Page 1

DCS-E 3kW Series DC

Power Supplies

Operation Manual

This manual covers models:

DCS8-350E DCS55-55E

DCS12-250E DCS60-50E

DCS20-150E DCS80-37E

DCS40-75E DCS150-20E

M362295-01 Rev C www.programmablepower.com

Page 2

Page 3

Page 4

Page 5

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement,

process control, power bus simulation and power conditioning applications across diverse

industrial segments. From bench top supplies to rack-mounted industrial power subsystems,

AMETEK Programmable Power is the proud manufacturer of Elgar, Sorensen, California

Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromec hanical

devices with annualized sales of $2.5 billion. The Company has over 11,000 colleagues working

at more than 80 manufacturing facilities and more than 80 sales and service centers in the United

States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc.

Other trademarks, registered trademarks, and product names are the property of their respective

owners and are used herein for identification purposes only.

Notice of Copyright

DCS-E 3kW Series DC Power Supplies Operation Manual

Power, Inc. All rights reserved.

© 2006-2008 AMETEK Programmable

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC.

(“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL,

WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH

INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE

TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED AMETEK CONTENT

IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION, WHICH IS POSTED AT

WWW.PROGRAMMABLEPOWER.COM.

Date and Revision

December 2008 Revision B

Part Number

M362295-01

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales@programmablepower.com

service@programmablepower.com

Web: www.programmablepower.com

i

Page 6

This page intentionally left blank.

ii

Page 7

G

G

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your

particular application.

WARNIN

WARNIN

Only qualified personnel who deal with attendant hazards in power supplies, are allowed to perform

installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or

chassis. Similarly, other power ground lines including those to application and maintenance

equipment must be grounded properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any

cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY may be normally generated on the output terminals. The customer/user must

ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety

glasses during open cover checks to avoid personal injury by any sudden component failure.

Neither AMETEK Programmable Power Inc., San Diego, California, USA, nor any of the subsidiary

sales organizations can accept any responsibility for personnel, material or inconsequential injury,

loss or damage that results from improper use of the equipment and accessories.

Hazardous voltages may be present when covers are removed. Qualified

personnel must use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating above

(below) chassis ground.

The equipment used contains ESD sensitive parts. When installing

equipment, follow ESD Safety Procedures. Electrostatic discharges might

cause damage to the equipment.

SAFETY SYMBOLS

iii

Page 8

This page intentionally left blank.

iv

Page 9

Product Family: DCS-E 3kW Series DC Power Supplies

Warranty Period: Five Years

WARRANTY TERMS

AMETEK Programmable Power, Inc. (“AMETEK”), provides this written warranty covering the

Product stated above, and if the Buyer discovers and notifies AMETEK in writing of any defect in

material or workmanship within the applicable warranty period stated above, then AMETEK may,

at its option: repair or replace the Product; or issue a credit note for the defective Product; or

provide the Buyer with replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in

accordance with the return procedure specified below. AMETEK will, at its expense, deliver the

repaired or replaced Product or parts to the Buyer. Any warranty of AMETEK will not apply if the

Buyer is in default under the Purchase Order Agreement or where the Product or any part

thereof:

• is damaged by misuse, accident, negligence or failure to maintain the same as

specified or required by AMETEK;

• is damaged by modifications, alterations or attachments thereto which are not

authorized by AMETEK;

• is installed or operated contrary to the instructions of AMETEK;

• is opened, modified or disassembled in any way without AMETEK’s consent; or

• is used in combination with items, articles or materials not authorized by AMETEK.

The Buyer may not assert any claim that the Products are not in conformity with any warranty

until the Buyer has made all payments to AMETEK provided for in the Purchase Order Agreement.

PRODUCT RETURN PROCEDURE

1. Request a Return Material Authorization (RMA) number from the repair facility (must be

done in the country in which it was purchased):

• In the USA, contact the AMETEK Repair Department prior to the return of the

product to AMETEK for repair:

Telephone: 800-733-5427, ext. 2295 or ext. 2463 (toll free North America)

858-450-0085, ext. 2295 or ext. 2463 (direct)

• Outside the United States, contact the nearest Authorized Service Center

(ASC). A full listing can be found either through your local distributor or our

website, www.programmablepower.com, by clicking Support and going to the

Service Centers tab.

2. When requesting an RMA, have the following information ready:

• Model number

• Serial number

• Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by AMETEK, to be in specification is subject to

an evaluation fee and applicable freight charges.

v

Page 10

This page intentionally left blank.

vi

Page 11

ABOUT THIS MANUAL

This manual has been written expressly for the Sorensen DCS-E 3kW Series of power supplies,

which have been designed and certified to meet the Low Voltage and Electromagnetic

Compatibility Directive Requirements of the European Community. Units that comply with the

directive are designated by an ‘E’ after the model designator (e.g., DCS 60-50E indicates that the

model is certified) when configured for 230 VAC input only.

Since the goal of the Low Voltage Directive is to ensure the safety of the equipment operator,

universal graphic symbols have been used both on the unit itself and in this manual to warn the

operator of potentially hazardous situations (see Safety Symbols on page ii).

This manual is designed for the user who is familiar with basic electrical laws especially as they

apply to the operation of power supplies. This implies recognition of Constant Voltage and

Constant Current operating modes and the control of input and output power, as well as the

observance of safety techniques while effecting supply or pin connections and any changes in

switch and jumper settings. The more knowledgeable user will find that the detailed schematics

and circuit descriptions available on our website, www.programmablepower.com will enable

greater flexibility in troubleshooting and in configuring new applications.

Section 1 Introducing the DCS-E Series 3kW Supply describes the power supply, lists its

features, and provides specifications .

Section 2 Installation reviews safety and inspection procedures, then goes through the basic

set up procedures. Directions for the assembling of the AC input connector, for the testing of basic

functions, and for connecting the load are also included.

Section 3 Basic Operation provides procedures for local programming mode operation (Constant

Voltage and Constant Current) and remote sensing.

Section 4 Advanced Operation covers remote programming mode operation as well as

procedures for using advanced programming features such as Over Voltage Protection (OVP),

Output Power ON/OFF, and Remote Monitoring. This section also provides procedures for using

multiple supplies in series, in parallel, and in split supply configurations.

Section 5 Theory of Operation provides a block diagram of the power supply, an explanation of

the functions within each block, and more detailed descriptions of the circuitry.

Section 6 Maintenance covers service, calibration and repairs, and includes parts lists.

Section 7 Application Notes is reserved for additional system information.

vii

Page 12

This page intentionally left blank.

viii

Page 13

CONTENTS

SECTION 1 INTRODUCING THE DCS-E SERIES 3KW SUPPLY....1-1

1.1 Description.......................................................................................................1-1

1.2 Features........................................................................................................... 1-1

1.3 Specifications...................................................................................................1-2

1.3.1 Electrical Specifications1......................................................................1-2

1.3.2 Mechanical Specifications....................................................................1-3

SECTION 2 INSTALLATION .........................................................2-1

2.1 Introduction......................................................................................................2-1

2.2 Safety 2-1

2.2.1 High Energy/High Voltage Warning.....................................................2-1

2.2.2 AC Source Grounding..........................................................................2-2

2.2.3 Operating and Servicing Precautions ..................................................2-2

2.2.4 Parts and Modifications........................................................................2-2

2.3 Initial Inspection...............................................................................................2-3

2.3.1 Physical Check ....................................................................................2-3

2.4 Location, Mounting, and Ventilation................................................................. 2-3

2.4.1 Unit Dimensions...................................................................................2-3

2.4.2 Rack Mounting.....................................................................................2-4

2.5 AC Input Power................................................................................................ 2-4

2.5.1 AC Input Power Connection.................................................................2-4

2.5.2 AC Input Power Requirements ............................................................2-4

M362295-01 Rev C iii

Page 14

Contents Sorensen DCS-E Series 3kW Supplies

2.5.3 AC Input Connector Assembly.............................................................2-5

2.5.4 Strain Relief Assembly.........................................................................2-6

2.6 Initial Functional Tests .....................................................................................2-8

2.6.1 Power-on Check...................................................................................2-8

2.6.2 Voltage Mode Operation Check...........................................................2-8

2.6.3 Current Mode Operation Check ...........................................................2-9

2.6.4 Front Panel Function Checks...............................................................2-9

2.7 Load Connection............................................................................................2-10

2.7.1 Load Wiring........................................................................................2-10

2.7.2 Making the Connections.....................................................................2-11

2.7.3 Connecting Single Loads ...................................................................2-12

2.7.4 Connecting Multiple Loads.................................................................2-12

SECTION 3 BASIC OPERATION .................................................. 3-1

3.1 Introduction ......................................................................................................3-1

3.2 Standard Operation..........................................................................................3-1

3.2.1 Operating Modes and Automatic Crossover ........................................3-1

3.2.2 Local Programming Mode Operation ...................................................3-3

3.3 Using Remote Sensing ....................................................................................3-4

3.3.1 Connecting Remote Sense Lines.........................................................3-4

SECTION 4 ADVANCED OPERATION .......................................... 4-1

4.1 Introduction ......................................................................................................4-1

4.2 Configuring for Remote Programming, Sensing, and Monitoring.....................4-2

4.2.1 Programming, Monitoring, and Control Functions................................4-2

4.2.2 Locating Jumpers, Switch, and Connector...........................................4-4

4.2.3 Resetting Jumpers and Switch.............................................................4-5

4.2.4 Making J3 Connections........................................................................4-6

4.3 Remote Programming: Output Voltage and Current Limit..................................4-7

iv M362295-01 Rev Cl

Page 15

Sorensen DCS-E Series 3kW Supplies Contents

4.3.1 Programming Output Voltage and Current Limit with the REM/LOC Switch

4-8

4.3.2 Programming Output Voltage ..............................................................4-9

4.3.3 Programming Output Current Limit....................................................4-12

4.4 Using Over Voltage Protection (OVP) ...........................................................4-14

4.4.1 Front Panel OVP Operation...............................................................4-14

4.4.2 Resetting the OVP Circuit..................................................................4-14

4.4.3 Programming OVP with an External Voltage Source......................... 4-15

4.5 Using the Shutdown Function........................................................................4-16

4.5.1 STANDBY Switch ..............................................................................4-16

4.5.2 Programming the Shutdown Function................................................ 4-16

4.5.3 Shutdown Application - Contact Closure ...........................................4-19

4.6 Remote Monitoring of Readback Signals and Status Indicators.................... 4-21

4.6.1 Readback Signals..............................................................................4-21

4.6.2 Status Indicators................................................................................4-21

4.7 Using Multiple Supplies .................................................................................4-22

4.7.1 Configuring Multiple Supplies for Series Operation...........................4-22

4.7.2 Configuring Multiple Supplies for Parallel Operation .........................4-23

4.7.3 Configuring Multiple Supplies for Split Supply Operation ..................4-24

4.8 Output Voltage Biasing..................................................................................4-25

SECTION 5 THEORY OF OPERATION ..........................................5-1

5.1 Introduction......................................................................................................5-1

5.2 Basic Functional Blocks...................................................................................5-1

5.2.1 AC Input and RFI Filter (A5 PCB)........................................................5-2

5.2.2 AC Input Rectifier and Inrush Limiting Circuit (A6 PCB)......................5-2

5.2.3 PWM, Sync and Power Transformer Drive Circuit (A3 PCB)...............5-2

5.2.4 Power Transformer, Output Rectifiers, Output Filter Inductor and

M362295-01 Rev C

Capacitors, and Local Sense Connections (Power Stage, A7 PCB and

A8 PCB)...............................................................................................5-2

v

Page 16

Contents Sorensen DCS-E Series 3kW Supplies

5.2.5 Output Current Shunt, Shunt Amplifier, and Down Programmer (A4 PCB)

5-2

5.2.6 Control, Programming, OVP, Shutdown, Monitoring, and Auxiliary Supply

Circuits (A2 PCB).................................................................................5-3

5.2.7 Front Panel Displays and Local Operating Mode Controls (A1 PCB) ..5-4

5.3 Detailed Circuit Descriptions............................................................................5-4

5.3.1 AC Input and RFI Filter Circuit (A5 PCB) .............................................5-5

5.3.2 Input Rectifier and Inrush Limiting Circuit (A6 PCB) ............................5-5

5.3.3 PWM, Sync Circuit, Power Transformer Drive Circuit, and Power

Transistor Bridge (A3 PCB)..................................................................5-5

5.3.4 Power Transformer, Output Rectifiers, Output Filter Inductor and

Capacitor, and Down Programmer Circuit (A4 PCB, A7 PCB, A8 PCB,

and Power Stage Assembly)................................................................5-6

5.3.5 Auxiliary Supply, OVP, Control, Programming, Monitor Circuit (A2 PCB)57

5.3.6 Front Panel Displays and Controls (A1 PCB).....................................5-14

SECTION 6 MAINTENANCE......................................................... 6-1

6.1 Introduction ......................................................................................................6-1

6.1.1 Units Under Warranty...........................................................................6-1

6.2 General Service and Repair.............................................................................6-1

6.2.1 Periodic Maintenance...........................................................................6-1

6.2.2 Servicing Precautions...........................................................................6-2

6.2.3 Parts Replacement and Repairs ..........................................................6-2

6.2.4 Unusual or Erratic Operation................................................................6-2

6.3 Calibrating for Programming Accuracy ............................................................6-2

6.3.1 Voltage Programming Circuit Calibration.............................................6-3

6.3.2 Current Programming Circuit Calibration .............................................6-3

6.4 Replaceable Parts............................................................................................6-4

6.4.1 Parts Replacement and Modifications..................................................6-4

6.4.2 Ordering Parts......................................................................................6-4

6.4.3 DCS-E 3kW Parts Lists by Model Number...........................................6-5

vi M362295-01 Rev Cl

Page 17

Sorensen DCS-E Series 3kW Supplies Contents

SECTION 7 APPLICATION NOTES ...............................................7-1

7.1 Battery Charging.............................................................................................. 7-1

7.2 Load Considerations........................................................................................7-1

7.2.1 Inductive Loads....................................................................................7-1

LIST OF FIGURES

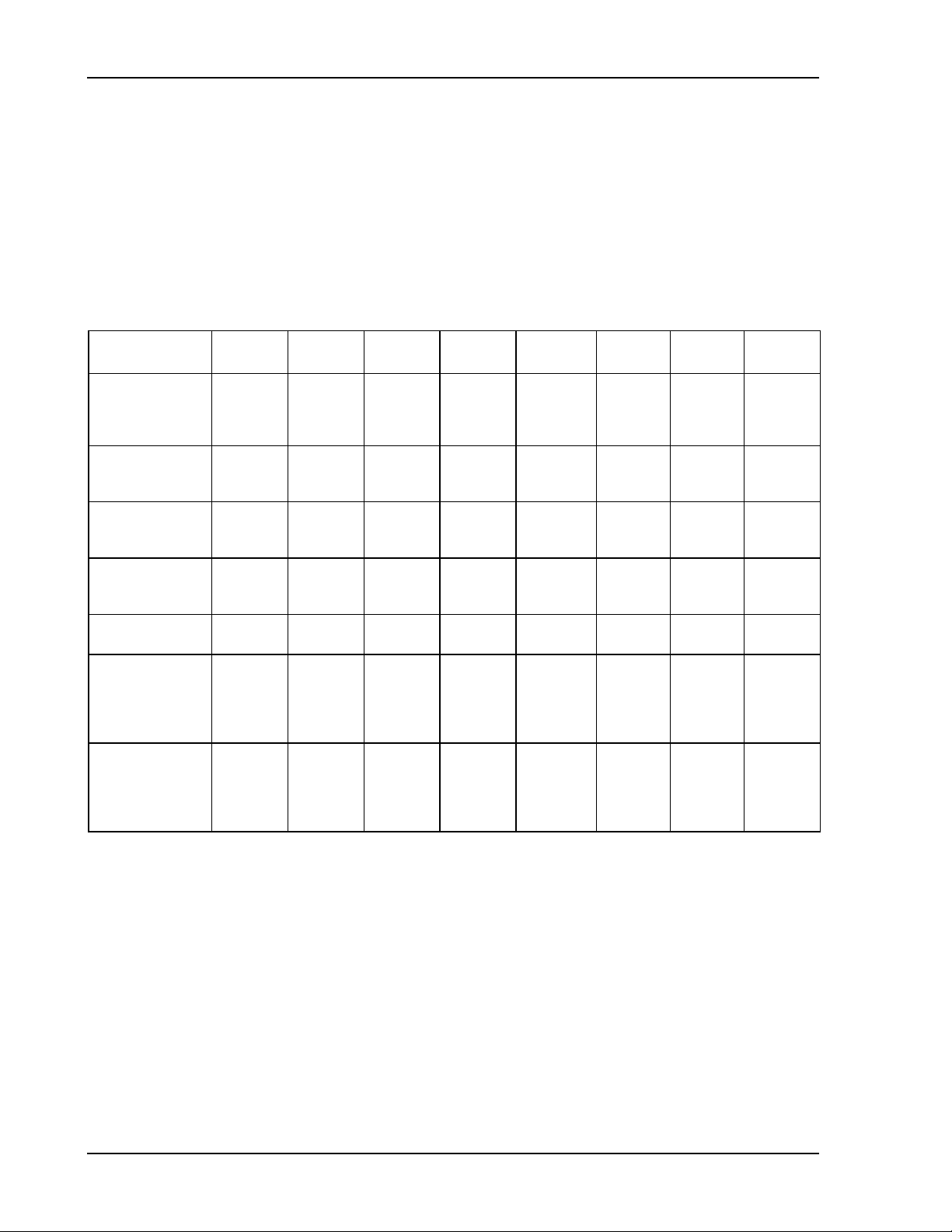

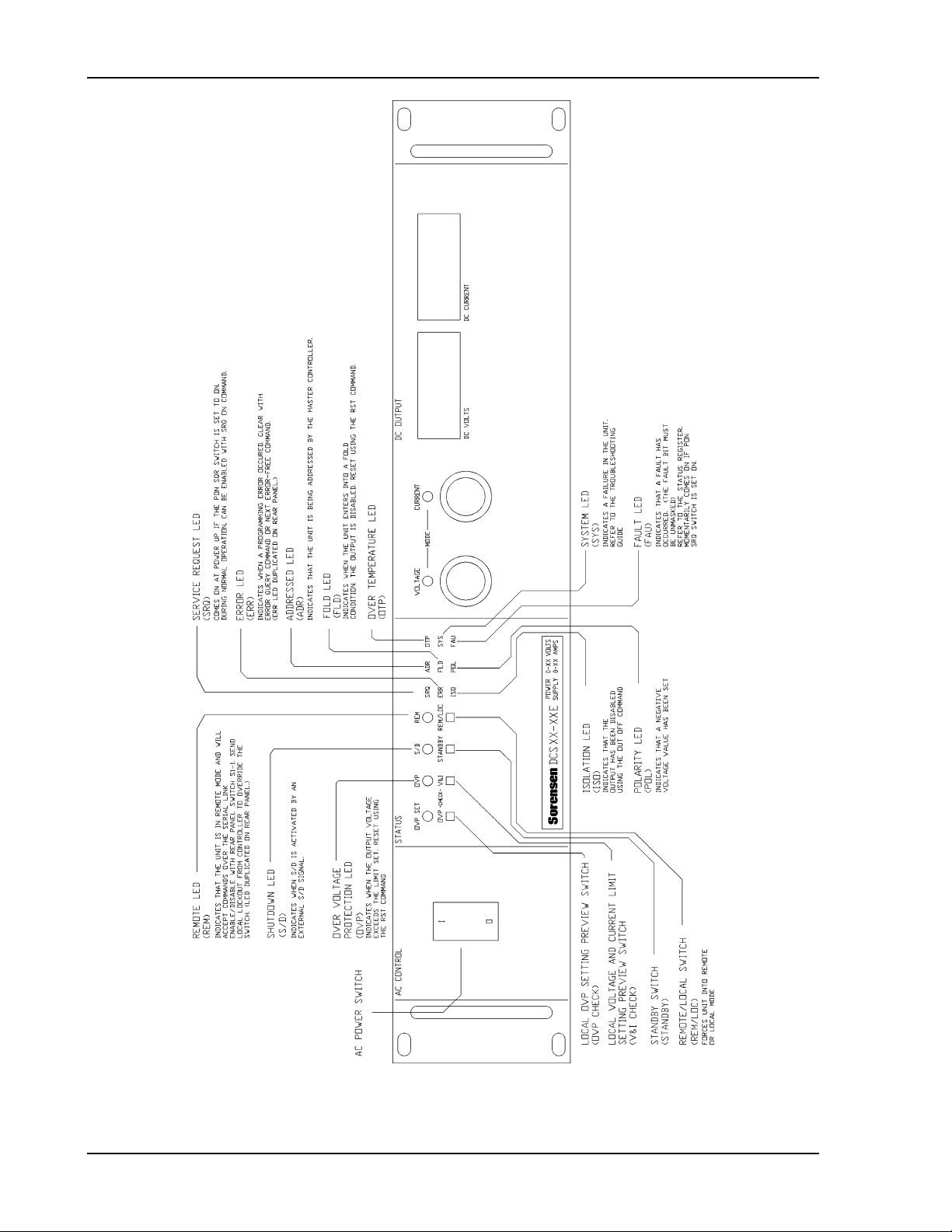

Figure 1-1 DCS-E Series (3kW) Supply Front Panel Controls and Indicators............1-4

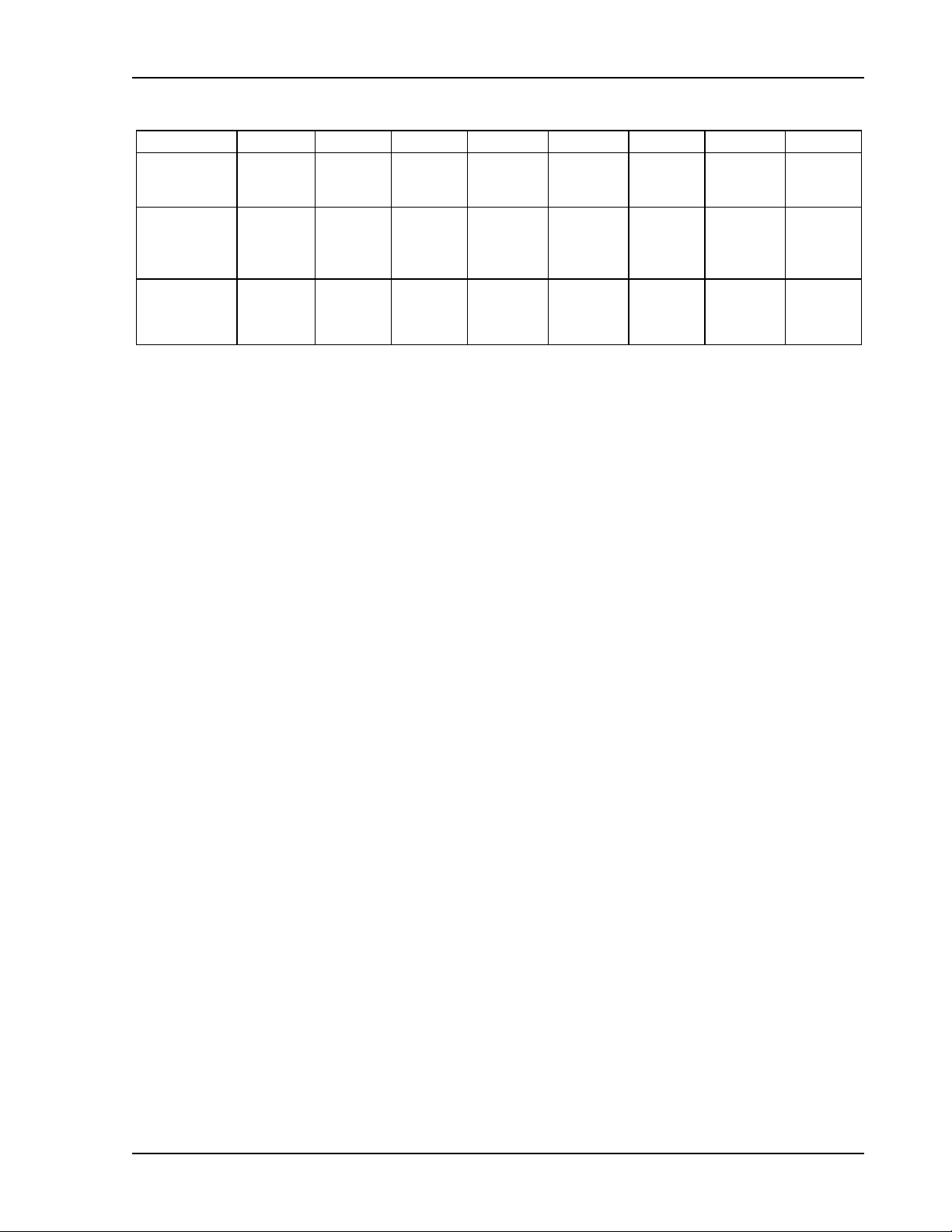

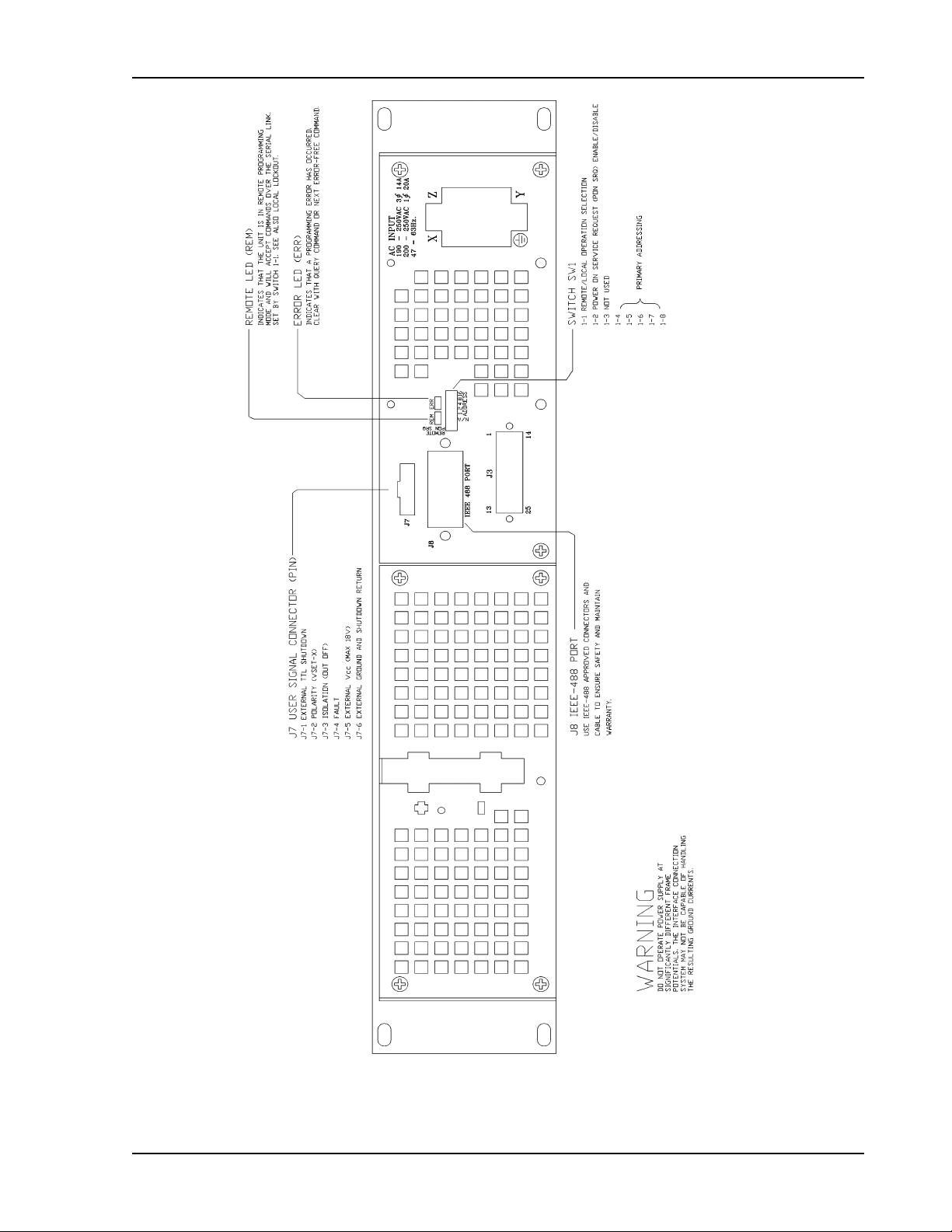

Figure 1-2 DCS-E Series (3kW) Supply Rear Panel Connectors and Terminals

(including optional internal GPIB Interface)..............................................1-5

Figure 2-1 AC Connector and Contacts ..................................................................... 2-5

Figure 2-2 Wire Preparation.......................................................................................2-5

Figure 2-3 Contact Orientation...................................................................................2-6

Figure 2-4 AC Wire Locations .................................................................................... 2-6

Figure 2-5 Strain Relief, as Supplied.......................................................................... 2-7

Figure 2-6 Strain Relief Assembly.............................................................................. 2-7

Figure 2-7 Connector J3 Default Configuration.......................................................... 2-8

Figure 2-8 Maximum Load Wire Length...................................................................2-11

Figure 2-9 Single Load with Local Sensing (Default) ............................................... 2-12

Figure 2-10 Single Load with Remote Sensing........................................................2-12

Figure 2-11 Multiple Loads with Local Sensing........................................................ 2-13

Figure 2-12 Multiple Loads with Remote Sensing....................................................2-13

Figure 3-1 Operating Modes.......................................................................................3-2

Figure 3-2 Local Mode Default Configuration.............................................................3-3

Figure 3-3 Connecting Remote Sense Lines..............................................................3-5

Figure 4-1 Connector J3 Pin Descriptions (for Remote Programming,

Remote Monitoring, and Sense Connections).......................................... 4-3

Figure 4-2 Internal Jumpers and Switch (Default Settings Shown)............................4-4

Figure 4-3 Programming Output Voltage and Current Limit Using the

Figure 4-4 Programming Output Voltage with a 0-5 Vdc Source ...............................4-9

M362295-01 Rev C

REM/LOC Switch......................................................................................4-8

vii

Page 18

Contents Sorensen DCS-E Series 3kW Supplies

Figure 4-5 Programming Output Voltage with a 0-10 Vdc Source............................4-10

Figure 4-6 Programming Output Voltage with a 0-1 mA Source...............................4-10

Figure 4-7 Programming Output Voltage with a 5k ohm Resistance........................4-11

Figure 4-8 Programming Output Current Limit with a 0-5 Vdc Source .....................4-12

Figure 4-9 Programming Output Current Limit with a 0-10 Vdc Source ...................4-12

Figure 4-10 Programming Output Current Limit with a 0-1 mA Source ....................4-13

Figure 4-11 Programming Output Current Limit with a 5k ohm Resistance..............4-13

Figure 4-12 Remote Programming of OVP with a 0-5 Vdc External

Voltage Source.....................................................................................4-15

Figure 4-13 Remote Programming of OVP with a 0 –10 Vdc External

Voltage Source.....................................................................................4-16

Figure 4-14 Using Shutdown with a TTL Compatible (Positive Logic)......................4-17

Figure 4-15 Using Shutdown with a TTL Compatible (Negative Logic)....................4-17

Figure 4-16 Using Shutdown with an AC or DC Input (Positive Logic).....................4-18

Figure 4-17 Using Shutdown with an AC or DC Input (Negative Logic) ...................4-18

Figure 4-18 Using Shutdown with Contact Closure

of a Normally OPEN Relay (Positive Logic)..........................................4-19

Figure 4-19 Using Shutdown with Contact Closure

of a Normally OPEN Relay (Negative Logic)........................................4-20

Figure 4-20 Using Shutdown with Contact Closure

of a Normally CLOSED Relay (Positive Logic).....................................4-20

Figure 4-21 Using Shutdown with Contact Closure

of a Normally CLOSED Relay (Negative Logic) ...................................4-20

Figure 4-22 Series Operation of Multiple Supplies ...................................................4-22

Figure 4-23 Parallel Operation of Multiple Supplies..................................................4-23

Figure 4-24 Split Supply Operation of Multiple Supplies

(Two Positive Voltages)........................................................................4-24

Figure 4-25 Split Supply Operation of Multiple Supplies

(Positive-Negative Supply) ...................................................................4-25

viii M362295-01 Rev Cl

Page 19

SECTION 1

INTRODUCING THE DCS-E

SERIES 3KW SUPPLY

1.1 DESCRIPTION

The DCS-E Series System Supplies are 3000–watt supplies designed to provide highly stable,

continuously variable output voltage and current for a broad range of development, system, and

burn-in applications. The DCS-E Series employs high frequency switching regulator technology

to achieve high power density and small package size.

The series consists of several models designated by the DCS prefix, followed by their output

voltage and current ratings. For example, the model number DCS 60-50E indicates that the unit

is rated at 0-60 Vdc and 0-50 Amps.

1.2 FEATURES

• Eight models with voltage ranges from 0-8 Vdc to 0-150 Vdc and current outputs from

20A to 350A.

• Input voltage 190-250 Vac, Three Phase, 47-63 Hz or 200-250 Vac, Single Phase, 47-63

Hz. (Output power limited to 2500W for single-phase input.)

• Simultaneous digital display of both DC output voltage and current.

• Ten-turn potentiometer voltage and current controls permit high resolution setting of the

output voltage and current from zero to the model-rated output.

• Front panel push button control of Output Standby Mode, OVP reset, Remote/Local

Programming Mode selection, and preview of voltage, current, or OVP setpoints.

• External indicator signals for Remote Monitoring of OVP Status, Local/Remote

Programming Status, Thermal Shutdown, and Output Voltage and Current.

• Current or Voltage Mode operation with Automatic Mode Crossover to respond to

varying load requirements.

• Flexible output configuration where multiple units can be connected in series or in

parallel to provide increased voltage or increased current.

• Remote Sensing to compensate for losses in power leads up to 1V per lead.

• Adjustable Over Voltage Protection (OVP).

M362295-01 Rev C 1-1

Page 20

Introduction Sorensen DCS-E Series 3kW Supplies

• External Shutdown using AC, DC, or TTL compatible signals (positive or negative logic).

• Remote Voltage, Current Limit, and OVP Programming with selectable programming

ranges.

• Optional IEEE-488 (GPIB) interface for complete digital remote programming and

readback capability.

1.3 SPECIFICATIONS

1.3.1 Electrical Specifications1

Models

Output Ratings

Output Voltage

Output Current

Output Power

Line Regulation2

Voltage

Current

Load Regulation3

Voltage

Current

Meter Accuracy

Voltage

Current

OVP Adjustment

Range

Output Noise and

Ripple (V)

Rms

p–p

(20 Hz – 20 MHz)

Analog

Programming

Linearity

Voltage

Current

1

Specifications are warranted over a temperature range of 0–50°C with default local sensing. From 50–70°C, derate 2% per °C.

2

For input voltage variation over the AC input voltage range, with constant rated load.

3

For 0-100% load variation, with constant nominal line voltage.

DCS

8-350E

0-8V

0-350A

2800W

8 mV

350 mA

8 mV

350 mA

0.09V

4.5A

0.4-8.8V 0.6-13.2V 1-22V

10 mV

100 mV

80 mV

3500 mA

DCS

12-250E

0-12V

0-250A

3000W

12 mV

250 mA

12 mV

250 mA

0.13V

3.5A

10 mV

100 mV

120 mV

2500 mA

DCS

20-150E

0-20V

0-150A

3000W

20 mV

150 mA

20 mV

150 mA

0.2V

0.1.6A

10 mV

100 mV

200 mV

1500 mA

DCS

40-75E

0-40V

0-75A

3000W

40 mV

75 mA

40 mV

75 mA

0.5V

0.85A

2-44V

20 mV

100 mV

400 mV

750 mA

DCS

55-55E

0-55V

0-55A

3025W

55 mV

55 mA

55 mV

55 mA

0.65V

0.65A

2.75-60.5V 3-66V

20 mV

100 mV

550 mV

550 mA

DCS

60-50E

0-60V

0-50A

3000W

60 mV

50 mA

60 mV

50 mA

0.7V

0.6A

20 mV

100 mV

600 mV

500 mA

DCS

80-37E

0-80V

0-37A

2960W

80 mV

37 mA

80 mV

37 mA

0.9V

0.47A

4-88V

20 mV

100 mV

800 mV

370 mA

DCS

150-20E

0-150V

0-20A

3000W

150 mV

20 mA

150 mV

20 mA

1.6V

0.30A

7.5-165V

30 mV

200 mV

1.5V

200 mA

AC Input: 200-250 Vac at 20 Arms Single Phase or 190-250 Vac at 14 Arms Three Phase

(Output power limited to 2500W for single phase input)

Maximum Voltage Differential from output to safety ground: 150 Vdc

1-2 M362295-01 Rev C

Page 21

Sorensen DCS-E Series 3kW Supplies Introduction

ADDITIONAL CHARACTERISTICS

Models DCS8-350E DCS12-250E DCS20-150E DCS40-75E DCS55-55E DCS60-50E DCS80-37E DCS150-20E

Stability4

Voltage

Current

Temperature

Coefficient5

Voltage

Current

Maximum

Remote Sense

Line Drop

Compensation

4

Maximum drift over 8 hours with constant line, load, and temperature, after 90–minute warmup.

5

Change in input per °C change in ambient temperature with constant and load.

4 mV

175 mA

1.6 mV/°C

105 mA/°C

1V/line 1V/line 1V/line 1V/line 1V/line 1V/line 1V/line 1V/line

6 mV

125 mA

2.4 mV/°C

75 mA/°C

10 mV

75 mA

4 mV/°C

45 mA/°C

20 mV

37.5 mA

8 mV/°C

22.5 mA/°C

27.5 mV

27.5 mA

11 mV/°C

16.5 mA/°C

30 mV

25 mA

12 mV/°C

15 mA/°C

40 mV

18.5 mA

16 mV/°C

11.1 mA/°C

75 mV

10 mA

30 mV/°C

6.0 mA/°C

Operating Ambient Temperature:

0 - 50°C No derating. From 50 - 70°C, derate output 2% per °C

Storage Temperature Range: -55 to +85°C

Humidity Range: 0 - 80 % Non-condensing

Time Delay from power on until output stable: 5 seconds maximum

Switching Frequency: Nominal 30 kHz (60 kHz output ripple)

Voltage Mode Transient Response Time:

1 mS recovery to 1% band for 30% step load change from 70% to 100% or 100% to 70%

Remote Start/Stop and Interlock:

TTL Compatible Input, Contact Closure, 12 – 250 Vac or 12 – 130 Vdc

Remote Analog Programming (Full Scale Input)

Parameter Resistance Voltage Current

Voltage 0 - 5k 0 - 5V, 0 - 10V 0 - 1 mA

Current 0 - 5k 0 - 5V, 0 - 10V 0 - 1 mA

OVP — 0 - 5V, 0 - 10V —

1.3.2 Mechanical Specifications

Size: 87.6 mm H x 482.6 mm W x 508 mm D (3.45 in H x 19 in W x 20 in D)

Weight: 16 kg (35 lbs) (approx.)

Output Connector:

Nickel-plated copper bus bars: 2.25" x 1.0" x 0.125" (2.25" x 1.0" x 0.25" for 8V & 12V models)

Bus bar load wiring mounting holes:

One 0.332" diameter hole;

1

/4" hardware (5/16" hardware for 8V and 12V models)

Two 0.190" diameter holes on 0.5" centers; #10 hardware

Input Connector:

Chassis-Mounted Part: Housing Tyco 641685-1; Contact pins Tyco 350821-1

Mating Connector Parts: Housing Tyco 643267-1; Contact pins Tyco 350821-1

M362295-01 Rev C 1-3

Page 22

Introduction Sorensen DCS-E Series 3kW Supplies

Figure 1-1 DCS-E Series (3kW) Supply Front Panel Controls and Indicators

1-4 M362295-01 Rev C

Page 23

Sorensen DCS-E Series 3kW Supplies Introduction

Figure 1-2 DCS-E Series (3kW) Supply Rear Panel Connectors and Terminals

(including optional internal GPIB Interface)

M362295-01 Rev C 1-5

Page 24

Introduction Sorensen DCS-E Series 3kW Supplies

This page intentionally left blank.

1-6 M362295-01 Rev C

Page 25

SECTION 2

INSTALLATION

2.1 INTRODUCTION

This section provides recommendations and procedures for inspecting, testing, and installing

the DCS-E Series power supply.

1. Read and follow the safety recommendations (Section 2.2)

2. Perform an initial physical inspection of the supply (Section 2.3)

3. Install the supply (bench or rack mount), ensuring adequate ventilation (Section 2.4)

4. Assemble and connect the AC input power connector (Section 2.5.1)

5. Perform initial function tests for voltage mode operation, current mode operation, and

front panel controls (Section 2.6)

6. Connect the load (Section 2.7)

Instructions for Local Programming Mode operation (Constant Voltage and Constant Current)

are given in Section 3 Basic Operation. Remote Programming operation, monitoring, and

programmable functions are described in Section 4 Advanced Operation.

2.2 SAFETY

Please review the following points for both personal and equipment safety while using the

DCS-E Series power supplies.

2.2.1 High Energy/High Voltage Warning

Exercise caution when using and servicing power supplies. High energy levels can

be stored at the output voltage terminals on all power supplies in normal operation.

In addition, potentially lethal voltages exist in the power circuit and the output

connector of power supplies that are rated at 40V and over. Filter capacitors store

potentially dangerous energy for some time after power is removed.

Use extreme caution when biasing the output relative to the chassis due to potential

high voltage levels at the output terminals. The output of the DCS-E Series supplies

(3kW models) may be biased up to a maximum of 150 Vdc relative to the chassis.

M362295-01 Rev C 2-1

Page 26

Installation Sorensen DCS-E Series 3kW Supplies

2.2.2 AC Source Grounding

Ensure the power supply is connected to an appropriately rated AC outlet with the

recommended AC input connector as set out in Section 2.5.1 AC Input Power Connection.

There is a shock hazard if the power supply chassis and cover are not connected to an

electrical ground via the safety ground in the AC input connector. The third wire in a single

phase AC input connector and the fourth wire in a three phase AC input connector must be

connected to an electrical ground at the power outlet. Any disconnection of this ground will

cause a potential shock hazard to operating personnel.

This power supply is equipped with an AC line filter to reduce electromagnetic interference and

must be connected to a properly grounded receptacle, or a shock hazard will exist.

Operating the supply at line voltages or frequencies in excess of those specified may cause

leakage currents in excess of 5.0 mA peak from the AC line to the chassis ground.

2.2.3 Operating and Servicing Precautions

Exceeding the maximum model-rated input voltage may cause permanent damage to the unit.

Always disconnect power, discharge circuits, and remove external voltage sources before

making internal adjustments or replacing components. When performing internal adjustments or

servicing the power supply, ensure another person with first aid and resuscitation certification is

present. Repairs must be made by experienced technical personnel only.

Be sure to isolate the power supply from the input line with an isolation transformer when using

grounded test equipment, such as an oscilloscope, in the power circuit.

The power supply must not be operated where flammable gases or fumes exist.

2.2.4 Parts and Modifications

Do not use substitute parts or make unauthorized modifications to the power supply to ensure

that its safety features are not degraded. Contact the manufacturer for service and repair help.

2-2 M362295-01 Rev C

Page 27

Sorensen DCS-E Series 3kW Supplies Installation

2.3 INITIAL INSPECTION

On first receiving your DCS-E Series power supply, perform a quick physical check, paying

particular attention to front panel controls and indicators as well as rear panel connectors and

terminals. See Figure 1-1 and Figure 1-2 for front and rear panel diagrams.

2.3.1 Physical Check

After unpacking, perform an initial inspection to ensure the unit and parts shipped with it have

not been damaged in transit. The package should contain the power supply, a manual, one (1)

AC input connector, and five (5) contact pins.

1. Inspect for dents and scratches to the cover and chassis; for scratches and cracks on

the front and rear panels; and for any broken controls, connectors, or displays.

2. Turn front panel controls from stop to stop. Rotation should be smooth.

3. Test the action of the power switch. Switching action should be positive.

4. If internal damage is suspected, remove the cover and check for printed circuit board

and/or component damage. Reinstall cover.

If damage is found to have occurred, save all packing materials and notify the carrier

immediately. Refer to the terms of the warranty. Direct repair problems to the manufacturer.

Note: Section 2.6 Initial Functional Tests contains electrical and operational tests you can

perform to ensure the unit is in proper working order after shipment. The tests are to be

performed once the AC input connector has been assembled but before the load has

been connected to the power supply.

2.4 LOCATION, MOUNTING, AND VENTILATION

The DCS-E system supply may be used in rack mounted or in benchtop applications. In either

case, you must allow at least 1U (1.75“) clearance for cooling air to reach the ventilation inlets

on the top of each unit. You must also allow sufficient space for unobstructed airflow on each

side and rear of all units so that the operating ambient temperature is within specification (see

Section 1.3, Specifications, in this manual).

Obstructing the air inlets and/or exhaust may cause fire and irreversible

damage to the unit.

CAUTION!

2.4.1 Unit Dimensions

Single Unit Height Width Depth Weight

Standard 3.45 in 19 in 20 in 35 lbs

Metric 87.6 mm 482.6 mm 508 mm 16 kg

M362295-01 Rev C 2-3

Page 28

Installation Sorensen DCS-E Series 3kW Supplies

2.4.2 Rack Mounting

The supply is designed to fit in a standard 19” equipment rack. Bolt holes in the chassis sides

are provided for rack mount slides such as the ZERO #C300S18 slides. When installing the unit

in a rack, be sure to provide adequate support for the rear of the unit while not obstructing the

ventilation on the top, sides and rear of all units. (See Section 2.4, Location, Mounting, and

Ventilation in this manual).

3

/

16" into the side of the

CAUTION!

Rack mounting bolts must not extend more than

power supply.

2.5 AC INPUT POWER

Section 2.5.1 AC Input Power Connection gives instructions for making connections to either

single phase or three phase AC power sources. Order replacement AC input connectors and

contacts using the following part numbers.

Chassis-Mounted Parts

Mating Connector Parts

Housing Tyco 641685-1

Contact Pins Tyco 350821-1

Connector Housing Tyco 643267-1

Contact Pins Tyco 350821-1

2.5.1 AC Input Power Connection

Before you can use the DCS-E system supply, you must determine your AC input power

requirements and assemble an appropriate line cord and connector. The power supply is

shipped with a kit of connector and strain relief parts which you assemble using the procedures

in this section.

2.5.2 AC Input Power Requirements

This supply may be operated from either a single phase or a three phase AC power source. The

specifications for input voltage, current, and frequency are listed below.

AC Input Voltage Range Maximum Input Current Frequency

200-250 Vac Single Phase 20 Arms 47-63 Hz

190-250 Vac Three Phase 14 Arms 47-63 Hz

The maximum output power must be limited to 2500 Watts when the power

supply is used with a single phase input to avoid tripping the power

CAUTION!

2-4 M362295-01 Rev C

supply's input circuit breaker.

Page 29

Sorensen DCS-E Series 3kW Supplies Installation

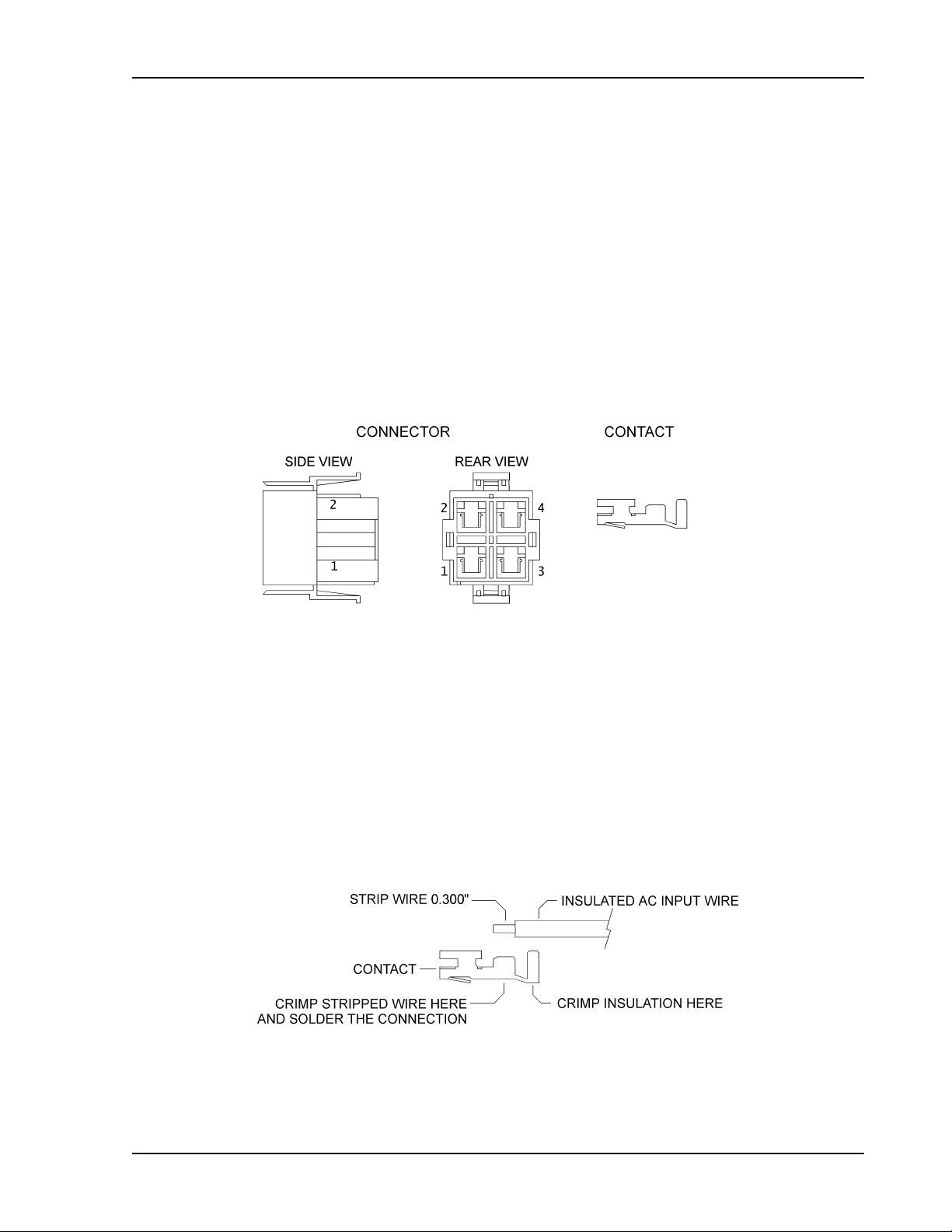

2.5.3 AC Input Connector Assembly

Each unit is shipped with a connector and contacts which mate with the chassis-mounted AC

connector located on the rear panel. See Figure 2-1 AC Connector and Contacts.

P

ARTS SUPPLIED

• One (1) connector Part number MI-6432-672, Tyco 643267-1

• Five (5) contacts Part number MC-3508-211, Tyco 350821-1

A

DDITIONAL PARTS REQUIRED

• 8 to 12 AWG wiring: three (3) wires for single phase inputs or four (4) wires for three

phase inputs. The neutral CONNECTOR wire of three-phase four (4) wire systems is not

required.

Figure 2-1 AC Connector and Contacts

IRE PREPARATION

W

1. Trim outer wire jacket 2". (Necessary for strain relief. See Section 2.5.4.)

2. Strip 0.300" at the end of the insulated AC input wire.

3. Crimp the stripped wire into the contact as indicated in Figure 2-2, then solder the

connection.

4. Crimp the contact around the wire insulation as indicated in Figure 2-2.

Figure 2-2 Wire Preparation

M362295-01 Rev C 2-5

Page 30

Installation Sorensen DCS-E Series 3kW Supplies

CONTACT INSTALLATION

5. Insert contact with attached wire into the connector until lock snaps into place. See

Figure 2-3 and Figure 2-4 to complete the connector for either single or three phase

input.

Figure 2-3 Contact Orientation

Figure 2-4 AC Wire Locations

2.5.4 Strain Relief Assembly

The strain relief is assembled from supplied pieces and attaches to the AC input connector to

provide support for the AC input cord.

P

ARTS SUPPLIED

• Two (2) pieces strain relief Part number MI-6432-661, Tyco 643266-1

• Two (2) screws Part number MS-6PPS-10 (screw #6-32, 5/8” long, self tapping)

A

SSEMBLY INSTRUCTIONS

1. Snap off the rectangular bushing attached to each piece of the strain relief.

See Figure 2-5.

2. Install bushings on strain relief pieces, if required:

If cable diameter is within 0.1" to 0.4", install bushings.

If cable diameter is within 0.5" to 0.74", do not use bushings.

2-6 M362295-01 Rev C

Page 31

Sorensen DCS-E Series 3kW Supplies Installation

Figure 2-5 Strain Relief, as Supplied

3. Insert strain relief tab A into AC input connector slot B. Insert second strain relief tab A

into AC input connector slot C. See Figure 2-6.

4. Install screws in holes provided on outside of strain relief pieces. Thread through to

screw standoff inside opposite piece. Tighten to clamp outer jacket of AC wire securely,

ensuring that the side of the strain relief slips into the corresponding rabbet on the

opposite piece.

Figure 2-6 Strain Relief Assembly

M362295-01 Rev C 2-7

Page 32

Installation Sorensen DCS-E Series 3kW Supplies

2.6 INITIAL FUNCTIONAL TESTS

The initial functional test procedure includes power-on and front panel function checks as well

as voltage or current mode operation checks. See Figure 1-1 and Figure 1-2 for front and rear

panel diagrams.

Before starting this procedure, ensure that the J3

programming connector is in place on the rear panel

with jumpers connected for local operation as shown in

Figure 2-7. This is the default configuration as shipped

from the factory. If the unit has been in use and is being

retested, ensure you disconnect the load, reset the J3

jumpers to the default, and turn the OVP potentiometer

to maximum before performing these tests.

2.6.1 Power-on Check

1. Ensure that the AC power switch is in the OFF position.

Note: AC power must be off for a minimum of 45 seconds before powering on again.

Figure 2-7 Connector J3

Default Configuration

2. Turn the voltage and current controls fully counter-clockwise.

3. Connect the unit to an AC outlet.

4. Turn the front panel AC power switch ON.

After a short, power-on delay, the front panel digital meters will light up. Both voltmeter and

ammeter displays will read zero. The green voltage mode LED will be illuminated.

2.6.2 Voltage Mode Operation Check

1. Ensure the voltage and current controls on the front panel are turned fully counterclockwise.

2. Connect a Digital Voltmeter (DVM) to the output terminals on the rear panel, observing

correct polarity. The DVM must be rated better than 0.5% accuracy.

3. Turn the CURRENT control a 1/2-turn clockwise. Slowly turn the VOLTAGE control

clockwise and observe both the front panel voltmeter and the DVM.

4. Compare the DVM reading with the front panel voltmeter reading to verify the accuracy

of the internal voltmeter.

The minimum control range will be from zero to the maximum rated output for this particular

power supply model. The green voltage mode LED will be illuminated.

5. Turn the front panel AC power switch OFF.

2-8 M362295-01 Rev C

Page 33

Sorensen DCS-E Series 3kW Supplies Installation

2.6.3 Current Mode Operation Check

1. Ensure the front panel AC power switch is set to OFF.

2. Turn the voltage and current controls on the front panel fully counter-clockwise.

3. Turn the VOLTAGE control one (1) or two (2) turns clockwise.

4. Connect a DC shunt across the output terminals on the rear panel, using appropriately

gauged wire and hardware. The recommended current ratings for the DC shunt and the

wire must be at least 10% more than the output current of the power supply model.

5. Connect a Digital Voltmeter (DVM) across the DC shunt. The DC shunt-DVM

combination must be rated better than 0.5% accuracy.

6. Turn the AC power switch ON.

7. Turn the CURRENT control slowly clockwise.

8. Compare the DVM reading with the front panel ammeter reading using I=V/R where V is

the DVM reading and R is the DC shunt resistance.

The control range will be from zero to the maximum rated output for the power supply model.

The red current mode LED will be illuminated.

2.6.4 Front Panel Function Checks

1. Press OVP CHECK switch and check that the voltmeter displays approximately the

model-rated output voltage plus 10%.

2. Turn OVP SET potentiometer counter-clockwise and check that the voltmeter reading

decreases. Continued turning (up to 20 turns) will see the reading decrease to

approximately 5% of the model-rated voltage output. Turn the potentiometer clockwise

until the voltmeter once again displays approximately the model-rated output voltage

plus 10%.

3. With voltage and current controls turned all the way in a clockwise direction, press the V

& I CHECK switch and check that the voltmeter and ammeter display a minimum of the

power supply model output ratings.

4. With voltage and current controls turned all the way in a clockwise direction, push the

STANDBY switch to its IN position and check that the voltmeter reading falls to zero and

the S/D (Shutdown) LED illuminates. Push the STANDBY switch once again to reset it to

its OUT position. The S/D LED will turn off.

5. Push REM/LOC switch to IN position and check that the REM LED illuminates and the

voltmeter reading falls to zero. Reset the REM/LOC switch to its OUT position for local

(default) operation.

M362295-01 Rev C 2-9

Page 34

Installation Sorensen DCS-E Series 3kW Supplies

2.7 LOAD CONNECTION

This section provides recommendations for load wiring and connecting as they apply to both

single and multiple load configurations.

2.7.1 Load Wiring

When connecting load wiring to the power supply, you must consider the following factors:

• the current carrying capacity of the wire,

• the maximum load wiring length for operation with sense lines, and

• noise and impedance effects of the load lines.

C

URRENT CARRYING CAPACITY

As a minimum, load wiring must have a current capacity greater than the output current rating of

the power supply. This ensures that the wiring will not be damaged even if the load is shorted.

The table below shows the maximum current rating, based on 450 amps per square centimeter,

for various gauges of wire rated for 105°C operation. Operation at the maximum current rating

results in approximately a 30-degree temperature rise for a wire operating in free air. Where

load wiring must operate in areas with elevated ambient temperatures or bundled with other

wiring, larger gauges or higher temperature-rated wiring should be used.

AWG Maximum Current AWG Maximum Current

16 7 4 106

14 11 2 170

12 18 1 209

10 23 1/0 270

8 39 2/0 330

6 67 3/0 350

L

OAD WIRING LENGTH FOR OPERATION WITH SENSE LINES

For applications using remote sensing, the voltage drop across each load line must be limited to

1V or less. Figure 2-8 shows the maximum allowable wire length that may be used for a given

load current and wire size to ensure that this limit is not exceeded.

2-10 M362295-01 Rev C

Page 35

Sorensen DCS-E Series 3kW Supplies Installation

Figure 2-8 Maximum Load Wire Length

OISE AND IMPEDANCE EFFECTS

N

To minimize noise pickup or radiation, load wires should be shielded-twisted pair wiring of as

short a length as possible. Connect the shield to the chassis via a rear panel mounting screw.

Where shielding is impossible or impractical, simply twisting the wires together will offer some

noise immunity. When using local sense connections, use the largest practical wire size to

minimize the effects of load line impedance on the regulation of the supply.

2.7.2 Making the Connections

Load connections to the power supply are made at the positive and negative output terminals

(or bus bars) at the rear of the power supply. Refer to the rear panel diagram in Figure 1-2. The

power supply provides three load wiring mounting holes on each bus bar terminal as specified

in the following table.

Load Wiring Mounting Holes Diameter Hardware Size

One (1) per terminal 0.332" 1/4" (5/16" for 8V and 12V models)

Two (2) per terminal 0.190" on 0.5" centers #10

When making connections to the bus bars, ensure each terminal's mounting hardware and

wiring assembly is placed to avoid touching the other terminal (or EMI core)

power supply output. Heavy connecting cables must have some form of strain relief to avoid

loosening the connections or bending the bus bars.

and shorting the

M362295-01 Rev C 2-11

Page 36

Installation Sorensen DCS-E Series 3kW Supplies

2.7.3 Connecting Single Loads

Figure 2-9 and Figure 2-10 show recommended load and sensing connections for single loads.

Local sense lines shown are default J3 connections. Refer to Section 3.3.1 Connecting

Remote Sense Lines for more information about the sense line shield.

Figure 2-9 Single Load with Local Sensing (Default)

Figure 2-10 Single Load with Remote Sensing

2.7.4 Connecting Multiple Loads

Proper connection of distributed loads is an important aspect of power supply applications. Two

common methods of connection are the parallel power distribution method and the radial

distribution method.

P

ARALLEL POWER DISTRIBUTION

This common method involves connecting leads from the power supply to one load, from that

load to the next load, and so on for each load in the system. This distribution method results in

the voltage at each load depending on the current drawn by the other loads, allowing dc ground

loops to develop. Except for low current applications, this method is not recommended.

2-12 M362295-01 Rev C

Page 37

Sorensen DCS-E Series 3kW Supplies Installation

RADIAL DISTRIBUTION METHOD

With this method, power is connected to each load individually from a single pair of terminals

designated as the positive and negative distribution terminals. These terminals may be the

power supply output terminals, the terminals of one of the loads, or a distinct set of terminals

especially established for distribution use. Connecting the sense leads to these terminals will

compensate for losses and minimize the effect of one load upon another.

Figure 2-11 and Figure 2-12 show recommended load and sensing connections for multiple

loads. Local sense lines shown are default J3 connections. Refer to Section 3.3.1 Connecting

Remote Sense Lines for more information about grounding the sense line shield.

Figure 2-11 Multiple Loads with Local Sensing

Figure 2-12 Multiple Loads with Remote Sensing

M362295-01 Rev C 2-13

Page 38

Installation Sorensen DCS-E Series 3kW Supplies

This page intentionally left blank.

2-14 M362295-01 Rev C

Page 39

SECTION 3

BASIC OPERATION

3.1 INTRODUCTION

Once the power supply installation is complete and both the AC input power and the load have

been connected (see Section 2 Installation), the DCS-E Series power supply is in its default

configuration and is ready to operate in local programming mode.

This section covers Constant Voltage and Constant Current Mode operation as controlled by

local programming (Section 3.2). Remote sensing for voltage mode operation is described and

illustrated in Section 3.3.

Remote Programming operation, monitoring, and programmable functions are described in

Section 4 Advanced Operation.

3.2 STANDARD OPERATION

The DCS-E Series power supply has two basic operating modes: Constant Voltage Mode and

Constant Current Mode, and two control modes: Local Programming Mode (default setting)

and Remote Programming Mode. Both operating modes are available regardless of which

control mode is used.

This section deals with power supply operations using the default Local Programming Mode in

both Constant Voltage Mode and Constant Current Mode. Remote Programming Mode as well

as monitoring and programmable functions information is found in Section 4 Advanced

Operation. See also Section 3.3 for remote sense operations.

3.2.1 Operating Modes and Automatic Crossover

Whether controlled by local or remote programming, the power supply has two basic operating

modes: Constant Voltage Mode and Constant Current Mode. The mode in which the power

supply operates at any given time depends on the combination of:

• the output voltage setting V

• the output current limit setting I

• the resistance of the attached load R

M362295-01 Rev C 3-1

SET

,

SET

, and

.

L

Page 40

Basic Operation Sorensen DCS-E Series 3kW Supplies

Figure 3-1 provides a graphical representation of the relationships between these variables.

C

ONSTANT VOLTAGE MODE OPERATION

The power supply will operate in constant voltage mode whenever the load current I

than the current limit setting I

SET

, or: I

< I

L

(Note: IL = V

SET

SET

/ RL)

is less

L

In constant voltage mode, the power supply maintains the output voltage at the selected value

(V

) while the load current I

SET

C

ONSTANT CURRENT MODE OPERATION

varies with the load requirements.

L

The power supply will operate in constant current mode whenever the load resistance is low

enough that the load current I

is greater than the current limit setting I

L

SET

, or: IL > I

SET

In constant current mode, the power supply maintains the output current at the selected value

(I

) while the load voltage varies with the load requirements.

SET

Figure 3-1 Operating Modes

UTOMATIC MODE CROSSOVER

A

This feature allows the power supply to automatically switch operating modes in response to

changing load requirements. If, for instance, the power supply was operating in Constant

Voltage Mode (I

than the current limit setting (I

< I

L

), and the load changed so that the load current (IL) became greater

SET

), the power supply would automatically switch into Constant

SET

Current Mode. If the additional load was subsequently removed so that the load current was

again less than the current limit setting, the supply would automatically return to Constant

Voltage Mode.

3-2 M362295-01 Rev C

Page 41

Sorensen DCS-E Series 3kW Supplies Basic Operation

3.2.2 Local Programming Mode Operation

Units are shipped from the factory configured for local programming mode operation. In local

programming mode:

• Output voltage and current limit settings are adjusted with the front panel controls.

• The sense point of the supply is at the output terminals.

• The front panel OVP potentiometer determines the OVP set point. See Section 4.4

Using Over Voltage Protection (OVP) for the adjustment procedure.

L

OCAL MODE DEFAULT CONFIGURATION

Figure 3-2 shows the default factory settings for the internal jumpers JMP1 and JMP2, for

switch SW1, and for rear panel connector J3. These controls are used to select among the

various options for programming, sensing, and monitoring. See Section 4.2 Configuring for

Remote Programming, Sensing, and Monitoring.

Figure 3-2 Local Mode Default Configuration

ETTING OUTPUT VOLTAGE AND CURRENT LIMIT

S

After installing the power supply and connecting the load as described in Section 2

Installation, set the required output voltage and current limit according to the following front

panel procedure:

1. Turn both the voltage and current controls fully counter-clockwise.

2. Turn the AC power ON.

3. Press the STANDBY switch to its IN position to disable the power supply output.

4. Press and hold the V & I CHECK button to display the voltage and current control

settings on the voltmeter and ammeter displays.

5. Adjust the voltage control to the required voltage (the compliance voltage for

applications using current mode operation).

6. Adjust the current control to the required current limit setting.

7. Release the V & I CHECK button.

8. Press the STANDBY switch to its OUT position to apply power to the load.

M362295-01 Rev C 3-3

Page 42

Basic Operation Sorensen DCS-E Series 3kW Supplies

3.3 USING REMOTE SENSING

Remote sensing is used during voltage mode operation to shift the power supply's regulation

point from its output terminals (default sense point) to the load or distribution terminals by using

a separate pair of wires to monitor the load voltage. Remote sensing allows the power supply to

compensate for voltage losses in the load lines (up to 1V per line) which will otherwise degrade

the regulation of the supply. The sense line connection points are located on the rear panel J3

connector. See Section 4.2 for more information about making J3 connector changes.

Do not use remote sensing with multiple supplies connected in series or

in parallel.

CAUTION!

3.3.1 Connecting Remote Sense Lines

To connect remote sense lines, refer to Figure 3-3 and to the following procedure:

1. Ensure the power supply is turned OFF. Allow five (5) minutes to elapse to dissipate

stored energy before altering J3 connector pin connections.

2. Remove the local sense jumpers connecting J3 pins 13 to 25 (positive sense) and pins

12 to 24 (negative sense or return sense).

3. Connect the positive sense lead to pin 13 and the negative lead to pin 12. Use shieldedtwisted pair wiring of 24 AWG or larger for sense lines.

4. Ground the sense line shield, at one point only, to the power supply's return output

connection at the load, or, to the power supply's return output at its output terminal, or to

the power supply's chassis.

5. The optimal point for the shield ground must be determined by experiment, but the most

common connection point is at the power supply's return output connection at the load.

6. Turn the power supply ON.

Notes:

1. If the power supply is operated with remote sense lines connected and with either of the

positive or negative load lines not connected, the power supply shutdown circuit will be

activated, causing the output voltage and current to fall to zero.

2. If the power supply is operated without remote sense lines or local sense jumpers in

place, the supply will continue to work, but supply regulation will be degraded and/or

erratic.

3-4 M362295-01 Rev C

Page 43

Sorensen DCS-E Series 3kW Supplies Basic Operation

Figure 3-3 Connecting Remote Sense Lines

Do not use remote sensing with multiple supplies connected in series or

in parallel.

CAUTION!

M362295-01 Rev C 3-5

Page 44

Basic Operation Sorensen DCS-E Series 3kW Supplies

This page intentionally left blank.

3-6 M362295-01 Rev C

Page 45

SECTION 4

ADVANCED OPERATION

4.1 INTRODUCTION

All DCS-E Series power supplies offer the following standard features:

• Remote Programming of Output Voltage and Current Limit with 0-5V, 0-10V, 0-1 mA,

and 0-5k ohms (Section 4.3)

• Overvoltage Protection (OVP) with front panel controls or 0-5V and 0-10V programming

(Section 4.4)

• Programmable Shutdown with AC, DC, or TTL compatible signals and contact closure

(Section 4.5)

• Remote Monitoring of Status Indicators for thermal shutdown, OVP status, remote/local

programming mode, and voltage/current mode operation (Section 4.6)

• Calibrated Readback Signals for output voltage and output current with selectable 0-5V

or 0-10V scales (Section 4.6)

• Multiple Supply Configurations such as series, parallel, and split supply (Section 4.7)

• Remote Voltage Sensing (Section 3.3)

• Output Voltage Biasing (Section 4.8)

Accessing these features may require that you use one or more of the following procedures:

• Using the front panel REM/LOC (Remote/Local Programming) switch.

• Reconfiguring the rear panel J3 connector.

• Making connections to the J3 connector.

• Resetting internal jumpers JMP1 and JMP2.

• Resetting internal switch SW1.

M362295-01 Rev C 4-1

Page 46

Advanced Operation Sorensen DCS-E Series 3kW Supplies

4.2 CONFIGURING FOR REMOTE PROGRAMMING, SENSING, AND MONITORING

This section lists switch, connector, and jumper functions for the DCS-E Series (3kW) supply.

Subsequently, it provides a location diagram (Section 4.2.2), in addition to procedures for

resetting the internal jumpers and switches (Section 4.2.3), and for reconfiguring or making

connections to the J3 connector (Section 4.2.4).

You will find remote programming procedures and diagrams covered in more detail in

Section 4.3, remote sensing in Section 3.3, and remote monitoring of readback signals and

status indicators in Section 4.6.

4.2.1 Programming, Monitoring, and Control Functions

FRONT PANEL REM/LOC SWITCH

You can use the REM/LOC (Remote/Local Programming) switch for remote programming.

When set to REM (Remote Programming), control of BOTH output voltage AND current limit is

passed to external voltage and/or current sources which are connected to the J3 connector.

Resetting the switch to LOC returns the supply to local (front panel) control. See Section 4.3 for

more information about using this switch.

E

XTERNAL J3 CONNECTOR

The external J3 connector provides user access to the following functions:

• Remote programming of output voltage OR current limit, and for OVP

• Remote monitoring of the following readback signals and status indicators

Readback Signals Status Indicators

Calibrated output voltage Thermal shutdown

Calibrated output current OVP circuit

Remote/local programming mode

• Remote programming of the shutdown function using AC, DC, or TTL compatible signals

• Remote sensing of output voltage

See Figure 4-1 Connector J3.

Use extreme caution when biasing the output relative to the chassis due to

WARNING!

potential high voltage levels at the output and J3 terminals.

4-2 M362295-01 Rev C

Page 47

Sorensen DCS-E Series 3kW Supplies Advanced Operation

Figure 4-1 Connector J3 Pin Descriptions

(for Remote Programming, Remote Monitoring, and Sense Connections)

M362295-01 Rev C 4-3

Page 48

Advanced Operation Sorensen DCS-E Series 3kW Supplies

INTERNAL SWITCH AND JUMPERS

If you should need to change any of the standard configurations of the supply, internal jumpers

JMP1 and JMP2, and switch SW1 enable you to select: voltage and current programming scale

factor, over voltage protection (OVP) programming mode and scale, voltage and current monitor

range, and shutdown circuit logic.

4.2.2 Locating Jumpers, Switch, and Connector

Switch SW1 and jumpers JMP1 and JMP2 are located on the main printed circuit board (A2)

inside the power supply. The J3 connector is located on the unit's rear panel. See Section 4.2.3

Resetting Jumpers and Switch and Section 4.2.4 Making J3 Connections.

Figure 4-2 Internal Jumpers and Switch (Default Settings Shown)

4-4 M362295-01 Rev C

Page 49

Sorensen DCS-E Series 3kW Supplies Advanced Operation

4.2.3 Resetting Jumpers and Switch

Most applications will use the default factory settings of the internal jumpers, JMP1 and JMP2,

or of the internal 8-position DIP switch, SW1. If the jumpers and switch should require resetting,

read Section 2.2 Safety, and follow the procedures in this section.

The steps to follow are: Dissipating stored energy

Removing the cover

Removing the option board (when required)

Resetting JMP1, JMP2 and SW1

Replacing the option board

Replacing the cover

Powering up

D

ISSIPATING STORED ENERGY

1. Ensure the power supply is turned OFF. Disconnect the AC input connector. Allow

five (5) minutes to elapse to dissipate stored energy before removing the cover.

R

EMOVING THE COVER

2. Unscrew and remove the eight (8) flathead Philips screws from the top of the cover:

two (2) are located near the front panel, six (6) near the rear panel. (Use a #1 Philips

screwdriver.)

3. Loosen but do not remove the six (6) Philips screws located three (3) to a side in the

slots along each side of the power supply.

4. Lift cover off and set aside.

R

EMOVING THE OPTION BOARD (WHEN REQUIRED)

The power supply may have either of two option circuit boards installed over the A2 circuit board

where the jumpers and switches are located. The option board must be removed to allow

access to them.

5. Unplug any external mating connector and attached wiring.

6. Use a nut driver to remove the jackscrews that fasten the option board to the rear panel.

7. Unscrew the mounting screws that fasten the option board down.

8. Unplug any attached cables.

9. Lift out the option board and set aside.

R

ESETTING JMP1, JMP2, AND SW1

10. Lift the appropriate jumper from its pin header and replace it as the programming

requires. The default location is B-C for both JMP1 and JMP2. Alternate locations are

A-B in each case.

11. Push the dual position SW1 switches closed (ON) or open (OFF) as required by the

application.

M362295-01 Rev C 4-5

Page 50

Advanced Operation Sorensen DCS-E Series 3kW Supplies

REPLACING THE OPTION BOARD (WHEN REQUIRED)

12. Place the option board into its original location over the A2 circuit board.

13. Reinstall the mounting screws into the standoffs. Reattach any cables.

14. Reinstall the jackscrews with the nut driver.

15. Reconnect any external cables and connector.

EPLACING THE COVER

R

16. Place the cover in its original location.

17. Reinstall the eight (8) flathead Philips screws on the top of the cover, then tighten the

six (6) Philips screws in the side slots.

P

OWERING UP

18. Reconnect the AC input connector. Turn the power supply ON.

4.2.4 Making J3 Connections

Some applications will use only the default factory connections on the J3 connector located on

the rear panel. Other applications will require replacing pin-to-pin connections or making

connections to external devices such as voltage sources, current sources, or resistances. Read

Section 2.2 Safety, and follow the procedures in this section whenever the rear panel

connector, J3, is to be reconfigured.

The steps to follow are: Dissipating stored energy

Making the connections

Powering up

Refer to the

M

AKING THE CONNECTION

DISSIPATING STORED ENERGY and POWERING UP steps in Section 4.2.3.

To make pin-to-pin connections:

1. Unsolder any pin-to-pin jumpers as required by the application.

2. Solder new connections using any appropriate single bus wire such as AWG 20 to 24.

To connect external source leads, resistance leads, or monitoring or sense lines:

3. Unsolder any jumpers as required by the application.

4. Solder leads to the specified pin using the recommended wiring and/or grounding point

for the application. Pin, wiring, and grounding specifications for particular applications

can be found in Section 4 Advanced Operation except for remote sensing

specifications that are in Section 3.3 Using Remote Sensing.

4-6 M362295-01 Rev C

Page 51

Sorensen DCS-E Series 3kW Supplies Advanced Operation

4.3 REMOTE PROGRAMMING: OUTPUT VOLTAGE AND CURRENT LIMIT

Remote programming allows control of the power supply's output voltage and/or current limit to

shift from local operation at the front panel voltage and current controls to external analog input

sources. As a programming source is varied, the power supply's output varies proportionally

over its output range.

The analog programming signals are connected to the rear panel J3 connector. To provide the

lowest noise performance, shielded-twisted pair wiring is recommended for making

connections from external circuits to the J3 connector. Use the shortest leads possible.

Ground the shield to pin 6 on J3 or to the chassis via one of the J3 connector screws.

The remote programming input is internally referenced to the supply's negative

output. Do not connect remote programming input lines (J3 pins 9 and 10) to

CAUTION!

R

EMOTE PROGRAMMING OPTIONS

the supply's positive output.

The following table summarizes access options for programming output voltage and current limit

with the input scales supported for the DCS-E Series (3kW) supply. Refer to Section 4.3.1 for a

procedure and a connection diagram for programming output voltage and current limit using the

REM/LOC switch. Subsequent sections provide short procedures and diagram the J3 connector

configurations and connections required for remote programming of output voltage and/or

current limit without using the REM/LOC switch.

Remote Programming Options Control of ... Programming Scales *

Programming with the Output Voltage and 0-5V

REM/LOC Switch Current Limit 0-1 mA

Programming without Output Voltage and/or 0-5V, 0-10V

the REM/LOC Switch Current Limit 0-1 mA

* These scales may be used in any combination.

Notes for Programming with a 0-10V Source:

1. Programming with a 0-10V external voltage source requires that you reset internal

jumpers JMP1 and/or JMP2 in addition to performing any external operations. As in any

situation that requires removing the supply's cover, following safe procedures is

necessary. Review Section 2.2 Safety and follow the procedures for removing the cover

and resetting JMP1 and JMP2 in Section 4.2.3.

0-10V (see Notes below)

0-5k

Local control

0-10V (see Notes below)

2. Resetting internal jumpers may require a recalibration of the programming circuit to

maintain programming accuracy. See Section 6.3 Calibrating for Programming

Accuracy.

M362295-01 Rev C 4-7

Page 52

Advanced Operation Sorensen DCS-E Series 3kW Supplies

Section 4.2 Configuring for Remote Programming, Sensing, and Monitoring explains how

to use the front panel REM/LOC switch, how to reconfigure or make connections to the external

J3 connector, and how to access internal jumpers JMP1 and JMP2 to change their settings.

4.3.1 Programming Output Voltage and Current Limit with the REM/LOC Switch

The front panel REM/LOC (Remote/Local Programming) switch will allow you to switch back

and forth between remote and local operation when programming output voltage and current

limit with external voltage and/or current sources.

For programming output voltage and current limit using the REM/LOC switch:

1. Connect the programming source between pins 9 (voltage programming input/positive)

and 12 (return).

2. Connect the programming source between pins 10 (current limit programming

input/positive) and 12 (return).

3. Set the front panel REM/LOC switch to REM.

Figure 4-3 Programming Output Voltage and Current Limit Using the REM/LOC Switch

Notes for 0-10V Programming:

1. To program both output voltage and current limit with a 0-10V source and use the REM/LOC

switch, set internal jumpers JMP1 and JMP2 to their A-B locations before connecting the

voltage and current limit programming inputs. Review Section 2.2 Safety and follow the