Page 1

DCS-E 1kW Series &

DCS-E 1.2kW Series

DC Power Supplies

Operation Manual

This manual covers models:

DCS8-125E DCS33-33E DCS60-18E DCS150-7E

DCS8-140E DCS33-36E DCS60-20E DCS150-8E

DCS10-100E DCS40-25E DCS80-13E DCS300-3.5E

DCS10-120E DCS40-30E DCS80-15E DCS300-4E

DCS20-50E DCS50-20E DCS100-10E DCS600-1.7E

DCS20-60E DCS50-24E DCS100-12E DCS600-2E

M362500-01 Rev H www.programmablepower.com

Page 2

Page 3

Page 4

Page 5

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement,

process control, power bus simulation and power conditioning applications across diverse

industrial segments. From bench top supplies to rack-mounted industrial power subsystems,

AMETEK Programmable Power is the proud manufacturer of Elgar, Sorensen, California

Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical

devices with annualized sales of $2.5 billion. The Company has over 11,000 colleagues working

at more than 80 manufacturing facilities and more than 80 sales and service centers in the United

States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc.

Other trademarks, registered trademarks, and product names are the property of their respective

owners and are used herein for identification purposes only.

Notice of Copyright

DCS-E 1kW Series & DCS-E 1.2kW Series DC Power Supplies Operation Manual

AMETEK Programmable Power, Inc. All rights reserved.

© 2006-2008

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC.

(“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL,

WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH

INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE

TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED AMETEK CONTENT

IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION, WHICH IS POSTED AT

WWW.PROGRAMMABLEPOWER.COM.

Date and Revision

January 2015 Revision H

Part Number

M362500-01

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales.ppd@ametek.com

service.ppd@ametek.com

Web: www.programmablepower.com

i

Page 6

This page intentionally left blank.

ii

Page 7

WARNING

Hazardous voltages may be present when covers are removed. Qualified

personnel must use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating above

(below) chassis ground.

WARNING

The equipment used contains ESD sensitive parts. When installing

equipment, follow ESD Safety Procedures. Electrostatic discharges might

cause damage to the equipment.

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your

particular application.

Only qualified personnel who deal with attendant hazards in power supplies, are allowed to perform

installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or

chassis. Similarly, other power ground lines including those to application and maintenance

equipment must be grounded properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any

cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY may be normally generated on the output terminals. The customer/user must

ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety

glasses during open cover checks to avoid personal injury by any sudden component failure.

Neither AMETEK Programmable Power Inc., San Diego, California, USA, nor any of the subsidiary

sales organizations can accept any responsibility for personnel, material or inconsequential injury,

loss or damage that results from improper use of the equipment and accessories.

SAFETY SYMBOLS

iii

Page 8

This page intentionally left blank.

iv

Page 9

Product Family: DCS-E 1kW Series & DCS-E 1.2kW Series DC Power Supplies

Warranty Period: Five Years

WARRANTY TERMS

AMETEK Programmable Power, Inc. (“AMETEK”), provides this written warranty covering the

Product stated above, and if the Buyer discovers and notifies AMETEK in writing of any defect in

material or workmanship within the applicable warranty period stated above, then AMETEK may,

at its option: repair or replace the Product; or issue a credit note for the defective Product; or

provide the Buyer with replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in

accordance with the return procedure specified below. AMETEK will, at its expense, deliver the

repaired or replaced Product or parts to the Buyer. Any warranty of AMETEK will not apply if the

Buyer is in default under the Purchase Order Agreement or where the Product or any part

thereof:

is damaged by misuse, accident, negligence or failure to maintain the same as

specified or required by AMETEK;

is damaged by modifications, alterations or attachments thereto which are not

authorized by AMETEK;

is installed or operated contrary to the instructions of AMETEK;

is opened, modified or disassembled in any way without AMETEK’s consent; or

is used in combination with items, articles or materials not authorized by AMETEK.

The Buyer may not assert any claim that the Products are not in conformity with any warranty

until the Buyer has made all payments to AMETEK provided for in the Purchase Order Agreement.

PRODUCT RETURN PROCEDURE

1. Request a Return Material Authorization (RMA) number from the repair facility (must be

done in the country in which it was purchased):

In the USA, contact the AMETEK Repair Department prior to the return of the

product to AMETEK for repair:

Telephone: 800-733-5427, ext. 2295 or ext. 2463 (toll free North America)

858-450-0085, ext. 2295 or ext. 2463 (direct)

Outside the United States, contact the nearest Authorized Service Center

(ASC). A full listing can be found either through your local distributor or our

website, www.programmablepower.com, by clicking Support and going to the

Service Centers tab.

2. When requesting an RMA, have the following information ready:

Model number

Serial number

Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by AMETEK, to be in specification is subject to

an evaluation fee and applicable freight charges.

v

Page 10

This page intentionally left blank.

vi

Page 11

CONTENTS

SECTION 1 FEATURES AND SPECIFICATIONS .................................. 1-1

1.1 Description ..................................................................................................... 1-1

1.2 Operating Modes ............................................................................................ 1-1

1.3 Power Supply Features .................................................................................. 1-1

1.4 Specifications ................................................................................................. 1-3

1.4.1 Electrical Specifications for 1kW Models .......................................... 1-3

1.4.2 Electrical Specifications for 1.2kW Models ....................................... 1-4

1.4.3 Physical Specifications ..................................................................... 1-5

1.4.4 Mechanical Specifications ................................................................ 1-6

SECTION 2 INSTALLATION AND OPERATION ................................... 2-1

2.1 General .......................................................................................................... 2-1

2.2 Initial Inspection ............................................................................................. 2-1

2.3 Installation ...................................................................................................... 2-1

2.3.1 Input Voltage Selection..................................................................... 2-1

2.3.2 Input Line Impedance ....................................................................... 2-2

2.3.3 Ventilation Requirements ................................................................. 2-2

2.3.4 Output Voltage Biasing ..................................................................... 2-2

2.3.5 Rack Mounting ................................................................................. 2-3

2.4 Controls, Connectors, and Indicators ............................................................. 2-5

2.4.1 Front Panel ....................................................................................... 2-5

2.4.2 Rear Panel ....................................................................................... 2-5

2.4.3 J3 Program, Sense and Monitor Connector Description ................... 2-6

2.5 Initial Functional Tests .................................................................................... 2-7

2.6 Standard Operation ........................................................................................ 2-8

M362500-01 Rev H vii

Page 12

Contents Sorensen DCS Series 1kW and 1.2kW Supplies

2.6.1 Load Conductor Ratings ................................................................... 2-8

2.6.2 Load Connection and Grounding ...................................................... 2-8

2.6.3 Inductive Loads ................................................................................ 2-9

2.6.4 Remote Sensing ............................................................................. 2-10

2.6.5 Negative Output Operation ............................................................. 2-11

2.7 Single Supply Operation (Local Mode) ......................................................... 2-11

2.8 Multiple Supplies .......................................................................................... 2-12

2.8.1 Series Operation ............................................................................. 2-12

2.8.2 Parallel Operation ........................................................................... 2-12

2.8.3 Split Supply Operation .................................................................... 2-13

2.9 Over Voltage Protection (OVP) ..................................................................... 2-13

2.9.1 Front Panel OVP Operation ............................................................ 2-13

2.9.2 Remote Programming of OVP With External Voltage Sources ....... 2-14

2.9.3 Remote Programming of OVP with an External Resistance ........... 2-15

2.9.4 Remote Programming of OVP with External Current Sources ........ 2-16

2.9.5 Remote OVP Sensing..................................................................... 2-17

2.10 Remote ON/OFF .......................................................................................... 2-17

2.10.1 Remote ON/OFF by Contact Closure ............................................. 2-18

2.11 Remote Programming of Output Voltage and Current Limit ......................... 2-18

2.11.1 Programming With External Voltage Sources ................................. 2-19

2.11.2 Programming With an External Resistance .................................... 2-20

2.11.3 Programming With an External Current Source .............................. 2-22

2.12 Remote Monitoring and Status Indicators ..................................................... 2-23

SECTION 3 THEORY OF OPERATION ................................................ 3-1

3.1 Power Circuit (A2 Assembly) .......................................................................... 3-1

3.1.1 Basic Off-Line Switching Regulator Theory ...................................... 3-1

3.1.2 Simplified Full Bridge Converter Theory ........................................... 3-3

3.1.3 Detailed Circuit Description ............................................................... 3-3

3.2 Meter Circuit (A1 Assembly) ........................................................................... 3-9

3.2.1 Voltmeter ........................................................................................ 3-10

3.2.2 Current Meter ................................................................................. 3-10

SECTION 4 MAINTENANCE, TROUBLESHOOTING, AND CALIBRATION

4-1

4.1 General .......................................................................................................... 4-1

viii M362500-01 Rev H

Page 13

Sorensen DCS Series 1kW and 1.2kW Supplies Contents

ix

4.2 Periodic Service ............................................................................................. 4-1

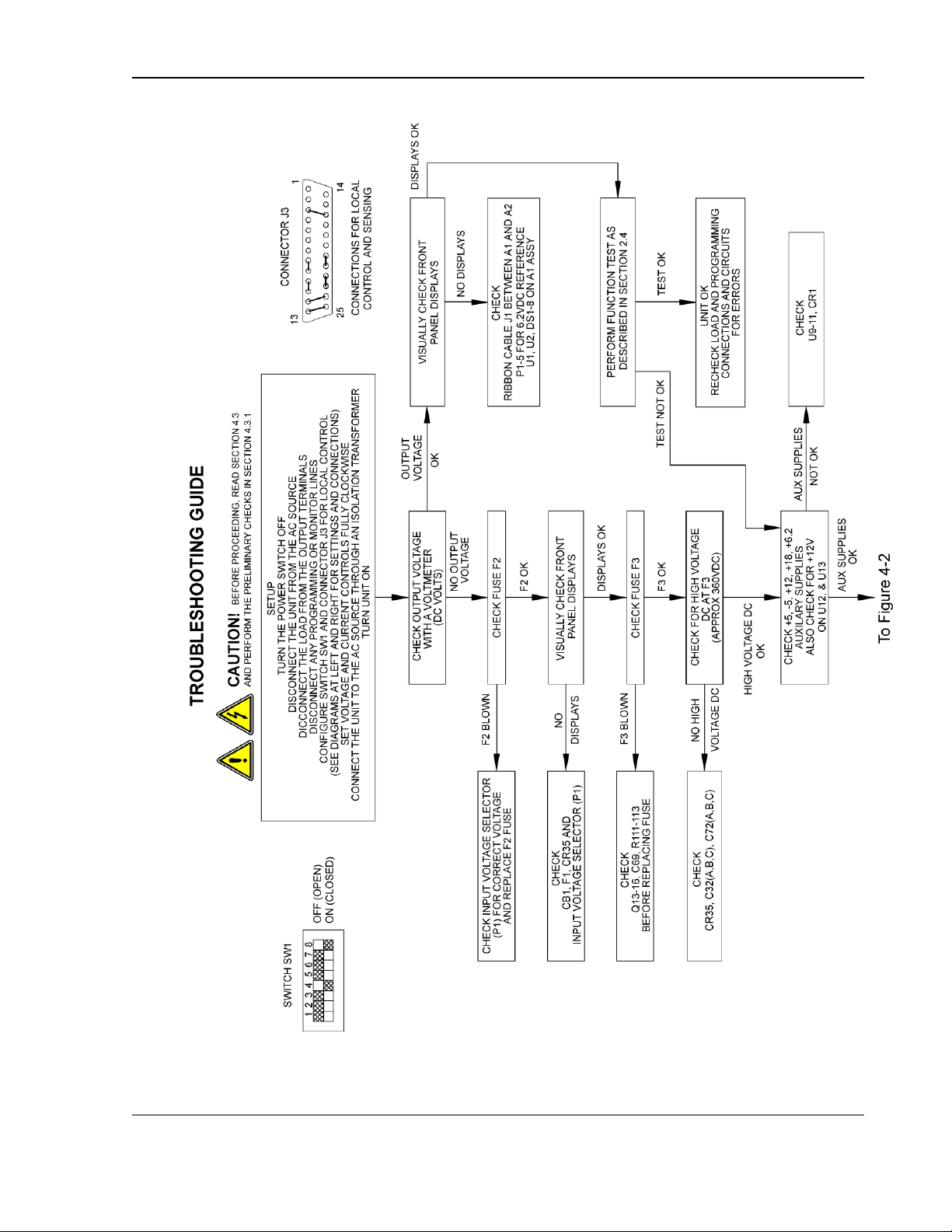

4.3 Troubleshooting ............................................................................................. 4-1

4.3.1 Preliminary Checks .......................................................................... 4-2

4.3.2 Troubleshooting at the Operation Level ............................................ 4-2

4.4 Calibration ...................................................................................................... 4-3

SECTION 5 PARTS LISTS .................................................................... 5-1

5.1 General .......................................................................................................... 5-1

5.2 Parts Ordering ................................................................................................ 5-1

5.3 Parts Lists ...................................................................................................... 5-2

M362500-01 Rev H

Page 14

Contents Sorensen DCS Series 1kW and 1.2kW Supplies

LIST OF FIGURES

Figure 2-1 DCS Series Power Supply ................................ ......................................... 2-4

Figure 2-2. Diode Connection ..................................................................................... 2-9

Figure 3-1 Simplified Full Bridge Converter ................................................................. 3-2

x M362500-01 Rev H

Page 15

Sorensen DCS Series 1kW and 1.2kW Supplies Contents

xi

Figure 4-1 Trimpot Locations ...................................................................................... 4-4

M362500-01 Rev H

Page 16

Contents Sorensen DCS Series 1kW and 1.2kW Supplies

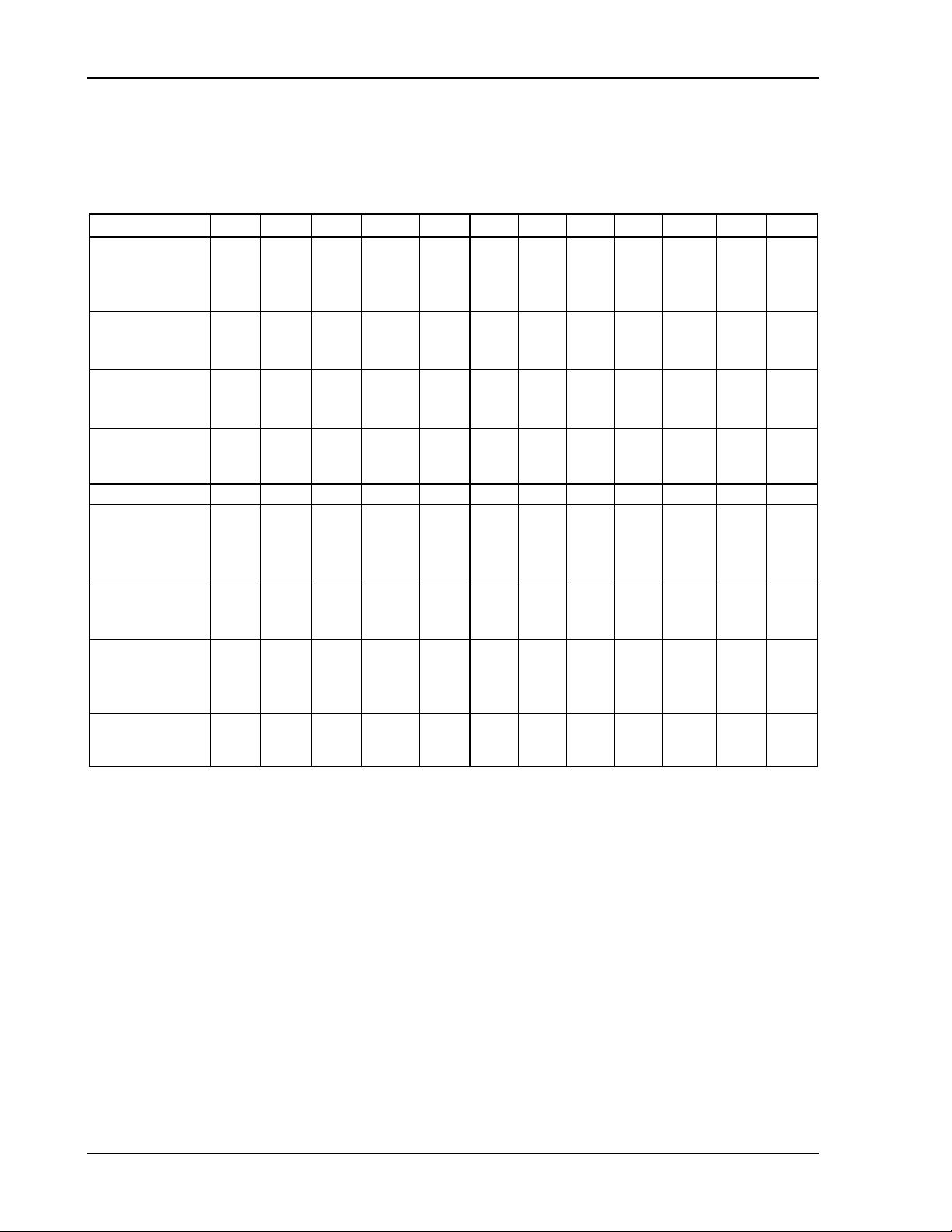

LIST OF TABLES

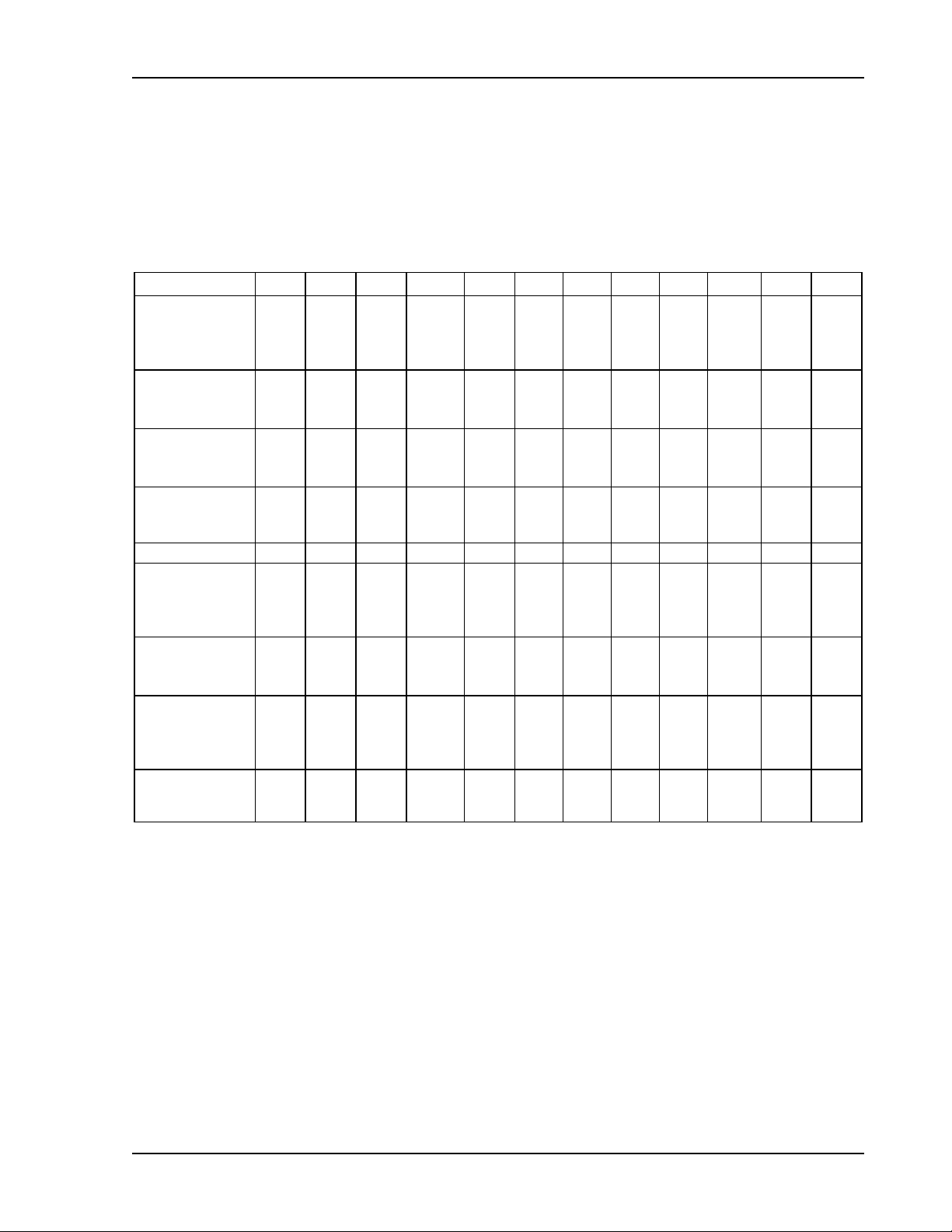

Table 2–1 Wire Size and Length ................................................................................. 2-8

Table 4–1 Troubleshooting Guide ............................................................................... 4-2

Table 5–1 DCS 1kW and 1.2kW Fuse Ratings ........................................................... 5-2

Table 5–2 DCS 1kW Parts Lists by Model Number ..................................................... 5-2

Table 5–3 DCS 1kW Parts Lists .................................................................................. 5-3

Table 5–4 DCS 1.2kW Parts Lists by Model Number .................................................. 5-4

Table 5–5 DCS 1.2kW Parts Lists ............................................................................... 5-5

xii M362500-01 Rev H

Page 17

SECTION 1

FEATURES AND SPECIFICATIONS

1.1 Description

DCS Series power supplies are 1000W and 1200W supplies designed to provide highly stable,

continuously variable output voltage and current for a broad range of development, system, and

burn-in applications. The DCS Series employs high frequency switching regulator technology

to achieve high power density and small package size.

The series consists of twelve 1000W models and twelve 1200W models. The model numbers

are designated by the DCS prefix, followed by the output voltage and current ratings. For

example, the model number DCS 60-18E indicates that the unit is rated at 0-60 Vdc and 0-18

Amps while a model DCS 20-50E is rated at 0-20 Vdc and 0-50 Amps.

1.2 Operating Modes

The DCS Series supply has two basic operating modes: Constant Voltage and Constant

Current. In constant voltage mode the output voltage is regulated at the selected value while

the output current varies with the load requirements. In constant current mode the output

current is regulated at the selected value while output the voltage varies with the load

requirements.

An automatic crossover system enables the unit to switch operating modes in response to

varying load requirements. If, for example, the unit is operating in voltage mode and the load

current attempts to increase above the setting of the current control, the unit will switch

automatically from voltage mode to current mode. If the load current is subsequently reduced

below the setting of the current control the unit will return to voltage mode automatically.

1.3 Power Supply Features

Twelve 1kW models with voltage ranges from 0-8 Vdc to 0-600 Vdc and current

outputs from 1.7A to 125A.

Twelve 1.2kW models with voltage ranges from 0-8 Vdc to 0-600 Vdc and current

outputs from 2A to 140A.

115/230 Vac selectable input voltage, 50-60 Hz single phase,

Installation Category II. For Indoor Use.

M362500-01 Rev H 1-1

Page 18

Features and Specifications Sorensen DCS Series 1kW and 1.2kW Supplies

Simultaneous digital display of both voltage and current.

Automatic mode crossover into current or voltage mode.

Ten turn potentiometer voltage and current controls permit high resolution setting of

the output voltage and current from zero to the rated output.

Flexible output configuration: multiple units can be connected in parallel or series to

provide increased current or voltage.

High frequency switching technology allows high power density, providing increased

power output in a small, light package.

Remote sensing to compensate for losses in power leads.

Adjustable Over-Voltage Protection (OVP)

External TTL, AC or DC shutdown

Remote voltage, resistive, current limit and OVP programming with selectable

programming constants.

External indicator signals for remote monitoring of OVP status, local/remote

programming status, thermal shutdown, and output voltage and current.

Optional IEEE-488 interface for complete remote programming and readback

capability.

1-2 M362500-01 Rev H

Page 19

Sorensen DCS Series 1kW and 1.2kW Supplies Features and Specifications

Models

8-125

10-100

20-50

33-33

40-25

50-20

60-18

80-13

100-10

150-7

300-3.5

600-1.7

Output Ratings:

Output Voltage

Output Current

Output Power

0-8V

0-125A

1000W

0-10V

0-100A

1000W

0-20V

0-50A

1000W

0-33V

0-33A

1089W

0-40V

0-25A

1000W

0-50V

0-20A

1000W

0-60V

0-18A

1080W

0-80V

0-13A

1040W

0-100V

0-10A

1000W

0-150V

0-7A

1050W

0-300V

0-3.5A

1050W

0-600V

0-1.7A

1020W

Line Regulation:1

Voltage

Current

8 mV

125 mA

10 mV

100 mA

20 mV

50 mA

33 mV

33 mA

40 mV

25 mA

50 mV

20 mA

60 mV

18 mA

80 mV

13 mA

100 mV

10 mA

150 mV

7 mA

300 mV

3.5 mA

600 mV

1.7 mA

Load Regulation:2

Voltage

Current

8 mV

125 mA

10 mV

100 mA

20 mV

50 mA

33 mV

33 mA

40 mV

25 mA

50 mV

20 mA

60 mV

18 mA

80 mV

13 mA

100 mV

10 mA

150 mV

7 mA

300 mV

3.5 mA

600mV

1.7 mA

Meter Accuracy:

Voltage

Current

0.09V

1.35A

0.11V

1.1A

0.3V

0.6A

0.43V

0.43A

0.5V

0.35A

0.6V

0.30A

0.7V

0.28A

0.9V

0.23A

1.1V

0.11A

1.6V

0.08A

4.0V

0.045A

7.0V

0.018A

OVP Adjustment Range

0.4-8.8V

0.5-11V

1.0-22V

1.65-36.3V

2-44V

2.5-55V

3-66V

4-88V

5-110V

7.5-165V

15-330V

30-660V

Output Noise/Ripple(V)3

Rms

p-p

(20Hz-20MHz)

4 mV

60 mV

4 mV

60 mV

4 mV

60 mV

4 mV

60 mV

4 mV

60 mV

4 mV

60 mV

4 mV

60 mV

4 mV

60 mV

6 mV

60 mV

12 mV

160 mV

20 mV

200 mV

50 mV

300 mV

Stability:4

Voltage

Current

4 mV

62.5 mA

5 mV

50 mA

10 mV

25 mA

16.5 mV

16.5 mA

20 mV

12.5 mA

25 mV

10 mV

30 mV

9 mA

40 mV

6.5 mA

50 mV

5 mA

75 mV

3.5 mA

150 mV

1.75 mA

300 mV

0.85 mA

Temperature

Coefficient:5

Voltage

Current

1.6 mV

37.5 mA

2 mV

30 mA

4 mV

15 mA

6.6 mV

9.9 mA

8 mV

7.5 mA

10 mV

6 mA

12 mV

5.4 mA

16 mV

3.9 mA

20 mV

3 mA

30 mV

2.1 mA

60 mV

1.05 mA

120 mV

0.51 mA

Maximum Remote

Sense Line Drop6

Compensation/line

4V 4V 4V 4V 4V 4V 4V 4V 4V 4V 4V 4V

1.4 Specifications

1.4.1 Electrical Specifications for 1kW Models

Specifications are warranted over a temperature range of 0-50°C with default local sensing.

From temperatures of 50-70°C, derate output 2% per °C.

1

For input voltage variation over the AC input voltage range, with constant rated load

2

For 0-100% load variation, with constant nominal line voltage

3

Typical P-P noise and ripple

4

Maximum drift over 8 hours with constant line, load, and temperature, after 20-minute warm-up

5

Change in output per °C change in ambient temperature, with constant line and load

6

Line drop subtracts from the maximum available output voltage at full rated power

AC Input: 200-250 Vac at 9A rms or 100-130 Vac at 18A rms, 47-63 Hz

Maximum Voltage Differential from output to safety ground: 150 Vdc

M362500-01 Rev H 1-3

Page 20

Features and Specifications Sorensen DCS Series 1kW and 1.2kW Supplies

Models

8-140

10-120

20-60

33-36

40-30

50-24

60-20

80-15

100-12

150-8

300-4

600-2

Output Ratings:

Output Voltage

Output Current

Output Power

0-8V

0-140A

1200W

0-10V

0-120A

1200W

0-20V

0-60A

1200W

0-33V

0-36A

1200W

0-40V

0-30A

1200W

0-50V

0-24A

1200W

0-60V

0-20A

1200W

0-80V

0-15A

1200W

0-100V

0-12A

1200W

0-150V

0-8A

1200W

0-300V

0-4A

1200W

0-600V

0-2A

1020W

Line Regulation:7

Voltage

Current

8 mV

140 mA

10 mV

120 mA

20 mV

60 mA

33 mV

36 mA

40 mV

30 mA

50 mV

24 mA

60 mV

20 mA

80 mV

15 mA

100 mV

12 mA

150 mV

8 mA

300 mV

4 mA

600 mV

2 mA

Load Regulation:8

Voltage

Current

8 mV

140 mA

10 mV

120 mA

20 mV

60 mA

33 mV

36 mA

40 mV

30 mA

50 mV

24 mA

60 mV

20 mA

80 mV

15 mA

100 mV

12 mA

150 mV

8 mA

300 mV

4 mA

600 mV

2 mA

Meter Accuracy:

Voltage

Current

0.09V

1.55A

0.11V

1.3A

0.3V

0.7A

0.43V

0.46A

0.5V

0.40A

0.6V

0.34A

0.7V

0.3A

0.9V

0.25A

1.1V

0.13A

1.6V

0.09A

4.0V

0.05A

7.0V

0.021A

OVP Adjustment Range

0.4-8.8V

0.5-11V

1.0-22V

1.65-36.3V

2-44V

2.5-55V

3-66V

4-88V

5-110V

7.5-165V

15-330V

30-660V

Output Noise/Ripple(V)

9

Rms

p-p

(20Hz-20MHz)

5 mV

60 mV

5 mV

60 mV

5 mV

60 mV

5 mV

60 mV

5 mV

60 mV

5 mV

60 mV

5 mV

60 mV

5 mV

60 mV

10 mV

60 mV

15 mV

160 mV

25 mV

200 mV

50 mV

300 mV

Stability:10

Voltage

Current

4 mV

70 mA

5 mV

60 mA

10 mV

30 mA

16.5 mV

18 mA

20 mV

15 mA

25 mV

12 mV

30 mV

10 mA

40 mV

7.5 mA

50 mV

6 mA

75 mV

4 mA

150 mV

2 mA

300 mV

1 mA

Temperature

Coefficient:11

Voltage

Current

1.6 mV

42 mA

2 mV

36 mA

4 mV

18 mA

6.6 mV

10.8 mA

8 mV

9 mA

10 mV

7.2 mA

12 mV

6 mA

16 mV

4.5 mA

20 mV

3.6 mA

30 mV

2.4 mA

60 mV

1.2 mA

120 mV

0.6 mA

Maximum Remote

Sense Line Drop12

Compensation/line

2V 2V 4V 4V 4V 4V 4V 4V 4V 4V 4V 4V

1.4.2 Electrical Specifications for 1.2kW Models

Specifications are warranted over a temperature range of 0-50°C with default local sensing.

From temperatures of 50-70°C, derate output 2% per °C.

7

8

9

10

11

12

AC Input: 200-250 Vac at 10A rms or 100-130 Vac at 20A rms, 47-63 Hz

Maximum Voltage Differential from output to safety ground: 150 Vdc

1-4 M362500-01 Rev H

For input voltage variation over the AC input voltage range, with constant rated load

For 0-100% load variation, with constant nominal line voltage

Typical P-P noise and ripple

Maximum drift over 8 hours with constant line, load, and temperature, after 20-minute warm-up

Change in output per °C change in ambient temperature, with constant line and load

Line drop subtracts from the maximum available output voltage at full rated power

Page 21

Sorensen DCS Series 1kW and 1.2kW Supplies Features and Specifications

Parameter

Resistance

Voltage

Current

Voltage

5 k

5V, 10V

1 mA

Current

5 k

5V, 10V

1 mA

OVP

5 k

5V, 10V

1 mA

1.4.3 Physical Specifications

Altitude: 2000M (6562 ft.)

Storage Temperature Range: -55 to +85°C

Humidity Range: 0 to 80% Non-condensing

Time Delay from power on until output stable: 3 seconds maximum

Voltage Mode Transient Response Time: 500S recovery to 1% band for 30% step load

change from 70% to 100% or 100% to 70%

Remote Start/Stop and Interlock: TTL compatible input, Contact Closure, 12-250 Vac or

12-130 Vdc

Switching Frequency: Nominal 70 kHz typical (140 kHz output ripple)

Analog Programming Linearity: Typical error is less than 0.5% setting.

Maximum error is 1% of rated output.

Agency Approvals: Regulatory NRTL to UL 1012/CSA 107.1

CE compliant (LVD and EMC directives)

Remote Analog Programming (Full Scale Input):

Scales are selectable via an internally-mounted switch.

M362500-01 Rev H 1-5

Page 22

Features and Specifications Sorensen DCS Series 1kW and 1.2kW Supplies

1.4.4 Mechanical Specifications

Size: 44mm H x 482.6mm W x 508mm D (1.75” H x 19” W x 20” D)

Weight: 8.2 kg (18 lbs)

OUTPUT CONNECTOR

Models DCS-E 8V through DCS 100V

Connector type: Nickel plated copper bus bars.

Approximate dimensions: 1.365" x 0.8" x 0.125"

Distance between positive and negative bus bar centers: 2.2"

Load wiring mounting holes: Two 0.257" diameter holes on 0.5" centers (1/4" hardware)

Two 0.191" diameter holes on 0.4" centers (#10 hardware)

Models DCS-E 150V through DCS 600V

Connector type: Six–pin Amp Universal Mate-N-Lok connector

Chassis mounted parts: Housing: Amp part number 1-480705-0

Pins: Amp part number 350547-1

Mating connector parts: Housing: Amp part number 1-480704-0

Socket pins: Amp part number 350550-1

Note: Six Socket pins and one mating connector housing are supplied with each 150V through

600V unit.

INPUT CONNECTOR

2 position terminal block plus safety ground screw.

Note: Input power cord not supplied.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

1-6 M362500-01 Rev H

Page 23

CAUTION

Attempted operation of the DCS power supply with the incorrect input voltage

may result in internal damage to the unit.

SECTION 2

INSTALLATION AND OPERATION

2.1 General

After unpacking, perform an initial inspection and function test to ensure that the unit is in good

working order. If the unit was damaged in shipment, notify the carrier immediately. Direct

repair problems to the Customer Service Department at 1-800-733-5427.

2.2 Initial Inspection

The equipment should be inspected for damage as follows:

Inspect for obvious signs of physical damage.

Turn front panel controls from stop to stop. Rotation should be smooth.

Test the action of the power switch. Switching action should be positive.

If internal damage is suspected, remove the cover and check for printed circuit

board and/or component damage. Reinstall cover.

2.3 Installation

2.3.1 Input Voltage Selection

Before using the DCS power supply, the correct AC input voltage must be selected and an

appropriate line cord and plug attached, or hook up wire sized for input current based on NEC

or local electrical code. The frequency of the AC input voltage must be maintained between 47

and 63 Hz.

All units are shipped in a configuration requiring a 200-250 Vac input. The unit can be converted for use with a 100-130 Vac input or purchased preset for 115 Vac with the M1 Option.

For use with a 200-250 Vac input, connect a 250 Vac 15 Amp rated plug and cord to the rear

panel AC connector and the safety ground screw. (Note that the NEUT. and LINE designations

above the AC connector do not apply to 200-250V operation.)

M362500-01 Rev H 2-1

Page 24

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

WARNING

If the output voltage is to be biased relative to safety ground, the power

supply outputs may be biased up to a maximum of 150 Vdc with respect

to the chassis.

NOTE: To provide protection for personnel in the case of unit failure and to

ensure proper power supply operation, the safety ground wire of the AC input line

cord must always be connected to the ground screw provided.

NOTE: To provide external overcurrent protection customer/user should use an

AC Input circuit breaker rated 30 Amp, , 125V when using the 100-130 input

configuration. For 200-250V input configuration, a 15 Amp, 250V circuit breaker

should be used

To convert the unit for use with a 100-130 Vac input, perform the following steps:

1. Ensure that the unit is switched off and disconnected from any power source.

2. Remove the Phillips head screws that secure the cover and then remove the cover.

3. Remove the 230 Vac voltage selector jumper located at the front center of the PCB from

its mating header (P1 on the PCB) and install the attached 115 Vac jumper in its place.

4. Remove the adhesive backed 115 Vac 20A label from fan and cover the 230 Vac 10A

input specification above the rear panel AC connector.

5. Reinstall the cover and replace screws.

6. Install a 125 Vac 30 Amp rated plug and cord ensuring that the neutral (white) wire and

line (black) wire are connected in the correct positions and that the safety ground wire is

connected to the ground screw.

Note that both the 1kW and 1.2kW models can exceed the 15A standard wall outlet

capacity at full load.

2.3.2 Input Line Impedance

The maximum input line impedance for operation at full rated output is 0.5 ohm. Higher source

impedances can be tolerated by raising the input line voltage or by reducing the output voltage

and/or current.

2.3.3 Ventilation Requirements

The DCS power supply may be used in rack mounted or benchtop applications. In either case

sufficient space must be allowed for cooling air to reach the ventilation inputs on each side of

the unit and for the fan exhaust air to exit from the rear of the unit.

2.3.4 Output Voltage Biasing

2-2 M362500-01 Rev H

Page 25

Sorensen DCS Series 1kW and 1.2kW Supplies Installation and Operation

2.3.5 Rack Mounting

The DCS power supply is designed to fit in a standard 19" equipment rack. When installing the

unit in a rack, be sure to provide adequate support for the rear of the unit while not obstructing

the ventilation inlet on the sides of the unit. Use adjustable support angles such as Hammond

RASA22WH2, or a support bar such as Hammond RASB19WH2.

M362500-01 Rev H 2-3

Page 26

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

Figure 2-1 DCS Series Power Supply

2-4 M362500-01 Rev H

Page 27

Sorensen DCS Series 1kW and 1.2kW Supplies Installation and Operation

2.4 Controls, Connectors, and Indicators

Refer to Figure 2-1 and the descriptions below.

2.4.1 Front Panel

(1) AC Power Switch

(2) AC Input Circuit Breaker

(3) OVP Adjust Potentiometer: Manual adjustment for OVP trip level

(4) OVP LED: Indicates that the OVP circuit has been activated when illuminated

(5) Shutdown LED: Indicates activation of the remote shutdown circuit when illuminated

(6) Remote Programming LED: Indicates operation by remote programming when illuminated

(7) Over-Temperature LED: Indicates that the power supply is shut down due to an internal

over-temperature condition when illuminated

(8) Voltage Mode LED: Indicates operation in voltage mode when illuminated

(9) Output Voltage Control: Multi-turn potentiometer used to adjust the output voltage in local

mode

(10) Current Mode LED: Indicates operation in current mode when illuminated

(11) Output Current Control: Multi-turn potentiometer used to adjust the output current limit in

local mode

(12) Digital Voltmeter

(13) Digital Ammeter

2.4.2 Rear Panel

(14) Positive Output for 8, 10, 20, 33, 40, 50, 60, 80, and 100 volt models

(15) Output and Sense Connector for 150, 300 and 600 volt models

(16) Negative Output for 8, 10, 20, 33, 40, 50, 60, 80, and 100 volt models

(17) Programming, Sense and Monitor Connector J3: Input connector for programming

signals. Also provides access to sense connections and monitoring points. See Section

2.4.3 for individual pin descriptions. Note: The positive output and positive sense are not

available at connector J3 on 150, 300, and 600 volt models.

(18) AC Input Safety Ground Screw

(19) AC Input Connector

M362500-01 Rev H 2-5

Page 28

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

Pin #

Function

1

AC/DC Shutdown Input (12-250 Vac or 12-130 Vdc)

2

Return for Shutdown Input Signals

3

OVP Programming Input (0-5V, 0-10V, or 0-1mA)

Jumpered to pin 16 for local mode operation

4

Remote Programming Indicator (high=remote programming, low=local control)

5

Operating Mode Indicator (high=voltage mode, low=current mode)

6

Ground

7

Output Current Monitor (calibrated) 0-5V=0-100%

8

Front Panel Voltage Control (remote programming)

Input for 0-1mA remote programming signal

Jumpered to pin 9 for local operation and remote current source programming

9

Remote Voltage Programming Input (0-5V or 0-10V)

Jumpered to pin 8 for local operation and remote current source programming

10

Remote Current Programming Input (0-100mV, 0-5V, or 0-10V)

Jumpered to pin 11 for local operation and remote current source programming

11

Front Panel Current Control (remote programming)

Input for 0-1mA external programming signal

Jumpered to pin 10 for local operation and remote current source programming

12.

Return Sense (return for remote programming inputs)

13

Positive Sense

14

TTL Shutdown Input

15

+12 Vdc Output (1k ohm source impedance)

16

1mA Current Source for Local OVP Control or Remote Resistive OVP Programming

17

OVP Status (high=OVP circuit activated)

18

Thermal Shutdown Indicator (high=shutdown)

19

Output Voltage Monitor (uncalibrated) 0-5V=0-100%

20

Front Panel Voltage Control (local mode); jumpered to pin 21 for local operation

21

1mA Current Source for Local Operation or Remote Resistive Programming of

Output Voltage; jumpered to pin 20 for local operation

22

1mA Current Source for Local Operation or Remote Resistive Programming of

Output Current Limit; jumpered to pin 23 for local operation

23

Front Panel Current Control (local mode); jumpered to pin 22 for local operation

24

Return (for local sense connections only)

25

Positive Output (for local sense connections only)

2.4.3 J3 Program, Sense and Monitor Connector Description

D-subminiature 25-pin female; mating connector: 25-pin Male ITT Cannon DB25P or equivalent

Note: Pins 25 and 13 not connected on 150, 300, and 600V models.

2-6 M362500-01 Rev H

Page 29

Sorensen DCS Series 1kW and 1.2kW Supplies Installation and Operation

CONNECTOR J3

13

25

1

14

2.5 Initial Functional Tests

Before connecting the unit to an AC outlet, make sure that the power switch is in the OFF

position and that the voltage and current controls are turned fully counter clockwise. Check that

the J3 mating connector on the rear of the unit is in place with jumpers connected for local

operation as shown below. (This is the default configuration as shipped from the factory).

Connect the unit to a 230 Vac grounded outlet (115 Vac outlet if previously configured for

115 Vac operation as per instructions in section 2.3.1) and switch the unit on. After a short

power on delay the front panel meters should light up with both displays reading zero.

Note: AC power must be off for a minimum of 45 seconds before powering on again.

Connector J3 Configuration for Local Operation

To check voltage mode operation, proceed as follows:

Connect a DVM, rated better than 0.5% accuracy, to the rear output terminals,

observing correct polarity.

Rotate the CURRENT control 1/2 turn clockwise. Slowly rotate the VOLTAGE control

clockwise and observe both the internal and external meters. Minimum control range

should be from zero to the maximum rated output. Compare the test meter reading

with the front panel voltmeter reading. Check that the green voltage mode indicator

led is ON.

Set the POWER switch to OFF.

To check current mode operation, proceed as follows:

Rotate the VOLTAGE and CURRENT controls fully counterclockwise.

Rotate the VOLTAGE control 1/2 turn clockwise.

Connect a high current DC ammeter across the rear output terminals, observing

correct polarity. Select leads of sufficient current carrying capacity and an ammeter

range compatible with the unit’s rated current output. The ammeter should have an

accuracy of better than 0.5%.

Set the POWER switch to ON.

Rotate the CURRENT control slowly clockwise. The control range should be from

zero to the maximum rated output. Compare the test meter reading with the reading

on the front panel ammeter. Check that the red current mode indicator led is ON.

Set the POWER switch to OFF.

M362500-01 Rev H 2-7

Page 30

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

2.6 Standard Operation

Reliable performance of the DCS power supply can be obtained if certain basic precautions are

taken when connecting it for use on the lab bench or installing it in a system.

To obtain a stable, low noise output, careful attention should be paid to factors such as

conductor ratings, system grounding techniques and the way in which the load and remote

sensing connections are made.

2.6.1 Load Conductor Ratings

Table 2–1 lists the maximum allowable load wiring length (in feet) for a specified wire gauge

and power supply model operating at full rated output. The lengths indicated are based on PVC

insulated wire with a maximum operating temperature of 105°C. To overcome impedance and

coupling effects, which can degrade the power supply performance, use leads of the largest

gauge and shortest length possible.

Wire Size (AWG)

Model 2 4 6 8 10 12 14 16 18

8V 19 12 – – – – – – –

10V 19 12 – – – – – – –

20V 30 30 30 23 – – – – –

33V 30 30 30 30 22 14 – – –

40V 30 30 30 30 30 18 – – –

50V 30 30 30 30 30 23 13 – –

60V 30 30 30 30 30 26 16 10 –

80V 30 30 30 30 30 30 22 20 –

100V 30 30 30 30 30 30 22 20 –

150V 30 30 30 30 30 30 28 26 –

300V 30 30 30 30 30 30 30 30 –

600V 30 30 30 30 30 30 30 30 30

Table 2–1 Wire Size and Length

2.6.2 Load Connection and Grounding

Proper connection of distributed loads is an important aspect of power supply application. A

common mistake is to connect leads from the power supply to one load, from that load to the

next load, and so on for each load in the system. In this parallel power distribution method,

the voltage at each load depends on the current drawn by the other loads and DC ground loops

are developed. Except for low current applications, this method should not be used.

2-8 M362500-01 Rev H

Page 31

Sorensen DCS Series 1kW and 1.2kW Supplies Installation and Operation

The preferred way to distribute power is by the radial distribution method in which power is

connected to each load individually from a single pair of terminals designated as the positive

and negative distribution terminals. The pair of terminals may be the power supply output

terminals, the terminals of one of the loads or a distinct set of terminals specially established for

distribution. Connecting the sense leads to these terminals will compensate for losses and

minimize the effect of one load upon another.

2.6.3 Inductive Loads

To prevent damage to the power supply from inductive kickback, connect a diode rated at

greater than or equal to the supply’s output voltage and current across the output. It is

recommended that diode and cathode connections be made as follows:

Connect a blocking diode in series with the output to protect the power supply

Connect cathode of the freewheeling diode to the cathode of the blocking diode and the

anode to return.

The Peak Reverse Voltage ratings should be a minimum of 2-3 times the Power Supply

maximum output voltage. The Continuous Forward Current ratings should be a minimum of 1.5

times the Power Supply maximum output current. Heatsink may be required. There also may be

a need for higher voltage rated parts, dependent on load circuit design and inductor values.

Figure 2-2. Diode Connection

Customer Application Notes:

When positive sense is connected to anode of Blocking Diode (as shown in Figure 2-2),

voltage applied to the customer load will be lower than the output of the power supply due

to drop-off blocking diode voltage.

When load regulation is required, the positive sense can be connected directly to the load,

but the battery can be discharged thru the sense.

M362500-01 Rev H 2-9

Page 32

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

NOTE

On 8V–100V models, the sense leads must always be connected, either

for remote or local sensing. Operation of the supply with the sense leads

disconnected will cause the output to fall to zero or to be unregulated.

CAUTION

Never use the sense connections without the normal power lead connections

to the output terminals. Avoid reversing positive and negative sense lead

connections, this could result in damage to the load.

2.6.4 Remote Sensing

The use of remote sensing permits the regulation point of the power supply to be shifted from

the output terminals to the load or other distribution terminals thereby automatically

compensating for the voltage losses in the leads supplying the load (provided these losses do

not exceed 1V/line [0.5V/line for the DCS 8-125 and DCS 10-100 models]). For example, with

the voltmeter reading 10.0 volts and the sense lines connected directly to the load, the load

voltage will remain regulated at 10.0 volts regardless of the voltage drops in the power leads

and variations in the load current.

On 8V, 10V, 20V, 33V, 40V, 50V, 60V, 80V, and 100V models, the positive sense connection is

available at pin 13 of connector J3 and the return sense connection is available at pin 12. For

local sensing (regulation at the power supply output terminals) the sense pins are connected to

pins 25 (positive output) and 24 (return) of connector J3. For remote sensing the local

operation jumpers are removed and pins 13 and 12 are connected directly to the positive and

negative terminals of the load.

On 150, 300 and 600V models, the sense connections are available through the output

connector (see Figure 2-1 for the exact pin out). On these models, no sense line jumpers are

required for local operation.

Sense wires can be any size (24AWG or larger) but in high noise environments or when the

lowest possible power supply ripple is required, sense wires must be twisted and/or shielded.

2-10 M362500-01 Rev H

Page 33

Sorensen DCS Series 1kW and 1.2kW Supplies Installation and Operation

WARNING

Operation of the 300V or 600V models in the negative output mode is in violation

of the European Community’s Low Voltage Directive.

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

CONNECTOR J3

13

25

1

14

SWITCH SW1

OPEN

2.6.5 Negative Output Operation

Operation of the unit as a negative output supply may be accomplished by referencing the

positive output terminal to the power supply chassis or some other common system ground.

This mode of operation is limited to 8V–150V models only due to the metal shell 25-pin “D”

connector supplied with the unit which mates to J3.

Note: If a -300V or -600V supply is required, please contact the Sales Department or

Customer Service for availability.

2.7 Single Supply Operation (Local Mode)

To operate the DCS power supply in local mode, first install the unit and connect the load

following the instructions in Sections 2.1 to 2.6. Check that switch SW1 (mounted internally on

the main printed circuit board) is set for local operation, and that the J3 mating connector on the

rear of the unit is in place with jumpers connected for local operation. Note that this is the

default configuration as shipped from the factory; see the diagram below. Set both the current

and voltage controls fully counterclockwise.

Switch SW1

SW1-1 Off (Open)

SW1-2 Off (Open)

SW1-3 Off (Open)

SW1-4 On (Closed)

SW1-5 Off (Open)

SW1-6 Off (Open)

SW1-7 Off (Open)

SW1-8 On (Closed)

Switch SW1 and Connector J3 Configuration for Local Operation

(Default factory settings)

M362500-01 Rev H 2-11

Page 34

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

CAUTION

To prevent internal damage, ensure that the OVP trip level of all supplies is

set to maximum.

For voltage mode operation, turn the current control fully clockwise and then adjust the

voltage control to obtain the desired output voltage. For current mode operation, turn the

voltage control 1/2 turn clockwise, the current control fully counterclockwise and connect an

appropriately sized shorting jumper across the output terminals. Turn the current control

clockwise until the desired output current is obtained. Turn the power supply off, remove the

shorting jumper, turn the voltage control fully clockwise and turn the power supply on.

Note that for a short period (less than 2 seconds) after power on, the power supply output is

disabled and the current mode LED is illuminated while the main filter capacitors charge

through the inrush limiter.

2.8 Multiple Supplies

DCS Series power supplies of the SAME MODEL may be operated with outputs in series or

parallel to obtain increased load voltage or current. Split supply operation allows two positive or

a positive and negative output to be obtained.

2.8.1 Series Operation

Series operation is used to obtain a higher voltage single output supply using two or more

single units. Connect the negative terminal (–) of one supply to the positive terminal (+) of the

next supply of the same model. The total voltage available is the sum of the maximum voltages

of each supply (add voltmeter readings).

Notes:

1. The maximum allowable sum of the output voltages is 300V. This is limited by the

creepage/clearance distances internal to the construction of the metal shell 25-pin

‘D’ connector mated to J3. If a higher output voltage range is required, contact the

Sales Department or Customer Service for availability.

2. The maximum allowable current for a series string of power supplies is the rated

output current of a single supply in the string.

3. Remote sensing should not be used during series operation.

2.8.2 Parallel Operation

Parallel operation is used to obtain a higher current single output supply using two or more

single units. Set all of the outputs to the same voltage before connecting the positive terminals

(+) and negative terminals (–) in parallel. The total current available is the sum of the maximum

currents of each supply.

2-12 M362500-01 Rev H

Page 35

Sorensen DCS Series 1kW and 1.2kW Supplies Installation and Operation

CAUTION

Refer to Section 2.6.5 for additional information pertaining to negative output

configured supplies.

2.8.3 Split Supply Operation

Split supply operation is used to obtain two positive voltages with a common ground, or a

positive-negative supply.

To obtain two positive voltages, connect the negative terminals of both supplies together.

The positive terminals will supply the required voltages with respect to the common connection.

To obtain a positive-negative supply, connect the negative terminal of one supply to the

positive terminal of the second supply. The positive terminal of the first supply then provides a

positive voltage relative to the common connection while the negative terminal of the second

supply provides a negative voltage. The current limits can be set independently. The

maximum current available in split operation is equal to the rated output of the supplies used.

2.9 Over Voltage Protection (OVP)

The OVP circuit allows for protection of the load in the event of a remote programming error,

incorrect voltage control adjustment, or power supply failure. The protection circuit monitors the

output and reduces the output voltage and current to zero whenever a preset voltage limit is

exceeded. A red LED on the front panel indicates when the OVP circuit has been activated.

Resetting the OVP circuit after activation requires removal of the over-voltage condition and

powering the unit OFF and back ON or momentarily activating the remote shut down circuit

(See Section 2.10 for information on shut down circuit operation). The OVP trip level can be

set using either the front panel potentiometer or by using one of three remote programming

methods (voltage, resistance or current) through the J3 connector at the rear of the unit.

2.9.1 Front Panel OVP Operation

To set the trip level from the front panel, use the following procedure:

1. With the unit off and disconnected from its AC source remove the cover and check

that switches SW1-4 and SW1-8 are closed (factory default setting). Also check

that the jumper between pins 3 and 16 of connector J3 is in place.

2. Using a small flat bladed screwdriver through the OVP ADJUST hole in the front

panel, turn the adjusting screw fully clockwise (until audible clicking is heard or 20

turns maximum).

3. Turn the unit on and adjust the output to the desired trip voltage.

4. Slowly turn the adjusting screw counterclockwise until the red OVP indicator lights

and the power supply output shuts off.

5. Turn the POWER switch to OFF.

6. Turn the voltage control knob to minimum.

7. Turn the POWER switch back ON and increase the voltage to check that the power

supply shuts off the output at the desired voltage.

M362500-01 Rev H 2-13

Page 36

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

CONNECTOR J3

0-5V

1312

25

3 1

14

SWITCH SW1

OPEN

2.9.2 Remote Programming of OVP With External Voltage Sources

To remotely program the OVP trip level using a 0-5V or 0-10V DC voltage source, use the

following procedure:

1. With the unit off and disconnected from its AC source, remove the cover and set

switch SW1-4 closed (default factory setting) for 0-5V programming or open for 010V programming. Also check that switch SW1-8 is closed (default factory setting).

Set the front panel OVP adjusting potentiometer fully clockwise (until audible clicking

is heard or 20 turns maximum).

2. Remove the default jumper connecting pins 16 and 3 of connector J3 and connect

the voltage source between pins 3 (positive) and 12 (negative). Set the

programming source voltage to maximum.

3. Turn the unit on and adjust the output to the desired trip voltage.

4. Slowly reduce the programming voltage until the red OVP indicator lights and the

power supply shuts down.

5. Turn the POWER switch to OFF.

6. Turn the voltage control knob to minimum.

7. Turn the POWER switch back ON and increase the voltage to check that the power

supply shuts off the output at the desired voltage.

Switch SW1

SW1-1 Off (Open)

SW1-2 Off (Open)

SW1-3 Off (Open)

SW1-4 On (Closed)

SW1-5 Off (Open)

SW1-6 Off (Open)

SW1-7 Off (Open)

SW1-8 On (Closed)

Switch SW1 and Connector J3 Configuration

for 0-5 Vdc OVP Programming

(J3 sense line, voltage control and current control jumpers shown set for local operation)

2-14 M362500-01 Rev H

Page 37

Sorensen DCS Series 1kW and 1.2kW Supplies Installation and Operation

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

CONNECTOR J3

0-10V

1312

25

3 1

14

SWITCH SW1

OPEN

Switch SW1

SW1-1 Off (Open)

SW1-2 Off (Open)

SW1-3 Off (Open)

SW1-4 Off (Open)

SW1-5 Off (Open)

SW1-6 Off (Open)

SW1-7 Off (Open)

SW1-8 On (Closed)

Switch SW1 and Connector J3 Configuration

for 0-10 Vdc OVP Programming

(J3 sense line, voltage control and current control jumpers shown set for local operation)

2.9.3 Remote Programming of OVP with an External Resistance

To remotely program the OVP trip level using a 5k ohm external potentiometer, use the

following procedure.

1. With the unit off and disconnected from its AC source remove the cover, set switch

SW1-8 open and check that switch SW1-4 is closed (default factory setting for

switch SW1-4).

2. Connect the counterclockwise end of the 5k potentiometer to pins 3 and 16 of

connector J3. Connect the tap and the clockwise end of the potentiometer to pin 12.

Set the potentiometer fully clockwise.

3. Turn the unit on and adjust the output to the desired trip voltage.

4. Slowly turn the potentiometer counterclockwise until the red OVP indicator lights and

the power supply shuts down.

5. Turn the POWER switch to OFF.

6. Turn the voltage control knob to minimum.

7. Turn the POWER switch back ON and increase the voltage to check that the power

supply shuts off the output at the desired voltage.

M362500-01 Rev H 2-15

Page 38

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

CONNECTOR J3

5k OHMS

CCW

13122510

22

1

3

1416

SWITCH SW1

OPEN

Switch SW1

SW1-1 Off (Open)

SW1-2 Off (Open)

SW1-3 Off (Open)

SW1-4 On (Closed)

SW1-5 Off (Open)

SW1-6 Off (Open)

SW1-7 Off (Open)

SW1-8 Off (Open)

Switch SW1 and Connector J3 Configuration

for 0-5k OVP Programming

(J3 sense line, voltage control and current control jumpers shown set for local operation)

2.9.4 Remote Programming of OVP with External Current Sources

To remotely program the OVP trip level using a 0-1mA current source use the following

procedure.

1. With the unit off and disconnected from its AC source remove the cover and set

switches SW1-4 and SW1-8 closed (default factory setting).

2. Using a small flat bladed screwdriver through the OVP ADJUST hole in the front

panel, turn the adjusting screw fully clockwise (until audible clicking is heard or 20

turns maximum).

3. Remove the default jumper connecting pins 16 and 3 of connector J3 and connect

the current source between pins 3 (positive) and 12 (negative). Set the

programming source to 1mA.

4. Turn the unit on and adjust the output to the desired trip voltage.

5. Slowly reduce the programming current until the red OVP indicator lights and the

power supply shuts down.

6. Turn the POWER switch to OFF.

7. Turn the voltage control knob to minimum.

8. Turn the POWER switch back ON and increase the voltage to check that the power

supply shuts off the output at the desired voltage.

2-16 M362500-01 Rev H

Page 39

Sorensen DCS Series 1kW and 1.2kW Supplies Installation and Operation

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

CONNECTOR J3

0-1mA

1312

25

3 1

14

SWITCH SW1

OPEN

Switch SW1

SW1-1 Off (Open)

SW1-2 Off (Open)

SW1-3 Off (Open)

SW1-4 On (Closed)

SW1-5 Off (Open)

SW1-6 Off (Open)

SW1-7 Off (Open)

SW1-8 On (Closed)

Switch SW1 and Connector J3 Configuration

for 0-1mA Current Source OVP Programming

(J3 sense line, voltage control and current control jumpers shown set for local operation)

2.9.5 Remote OVP Sensing

The default configuration for the OVP circuit senses the output voltage at the power supply

output terminals. For applications using remote sensing where there is a need to accurately

monitor the actual load voltage, the following procedure allows the OVP sense point to be

shifted from the power supply output to the sense line connection points.

1. Shut the unit off and disconnect it from its power source. Remove the cover from

the unit.

2. Unsolder or clip out R412, the zero ohm OVP sense link located next to the output

filter capacitor C53.

3. Install a piece of insulated #22 AWG wire from the via marked C (near R412) to the

via marked C1 (near capacitor C51).

4. Reinstall the cover and reconnect the unit to its power source.

To return to local OVP sensing, remove the jumper installed in step 3 above and install a

jumper across R412 removed in step 2.

2.10 Remote ON/OFF

This feature is useful in test applications requiring remote ON-OFF control of the output. The

remote ON-OFF control circuit uses either a TTL compatible or a 12-250 Vac (or 12-130 Vdc)

input to remotely control (disable or enable) the power supply output. For TTL operation, a logic

M362500-01 Rev H 2-17

Page 40

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

SELECTS

REMOTE CURRENT LIMIT

5V OR 10V PROGRAMMING

OF

SELECTS REMOTE

RESISTIVE OVP

PROGRAMMING SCALE

SELECTS

REMOTE VOLTAGE LIMIT

5V OR 10V PROGRAMMING

OF

SELECTS REMOTE OVP

PROGRAMMING SCALE

NOT USED

NOT USED

OPEN

level signal between pins 14 (positive) and 2 (return) of connector J3 determines the output

conditions:

TTL LOW = OUTPUT ON

TTL HIGH = OUTPUT OFF

For AC or DC operation, an input of 12-250 Vac (or 12-130 Vdc) between pins 1 (positive for

DC input) and 2 (return) of connector J3 will disable the output of the supply.

A red LED on the front panel indicates when the shutdown circuit is activated. The input lines

are optically isolated and can therefore be accessed by circuits with a voltage differential of up

to 600 Vdc.

2.10.1 Remote ON/OFF by Contact Closure

An external relay may be used to operate the ON/OFF control circuit as follows. Connect one

side of a normally open relay to pin 15 of connector J3 (+12V). Connect the other side of the

relay to pin 14 (TTL Shutdown). Also connect J3 pin 2 (Shutdown return) to pin 6 (Ground).

Using this configuration, the power supply will be OFF when the relay coil is energized and ON

when the relay is de-energized.

If a normally closed relay is substituted for the normally open relay in the configuration

described above, the power supply will be ON when the relay coil is energized and OFF when

the relay is de-energized.

2.11 Remote Programming of Output Voltage and

Current Limit

The output voltage and current limit of the power supply can be remotely programmed through

the rear panel J3 connector using external voltage sources, current sources and

resistances. Switch SW1 on the A2 printed circuit board controls the programming as

diagrammed below. When the supply is controlled by remote programming, the green

REMOTE led on the front panel is illuminated.

Switch SW1 and Functions

Note: To set SW1, shut the unit off, disconnect the AC source, and remove the cover. Make

the desired switch settings, reinstall the cover, and reconnect the unit to its AC source.

2-18 M362500-01 Rev H

Page 41

Sorensen DCS Series 1kW and 1.2kW Supplies Installation and Operation

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

CONNECTOR J3

0-5V

1312

25

9 1

14

SWITCH SW1

OPEN

SW1-1 Off (Open)

SW1-5 Off (Open)

SW1-2 Off (Open)

SW1-6 Off (Open)

SW1-3 Off (Open)

SW1-7 Off (Open)

SW1-4 On (Closed)

SW1-8 On (Closed)

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

CONNECTOR J3

0-10V

1312

25

9 1

14

SWITCH SW1

OPEN

SW1-1 Off (Open)

SW1-5 Off (Open)

SW1-2 Off (Open)

SW1-6 Off (Open)

SW1-3 On (Closed)

SW1-7 Off (Open)

SW1-4 On (Closed)

SW1-8 On (Closed)

2.11.1 Programming With External Voltage Sources

The output voltage can be programmed using either a 0-5 Vdc or 0-10 Vdc external voltage

source. To program the output voltage with a 0-5 Vdc source, set switch SW1-3 open (default

factory setting) and remove the jumpers connecting pins 8 to 9 and 20 to 21 on connector J3.

Connect the external source between pins 9 (positive) and 12 (return). Varying the external

voltage from 0-5V will cause the output to vary from 0-100% of rated output.

Switch SW1

Switch SW1 and Connector J3 Configuration

for 0-5V Programming of the Output Voltage

(J3 sense line, OVP and current control jumpers shown set for local operation)

For programming with a 0-10 Vdc source, close switch SW1-3 and replace the 0-5V source with

a 0-10V source.

Switch SW1

M362500-01 Rev H 2-19

Switch SW1 and Connector J3 Configuration

for 0-10V Programming of the Output Voltage

(J3 sense line, OVP and current control jumpers shown set for local operation)

Page 42

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

SW1-1

SW1-2

PROGRAMMING VOLTAGE

OPEN

OPEN

0-5 Vdc and Local Mode

CLOSED

CLOSED

Not Used

CLOSED

OPEN

0-10 Vdc

OPEN

CLOSED

Not Used

CONNECTOR J3

0-100mV, 0-5V or 0-10V

13122510 1

14

The output current limit can be programmed using a 0-5 Vdc or 0-10 Vdc external voltage

source. Selection of the programming voltage is done using switches SW1-1 and SW1-2 as

indicated below:

To remotely program the output current limit, set switches SW1-1 and SW1-2 as shown above,

remove the jumpers connecting pins 10 to 11 and 22 to 23 of connector J3 and connect the

external voltage source between pins 10 (positive) and 12 (return). Varying the voltage source

from 0-100% causes the current limit to vary from 0-100% of the rated maximum.

(J3 sense line, OVP and voltage control jumpers shown set for local operation)

2.11.2 Programming With an External Resistance

The output voltage and current limit can be programmed using a 5k ohm external

potentiometer.

To program the output voltage, set switch SW1-3 open (default factory setting) and remove

the jumpers connecting pins 8 to 9 and 20 to 21 on connector J3. Connect pins 9 and 21 to the

counterclockwise end of the 5k potentiometer and connect the tap and clockwise end of the

potentiometer to pin 12. Adjusting the tapped resistance from 0-5k will vary the output voltage

from 0-100% of the rated output.

Connector J3 Configuration

for Remote Programming of the Output Current Limit

2-20 M362500-01 Rev H

Page 43

Sorensen DCS Series 1kW and 1.2kW Supplies Installation and Operation

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

CONNECTOR J3

5k OHMS

CCW

1312259

21

1

14

SWITCH SW1

OPEN

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

CONNECTOR J3

5k OHMS

CCW

13122510

22

1

14

SWITCH SW1

OPEN

Switch SW1

SW1-1 Off (Open)

SW1-2 Off (Open)

SW1-3 Off (Open)

SW1-4 On (Closed)

SW1-5 Off (Open)

SW1-6 Off (Open)

SW1-7 Off (Open)

SW1-8 On (Closed)

Switch SW1 and Connector J3 Configuration

for Resistive Programming of the Output Voltage

(J3 sense line, OVP and current control jumpers shown set for local operation)

To program the output current limit, set switches SW1-1 and SW1-2 open (default factory

setting) and remove the jumpers connecting pins 10 to 11 and 22 to 23 on connector J3.

Connect pins 10 and 22 to the counterclockwise end of the 5k potentiometer and connect the

tap and clockwise end of the potentiometer to pin 12. Adjusting the tapped resistance from

0-5k will vary the current limit from 0-100% of the rated output.

Switch SW1

SW1-1 Off (Open)

SW1-2 Off (Open)

SW1-3 Off (Open)

SW1-4 On (Closed)

SW1-5 Off (Open)

SW1-6 Off (Open)

SW1-7 Off (Open)

SW1-8 On (Closed)

Switch SW1 and Connector J3 Configuration

for Resistive Programming of the Output Current Limit

(J3 sense line, OVP and voltage control jumpers shown set for local operation)

M362500-01 Rev H 2-21

Page 44

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

CONNECTOR J3

0-1mA

1312

25

8 1

14

SWITCH SW1

OPEN

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

CLOSED

CONNECTOR J3

0-1mA

13122511 1

14

SWITCH SW1

OPEN

2.11.3 Programming With an External Current Source

The output voltage and current limit can be programmed using an external 0-1mA current

source.

To program the output voltage, set the front panel voltage control to maximum, set switch

SW1-3 open (default factory setting) and remove the jumper between pins 20 and 21 of

connector J3. Connect the external current source between pins 8 (positive) and 12 (return) of

connector J3. Varying the current source from 0-1mA will vary the output voltage from 0-100%

of the rated output.

Switch SW1 and Connector J3 Configuration

for 0-1mA Current Programming of the Output Voltage

(J3 sense line, OVP and current control jumpers shown set for local operation)

To program the output current limit, set the current control to maximum, set switches SW1-1

and SW1-2 open (factory setting) and remove the jumper between pins 22 and 23 of connector

J3. Connect the external current source between pins 11 (positive) and 12 (return). Varying

the current source from 0-1mA causes the current limit to vary from 0-100% of rated maximum.

Switch SW1 and Connector J3 Configuration

for 0-1mA Current Programming of the Output Current Limit

(J3 sense line, OVP and voltage control jumpers shown set for local operation)

2-22 M362500-01 Rev H

Page 45

Sorensen DCS Series 1kW and 1.2kW Supplies Installation and Operation

Indicator Signal

J3 Connector Pin

Signal Voltage

Source Impedance

Thermal Shutdown

18

+10V

750

OVP Circuit Activated

17

+9V

750

Remote Programming

4

+10V

750

Voltage Mode

Operation

5

+10V

750

Current Mode

Operation

5

-3V

750

Monitor Signal

J3 Connector Pin

Jumper Selection

Output Signal

Range

Source

Impedance

Output Voltage

19 (+)

6 (RTN)

JP1

OUT

IN

0–5V

0–10V

100

Output Current

7 (+)

6 (RTN)

JP2

OUT

IN

0–5V

0–10V

100

2.12 Remote Monitoring and Status Indicators

Readback signals for remote monitoring of the output voltage and current are available at

connector J3 on the rear of the unit. A 0-5V (uncalibrated) signal between pins 19 (positive)

and 12 (negative) represents 0-100% of the rated output voltage. A 0-5V (calibrated) signal

between pins 7 (positive) and 12 (negative) represents 0-100% of the rated output current. The

offset and gain of the current readback signal may be adjusted through holes in the cover of the

unit (see Section 4.4 Calibration for location of adjusting holes).

Status indicators for thermal shutdown, OVP operation, remote programming and operating

mode are also available through the J3 connector. The table below lists the various signals, the

J3 connector pins where they are available, the approximate magnitude of the signal (measured

with respect to pin 6 of connector J3) and the source impedance through which the signal is

fed.

M362500-01 Rev H 2-23

Page 46

Page 47

CAUTION

Potentially LETHAL VOLTAGES exist on the A2 circuit board on the primary side

of the isolation barrier. Troubleshoot with care, preferably with power off and

recognizing that filter capacitors store potentially LETHAL and DESTRUCTIVE

ENERGY even for some time AFTER POWER is REMOVED. Always use an

isolation transformer connected ONLY to the power supply input when making

test measurements on the primary side circuits.

SECTION 3

THEORY OF OPERATION

3.1 Power Circuit (A2 Assembly)

This section describes the operation of the A2 assembly switching regulator power circuit.

Three subsections cover basic switching regulator theory, a simplified description of the

Sorensen full bridge converter, and a more detailed circuit description intended for

troubleshooting purposes.

3.1.1 Basic Off-Line Switching Regulator Theory

An off-line switching power supply first converts the AC input line voltage to high voltage DC by

diode rectification and then chops the DC at a high frequency. This high frequency waveform is

applied to the primary of a power transformer that provides a step-up or step-down in voltage

and electrical isolation on its secondary. The secondary waveform is rectified and filtered,

giving a smooth DC output voltage. Feedback from the secondary circuit is applied to a pulse

width modulator (PWM) control circuit which controls the on-time of the primary circuit switching

waveform. This increases or decreases the voltage on the secondary of the power transformer

so that output regulation is obtained.

The use of high frequency transformers in switching power supplies has the advantage of

requiring less volume, less weight, and dissipating less heat than the lower frequency

transformers in conventional linear power supplies.

M362500-01 Rev H 3-1

Page 48

Theory of Operation Sorensen DCS Series 1kW and 1.2kW Supplies

Figure 3-1 Simplified Full Bridge Converter

3-2 M362500-01 Rev H

Page 49

Sorensen DCS Series 1kW and 1.2kW Supplies Theory of Operation

CAUTION

Potentially LETHAL VOLTAGES exist on the A2 circuit board on the primary side

of the isolation barrier. Troubleshoot with care, preferably with power off and

recognizing that filter capacitors store potentially LETHAL and DESTRUCTIVE

ENERGY even for some time AFTER POWER is REMOVED. Always use an

isolation transformer connected ONLY to the power supply input when making

test measurements on the primary side circuits.