Page 1

DCS-E 1kW Series,

DLM-E 3kW & 4kW

Power Supplies

M51A Option: Isolated Analog

Programming Manual

M362250-01 Rev C www.programmablepower.com

Page 2

Page 3

Page 4

Page 5

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement,

process control, power bus simulation and power conditioning applications across diverse

industrial segments. From bench top supplies to rack-mounted industrial power subsystems,

AMETEK Programmable Power is the proud manufacturer of Elgar, Sorensen, California

Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromec hanical

devices with annualized sales of $2.5 billion. The Company has over 11,000 colleagues working

at more than 80 manufacturing facilities and more than 80 sales and service centers in the United

States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc. Sorensen is a trademark of AMETEK , Inc.

Other trademarks, registered trademarks, and product names are the property of their respective

owners and are used herein for identification purposes only.

Notice of Copyright

DCS-E 1kW Series, DLM-E 3kW & 4kW Power Supplies M51A Option: Isolated Analog

Programming Manual

© 2004 AMETEK Programmable Power, Inc. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC.

(“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL,

WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH

INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF TH E

TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED AMETEK CONTENT

IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION, WHICH IS POSTED AT

WWW.PROGRAMMABLEPOWER.COM.

Date and Revision

November 2008 Revision C

Part Number

M362250-01

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales@programmablepower.com

service@programmablepower.com

Web: www.programmablepower.com

i

Page 6

This page intentionally left blank.

ii

Page 7

G

G

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your

particular application.

WARNIN

WARNIN

Only qualified personnel who deal with attendant hazards in power supplies, are allowed to perform

installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or

chassis. Similarly, other power ground lines including those to application and maintenance

equipment must be grounded properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any

cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY may be normally generated on the output terminals. The customer/user must

ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety

glasses during open cover checks to avoid personal injury by any sudden component failure.

Neither AMETEK Programmable Power Inc., San Diego, California, USA, nor any of the subsidiary

sales organizations can accept any responsibility for personnel, material or inconsequential injury,

loss or damage that results from improper use of the equipment and accessories.

Hazardous voltages may be present when covers are removed. Qualified

personnel must use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating above

(below) chassis ground.

The equipment used contains ESD sensitive parts. When installing

equipment, follow ESD Safety Procedures. Electrostatic discharges might

cause damage to the equipment.

SAFETY SYMBOLS

iii

Page 8

This page intentionally left blank.

iv

Page 9

CONTENTS

SECTION 1 M51A OPTION OVERVIEW .............................................1-1

1.1 Introduction ...................................................................................................... 1-1

1.2 General Description ......................................................................................... 1-1

1.3 Specifications................................................................................................... 1-2

1.3.1 Electrical Specifications ....................................................................... 1-2

1.3.2 Supplemental Characteristics .............................................................. 1-2

SECTION 2 ISOLATED ANALOG PROGRAMMER OPERATION .........2-1

2.1 SW1 Switch ..................................................................................................... 2-1

2.1.1 SW1 Switch Setup ............................................................................... 2-2

2.2 ISOLATED ANALOG PROGRAMMER Connector (J4)................................... 2-3

2.2.1 ISOLATED ANALOG PROGRAMMER Functions ............................... 2-4

2.3 Remote Programming Configuration ............................................................... 2-7

2.3.1 Voltage Source Programming of Output Voltage................................. 2-7

2.3.2 Voltage Source Programming of Output Current................................. 2-8

2.3.3 Voltage Source Programming of OVP ................................................. 2-9

2.3.4 Resistance Programming of Output Voltage ..................................... 2-10

2.3.5 Resistance Programming of Output Current...................................... 2-11

2.3.6 Resistance Programming of OVP...................................................... 2-12

2.3.7 4-20mA Current Source Programming of Output Voltage ................. 2-13

2.3.8 4-20mA Current Source Programming of Output Current.................. 2-14

2.3.9 Programming the Shutdown Function ............................................... 2-15

2.3.10 TTL Shutdown ................................................................................. 2-15

2.3.11 Shutdown Application – Contact Closure ........................................ 2-16

2.3.12 Local/Remote Application ................................................................ 2-18

2.4 Remote Monitoring ........................................................................................ 2-19

2.5 Remote Digital Status Signals ....................................................................... 2-19

M51A Option v

Page 10

Contents DLM-E Series and DCS-E Series

LIST OF TABLES

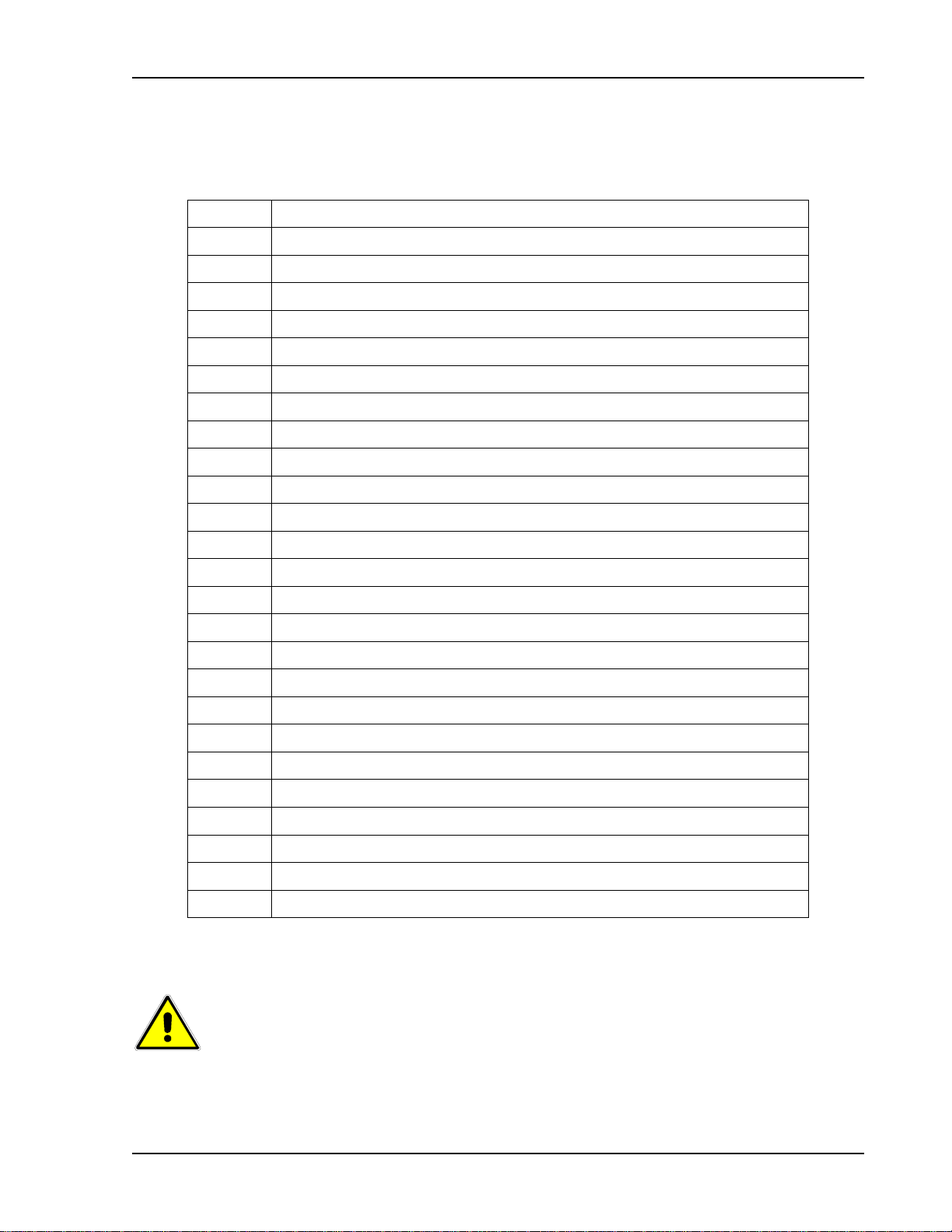

Table 2–1. SW1 SETUP Switch.................................................................................. 2-1

Table 2–2. ISOLATED ANALOG PROGRAMMER Connector Pinout ........................ 2-3

Table 2–3. Remote Monitoring................................................................................. 2-19

Table 2–4. Remote Digital Status Signals ............................................................... 2-19

LIST OF FIGURES

Figure 2–1. Rear Panel View, DLM-E Series 3kW and 4kW Power Supply ............... 2-2

Figure 2–2. Rear Panel View, DCS-E Series 1kW Power Supply .............................. 2-2

Figure 2–3. Using Shutdown with a DC Input (Positive Logic) ................................. 2-15

Figure 2–4. Using Shutdown with Contact Closure of a Normally OPEN Relay

(SW1-6 ON)........................................................................................... 2-16

Figure 2–5. Using Shutdown with Contact Closure of a Normally OPEN Relay

(SW1-6 OFF) ......................................................................................... 2-17

Figure 2–6. Using Shutdown with Contact Closure of a Normally CLOSED Relay

(SW1-6 ON)........................................................................................... 2-17

Figure 2–7 Using Local/Remote Operation with Contact Closure ............................ 2-18

vi M51A Option

Page 11

SECTION 1

M51A OPTION OVERVIEW

1.1 Introduction

This manual is to be used in conjunction with the DCS-E 1kW Series & DCS-E 1.2kW Series

DC Power Supplies Operation Manual, Sorensen Document No. M362500-01 and the DLM-E

3Kw & 4Kw Series Power Supplies Operation Manual, Sorensen Document No. M362000-01.

The Sorensen M51A Option provides a remote isolated analog programming interface, which

has safety isolation from the output terminals. This allows the remote analog interface to be

connected to user–accessible, Safety Extra Low Voltage, (SELV) control circuits, even though

the output terminals are floated at a high potential with respect to the chassis.

1.2 General Description

The M51A Option provides isolation for all programming, monitoring, and digital I/O signals that

are available through the standard rear panel analog interface connector. This isolation barrier

eliminates the connection that exists in the standard models between the non-isolated remote

interface circuits and the power supplies output return (negative) terminal. All control and

monitoring signals on the M51A option are optically coupled from the power supply output, and

can are user accessible irrespective of the float potentials that could exist at the output

terminals.

The M51A Option provides a full complement of programming, monitoring, and control

functions. Remote programming is available for output voltage, current, and overvoltage

protection (OVP). Analog output monitor signals are available for the output voltage and

current. Digital I/O signals provide indication of the operational state, and a means of enabling

the remote interface and the output.

The type and range of the control and monitor signals are user-selectable with a rear panel

setup switch and connector jumpers. The output voltage, current, and OVP can be programmed

with a 0-5VDC, 0-10VDC, or 0-5kΩ resistance; in addition, the output voltage and current can

be programmed with 4-20mA signals. The output voltage and current monitors can produce

0-5VDC, 0-10VDC, or 4-20mA signals. Isolated 1mA current sources are provided to facilitate

the utilization of 0-5kΩ programming resistances.

Except for the isolated remote analog interface, the installation and operation of the power

supplies remains as presented in the Operation Manual. The following sections provide a

detailed description of the new features and the differences in operation.

M51A Option 1-1

Page 12

M51A Option Overview DLM-E Series and DCS-E Series

1.3 Specifications

1.3.1 Electrical Specifications

Remote Voltage Programming Accuracy, 0-5/10V Inputs:

Output Voltage: 0.5% of Vmax

Output Current: 0.75% of Imax

OVP: 1.0% of 1.1 X Vmax

Remote 4-20 mA Programming Accuracy:

Output Voltage: 1.0% of Vmax

Output Current: 1.0% of Imax

Burden voltage of 6.25 VDC (312.5 ohms nominal)

1.3.2 Supplemental Characteristics

Remote Resistance Programming Accuracy, 0-5kΩ Input:

Output Voltage: 1.0% of Vmax

Output Current: 1.5% of Imax

OVP: 1.5% of 1.1 X Vmax

Remote Monitor Accuracy:

Output Voltage, 0-5/10V ranges: 0.5% of Vmax

Output Voltage, 4-20mA: 1.0% of Vmax

Output Current, 0-5/10V ranges: 0.75% of Imax

Output Current, 4-20mA: 1.0% of Imax

Electrical Isolation:

500 VDC from all isolated inputs to supply output

1-2 M51A Option

Page 13

SECTION 2

ISOLATED ANALOG

PROGRAMMER OPERATION

2.1 SW1 Switch

The SW1 SETUP switch is accessible from the rear panel of the unit. It provides user selection

of the programming/monitoring ranges and shutdown logic signal level. Setting a switch to the 1

or 0 position changes a range. The factory default settings are shown below.

Refer to Figure 2–1 for a rear panel view of the DLM-E 3kW and 4kW models.

Refer to Figure 2–2 for a rear panel view of the DCS-E 1kW models.

Switch

Position

1

2

3

4

5

6

* Indicates default settings

Output Voltage Monitor

Output Current Monitor

Remote ON-OFF Level

Function OFF (0) Position ON (1) Position

Voltage Programming

Range Select

Current Programming

Range Select

OVP Programming

Range Select

Range Select

Range Select

Select

0-10 VDC

0-10 VDC * 0-5 VDC, 4-20mA

0-10 VDC * 0-5 VDC

* 0-5 VDC 0-10 VDC

* 0-5 VDC 0-10 VDC

Active Low Signal * Active High Signal

* 0-5 VDC, 4-20mA

Table 2–1. SW1 SETUP Switch

M51A Option 2-1

Page 14

Isolated Analog Programmer Operation DLM-E Series and DCS-E Series

2.1.1 SW1 Switch Setup

The following sections describe the functions of the various switch positions:

Voltage Programming Range Select (V PROG): SW1-1, ON (1) position, selects 0-5VDC

programming range for the output voltage. Must also be set to ON (1) position when the Isolated

Analog Programmer is wired for 4-20mA input programming. OFF (0) position, selects 010VDC programming for the output voltage.

Current Programming Range Select (I PROG): SW1-2, ON (1) position selects 0-5VDC

programming range for the output current. Must also be set to ON (1) position when the Isolated

Analog Programmer is wired for 4-20mA input programming. OFF (0) position, selects 0-10VDC

programming for the output voltage.

OVP Programming Range Select (OVP PROG): SW1-3, ON (1) position selects 0-5VDC

programming of OVP threshold. OFF (0) position, selects 0-10VDC programming for OVP

threshold.

Output Voltage Monitor Range Select (V MON): SW1-4, ON (1) position selects 0-10VDC

range for readback of output voltage. OFF (0) position selects 0-5VDC readback of output

voltage. 4-20mA readback for output voltage is independent of the position of this switch.

Output Current Monitor Range Select (I MON): SW1-5, ON (1) position selects 0-10VDC

range for readback of output current. OFF (0) position selects 0-5VDC readback of output

current. 4-20mA readback for output current is independent of the position of this switch.

Remote ON-OFF Level Select (S/D): SW1-6, ON (1) position selects ACTIVE-HIGH logic level

for disabling the output with the S/D signal of the Isolated Analog Programmer connector. OFF

(0) position selects the ACTIVE-LOW logic level for disabling the output with the S/D signal of

the Isolated Analog connector.

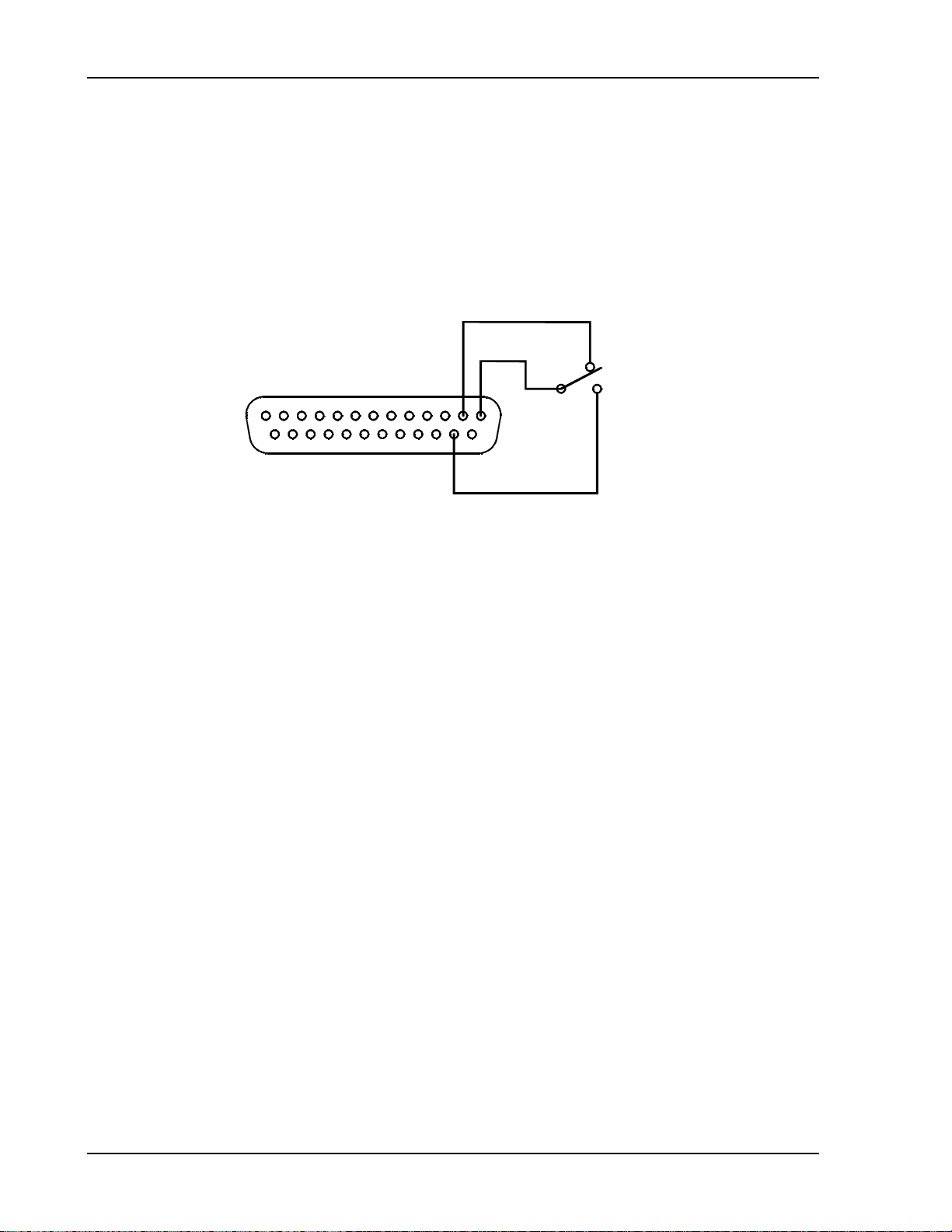

Figure 2–1. Rear Panel View, DLM-E Series 3kW and 4kW Power Supply

Figure 2–2. Rear Panel View, DCS-E Series 1kW Power Supply

2-2 M51A Option

Page 15

DLM-E Series and DCS-E Series Isolated Analog Programmer Operation

2.2 ISOLATED ANALOG PROGRAMMER Connector (J4)

The ISOLATED ANALOG PROGRAMMER connector is a 25-position female

Subminiature-D type. The table below defines each pins function.

Pin Function

1 ANALOG-CONTROL input

2 Isolated Analog Common

3 OVP programming input

4 Voltage monitor output, 4-20mA

5 VOLTAGE-MODE status output

6 Isolated Analog Common

7 Current monitor output, 0-5/10V

8 4-20mA voltage programming offset signal (-2.5VDC)

9 Voltage programming input, 0-5/10V

10 Current programming input, 0-5/10V

11 4-20mA current programming offset signal (-2.5VDC)

12 Isolated Analog Common

13 Return for 4-20mA current programming signal

14 Shut-Down input

15 Auxiliary 16VDC output (+)

16 OVP resistance programming output, 1mA source

17 OVP status output

18 FAULT status output

19 Voltage monitor output, 0-5/10V

20 Input for 4-20mA current programming offset signal (-2.5VDC)

21 Voltage resistance programming output, 1mA source

22 Current resistance programming output, 1mA source

23 Input for 4-20mA current programming offset signal (-2.5VDC)

24 Current monitor output, 4-20mA

25 Return for 4-20mA voltage programming

Table 2–2. ISOLATED ANALOG PROGRAMMER Connector Pinout

CAUTION

The signals of the ISOLATED ANALOG PROGRAMMER have an

internal connection to chassis ground. Damage could result if the

voltage from signal returns, Pin-2, 6, 12, 13, and 25 to chassis ground

exceeds 60VDC.

M51A Option 2-3

Page 16

Isolated Analog Programmer Operation DLM-E Series and DCS-E Series

2.2.1 ISOLATED ANALOG PROGRAMMER Functions

The following sections describe the functions of the various signals of the ISOLATED ANALOG

Programmer. Circuit is SELV, and all connections have electrical isolation from the output of the

unit. Pin numbers correspond to the rear panel J4 connector pin out of Table 2–2.

Digital Control Input Signals

ANALOG-CONTROL (Remote/Local): Pin-1, enables remote analog programming with an

active-low logic level. When a low level is applied, the supply will power-up with the analog

interface in control of the output voltage. When high, the power supply will be in local control

mode. Signal return is at J4-2.

EXTERNAL SHUT DOWN (S/D): Pin-14, disables the output when applied and supply is

working in the Remote Control mode. Logic level can be selected with switch SW1-6 to be

active high or low. Signal return is at J4-2.

Digital Control Status Output Signals

VOLTAGE-MODE: Pin-5, nominal 5VDC logic level indicates operation in constant-voltage

mode. Low logic level indicates operation in constant current mode. Signal return is at J4-2.

OVP: Pin-17, nominal 5VDC logic level indicates that the output has been disabled because of

overvoltage protection. Signal return is at J4-2.

FAULT: Pin-18, nominal 5VDC logic level indicates that the output is disabled because of an

over temperature or shutdown fault. Signal return is at J4-2.

Analog Monitor Signals

VOLTAGE MONITOR, 0-5/10V: Pin-19, provides an analog readback of the output voltage

with a 0-5VDC or 0-10VDC signal (user selectable with switch SW1-4) indicating 0-100% of full

scale output. Signal is referenced to J4-6.

VOLTAGE MONITOR, 4-20mA: Pin-4, provides an analog readback of the output voltage with

a 4-20mA signal indicating 0-100% of full scale output. Signal return for the 4-20mA current is

J4-6.

CURRENT MONITOR, 0-5/10V: Pin-7, provides an analog readback of the output current with

a 0-5VDC or 0-10VDC signal (user selectable with switch SW1-5) indicating 0-100% of full scale

output. Signal return is at J4-6.

CURRENT MONITOR, 4-20mA: Pin-24, provides an analog readback of the output current

with a 4-20mA signal indicating 0-100% of full scale output. Signal return for the 4-20mA current

is J4-6.

2-4 M51A Option

Page 17

DLM-E Series and DCS-E Series Isolated Analog Programmer Operation

Analog Programming Signals

OVP PROGRAMMING INPUT: Pin-3, an input signal of 0-5 volts or 0-10 volts (user selectable

with switch SW1-3) programs the OVP threshold from 5-110% of full scale output voltage.

Signal return is at J4-12.

Note: The OVP input is programmed to 110% by an internal connection between the 1mA

source on Pin-16 to a separate circuit. This allows the user to program remotely without having

to provide a separate programming source or jumper to the OVP input.

VOLTAGE PROGRAMMING INPUT: Pin-9, an input signal of 0-5 volts, 0-10 volts or 4-20mA

programs the output voltage from 0-100% of full scale.

a) An input signal of 0-5 volts or 0-10 volts (user selectable with switch SW1-1) programs the

output voltage from 0-100% of full scale. Signal return is at J4-12.

b) An input signal of 4-20mA (with switch SW1-1 set to ON (1) position, programs the output

voltage from 0-100% of full scale. Jumpers from J4-25 to J4-12 and J4-20 to J4-8 are also

required. Signal return for the 4-20mA current is J4-25.

CURRENT PROGRAMMING INPUT: Pin-10, an input signal of 0-5 volts, 0-10 volts or 4-20mA

programs the output current from 0-100% of full scale.

a) An input signal of 0-5 volts or 0-10 volts (user selectable with switch SW1-2) programs the

output current from 0-100% of full scale. Signal return is at J4-12.

b) An input signal of 4-20mA (with switch SW1-2 set to ON (1) position) programs the output

current from 0-100% of full scale. Jumpers from J4-13 to J4-12 and J4-23 to J4-11 are also

required. Signal return for the 4-20mA current is J4-23.

OVP RESISTANCE PROGRAMMING OUTPUT: Pin-16, provides a 1mA current source which

when connected to Pin-3, the OVP PROG INPUT, with a 0-10KΩ external resistor connected

between Pin-16 and Pin-12, programs the OVP threshold from 5-110% of full scale output

voltage. Switch SW1-3 must be set to ON (1) to select 0-5VDC input range.

Note: The OVP input is programmed to 110% by an internal connection between the 1mA

source on Pin-16 to a separate circuit. This allows the user to program remotely without having

to provide a separate programming source or jumper to the OVP input.

VOLTAGE RESISTANCE PROGRAMMING OUTPUT: Pin-21, provides a 1mA current source

which when connected to Pin-9, the V PROG INPUT, with a 0-5KΩ external resistor connected

between Pin-21 and Pin-12, programs the output voltage from 0-100% of full scale output.

Switch SW1-1 must be set to ON (1) to select 0-5VDC input range.

CURRENT RESISTANCE PROGRAMMING OUTPUT: Pin-22, provides a 1mA current source

which when connected to Pin-10, the I PROG INPUT, with a 0-5KΩ external resistor connected

between Pin-22 and Pin-12, programs the output current from 0-100% of full scale output.

Switch SW1-2 must be set to ON (1) to select 0-5VDC input range.

M51A Option 2-5

Page 18

Isolated Analog Programmer Operation DLM-E Series and DCS-E Series

Auxiliary Sources

AUXILIARY DC OUTPUT: Pin-15, 16VDC source for use with logic and programming circuits.

Source capability is adequate to provide for full scale programming of output voltage, current, or

OVP when the user connects it to the appropriate programming input(s). Source is referenced

to Pin-6. Can be used as a source for 4-20mA programming current.

AUXILIARY DC RETURN: Pin-6, return for AUXILIARY source output.

4-20MA CURRENT PROGRAMMING OFFSET SIGNAL (-2.5VDC): Pin-8, provides a negative

2.5VDC to zero out the 4mA signal generated by internal circuits when using 4-20mA

programming of output voltage. Jumpers to Pin-20.

4-20MA CURRENT PROGRAMMING OFFSET SIGNAL (-2.5VDC): Pin-11, provides a

negative 2.5VDC to offset the signal generated by internal circuits when using 4-20mA

programming of output current. Jumpers to Pin-23.

2-6 M51A Option

Page 19

DLM-E Series and DCS-E Series Isolated Analog Programmer Operation

2.3 Remote Programming Configuration

2.3.1 Voltage Source Programming of Output Voltage

SW1 Switch Settings

SW1-1 ON (1)= 0–5V

SW1-1 OFF (0)= 0–10V

291213 1

25

14

Set up for voltage source programming of the output voltage as follows:

1. Set SW1-1, V PROG, to ON (1) for 0-5VDC programming range.

2. Set SW1-1, V PROG, to OFF (0) for 0-10VDC programming range.

3. Connect the external programming voltage source to the ISOLATED ANALOG

PROGRAMMER connector, J4, with positive to Pin-9 and negative to Pin-12.

4. Connect Pin-1, ANALOG-CONTROL, of the ISOLATED ANALOG PROGRAMMER

connector, J4, to Pin-2 to enable remote control.

5. Program the other parameters to the desired limit values.

M51A Option 2-7

Page 20

Isolated Analog Programmer Operation DLM-E Series and DCS-E Series

2.3.2 Voltage Source Programming of Output Current

SW1 Switch Settings

SW1-2 ON (1) = 0–5V

SW1-2 OFF (0)= 0–10V

2101213 1

25

14

Set up for voltage source programming of the output voltage as follows:

1. Set SW1-2, I PROG, to ON (1) for 0-5VDC programming range.

2. Set SW1-1, V PROG, to OFF (0) for 0-10VDC programming range.

3. Connect the external programming voltage source to the ISOLATED ANALOG

PROGRAMMER connector, J4, with positive to Pin-10 and negative to Pin-12.

4. Connect Pin-1, ANALOG-CONTROL, of the ISOLATED ANALOG PROGRAMMER

connector, J4, to Pin-2 to enable remote control.

5. Program the other parameters to the desired limit values.

2-8 M51A Option

Page 21

DLM-E Series and DCS-E Series Isolated Analog Programmer Operation

2.3.3 Voltage Source Programming of OVP

SW1 Switch Settings

SW1-3 ON (1) = 0–5V

SW1-3 OFF(0) = 0–10V

2361213 1

25

1416

Set up for voltage source programming of OVP as follows:

1. Set SW1-3, OVP PROG, to ON (1) for 0-5VDC programming range.

2. Set SW1-3, OVP PROG, to OFF (0) for 0-10VDC programming range.

3. Connect the external programming voltage source to the ISOLATED ANALOG

PROGRAMMER connector, J4, with positive to Pin-5 and negative to Pin-12.

4. Connect Pin-1, ANALOG-CONTROL, of the ISOLATED ANALOG PROGRAMMER

connector, J4, to Pin-2 to enable remote control.

5. Connect Pin 16, OVP RESISTANCE PROGRAMMING OUTPUT, of the ISOLATED

ANALOG PROGRAMMER connector, J4, to Pin 6 to disable the default OVP

programming connection.

6. Program the other parameters to the desired limit values.

M51A Option 2-9

Page 22

Isolated Analog Programmer Operation DLM-E Series and DCS-E Series

2.3.4 Resistance Programming of Output Voltage

SW1 Switch Settings

SW1-1 ON (1) = 0–5K

291213 1

25 21

14

Set up for resistance programming of the output voltage as follows:

1. Set SW1-1, V PROG, to ON (1) for 0-5VDC programming range.

2. Connect the external programming resistance, 0-5kΩ, to the ISOLATED ANALOG

PROGRAMMER connector, J4, from Pin-9 to Pin-12.

3. Connect a jumper from Pin-21 to Pin-9 to connect the 1mA current source.

4. Connect Pin-1, ANALOG-CONTROL, of the ISOLATED ANALOG PROGRAMMER

connector, J4, to Pin-2 to enable remote control.

5. Program the other parameters to the desired limit values.

2-10 M51A Option

Page 23

DLM-E Series and DCS-E Series Isolated Analog Programmer Operation

2.3.5 Resistance Programming of Output Current

SW1 Switch Settings

SW1-2 ON (1) = 0–5K

2101213 1

25 22

14

Set up for resistance programming of the output current as follows:

1. Set SW1-2, I PROG, to ON (1) for 0-5VDC programming range.

2. Connect the external programming resistance, 0-5kΩ, to the ISOLATED ANALOG

PROGRAMMER connector, J4, from Pin-10 to Pin-12.

3. Connect a jumper from Pin-22 to Pin-10 to connect the 1mA current source.

4. Connect Pin-1, ANALOG-CONTROL, of the ISOLATED ANALOG PROGRAMMER

connector, J4, to Pin-2 to enable remote control.

5. Program the other parameters to the desired limit values.

M51A Option 2-11

Page 24

Isolated Analog Programmer Operation DLM-E Series and DCS-E Series

2.3.6 Resistance Programming of OVP

SW1 Switch Settings

SW1-3 ON (1) = 0–5K

2361213 1

25

141621

Set up for resistance programming of the output voltage as follows:

1. Set SW1-3, OVP PROG, to ON (1) for 0-5VDC programming range.

2. Connect the external programming resistance, 0-5KΩ, to the ISOLATED ANALOG

PROGRAMMER connector, from Pin-3 to Pin-12.

3. Connect a jumper from Pin-3 to Pin-21 or Pin-22, (whichever one is available) to connect

the 1mA current source.

4. Connect Pin-1, ANALOG-CONTROL, of the ISOLATED ANALOG PROGRAMMER

connector, J4, to Pin-2 to enable remote control.

5. Program the other parameters to the desired limit values.

6. Connect Pin-16, OVP Default Programming Input, of the ISOLATED ANALOG

PROGRAMMER connector (J4) to Pin-6 to disable the default OVP programming

connection.

2-12 M51A Option

Page 25

DLM-E Series and DCS-E Series Isolated Analog Programmer Operation

5

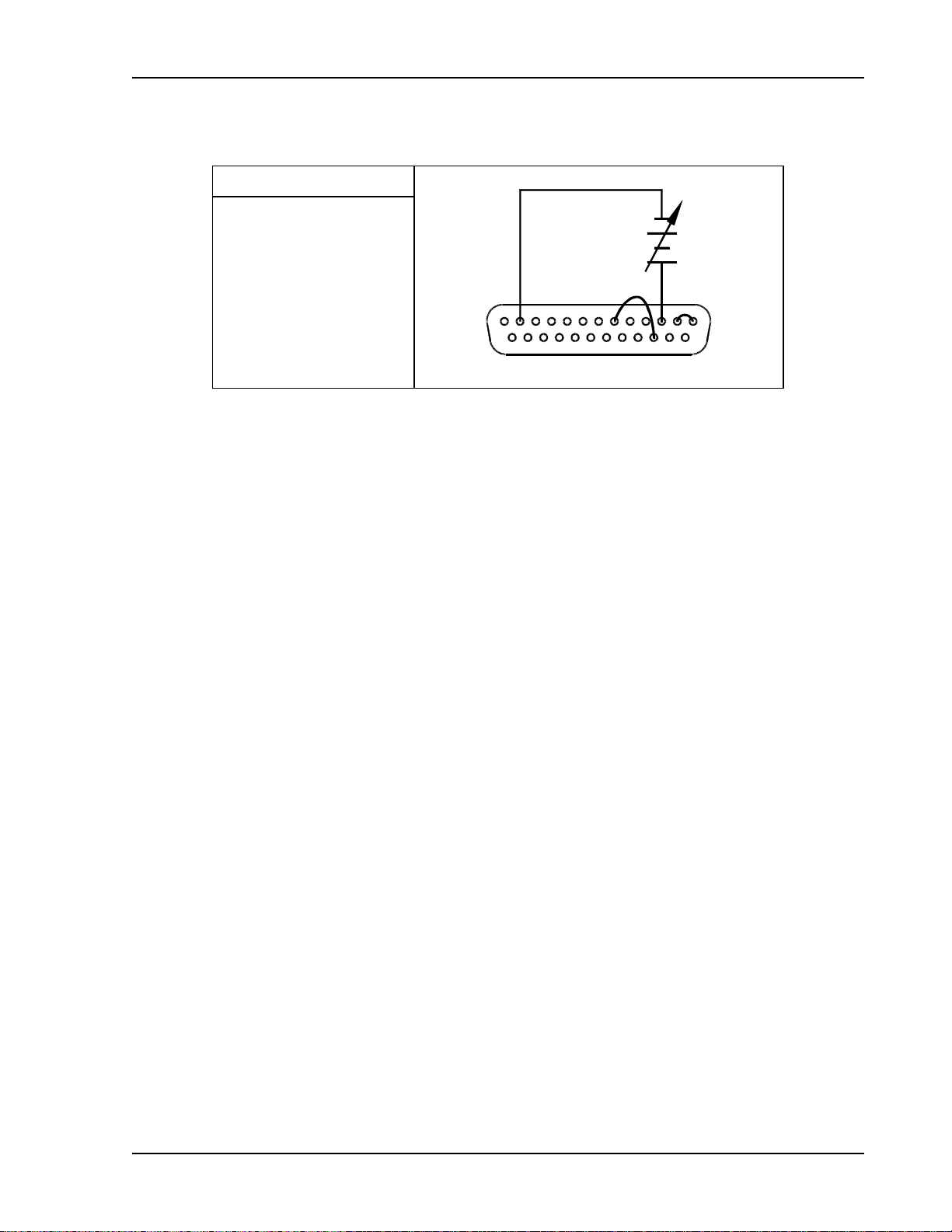

2.3.7 4-20mA Current Source Programming of Output Voltage

SW1 Switch Settings

SW1-1 ON (1) = 4-20mA

4-20mA

8

91213 12

2

1420

Set up for 4-20 mA programming of the output voltage as follows:

1. Set SW1-1, V PROG, to ON (1) for 4-20mA programming range.

2. Connect the external programming current source to the ISOLATED ANALOG

PROGRAMMER connector, J4, with the source to Pin-9 and the return to Pin-25.

3. Connect a jumper from Pin-25 to Pin-12 to connect the 4-20mA current sense resistors

to common.

4. Connect a jumper from Pin 20 to Pin 8 to provide the negative 2.5VDC to zero out the

4mA signal generated by internal circuits.

5. Connect Pin-1, ANALOG-CONTROL, of the ISOLATED ANALOG PROGRAMMER

connector, J4, to Pin-2 to enable remote control.

6. Program the other parameters to the desired limit values.

M51A Option 2-13

Page 26

Isolated Analog Programmer Operation DLM-E Series and DCS-E Series

5

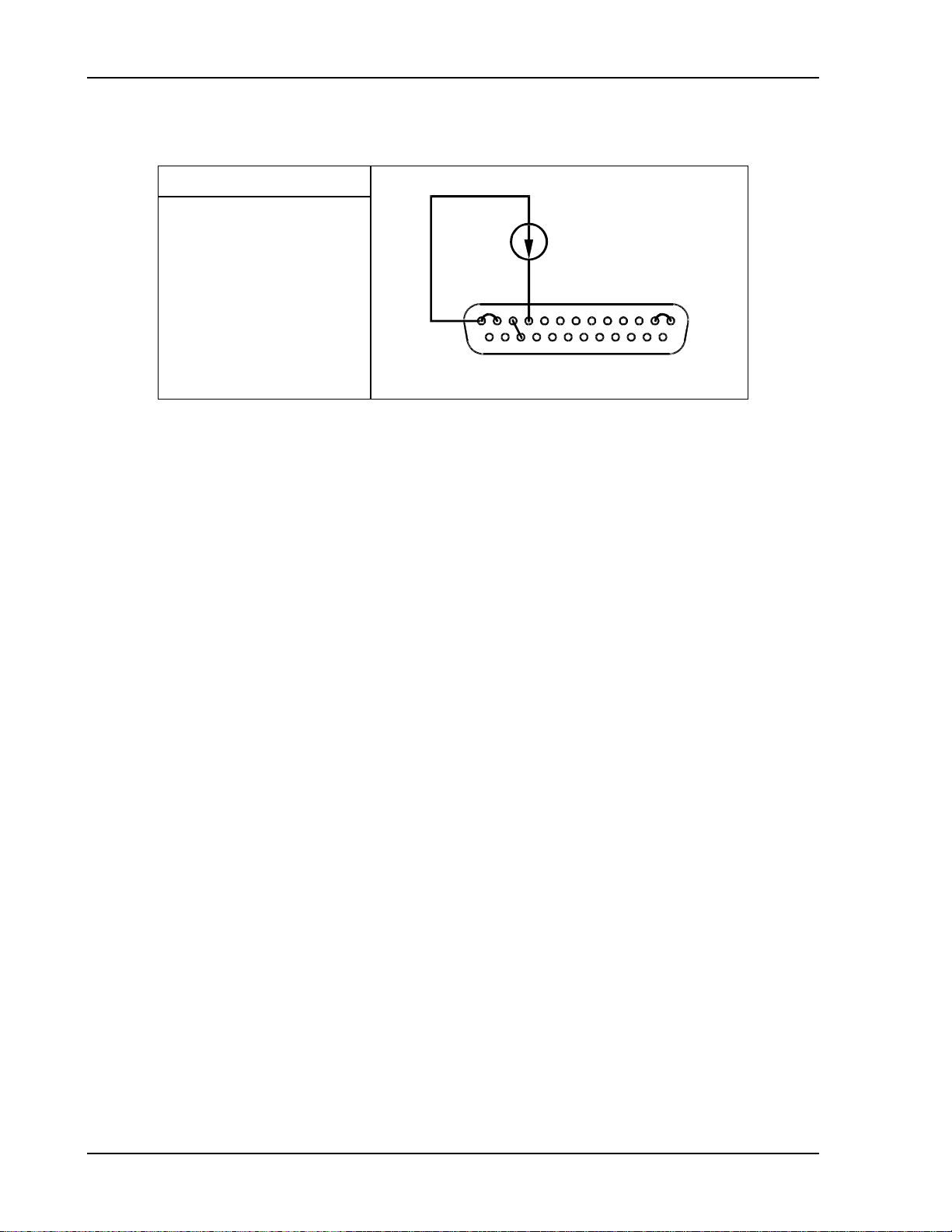

2.3.8 4-20mA Current Source Programming of Output Current

SW1 Switch Settings

SW1-2 ON (1) = 4-20mA

4-20mA

10

111213 12

2

1423

Set up for 4-20 mA programming of the output current as follows:

1. Set SW1-2, I PROG, to ON (1) for 4-20mA programming range.

2. Connect the external programming current source to the ISOLATED ANALOG

PROGRAMMER connector, J4, with the source to Pin-10 and the return to Pin-13.

3. Connect a jumper from Pin-13 to Pin-12 to connect the 4-20mA current sense resistors

to common.

4. Connect a jumper from Pin 23 to Pin 11 to provide the negative 2.5VDC to zero out the

4mA signal generated by internal circuits.

5. Connect Pin-1, ANALOG-CONTROL, of the ISOLATED ANALOG PROGRAMMER

connector, J4, to Pin-2 to enable remote control.

6. Program the other parameters to the desired limit values.

2-14 M51A Option

Page 27

DLM-E Series and DCS-E Series Isolated Analog Programmer Operation

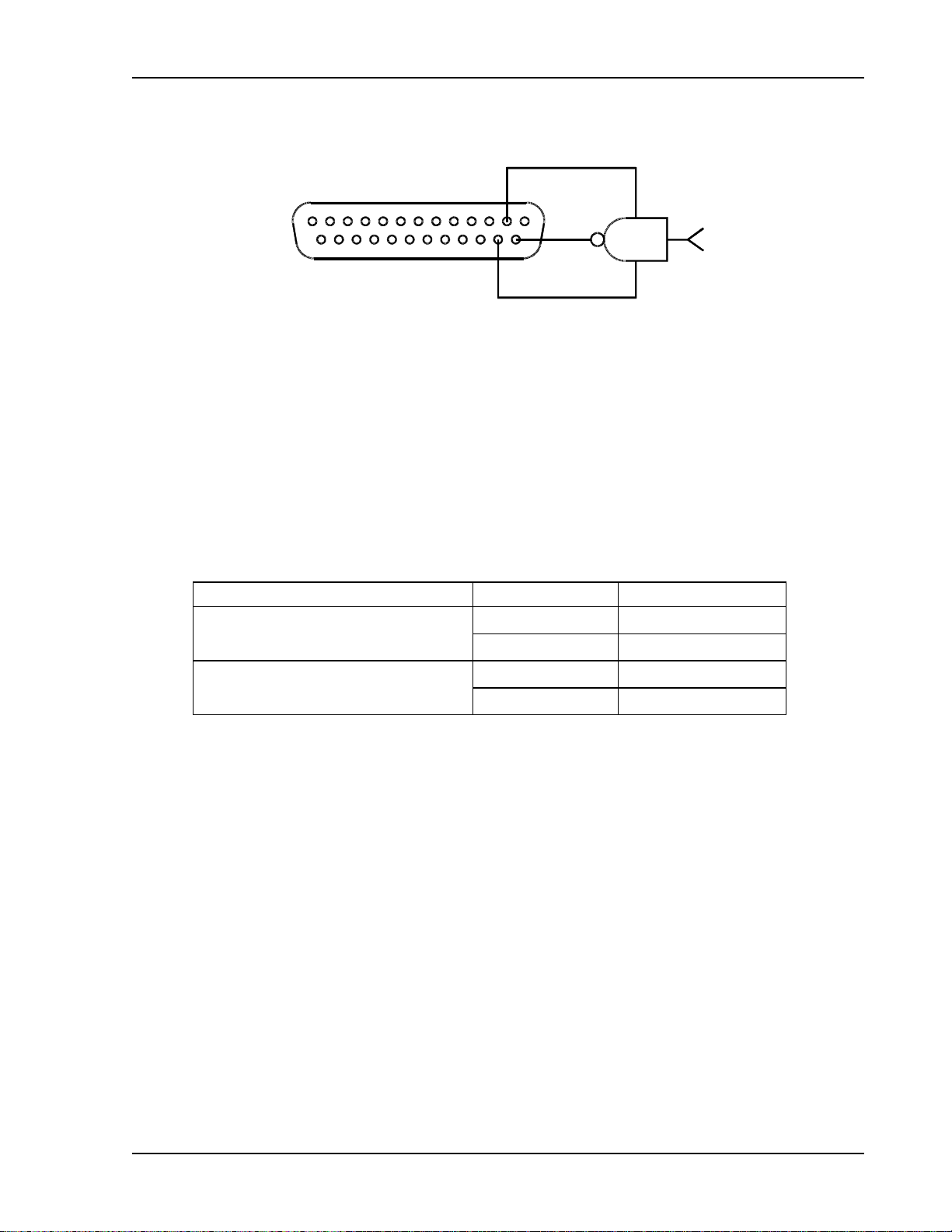

2.3.9 Programming the Shutdown Function

2131

GND

14

25

15

+5V

Figure 2–3. Using Shutdown with a DC Input (Positive Logic)

2.3.10 TTL Shutdown

Set up for Shutdown input signal as follows:

1. Connect the shutdown signal source to the ISOLATED ANALOG PROGRAMMER

connector, J4, with positive to Pin-14 and the return to Pin-2.

2. Set switch SW1-6 to select the desired logic as defined in the following table.

Switch SW1-6 Setting Signal Level Output Condition

Low OFF

OFF (0) = Negative Logic

High ON

High OFF

ON (1) = Positive Logic

Low ON

M51A Option 2-15

Page 28

Isolated Analog Programmer Operation DLM-E Series and DCS-E Series

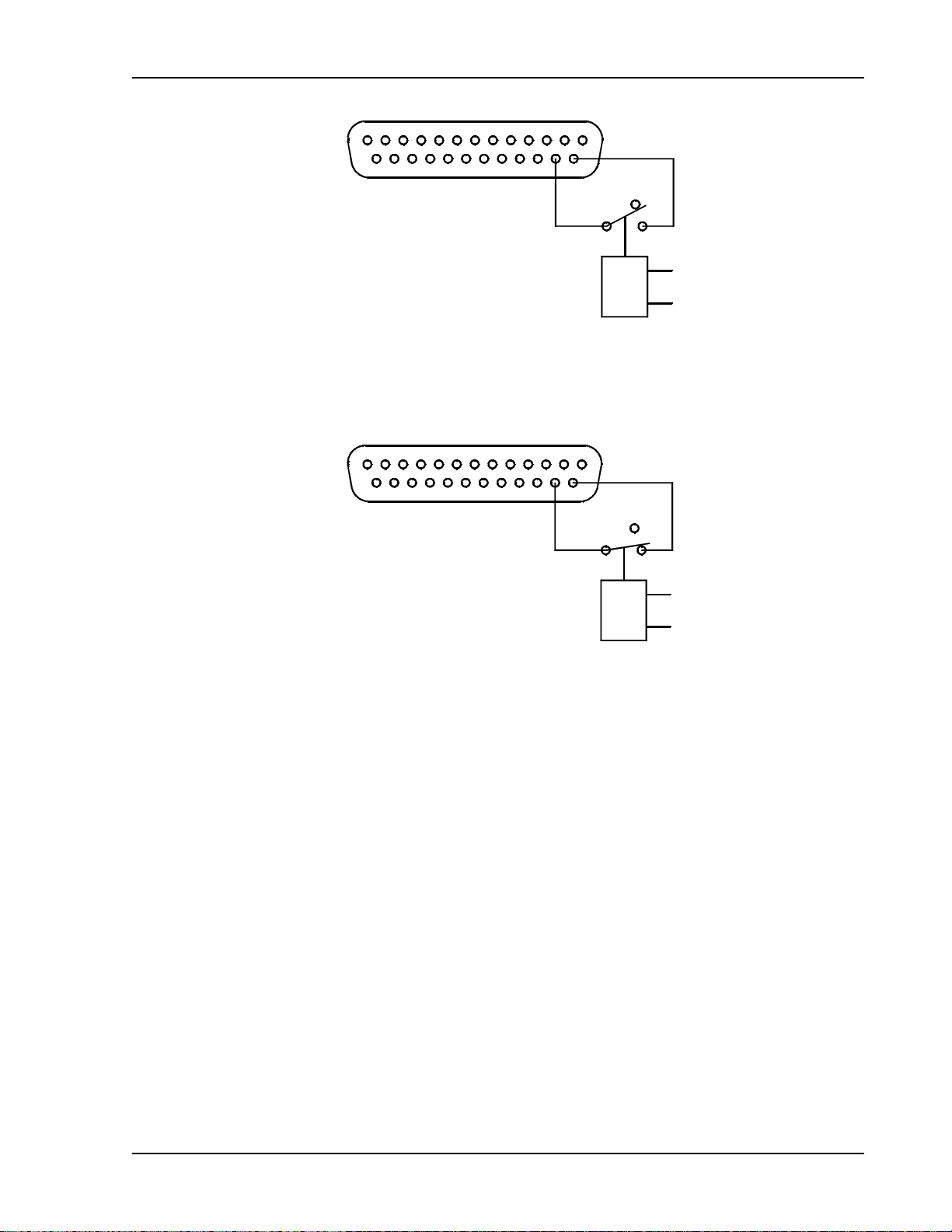

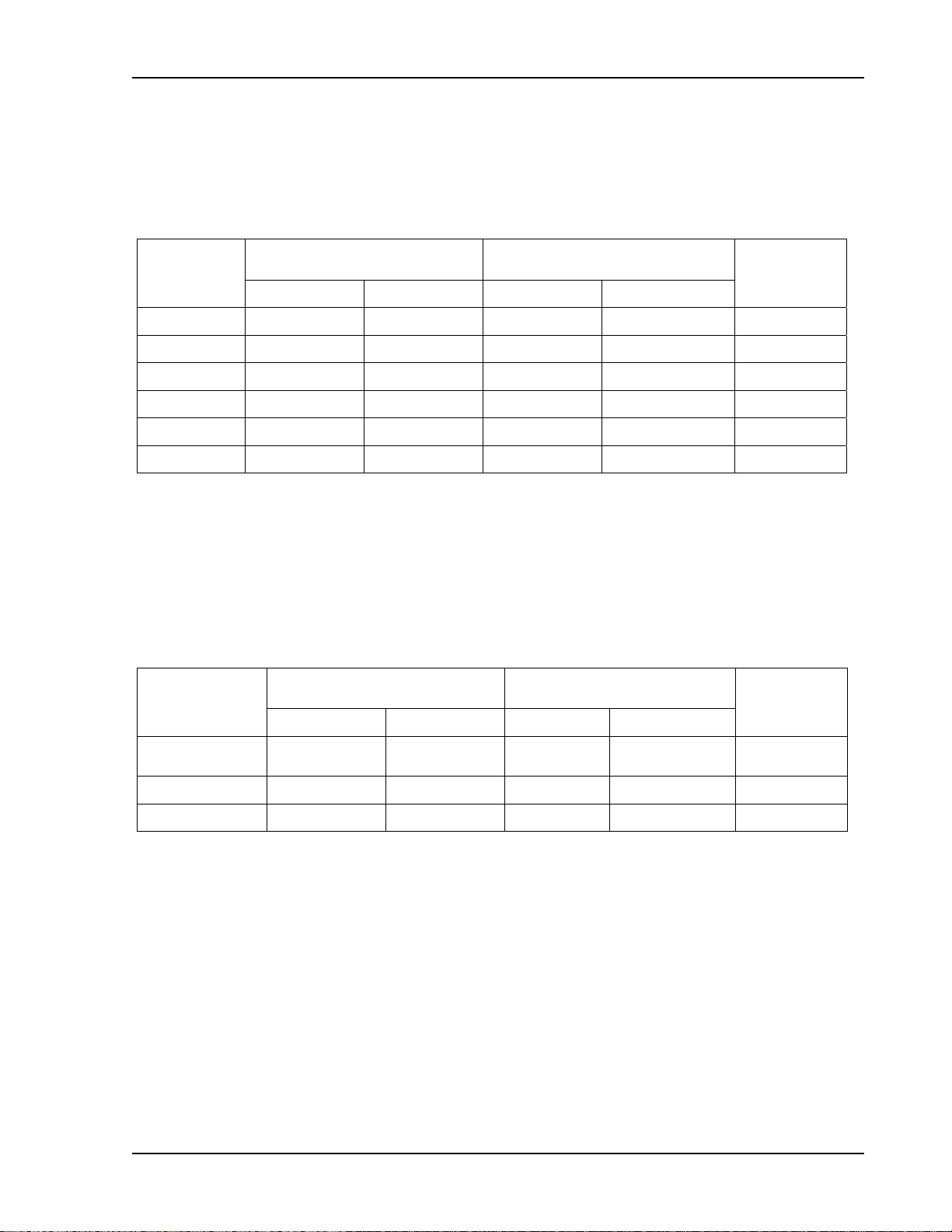

2.3.11 Shutdown Application – Contact Closure

An external relay, whether normally open or normally closed, may be used to activate the

Shutdown circuit. Either positive or negative logic may be used.

Set up for Shutdown input signal as follows:

1. Connect one side of the external relay to pin 15 (+16 VDC Auxiliary Output) on

connector J4. Connect the other side of the relay to pin 14 (Remote Shutdown Input).

2. Set rear panel DIP switch SW1-6 to select the desired circuit logic as defined in the

following table.

Relay Switch SW1-6 Setting Relay Coil State Output

ON (1) (Positive Logic)

Normally Open Relay

OFF (0) (Negative Logic)

ON (1) (Positive Logic)

Normally Closed Relay

OFF (0) (Negative Logic)

Energized OFF

De-energized ON

Energized ON

De-energized OFF

Energized ON

De-energized OFF

Energized OFF

De-energized ON

Figure 2–4.

13 1

14

25 15

Using Shutdown with Contact Closure of a Normally OPEN Relay (SW1-6 ON)

2-16 M51A Option

Page 29

DLM-E Series and DCS-E Series Isolated Analog Programmer Operation

13 1

14

25 15

Figure 2–5.

Using Shutdown with Contact Closure of a Normally OPEN Relay (SW1-6 OFF)

Figure 2–6.

13 1

14

25 15

Using Shutdown with Contact Closure of a Normally CLOSED Relay (SW1-6 ON)

M51A Option 2-17

Page 30

Isolated Analog Programmer Operation DLM-E Series and DCS-E Series

2.3.12 Local/Remote Application

An external relay or switch may be used to select the Local/Remote function.

1. Connect one side of the contacts to Pin-15 (+16 VDC Auxiliary Output) on connector J4.

Connect the other contact to Pin-2. Connect the wiper to Pin-1, Analog Control Input.

2. Remote operation results when Pin-1 is low (Pin 1-2) and local supply operation results

when Pin-1 is high (Pin1-15).

Remote

13 1

2

Local

25 15

14

Figure 2–7 Using Local/Remote Operation with Contact Closure

2-18 M51A Option

Page 31

DLM-E Series and DCS-E Series Isolated Analog Programmer Operation

2.4 Remote Monitoring

Analog signals are available for monitoring the output voltage and current. These signals vary

proportionally to the output parameters, and have user selectable ranges of 0-5VDC, 0-10VDC,

or 4-20mA for an output change from zero to full scale. Refer to Table 2–3 for information on

configuring the monitors.

Output

Monitor

Signal

Voltage Pin-19 Pin-12 4 - V MON ON (1) 0-10VDC

Voltage Pin-19 Pin-12 4 - V MON OFF (0) 0-5VDC

Voltage Pin-4 Pin-12 N/A N/A 4-20mA

Current Pin-7 Pin-12 5 - I MON ON (1) 0-10VDC

Current Pin-7 Pin-12 5 - I MON OFF (0) 0-5VDC

Current Pin-24 Pin-12 N/A N/A 4-20mA

Isolated Analog

Programmer Connector J4

Signal Return Position Setting

Table 2–3. Remote Monitoring

SW1 SETUP Switch

Signal

Range

2.5 Remote Digital Status Signals

Digital signals are available for remote monitoring the operational status of the unit. Refer to

Table 2–4 for information on the characteristics of the signals.

Status

Indicator

Signal

VOLTAGE-

MODE

OVP Pin-17 Pin-6 5V 0V 1kΩ

FAULT Pin-18 Pin-6 5V 0V 1kΩ

Isolated Analog Interface

Connector J4

Signal Return Asserted Not Asserted

Pin-5 Pin-6 5V 0V 1kΩ

Table 2–4. Remote Digital Status Signals

Logic Levels (with No

Signal Output Current)

Output

Resistance

M51A Option 2-19

Page 32

Isolated Analog Programmer Operation DLM-E Series and DCS-E Series

This page intentionally left blank.

2-20 M51A Option

Loading...

Loading...