Data Sheet SSM2517

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

BALLA1

CORNER

OUT+ PGNDPVDD

A

OUT– LRSEL VDD

B

PCLK PDAT GAIN_FS

C

TOP VIEW

(BALL SIDE DOW N)

Not to Scal e

Figure 3. Pin Configuration

Table 6. Pin Function Descriptions

Pin No. Mnemonic Function Description

A1 OUT+ Output Noninverting Output.

A2 PVDD Supply Amplifier Power, 2.5 V to 5.5 V.

A3 PGND Ground Amplifier Ground.

B1 OUT− Output Inverting Output.

B2 LRSEL Input Left/Right Channel Select. Pull up to VDD for right channel; tie to ground for left channel.

B3 VDD Supply Digital Power, 1.62 V to 3.6 V.

C1 PCLK Input PDM Interface Master Clock.

C2 PDAT Input PDM Data Signal.

C3 GAIN_FS Input Gain and Sample Rate Selection Pin.

321

09211-003

Rev. B | Page 7 of 16

SSM2517 Data Sheet

TYPICAL PERFORMANCE CHARACTERISTICS

100

RL = 8Ω + 33µH

GAIN = 5V

SAMPLE RATE = 64×

(3.072MHz)

10

100

RL = 8Ω + 33µH

GAIN = 5V

SAMPLE RATE = 128×

(6.144MHz)

10

1

THD + N (%)

0.1

0.01

0.001 0.01 0.1 1 10

PVDD = 2.5V

PVDD = 3.6V

PVDD = 5V

OUTPUT PO WER (W)

Figure 4. THD + N vs. Output Power into 8 Ω, Gain = 5 V, f

100

RL = 8Ω + 33µH

GAIN = 3.6V

SAMPLE RATE = 64×

(3.072MHz)

10

1

THD + N (%)

0.1

0.01

0.001 0.01 0.1 1 10

PVDD = 2.5V

PVDD = 3.6V

PVDD = 5V

OUTPUT PO WER (W)

Figure 5. THD + N vs. Output Power into 8 Ω, Gain = 3.6 V, f

= 64×

S

= 64×

S

1

THD + N (%)

0.1

0.01

09211-010

0.001 0.01 0.1 1 10

Figure 7. THD + N vs. Output Power into 8 Ω, Gain = 5 V, f

100

RL = 8Ω + 33µH

GAIN = 3.6V

SAMPLE RATE = 128×

(6.144MHz)

10

1

THD + N (%)

0.1

0.01

09211-012

0.001 0.01 0.1 1 10

Figure 8. THD + N vs. Output Power into 8 Ω, Gain = 3.6 V, f

PVDD = 2.5V

OUTPUT PO WER (W)

PVDD = 2.5V

OUTPUT PO WER (W)

PVDD = 3.6V

PVDD = 5V

PVDD = 3.6V

PVDD = 5V

= 128×

S

= 128×

S

09211-011

09211-013

100

RL = 4Ω + 15µH

GAIN = 5V

SAMPLE RATE = 64×

(3.072MHz)

10

PVDD = 3.6V

1

THD + N (%)

0.1

0.01

0.001 0.01 0.1 1 10

PVDD = 2.5V

PVDD = 5V

OUTPUT PO WER (W)

Figure 6. THD + N vs. Output Power into 4 Ω, Gain = 5 V, f

= 64×

S

09211-014

Rev. B | Page 8 of 16

100

RL = 4Ω + 15µH

GAIN = 5V

SAMPLE RATE = 128×

(6.144MHz)

10

PVDD = 3.6V

1

THD + N (%)

0.1

0.01

0.001 0.01 0.1 1 10

PVDD = 2.5V

PVDD = 5V

OUTPUT PO WER (W)

Figure 9. THD + N vs. Output Power into 4 Ω, Gain = 5 V, f

= 128×

S

09211-015

Data Sheet SSM2517

100

RL = 4Ω + 15µH

GAIN = 3.6V

SAMPLE RATE = 64×

(3.072MHz)

10

PVDD = 3.6V

100

RL = 4Ω + 15µH

GAIN = 3.6V

SAMPLE RATE = 128×

(6.144MHz)

10

PVDD = 3.6V

1

THD + N (%)

0.1

0.01

0.001 0.01 0.1 1 10

PVDD = 2.5V

PVDD = 5V

OUTPUT PO WER (W)

Figure 10. THD + N vs. Output Power into 4 Ω, Gain = 3.6 V, f

100

RL = 8Ω + 33µH

PVDD = 5V

GAIN = 5V

SAMPLE RATE = 64×

10

(3.072MHz)

1

THD + N (%)

0.1

0.01

10 100 1k 10k 100k

1.0W

0.25W

FREQUENCY (Hz)

0.5W

Figure 11. THD + N vs. Frequency, PVDD = 5 V, Gain = 5 V,

= 8 Ω, fS = 64×

R

L

= 64×

S

1

THD + N (%)

0.1

0.01

09211-016

0.001 0.01 0.1 1 10

Figure 13. THD + N vs. Output Power into 4 Ω, Gain = 3.6 V, f

100

RL = 4Ω + 15µH

PVDD = 5V

GAIN = 5V

SAMPLE RATE = 64×

10

(3.072MHz)

1

THD + N (%)

0.1

0.01

09211-018

10 100 1k 10k 100k

PVDD = 2.5V

OUTPUT PO WER (W)

1.0W

0.25W

FREQUENCY (Hz)

0.5W

PVDD = 5V

= 128×

S

09211-017

09211-019

Figure 14. THD + N vs. Frequency, PVDD = 5 V, Gain = 5 V,

= 4 Ω, fS = 64×

R

L

100

RL = 8Ω + 33µH

PVDD = 3.6V

GAIN = 3.6V

SAMPLE RATE = 64×

10

(3.072MHz)

1

THD + N (%)

0.1

0.01

10 100 1k 10k 100k

0.5W

0.25W

0.125W

FREQUENCY (Hz)

Figure 12. THD + N vs. Frequency, PVDD = 3.6 V, Gain = 3.6 V,

= 8 Ω, fS = 64×

R

L

09211-020

Rev. B | Page 9 of 16

100

RL = 4Ω + 15µH

PVDD = 3.6V

GAIN = 3.6V

SAMPLE RATE = 64×

10

(3.072MHz)

1

THD + N (%)

0.1

0.01

10 100 1k 10k 100k

0.5W

0.125W

FREQUENCY (Hz)

0.25W

Figure 15. THD + N vs. Frequency, PVDD = 3.6 V, Gain = 3.6 V,

= 4 Ω, fS = 64×

R

L

09211-021

SSM2517 Data Sheet

100

RL = 8Ω + 33µH

PVDD = 2.5V

GAIN = 3.6V

SAMPLE RATE = 64×

10

(3.072MHz)

100

RL = 4Ω + 15µH

PVDD = 2.5V

GAIN = 3.6V

SAMPLE RATE = 64×

10

(3.072MHz)

1

THD + N (%)

0.1

0.01

10 100 1k 10k 100k

0.2W

0.05W

FREQUENCY (Hz)

0.1W

Figure 16. THD + N vs. Frequency, PVDD = 2.5 V, Gain = 3.6 V,

= 8 Ω, fS = 64×

R

L

4.0

GAIN = 5V

SAMPLE RATE = 64×

(3.072MHz)

3.5

RL = 8Ω + 33µH

3.0

2.5

QUIESCENT CURRENT (mA)

2.0

1.5

2.5 3.0 3.5 5.55.04.54.0 6.0

RL = 4Ω + 15µH

NO LOAD

SUPPLY VOLTAGE (V)

Figure 17. Quiescent Current (H-Bridge) vs. Supply Voltage,

Gain = 5 V, f

= 64×

S

1

THD + N (%)

0.1

0.01

09211-022

10 100 1k 10k 100k

0.25W

0.05W

FREQUENCY (Hz)

0.1W

09211-023

Figure 19. THD + N vs. Frequency, PVDD = 2.5 V, Gain = 3.6 V,

= 4 Ω, fS = 64×

R

L

0

RL = 8Ω + 33µH

PVDD = 3.6V

–20

GAIN = 3.6V

SAMPLE RATE = 128×

–40

(6.144MHz)

–60

–80

–100

AMPLITUDE (dBV)

–120

–140

–160

0 2 4 6 8 101214161820

09211-024

FREQUENCY (kHz)

09211-033

Figure 20. Output Spectrum vs. Frequency, PVDD = 3.6 V, Gain = 3.6 V,

= 8 Ω, fS = 128×

R

L

1.8

RL = 8Ω + 33µH

1.6

GAIN = 5V

SAMPLE RATE = 64×

1.4

(3.072MHz)

1.2

1.0

0.8

0.6

OUTPUT POWER (W)

0.4

0.2

0

THD + N = 10%

THD + N = 1%

2.5 5.0

3.0 3.5 4.0 4.5

SUPPLY VOLTAGE (V)

Figure 18. Maximum Output Power vs. Supply Voltage, Gain = 5 V,

= 8 Ω, fS = 64×

R

L

09211-025

Rev. B | Page 10 of 16

1.8

RL = 8Ω + 33µH

1.6

GAIN = 5V

SAMPLE RATE = 128×

1.4

(6.144MHz)

1.2

1.0

0.8

0.6

OUTPUT POWER (W)

0.4

0.2

THD + N = 10%

THD + N = 1%

0

2.5 5.0

3.0 3.5 4.0 4.5

SUPPLY VOLTAGE (V)

Figure 21. Maximum Output Power vs. Supply Voltage, Gain = 5 V,

= 8 Ω, fS = 128×

R

L

09211-026

Data Sheet SSM2517

C

3.5

RL = 4Ω + 15µH

GAIN = 5V

3.0

SAMPLE RATE = 64×

(3.072MHz)

2.5

3.5

RL = 4Ω + 15µH

GAIN = 5V

3.0

SAMPLE RATE = 128×

(6.144MHz)

2.5

2.0

1.5

OUTPUT POWER (W)

1.0

0.5

0

2.5 5.0

THD + N = 10%

THD + N = 1%

3.0 3.5 4.0 4.5

SUPPLY VOLTAGE (V)

Figure 22. Maximum Output Power vs. Supply Voltage, Gain = 5 V,

= 4 Ω, fS = 64×

R

L

100

PVDD = 2.5V

90

80

70

60

50

40

EFFICIENCY (%)

30

RL = 8Ω + 33µH

20

GAIN = 5V

SAMPLE RATE = 64×

10

(3.072MHz)

0

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

Figure 23. Efficiency vs. Output Power into 8 Ω, Gain = 5 V, f

PVDD = 3.6V

PVDD = 5V

OUTPUT PO WER (W)

= 64×

S

2.0

1.5

OUTPUT POWER (W)

1.0

0.5

0

2.5 5.0

09211-027

THD + N = 10%

THD + N = 1%

3.0 3.5 4.0 4.5

SUPPLY VOLTAGE (V)

09211-028

Figure 25. Maximum Output Power vs. Supply Voltage, Gain = 5 V,

= 4 Ω, fS = 128×

R

L

100

90

80

70

60

Y (%)

50

40

EFFICIEN

30

RL = 4Ω + 15µH

20

GAIN = 5V

SAMPLE RATE = 64×

10

(3.072MHz)

0

0

09211-029

0.2

Figure 26. Efficiency vs. Output Power into 4 Ω, Gain = 5 V, f

PVDD = 2.5V

0.4

0.6

PVDD = 5V

PVDD = 3.6V

0.8

1.0

1.2

1.4

OUTPUT PO WER (W)

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.4

3.2

09211-031

= 64×

S

450

RL = 8Ω + 33µH

GAIN = 5V

400

SAMPLE RATE = 64×

(3.072MHz)

350

300

250

PVDD = 2.5V

200

150

SUPPLY CURRENT (mA)

100

50

0

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

PVDD = 3.6V

OUTPUT PO WER (W)

PVDD = 5V

Figure 24. Supply Current (H-Bridge) vs. Output Power into 8 Ω,

Gain = 5 V, f

= 64×

S

09211-032

800

RL = 4Ω + 15µH

GAIN = 5V

700

SAMPLE RAT E = 64×

(3.072MHz)

600

500

400

PVDD = 2.5V

300

SUPPLY CURRENT (mA)

200

100

0

0 0.5 1.0 1.5 2.0 2.5 3.0

PVDD = 3.6V

OUTPUT PO WER (W)

PVDD = 5V

Figure 27. Supply Current (H-Bridge) vs. Output Power into 4 Ω,

Gain = 5 V, f

= 64×

S

09211-036

Rev. B | Page 11 of 16

SSM2517 Data Sheet

0

–10

–20

–30

–40

–50

PSRR (dB)

–60

–70

–80

–90

–100

10 100 1k 10k 100k

PVDD = 3.6V

PVDD = 5V

FREQUENCY (Hz)

Figure 28. Power Supply Rejection Ratio (PSRR) vs. Frequency

9211-034

5

4

3

2

1

VOLTAGE (V)

0

–1

–2

–40 0 60 120 160–20 20 8040 1 00 140

PCLK

TIME (µs)

OUTPUT

Figure 29. Turn-On Response

09211-035

Rev. B | Page 12 of 16

Data Sheet SSM2517

THEORY OF OPERATION

MASTER CLOCK

The SSM2517 requires a clock present at the PCLK input pin.

This clock must be fully synchronous with the incoming digital

audio on the serial interface. The clock frequencies must fall

into one of these ranges: 1.84 MHz to 3.23 MHz or 3.68 MHz

to 6.46 MHz.

POWER SUPPLIES

The SSM2517 requires two power supplies: PVDD and VDD.

PVDD

The PVDD pin supplies power to the full-bridge power stage

of a MOSFET and its associated drive, control, and protection

circuitry. It also supplies power to the digital-to-analog converter

(DAC) and to the Class-D PDM modulator. PVDD can operate

from 2.5 V to 5.5 V and must be present to obtain audio output.

Lowering the supply voltage of PVDD results in lower maximum

output power and, therefore, lower power consumption.

VDD

The VDD pin provides power to the digital logic circuitry.

VDD can operate from 1.62 V to 3.6 V and must be present

to obtain audio output. Lowering the supply voltage of VDD

results in lower power consumption but does not affect audio

performance.

POWER CONTROL

On device power-up, PVDD must first be applied to the device,

which latches in the designated GAIN_FS pin functionality.

The SSM2517 contains a smart power-down feature. When

enabled, the smart power-down feature looks at the incoming

digital audio and, if it receives the PDM stop condition of at

least 128 repeated 0xAC bytes (1024 clock cycles), it places the

SSM2517 in the standby state. In the standby state, the PCLK can

be removed, resulting in a full power-down state. This state is

the lowest power condition possible. When the PCLK is turned

on again and a single non-stop condition input is received, the

SSM2517 leaves the full power-down state and resumes normal

operation.

POWER-ON RESET/VOLTAGE SUPERVISOR

The SSM2517 includes an internal power-on reset and voltage

supervisor circuit. This circuit provides an internal reset to all

circuitry whenever PVDD or VDD is substantially below the

nominal operating threshold. This circuit simplifies supply

sequencing during initial power-on.

The circuit also monitors the power supplies to the SSM2517. If

the supply voltages fall below the nominal operating threshold,

this circuit stops the output and issues a reset. This ensures that

no damage occurs due to low voltage operation and that no

pops can occur under nearly any power removal condition.

SYSTEM GAIN/INPUT FREQUENCY

The GAIN_FS pin is used to set the internal gain and filtering

configuration for different sample rates of the SSM2517. This pin

can be set to one of four states by connecting the pin to PVDD or

PGND (see Tab l e 7 ). The internal gain and filtering can also be

set via PDM pattern control, allowing these settings to be modified during operation (see the PDM Pattern Control section).

Table 7. GAIN_FS Function Descriptions

Device Setting GAIN Pin Configuration

fS = 64 × PCLK, Gain = 5 V

fS = 128 × PCLK, Gain = 5 V

fS = 64 × PCLK, Gain = 3.6 V Pull up to PVDD

fS = 128 × PCLK, Gain = 3.6 V Pull down to PGND

The SSM2517 has an internal analog gain control such that

when GAIN_FS is tied to PGND or PVDD via a 47 kΩ resistor

(5 V gain setting), a −6.02 dBFS PDM input signal results in

an amplifier output voltage of 5 V peak. This setting should

produce optimal noise performance when PVDD = 5 V.

When the GAIN_FS pin is tied directly to PGND or PVDD, the

gain is adjusted so that a −6.02 dBFS PDM input signal results

in an amplifier output voltage of 3.6 V peak. This setting should

produce optimal noise performance when PVDD = 3.6 V.

The SSM2517 can handle input sample rates of 64 × f

and 128 × f

(~6 MHz). Different internal digital filtering is used

S

in each of these cases. Selection of the sample rate is also set via

the GAIN_FS pin (see Table 7 ).

Because the 64 × f

mode provides better performance with lower

S

power consumption, its use is recommended. The 128 × f

should be used only when overall system noise performance is

limited by the source modulator.

Pull up to PVDD with a 47 kΩ

resistor

Pull down to PGND with a 47 kΩ

resistor

(~3 MHz)

S

mode

S

Rev. B | Page 13 of 16

SSM2517 Data Sheet

PDM PATTERN CONTROL

The SSM2517 has a simple control mechanism that can set the

part for low power states and control functionality. This is

accomplished by sending a repeating 8-bit pattern to the device.

Different patterns set different functionality (see Tab l e 8).

Any pattern must be repeated a minimum of 128 times. The

part is automatically muted when a pattern is detected so that

a pattern can be set while the part is operational without a

pop/click due to pattern transition.

All functionality set via patterns returns to its default value after

a clock-loss power-down.

Table 8. PDM Watermarking Pattern Control Descriptions

Pattern Control Description

0xAC

Power-down. All blocks off except for PDM interface.

Normal start-up time.

0xD8

Gain optimized for PVDD = 5 V operation.

Overrides GAIN_FS pin setting.

0xD4

Gain optimized for PVDD = 3.6 V operation.

Overrides GAIN_FS pin setting.

0xD2

Gain optimized for PVDD = 2.5 V operation.

Overrides GAIN_FS pin setting.

0xD1 fS set to opposite value determined by GAIN_FS pin.

0xE1 Ultralow EMI mode.

0xE2 Half clock cycle pulse mode for power savings.

0xE4 Special 32 kHz/128 × fS operation mode.

EMI NOISE

The SSM2517 uses a proprietary modulation and spreadspectrum technology to minimize EMI emissions from the

device. For applications that have difficulty passing FCC

Class-B emission tests, the SSM2517 includes a modulation

select mode (ultralow EMI emissions mode) that significantly

reduces the radiated emissions at the Class-D outputs, particularly above 100 MHz. This mode is enabled by activating PDM

Water ma r ki n g Pa t t er n 0 x E1 ( se e Tabl e 8).

OUTPUT MODULATION DESCRIPTION

The SSM2517 uses three-level, Σ-Δ output modulation. Each

output can swing from PGND to PVDD and vice versa. Ideally,

when no input signal is present, the output differential voltage is

0 V because there is no need to generate a pulse. In a real-world

situation, noise sources are always present.

Due to this constant presence of noise, a differential pulse is

generated, when required, in response to this stimulus. A small

amount of current flows into the inductive load when the differential pulse is generated.

Most of the time, however, the output differential voltage is 0 V,

due to the Analog Devices, Inc., three-level, Σ-Δ output modulation. This feature ensures that the current flowing through the

inductive load is small.

When the user wants to send an input signal, an output pulse

(OUT+ and OUT−) is generated to follow the input voltage.

The differential pulse density (VOUT) is increased by raising

the input signal level. Figure 30 depicts three-level, Σ-Δ output

modulation with and without input stimulus.

OUTPUT = 0V

OUT+

OUT–

VOUT

OUTPUT > 0V

OUT+

OUT–

VOUT

OUTPUT < 0V

OUT+

OUT–

VOUT

Figure 30. Three-Level, Σ-Δ Output Modulation With and Without Input Stimulus

+5V

0V

+5V

0V

+5V

0V

–5V

+5V

0V

+5V

0V

+5V

0V

+5V

0V

+5V

0V

0V

–5V

9211-009

Rev. B | Page 14 of 16

Data Sheet SSM2517

APPLICATIONS INFORMATION

LAYOUT

As output power increases, care must be taken to lay out PCB

traces and wires properly among the amplifier, load, and power

supply. A good practice is to use short, wide PCB tracks to

decrease voltage drops and minimize inductance. The PCB

layout engineer must avoid ground loops where possible to

minimize common-mode current associated with separate paths

to ground. Ensure that track widths are at least 200 mil per inch

of track length for lowest DCR, and use 1 oz or 2 oz copper PCB

traces to further reduce IR drops and inductance. A poor layout

increases voltage drops, consequently affecting efficiency. Use

large traces for the power supply inputs and amplifier outputs to

minimize losses due to parasitic trace resistance.

Proper grounding guidelines help to improve audio performance,

minimize crosstalk between channels, and prevent switching

noise from coupling into the audio signal. To maintain high

output swing and high peak output power, the PCB traces that

connect the output pins to the load, as well as the PCB traces to

the supply pins, should be as wide as possible to maintain the

minimum trace resistances. It is also recommended that a large

ground plane be used for minimum impedances.

In addition, good PCB layout isolates critical analog paths from

sources of high interference. High frequency circuits (analog

and digital) should be separated from low frequency circuits.

Properly designed multilayer PCBs can reduce EMI emissions

and increase immunity to the RF field by a factor of 10 or more,

compared with double-sided boards. A multilayer board allows

a complete layer to be used for the ground plane, whereas the

ground plane side of a double-sided board is often disrupted by

signal crossover.

POWER SUPPLY DECOUPLING

To ensure high efficiency, low total harmonic distortion (THD),

and high PSRR, proper power supply decoupling is necessary.

Noise transients on the power supply lines are short-duration

voltage spikes. These spikes can contain frequency components

that extend into the hundreds of megahertz.

The power supply inputs must be decoupled with a good quality,

low ESL, low ESR capacitor, with a minimum value of 4.7 μF

for the PVDD pin and 0.1 μF for the VDD pin. This capacitor

bypasses low frequency noises to the ground plane. For high

frequency transient noises, use a 0.1 μF capacitor as close as

possible to the PVDD and VDD pins of the device. Placing the

decoupling capacitors as close as possible to the SSM2517 helps

to maintain efficient performance.

Rev. B | Page 15 of 16

SSM2517 Data Sheet

OUTLINE DIMENSIONS

0.655

0.600

0.545

SEATING

PLANE

0.350

0.320

0.290

123

A

B

BALL A1

IDENTIFIER

1.490

1.460 SQ

1.430

C

101507-C

TOP VIEW

(BALL SIDE DOWN)

0.385

0.360

0.335

0.50

BALL PITCH

0.270

0.240

0.210

BOTTOM VIEW

(BALL SIDE UP)

Figure 31. 9-Ball Wafer Level Chip Scale Package [WLCSP]

(CB-9-2)

Dimensions shown in millimeters

ORDERING GUIDE

Model1 Temperature Range Package Description Package Option

SSM2517CBZ-R7 −40°C to +85°C 9-Ball Wafer Level Chip Scale Package [WLCSP] CB-9-2

SSM2517CBZ-RL −40°C to +85°C 9-Ball Wafer Level Chip Scale Package [WLCSP] CB-9-2

EVAL-SSM2517Z Evaluation Board

1

Z = RoHS Compliant Part.

©2010-2011 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D09211-0-9/11(B)

Rev. B | Page 16 of 16

Loading...

Loading...