Page 1

CW-P SERIES

PROGRAMMABLE

AC POWER SOURCE

Operation Manual

October 2013 Document No. M161691-01 Rev K

This manual covers models:

CW 801P

CW 1251P

CW 2501P

CW 801P–H

CW 1251P–H

CW 2501P–H

CW 801P–V

CW 1251P–V

CW 2501P–V

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email:

Domestic Sales: domorders.sd@ametek.com

International Sales: intlorders.sd@ametek.com

Customer Service: service.ppd@ametek.com

Web: www.programmablepower.com

Page 2

Page 3

Page 4

Page 5

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement,

process control, power bus simulation and power conditioning applications across diverse

industrial segments. From bench top supplies to rack-mounted industrial power subsystems,

AMETEK Programmable Power is the proud manufacturer of Elgar, Sorensen, California

Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical

devices with annualized sales of $2.5 billion. The Company has over 11,000 colleagues working

at more than 80 manufacturing facilities and more than 80 sales and service centers in the United

States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc.

Other trademarks, registered trademarks, and product names are the property of their respective

owners and are used herein for identification purposes only.

Notice of Copyright

CW-P Series Programmable AC Power Source, Operation Manual

Power, Inc. All rights reserved.

© 2010 AMETEK Programmable

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC.

(“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL,

WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH

INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE

TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED AMETEK CONTENT

IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION, WHICH IS POSTED AT

WWW.PROGRAMMABLEPOWER.COM.

Date and Revision

October 2013 Revision K

Part Number

M161691-01

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales.ppd@ametek.com

service.ppd@ametek.com

Web: www.programmablepower.com

i

Page 6

This page intentionally left blank.

ii

Page 7

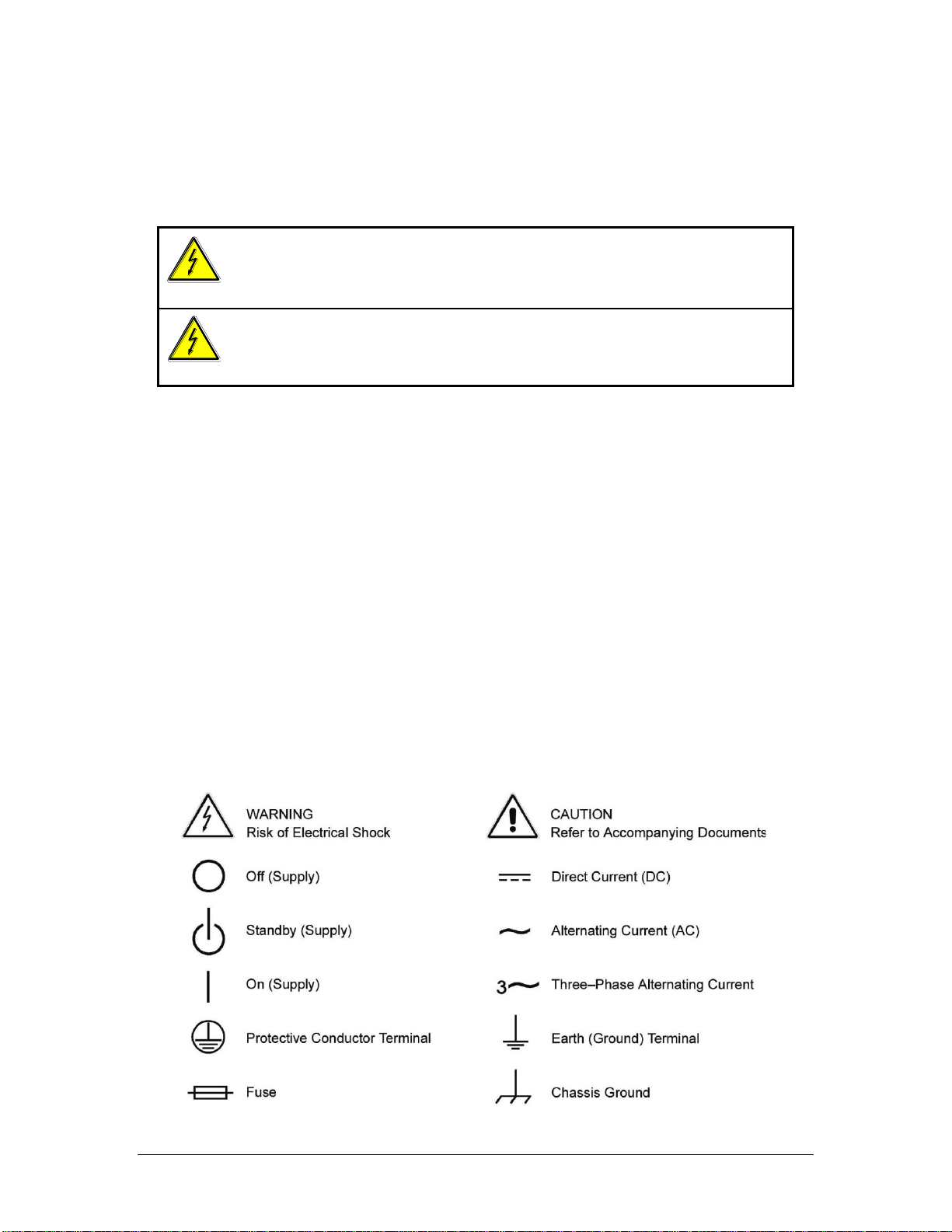

WARNING

Hazardous voltages may be present when covers are removed. Qualified

personnel must use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating above

(below) chassis ground.

WARNING

The equipment used contains ESD sensitive ports. When installing

equipment, follow ESD Safety Procedures. Electrostatic discharges might

cause damage to the equipment.

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your

particular application.

Only qualified personnel who deal with attendant hazards in power supplies, are allowed to perform

installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or

chassis. Similarly, other power ground lines including those to application and maintenance

equipment must be grounded properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any

cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY may be normally generated on the output terminals. The customer/user must

ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety

glasses during open cover checks to avoid personal injury by any sudden component failure.

Neither AMETEK Programmable Power Inc., San Diego, California, USA, nor any of the subsidiary

sales organizations can accept any responsibility for personnel, material or inconsequential injury,

loss or damage that results from improper use of the equipment and accessories.

SAFETY SYMBOLS

iii

Page 8

Product Family: CW801P, CW1251P, CW2501P, CW801P-H, CW1251P-H,

CW2501P-H, CW801P-V, CW1251P-V, CW2501P-V

Warranty Period: One Year

WARRANTY TERMS

AMETEK Programmable Power, Inc. (“AMETEK”), provides this written warranty covering the

Product stated above, and if the Buyer discovers and notifies AMETEK in writing of any defect in

material or workmanship within the applicable warranty period stated above, then AMETEK may,

at its option: repair or replace the Product; or issue a credit note for the defective Product; or

provide the Buyer with replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in

accordance with the return procedure specified below. AMETEK will, at its expense, deliver the

repaired or replaced Product or parts to the Buyer. Any warranty of AMETEK will not apply if the

Buyer is in default under the Purchase Order Agreement or where the Product or any part

thereof:

is damaged by misuse, accident, negligence or failure to maintain the same as

specified or required by AMETEK;

is damaged by modifications, alterations or attachments thereto which are not

authorized by AMETEK;

is installed or operated contrary to the instructions of AMETEK;

is opened, modified or disassembled in any way without AMETEK’s consent; or

is used in combination with items, articles or materials not authorized by AMETEK.

The Buyer may not assert any claim that the Products are not in conformity with any warranty

until the Buyer has made all payments to AMETEK provided for in the Purchase Order Agreement.

PRODUCT RETURN PROCEDURE

1. Request a Return Material Authorization (RMA) number from the repair facility (must be

done in the country in which it was purchased):

In the USA, contact the AMETEK Repair Department prior to the return of the

product to AMETEK for repair:

Telephone: 800-733-5427, ext. 2295 or ext. 2463 (toll free North America)

858-450-0085, ext. 2295 or ext. 2463 (direct)

Outside the United States, contact the nearest Authorized Service Center

(ASC). A full listing can be found either through your local distributor or our

website, www.programmablepower.com, by clicking Support and going to the

Service Centers tab.

2. When requesting an RMA, have the following information ready:

Model number

Serial number

Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by AMETEK, to be in specification is subject to

an evaluation fee and applicable freight charges.

iv

Page 9

CONTENTS

SECTION 1 INTRODUCTION ............................................................. 0-1

SECTION 2 SPECIFICATIONS .......................................................... 1-1

2.1 Output ................................................................................................... 1-1

2.2 Measurement ....................................................................................... 1-3

2.3 Input ..................................................................................................... 1-5

2.4 Protection ............................................................................................. 1-6

2.5 Rear Panel Connections....................................................................... 1-6

2.6 General ................................................................................................. 1-6

2.7 Options and Accessories ...................................................................... 1-7

SECTION 3 INSTALLATION .............................................................. 2-1

3.1 Unpacking ............................................................................................ 2-1

3.2 Wire Gauge Selection .......................................................................... 2-2

3.3 Mounting Instructions ........................................................................... 2-5

3.4 Cooling ................................................................................................. 2-5

3.5 Power In Connections ........................................................................ 2-10

3.5.1 Single–Phase Supply Connections ......................................... 2-10

3.5.2 Split-Phase Supply Connections 120–0–120V ....................... 2-11

3.5.3 Three–Phase Supply Connections ......................................... 2-11

3.6 Power Out Connections ...................................................................... 2-12

3.7 Sense Connections ............................................................................ 2-13

Operation Manual v

Page 10

Contents Elgar CW-P Series

3.8 Remote Control Signal ........................................................................ 2-15

3.8.1 Analog Amplitude Control ........................................................ 2-15

3.8.2 Lock to External Frequency Source ........................................ 2-15

3.8.3 Sync Output Pulse ................................................................... 2-16

3.9 Master/Slave Configurations ............................................................... 2-16

3.9.1 Setup for Single–Phase, Two Units ......................................... 2-17

3.9.2 Setup for Three–Phase, Two Units per Phase ........................ 2-20

SECTION 4 OPERATION .................................................................. 3-1

4.1 CW Front Panel Controls and Indicators .............................................. 3-1

4.2 Front Panel Overview ............................................................................ 3-4

4.3 Power Up .............................................................................................. 3-5

4.4 Programmed Frequency Steps ............................................................. 4-6

SECTION 5 PROGRAMMING ............................................................ 4-1

5.1 Programming the CW Via the Front Panel ............................................ 4-1

5.1.1 VOLTAGE/POWER Section ...................................................... 4-2

5.1.2 CURRENT/FREQUENCY Section ............................................. 4-2

5.2 Measurement Operations ..................................................................... 4-2

5.2.1 Supply Measurements on the Left Display ................................ 4-2

5.2.2 Supply Measurements on the Right Display .............................. 4-3

5.3 Menu Operations .................................................................................. 4-4

5.3.1 Self Test .................................................................................... 4-5

5.3.2 Set GPIB Port ............................................................................ 4-5

5.3.3 Specify Current Limit Type ........................................................ 4-6

5.3.4 Specify Shutdown Delay ............................................................ 4-6

5.3.5 Specify Program Keys Locked Mode ........................................ 4-6

5.3.6 Store Present Machine Settings ................................................ 4-6

5.3.7 Recall Machine Settings ............................................................ 4-7

5.3.8 Specify Relay State After Power Up Initialization ...................... 4-7

5.3.9 Clock Direction .......................................................................... 4-7

5.3.10 Analog Input State .................................................................... 4-7

vi Operation Manual

Page 11

Elgar CW-P Series Contents

vii

5.3.11 RMS Voltage Loop .................................................................. 4-8

5.3.12 Phase A Offset ........................................................................ 4-8

5.3.13 Phase B Offset ........................................................................ 4-8

5.3.14 Phase C Offset ........................................................................ 4-8

5.3.15 Slave Channel ......................................................................... 4-8

5.3.16 Slave Address ......................................................................... 4-8

5.3.17 Slave Configuration ................................................................. 4-8

SECTION 6 MAINTENANCE .............................................................. 5-1

6.1 Periodic Service .................................................................................... 5-1

6.2 Fuse Replacement ............................................................................... 5-1

LIST OF FIGURES

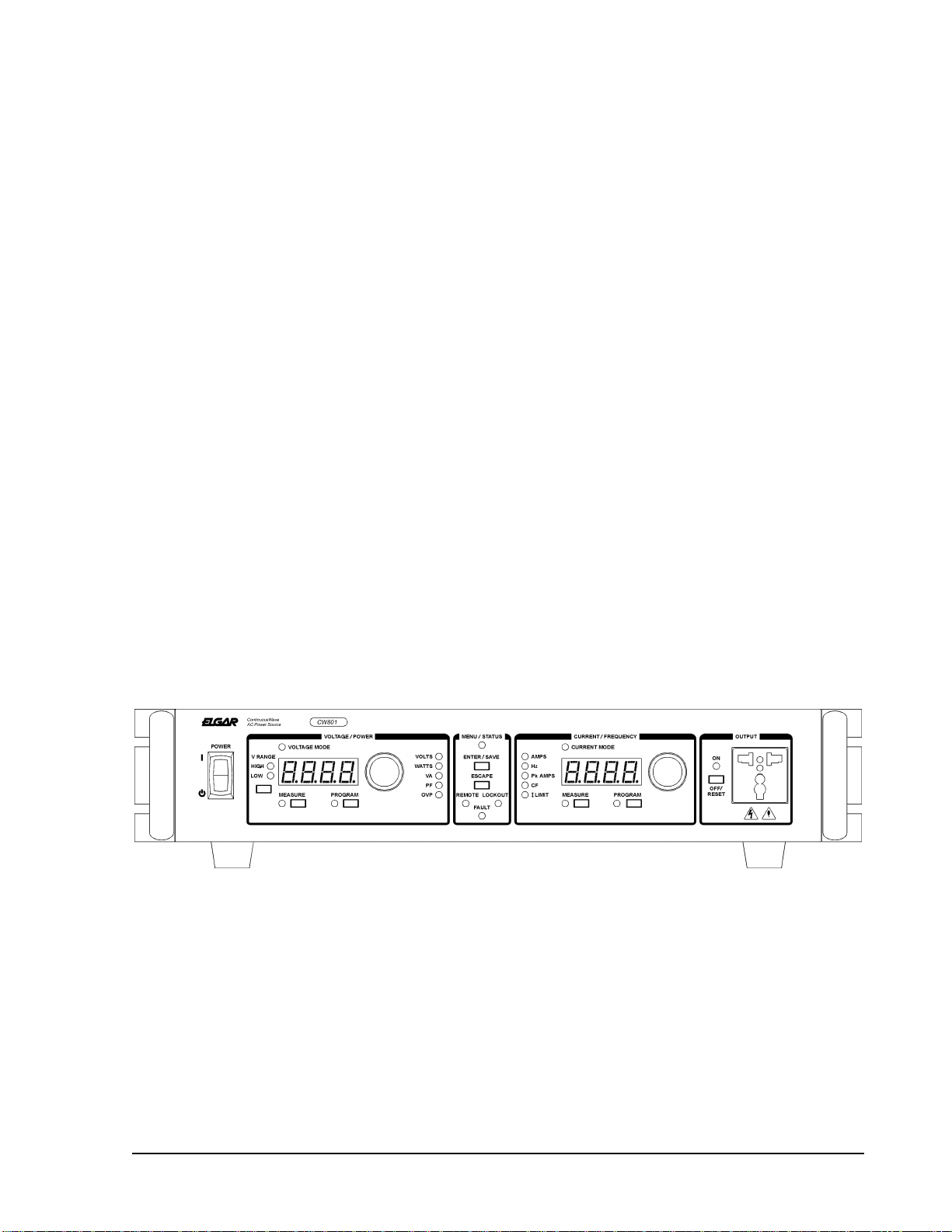

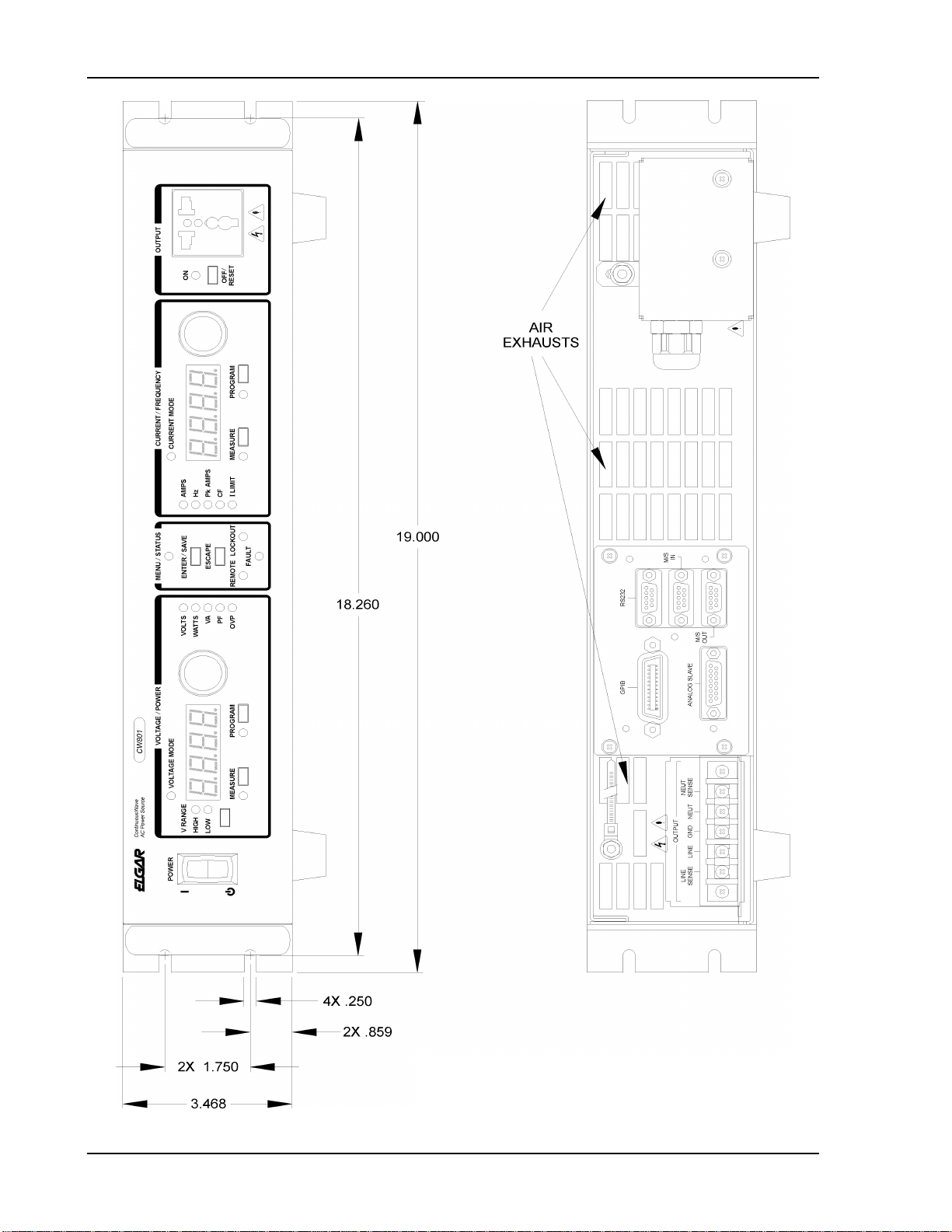

Figure 1–1 ContinuousWave Front Panel (Model CW 801P) ...................... 1-1

Figure 3–1 Slide Mounting ........................................................................... 3-5

Figure 3–2 Mounting Dimensions, Front and Rear Views

(CW 801P and CW 1251P) ....................................................... 3-6

Figure 3–3 Mounting Dimensions, Front and Rear Views (CW 2501P) ....... 3-7

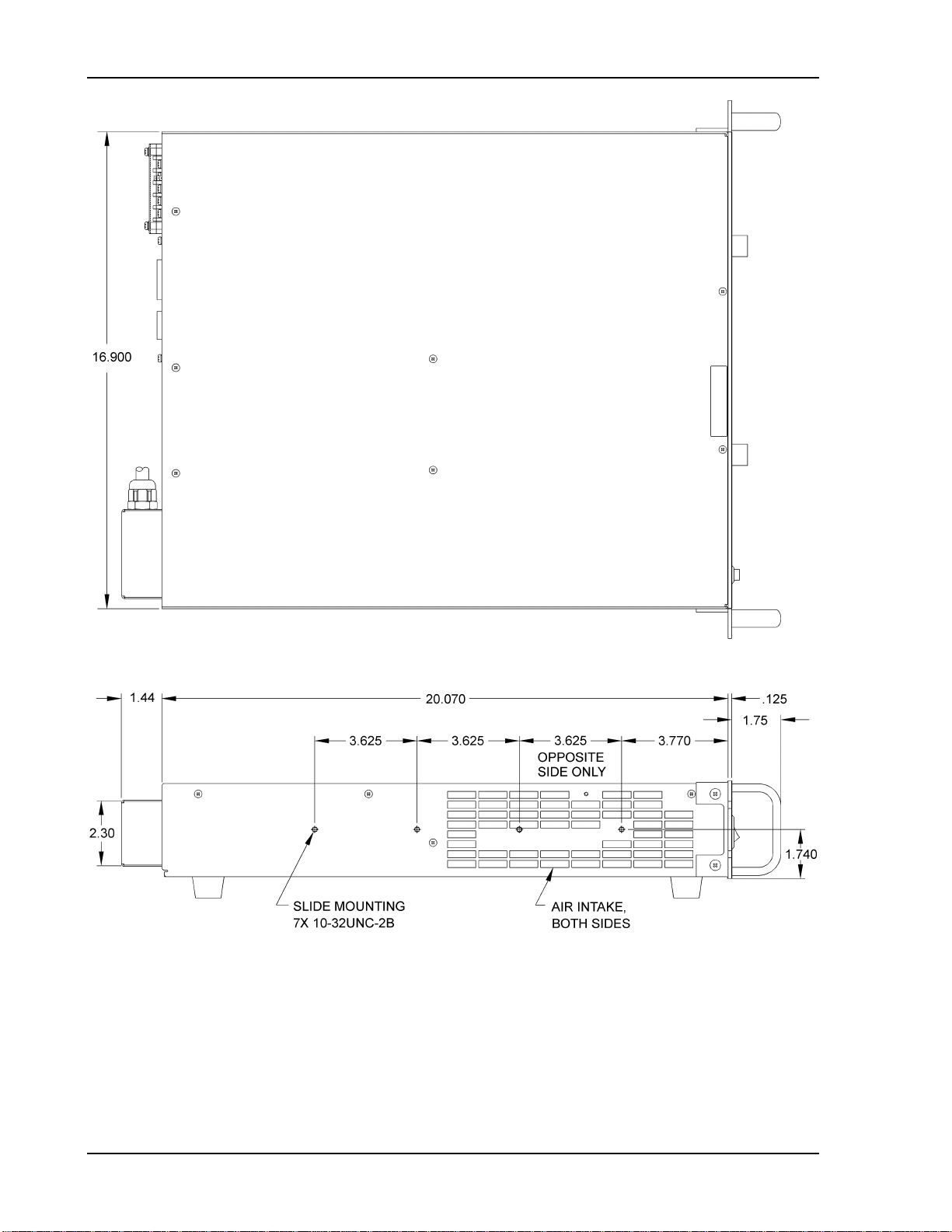

Figure 3–4 Mounting Dimensions, Top and Side Views

(CW 801P and CW 1251P) ....................................................... 3-8

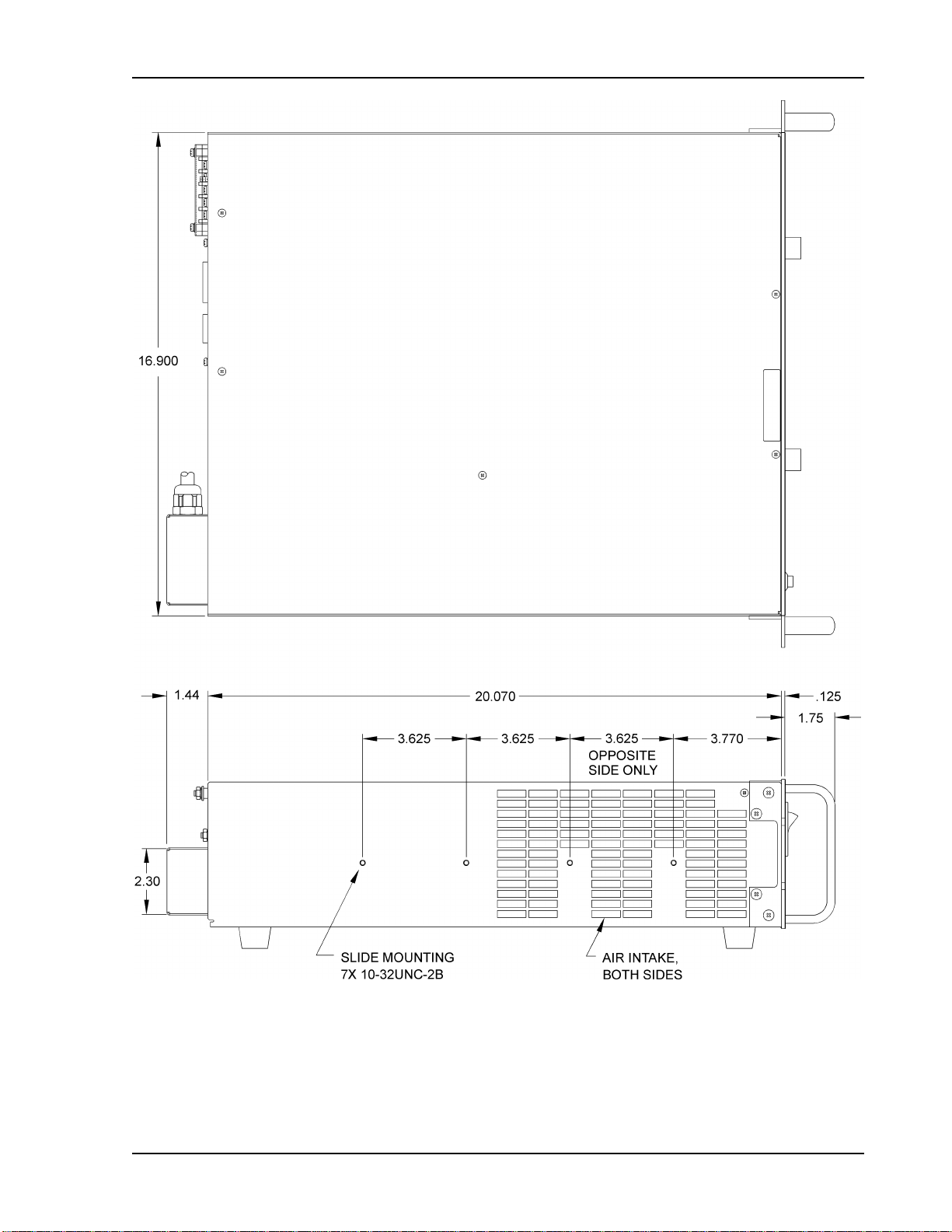

Figure 3–5 Mounting Dimensions, Top and Side Views (CW 2501P) ........ 3-9

Figure 3–6 Input Power Connections ........................................................ 3-10

Figure 3–7 Output Power Connections ...................................................... 3-12

Figure 3–8 Output Voltage Sensing Configuration .................................... 3-13

Figure 3–9 Sense Connections ................................................................. 3-14

Figure 3–10 M/S IN Connector .................................................................... 3-15

Figure 3–11 Wiring Diagram for One Phase, Master/Slave Configuration .. 3-17

Figure 3–12 Wiring Diagram fo r Three Phase, Master/Slave Configuration 3-20

Figure 4–1 Front Panel Controls (CW 801P) ............................................... 4-1

Operation Manual

Page 12

Contents Elgar CW-P Series

LIST OF TABLES

Table 3–1 Recommended Wire Gauge Selection Guide ............................... 2-2

Table 3–2 Recommended Cables ............................................................... 2-11

Table 6–1 Replacement Fuses ...................................................................... 5-1

viii Operation Manual

Page 13

SECTION 0

INTRODUCTION

Elgar's ContinuousWave™ (CW) Series power sources deliver 800 VA or 1250 VA in a

2U high (3.5 inches), and 2500 VA in a 5.25–inch benchtop or rackmount chassis.

Higher power and multiphase can be achieved by paralleling and multiphase

interconnection. This requires optional slave cables. The switchmode Power Factor

Corrected (PFC) input stage allows a wide range of input voltage and maximizes the

power available from a wall outlet.

The CW series units are available in manual and programmable versions. This

operation manual covers the programmable versions only.

Voltage, current, and frequency settings are quickly adjusted from the front panel

encoders. In addition, the sources can be programmed remotely from the rear panel

GPIB, RS-232, or analog port. The output is protected against overvoltage, overcurrent,

and overtemperature conditions. A two-speed fan results in quieter operation at lower

power levels.

Figure 1–1 ContinuousWave Front Panel (Model CW 801P)

Key features of the CW Series AC power sources include:

• High performance/value design

• 800, 1250, and 2500 VA units available

• Low profile 3.5" rack height required for up to 1250 VA;

5.25" rack height required for 2500 VA

• Bench top or rack mount (optional slides available)

Operation Manual 0-1

Page 14

Introduction Elgar CW-P Series

• 1 phase 45 to 500 Hz AC output; 45-1000 Hz with H–Option.

Units may be connected in multiphase configuration and/or paralleled for higher

powers. (Consult factory for more than two units paralleled.) Multiphase/paralleling

cables are optional.

• Transformer coupled output with disconnect relays

• 0 to 135V and 0 to 270V ranges; 0 to 155V and 0 to 310V ranges with V–Option

• CW 801P and CW 1251P versions have universal output socket on front panel.

All units have output power available at rear of unit.

• Remote sense leads for accurate output voltage

• Input PFC provides maximum utilization of available outlet current and wide range of

input voltage and frequency

• CE mark

• UL/CUL (consult factory for availability)

• GPIB and RS-232 control

• Two large, 7-segment LED, 4-digit displays on front panel

• Set volts, overvoltage, frequency, current, and overcurrent by two front panel

encoders

• Measure voltage, wattage, VA, power factor, current, peak current, and crest factor

• Display overvoltage, frequency, and overcurrent setting

• Over current shutdown or constant current mode menu-selectable

• Enable/disable output voltage rms loop menu-selectable

• Sync in, clock out, and analog programming of output voltage available through rear

panel connector. These items are menu-selectable.

• Front panel lockout; measurement active

• Stored settings including: Power up to previous front panel setting or 0V

• 2-speed fan for low noise

• Side air intake, exhaust to rear

• All connectors on rear

(output power also available at front for CW 801P and CW 1251P)

• Chassis depth 20" (front panel and rear connectors add additional depth)

• W ill fit in 24" RETMA rack system

• 1-year calibration interval, covers on soft calibration

0-2 Operation Manual

Page 15

1.1 Output

SECTION 1

SPECIFICATIONS

POWER

CW 801P 800 VA

CW 1251P 1250 VA

CW 2501P 2500 VA

Power Factor of Load 0 lag to 0 lead

Phase All models single phase output

VOLTAGE

Ranges

Accuracy ±0.1% of full scale <100 Hz, ±0.2% of full scale ≥100 Hz

Resolution 0.1 VRMS

0 to 135 VRMS or 0 to 270 VRMS, user selectable

V–Option: 0 to 155 VRMS or 0 to 310 VRMS, user

selectable

at >5 VRMS output

H–Option: ± 0.3% of full scale >500 Hz

AC Noise Level CW 801/1251P: <50 mVRMS typical in low-voltage range

<85 mVRMS typical in high-voltage range

CW 2501P: <100 mVRMS typical in low-voltage range

<170 mVRMS typical in high-voltage range

H–Option/V–Option:

CW 801/1251P: <75 mVRMS typical in low-voltage range

<125 mVRMS typical in high-voltage range

CW 2501P: <125 mVRMS typical in low-voltage range

<225 mVRMS typical in high-voltage range

Operation Manual 1-1

Page 16

Specifications Elgar CW-P Series

0.65% maximum up to 60 Hz; add 0.05%/10 Hz from 60 Hz

Option: 0.5%, typical up to 60Hz; add 0.05% from >60Hz to

100Hz; add 0.5%/100Hz from >100Hz up to 3.7%; increasing

CW 1251P(–H)

9.4 ARMS (135 VAC range), 4.7 ARMS (270 VAC range)

CW 1251P–V

8.2 ARMS (155 VAC range), 4.1 ARMS (310 VAC range)

≤500 Hz; ±1.0%

Total Harmonic

Distortion

to 100 Hz; add 0.4%/100 Hz from >100 Hz

H-

to 6% at 10% of full-scale voltage, 100% full-scale current,

and full-scale frequency

Amplitude Stability ±0.05% of full scale over 8 hours at constant line, load and

temperature after 15 minute warm-up typical

Load Regulation ±0.1% full scale voltage for full resistive load to no load

(<10 mVRMS typical, measured at point of sense)

Line Regulation ±0.1% of full scale voltage for a ±10% line change from

nominal line voltage

(<5 mVRMS typical, measured at point of sense)

Remote Voltage Sense 5 VRMS total lead voltage drop

CURRENT

CW 801P(–H) 6.0 ARMS (135 VAC range), 3.0 ARMS (270 VAC range)

CW 2501P(–H) 18.6 ARMS (135 VAC range) , 9. 3 AR MS (270 VAC range)

CW 801P–V 5.2 ARMS (155 VAC range), 2.6 ARMS (310 VAC range)

CW 2501P–V 16.2 ARMS (155 VAC range), 8.1 AR M S ( 310 VAC range)

Accuracy ±0.5% of full scale typical; for linear loads and

>0.12 ARMS for CW 801P, >0.19 ARMS for CW 1251P,

>0.37 ARMS for CW 2501P

H–Option/V–Option: ±0.75% of full scale and

of full scale and >500Hz

Resolution 0.01 ARMS

FREQUENCY

Range 45 to 500 Hz (45 to 1000 Hz for H-Option)

Accuracy ±0.02% maximum

Resolution 0.1 Hz, 0.01 Hz for remote programming

1-2 Operation Manual

Page 17

Elgar CW-P Series Specifications

PHASE

Range -359 to +359 degrees

Accuracy Within 100 microseconds of equivalent angle

Resolution 1 degree

Positive phase indicates time lag from reference

1.2 Measurement

VOLTAGE

Range 0 to 270 VRMS; V–Option: 0 to 310 VRMS

Accuracy ±0.1% of range <100 Hz; ±0.2% of range ≥100Hz;

Resolution 0.1 VRMS

CURRENT*

at >5 VRMS output; measured at point of remote sense

H-Option: ±0.3% of range >500 Hz

Range

CW 801P 0 to 6.0 ARMS

CW 1251P 0 to 9.4 ARMS

CW 2501P 0 to 18.6 ARMS

Accuracy ±0.5% of range typical; for linear loads and

>0.12 ARMS for CW 801P, >0.19 ARMS for CW 1251P,

>0.37 ARMS for CW 2501P

H–Option/V–Option: ±0.75% of range and ≤500 Hz;

±1.0% of range and >500 Hz

Resolution 0.01 ARMS

PEAK INSTANTANEOUS CURRENT*

Range

CW 801P 0 to 25A

CW 1251P 0 to 35A

CW 2501P 0 to 70A

Accuracy ±2% of range typical; at >2% current range

Resolution 0.1A

Operation Manual 1-3

Page 18

Specifications Elgar CW-P Series

(Available in Remote Mode only)

PEAK INRUSH CURRENT*

Range

CW 801P 0 to 25A

CW 1251P 0 to 35A

CW 2501P 0 to 70A

Accuracy ±2% of range, typical; at >2% of RMS current range

Resolution 0.1A

FREQUENCY

Range 45 to 500 Hz

H-Option: 45 to 1000 Hz

Accuracy ±0.02% of value

Resolution of Display 0.1 Hz

POWER*

Range

CW 801P 0 to 800W

CW 1251P 0 to 1250W

CW 2501P 0 to 2500W

Accuracy ±2% of range for linear loads, typical

Resolution 1W

APPARENT POWER*

Range

CW 801P 0 to 800 VA

CW 1251P 0 to 1250 VA

CW 2501P 0 to 2500 VA

Accuracy ±2% of range for linear loads, typical

Resolution 1 VA

1-4 Operation Manual

Page 19

Elgar CW-P Series Specifications

801P, >68% typical;

POWER FACTOR*

Range 0 to 1

Accuracy ±4% of range for linear loads, typical; at >10% of power

Resolution 0.01

CREST FACTOR*

Range 0 to 3.5

Accuracy ±5% of range, typical; at 10% of RMS current range

Resolution 0.01

range

1.3 Input

VOLTAGE AND FREQUENCY

CW 801P 90 to 264 VRMS, 47 to 63 Hz, single-phase

CW 1251P 103 to 264 VRMS, 47 to 63 Hz, single-phase

CW 2501P 180 to 264 VRMS, 47 to 63 Hz, single-phase

CURRENT

CW 801P(–H)(–V) 13.5 ARMS, maximum at 90 VRMS

CW 1251P(–H)(–V) 17.7 ARMS , maximum at 103 VRMS

CW 2501P(–H)(–V) 19.7 ARMS , maximum at 180 VRMS

POWER FACTOR

EFFICIENCY

*Note: In a parallel system, the current/power displayed on the master unit is the sum

of all units in the system.

>0.99 typical at full load nominal line

>73% typical at full load

H–Option/V–Option at 1,000 Hz: CW

CW 1251P, >70% typical; CW 2501P, >72% typical

Operation Manual 1-5

Page 20

Specifications Elgar CW-P Series

1.4 Protection

Overcurrent: Shutdown mode

Accuracy: +/- 1% of full scale, for linear loads with current

>0.2 ARMS for CW 801P / CW 1251P, >0.4ARMS for CW 2501P

Over Voltage: Accuracy: +/-2% of full scale

Range: 35-300 VAC; V–Option: 35-344 VAC

Over Temperature: Internal monitor

Isolation Range: 500 VRMS between either output terminal and chassis.

1.5 Rear Panel Connections

GPIB

RS-232

M/S OUT

M/S IN

ANALOG SLAVE

Power In and Power Out Terminal Strips (see Sections 3.5 and 3.6)

1.6 General

DIMENSIONS

CW 801P: 3.5" (89 mm) H x 19" (483 mm) W x 20.6" (524 mm) D

CW 1251P: 3.5" (89 mm) H x 19" (483 mm) W x 20.6" (524 mm) D

CW 2501P: 5.25" (133 mm) H x 19" (483 mm) W x 20.6" (524 mm) D

WEIGHT

CW 801P: 48 lbs. (22 kg)

CW 1251P: 53 lbs. (24 kg)

CW 2501P: 86 lbs. (40 kg)

1-6 Operation Manual

Page 21

Elgar CW-P Series Specifications

SHIPPING WEIGHT

CW 801P: 55.25 lbs. (25 kg)

CW 1251P: 60.25 lbs. (27 kg)

CW 2501P: 93.25 lbs. (43 kg)

REGULATORY COMPLIANCE

CE mark

UL and CUL (consult factory for availability)

ENVIRONMENTAL

Cooling: Dual fan speed with side air intake, exhaust to rear

Operating

Temperature: 0 to 40°C

Storage

Temperature: -40 to +70°C

Humidity: 0 to 85% at 25°C derate to 50% above 40°C (non-condensing)

Altitude: Operating full power available up to 6,000 feet, non-operating to

40,000 feet

Installation Category III, Pollution Degree 2

FOR INDOOR USE ONLY

1.7 Options and Accessories

Rack Slide Kit (Elgar part number K161570-01)

Multiphase/Parallel Cable (Elgar part number 890-499-00)

Master/Slave Cable (Elgar part number 890-497-40)

S: Sync In/Out (Clock/Lock)

H: Expanded Frequency Range 45 to 1000 Hz

V: Expanded Voltage Range 0-155/0-310 VRMS

Note: Product specifications are subject to change without notice.

Operation Manual 1-7

Page 22

Specifications Elgar CW-P Series

This page intentionally left blank.

1-8 Operation Manual

Page 23

SECTION 2

INSTALLATION

The Elgar CW series power supply has been fully calibrated and tested prior to

shipment. The instrument is ready for immediate use upon receipt.

CAUTION! The CW unit weighs from 48 to 86 lbs. (22 to 40 kg),

depending on the model. A two–person lift is recommended.

WARNING!

equipment. Please read the Safety Notice at the beginning of this

manual prior to installation, operation, or maintenance.

Hazardous voltages are present when operating this

2.1 Unpacking

Perform a visual inspection of the shipping container prior to accepting the package

from the carrier. If extensive damage to the shipping container is evident, a description

of the damage should be noted on the carrier's receipt and signed by the driver of the

carrier agent.

Perform a visual inspection of the instrument when it is removed from the shipping

container. Check for shipping damage such as dents, scratches, distortion, and

damaged connectors.

If damage is not apparent until the instrument is unpacked, a claim for concealed

damage should be placed with the carrier. In addition, the shipping container(s) and

filler material should be saved for inspection. Forward a report of damage to the Elgar

Service Department. Elgar will provide instructions for repair or replacement of the

instrument.

If the instrument needs to be returned to Elgar, suitable shipping containers and

packing materials must be used. If proper packing material is not available, contact

Elgar to provide containers and shipping instructions.

Before shipping a product to Elgar, you must obtain a Return Material Authorization

(RMA) number from Elgar’s Repair Department. See the warranty page at the front of

this manual for details.

Operation Manual 2-1

Page 24

Installation Elgar CW-P Series

14

15

0.257

3.85

4

70

0.025

1.75

2

95

0.015

1.42

2.2 Wire Gauge Selection

The following guidelines assist in determining the optimum cable specification for

your power applications. These guidelines are equally applicable to both DC and low

frequency AC (up to 450 Hz) power cabling. The same engineering rules apply whether

going into or out of an electrical device. Thus, this guide applies equally to the input

cable and output cable for this Elgar instrument and application loads.

Power cables must be able to safely carry maximum load current without overheating

or causing insulation destruction. It is important to everyday performance to minimize

IR (voltage drop) loss within the cable. These losses have a direct effect on the quality

of power delivered to and from instruments and corresponding loads.

When specifying wire gauge, the operating temperature needs to be considered. Wire

gauge current capability and insulation performance drops with the increased

temperature developed within a cable bundle and with increased environmental

temperature. Thus, short cables with generously derated gauge and insulation

properties are recommended for power source applications.

Avoid using published commercial utility wiring codes, which are designed for the

internal wiring of homes and buildings. Although these codes accommodate the safety

factors of wiring loss, heat, breakdown insulation, aging, etc., they consider that up to

5% voltage drop is acceptable. Such a loss directly detracts from the quality

performance specifications of this Elgar instrument. Frequently, these codes do not

consider bundles of wire within a cable arrangement.

In high performance applications, as in motor start-up and associated inrush/ transient

currents, additional consideration is required. The cable wire gauge must consider

peak voltages and currents that may be up to ten times the average values. An

underrated wire gauge adds losses that alter the inrush characteristics of the

application and thus the expected performance.

Table 3–1 identifies popular ratings for DC and AC power source cable wire gauges.

Column 1

Size (AWG)

12 20 0.162 3.24

10 30 0.102 3.06

8 40 0.064 2.56

6 55 0.043 2.36

1/0 125 0.010 1.25

3/0 165 0.006 1.04

Column 2

Amperes (Max)

Column 3

Ohms/100 ft (1 w ay)

Column 4

IR Drop/100 ft (Col 2 x Col 3)

Table 3–1 Recommended Wire Gauge Selection Guide

2-2 Operation Manual

Page 25

Elgar CW-P Series Installation

The following notes apply to Table 3–1 and to the power cable definition:

1. The above figures are based upon insulated copper conductors at 25E C

(77E F), two current carrying conductors in the cable plus a safety (chassis)

ground.

Columns 3 and 4 refer to “one way” ohms and IR drop of current carrying

conductors (e.g., a 50-foot cable contains 100 feet of current carrying

conductor).

2. Determine which wire gauge for the application by knowing the expected peak

load current (I

), the maximum tolerated voltage loss (V

peak

) within the cable,

loss

and the one way cable length.

The formula below determines which ohms/100 feet entry is required from

Column 3. Read the corresponding wire gauge from Column 1.

(Column 3 value) =

V

/[I

loss

x 0.02 x (cable length)]

peak

Where:

Column 3 value =

Entry of the table above.

Cable length =

One way cable length in feet.

V

=

loss

Maximum loss, in volts, permitted within cable.

Special case

: Should the V

requirement be very loose, I

loss

may exceed the

peak

maximum amperes (Column 2). In this case, the correct wire gauge is selected

directly from the first two columns of the table.

Example:

drop (V

A 20 ampere (I

) along its 15-foot cable (one way cable length) requires (by formula)

loss

) circuit which may have a maximum 0.5 volt

peak

a Column 3 resistance value of 0.083. This corresponds to wire gauge size 8

AWG.

If the cable length was 10 feet, the Column 3 value would be 0.125 and the

corresponding wire gauge would be 10 AWG.

3. Aluminum wire is not recommended due to soft metal migration at the terminals

which may cause long term (on the order of years) poor connections and

oxidation. If used, increase the wire gauge by two sizes (e.g., specify 10 gauge

aluminum instead of 14 gauge aluminum).

Operation Manual 2-3

Page 26

Installation Elgar CW-P Series

4. Derate the above wire gauge (use a heavier gauge) for higher environmental

temperatures since conductor resistance increases with temperature.

Temperature

Current Capability

40°C 104°F 80%

5. Derate the above wire gauge (use a heavier gauge) for an increased number of

current carrying conductors. This offsets the thermal rise of bundled conductors.

No. of Conductors

Current Capability

3 to 6 80%

Above 6 70%

6. The preferred insulation material is application dependent. Elgar's recommendation is any flame retardant, heat resistant, moisture resistant thermoplastic

insulation rated to a nominal 75°C (167°F). Voltage breakdown must exceed the

combined effects of:

• The rated output voltage;

• Transient voltages induced onto the conductors from any source;

• The differential voltage to other nearby conductors; and,

• Safety margins to accommodate degradations due to age, mechanical

abrasion and insulation migration caused by bending and temperature.

7. As frequency increases, the magnetic field of the current carrying conductors

becomes more significant in terms of adverse coupling to adjacent electrical

circuits. Use twisted pairs to help cancel these effects. Shielded twisted pairs

are even better. Avoid close coupling with nearby cables by using separate

cable runs for high power and low power cables.

8. The above general values and recommendations should be reviewed, modified,

and amended as necessary for each application. Cables should be marked with

appropriate safety WARNING decals as hazardous voltages may be present.

2-4 Operation Manual

Page 27

Elgar CW-P Series Installation

2.3 Mounting Instructions

Refer to Figure 3–1 through Figure 3–4 for mounting dimensions and other installation

information for the CW Series power supplies.

The units are equipped with mounting feet for bench top use. They are mounted to the

chassis with pem-nuts and may be removed easily for rack mount application.

The units are 3.5" and 5.25" (89 mm and 133 mm) high, and are designed to be

installed in a standard 19" (483 mm) RETMA rack. Pem-nuts have been built into the

chassis for mounting optional slides. The CW mounting kit, Elgar part number

K161570-01, contains the appropriate slides and mounting brackets.

If you elect not to use slides, mount the unit with standard support angles to sustain the

weight of the unit in the rack. Note that the front panel mounting ears are not intended

to support its weight in rack mounting.

For installations that include slides, use a #10 lock washer, as supplied in the CW-P

mounting kit, with each of the two mounting screws indicated in Figure 3–1.

These washers are required on the right side only to limit the depth of screw penetration

into the chassis, which must be less than 0.25".

Figure 3–1 Slide Mounting

2.4 Cooling

The CW unit employs internal fans to circulate cooling air. The air is drawn into the

chassis along its sides, and is exhausted through the rear panel. For maximum product

life and reliability, do not allow the airflow to be impeded.

CAUTION!

Avoid blocking the instrument air intakes or exhaust.

Operation Manual 2-5

Page 28

Installation Elgar CW-P Series

Figure 3–2 Mounting Dimensions,

Front and Rear Views (CW 801P, CW 1251P)

2-6 Operation Manual

Page 29

Elgar CW-P Series Installation

Figure 3–3 Mounting Dimensions,

Front and Rear Views (CW 2501P)

Operation Manual 2-7

Page 30

Installation Elgar CW-P Series

Figure 3–4 Mounting Dimensions,

Top and Side Views (CW 801P and CW 1251P)

2-8 Operation Manual

Page 31

Elgar CW-P Series Installation

Figure 3–5 Mounting Dimensions,

Top and Side Views (CW 2501P)

Operation Manual 2-9

Page 32

Installation Elgar CW-P Series

2.5 Power In Connections

Connect input power to the INPUT terminal block on the rear panel as specified below.

Refer to Figure 3–6.

Figure 3–6 Input Power Connections

WARNING!

For input voltages >120V, do not reverse LINE and NEUT.

Reversed connections will result in pulsing noises from the supply.

2.5.1 Single–Phase Supply Connections

1. Remove the protective cover from the terminal block.

2. Route the cables through the strain relief device. Refer to Table 3–2 for cable

recommendations.

3. Connect SAFETY GROUND to the GROUND stud located next to the INPUT

terminal block. For additional safety, include a loop between the GROUND stud and

the strain relief device, as shown in Figure 3–6.

4. Connect shields, if any, to the GND connector of the INPUT terminal block.

5. Connect NEUTRAL, if available, to the NEUT connector.

6. Connect LINE to the LINE connector.

7. Reinstall the protective cover on the terminal block. Tighten the strain relief device.

2-10 Operation Manual

Page 33

Elgar CW-P Series Installation

CW Model

North American

International

2

terminal must be connected to earth ground. This unit should not be operated

without an adequate ground connection.

disconnection device for the CW system.

2.5.2 Split-Phase Supply Connections 120–0–120V

1. Remove the protective cover from the terminal block.

2. Route the cables through the strain relief device. Refer to Table 3–2 for cable

recommendations.

3. Connect NEUT to 120V.

4. Connect LINE to the other 120V.

Wiring across the full voltage will allow lower line currents to be used.

5. Reinstall the protective cover on the terminal block. Tighten the strain relief device.

2.5.3 Three–Phas e Supply Connections

1. Remove the protective cover from the terminal block.

2. Route the cables through the strain relief device. Refer to Table 3–2 for cable

recommendations.

3. Connect one phase to LINE and Neutral to NEUT. If Neutral is not available,

connect LINE and NEUT across any of the phases.

4. Reinstall the protective cover on the terminal block. Tighten the strain relief device.

CW 801P

CW 1251P and CW 2501P

18A/300V, 3x14 AWG

O.D.=9.6 mm

25A/300V, 3x12 AWG

O.D.=11.3 mm

16A/300V, 3x1.5 mm

O.D.=8.0–9.8 mm

25A/300V, 3x2.5 mm2

O.D.=9.6–12.0 mm

VDE approved

Table 3–2 Recommended Cables

WARNING! To protect the operator, the wire connected to the GND

CAUTION! A device to disconnect the CW system from the energy supply

source is required. This switch or circuit breaker must be close to the CW

system, within easy reach of the operator, and clearly labeled as the

CAUTION! Use wire rated for currents drawn as specified

on equipment label.

Operation Manual 2-11

Page 34

Installation Elgar CW-P Series

NEUTRAL to be grounded.)

2.6 Power Out Connections

1. Remove the protective cover from the terminal block.

2. A factory jumper has been added to connect NEUTRAL to GROUND.

If the front connector requires LINE and NEUTRAL to be reversed, move

this jumper to connect LINE to GROUND. See Figure 3–7 below. Most loads

require NEUTRAL to be grounded.

The factory jumper may be removed if the load has a GROUND or if LINE or

NEUTRAL voltages are held to less than 500 VRMS with respect to chassis.

3. Reinstall the protective cover on the terminal block.

WARNING! Verify that the load is set up to be LINE GROUNDED

or NEUTRAL GROUNDED. (Equipment with polarized plugs requires

2-12 Operation Manual

Figure 3–7 Output Power Connections

Page 35

Elgar CW-P Series Installation

2.7 Sense Connections

The CW Series unit can be used with or without remote sense leads connected to the

load. Where the sense leads (line and neutral sense) are connected determines the

point at which the CW output voltage will be precisely regulated.

As shipped, the units are configured for local sense operation. This is achieved by

connecting shorting jumpers between the sense and AC output terminals of the rear

panel output terminal block, as shown in Figure 3–8.

When using remote sensing, the shorting jumpers must be removed, and the remote

sense leads connected from the CW sense terminals to the load. The point of voltage

regulation will now be at the load, and any voltage drop across the interconnecting

output cable will be compensated.

In the event that the external remote sense circuit opens, the CW maintains control of

the output voltage by utilizing a redundant sense circuit. This redundant circuit is

comprised of 10kΩ resistors internally connected from the AC output terminals to the

voltage control circuitry. However, since the unit is calibrated with the sense leads

connected, this mode of operation will incur reduced accuracy in the AC output voltage

because of the presence of the 10kΩ resistors.

Figure 3–8 Output Voltage Sensing Configuration

Operation Manual 2-13

Page 36

Installation Elgar CW-P Series

To utilize remote sensing at the user's load, follow these steps:

1. Remove the protective cover from the terminal block.

2. Route the cables through the strain relief device located above the terminal block.

Twisted shielded leads for power and sense leads are recommended for the lowest

noise operation. If used, shields should be connected to a CW output terminal block

GND ground connector, as shown in Figure 3–9.

3. Disconnect local–sense shorting jumpers. See Figure 3–9

4. Connect the sense leads as shown in Figure 3–9.

5. Reinstall the protective cover on the terminal block.

Figure 3–9 Sense Connections

2-14 Operation Manual

Page 37

Elgar CW-P Series Installation

2.8 Remote Control Signal

Remote control allows you to set output voltage, lock to an external frequency source,

or send out a TTL compatible sync signal.

The 9-pin Subminiature-D master/slave connector labeled M/S IN on the rear panel

allows you to make the necessary connections for remote control. See Figure 3–10.

Pins 1, 2, 3, 6, 7, and 8 of the M/S IN connector provide control signals for

multiphase/paralleled systems; do not make any user connections to these pins. In a

multiphase/paralleled system, the master unit uses the M/S IN connector for analog

amplitude control or synchronizing to external frequency sources.

Pin Number Function

4 User Ground (at GPIB Ground potential)

5 Analog Amplitude Control

(0 to 5 VDC for zero to set maximum voltage)

9 Clock Lock Input/Output

1, 2, 3, 6, 7, 8 Do not make connection

Figure 3–10 M/S IN Connector

2.8.1 Analog Ampli tude Control

• Set unit to Analog In (analog input state = ON. See Section 5.3.10).

• Set HIGH or LOW range, and maximum output voltage (corresponding to 5 VDC

analog amplitude control) by front panel, GPIB, or RS232 command.

• 0 to 5 VDC will set the output from 0 to the maximum voltage programmed (on the

range selected), as set by front panel controls, GPIB, or RS232 command.

• If needed, set ‘Program keys locked mode.’ See section 5.3.5.

2.8.2 Lock to Ext ernal Frequency Source

• Set direction of Clock to ‘IN’ (see Section 5.3.9).

• Signal can be 2 to 12V amplitude, and at least 10 microseconds wide. Triggering

shall occur on the leading edge of the pulse. For zero programmed phase delay the

output sinewave shall go from zero to positive.

• Delay angle can be programmed 0 to 359 degrees with a resolution of 1 degree.

• Input impedance is typically 10k ohm.

Operation Manual 2-15

Page 38

Installation Elgar CW-P Series

2.8.3 Sync Out put Pulse

• Set direction of Clock to ‘OUT’ (see Section 5.3.9).

• Sync can be programmed relative to zero to positive crossing of output sinewave.

Waveform amplitude typically 5V. Pulse width typically 10 microseconds. Signal

shall start with a zero volt to positive voltage edge, ±100 µS.

• Programming range is 0 to 359 degrees of lag. Resolution 1 degree.

• Output impedance is typically less than 1k ohm.

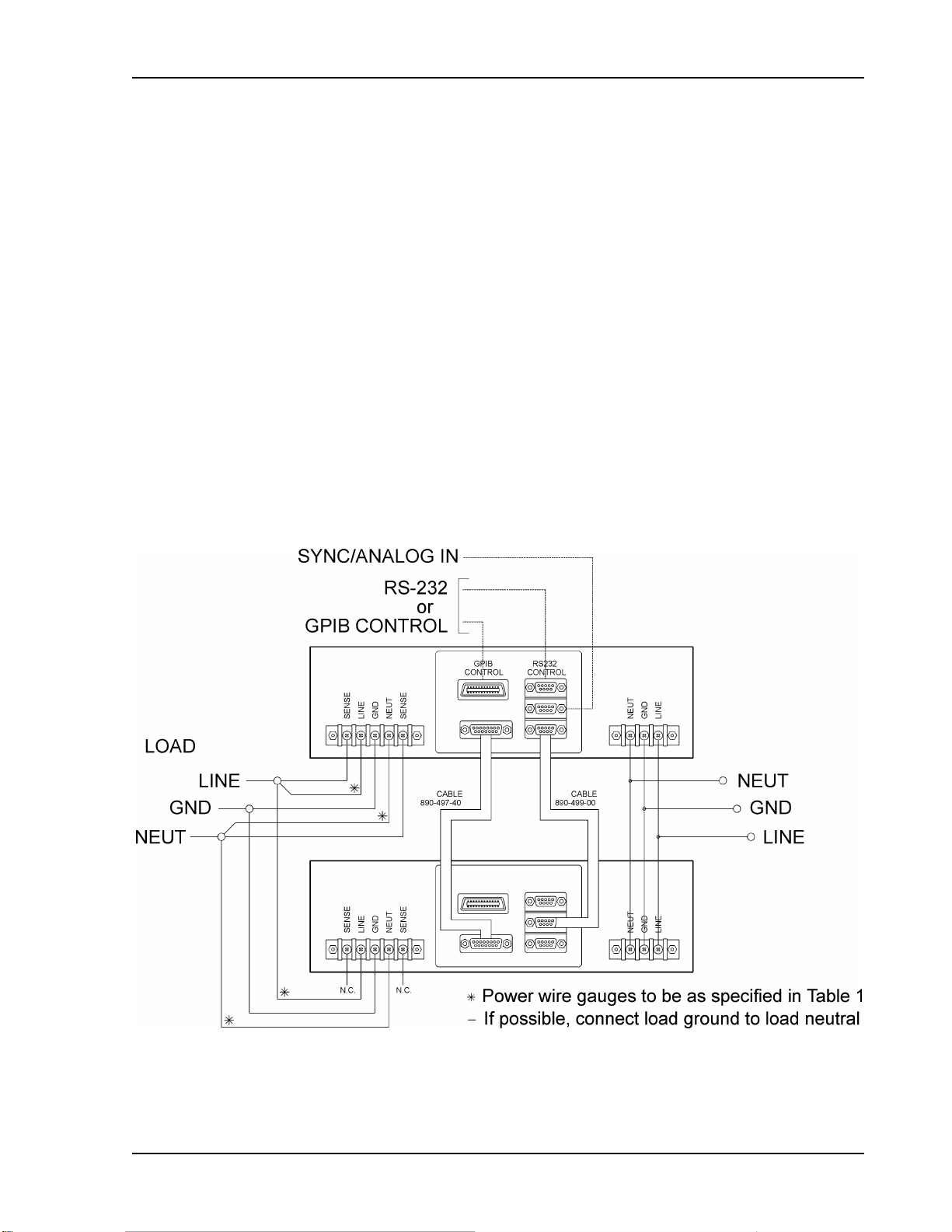

2.9 Master/Slave Configurations

The CW-P series programmable power supply can be paralleled to achieve higher

power. One, two, or three phase(s) can be paralleled to a depth of two units per phase.

A given phase will have one “Master” and one or more “Slaves.” The master and slave

require special cables (two) between them. The outputs must be connected together

with equal gauge and length power leads, the sense leads must be connected on the

master, and each unit requires special programming. Programming of the units is

performed from the front panel through the menu systems, or through the GPIB/

RS-232 command interface. Once a unit is configured to be a slave, its command

interface is not to be used when load wiring is connected.

When a multi-phase master/slave configuration is configured, the only GPIB/RS-232

connected unit is to be the A phase master. Attempting to control any other units in the

array is specified as an illegal operation, and the results are undefined and potentially

destructive. The command interfaces of a slave are allowed to remain operational for

the purpose of returning the unit to a standalone or different slave configuration.

Note: Remove load wiring before reconfiguring a slave unit via the menu or command

interfaces.

The CW-P series power supplies are configured for master/slave operations in the

following order:

1. Disconnect load wiring to the individual CW power supply.

2. Disconnect any master/slave wiring (M/S IN, M/S OUT, and Analog Slave cables).

3. Ensure that source mains are connected and power up the CW.

4. Through the front panel menu system or through the command interface, specify

the location of the CW in the master/slave matrix. See Sections 3.9.1 and 3.9.2 for

examples.

5. Perform steps 1-3 for all CW units in the matrix.

2-16 Operation Manual

Page 39

Elgar CW-P Series Installation

6. Power up all CW units simultaneously, and ensure that each unit is reporting its

address properly on the front panel.

7. Power down all CW units.

8. Connect load wiring as documented below.

9. Connect M/S OUT and M/S IN cables (Elgar PN 890-499-00) between each CW

in a daisy chain pattern.

10. Connect master/slave, analog slave cables (Elgar PN 890-497-40) from master to

slave, one on each master/slave pair.

11. Power up all CW units simultaneously, or the master unit last.

12. Perform all control operations on the A phase CW master unit.

This manual provides methods used to parallel a configuration of two units per phase.

2.9.1 Setup for Single–Phase, Two Units

Figure 3–11 Wiring Diagram for One Phase, Master/Slave Configuration

Operation Manual 2-17

Page 40

Installation Elgar CW-P Series

Setup 1–Phase Master/Sl ave Pair Using Menu System

1. Ensure load wiring is removed from the two CW units.

2. Ensure no master/slave cables are attached to “Analog Slave” connectors on CW

units.

3. Ensure no master/slave cables are connected to the “M/S IN “ and “M/S OUT”

connectors.

4. Connect the mains wiring to the line terminals.

5. Power up both CW units.

6. On the master CW press the “ENTER/SAVE” button.

7. Rotate the left knob CW until the left display reads “ConF”.

8. Rotate the right knob until the right display reads A0A1.

9. Press the ENTER/SAVE button.

10. Press the ENTER/SAVE button.

11. Rotate the left knob CW until the left display reads “Addr”.

12. Rotate the right knob until the right display reads 0.

13. Press the ENTER/SAVE button.

14. Press the ENTER/SAVE button.

15. Rotate the left knob CW until the left display reads “ChAn”.

16. Rotate the right knob until the right display reads A.

17. Press the ENTER/SAVE button.

18. On the slave CW press the ENTER/SAVE button.

19. Rotate the left knob until the left display reads “Addr”.

20. Rotate the right knob until the right display reads “1”.

21. Press the ENTER/SAVE button.

22. Power down both CW power supplies.

23. Connect Elgar cable 890-497-40 between the master “Analog Slave” and the

slave “Analog Slave” connectors.

2-18 Operation Manual

Page 41

Elgar CW-P Series Installation

24. Connect the Elgar cable 890-499-00 between the master “M/S OUT” and the slave

“M/S IN” connectors.

25. Connect the load wiring as shown in Figure 3–11 above.

26. Power up both CW units simultaneously.

27. Control the master/slave pair by controlling the CW master via the front panel or

its command interface.

Setup 1-Phase Master/Slave Pair Using Remote Command Interface

The CW master/slave attributes can be controlled using the GPIB/RS-232 command

interface instead of using the front panel menu system. When adjusting the parameters

in this manner, the CW voltage sourcing commands must not be controlled through the

command interface of a slaved unit.

1. Setting the A Phase Master configuration parameter via the command interface:

• SYST:SLAVECONFIG A0A1 Specifies that this A phase master has onl y one s l av e

• SYST:SLAVECONFIG A0B1 Specifies that this A phase master has a B phase

slave and each unit has a slave for a total of 4 CW units.

• SYST:SLAVECONFIG A0C1 Specifies that this A phase master has a B phase

slave and a C phase slave and each unit has a slave for a total of 6 CW units.

• SYST:SLAVECONFIG? Returns the present parameter setting

Note: The SLAVECONFIG parameter only applies if the SLAVEADDR is set to 0

and the SLAVECHAN is set to A on the A master unit. Only the A phase master uses

this parameter.

2. Setting the Slave address parameter via the command interface:

• SYST:SLAVEADDR 0 Specifies that this CW is the top unit for A,B or C phases

• SYST:SLAVEADDR? Returns the present address parameter

3. Setting the Slave phase parameter via the command interface:

• SYST:SLAVECHAN A Specifies that this CW is in the A channel, either the master

or a slave.

• SYST:SLAVECHAN B Specifies that this CW is in the B channel and,

by definition, a slave.

• SYST:SLAVECHAN C Specifies that this CW is in the C channel and,

by definition, a slave.

• SYST:SLAVECHAN? Returns the present phase assignment set

Operation Manual 2-19

Page 42

Installation Elgar CW-P Series

2.9.2 Setup for Three–Phase, Two Units per Phase

Figure 3–12 Wiring Diagram for Three Phase, Master/Slave Configuration

2-20 Operation Manual

Page 43

Elgar CW-P Series Installation

Setup Six CW Units as 3–Phase Master/Slave Set using M enu S ystem

1. Ensure load wiring is removed from the six CW units.

2. Ensure no master/slave cables are attached to “Analog Slave” connectors on

CW’s.

3. Ensure no master/slave cables are connected to the “M/S IN “ and “M/S OUT”

connectors.

4. Connect the mains wiring to the line terminals.

5. Assign labels to the six CW units “A master”, “B master”, “C master”, “A slave”, “B

slave”, “C slave”.

6. Power up six CW units.

7. Set up the A phase.

8. On the A master CW press the “ENTER/SAVE” button.

9. Rotate the left knob CW until the left display reads “ConF”.

10. Rotate the right knob until the right display reads A0C1.

11. Press the ENTER/SAVE button.

12. Press the ENTER/SAVE button.

13. Rotate the left knob until the left display reads “ChAn”.

14. Rotate the right knob until the right display reads “A”.

15. Press the ENTER/SAVE button.

16. Press the ENTER/SAVE button.

17. Rotate the left knob until the left display reads “Addr”.

18. Rotate the right knob until the right display reads “0”.

19. Press the ENTER/SAVE button.

20. On the A slave CW press the ENTER/SAVE button.

21. Rotate the left knob until the left display reads “Addr”.

22. Rotate the right knob until the right display reads “1”.

23. Press the ENTER/SAVE button.

24. Press the ENTER/SAVE button.

25. Rotate the left knob until the left display reads “ChAn”.

Operation Manual 2-21

Page 44

Installation Elgar CW-P Series

26. Rotate the right knob until the right display reads “A”.

27. Press the ENTER/SAVE button.

28. Set up the B phase.

29. On the B master CW press the “ENTER/SAVE” button.

30. Rotate the left knob until the left display reads “Addr”.

31. Rotate the right knob until the right display reads “0”.

32. Press the ENTER/SAVE button.

33. Press the ENTER/SAVE button.

34. Rotate the left knob until the left display reads “ChAn”.

35. Rotate the right knob until the right display reads “B”.

36. Press the ENTER/SAVE button.

37. On the B slave CW press the ENTER/SAVE button.

38. Rotate the left knob until the left display reads “Addr”.

39. Rotate the right knob until the right display reads “1”.

40. Press the ENTER/SAVE button.

41. Press the ENTER/SAVE button.

42. Rotate the left knob until the left display reads “ChAn”.

43. Rotate the right knob until the right display reads “B”.

44. Press the ENTER/SAVE button.

45. Set up the C phase.

46. On the C master CW press the “ENTER/SAVE” button.

47. Rotate the left knob until the left display reads “Addr”.

48. Rotate the right knob until the right display reads “0”.

49. Press the ENTER/SAVE button.

50. Press the ENTER/SAVE button.

51. Rotate the left knob until the left display reads “ChAn”.

52. Rotate the right knob until the right display reads “C”.

53. Press the ENTER/SAVE button.

2-22 Operation Manual

Page 45

Elgar CW-P Series Installation

54. On the C slave CW press the ENTER/SAVE button.

55. Rotate the left knob until the left display reads “Addr”.

56. Rotate the right knob until the right display reads “1”.

57. Press the ENTER/SAVE button.

58. Press the ENTER/SAVE button.

59. Rotate the left knob until the left display reads “ChAn”.

60. Rotate the right knob until the right display reads “C”.

61. Press the ENTER/SAVE button.

62. Power down six CW power supplies.

63. Connect Elgar cable 890-497-40 between the A master “Analog Slave” and the

A slave “Analog Slave” connectors.

64. Connect Elgar cable 890-497-40 between the B master “Analog Slave” and the

B slave “Analog Slave” connectors.

65. Connect Elgar cable 890-497-40 between the C master “Analog Slave” and the

C slave “Analog Slave” connectors.

66. Connect up all of the daisy chained cables. The unit order is suggested below in

steps 67 through 71. As long as A master is the origin, all other daisy chained

units can be in any order.

67. Connect the Elgar cable 890-499-00 between the A master “M/S OUT” and the

A slave “M/S IN”.

68. Connect the Elgar cable 890-499-00 between the A slave “M/S OUT” and the

B master “M/S IN”.

69. Connect the Elgar cable 890-499-00 between the B master “M/S OUT” and the

B slave “M/S IN”.

70. Connect the Elgar cable 890-499-00 between the B slave “M/S OUT” and the

C master “M/S IN”.

71. Connect the Elgar cable 890-499-00 between the C master “M/S OUT” and the

C slave “M/S IN”.

72. Connect the load wiring as shown in Figure 3–12 above.

73. Power up six CW units simultaneously.

74. Control the master/slave array by controlling the CW A master via the front panel

or its command interface.

Operation Manual 2-23

Page 46

Installation Elgar CW-P Series

This page intentionally left blank.

2-24 Operation Manual

Page 47

SECTION 3

OPERATION

This section details the front panel operations of the CW series power source, including

the initialization process and some system operations.

3.1 CW Front Panel Controls and Indicators

The controls and indicators on the front panel of the CW are detailed below.

Refer to Figure 4–1.

Figure 4–1 Front Panel Controls (CW 801P)

Power Switch

Press the top portion of the switch to turn power on, press the bottom portion of

the switch to turn the power supply off. When power is turned on, the unit goes

through a power up cycle that may take several seconds before it is ready for

operation.

VOLTAGE/POWER Section

These controls and indicators, located on the left side of the front panel, are

used to measure and program the voltage/power parameters.

Operation Manual 3-1

Page 48

Operation Elgar CW-P Series

Numeric Display. The large, four-digit display in the VOLTAGE/POWER

section is a digital voltmeter that measures and displays the power supply’s

voltage/power parameters. If the CW is operating with output power turned off,

this meter displays the voltage that the output will assume when it is turned on.

VOLTAGE MODE Lamp. This LED, located directly over the numeric display,

indicates that the power supply is operating in the constant output voltage mode.

This is the most common operation mode used. If the output current rises above

the level set by the current program level, this lamp turns off and the CURRENT

MODE lamp turns on.

V RANGE Button. This button allows you to select the 0V–135V range or the

0V–270V range of output voltage. The High or Low LED indicates the currently

selected voltage range. The output current available on the low voltage range is

twice that available on the high voltage range.

LEDs. The indicator lights on the right side of the VOLTAGE/POWER section

(VOLTS, WATTS, VA, PF, OVP) identify the currently displayed measurement

during the Program and Measure functions.

MEASURE Button. Use this button to specify what measurement is

displayed. As you press the button repeatedly to cycle through the parameters,

the associated LED illuminates to indicate the measurement shown in the fourdigit display. The MEASURE lamp is illuminated when using the Measure

function.

PROGRAM Button. Press this button to change the output voltage or OVP

setpoint. The PROGRAM lamp is illuminated when using the Program function.

Rotary Knob. This large, multi-turn knob allows you to easily select the

desired power supply voltage/power parameters.

MENU/STATUS Section

These controls and indicators, located in the center of the front panel, are used

to make changes to non-displayed system parameters.

ENTER/SAVE Button. Press this button to enter the Menu system in order to

display and/or make changes to the system parameter settings. After specifying

the new setting, press this button again to accept and apply the change to the

currently selected parameter.

To modify more than one item in the menu system, press ENTER/SAVE after

each parameter modification once to save the change, and once more to reenter the menu system.

3-2 Operation Manual

Page 49

Elgar CW-P Series Operation

ESCAPE Button. Press this button to exit the Menu function without saving

parameter changes. Note that this button only abandons the change to the

currently selected parameter; previous parameter modifications that were

completed using the ENTER/SAVE button are unaffected.

REMOTE Lamp. When lit, this lamp indicates remote programming is

enabled. When flashing, this lamp indicates that a remote programming error

has been encountered. To clear, touch a PROGRAM key or send the “*RST”

over the command interface.

LOCKOUT Lamp. When lit, this lamp indicates that the front panel

PROGRAM buttons are locked out.

FAULT Lamp. When lit, this lamp indicates that a fault condition has been

detected, and that the system output has been turned off automatically. Some

conditions that cause this to occur include: output over-voltage, output overcurrent, high internal temperature, or an internal system failure.

CURRENT/FREQUENCY Section

These controls and indicators, located on the right side of the front panel, are

used to select and display the current limit and frequency setpoints.

Numeric Display. The large, four-digit display in the

CURRENT/FREQUENCY section shows the currently selected measurement.

CURRENT MODE Lamp. This lamp, located directly over the numeric

display, indicates when the output current has reached its selected limiting value,

i.e., the power supply is operating in the constant current mode.

LEDs. The indicator lights on the left side of the CURRENT/FREQUENCY

section (AMPS, Hz, Pk AMPS, CF, I LIMIT) identify the currently displayed

measurement during the Program and Measure functions.

MEASURE Button. Use this button to specify what measurement is

displayed. As you press the button repeatedly to cycle through the parameters,

the associated LED illuminates to indicate the measurement shown in the fourdigit display. The MEASURE lamp is illuminated when using the Measure

function.

PROGRAM Button. Press this button to change the current limit and

frequency setpoints. The PROGRAM lamp is illuminated when using the

Program function.

Rotary Knob. This large, multi-turn knob allows you to easily select the

desired power supply current/frequency parameters.

Operation Manual 3-3

Page 50

Operation Elgar CW-P Series

OUTPUT Section

This section is used to open and close the output relay. Output terminals are

available in the universal AC connector located in the OUTPUT section, as well

as on the rear panel of the CW unit.

Output ON Lamp. When lit, this lamp indicates that the CW output relay has

been set to the on position, and power is on the output terminals.

Output OFF/RESET Button. This switch allows you to energize or deenergize the output terminals of the power supply. If the unit is operating in the

fault mode, and if the fault condition has cleared, then cycling this switch will

restore normal operation.

3.2 Front Panel Overview

After performing the power-up operations, the CW reads storage location 0 for the

voltage range and the five program values. The CW enters into left and right measure

modes. The VOLTS LED on the left, and the AMPS LED on the right will be illuminated

and the measured volts and measured amps will be displayed.

Specify which measurement to display in the VOLTAGE/POWER section of the front

panel by pressing the left MEASURE button until the VOLTS, WATTS, VA, PF, or OVP

appears on the left display. The relevant LED will be illuminated.

Press the right MEASURE button to specify which parameter, AMPS, Hz, Pk AMPS,

CF, or I LIMIT, is displayed in the CURRENT/FREQUENCY section of the front panel.

The relevant LED will be illuminated.

Press the left PROGRAM button to program the left side Voltage or OVP setpoints.

Once in Program mode, the last program operation is automatically re-entered, the

relevant LED is lit, and the display changes to indicate the program value that is

selected to change. If the PROGRAM button is pressed again, the next programmable

setpoint parameter is displayed and the relevant LED is lit to annunciate the new

selection. While the PROGRAM LED is illuminated, turn the rotary knob to change the

displayed parameter. As the knob is rotated, the parameter is increased or decreased

in value. The change made to the programmable parameter overrides the original

value.

The CW output is opened and closed by pressing the OFF/RESET button in the

OUTPUT section of the front panel. The ON LED is illuminated when the output is

closed.

The voltage range is changed from High to Low or vice-versa by pressing the V RANGE

button when the left Program Volts mode is selected. When the range is changed, the

voltage is programmed to 0, the output relay will open if it is closed, and the left section

will remain in voltage program mode. The HIGH or LOW LED is illuminated to indicate

the presently selected range.

3-4 Operation Manual

Page 51

Elgar CW-P Series Operation

Enter the menu system, detailed in Section 5.3, by pressing the ENTER/SAVE button

once. After displaying and changing a menu parameter, press ENTER/SAVE again to

accept and apply the change. To change more than one item in the menu system,

press ENTER/SAVE after each parameter modification once to save and once to reenter the menu system. Press the ESCAPE button to abandon the present change

without saving. Once you have saved or abandoned your changes, the menu system is

exited and the displays revert to the measurements previously specified.

3.3 Power Up

At power-up the CW software will:

• Place “STBY 1.xx” on the displays. The number on the right is the version of the

boot eprom software.

• Displays “TEST x.xx” while the CW performs the self test functions. The rightmost

number is the version of the CW firmware application.

• Requests self test data from any attached and properly configured slaves in a

master-slave configuration.

• Displays “PASS x.xx” or “FAIL x.xx” to report the results of the testing.

• Upon passing the tests, the CW will read in the 0th system parameter set from

EEPROM memory and the CW (and any attached slaves) will be configured in

accordance with these parameters.

• If the CW has been configured previously to autostart after power cycle, the output

relay will close. If the CW is the master of a set of CW units, all relays will be

commanded to close.

• The VOLTAGE/POWER section of the front panel will now display measured volts.

The MEASURE and VOLTS LEDs will be illuminated. The V RANGE LED will be lit

according to the range recalled from location 0.

• The CRRENT/FREQUENCY section will display the measured current. The

MEASURE and AMPS LEDs will be illuminated.

• If the unit fails self test, the display will read “FAIL x.xx” and the output relay will be

inoperable.

Operation Manual 3-5

Page 52

Operation Elgar CW-P Series

3.4 Programmed Frequency Steps

The allowed frequency delta for programmed frequency steps is a function of

programmed output voltage and phase angle for models with the V-Option. At

programmed phase angles greater than 90º, and programmed output voltage greater

than 270 VRMS, the allowed frequency step is 45–500 Hz. At programmed phase

angles greater than 90º, and programmed output voltage of 310 VRMS, the allowed

frequency step is reduced to 45–250 Hz. Exceeding the allowed frequency step could

result in a fault shutdown of the unit.

3-6 Operation Manual

Page 53

SECTION 4

PROGRAMMING

4.1 Programming the CW Via the Front Panel

Press the PROGRAM button in the VOLTAGE/POWER section to enter Program mode.

The PROGRAM LED lights up and the last programmed value appears in the digital

display. The associated LED lights to show which item (voltage or overvoltage) is being

programmed. The rotary knob will be active and any change made to the setpoint being

adjusted is final as it is made. Press any button to exit the Program mode.

Front panel button functions are as follows:

• If the PROGRAM button is pressed, the CW moves the program focus to the next

program item in line.

• If a MEASURE button is pressed, the CW reverts to the previous Measurement

mode without changing the measurement focus.

• If the V RANGE button is pressed while in Program Voltage mode, the CW performs

a range change operation and the VOLTAGE/POWER section remains in Program

Voltage mode.

• If the ENTER/SAVE button in the MENU/STATUS section is pressed, the menu

system appears on the display.

• If the ESCAPE or ENTER/SAVE button in the MENU/STATUS section is pressed

when in the menu system, menu operations are terminated and Measurement mode

is re-entered.

• If there is no front panel activity for 10 seconds while in Menu or Program modes,

the CW reverts to the Measure modes. The PROGRAM and programmed

parameter LEDs turn off, and both MEASURE LEDs are lit.

• By rotating the programming knobs slowly, the changing parameter steps up/down

in small steps. By increasing the rotation speed of the knob, an “acceleration”

algorithm will increase the size of the changed value granularity and the parameter

will increase/decrease faster.

Operation Manual 4-1

Page 54

Programming Elgar CW-P Series

4.1.1 VOLTAGE/POWER Section

Change Voltage Range

To change the voltage range from High to Low or vice-versa, press the V RANGE

button after pressing PROGRAM. The output relay will open (if it was closed) and the

voltage will be set to 0. The unit will remain in program voltage mode to allow

reprogramming of the voltage.

Program Output Voltage Setpoint

Press the left PROGRAM button repeatedly until the VOLTS LED is illuminated. Rotate

the left knob until the display reads the voltage that is desired. The output will change to

source this displayed voltage.

Program Overvoltage Setpoint

Press the left PROGRAM button repeatedly until the OVP LED is illuminated. Rotate

the left knob until the display reads the over-voltage setpoint that is desired. The output

terminals will be protected for overvoltage sensed at or above this displayed voltage.

4.1.2 CURRENT/FREQUENCY Section

Program Current Limit

Press the right PROGRAM button repeatedly until the AMPS LED is illuminated. Rotate

the right knob until the display reads the current limit setpoint that is desired. The output

terminals will foldback or shutdown (user-selectable) at or above the displayed value.

See Section

Program Frequency

Press the right PROGRAM button repeatedly until the Freq LED is illuminated. Rotate

the right knob until the display reads the frequency setpoint that is desired. The output

terminals will source AC at the displayed frequency setpoint.

5.3.3.

4.2 Measurement Operations

4.2.1 Supply M easurements on the Left Display

To change which item is displayed at measure time, press MEASURE repeatedly until

the desired LED is illuminated.

Measured Output Voltage

When the left MEASURE and the VOLTS LEDs are illuminated, the output voltage is

displayed on the left display.

4-2 Operation Manual

Page 55

Elgar CW-P Series Programming

Measured Wattage

When the left MEASURE and the W ATTS LEDs are illuminated, the wattage being

sourced at the output terminals is displayed on the left display.

Displaying Overvoltage Setpoint

When the left MEASURE and the OVP LEDs are illuminated, the over-voltage setpoint

is displayed on the left display.

Measured Volt-Amps

When the left MEASURE and the VA LEDs are illuminated, the apparent power, in volt-

amps, being sourced at the output terminals is displayed on the left display.

Measured Power Factor

When the left MEASURE and the PF LEDs are illuminated, the power factor measured

at the output terminals is displayed on the left display.

4.2.2 Supply M easurements on the Right Display

To change which item is displayed at measure time, press MEASURE repeatedly until

the desired LED is illuminated.

Measured Current

When the right MEASURE and the AMPS LEDs are illuminated, the RMS current

measured at the output terminals is displayed on the right display.

Measured Frequency

When the right MEASURE and the Hz LEDs are illuminated, the frequency measured at

the output terminals is displayed on the right display.

Instantaneous Peak Current

When the right MEASURE and the Pk AMPS LEDs are illuminated, the instantaneous

peak current is displayed on the right display.

Measured Crest Factor

When the right MEASURE and the CF LEDs are illuminated, the crest factor measured

at the output terminals is displayed on the right display.

Note: When the output current is less than 5% of the full rated current, the crest factor

is not applicable.

The SLAVECONFIG parameter only applies if the SLAVEADDR is set to 0

and the SLAVECHAN is set to A on the A master unit. Only the A phase master uses

this parameter.

Operation Manual 4-3

Page 56

Programming Elgar CW-P Series

4.3 Menu Operations

There are two buttons in the Menu section of the front panel, ENTER/SAVE and

ESCAPE. Press the ENTER button to enter the Menu system. The MENU/STATUS

LED lights and the left and right displays are overridden to provide menu system

readouts. When in the Menu mode, the two MEASURE and two PROGRAM LEDs are

all turned off.

Use the Menu system to display and/or change the following parameters:

• Check the self-test result

• Set the GPIB port address

• Specify current Foldback/Shutdown

• Specify current shutdown delay

• Specify PROGRAM keys lock out

• Store system parameters

• Recall system parameters

• Specify whether the output relay will automatically close at power-up

• Specify Clock Signal as an Input or an Output

• Analog input

• RMS loop On/Off

• Phase A offset

• Phase B offset

• Phase C offset

• Slave channel

• Slave address

• Slave configuration

The menu is flat in its design and the various major nodes are available by rotating the

left knob either clockwise or counterclockwise to move either down or up on the list

given here.

4-4 Operation Manual

Page 57

Elgar CW-P Series Programming

The Menu LED is used to indicate if changes have been introduced into the menu

system. If there have been no changes, the LED will light steadily. If the operator has

introduced some change to a menu variable, the LED will blink.

The Menu LED is illuminated steadily when the menu system is entered, indicating that

nothing has yet been changed. When the LED is lit steadily, the ENTER/SAVE and

ESCAPE buttons perform the same action, that being the menu system will be exited

when either one is pressed.

When the menu item to be changed is selected with the left rotary knob, use the right

rotary knob to change the specific parameter selected. When you make any change to