Page 1

Reference Manual

Compact Temperature Calibrator

Jofra CTC-155/350/660 A/C

Page 2

Reference Manual

Compact Temperature Calibrator

JOFRA CTC-155/350/660 A/C

Copyright 2016 AMETEK Denmark A/S

Page 3

About this manual….

The structure of the manual

This reference manual is aimed at users who are familiar with AMETEK calibrators, as well

as those who are not. The manual is divided into 11 sections which describe how to set up,

operate, service and maintain the calibrator. The technical specifications are described and

accessories may be ordered from the list of accessories.

Safety symbols

This manual contains a number of safety symbols designed to draw your attention to

instructions which must be followed when using the instrument, as well as any risks involved.

Warning

Conditions and actions that may compromise the safe use of the

instrument and result in considerable personal or material damage.

Caution…

Conditions and actions that may compromise the safe use of the

instrument and result in slight personal or material damage.

Note…

Special situations which demand the user’s attention.

129375 00 2016-05-18 2

Page 4

List of contents

1.0 Introduction ................................................................................................................................. 4

1.1 Warranty ................................................................................................................................................ 5

1.2 Receiving the Compact Temperature Calibrator ................................................................................... 6

1.3 Dimensioning drawing ........................................................................................................................... 7

2.0 Safety instructions ...................................................................................................................... 8

3.0 Setting up the calibrator for use .............................................................................................. 11

3.1 Preparing the calibrator ....................................................................................................................... 11

3.2 Choosing an insertion tube ................................................................................................................. 12

3.2.1 Standard insertion tubes ........................................................................................................ 13

3.3 Inserting the sensor ............................................................................................................................. 14

3.4 Programming intelligent STS sensors ................................................................................................. 16

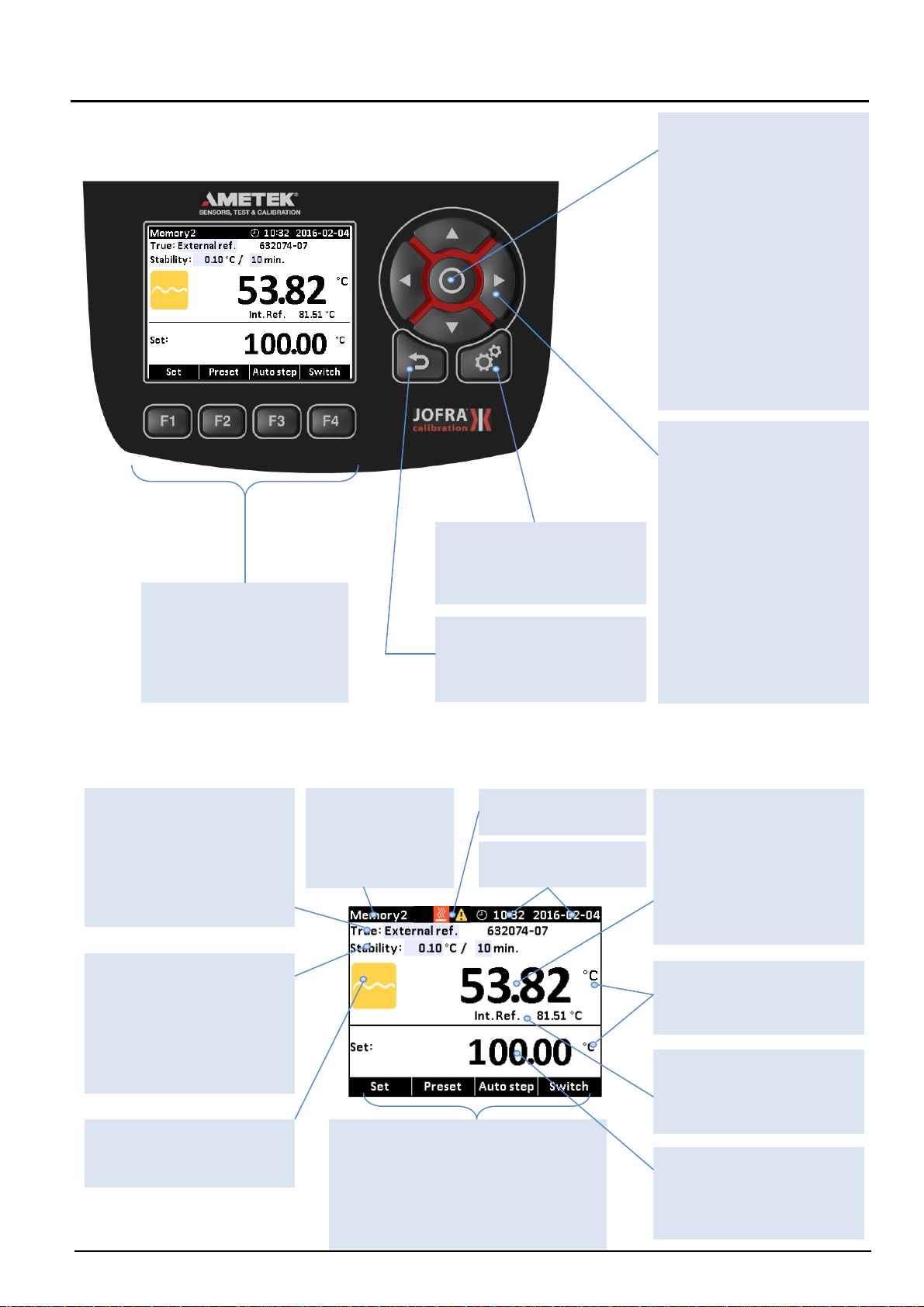

4.0 Calibrator Interface ................................................................................................................... 17

4.1 Keypad - Functions ............................................................................................................................. 17

4.2 Display - Functions .............................................................................................................................. 17

4.2.1 Main screen temperature values ............................................................................................ 18

4.2.2 Stability of temperature values ............................................................................................... 18

4.3 Input/Output Connections ................................................................................................................... 19

5.0 Operating the calibrator ........................................................................................................... 20

5.1 Operating principle .............................................................................................................................. 20

5.1.1 System menu .......................................................................................................................... 21

5.2 Starting the calibrator .......................................................................................................................... 23

5.3 Selecting a TRUE – reference sensor (C-models only) ...................................................................... 23

5.4 Stability setting .................................................................................................................................... 25

5.5 Selecting the set-temperature ............................................................................................................. 25

5.5.1 Editing the preset set-temperature ......................................................................................... 26

5.6 Auto Step function ............................................................................................................................... 28

5.6.1 Running an Auto Step test ..................................................................................................... 28

5.6.2 The calibrator's Auto Step procedure ..................................................................................... 29

5.7 Switch Test function ............................................................................................................................ 31

5.7.1 Running a Switch Test ........................................................................................................... 31

5.7.2 The calibrator's Switch Test procedure .................................................................................. 33

6.0 Storing and transporting the calibrator .................................................................................. 34

7.0 Error messages (List of alarms) .............................................................................................. 37

8.0 Returning the calibrator for service ........................................................................................ 40

9.0 Maintenance .............................................................................................................................. 42

9.1 Replacing the main fuses .................................................................................................................... 42

9.2 Maintenance mode .............................................................................................................................. 43

9.3 Cleaning .............................................................................................................................................. 47

9.4 Adjusting and calibrating the instrument ............................................................................................. 48

9.5 Maintenance of STS-reference sensor ............................................................................................... 48

10.0 Technical specifications .......................................................................................................... 49

11.0 List of accessories .................................................................................................................... 56

129375 00 2016-05-18 3

Page 5

1.0 Introduction

A

Congratulations on your new AMETEK JOFRA CTC Calibrator!

With the AMETEK JOFRA Compact Temperature Calibrator, you have chosen an extremely

effective instrument which we hope will live up to all your expectations.

This CTC calibrator is a fast, timesaving, and reliable true industrial temperature calibrator

designed for on-site use.

During the past several years, we have acquired extensive knowledge of industrial temperature

calibration. This expertise is reflected in our products which are all designed for daily use in an

industrial environment. Please note that we would be very interested in hearing from you if you

have any ideas or suggestions for changes to our products.

This reference manual applies to the following instruments:

JOFRA CTC-155 A – Temperature calibrator

JOFRA CTC-155 C – Temperature calibrator with reference sensor input

JOFRA CTC-350 A – Temperature calibrator

JOFRA CTC-350 C – Temperature calibrator with reference sensor input

JOFRA CTC-660 A – Temperature calibrator

JOFRA CTC-660 C – Temperature calibrator with reference sensor input

The calibrator has the following features and functions:

Wide temperature range

Fast heating and cooling time as well as a short stabilization time

Signal input for external reference sensor, which makes it possible to improve accuracy even

more.

External sensor control for running in two modes.

Multi-Information colour Display and Function keys

Useful features such as Set function, Preset mode, Auto Switch Test and Auto Stepping

IRI – Intelligent Recalibration Information

Plug and play STS reference sensors with memory chip

Broad range of inserts

Reference sensor protection

Silent mode operation

JOFRACAL calibration software

Protective carrying case with compartments for inserts, cables, manuals, plugs etc.

ISO-9001 certified

METEK Denmark A/S was ISO-9001 certified in September 1994 by Bureau Veritas

Certification Denmark.

129375 00 2016-05-18 4

Page 6

CE-label

Your new temperature calibrator bears the CE label and conforms to the

Electromagnetic Compatibility (EMC) Directive and the Low Voltage Directive.

Technical assistance

Please contact the dealer from whom you acquired the instrument if you require technical

assistance.

1.1 Warranty

This instrument is warranted against defects in workmanship, material and design for two (2)

years from date of delivery to the extent that AMETEK will, at its sole option, repair or replace

the instrument or any part thereof which is defective, provided, however, that this warranty shall

not apply to instruments subjected to tampering or, abuse, or exposed to highly corrosive

conditions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR

IMPLIED AND AMETEK HEREBY DISCLAIMS ALL OTHER WARRANTIES, INCLUDING,

WITHOUT LIMITATION, ANY WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR

MERCHANTABILITY. AMETEK SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO, ANY ANTICIPATED OR

LOST PROFITS.

This warranty is voidable if the purchaser fails to follow any and all instructions, warnings or

cautions in the instrument’s User Manual.

If a manufacturing defect is found, AMETEK will replace or repair the instrument or replace any

defective part thereof without charge; however, AMETEK’s obligation hereunder does not

include the cost of transportation, which must be borne by the customer. AMETEK assumes

no responsibility for damage in transit, and any claims for such damage should be presented

to the carrier by the purchaser.

129375 00 2016-05-18 5

Page 7

1.2 Receiving the Compact Temperature Calibrator

When you receive the instrument…

1) Unpack and check the calibrator and the accessories carefully.

2) Check the parts according to the list shown below.

If any of the parts are missing or damaged, please contact the dealer who sold

you the calibrator.

You should receive:

1 CTC Calibrator

1 USB memory stick containing electronic Reference manual and software

package JOFRACAL

1 mains cable

1 sets of test leads and test clips (black and red)

Thermal protection shield (CTC-660 only)

1 tool for insertion tube

1 USB cable

1 Calibration certificate (International traceable)

When reordering, please specify the part numbers according to the list of accessories,

section 11.0

129375 00 2016-05-18 6

Page 8

1.3 Dimensioning drawing

129375 00 2016-05-18 7

Page 9

2.0 Safety instructions

Read this manual carefully before using the instrument!

Please follow the instructions and procedures described in this manual. They are

designed to allow you to get the most out of your calibrator and avoid any personal

injuries and/or damage to the instrument.

Disposal – WEEE Directive

These calibrators contain Electrical and Electronic circuits and must be recycled or

disposed of properly (in accordance with the WEEE Directive 2002/96/EC).

Warning

About the use:

The calibrator must not be used for any purposes other than those described in

this manual, as it might cause a hazard.

The calibrator has been designed for indoor use only and is not to be used in

wet locations.

The calibrator is not to be used in hazardous areas, where vapour or gas leaks,

etc. may constitute a danger of explosion.

The calibrator is not designed for operation in altitudes above 2000 meters.

The calibrator is a CLASS I product and must be connected to a mains outlet with

a protective earth connection. Ensure the ground connection of the calibrator is

properly connected to the protective earth before switching on the calibrator.

Always use a mains power cable with a mains plug that connects to the protective

earth.

To ensure the connection to protective earth any extension cord used must also

have a protective earth conductor.

Only use a mains power cord with a current rating as specified by the calibrator

and which is approved for the voltage and plug configuration in your area.

Before switching on the calibrator make sure that it is set to the voltage of the

mains electricity supply.

Always position the calibrator to enable easy and quick disconnection of the

power source (mains inlet socket).

The calibrator must be kept clear within an area of 20 cm on all sides and 1 metre

above the calibrator due to fire hazard.

Never use heat transfer fluids such as silicone, oil, paste, etc. in the dry-block

calibrators. These fluids may penetrate the calibrator and cause electrical hazard,

damage or create poisonous fumes.

The calibrator must be switched off before any attempt to service the instrument

is made. There are no user serviceable parts inside the calibrator.

When cleaning the well or the insertion tube, REMEMBER to wear goggles when

using compressed air!

About the frontpanel:

The connectors, on the front panel of the calibrator, must NEVER be connected to

a voltage source.

Thermostats connected to the switch test input must not be connected to any

other voltage source during a test.

129375 00 2016-05-18 8

Page 10

About insertion tubes and insulation plugs:

Never leave hot insertion tubes, which have been removed from the calibrator,

unsupervised – they may constitute a fire hazard or personal injury.

If you intend to store the calibrator in the aluminium carrying case after use, you

must ensure that the instrument has cooled down to a temperature below

50°C/122°F before placing it in the carrying case.

Never place a hot insertion tube in the optional carrying case.

Use only insulation plugs supplied by AMETEK Denmark A/S.

About the fuses:

The fuse box must not be removed from the power control switch until the mains

cable has been disconnected.

The two main fuses must have the specified current and voltage rating and be of

the specified type. The use of makeshift fuses and the short-circuiting of

fuse holders are prohibited and may cause a hazard.

Caution – Hot surface

This symbol is visible on the grid plate.

Do not touch the grid plate, the well or the insertion tube as the calibrator is

heating up – they may be very hot and cause burns.

Do not touch the tip of the sensor when it is removed from the insertion tube/well

– it may be very hot and cause burns.

Do not touch the handle of the calibrator during use – it may be very hot and

cause burns.

Over 50°C/122°F

If the calibrator has been heated up to temperatures above 50°C/122°F, you must

wait until the instrument reaches a temperature below 50°C/122°F before you

switch it off.

Do not remove the insert from the calibrator before the insert has cooled down to

less than 50°C/122°F.

Caution – Cold surface

Below 0°C/32°F (applies only to the CTC-155 C models)

Do not touch the well or insertion tube when these are below 0°C/32°F - they

might create frostbite.

If the calibrator has reached a temperature below 0°C/32°F, ice crystals may form

on the insertion tube and the well. This, in turn, may cause the material surfaces

to oxidize

To prevent this from happening the insertion tube and the well must be dried. This

is done by heating up the calibrator to 100°C/212°F until all water left has

evaporated.

Remove the insulation plug while heating up.

It is very important that humidity in the well and insertion tube is removed to

prevent corrosion and frost expansion damages.

129375 00 2016-05-18 9

Page 11

Caution…

A

About the use:

Do not use the instrument if the internal fan is out of order.

Before cleaning the calibrator, you must switch it off, allow it to cool down and

remove all cables.

bout the well, insertion tube and grid plate:

The well and the insertion tube must be clean and dry before use.

Do not pour any form of liquids into the well. It might damage the well or cause

a hazard.

Scratches and other damage to the insertion tubes should be avoided by storing

the insertion tubes carefully when not in use.

The insertion tube must never be forced into the well. The well could be

damaged as a result, and the insertion tube may get stuck.

Before using new insertion tubes for the calibration, the insertion tubes must be

heated up to maximum temperature 350°C(662°F) / 660°C (1220°F) for a period

of minimum 30 minutes (CTC-350/660 only).

The insertion tube must always be removed from the calibrator after use.

The humidity in the air may cause corrosion oxidation on the insertion tube

inside the instrument. There is a risk that the insertion tube may get stuck if this

is allowed to happen.

If the calibrator is to be transported, the insertion tube must be removed from

the well to avoid damage to the instrument.

Note…

The product liability only applies if the instrument is subject to a manufacturing

defect. This liability becomes void if the user fails to follow the instructions set out

in this manual or uses unauthorised spare parts.

129375 00 2016-05-18 10

Page 12

3.0 Setting up the calibrator for use

3.1 Preparing the calibrator

Warning

The calibrator has been designed for indoor use only and is not to be used in

wet locations.

The calibrator is not to be used in hazardous areas, where vapour or gas leaks,

etc. may constitute a danger of explosion.

The calibrator is not designed for operation in altitudes above 2000 meters.

The calibrator is a CLASS I product and must be connected to a mains outlet with

a protective earth connection. Ensure the ground connection of the calibrator is

properly connected to the protective earth before switching on the calibrator.

Always use a mains power cable with a mains plug that connects to the protective

earth.

To ensure the connection to protective earth any extension cord used must also

have a protective earth conductor.

Only use a mains power cord with a current rating as specified by the calibrator

and which is approved for the voltage and plug configuration in your area.

Before switching on the calibrator make sure that it is set to the voltage of the

mains electricity supply.

Always position the calibrator to enable easy and quick disconnection of the

power source (mains inlet socket).

The calibrator must be kept clear within an area of 20 cm on all sides and 1 metre

above the calibrator due to fire hazard.

Note…

The instrument must not be exposed to draughts.

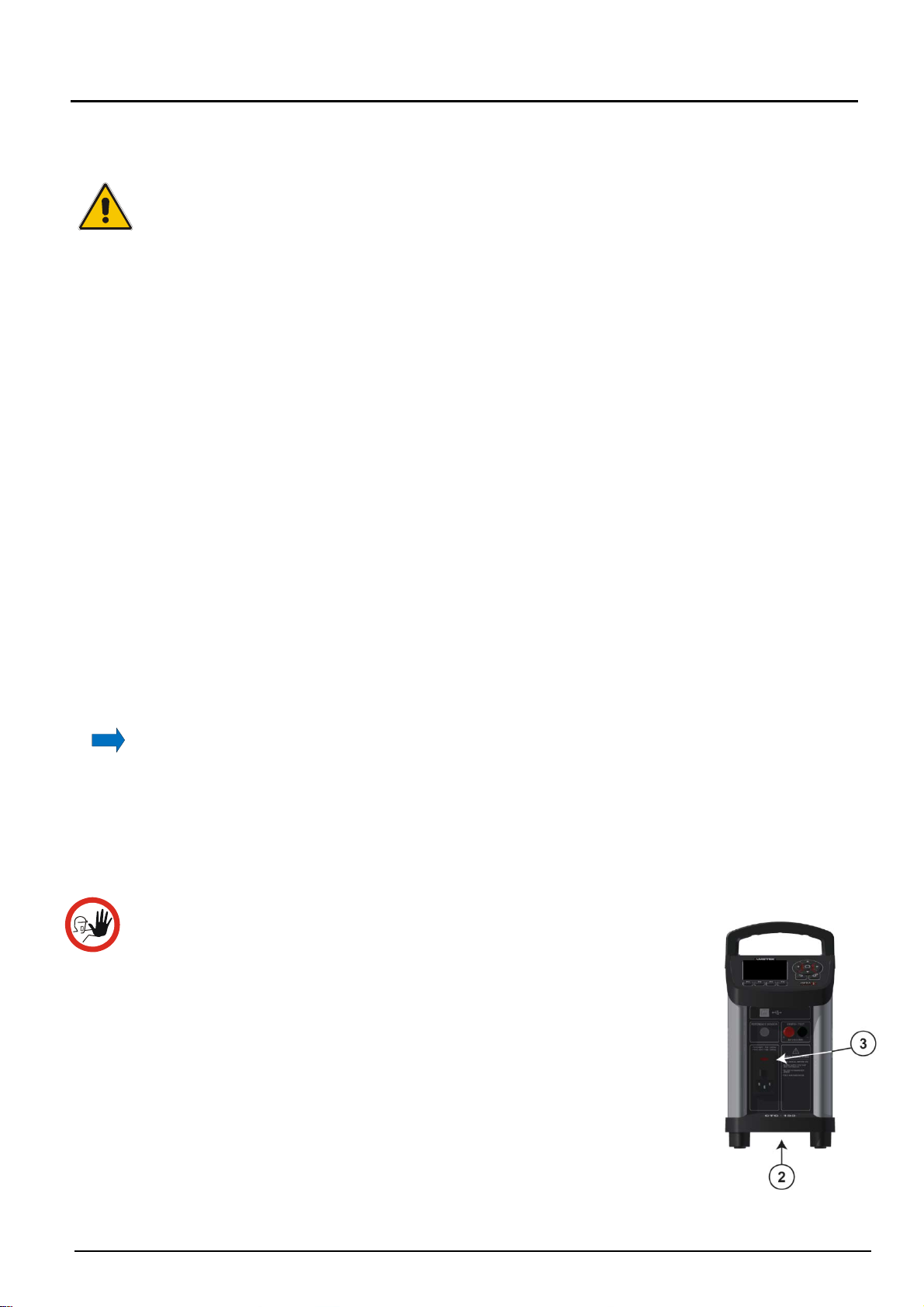

When setting up the calibrator, you must…

Place the calibrator on an even horizontal surface where you intend to use it.

Caution…

Do not use the instrument if the internal fan is out of order.

Ensure a free supply of air to the internal fan located at the bottom

of the instrument (pos. 2). The area around the calibrator should be

free of draught, dirt, flammable substances etc.

Check that the fuse size corresponds to the applied voltage on (pos.

3). The fuse is contained in the power control switch (on/off switch

(230V/115V)). To check; do as follows (see Fig. 1):

129375 00 2016-05-18 11

Page 13

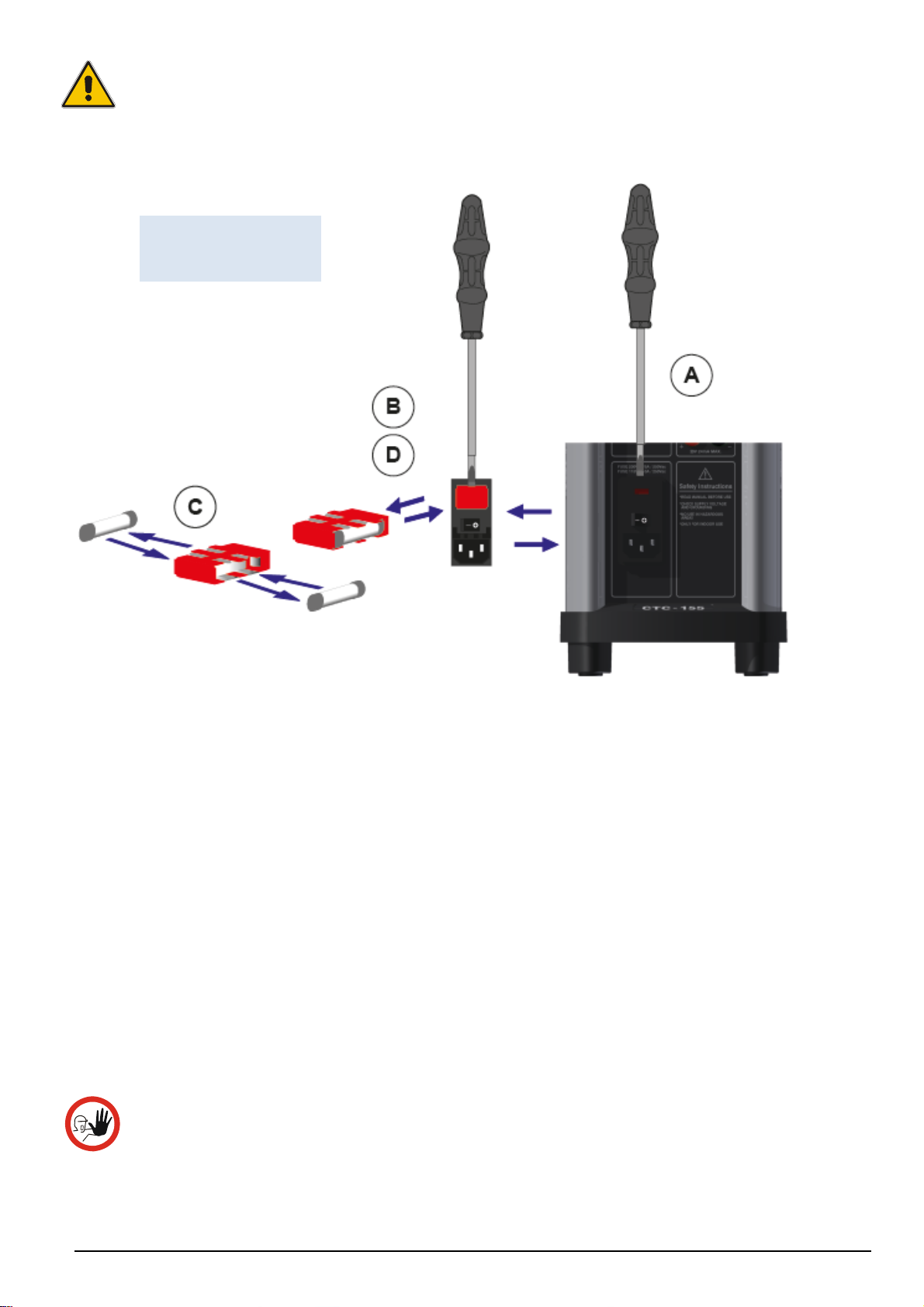

Warning

The two main fuses must have the specified current and voltage rating and be of the

specified type. The use of makeshift fuses and the short-circuiting of fuse holders are

prohibited and may cause a hazard.

A. Open the fuse box lid using a screwdriver.

B. Take out the fuse box.

C. Remove both fuses replacing them with two new fuses. These must be identical

D. Slide the fuse box back into place.

Fig. 1

Changing fuses

and should correspond to the line voltage. See section 11.0.

The calibrator is now ready for use.

Check that the earth connection for the instrument is present and attach the cable.

Select an insertion tube with the correct bore diameter. See section 3.2 for information

on how to select insertion tubes.

3.2 Choosing an insertion tube

Caution…

To get the best results out of your calibrator, the insertion tube dimensions, tolerance

129375 00 2016-05-18 12

and material are critical. We highly advise using the JOFRA insertion tubes, as they

guarantee trouble free operation. Use of other insertion tubes may reduce

performance of the calibrator and cause the insertion tube to get stuck.

Page 14

Caution…

Before using new insertion tubes for the calibration in the CTC-350/660 instruments

the insertion tubes must be heated up to maximum temperature 350°C(662°F) /

660°C (1220°F) for a period of minimum 30 minutes.

Insertion tubes are selected on the basis of the diameter of the sensor to be calibrated.

Use the table for insertion tubes in section 3.2.1 to find the correct parts number.

Alternatively, you may order an undrilled insertion tube and drill the required hole yourself. The

finished dimension should be as follows:

Sensor diameter ød+0.2 +0.05 / -0.00 mm.

Reference sensor hole ø4.2mm +0.05 / -0.00 mm

3.2.1 Standard insertion tubes

Caution…

To get the best results out of your calibrator, the insertion tube dimensions, tolerance

and material are critical. We highly advise using the JOFRA insertion tubes, as they

guarantee trouble free operation. Use of other insertion tubes may reduce

performance of the calibrator and cause the insertion tube to get stuck.

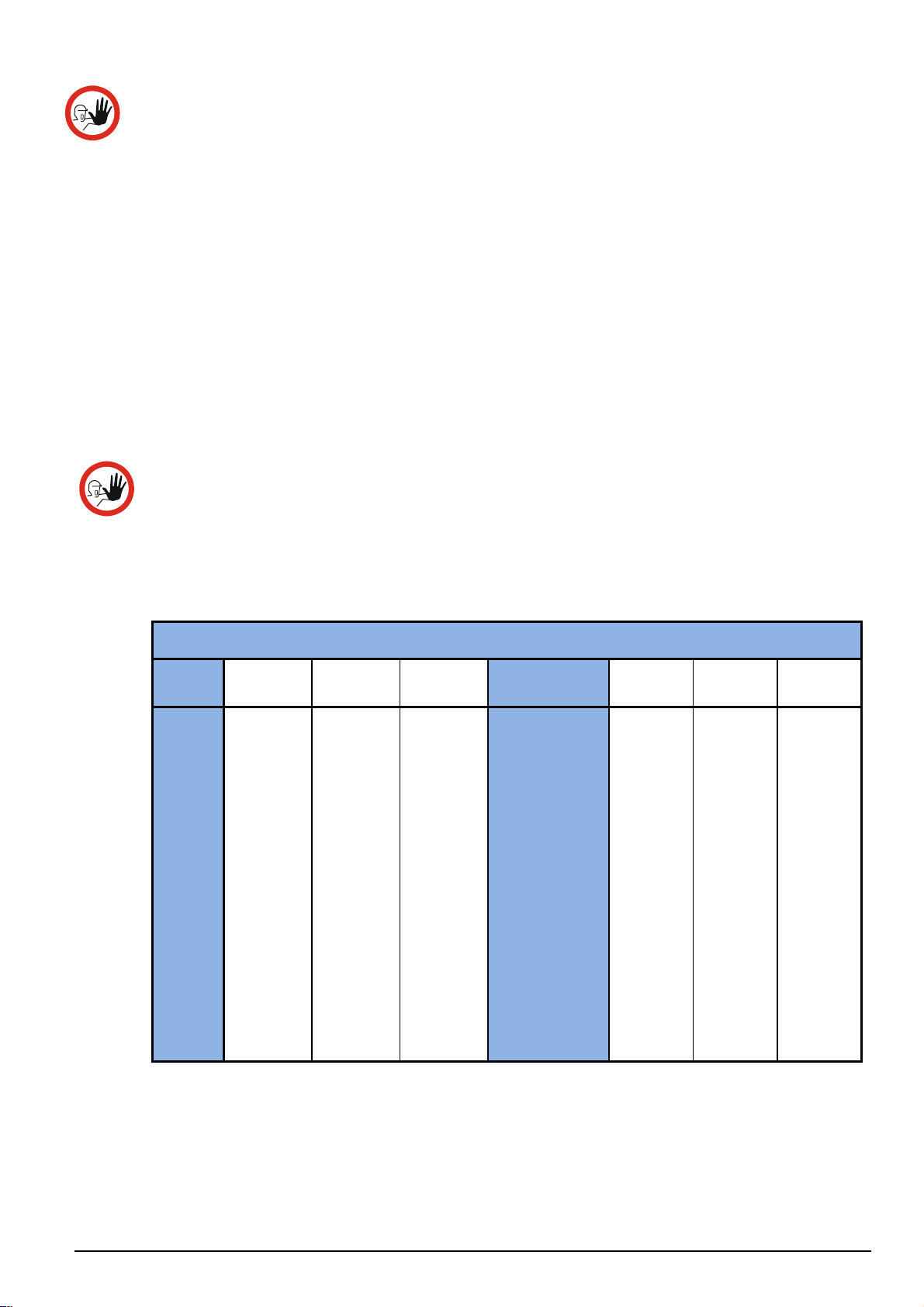

PARTS NO. FOR STANDARD INSERTION TUBES – SINGLE HOLES

Sensor

size

3 mm

4 mm

5 mm

6 mm

7 mm

8 mm

9 mm

10 mm

11 mm

12 mm

13 mm

14 mm

15 mm

16 mm*

18 mm*

20 mm*

CTC-155 CTC-350 CTC-660

129407

129408

129409

129410

129411

129412

129413

129414

129415

129416

129417

-

-

-

-

-

129429

129430

129431

129432

129433

129434

129435

129436

129437

129438

129439

129440

129441

129442

129443

129444

129459

129460

129461

129462

129463

129464

129465

129466

129467

129468

129469

129470

129471

129472

129473

129474

Sensor

size

Undrilled

Undrilled/ref. hole

1/8”

3/16”

1/4”

5/16”

3/8”

7/16”

1/2”

9/16”

5/8”

11/16”*

13/16”*

3/4”*

CTC-155 CTC-350 CTC-660

129418

129419

129420

129421

129422

129423

129424

129425

129426

129427

129428

-

-

-

129445

129446

129447

129448

129449

129450

129451

129452

129453

129454

129455

129456

129457

129458

129475

129476

129477

129478

129479

129480

129481

129482

129483

129484

129485

129486

129487

129488

The CTC-155 single-hole insertion tubes are delivered with a matching insulation plug.

*Note: Insertion tubes without reference holes.

129375 00 2016-05-18 13

Page 15

PART NO. FOR STANDARD INSERTION TUBES – MULTI-HOLE

Description

Metric Type 1

Sensor size

3, 4, 5, 6, 9 mm and

4mm REF

Inch Type 2

Sensor size

1/8”, 3/16”, 1/4”, 3/8” and

4 mm REF

CTC-155

129489 129491 129493

129490

CTC-350

129492

CTC-660

129494

The CTC-155 multi-hole insertion tubes are delivered with a matching insulation plug.

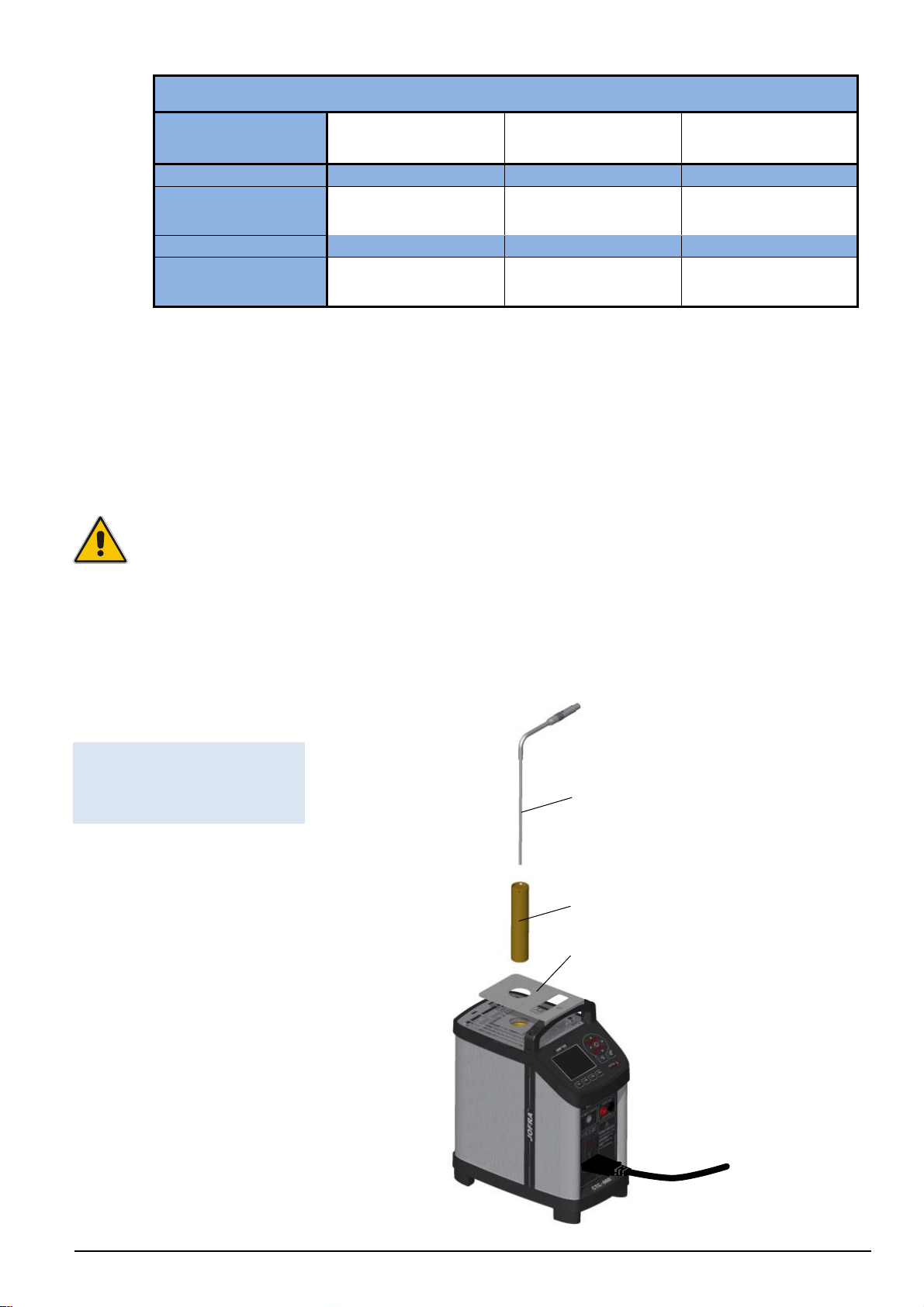

3.3 Inserting the sensor

Before inserting the sensor and switching on the calibrator, please note the following important

warning:

Warning

Never use heat transfer fluids such as silicone, oil, paste, etc. in the dry-block

calibrators.

These fluids may penetrate the calibrator and cause electrical hazard, damage or

create poisonous fumes.

Never try to modify the insulation plugs to make them fit the sensor. Use only

insulation plugs supplied by AMETEK Denmark A/S.

Insert the sensor as shown below in fig. 2.

Fig. 2

Inserting sensor and

insertion tube

Sensor under test

Insertion tube

Thermal protection shield

129375 00 2016-05-18 14

Page 16

Check that the insulation plug fits the diameter of the sensor. Otherwise replace it (CTC-155

only).

In order to spare the sensor and its connections it is recommended to use a thermal

protection shield (129264) at high temperatures (CTC-350/660 only).

Caution…

The well and the insertion tube must be clean before use.

Do not pour any form of liquids in the well. It might damage the well.

Scratches and other damage to the insertion tubes should be avoided by storing

the insertion tubes carefully when not in use.

The insertion tube must never be forced into the well. The well could be damaged

as a result, and the insertion tube may get stuck.

Caution – Hot surface

Do not touch the grid plate, the well or the insertion tube as the calibrator is

heating up – they may be very hot and cause burns.

Do not touch the tip of the sensor when it is removed from the insertion tube/well

– it may be very hot and cause burns.

Do not touch the handle of the calibrator during use – it may be very hot and

cause burns.

Do not remove the insertion tube from the calibrator before the insertion tube has

cooled down to less than 50°C/122°F.

Caution – Cold surface

Below 0°C/32°F (applies only to the CTC-155 models)

Do not touch the well or insertion tube when these are below 0°C/32°F - they might

create frostbite.

If the calibrator has reached a temperature below 0°C/32°F, ice crystals may form

on the insertion tube and the well. This, in turn, may cause the material surfaces to

oxidize

To prevent this from happening the insertion tube and the well must be dried. This is

done by heating up the calibrator to 100°C/212°F until all water left has evaporated.

Remove the insulation plug while heating up.

It is very important that humidity in the well and insertion tube is removed to prevent

corrosion and frost expansion damages.

129375 00 2016-05-18 15

Page 17

3.4 Programming intelligent STS sensors

Use the configuration software CON050 supplied with CTC to program and to update

calibration information in intelligent STS sensors.

For instructions read the software manual for CON050 installed on the USB key.

129375 00 2016-05-18 16

Page 18

play

y

4.0 Calibrator Interface

4.1 Keypad - Functions

Function keys

F1, F2, F3, F4

To operate the horizontal

menu bar use the

Functions keys.

System menu key

Press the key to enter the

System menu.

Back key

Press the key to cancel a

selection or return to

previous menu.

Arrow Keys

Serve different functions

depending on the mode of

operation.

Navigation mode: Use the

four keys to move the

cursor in the desired

direction.

Edit mode: The Up and

Down Arrow keys scroll

through the lists of options.

If entering a number, the

Left and Right Arrow keys

move the cursor one

character in the desired

direction.

Action key / Enter key

Action function: Open and

close edit fields or a menu

button. The action key also

accepts the selected

option or entered value.

Enter function: Accept

selected options or

entered values. When a

value is entered with the

Enter Key the cursor

selects the next

configurable field in the

list.

4.2 Display - Functions

Reference sensor info

Shows the reference sensor

selected. The serial number

of the external reference

sensor is read from the

intelligent reference sensor

and displayed in this field.

“Time to stable”

Selection

Shows the selected

specified stability criteria

and states a time when the

stable situation can be

achieved.

Process Indicator

Indicates the status of the

current process.

Memory reading

Shows the current

memory selected

from the System

menu.

Warning/Error

s

mbols. See 4.2.2

Real Time Clock and

date dis

Horizontal menu bar

Provides you with the relevant menu

options that can be selected at the

present point.

selected and activated by pressing the

function keys (F1, F2, F3 and F4).

Each option can be

.

True temperature

reading

Shows the numeric value

of the temperature being

measured. Can be either

the internal reference

sensor or an external

reference sensor.

Units

Shows the unit of the

current measurement.

Internal Reference

temperature reading

Shows the temperature of

the well.

Set temperature reading

Shows the numeric value

of the current set

temperature selected.

129375 00 2016-05-18 17

Page 19

4.2.1 Main screen temperature values

Two temperatures are always displayed:

TRUE temperature: This is the reference temperature of the calibrator. The TRUE

temperature can either be the internal reference or the external reference.

SET temperature: This is the target temperature for the well. SET temperature displays the

last value entered. If no value has been entered previously, "---,--" is displayed.

Additional temperatures displayed:

If External reference is selected as TRUE temperature, the temperature of the internal

reference is also displayed.

4.2.2 Stability of temperature values

The stability of the TRUE and SENSOR temperatures are indicated by the following

messages:

"Not stable": Indicates that the measured temperature is not yet within the specified

stability criteria.

Indicates "Time to stable": The temperature changes are within the specified stability

criteria (see section 10.0) and states a time (in minutes and seconds) when the stable

situation can be achieved.

Indicates that the “stable” situation is achieved and for how long the calibrator has

been stable. When the calibrator has been stable for more than 99 minutes, only the

stable sign is displayed (time is no longer displayed).

If External reference is selected as TRUE, the stability criteria will refer to this.

The criteria can be changed, however, if the temperature stability criteria is set

wider or the stability time is set shorter, the calibrator may not reach the SET

temperature.

If “Use stability criteria” is set to “Yes” for the SENSOR, the automatic calibration

function will continue to next temperature step only when both TRUE and

SENSOR indicate stability.

When the instrument is heating up and cooling down indication of this will be shown as

following symbols:

The instrument is heating up.

The instrument is cooling down (CTC-155 only).

The instrument is cooling down (CTC-350/660 only).

Heating and cooling symbols will be displayed in the upper black info bar when:

the well temperature is below 5°C.

the well temperature is above 45°C.

129375 00 2016-05-18 18

Page 20

Warning and error symbols will be displayed in the upper black info bar indicating that action

needs to be taken:

Warning symbol.

Error symbol.

If a warning or an error symbol occurs during operation, a list of alarms will be displayed

showing the warning and/or error messages. See section 7.0 – Error messages.

Note…

A warning will always surpass an error, even if the error occurs after the warning.

4.3 Input/Output Connections

Fig. 3

Input and Output

Device

USB 2.0 Device Port, 1 x

USB.

Reference Sensor

Input for reference

sensor.

Power Control Switch

With a cable connection

and On/Off switch. It also

contains the main fuse.

See section 3.1 for

information on how to

change the fuse. The text

above the Power Control

Switch indicates the fuse

value.

Warning

The input terminals must NEVER be connected to voltage exceeding 30V with

reference to ground.

Switch Test

Connection for

thermostat switch test.

Note that this connection

is for voltage free

switches.

129375 00 2016-05-18 19

Page 21

5.0 Operating the calibrator

5.1 Operating principle

Warning Caution…

Please inspect the Safety Instructions in section 2.0 before using the instrument.

The calibrator is operated using the Functions keys, the Arrow keys and the

Action/Enter key.

1. Press the Functions keys to operate the horizontal menu bar.

2. Press any of the (Arrow) keys to enter Navigation Mode. Editable fields will be

highlighted in blue.

3. Use the (Arrow) keys to move between the configurable fields within the

display. Selected fields will be highlighted in dark blue..

4. Press the (Enter) key to access the selected field for editing.

5. Use the (Up) and (Down) Arrow keys to select a new value.

6. Press the (Enter) key to accept the new value

7. To exit the Navigation Mode press the (Back) key. The (Back) key is also

used to cancel a selection or to return to a previous menu.

129375 00 2016-05-18 20

Page 22

5.1.1 System menu

The System menu can be accessed at any stage of operation:

1. Press the (System) key to display the System menu.

2. Use the (Up) and (Down) Arrow keys to scroll in the list.

System Settings menu

1. Use the (Enter) key and the (Up) and (Down) Arrow keys to access

editable fields, select new values and accept new values.

Note…

If the current set-temperature is higher than the new max-temperature, you will

need to adjust the set-temperature. The instrument will immediately begin to

cool (if required) as soon as the new max-temperature is accepted.

The calibration interval can be set between 1 and 99 months. When the

calibration interval is exceeded, a yellow warning symbol will appear in

the upper part of the display. The recalibration interval is not used for the

external reference sensor. The interval for this sensor is stored in the intelligent

sensor.

If the Ext. reference input setting is disabled, it will not be possible to select the

external reference or SET follows true from the Mode menu. Only the internal

reference can be selected and displayed in the main display (C-models only).

129375 00 2016-05-18 21

Page 23

If Silent mode is selected, the cooling speed will be reduced.

Presets menu

The preset temperatures can be changed manually using the (Arrows) keys.

Note…

Temperature range is limited by Min. SET Temp. and Max. SET Temp. settings

editable in the System Settings menu and by the temperature range of the

external reference sensor, if connected.

System Info menu

In the System Info menu important information such as serial numbers and

calibration dates of both the instrument and the external reference sensor are

given.

It is not possible to edit any fields in this menu.

Store menu (Save Settings)

After you have configured the instrument, you can save the setup for future use

using the Store function.

1. Use the (Up) and (Down) Arrow keys to select the Memory-setup you want to

modify, and press (Save). The new configuration is now saved.

F3

2. You can change the name of the highlighted saved setup by pressing (Enter),

and then using the (Up) and (Down) Arrow keys to change the characters.

129375 00 2016-05-18 22

Page 24

The name is limited to seven (7) characters.

3. Press to save the new name.

F3

Recall menu

To recall your memory setups select the Recall function.

1. Use the (Up) and (Down) Arrow keys to to scroll in the setup-list.

2. Select the requested setup, and press (Enter).

The name of the setup will appear in the upper-left corner of the display.

If selecting the Factory default function the active setup will be reset and change to

the initial setting.

5.2 Starting the calibrator

Switch on the calibrator using the power control switch (see section 4.3).

A start up screen is displayed and then replaced with the main menu screen:

The functions in the horizontal menu bar are available using the Functions soft keys

F1 – F4. For Operating principle – See section 5.1.

5.3 Selecting a TRUE – reference sensor (C-models only)

1. Press one of the (Arrow) keys and the (Enter) key to access the Mode

menu.

129375 00 2016-05-18 23

Page 25

You can choose between one of the following sensor constellations:

Internal reference source (A and C models)

External reference source (C models only)

SET follows TRUE (C-models only)

Internal reference source

The internal reference sensor will be displayed as the TRUE value on the main

screen.

The calibrator has a set of internal stability criteria it shall meet before stability is

indicated. The stability time may be set beyond the internal stability criteria.

The stability time can be set (in minutes) using integers from 5 – 99

External reference source (C-models only)

The TRUE value on the main screen will be read from the Intelligent Reference

Sensor connected to the REF. INPUT on the front panel (see section 4.3, fig 3). The

calibrator automatically reads the calibration data and serial number of the Sensor.

SET follows TRUE (C-models only)

This function enables you to reach the TRUE temperature measured by the

External reference sensor.

The TRUE value on the main screen will be read from the Intelligent Reference

Sensor connected to the REF. INPUT on the front panel (see section 4.3, fig 3). The

calibrator automatically reads the calibration data and serial number of the Sensor.

129375 00 2016-05-18 24

Page 26

Note…

that when “SET follow true” is selected, the calibrator will control the temperature

to the TRUE temperature. This means that it could take longer time before the

calibrator indicates stability.

5.4 Stability setting

True: Internal reference

When internal reference is selected the calibrator uses a set of minimum internal

stability criteria that shall be met before stability is indicated.

The stability time can be adjusted from the minimum internal stability time (typical 5

min) up to 99 min.

True: External reference

When internal reference is selected the user can adjust both stability tolerance and

stability time.

The Stability tolerance can be set between 0.01°C to 1.00°C. The tolerance should

be set low enough to utilize the good temperature stability of the calibrator –

however a low value also gives a longer time to be stable.

The stability time can be set from 1 – 99 minutes.

When the TRUE temperature has reached the specified Stability tolerance during

the specified Stability time, then the stability indicator in the main screen will turn

green.

5.5 Selecting the set-temperature

Note…

Temperature range is limited by Min. SET Temp. and Max. SET Temp. settings

editable in the System Settings menu and by the temperature range of the

external reference sensor, if connected.

The set-temperature can be entered both manually and by selecting a preset

temperature.

2. For manually use press (Set)

3. Use the (Arrow) keys to enter the temperature requested.

4. Press (Enter) to accept the entered temperature.

129375 00 2016-05-18 25

F1

Page 27

1. For selecting the preset temperature press (Preset).

F2

2. Select one of the 4 temperature options available from the menu bar by pressing

the correspondent Function key (F1 – F4).

3. The set-temperature is selected, once the Function key has been pressed.

The calibrator will now heat up / cool down.

The starting point is the last chosen set-temperature (even if the instrument has

been switched off).

The top display continuously shows the read-temperature and the lower display

shows the set-temperature.

In the top display the calibrator will indicate the estimated time in whole minutes

until the calibrator will be stable.

When the calibrator is stable the display will show a green checkmark

symbol and the instrument will emit an audible alarm. The instrument will indicate in

minutes and seconds for how long the instrument has been stable.

5.5.1 Editing the preset set-temperature

It is possible to change the preset set temperature to whatever value desired.

1. Press (Preset).

F2

2. Press one of the (Arrow) keys and an editable field displaying the preset set

temperatures appears.

129375 00 2016-05-18 26

Page 28

3. Navigate to the set temperature field using the arrows.

4. Press (Enter) to access the editable field and use the arrows (Up) and

(Down) to select a new set value.

5. Press (Enter) to accept the new set value.

6. Press (Back) to return to the previous menu.

129375 00 2016-05-18 27

Page 29

5.6 Auto Step function

Auto Step is used to step automatically between a range of different calibration

temperatures. This is useful when calibrating sensors in places which are hard to

reach, and when calibrating sensors for which the output is displayed in a different

location.

The function can be illustrated using the following example:

Note…

Temperature range is limited by Min. SET Temp. and Max. SET Temp. settings

editable in the System Settings menu and by the temperature range of the

external reference sensor, if connected.

5.6.1 Running an Auto Step test

1. Press (Auto Step) to access the Auto Step setup. If you wish to return to the

Main screen press (Main).

F3

F1

129375 00 2016-05-18 28

Page 30

2. Press one of the (Arrow) keys to access the editable fields for new values:

No of steps: the number of temperature steps per direction (T

set using integers from 2 to 12. You must select minimum 2

steps, maximum 12 steps.

Hold time: defines the time (in minutes) the temperature is maintained

(after it is stable) for each step.

Step values: must be set within the sensors permitted range.

3. Press (F4) to start the Auto Step test.

The Auto Step test is now in progress.

Tx) can be

1

While the Auto Step test is in progress, 4 options are available:

Stop : Press (F1) to stop the Auto Step test. The process will

end.

Pressing the (F4) key the process will start again running

step 1.

Previous : Press (F2) to force the test to jump a step backwards to the

previous running step regardless of the step’s stability.

Next : Press (F3) to force the test to jump a step forwards to the

next running step regardless of the step’s stability.

Pause : Press (F4) to pause the test. Pressing start (F4)

again, the process will continue running from the current step.

5.6.2 The calibrator's Auto Step procedure

1) Once the Auto Step test is started, the calibrator starts working towards the given

set-temperature. An audible alarm will be emitted once the calibrator is stable.

2) The calibrator will wait the specified amount of hold time. The instrument indicates

this by counting down the amount of time remaining:

3) The calibrator will then go to the next step. The procedure is the same as for the first

step. This process will be repeated until the last step has been executed and the

function has been completed.

129375 00 2016-05-18 29

Page 31

4) The measured TRUE temperatures for each step are displayed during operation.

129375 00 2016-05-18 30

Page 32

5.7 Switch Test function

Switch Test automatically locates the switch temperature of a thermostat.

Three parameters are required:

Start temperature (T1)

End temperature (T2)

Rate of change in temperature pr. minute (Rate).

Dead band of a thermostat can also be determined here. Where the dead band

determines the tolerance between the upper switch temperature and the lower switch

temperature of the thermostat.

The function can be illustrated using the following example:

T

T

T

T

T

max

open

close

T (°C/°F)

min

start

Shifting temperatureX

Calibrator stable

Heating with Rate from Setup

X

5.7.1 Running a Switch Test

T

open

Cooling with Rate from Setup

close

T

T

Dead

X

band

t (min)

Expected switch range

for thermostat

When choosing more test runs

Note…

Before running the Switch Test, make sure that the switch is connected to the Switch

Test input.

Note…

Temperature range is limited by Min. SET Temp. and Max. SET Temp. settings

editable in the System Settings menu and by the temperature range of the

external reference sensor, if connected.

129375 00 2016-05-18 31

Fig. 4

Switch Test input

Page 33

1. Press (Switch) to access the Switch Test setup. If you wish to return to the

F4

Main screen press (Main).

F1

The small graph illustrates the current T1, T2 and dead band selections. Note that T1

can be greater than T2.

2. Press one of the (Arrow) keys to access the editable fields for new values:

T

T

First set temperature

1 :

2

:

Second set temperature

Dead band : To determine dead band, toggle between "Yes" (a two-way-

temperature measurement) and "No" (a one-way-temperature

measurement). A dead band result is only measured when

dead band is set to “Yes”.

Rate : The permitted range is 0.01 - 10.0°C/min. / 0.02 - 18.0°F/min.

Test runs: Can be set from 1 to 3 making it possible to run the test more

than once.

Note…

the Rate should be set so that the thermostat sensor can follow the

temperature in the calibrator's well.

3. Press (F4) to start the Switch Test.

The Switch test is now in progress. See section 5.4.2 for the Switch Test

Procedure.

While the Switch Test is in progress, 2 options are available:

Stop : Press (F1) to stop the Switch Test. The process will end and

the results will be deleted from the results list.

Pressing the (F4) key the process will start from the

beginning heating towards T1.

129375 00 2016-05-18 32

Page 34

Results : Press (F3) to display the current Switch Test result. The

....

....

....

....

results change as the test progresses. The results list is also

accessible from the Switch Test menu screen.

5.7.2 The calibrator's Switch Test procedure

1) Once the Switch Test is started, the calibrator starts working towards T1 as quickly

as possible. The calibrator's temperature changes (heating or cooling) and switch

status are shown in the display.

2) When T1 is achieved and the temperature is stable, the text and the graphic in the

bottom of the screen will change accordingly.

3) The calibrator now starts working towards T2 at the specified Rate.

4) In a normal situation, the thermostat changes state before T2 is achieved. If T2 is

achieved and the temperature is stable, no results will be displayed.

5) When dead band is not selected (single temperature change) (the graphic indicates

the choice), the finished switch test result is displayed.

When dead band is selected (two switch changes), the calibrator starts working

towards T1 at the specified Rate.

6) Normally, the thermostat changes state before T1 is achieved. If T1 is reached and

the temperature is stable, no results will be displayed.

7) The finished switch test results are displayed in the results list by pressing

(F3).

The results show the temperature when the thermostat has closed and the

temperature when it has opened – whichever comes first. The difference between

these 2 temperatures is calculated as the dead band.

....

....

....

....

129375 00 2016-05-18 33

Page 35

6.0 Storing and transporting the calibrator

Warning

Caution…

The following guidelines should always be observed when storing and transporting

the calibrator. This will ensure that the instrument and the sensor remain in good

working order.

The calibrator must be switched off before any attempt to service the instrument is

made. There are no user serviceable parts inside the calibrator.

The following routine must be observed before the insertion tube is removed and the

instrument switched off:

Over 50°C/122°F

If the calibrator has been heated up to temperatures above 50°C/122°F, you must

wait until the instrument reaches a temperature below 50°C/122°F before you

switch it off.

Below 0°C/32°F

(applies only to the CTC-155 models)

Do not touch the well or insertion tube when these are below 0°C/32°F - they

might create frostbite.

If the calibrator has reached a temperature below 0°C/32°F, ice crystals may

form on the insertion tube and on the well. This, in turn, may cause the material

surfaces to oxidize.

To prevent this from happening, the insertion tube and the well must be dried.

This is done by heating up the calibrator to min. 100°C/212°F until all water left

has evaporated.

Remove the insulation plug while heating up.

It is very important that humidity in the well and insertion tube is removed to

prevent corrosion and frost expansion damages.

1. Switch off the calibrator using the power control switch.

Note that the calibration procedure may be interrupted at any time using the power

control switch. Switching off the calibrator during the calibration process will not

damage either the instrument or the sensor.

2. Remove the insertion tube from the calibrator using the tool for insertion tube

supplied with the instrument as shown in fig. 5.

129375 00 2016-05-18 34

Page 36

Fig. 5

Removing insertion

tube

Insertion tube

Tool for insertion tube

Caution – Hot surface

Do not remove the insert from the calibrator before the insert has cooled down to less

than 50°C/122°F

129375 00 2016-05-18 35

Caution…

The insertion tube must always be removed from the calibrator after use.

The humidity in the air may cause corrosion oxidation on the insertion tube inside

the instrument. There is a risk that the insertion tube may get stuck if this is allowed

to happen.

If the calibrator is to be transported long distances, the insertion tube must be

removed from the well to avoid damage to the instrument.

Page 37

Warning

Never leave hot insertion tubes which have been removed from the calibrator

unsupervised – they may constitute a fire hazard or personal injury.

If you intend to store the calibrator in the optional aluminium carrying case after use,

you must ensure that the instrument has cooled to a temperature below 50°C/122°F

before placing it in the carrying case.

Never place a hot insertion tube in the optional carrying case.

Do not touch the well or insertion tube when these are deep frozen – they might

create frostbite.

129375 00 2016-05-18 36

Page 38

7.0 Error messages (List of alarms)

If the calibrator detects an error during operation, the instrument will terminate all functions

and display a list of alarms. Make a note of the error message and contact your distributor or

AMETEK Denmark’s service department.

1. Press (Left) to access the System Info display for status information on the

Warning

The calibrator must be switched off before any attempt to service the instrument is

made. There are no user serviceable parts inside the calibrator.

Note…

AMETEK Denmark’s liability ceases if:

parts are replaced/repaired using spare parts which are not identical to those

recommended by the manufacturer.

non-original parts are used in any way when operating the instrument.

AMETEK Denmark’s liability is restricted to errors which originated from the factory.

instrument.

2. Press (Right) to return to the list of alarms.

Note…

Errors that are critical to safety and the calibrator remain on the list of alarms until the

instrument is switched off and on again.

The following alarms can occur:

Error message: Solution:

Wrong mains frequency

Please enter code to proceed

Mains frequency cannot be

measured

Temperature cut off error

Heater error

Contact your local distributor in order to obtain

a special pin code.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

129375 00 2016-05-18 37

Page 39

Heater 1-2 error

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Heater 3-4 error

Temperature control error

Ambient temperature too high

Well temperature too high

Watchdog reset has occurred

Software reset has occurred

Calibrator calibration date has been

exceeded

Reference input calibration date has

been exceeded

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

The instrument needs to be calibrated. Please

return the instrument to AMETEK Denmark’s

service department or to your national

laboratory.

The instrument needs to be calibrated. Please

return the instrument to AMETEK Denmark’s

service department or to your national

laboratory.

Reference sensor calibration date has

been exceeded

Communication error, RTC

Communication error, safety DAC

EEPROM read/write error

Calibrator coefficients have not been

set

Default configuration loaded

Model number has to be set

Default configuration loaded

Wrong PCB according to configured

variant

The instrument needs to be calibrated. Please

return the instrument to AMETEK Denmark’s

service department or to your national

laboratory.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Illegal hardware version

Fan speed to low

Extension board not connected

Please report the error to your local distributor

or to AMETEK Denmark’s service department

Please check that the fan is not blocked

Please report the error to your local distributor

.

or to AMETEK Denmark’s service department.

129375 00 2016-05-18 38

Page 40

Sensor type not found

Illegal sensor type

Internal RTD excitation current too low

Internal RTD excitation current too high

This particular external reference type is not

designed to be used in the CTC-calibrator

This particular external reference type is not

designed to be used in the CTC-calibrator

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

Please report the error to your local distributor

or to AMETEK Denmark’s service department.

129375 00 2016-05-18 39

Page 41

8.0 Returning the calibrator for service

When returning the calibrator to the manufacturer for service, please enclose a fully completed

service information form. Simply copy/print out the form on the following page and fill in the

required information.

The calibrator should be returned in the original packing.

Furthermore please follow the guidelines for transportation described in section 6.0 – Storing

and transporting the calibrator.

129375 00 2016-05-18 40

Page 42

Service info

Customer data: Date:

Customer name and address:_________________________________________________________________

Attention and dept.:_________________________________________________________________________

Fax no./phone no.:__________________________________________________________________________

Your order no.:_____________________________________________________________________________

Delivery address:___________________________________________________________________________

Distributor name:___________________________________________________________________________

Instrument data:

Model and serial no.:_________________________________________________________________________

Warranty claimed Yes:___________ No:___________ Original invoice no.:_______________________

____________________________________________________________________________________________________

Temp. Sensor Service request: This instrument is sent for

calibration input (please check off):

___ Calibration as left ___ Check

___ Calibration as found and as left ___ Service

___ Accredited calibration as left ___ Repair

___ Accredited calibration as found and as left.

____________________________________________________________________________________________________

Diagnosis data/cause for return:

Diagnosis/fault description:____________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

Special requests:____________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

Safety precautions: if the product has been exposed to any hazardous substances, it must be

thoroughly decontaminated before it is returned to AMETEK Denmark A/S. Details of the hazardous

substances and any precautions to be taken must be enclosed.

129375 00 2016-05-18 41

Page 43

9.0 Maintenance

9.1 Replacing the main fuses

Warning

The calibrator must be switched off before any attempt to service the instrument is

made. There are no user serviceable parts inside the calibrator.

The fuse box must not be removed from the power control switch until the mains

cable has been disconnected.

The two main fuses must have the specified current and voltage rating and be of the

specified type. The use of makeshift fuses and the short-circuiting of fuse holders

are prohibited and may cause a hazard.

Fig. 6

Replacing fuses

A. Locate the main fuses in the fuse box in the power control switch and check the

voltage of the power control switch (on/off switch (230V/115V)). If the voltage of the

power control switch differs from the line voltage, you must adjust the voltage of the

power control switch.

B. Open the lid of the fuse box using a screwdriver and remove the fuse box.

C. Replace the fuses. The fuses must be identical and should correspond to the line

voltage.

115V: 10AF/250V = 60B302

230V: 5AF/250V = 127573

If the fuses blow immediately after you have replaced them, the calibrator should be

returned to the manufacturer for service.

D. Slide the fuse box into place with the correct voltage turning upwards.

129375 00 2016-05-18 42

Page 44

9.2 Maintenance mode

The user can change the configuration of the instrument by accessing the Maintenance mode.

1. Press (Enter) while switching on the calibrator using the ON/OFF switch.

2. Wait a few seconds and press the (System) key to access the Maintenance

System menu.

From the Maintenance System menu you can access the System Settings, the

System Info, the Configuration and the Calibration date. You are also presented to

a selection of adjustment options.

The editable possibilities in the System Settings and the System Info are the same

as described in section 5.1.1.

Configuration

If the system is locked on a specific main frequency it is possible to change this

frequency.

The alarm list will be displayed with the following text:

Wrong mains frequency

Note…

In order to change the main frequency a pin code is needed. Please contact your

local distributor to obtain your special pin code.

1. Select the Configuration mode.

2. Type in the pin code obtained from the distributor using the (Up) and

(Down) keys. The pin code must consist of 4 digits.

129375 00 2016-05-18 43

Page 45

3. Select a new main frequency from the Main Frequency variant list

4. Press (Save) to save the configuration set up.

F4

Adjusting external reference input

In order to adjust the external reference input a 50Ω and a 330Ω resistance must

be connected to external reference input.

Fig. 7

Restistance connected

to the external ref. input

1. Select the Adjust ext. ref. Input mode.

Read and True are displayed, True as en editable line.

2. The Read value is automatically read and when the calibrator is stable an audible

alarm will be emitted.

3. Type in the True value of the connected resistance using the (Up) and

(Down) keys.

129375 00 2016-05-18 44

Page 46

4. Press Continue (F3) to activate the heating up/cooling down process and

wait until the first calibration temperature has been reached.

5. Once the calibrator indicates stability, press Continue (F3) again and wait

for the next stability indication.

6. Now the adjusting process is complete (the (Continue) key can only be

pressed twice), and a new calibration date must be typed in. The calibrator will

automatically ask for a new date.

Calibration date

1. Select the Calibration date mode.

2. Use the (Up) and (Down) keys to enter a new date.

3. Press (Enter) to accept the new date.

4. Press (F3) to continue to the next screen setup.

5. Continue pressing the (Continue) key until the process is completed.

Adjusting temperature, internal reference

Adjusting temperature, external reference

Adjusting temperature, internal & external reference

1. Place the reference sensor in the calibrator.

2. Select the Adjust temp., mode.

3. Press (Enter) and the calibrator starts heating up/cooling down to reach the

first calibration temperature.

4. When the calibrator is stable an audible alarm will be emitted.

5. Type in the reference temperature found using the reference thermometer. Use

the (Up) and (Down) keys to type in the value.

6. Press (Enter) to accept the value.

129375 00 2016-05-18 45

Page 47

7. Press Continue (F3) to activate the heating up/cooling down process and

wait for the stability indication.

8. Once the temperature is stable, press Continue (F3) again.

9. Continue pressing the (Continue) key until the adjusting process is

completed.

10. When the temperature has been adjusted a new calibration date must be typed in.

The calibrator automatically asks for a new date.

Adjusting temperature, self calibration

1. Place the external reference sensor in the calibrator and connect it to the external

reference input.

2. Select the Adjust temp., self calibration mode.

3. Press Start (F4). The self calibration starts running automatically step by

step as shown in the table below.

Adjustment temperature – Calibration Steps

CTC-155 CTC-350 CTC-660

-25°C, -10°C, 0°C, 50°C,

100°C, 155°C

50°C, 100°C, 200°C,

300°C, 350°C

50°C, 200°C, 350°C,

500°C, 660°C

129375 00 2016-05-18 46

Page 48

9.3 Cleaning

Caution…

Before cleaning the calibrator, you must switch it off, allow it to cool down and

remove all cables.

The insertion tube must always be removed from the calibrator after use.

The humidity in the air may cause corrosion oxidation on the insertion tube inside

the instrument. There is a risk that the insertion tube may get stuck if this is allowed

to happen.

Caution – Hot surface

Do not remove the insert from the calibrator before the insert has cooled down to

less than 50°C/122°F

Warning (all versions)

Never leave hot insertion tubes that have been removed from the calibrator

unsupervised – they may constitute a fire hazard or personal injury.

If you intend to store the calibrator in the optional aluminium carrying case after use,

you must ensure that the instrument has cooled to a temperature below 50°C/122°F

before placing it in the carrying case.

Do not touch the well or insertion tube when these are deep frozen – they can

create frostbite.

Users should/must carry out the following cleaning procedures as and when required:

The exterior of the instrument – Clean using water or isopropyl alcohol and a soft cloth.

The cloth should be wrung out hard to avoid any water penetrating the calibrator and

causing damage.

The keyboard may be cleaned using isopropyl alcohol when heavily soiled.

The insertion tube - Must always be clean and should be regularly wiped using a soft, lint-

free, dry cloth.

You must ensure there are no textile fibres on the insertion tube when it is inserted in the

well. The fibres may adhere to the well and damage it.

If the calibrator has reached a temperature below 0°C/32°F, ice crystals may form on the

insertion tube. This, in turn, may cause the material surfaces to oxidize (CTC-155 only).

To prevent this from happening, the insertion tube must be dried. This is done by heating up

the calibrator to min. 100°C/212°F until all water left has evaporated.

Remove the insulation plug while heating up.

It is very important that humidity in the insertion tube is removed to prevent corrosion and

frost expansion damages.

The well - Must always be clean.

Dust and textile fibres should be removed from the well using e.g. compressed air.

Warning

REMEMBER! Wear goggles when using compressed air!

129375 00 2016-05-18 47

Page 49

If the calibrator has reached a temperature below 0°C/32°F, ice crystals may form on the

well. This, in turn, may cause the material surfaces to oxidize (CTC-155 only).

To prevent this from happening, the well must be dried. This is done by heating up the

calibrator to min. 100°C/212°F until all water left has evaporated.

Remove the insulation plug while heating up.

It is very important that humidity in the well is removed to prevent corrosion and frost

expansion damages.

9.4 Adjusting and calibrating the instrument

You are advised to return the calibrator to AMETEK Denmark A/S or another accredited

laboratory at least once a year for calibration.

9.5 Maintenance of STS-reference sensor

Use the configuration software CON050 supplied with the CTC to update calibration

information in the intelligent reference sensor.

Read the STS- and CON050 manuals for instruction about calibration and up-/download

procedure.

The following information in the sensor is used by the CTC and must be filled in correctly:

Serial number

Model number

Sensor type

Temperature range Min/Max

Electrical output Min/Max

RTD type (CvD or ITS-90)

Calibration date

Calibration initials

Calibration period

R0, A, B and C (RTD type = CvD)

RTPW, A(LR), B(LR)C(LR)/C1(LR), C2(LR), C3(LR), C4(LR), C5(LR) A(HR), B(HR),

C(HR), D(HR) and W(HR) (RTD type = ITS-90)

All other data are not used by the CTC.

129375 00 2016-05-18 48

Page 50

*

10.0 Technical specifications

All specifications are given with an ambient temperature of 23°C/73.4°F ± 3°C/5.4°F

MECHANICAL SPECIFICATIONS CTC-155 A/C

Dimensions l w h

248 x 148 x 305 mm / 9.76 x 5.83 x 12.01 inch

Weight 5.5 kg / 12.1 lbs

Bore diameter/depth of well Ø26 mm / 100 mm – ø1.02 inch / 3.94 inch

Weight non-drilled insert 136 g / 4.8 oz

POWER SUPPLY

Line voltage/frequency 90-127VAC / 180-254VAC 47-63 Hz

Power consumption 100 VA max.

Type of connection IEC320

COMMUNICATION INTERFACES

Type of connections USB type B

ENVIRONMENT

Ambient operating temperature range 0-50°C / 32-122°F

Storage temperature range -20-50°C / -4-122°F

Humidity range 5-90% RH, non-condensing

Protection class IP10

Altitude 0-2000 m

READOUT SPECIFICATIONS

Resolution 1 / 0.1 / 0.01

Temperature units °C / °F / K

THERMAL SPECIFICATIONS CTC-155 A/C

Maximum temperature 155°C / 311°F

Minimum temperature *

-7°C / 19.4°F @ ambient temperature 50°C / 122°F

-25°C / -13°F @ ambient temperature 23°C / 73.4°F

-39°C / -38.2°F @ ambient temperature 0°C / 32°F

The minimum temperature will be affected by the number of sensors and the dimensions of the sensors being calibrated.

129375 00 2016-05-18 49

Page 51

THERMAL SPECIFICATIONS CTC-155 A/C

Well specifications

Loaded with up to 4 mm external reference, one 4 mm and

one 6 mm sensor :

30 mm / 1.18 inch axial homogeneity:

0.15°C / 0.37°F @ -25°C / -13°F to 23°C / 73.4°F

0.15°C / 0.27°F @ 23°C / 73.4°F to 155°C / 311°F

40 mm / 1.57 inch axial homogeneity:

0.25°C / 0.45°F @ -25°C / -13°F to 23°C / 73.4°F

0.30°C / 0.54°F @ 23°C / 73.4°F to 155°C / 311°F

Difference between borings :

0.02°C / 0.036 @ -25°C / -13°F to 23°C / 73.4°F

0.03°C / 0.054 @ 23°C / 73.4°F to 155°C / 311°F

Influence from 6 mm load :

0.20°C / 0.36°F

Influence from 6 mm load with Ext. Reference :

0.01°C / 0.02°F

Long term drift (1 year) :

±0.15°C / ±0.27°F

Temperature coefficient ±0.015°C/°C (0-20°C and 26-50°C) / ±0.027°F/°F (32-68°F

and 79-122°F)

Stability ±0.04°C / ±0.07°F

Total accuracy

Total accuracy – C models only

Internal reference:

±0.30°C / 0.72°F

With STS-120 A 915 External reference:

±0.20°C / 0.36°F

Heating time incl. insert -25°C / -13°F to 23°C / 73.4°F : 4 min.

23°C / 73.4°F to 155°C / 311°F : 13 min.

Time to stability 10 min.

Cooling time incl. insert 155°C / 311°F to 23°C / 73.4°F: 12 min. (12 min. silent

mode)

23°C / 73.4°F to –25°C / -13°F : 16 min. (20 min. silent

mode)

129375 00 2016-05-18 50

Page 52

MECHANICAL SPECIFICATIONS CTC-350 A/C

Dimensions l w h

248 x 148 x 305 mm / 9.76 x 5.83 x 12.01 inch

Weight 5.0 kg / 11.0 lbs

Bore diameter/depth of well Ø26 mm / 120 mm – ø1.02 inch / 4.72 inch

Weight non-drilled insert 160 g / 5.6 oz

POWER SUPPLY

Line voltage/frequency 90-127VAC / 180-254VAC 47-63 Hz

Power consumption 1150 VA max.

Type of connection IEC320

COMMUNICATION INTERFACES

Type of connections USB type B

ENVIRONMENT

Ambient operating temperature range 0-50°C / 32-122°F

Storage temperature range -20-50°C / -4-122°F

Humidity range 5-90% RH, non-condensing

Protection class IP10

Altitude 0-2000 m

READOUT SPECIFICATIONS

Resolution 1 / 0.1 / 0.01

Temperature units °C / °F / K

THERMAL SPECIFICATIONS CTC-350 A/C

Maximum temperature 350°C / 662°F

Minimum temperature

55°C / 131°F @ ambient temperature 50°C / 122°F

28°C / 82°F @ ambient temperature 23°C / 73.4°F

5°C / 41°F @ ambient temperature 0°C / 32°F

129375 00 2016-05-18 51

Page 53

THERMAL SPECIFICATIONS CTC-350 A/C

Well specifications

Loaded with up to 4 mm external reference, one 4 mm and

one 6 mm sensor :

30 mm / 1.18 inch axial homogeneity:

0.07°C / 0.13°F @ 28°C / 82.4°F to 200°C / 392°F

0.15°C / 0.27°F @ 200°C / 392°F to 350°C / 662°F

40 mm / 1.57 inch axial homogeneity:

0.10°C / 0.18°F @ 28°C / 82.4°F to 200°C / 392°F

0.20°C / 0.36°F @ 200°C / 392°F to 350°C / 662°F

Difference between borings :

0.02°C / 0.036 @ 28°C / 82.4°F to 200°C / 392°F

0.04°C / 0.072 @ 200°C / 392°F to 350°C / 662°F

Influence from 6 mm load :

0.25°C / 0.36°F @ 28°C / 82.4°F to 200°C / 392°F

0.35°C / 0.63°F @ 200°C / 392°F to 350°C / 662°F

Influence from 6 mm load with Ext. Reference :