Page 1

Revision F

January 2014

by AMETEK Programmable Power.

All rights reserved.

Copyright 2011

P/N M162084

CSW Series

AC Power Source

User Manual

Page 2

User Manual California Instruments

User's Manual

California Instruments AC Power Source

By AMETEK Programmable Power.

Models :

CSW5550

CSW5550-400

CSW11100

CSW11100-400

CSW16650

CSW16650-400

CSW22200

CSW22200-400

CSW27750

CSW27750-400

CSW33300

CSW33300-400

CSW38850

CSW38850-400

CSW44400

CSW44400-400

Copyright 2011 AMETEK Programmable Power. Rev C, January 2012.

2 CSW Series

Page 3

User Manual California Instruments

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement,

process control, power bus simulation and power conditioning applications across diverse industrial

segments. From bench top supplies to rack-mounted industrial power subsystems, AMETEK

Programmable Power is the proud manufacturer of Elgar, Sorensen, California Instruments and

Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical

devices with annualized sales of $2.5 billion. The Company has over 11,000 colleagues working at

more than 80 manufacturing facilities and more than 80 sales and service centers in the United

States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc. California Instruments is a trademark owned by

AMETEK, Inc. Other trademarks, registered trademarks, and product names are the property of their

respective owners and are used herein for identification purposes only.

Notice of Copyright

CSW Series User Manual

© 2011 AMETEK Programmable Power, Inc. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC. (“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMA GES, COSTS OR EXPENSES,

WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT

ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL

BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION,

THE ACCURACY CANNOT BE GUARANTEED. APPROVED AMETEK CONTENT IS CONTAINED

WITH THE ENGLISH LANGUAGE VERSION, WHICH IS POSTED AT

WWW.PROGRAMMABLEPOWER.COM.

Date and Revision

January 2014 Revision F

Part Number

M162084

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales.ppd@ametek.com

service.ppd@ametek.com

Web: www.programmablepower.com

CSW Series 3

Page 4

User Manual California Instruments

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your

particular application.

WARNING

WARNING

Only qualified personnel who deal with attendant hazards in power supplies, are allowed to perform

installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or

chassis. Similarly, other power ground lines including those to application and maintenance equipment

must be grounded properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any

cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY may be normally generated on the output terminals. The customer/user must ensure

that the output power lines are labeled properly as to the safety hazards and that any inadvertent

contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety

glasses during open cover checks to avoid personal injury by any sudden component failure.

Neither AMETEK Programmable Power Inc., San Diego, California, USA, nor any of the subsidiary

sales organizations can accept any responsibility for personnel, material or inconsequential injury, loss

or damage that results from improper use of the equipment and accessories.

Hazardous voltages may be present when covers are removed. Qualified

personnel must use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating above

(below) chassis ground.

The equipment used contains ESD sensitive parts. When installing

equipment, follow ESD Safety Procedures. Electrostatic discharges might

cause damage to the equipment.

SAFETY SYMBOLS

4 CSW Series

Page 5

User Manual California Instruments

CSW Series 5

Page 6

User Manual California Instruments

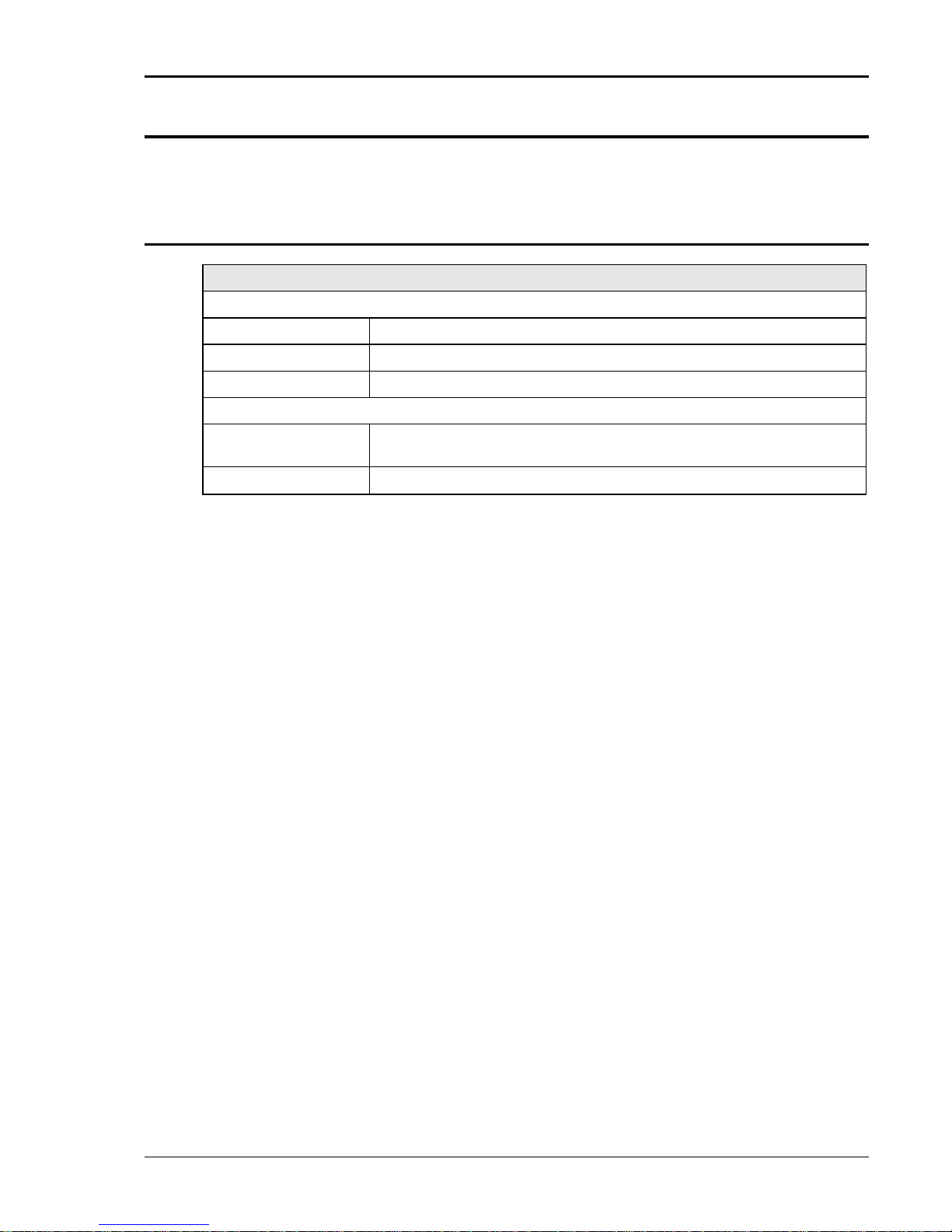

Product Family: CSW Series Power Source

Warranty Period: 1 Year

WARRANTY TERMS

AMETEK Programmable Power, Inc. (“AMETEK”), provides this written warranty covering the

Product stated above, and if the Buyer discovers and notifies AMETEK in writing of any defect in

material or workmanship within the applicable warranty period stated above, then AMETEK may, at

its option: repair or replace the Product; or issue a credit note for the defective Product; or provide

the Buyer with replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in

accordance with the return procedure specified below. AMETEK will, at its expense, deliver the

repaired or replaced Product or parts to the Buyer. Any warranty of AMETEK will not apply if the

Buyer is in default under the Purchase Order Agreement or where the Product or any part thereof:

is damaged by misuse, accident, negligence or failure to maintain the same as

specified or required by AMETEK;

is damaged by modifications, alterations or attachments thereto which are not

authorized by AMETEK;

is installed or operated contrary to the instructions of AMETEK;

is opened, modified or disassembled in any way without AMETEK’s consent; or

is used in combination with items, articles or materials not authorized by AMETEK.

The Buyer may not assert any claim that the Products are not in conformity with any warranty until

the Buyer has made all payments to AMETEK provided for in the Purchase Order Agreement.

PRODUCT RETURN PROCEDURE

Request a Return Material Authorization (RMA) number from the repair facility (must be done in

the country in which it was purchased):

In the USA, contact the AMETEK Repair Department prior to the return of the

product to AMETEK for repair:

Telephone: 800-733-5427, ext. 2295 or ext. 2463 (toll free North America)

858-450-0085, ext. 2295 or ext. 2463 (direct)

Outside the United States, contact the nearest Authorized Service Center (ASC). A

full listing can be found either through your local distributor or our website,

www.programmablepower.com, by clicking Support and going to the Service Centers

tab.

When requesting an RMA, have the following information ready:

Model number

Serial number

Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by AMETEK, to be in specification is subject to an

evaluation fee and applicable freight charges.

6 CSW Series

Page 7

User Manual California Instruments

Table of Contents

Introduction ................................................................................................................................ 12

1.

1.1 General Description ............................................................................................................................. 12

1.2 CSW Models ........................................................................................................................................ 13

2. Specifications ............................................................................................................................. 14

2.1 Electrical .............................................................................................................................................. 14

2.2 Mechanical .......................................................................................................................................... 24

2.3 Environmental ...................................................................................................................................... 24

2.4 Regulatory ........................................................................................................................................... 25

2.5 Front Panel Controls ............................................................................................................................ 25

2.6 Special Features, Options and Accessories ........................................................................................ 26

2.7 Supplemental Specifications ................................................................................................................ 27

3. Unpacking and Installation ....................................................................................................... 28

3.1 Unpacking ............................................................................................................................................ 28

3.2 Power Requirements ........................................................................................................................... 28

3.3 Mechanical Installation ........................................................................................................................ 29

3.4 Input Wiring – TB1 ............................................................................................................................... 29

3.5 Output Power Connections – TB2 ....................................................................................................... 30

3.6 Connectors - Rear Panel ..................................................................................................................... 32

3.7 Single-Phase and Three Phase Multiple Box System Configurations ................................................. 36

3.8 Output Voltage Ranges ....................................................................................................................... 37

3.9 Functional Test .................................................................................................................................... 37

3.10Tour of the Front Panel ........................................................................................................................ 43

3.11Menu Structure .................................................................................................................................... 49

3.12Output Programming ........................................................................................................................... 83

3.13Waveform Management ...................................................................................................................... 85

3.14Standard Measurements ..................................................................................................................... 89

3.15Advanced Measurements .................................................................................................................... 90

3.16Transient Programming ....................................................................................................................... 99

4. Principle of Operation ............................................................................................................. 104

4.1 General .............................................................................................................................................. 104

4.2 Overall Description ............................................................................................................................ 104

4.3 Controller (A2) (7006-714) ................................................................................................................. 104

4.4 Keyboard/Display Board (A1) (7006-716) .......................................................................................... 104

4.5 Remote Interface (A7) (7006-715) ..................................................................................................... 104

4.6 Analog Board (A3) (5162062) ............................................................................................................ 105

4.7 Auxiliary Power Supply (A8) (5162048) ............................................................................................. 105

4.8 PFC - DC/DC Module (A14, A15 and A16) (5161273)....................................................................... 107

4.9 Phase A, B and C Amplifiers (A17, A18, A19) (5161274-05) ............................................................. 109

4.10Output Filter Board (A9) (5162063) ................................................................................................... 109

4.11Circuit Breaker & Trip Circuit (A5)...................................................................................................... 109

5. Calibration ................................................................................................................................ 111

5.1 Calibration Equipment ....................................................................................................................... 111

5.2 Calibration Screen Access ................................................................................................................. 111

5.3 Routine Calibration ............................................................................................................................ 112

5.4 Non-Routine Calibration .................................................................................................................... 116

6. Service ...................................................................................................................................... 118

6.1 Cleaning ............................................................................................................................................ 118

6.2 General .............................................................................................................................................. 118

6.3 Basic operation .................................................................................................................................. 118

7. Top Assembly Replaceable Parts .......................................................................................... 121

CSW Series 7

Page 8

User Manual California Instruments

7.1 Sub assemblies ................................................................................................................................. 121

8. Options ..................................................................................................................................... 122

8.1 RTCA/DO-160 Option ....................................................................................................................... 122

8.2 IEC 61000-4-11 Option ..................................................................................................................... 139

8.3 IEC 61000-4-13 Option ..................................................................................................................... 147

8.4 Option –704: MilStd704 Tests ........................................................................................................... 159

8.5 ABD Option: Airbus ABD0100.1.8 Test ............................................................................................. 171

8.6 AMD Option: Airbus AMD24C Test ................................................................................................... 171

8.7 A350 Option: Airbus A350 (ABD0100.1.8.1) Test ............................................................................. 171

8.8 787 Option: Boeing B787-0147 Test ................................................................................................. 171

8.9 WHM Option ...................................................................................................................................... 172

9. Error Messages ........................................................................................................................ 175

10. Index .......................................................................................................................................... 180

8 CSW Series

Page 9

User Manual California Instruments

List of Figures

Figure 1-1 California Instruments CSW5550 (With Rack Mount Ears) ................................................................ 12

Figure 2-1: CSW5550 – Typical Current De-Rating Chart for 156v AC Range ................................................... 17

Figure 2-2: CSW5550 – Typical Current De-Rating Chart for 312v AC Range ................................................... 18

Figure 3-1:CSW5550 ........................................................................................................................................... 28

Figure 3-2:USB Connector pin orientation ........................................................................................................... 34

Figure 3-3: Rear Panel View for the CSW5550) .................................................................................................. 36

Figure 3-4: Output Power Connections for 1 Source and Multi-source Systems ................................................. 39

Figure 3-5: Functional Test Setup ....................................................................................................................... 40

Figure 3-6: Three CSW Sources, 9-phases with Clock/Lock ............................................................................... 41

Figure 3-7: Shuttle Knob ...................................................................................................................................... 44

Figure 3-8: FUNCTION keypad .......................................................................................................................... 45

Figure 3-9: Entering value from decimal keypad ................................................................................................ 46

Figure 3-10: Cursor UP key movement .............................................................................................................. 47

Figure 3-11: Cursor DOWN key movement ........................................................................................................ 47

Figure 3-12: Main Menu 1 screen ....................................................................................................................... 48

Figure 3-13: Menu 1 through 3 ........................................................................................................................... 49

Figure 3-14: PROGRAM Menu ........................................................................................................................... 53

Figure 3-15: MEASUREMENTS Screen, single phase and three phase modes ................................................ 55

Figure 3-16: HARMONICS/TRACE ANALYSIS screen ...................................................................................... 57

Figure 3-17: TRANSIENTS menu ....................................................................................................................... 60

Figure 3-18: VOLTAGE SURGE/SAG SETUP screen ....................................................................................... 61

Figure 3-19: VOLTAGE SWEEP/STEP SETUP screen ..................................................................................... 63

Figure 3-20: FREQUENCY SWEEP/STEP SETUP screen ................................................................................ 65

Figure 3-21: VOLTAGE/FREQUENCY SWEEP/STEP SETUP screen .............................................................. 66

Figure 3-22: START/VIEW TRANSIENT SEQUENCE screen ............................................................................ 67

Figure 3-23: WAVEFORMS menu ...................................................................................................................... 68

Figure 3-24: APPLICATIONS menu ................................................................................................................... 70

Figure 3-25: SETUP REGISTERS menu ............................................................................................................ 71

Figure 3-26: UTILITY menus .............................................................................................................................. 72

Figure 3-27: GPIB/RS232 SETUP menu ............................................................................................................ 75

Figure 3-28: VOLTAGE/CURRENT CONTROL SETUP menu ........................................................................... 76

Figure 3-29: INITIAL SETUP menus ................................................................................................................... 77

Figure 3-30:LIMIT SETUP menu ......................................................................................................................... 78

Figure 3-31: CONFIGURATION SETUP Menus .................................................................................................. 79

Figure 3-32: MEASUREMENT CAL FACTORS menu ........................................................................................ 81

Figure 3-33: OUTPUT CAL FACTORS menu ...................................................................................................... 81

Figure 3-34: Selecting a waveform ...................................................................................................................... 85

Figure 3-35: Selecting waveforms for single phase or all phases ....................................................................... 85

Figure 3-36: Custom waveform creation with GUI program ................................................................................. 86

Figure 3-37: Waveform crest factor affects max. rms voltage ............................................................................. 87

Figure 3-38: Waveform frequency domain view mode ....................................................................................... 88

Figure 3-39: Scrolling through tabular FFT data ................................................................................................. 92

Figure 3-40: Scrolling through bar chart FFT data .............................................................................................. 92

Figure 3-41: Scrolling through acquired waveform data ..................................................................................... 94

Figure 3-42: SET VOLT trigger source acquisition ............................................................................................. 96

Figure 3-43: Positive trigger delay (Post trigger data) ........................................................................................ 97

Figure 3-44: Negative trigger delay (Pre-trigger data) ........................................................................................ 98

Figure 3-45: Pulse Transients ............................................................................................................................. 99

Figure 3-46: List Transients .............................................................................................................................. 100

Figure 3-47: Switching waveforms in a transient list ......................................................................................... 102

Figure 3-48: START/VIEW TRANSIENT SEQUENCE menu ........................................................................... 103

Figure 4-1: Power Source Module Block Diagram ............................................................................................. 106

Figure 4-2: Internal Assembly Locations ........................................................................................................... 108

Figure 5-1: Test Equipment Hook-up for Calibration ......................................................................................... 115

Figure 5-2: Front Panel Assembly Adjustment Location (Top View) .................................................................. 116

Figure 8-1: Application Menu ............................................................................................................................. 124

Figure 8-2: DO160 Main Menu .......................................................................................................................... 124

Figure 8-3: Normal state .................................................................................................................................... 125

Figure 8-4: Voltage Modulation ......................................................................................................................... 127

Figure 8-5: Frequency Modulation ..................................................................................................................... 128

CSW Series 9

Page 10

User Manual California Instruments

Figure 8-6: Power Interrupt ............................................................................................................................... 129

Figure 8-7: Power Interrupt for Group 2 and 3 .................................................................................................. 130

Figure 8-8: Emergency Screen ......................................................................................................................... 131

Figure 8-9: Abnormal Screen ............................................................................................................................ 133

Figure 8-10: DO-160 DC Main Menu ................................................................................................................ 135

Figure 8-11: Normal State ................................................................................................................................. 135

Figure 8-12: Abnormal State ............................................................................................................................. 137

Figure 8-13: Application menu .......................................................................................................................... 141

Figure 8-14: IEC1000-4-11 Menu ...................................................................................................................... 141

Figure 8-15: IEC Dips and Interrupts ................................................................................................................. 142

Figure 8-16: Voltage Variation screen ............................................................................................................... 144

Figure 8-17: EN 61000-4-11 Voltage Variation specification- Edition 1.0 .......................................................... 145

Figure 8-18: EN 61000-4-11 Voltage Variation specification- Edition 2.0 .......................................................... 145

Figure 8-19: IEC 61000-4-11 GUI screen. ........................................................................................................ 146

Figure 8-20: Application menu .......................................................................................................................... 148

Figure 8-21: IEC 61000-4-13 Menu ................................................................................................................... 148

Figure 8-22: IEC 61000-4-13 FCurve ................................................................................................................ 150

Figure 8-23: IEC 61000-4-13 OSwing ............................................................................................................... 150

Figure 8-24: IEC 61000-4-13 Sweep ................................................................................................................. 151

Figure 8-25: IEC 61000-4-13 Harmonics .......................................................................................................... 152

Figure 8-26: IEC 61000-4-13 Inter harmonics ................................................................................................... 153

Figure 8-27: IEC 61000-4-13 Meister Curve ..................................................................................................... 154

Figure 8-28: IEC 61000-4-13 Test Flowchart Class 1 and 2 ............................................................................. 155

Figure 8-29: IEC 61000-4-13 Test Flowchart Class 3 ....................................................................................... 156

Figure 8-30: MENU 2 SCREEN ........................................................................................................................ 158

Figure 8-31: INTERHARMONICS SCREEN ..................................................................................................... 158

Figure 8-32: Application Menu .......................................................................................................................... 161

Figure 8-33: MIL704 Menu ............................................................................................................................... 161

Figure 8-34: Steady State Menu ....................................................................................................................... 161

Figure 8-35: Transient Menu ............................................................................................................................. 164

Figure 8-36: Emergency Menu ......................................................................................................................... 165

Figure 8-37: Abnormal Screen ......................................................................................................................... 166

Figure 8-38: MIL704 DC Menu .......................................................................................................................... 167

Figure 8-39: Steady State DC .......................................................................................................................... 167

Figure 8-40: Transient Menu ............................................................................................................................ 168

Figure 8-41: Abnormal Test Screen .................................................................................................................. 169

Figure 8-42: Emergency Test ............................................................................................................................ 170

Figure 8-43: Application Screen ........................................................................................................................ 172

Figure 8-44 Watt-Hour Meter Screen ................................................................................................................ 172

Figure 8-45: WH-Meter Screen With Function Active ........................................................................................ 172

10 CSW Series

Page 11

User Manual California Instruments

List of Tables

Table 3-1: Wire Sizes ......................................................................................................................................... 31

Table 3-2: System Interface Connector (J32) ..................................................................................................... 32

Table 3-3: RS232 Connector pin out ................................................................................................................... 34

Table 3-4: USB Connector pin out. ...................................................................................................................... 34

Table 3-5: RJ45 LAN Connector pin out. ............................................................................................................. 35

Table 5-1: Load Values for Output Current Calibration ...................................................................................... 112

Table 5-2: External Signal Input Connector Pins ............................................................................................... 113

Table 5-3: AC/DC Zero Adjustment ................................................................................................................... 117

Table 6-1: Basic Symptoms ............................................................................................................................... 118

Table 7-1: Replaceable Parts ........................................................................................................................... 121

Table 8-1: Normal Voltage and Frequency minimum ........................................................................................ 125

Table 8-2: Normal Voltage and Frequency Maximum ........................................................................................ 125

Table 8-3: Normal Voltage Unbalance ............................................................................................................... 126

Table 8-4: Normal VoltageSurge Sequence ...................................................................................................... 130

Table 8-5: Normal Frequency Transient Sequence ........................................................................................... 131

Table 8-6: Normal Frequency Variation Sequence ............................................................................................ 131

Table 8-7: Emergency Voltage and Frequency Minimum .................................................................................. 132

Table 8-8: Emergency Voltage and Frequency Maximum ................................................................................. 132

Table 8-9: Emergency Voltage Unbalance ........................................................................................................ 132

Table 8-10: Abnormal Voltage Minimum ........................................................................................................... 133

Table 8-11: Abnormal Voltage Maximum .......................................................................................................... 133

Table 8-12: Abnormal Frequency Transient ...................................................................................................... 134

Table 8-13: Normal Voltage Minimum ............................................................................................................... 135

Table 8-14: Normal Voltage Maximum .............................................................................................................. 136

Table 8-15: Voltage Surge ................................................................................................................................. 136

Table 8-16: Abnormal Voltage Surge ................................................................................................................ 138

Table 8-17: Phase mapping .............................................................................................................................. 140

Table 8-18: IEC 61000-3-34 Table C.2 .............................................................................................................. 140

Table 8-19: Dips and Interruptions Tests Performed During RUN ALL ............................................................ 143

Table 8-20: Voltage Variations Test Performed During RUN ALL .................................................................... 144

Table 9-1: Error Messages. ............................................................................................................................... 179

CSW Series 11

Page 12

User Manual California Instruments

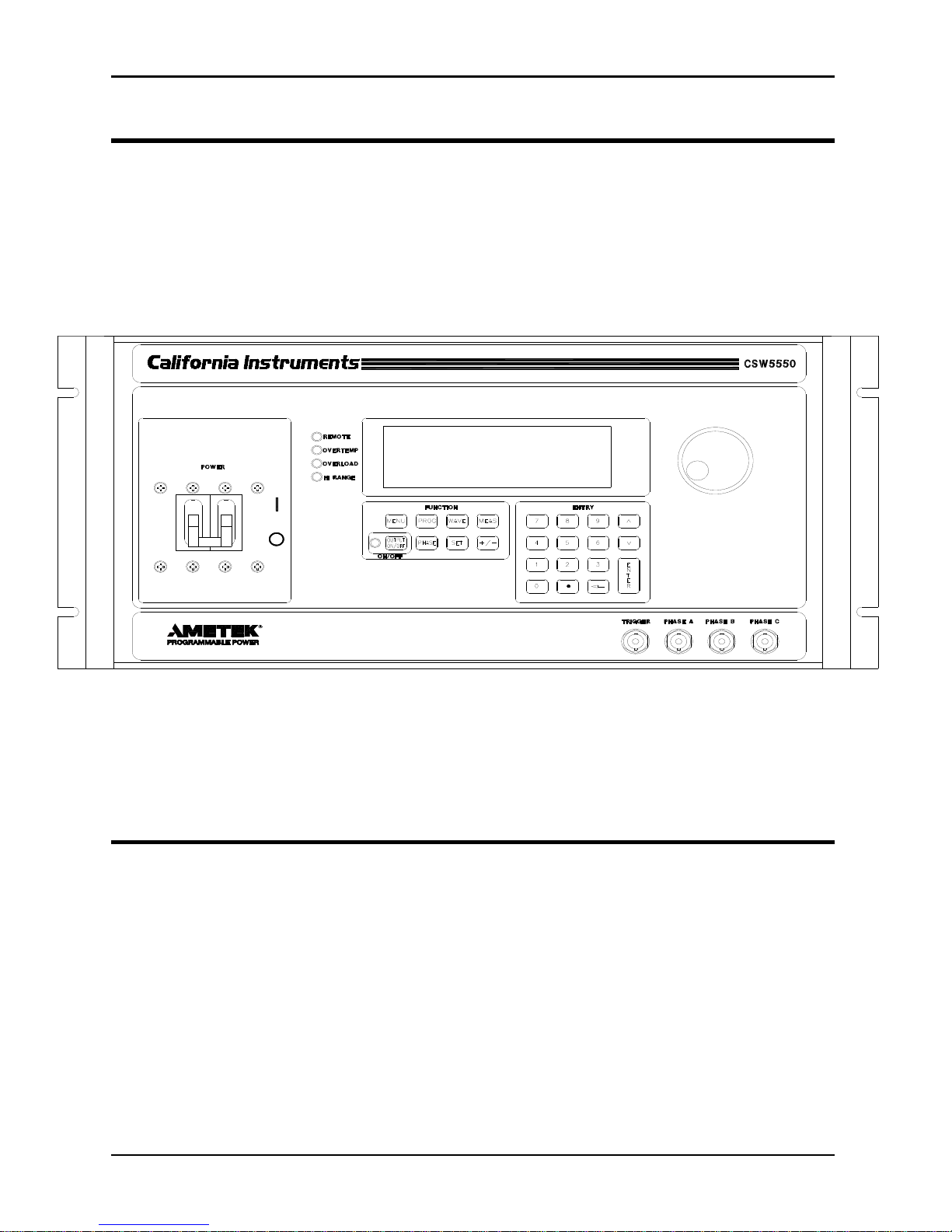

1. Introduction

This instruction manual contains information on the installation, operation, calibration and

maintenance of all power systems that use the CSW5550.

This user manual also covers higher power configurations consisting of multiple units of the

CSW5550 operated in parallel. Such models are the CSW11100, CSW16650, CSW22200,

CSW27750, CSW33300, CSW38850 and CSW44400.

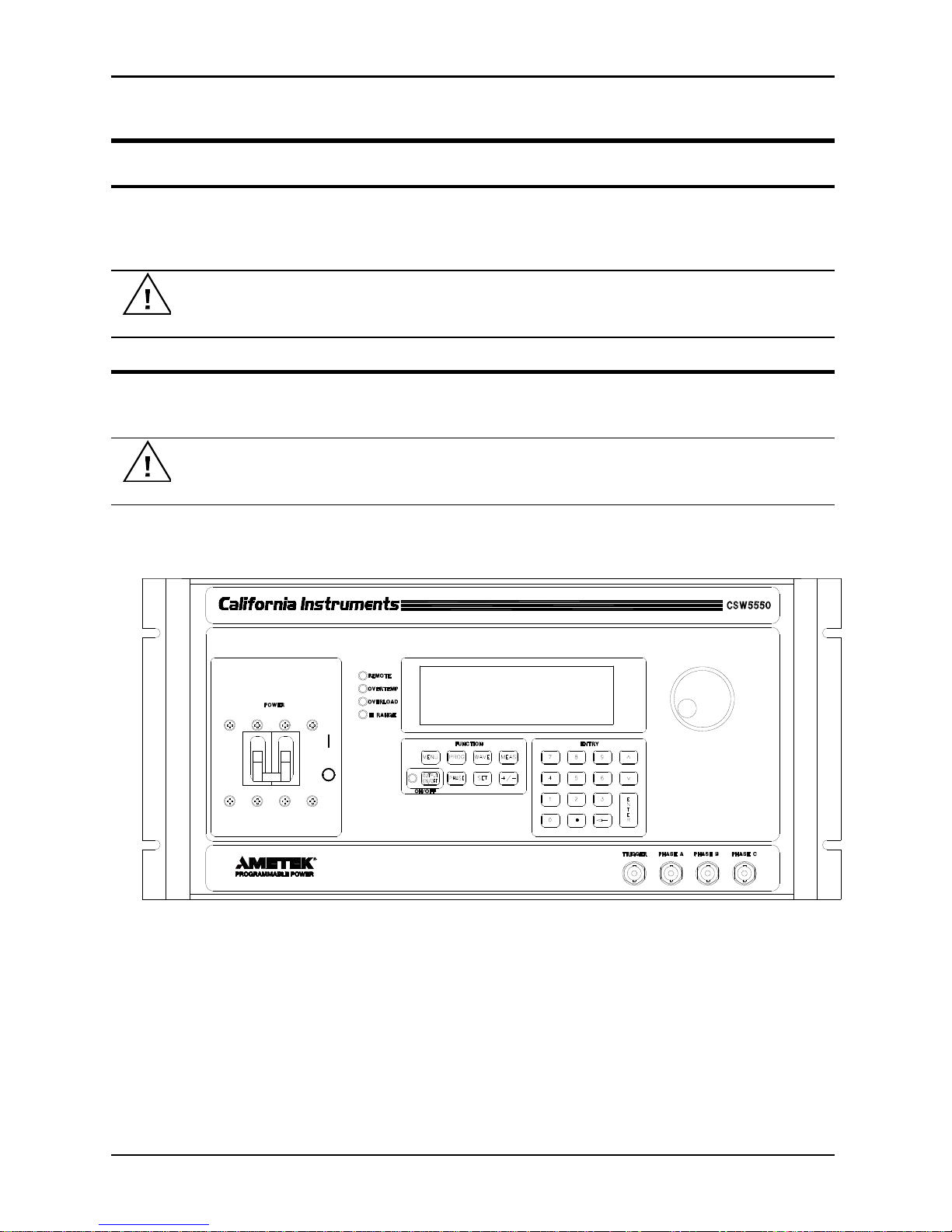

Figure 1-1 California Instruments CSW5550 (With Rack Mount Ears)

1.1 General Description

The CSW5550 is a high efficiency, lightweight AC power source that provides a precise output

with low distortion. The CSW Series offers a 0-156/0-312 AC or DC voltage range. Full power

is available from 115/230V to full-scale voltage using a constant power mode of operation.

Two to eight CSW5550 units can be connected in parallel as a single-phase or 3-phase power

system for an output of up to 44.4 KVA. They can be operated with AC or DC output.

The CSW5550 Series also offers AC+DC output mode.

Remote Interfaces

The CSW5550 has the standard GPIB, RS232 and USB remote interfaces. The LAN (Ethernet)

interface is offered as an option. With the LAN interface the RS232 interface will not be

functional.

12 CSW Series

Page 13

User Manual California Instruments

1.2 CSW Models

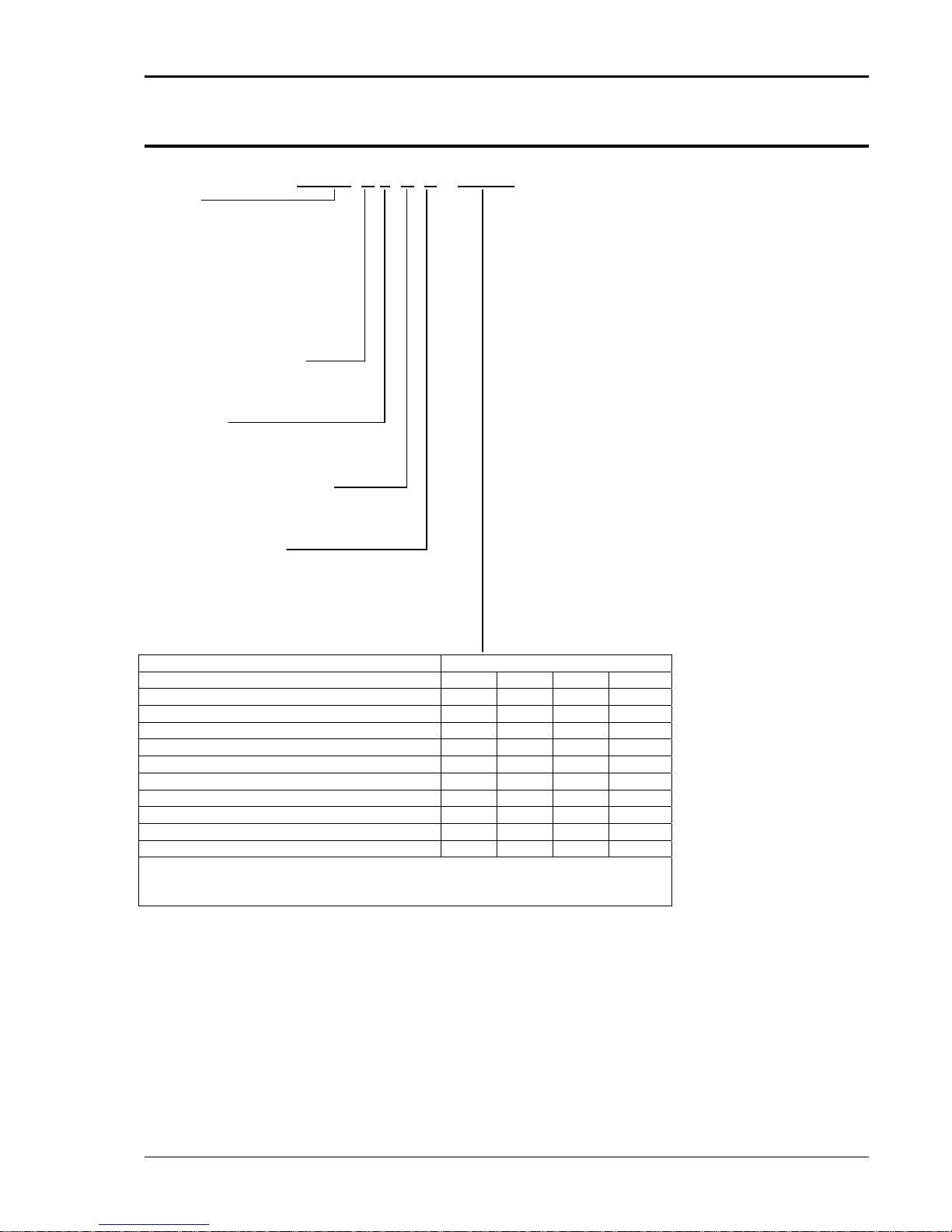

CSW5 C 0 C X 0 0 0 0

Model

CSW5550= CSW5

CSW11100 = CSW11

CSW16650 = CSW16

CSW22200 = CSW22

CSW27750 = CSW27

CSW33300 = CSW33

CSW38850 = CSW38

CSW44400 = CSW44

Initial Configuration

1-Phase = A

3-Phase = C

I/F Option

Std GPIB/USB/RS232 = 0

LAN/GPIB/USB = 2

AC Line Input Options

PFC USA = C

PFC International = G

Hardware Options

No Option = X

LKM = J

LKS = K

LF = H

LF & LKM = A

Firmware Options CODE

None 0 0 0 0

-RTCA/DO160 1 0 0 0

-IEC61000-4-11 0 4 0 0

-Mil Std 704 0 2 0 0

-704F 0 1 0 0

-A350 0 0 8 0

-ABD 0 0 4 0

-ABL 0 0 2 0

-AMD 0 0 0 8

-B787 0 0 0 4

-WHM 0 0 0 1

For multiple options use the HEX sum. For example A350 and ABD would be

00D0

Sum of 0 –9 = HEX 0 –9. Sum of 10 – 15 = HEX A - F

CSW Series 13

Page 14

User Manual California Instruments

2. Specifications

All specifications are for a single CSW5550 unit and 25 5C sine wave output with a resistive

load unless noted otherwise.

2.1 Electrical

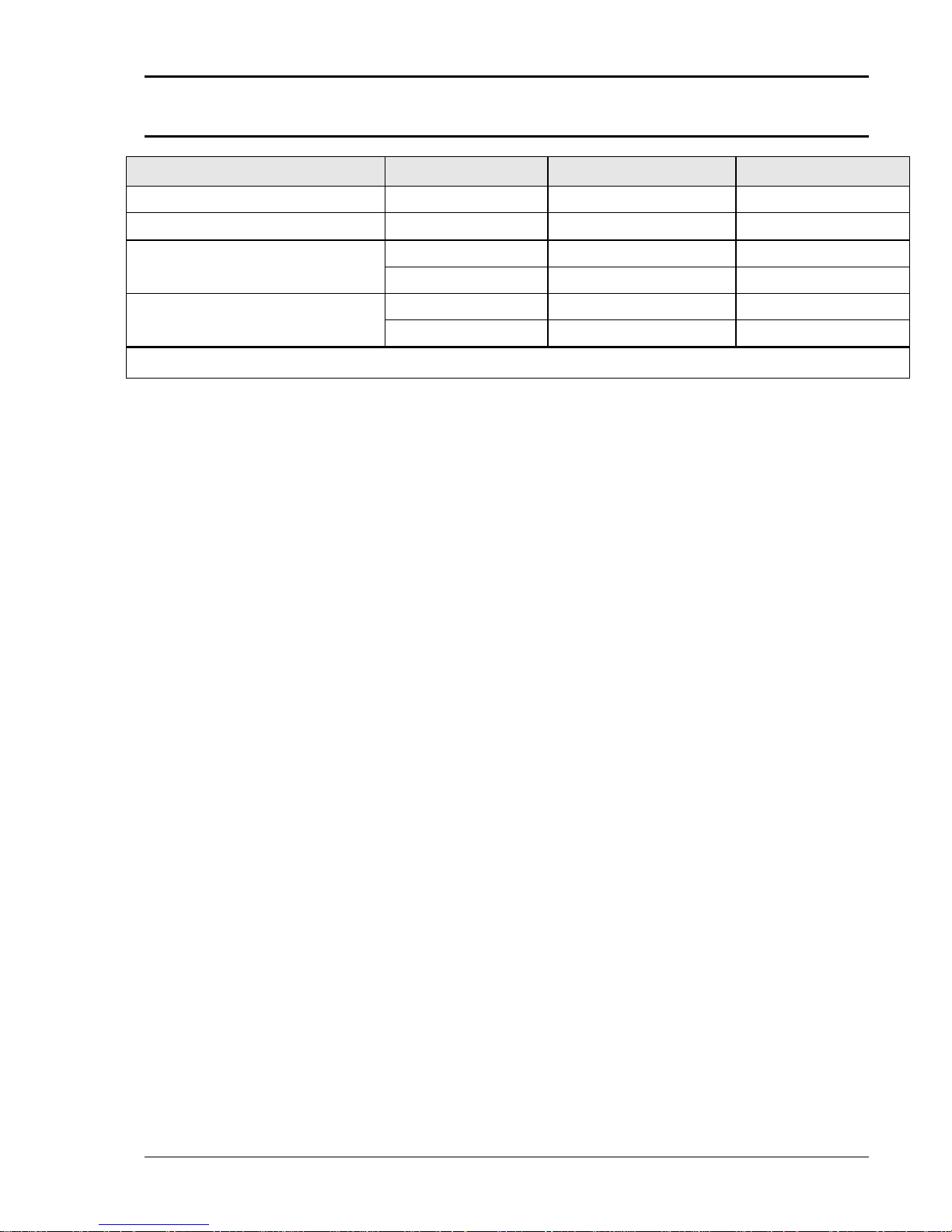

2.1.1 Input

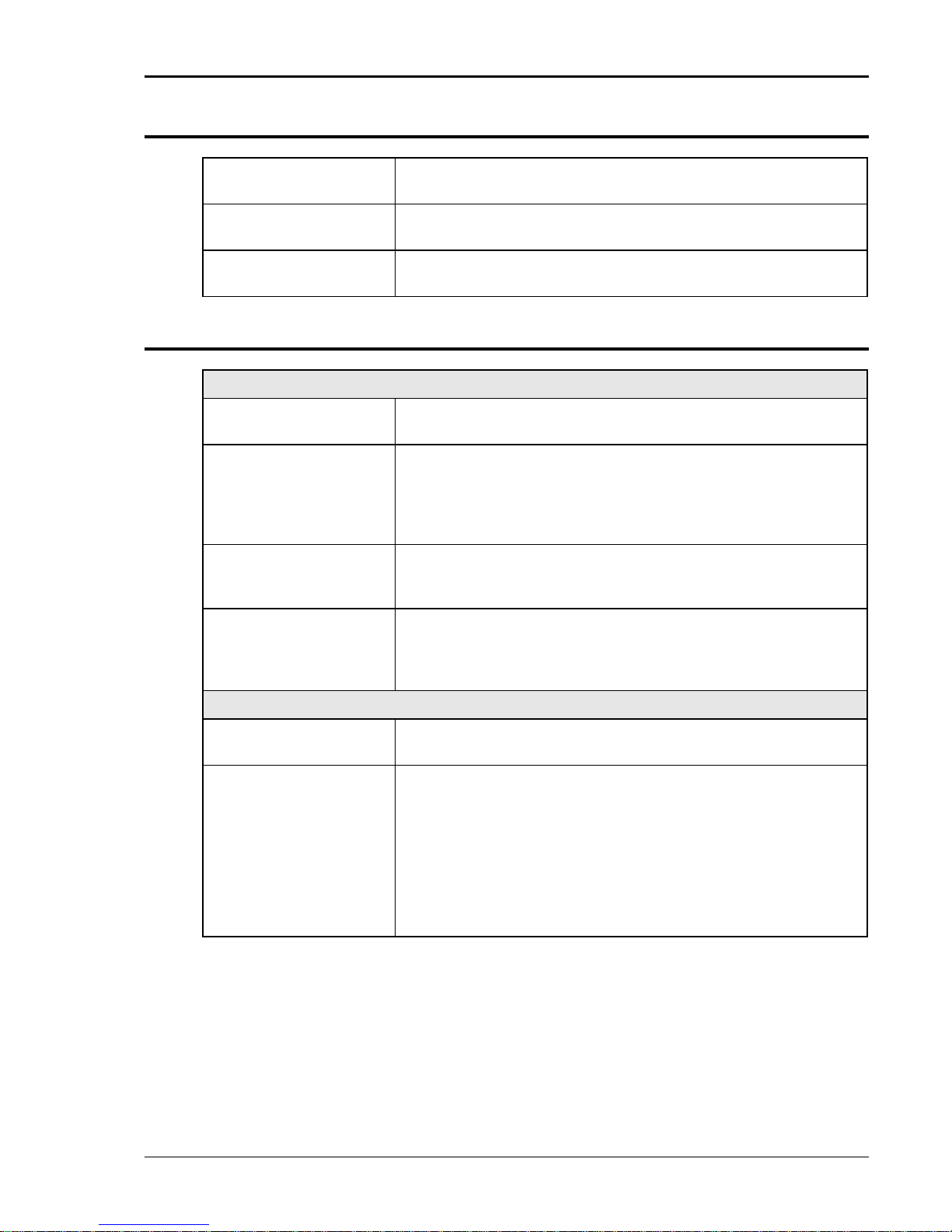

Function Specification

Input Power

Input Power Factor 0.99

Input Frequency Range 47 to 440 Hz

Efficiency 70% minimum at full-load

Ride-through or hold-up 10 mSec, minimum

Input Current See Table below

Input Turn-on Current

Surge

MAXIMUM LINE

CURRENT

USA 27A RMS Not Required 40A RMS

INTL 14A RMS 14A RMS 20A RMS

Standard: 208 to 240V

option: 380 to 415V

±10%, 3, 3 wire or

L-L

±10%, 3, 4 wire

L-L

Limited to less than peak value of RMS listed

in Tables below

MAXIMUM

NEUTRAL

CURRENT

Input Currents for 3-Phase Input Power

RECOMMENDED

CIRCUIT BREAKER

RATING (MAX.)

REQ’D INPUT

TERMINAL JUMPER

CONNECTIONS

USA ØA to ØB ØA, ØC

INTL

ØA to ØB,

ØB to ØC

CONNECT 1-

PHASE INPUT

POWER TO

ØA, Neutral

VOLTAGE

187-264

VRMS, L-L

187-264

VRMS, L-N

MAXIMUM

INPUT

CURRENT

RECOMMENDED

CIRCUIT BREAKER

RATING (MAX.)

30A RMS 40A RMS

45A RMS 40A RMS

* Only Phase A and Phase B are present at the output.

Single-Phase Input Configurations

14 CSW Series

Page 15

User Manual California Instruments

2.1.2 Output

(ALL SPECIFICATIONS ARE FOR AC AND DC UNLESS NOTED OTHERWISE)

Function Specification

Calibration Interval

Power Factor of Load 0 lagging to 0 leading

AC or DC Output

Voltage

Output Current Per

Phase

Crest Factor 3.25 (peak output current to RMS output current).

Output Frequency DC, or 40 Hz to 5 kHz

Frequency Resolution

( Without CLock/Lock

option enabled)

Frequency Accuracy: ±0.01% at 25ºC ±0.001%/ºC

Output Power 1850 VA, maximum, per phase

AC Noise Level >60 dB RMS below full output (sine wave, 40 to 500 Hz).

Voltage Program and

Measurement

Accuracy

Voltage Program

resolution

Voltage Stability

Voltage Distortion 0.25% maximum, 40 to 100 Hz; 0.5% maximum to 500 Hz; and 1% maximum

Load Regulation ±0.025% of full scale voltage for a full resistive load to no load; above 1 kHz,

Line Regulation ±0.025% of full scale for a ±10% input line change.

Phase Accuracy

Resistive Load

Phase Program

Resolution

External Amplitude

Mod

External Direct Input 0 to 5 VRMS (DC to 5 kHz) for 0 to full-scale output (±2% of full scale output to

DFI output Contact closure to indicate: Loss of AC line and indication of various Status

1 year

0 to 156 VRMS L-N range ; 0 to 312 VRMS L-N range

16A to 115V in 156V range; 8.0A to 230V in 312V range (1850 VA maximum).

Multiply current by the number of sources in a multiple power source system

16.00 - 81.91 Hz (0.01 Hz resolution)

81.0 – 819.1 Hz (0.1 Hz resolution)

820 – 5000 Hz (1 Hz resolution)

±0.1% of range. Above 1 kHz, add 0.2%/kHz. Add ±0.1% of full scale for "AC

PLUS DC" mode. Valid for 5 to 156 VRMS and 10 to 312 VRMS at 25°C

(77°F), sense leads connected. Temperature coefficient less than 50 ppm/°C

0.1 V from Front Panel

0.01 V from remote programming

±0.1% of full scale over 24 hours at constant line, load and temperature.

(Measured at Remote Sense point)

to 1 kHz plus 1%/kHz to 5 kHz (Full linear load or No load)

add ±0.015%/kHz

±1º, 40 to 1 kHz plus ±1º/kHz above 1 kHz

±0.1º

0 to 5 VRMS provides 0 to 20%(±2% of full scale output)

3 kHz. ±2% from 3 kHz to 5 kHz). Limited to ±7.25 Vpeak

that can be remotely programmed.

CSW Series 15

Page 16

User Manual California Instruments

Function Specification

External Gain Control, RPV 0 to +7.07 VDC for 0 to programmed output. 0 to full-scale output for CSW.

(±2% of full scale output

External Input Impedance 40K for each of the three inputs.

XLOAD The CSW5550 is guaranteed to be stable for power factors from 0 leading to 0

lagging. The most difficult load for most amplifiers is driving large capacitive

loads (10-10,000F).Though stable with its normal loop compensation, the

CSW can provide additional phase/gain margin with these unusual loads by

selecting XLOAD On. This significantly improves the transient response of the

amplifier.

X-Load should only be used for reactive loads, and with programmed

frequencies of less than 1000 Hz.

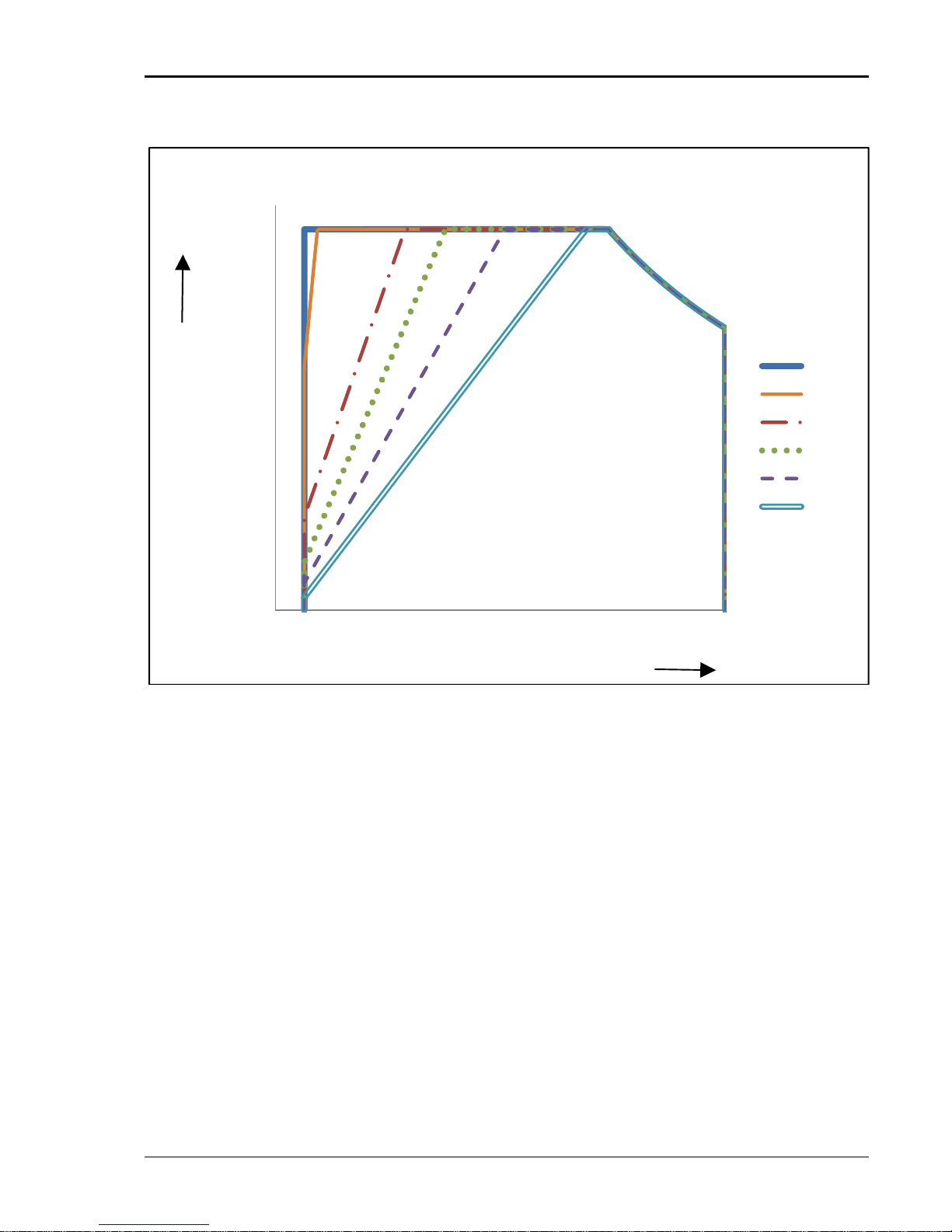

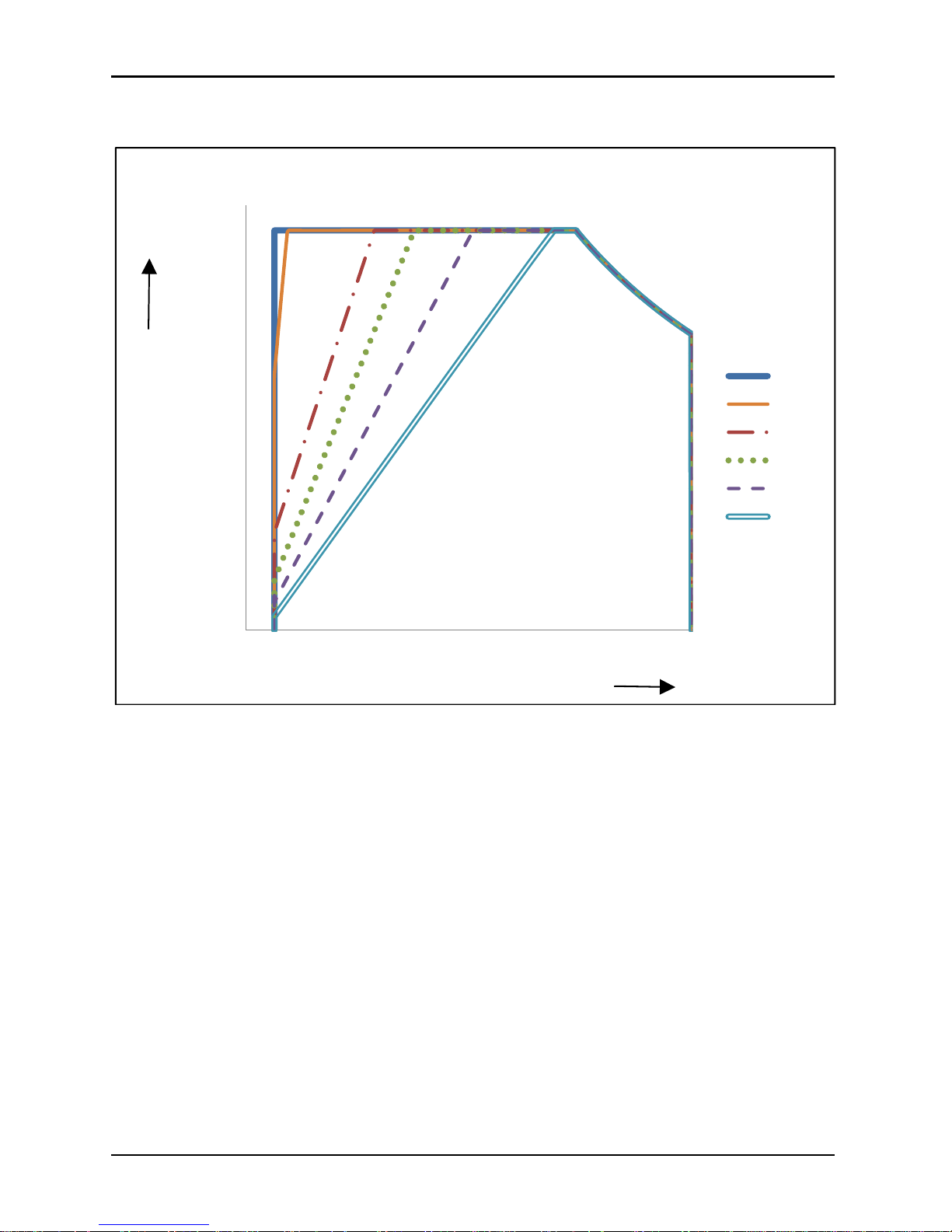

Output current for which specifications apply is de-rated for frequencies above 400Hz as a function of

voltage, and for maximum power of 1850 VA per phase, as shown in Figure 2-1 and Figure 2-2.

16 CSW Series

Page 17

User Manual California Instruments

OUTPUTCURRENTDE‐RATINGFROM45HzTO5kHz

Current

(RMS)

16

14

12

10

8

6

4

2

0

10

0 35 70 105 140

156

Figure 2-1: CSW5550 – Typical Current De-Rating Chart for 156v AC Range

per Phase

<400Hz

1KHz

2KHz

3KHz

4KHz

5KHz

Voltage (RMS)

CSW Series 17

Page 18

User Manual California Instruments

OUTPUTCURRENTDE‐RATINGFROM45HzTO5kHz

Current

(RMS)

8

7

6

5

4

3

2

1

0

0 70 140 210 280

20

<400Hz

1Khz

2Khz

3KHz

4KHz

5KHz

312

Figure 2-2: CSW5550 – Typical Current De-Rating Chart for 312v AC Range

per Phase

Voltage (RMS)

18 CSW Series

Page 19

User Manual California Instruments

Output Parameter CSW5550 (multiply current and power by the number of power

sources in multi-source power systems)

Current Limit

Range Programmable 0 to 100% of range for all ranges

Resolution 0.01 Arms

Accuracy ± 1% of Range. Add ±1.5%/kHz above 500 Hz

Frequency Range:

(Without Cloc/ Lock

option enabled)

Frequency Accuracy:

16.00 - 81.91 Hz (0.01 Hz resolution)

81.0 – 819.1 Hz (0.1 Hz resolution)

820 – 5000 Hz (1 Hz resolution)

0.01% of programmed value

DC Offset Voltage: Less than 20 mV with linear load in AC Output Mode.

AC Noise Level: >60 dB RMS below full output (sine wave, 40 to 500 Hz)

Output Impedance

(CSW5550 only)

1-phase mode, 312V range- meets requirements of IEC-1000-3-2,

Annex A, Supply Source. Valid for equipment classes A, B, C, and D

Peak Repetitive Current 52 amps for 156 V range 26 amps for 312 V range

Crest Factor: 3.25 (peak output current to RMS output current)

CSW Series 19

Page 20

User Manual California Instruments

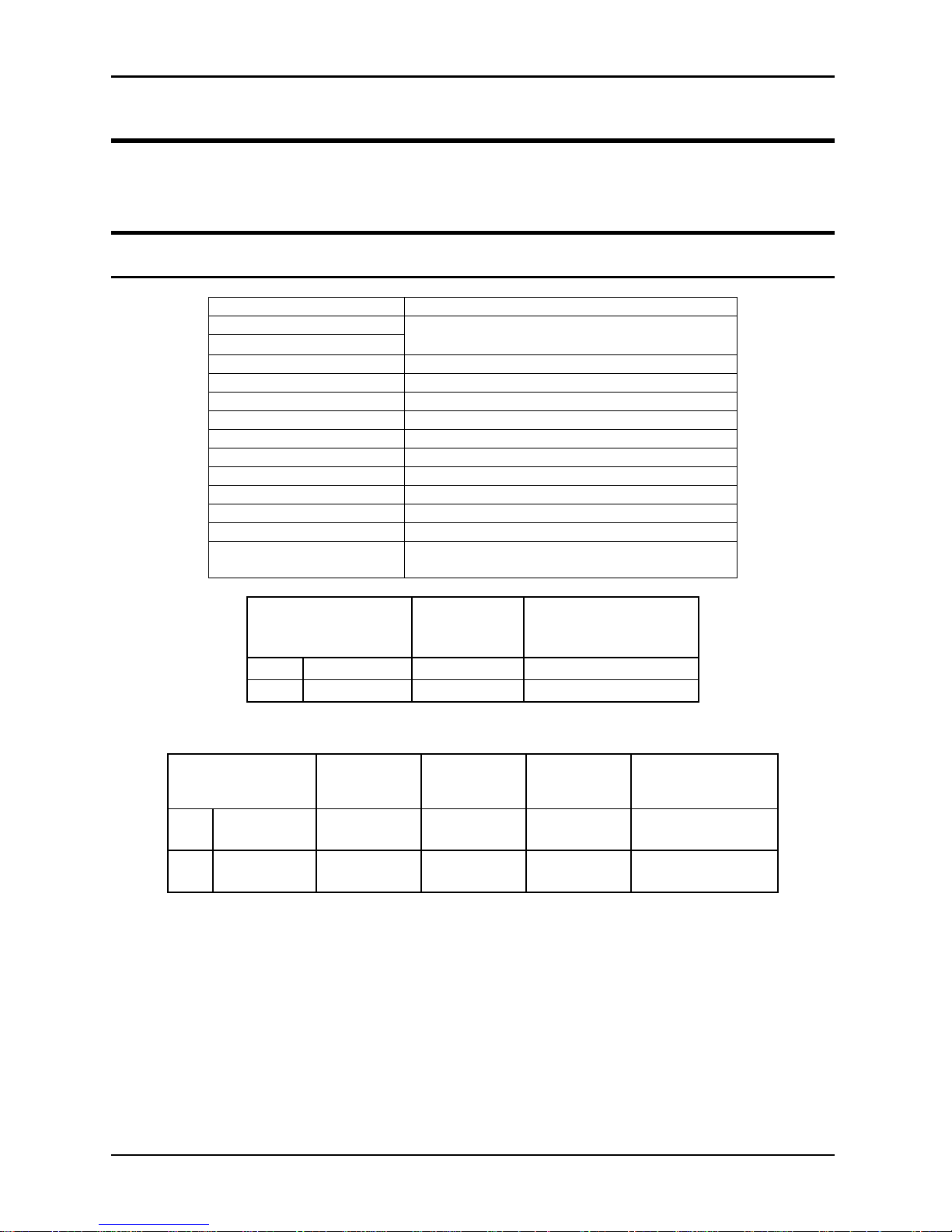

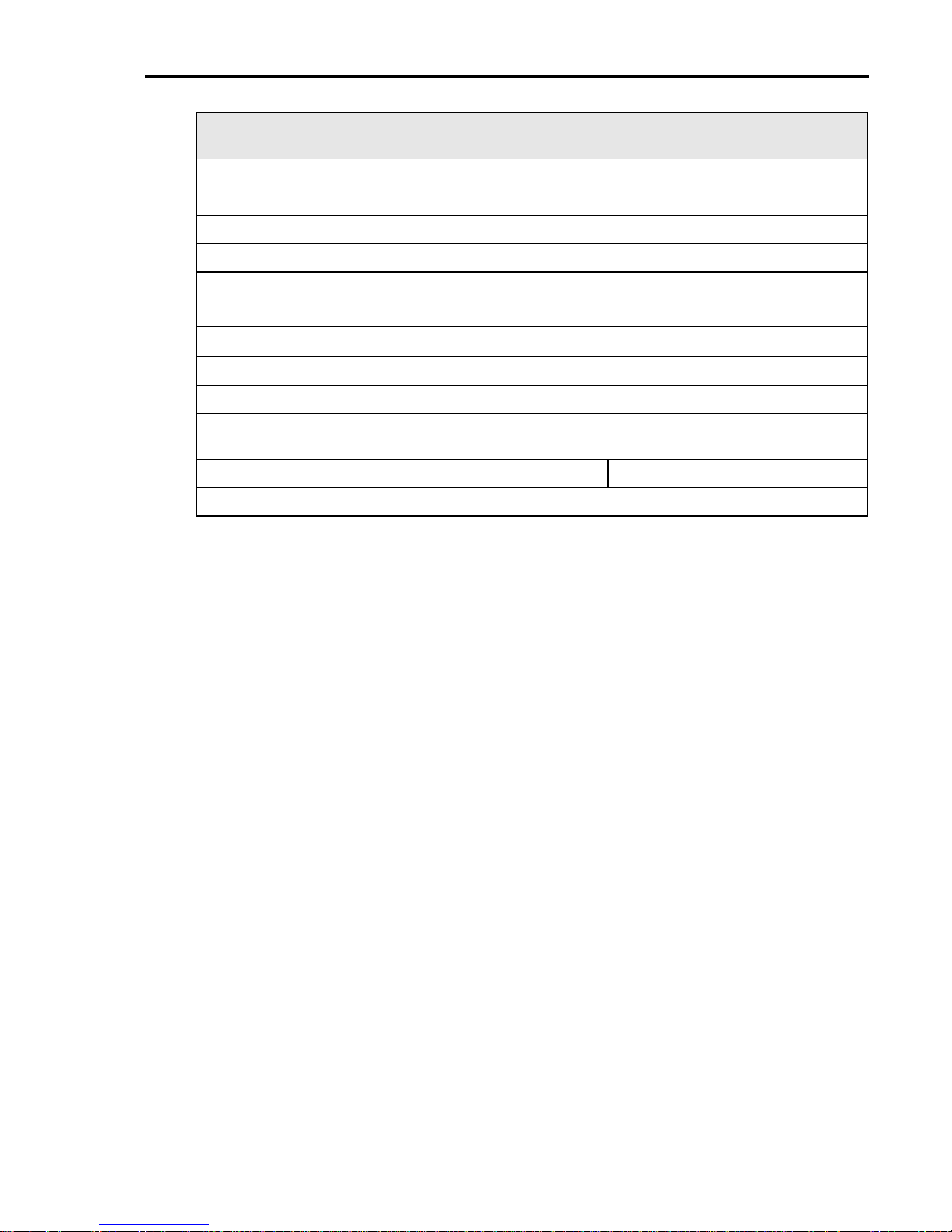

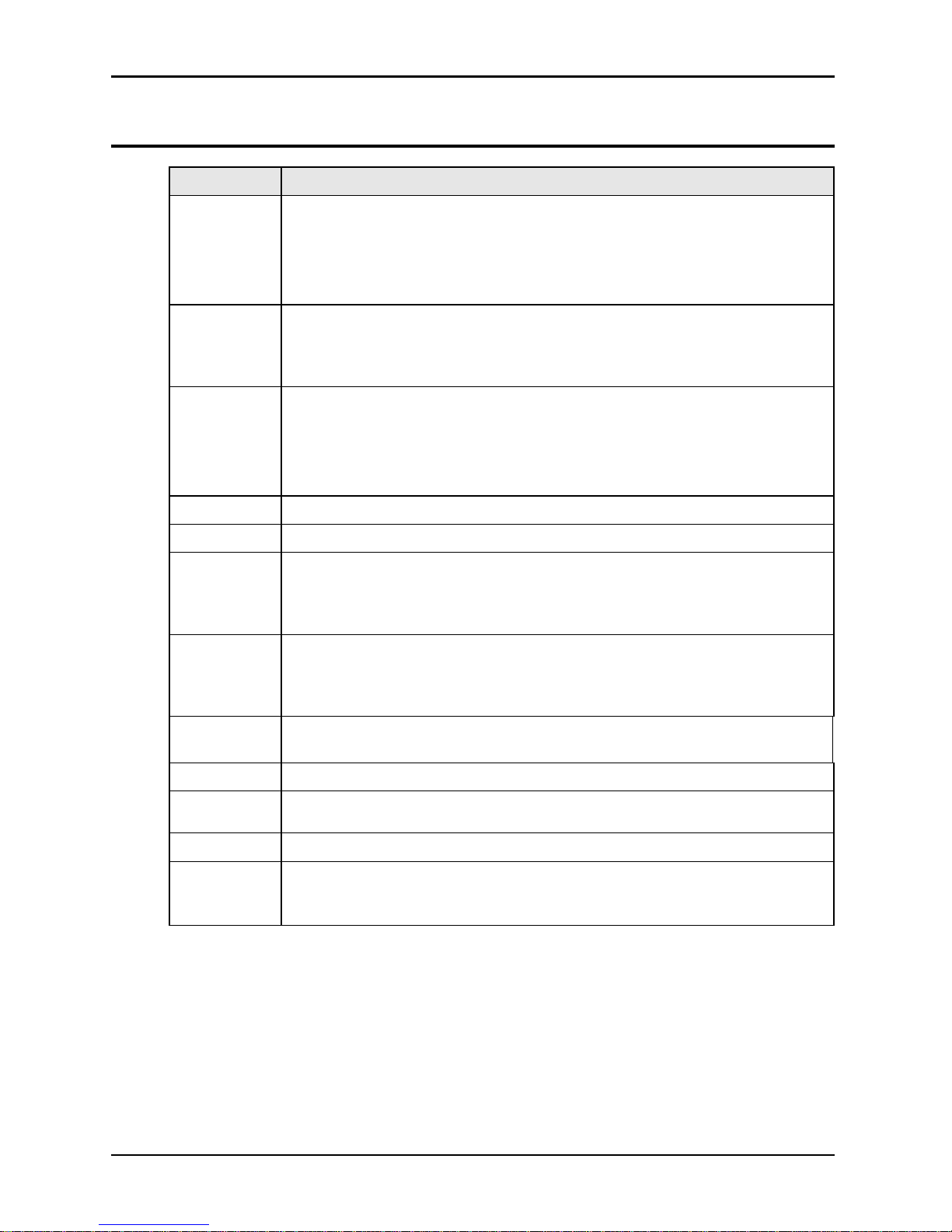

2.1.3 Measurements

(All specifications are at 25˚C unless noted otherwise)

Parameter

Frequency 2 counts

RMS Voltage ±0.1% of range from 5 to 156 or 10

RMS Current ±1% of range add ±1.5%/kHz above

Peak Current ±5% of range, 40 to 500 Hz; add

VA Power ±2.5% of range, DC or 40 to 500.

Real Power ±2.5% of range, DC or 40 to 500.

Power Factor

(>0.2kVA)

Temperature Coefficient <±50 ppm for all functions above↑

Frequency

Phase ±2˚, 40 to 500 Hz, add ±2˚/kHz

Current and Power Accuracy specifications are percent of Range. The Ranges are listed below .

Measurement bandwidth is limited to 16 Khz.

Accuracy ()

0 to 45

˚C

to 312 volts. Above 1kHz add

0.2%/kHz

500 Hz

Ranges: 0.5 to 16A: 156V range

0.5 to 8A: 312V range

Multiply by 3 for 1-phase mode

±1%/kHz 500 to 5 kHz

Ranges: 0 to 56A; 156V range

0 to 28A; 312V range

Multiply by 3 for 1-phase mode

Add ±1%/kHz above 500 Hz.

Ranges: 1.8kVA; 3-phase mode

5.6kVA; 1-phase mode

Add ±1%/kHz above 500 Hz.

Ranges: 1.8kW; 3-phase mode

5.6kW; 1-phase mode

±5% of range at full power, 40 to

500 Hz. Add ±1%/kHz above 500 Hz

2 counts (0 to 45

above 500 Hz. (0 to 45

˚C)

˚C)

Resolution

0.01: 16 to 81.91 Hz

0.1: 82.0 to 819.0 Hz

1: 820 to 5000 Hz

0.01 Volt

0.001 Amp

0.01 Amp

1 VA

1 W

0.01

0.01: 16 to 81.91 Hz

0.1: 82.0 to 819.0 Hz

1: 820 to 5000 Hz

±1˚ for outputs above 20 VRMS

20 CSW Series

Page 21

User Manual California Instruments

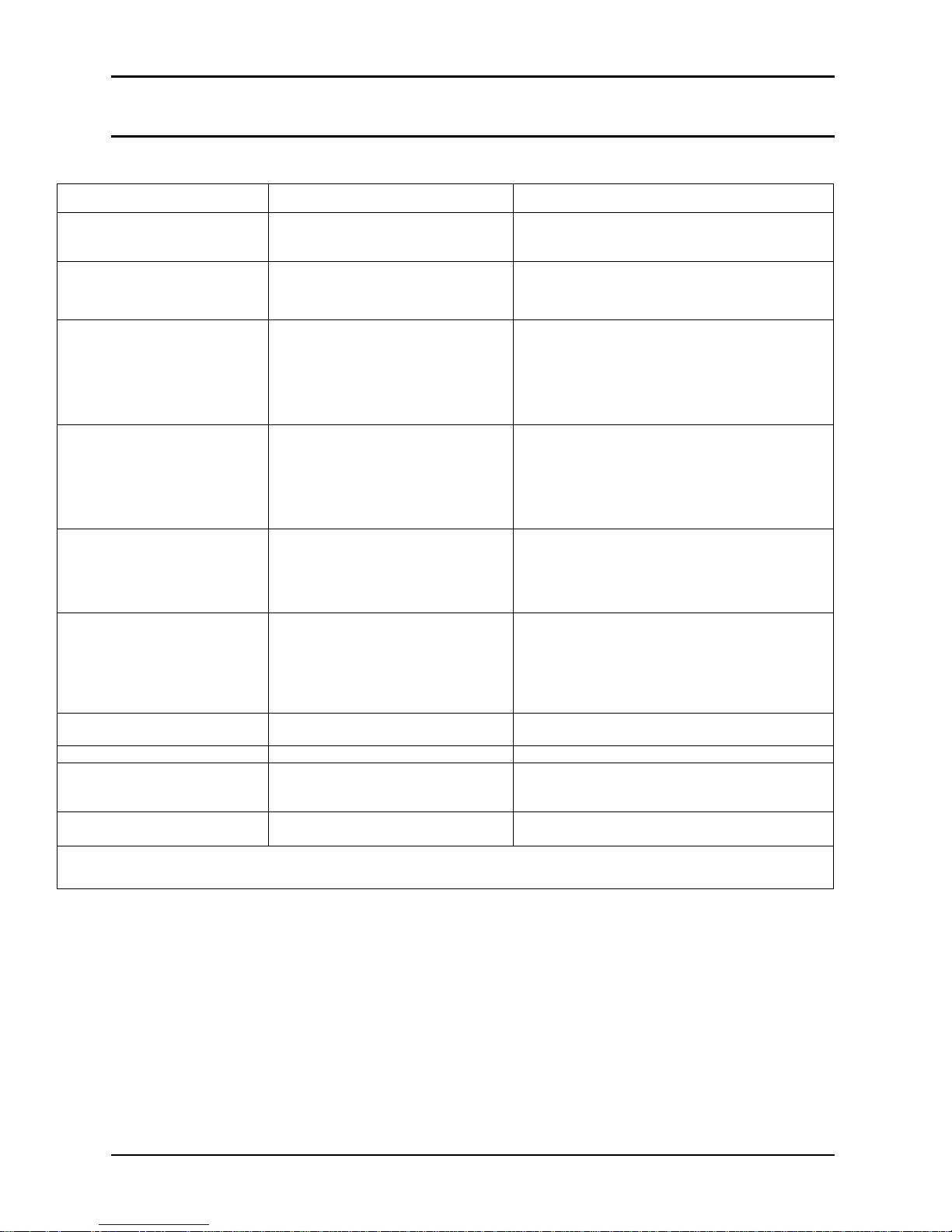

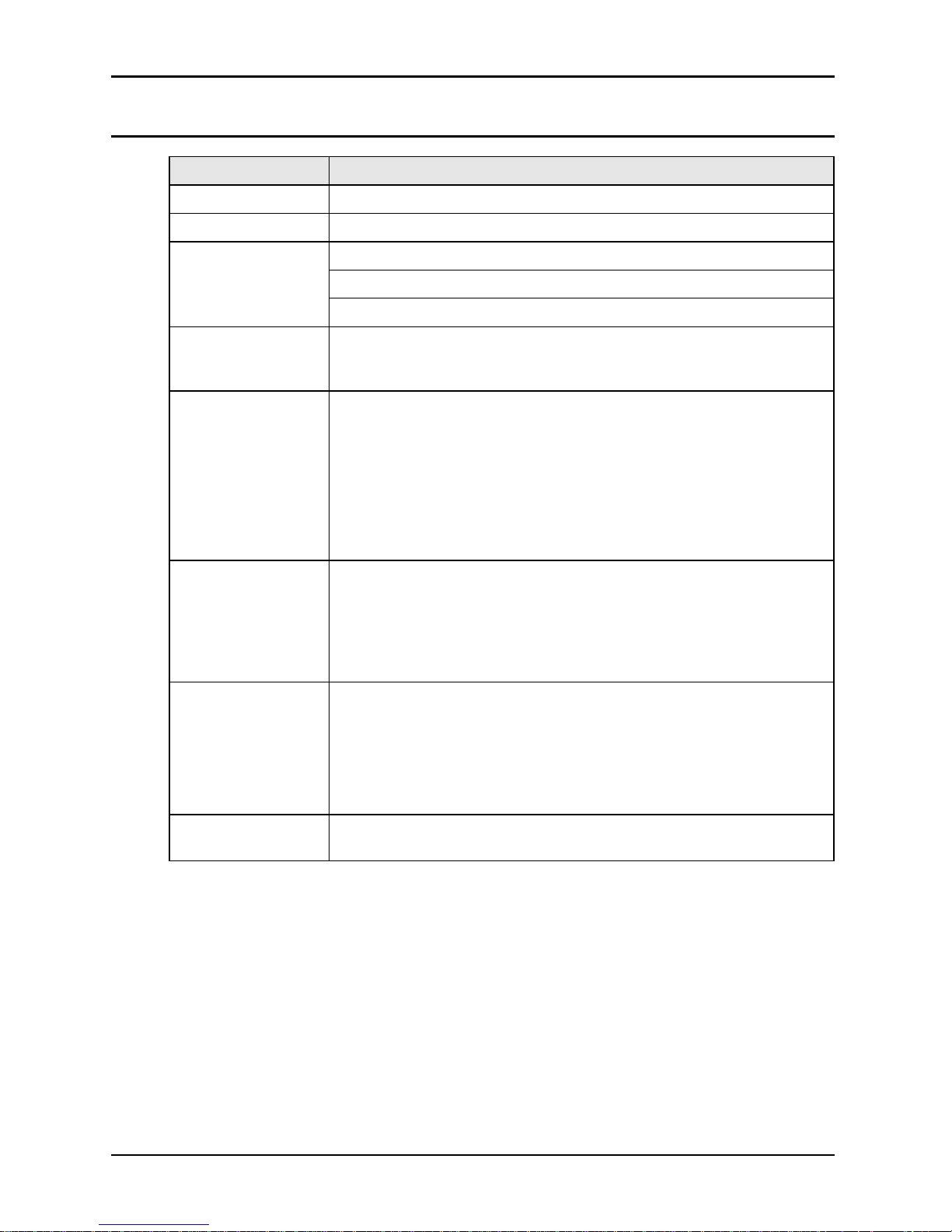

2.1.4 Harmonic Measurements (CSW series)

Parameter Range

Frequency fundamental 16.00 - 1000 Hz 2 counts 0.01 Hz to 1 Hz

Frequency harmonics 32.00 Hz - 16 kHz

Voltage Fundamental 0.25V 0.01V

Harmonic 2 - 50 0.25V + 0.1% + 0.1%/kHz 0.01V

Current Fundamental !% of Range 0.01A

Harmonic 2 - 50 1% of Range + 0.1%/kHz 0.01A

Harmonics frequency range in three-phase mode is 32 Hz - 16 kHz. Measurement bandwidth is limited to 16 Khz.

Accuracy ( )

2 typ. 0.5

Resolution

CSW Series 21

Page 22

User Manual California Instruments

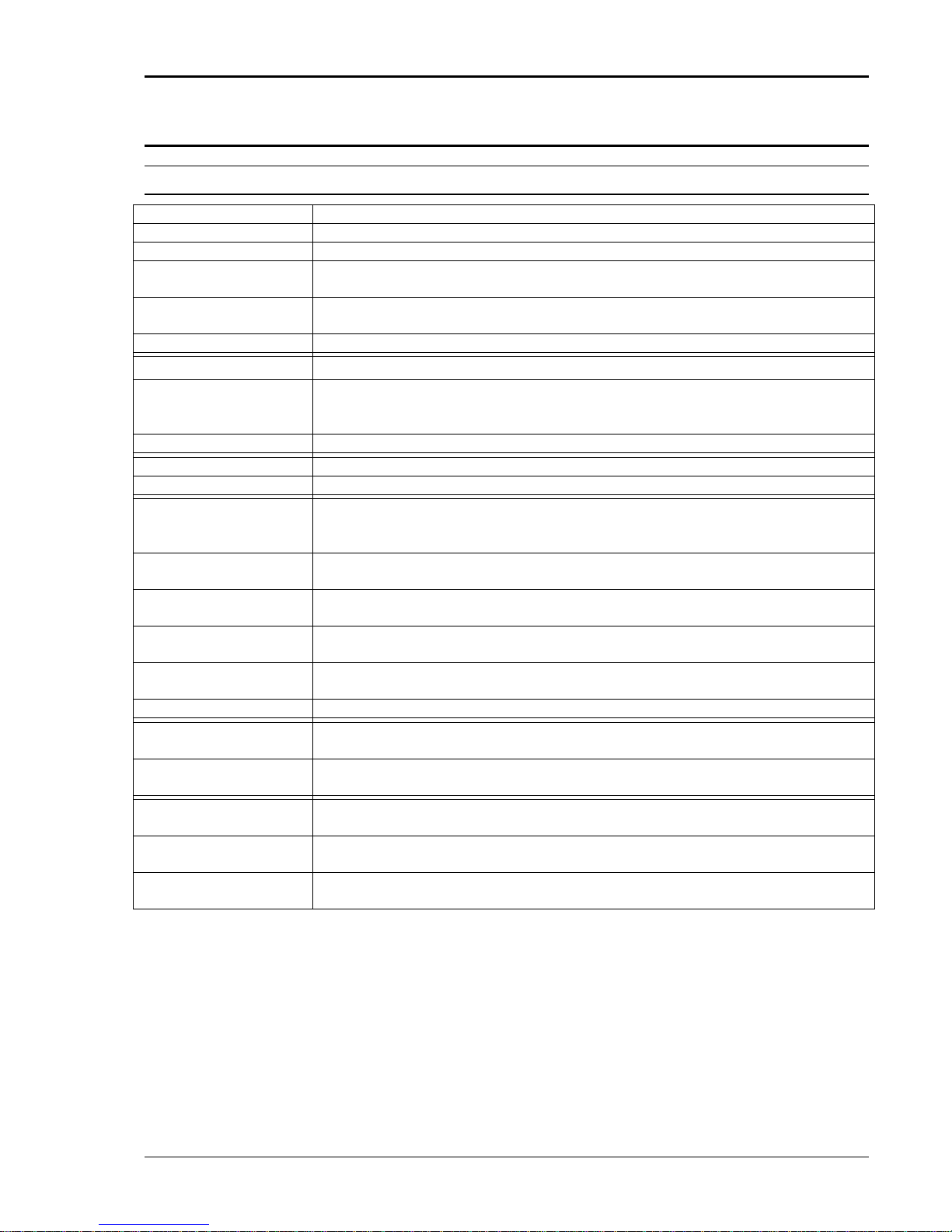

2.1.5 System Specification

Parameter Specification

NV memory storage: 16 complete instrument setups and transient lists, 100 events per list.

Waveforms Sine, square, clipped, user defined

Transients Voltage: drop, step, sag, surge, sweep

Frequency: step, sag, surge, sweep

Voltage and Frequency: step, sweep

IEEE-488 Interface: SH1, AH1, T6, L3, SR1, RL2, DC1, DT1

IEEE 488.2 and SCPI

Response time is 10 ms (typical)

RS232C Interface: Bi-directional serial interface

9 pin D-shell connector

Handshake: CTS, RTS

Data bits: 7, 8

Stop bits: 1,2

Baud rate: 9600, 19200, 38400 (Models without USB I/F)

Baud rate: 9600, 19200, 38400, 57600, 115200, 230400, 460800

IEEE 488.2 and SCPI.

Note: Disconnect any USB connection when using the RS232 interface.

USB Interface: Standard USB 1.1 peripheral.

Data transfer rate: 460,800 bps

Syntax: IEEE 488.2 and SCPI.

Note: Use of the USB port to control more than one power source

from a single PC is not recommended, as communication may not be

reliable. Use GPIB interface for multiple power source control.

LAN Interface: Option –LAN. When the LAN interface is installed, the RS232 interface is

disabled.

RJ45 Connector, 10BaseT, 100BaseT or 1000BaseT,

Data transfer rate: 460,800 bps

Protocol: TCP/IP.

Syntax: IEEE 488.2 and SCP

Note: Disconnect any USB connection when using the LAN interface.

Current Limit

Modes:

Two selectable modes of operation.

Constant current and constant voltage with hold-off time and trip.

22 CSW Series

Page 23

User Manual California Instruments

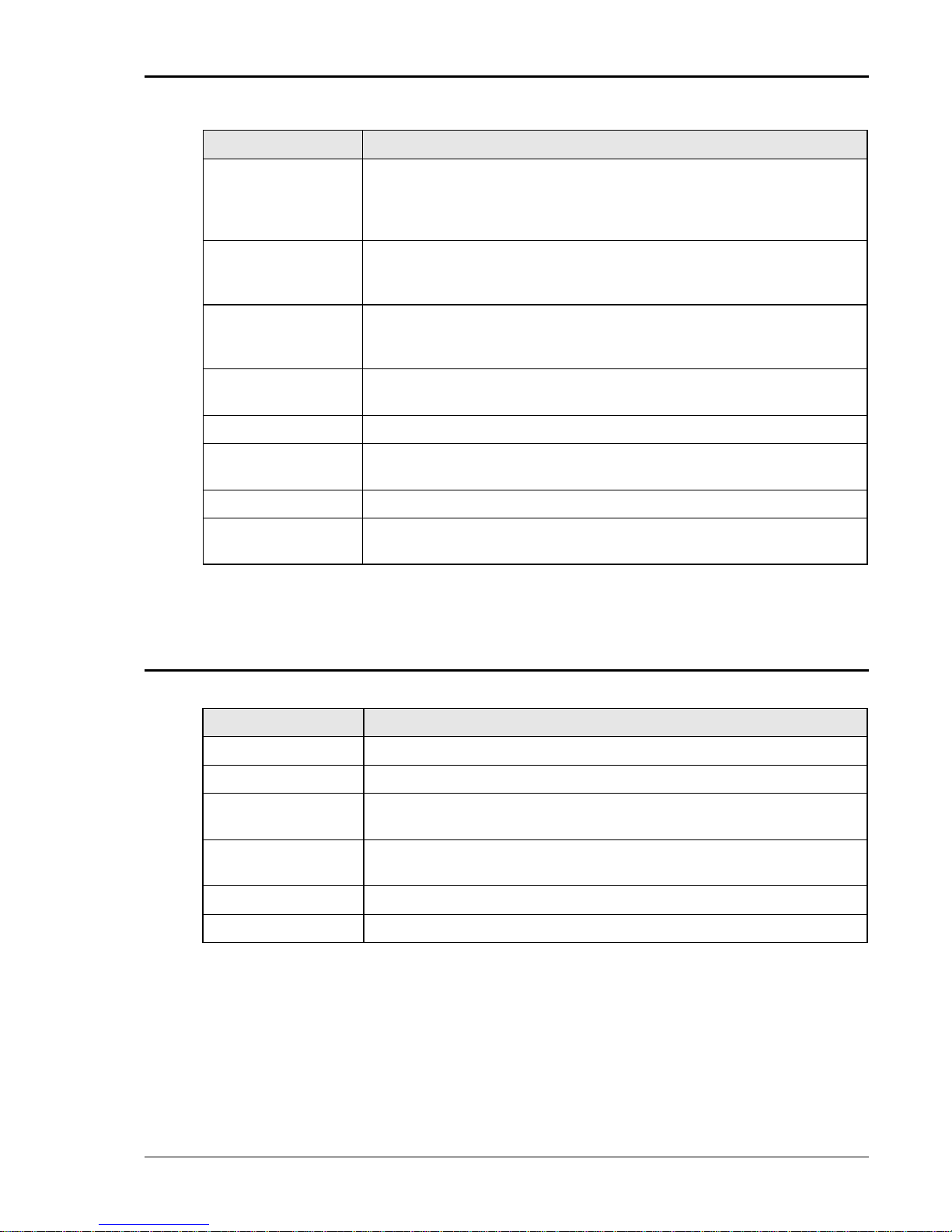

System Specification (continued)

Parameter Specification

Front Panel Trigger,

BNC connector

Output available at the front panel BNC connector that provides a

negative going pulse for any programmed voltage or frequency

change. The trigger can be reassigned as an output when running list

transients.

Front Panel Phase

A, B and C, BNC

connectors

These three outputs are representative of the programmed output

waveform, magnitude and frequency. 0 to 4.86 Vrms represents 0 to a

full-scale output voltage. The output impedance is 100 ohms.

External Signal Individual inputs for an external signal for each of the three phases. A 0

to 5.0 Vrms input provides a 0 to full-scale output voltage of the supplied

waveform

External Gain

Control (RPV)

Individual inputs for an external DC signal for each of the three phases. A

0 to ±7.07 VDC signal provides a 0 to full-scale output voltage.

/INHIBIT A logic Lo or contact closure input to inhibit the outputs

MOD An input for an amplitude modulation. 0 to 5 Vrms provides 0 to ≥20%

modulation for each of the three output phases

Trigger Input An input to trigger a function

External Synch A TTL input to frequency synchronize the outputs. The Phase A output

can be programmed relative to the external input.

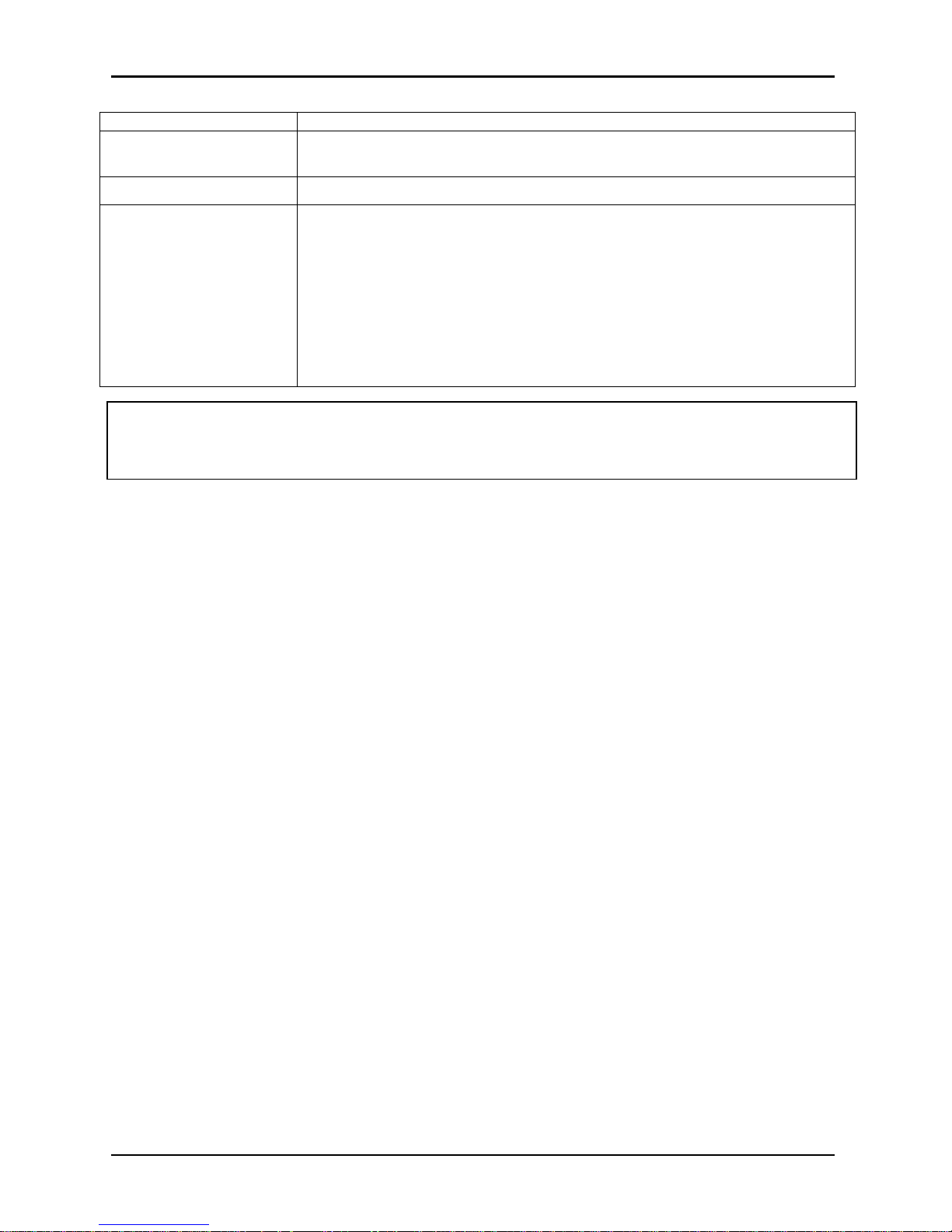

2.1.6 Unit Protection

Parameter Specification

Input Overcurrent: Circuit breaker with current trip control.

Input Overvoltage: Automatic trip of input circuit breaker.

Input Overvoltage

Transients:

Output Overcurrent: Adjustable level constant current mode with a maximum set point

Output Short Circuit: Peak and rms current limit.

Overtemperature: Automatic shutdown.

Surge protection to withstand EN50082-1 (IEC 801-4, 5) levels.

between 0% and 10% above programmed value.

CSW Series 23

Page 24

User Manual California Instruments

2.2 Mechanical

Parameter Specification

Dimensions: 19” (483 mm) wide x 8.75” (222 mm) high x 23.5” (597 mm) deep

chassis size which is available in a rack mount or stand-alone

configuration.

Unit Weight: 126.5 lb. (57.2 kg)

Material: Steel chassis and front panel, Aluminum top cover and rear panel.

Finish: Light textured painted external surfaces.

Front and rear panels semi-gloss polyurethane color no. 26440

(medium gray)

Top, bottom and sides semi-gloss polyurethane color no. 26622 (light

gray).

Cooling: Fan cooled with air intake on the sides and exhaust to the rear.

Internal

Construction:

Rear Panel

Connections:

2.3 Environmental

Parameter Specification

Operating Temp:

Storage Temp:

Altitude: < 2000 m

Modular sub assemblies.

(see section 3 for description of connections)

Input terminal block with cover

Output terminal block with cover

Remote voltage sense terminal block with cover

System interface (not for table top use, use only in rack enclosed

systems)

Clock and Lock (not for table top use, use only in rack enclosed

systems)

RS232, GPIB, USB, LAN (option)

0 to +45 C (32F to 113F)

-40 to +70C.

Relative Humidity:

Installation/Over voltage

Category:

Pollution Degree: 2

Indoor Use Only

Vibration: Designed to meet NSTA 1A transportation levels.

Shock: Designed to meet NSTA 1A transportation levels.

24 CSW Series

85% maximum at 25C decreasing linearly to 50% at 40C.

Page 25

User Manual California Instruments

2.4 Regulatory

Electromagnetic

Emissions and Immunity:

Acoustic Noise: 65 dBA maximum at 0% to 50% load, 75 dBA maximum greater

Safety: Designed EN61010-1 European safety standards as required for

2.5 Front Panel Controls

Controls:

Shuttle knob: Allows continuous change of all values including output calibration

Decimal keypad: A conventional decimal keypad facilitates quick entry of numerical

Up/down arrow keys: A set of up and down arrow keys is used to move the cursor

Designed to meet EN50081-2 and EN50082-2 European

Emissions and Immunity standards as required for the “CE” mark.

than 50% load to 100% load. Measured at one meter.

the “CE” mark.

and range change.

values such as voltage, current limit, etc. The large blue enter

key will make the value you enter effective. Using the SET key

allows the user to preset all parameter values and update them all

at once by pressing the Enter key.

position in all menus. This allows quick selection of the desired

function or parameter.

Function keys: Measure key will display most measurement values. Program key

will show all program parameters. Output on/off key for output

relay control. Phase key will switch display to show program and

measured values for each phase.

Displays:

LCD graphics display: A large high contrast LCD display with backlight provides easy to

read guidance through all setup operations.

Status indicators: Large and bright status indicators inform the user of important

power source conditions. The Remote lamp informs the user that

the unit is under remote control. The Overload lamp indicates that

excessive current is being drawn at the output. The Over

temperature lamp illuminates when internal heat sink

temperatures are too high. The Hi Range indicator is lit any time

the unit is switched to high output voltage range. The Output

On/Off indicator is on when the power source output relays are

closed.

CSW Series 25

Page 26

User Manual California Instruments

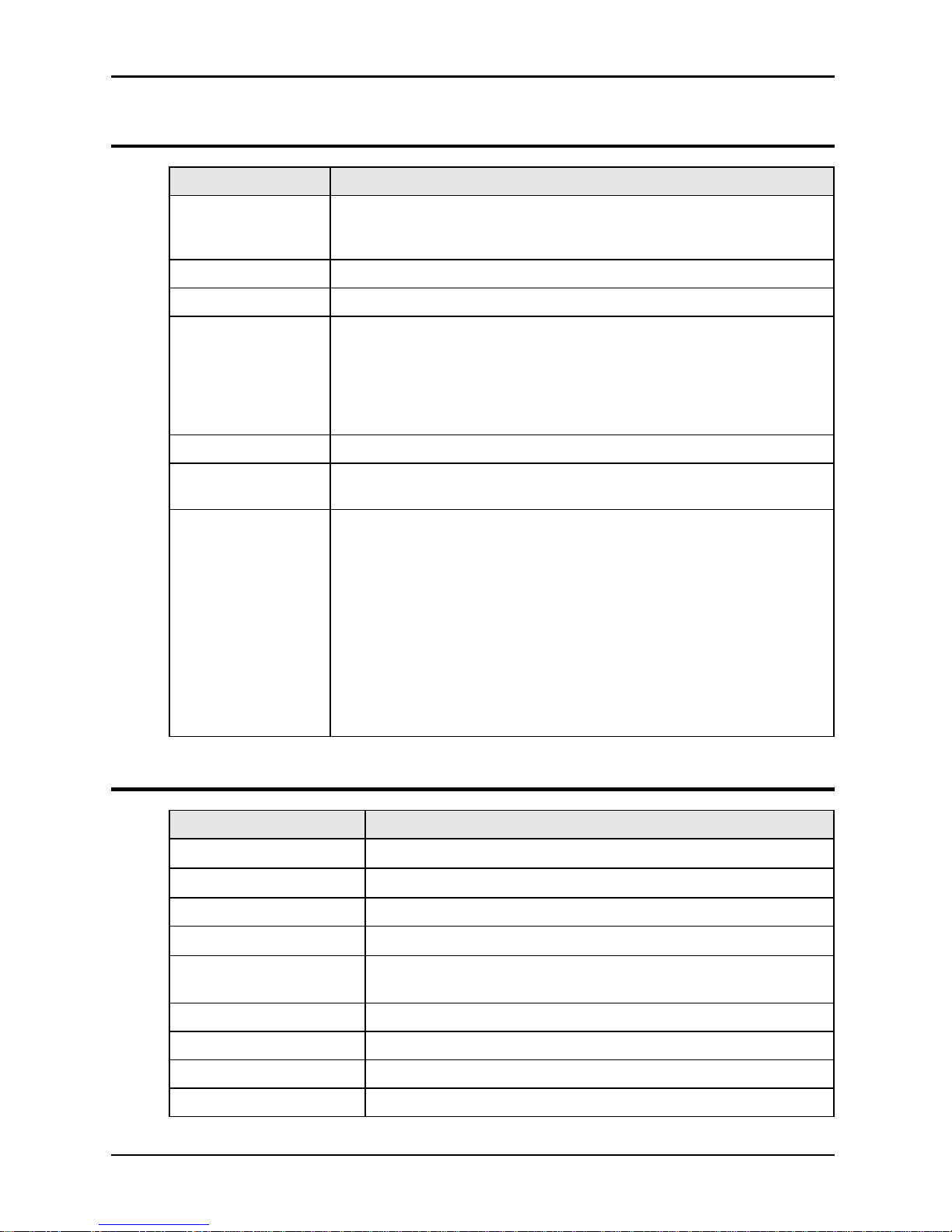

2.6 Special Features, Options and Accessories

Option Description

- 704 Mil Std 704D & E test firmware.

Mil Std 704A, B, C, & F test software (refer to Avionics Software Manual P/N

4994-971 for details).

Note: Requires use of CSWGui Windows application software provided on

CD ROM CIC496.

- 787 Boeing 787 Test software (refer to Avionics Software Manual P/N 4994-971

for details).

Note: Requires use of CSWGui Windows application software provided on

CD ROM CIC496.

- 160 RTCA/DO-160D test firmware

RTCA/DO-160E test software (refer to Avionics Software Manual P/N 4994971 for details)..

Note: Requires use of CSWGui Windows application software provided on

CD ROM CIC496.

- 411 IEC 1000-4-11 test firmware

- 413 IEC 1000-4-13 test hardware and firmware

-ABD Airbus ABD0100.1.8 Test software (refer to Avionics Software Manual P/N

4994-971 for details)..

Note: Requires use of CSWGui Windows application software provided on

CD ROM CIC496.

-AMD Airbus AMD24C Test software (refer to Avionics Software Manual P/N 4994971 for details)..

Note: Requires use of CSWGui Windows application software provided on

CD ROM CIC496.

-LAN Adds Ethernet interface (RJ45 connector) for local area network connection.

(Available on P/N 7000-485 and 7000-486 models only).

-LF Limits maximum output frequency to 500 Hz.

-FC Frequency accuracy is ± 0.15% of program value.

- RMS Rack mounting kit with slides. Removable rack ears/handles standard.

-LK Clock/ Lock Option. With this option enabled the programmed frequency

resolution is 1 Hz for all programmed values of frequency. If the upper

frequency limit is 819 Hz or less the standard program resolution applies.

26 CSW Series

Page 27

User Manual California Instruments

V

2.7 Supplemental Specifications

Supplemental specifications are not warranted and generally reflect typical performance

characteristics. These characteristics have been checked on a type test basis only and are not

verified on each unit shipped. They are provided for reference only.

2.7.1 Output

Output Parameter

oltage:

Slew rate: > TBD V/micro sec

Stability: 0.25 % over 24 hour period at constant line, load and temperature.

Settling time: < 0.5 msec

Frequency:

Temperature

coefficient:

Stability:

5 ppm per degree C

15 ppm per year

CSW Series 27

Page 28

User Manual California Instruments

3. Unpacking and Installation

3.1 Unpacking

Inspect the unit for any possible shipping damage immediately upon receipt. If damage is

evident, notify the carrier. DO NOT return an instrument to the factory without prior approval.

Do not destroy the packing container until the unit has been inspected for damage in shipment.

WARNING: This power source weighs 126.5 lb (57.2kg). Obtain adequate help when

moving or mounting the unit.

3.2 Power Requirements

The CSW5550 Power Source has been designed to operate from a 3-phase, 3-wire, 187 to 264

, AC line or a 3-phase, 4-wire, 342 to 457 V

V

L-L

CAUTION: Do not connect 400V into the 187-256V unit, the result could be a severely

damaged unit.

,AC line (option -400).

L-L

28 CSW Series

Figure 3-1:CSW5550

Page 29

User Manual California Instruments

3.3 Mechanical Installation

The CSW series power sources are completely self-contained power sources. They may be

used free standing on a bench top or rack mounted using the rack mount/handle kit. The units

are fan cooled, drawing air in from the sides and exhausting at the rear. The sides of each unit

must be kept clear of obstruction and a 6” clearance must be maintained to the rear. Special

consideration of overall air flow characteristics and the resultant internal heat rise must be

allowed for with systems installed inside enclosed cabinets to avoid self heating and over

temperature problems.

Refer to Paragraph 2.2 for information on outline and mounting dimensions of the unit. Refer to

Figure 3-3, Paragraph 3.6 and sub-paragraphs for rear panel connector information.

TYPE MANUFACTURER PART NUMBER

Mounting Kit (for slides) Jonathan BK-3

Slides Accuride C-3307-16D

Recommended Mounting Slide

3.4 Input Wiring – TB1

The input terminal block, TB1, is located at the rear of the unit. Ground (earth) wire must be

connected to the chassis of the AC power system. The mains source must have a current rating

equal to or greater than the input circuit breaker and the input wiring must be sized to satisfy the

applicable electrical codes. The input terminal block cover and strain relief must be installed in

table top applications to maintain protection against hazardous voltages.

CAUTION: Capacitors in the power source may hold a hazardous electrical charge

even if the power source has been disconnected from the mains supply. Allow

capacitors to discharge to a safe voltage before touching exposed pins of mains

supply connectors.

3.4.1 187 to 264 VRMS L–L 3-Phase Operation (3-Wire USA)

Connect the input wires to the phase A, B, and C input terminal block terminals

(no Neutral is required). Ensure that the chassis safety ground is also connected. Use cables with

ratings equal to or greater than the current rating listed on the unit or in Paragraph 3.5.1. Any phase

sequence of wiring can be used.

3.4.2 342 to 457 VRMS L–L 3-Phase Operation (4-Wire INTL)

It is essential that the Neutral connection is present when using the unit. Only units that are factory set at

this voltage will operate at this voltage.

Connect the input wires to phases A, B, C and Neutral of the input terminal block. Ensure that the

chassis safety ground is also connected. Use cables with ratings equal to or greater than the current

rating listed on the unit or in paragraph 2.1.1.

CSW Series 29

Page 30

User Manual California Instruments

3.4.3 Single-Phase Input Connections

The CSW system is designed for three-phase input power operation, either 3-wire (USA) or 4-wire

(EUR) plus a chassis safety ground. However, if only single-phase input power is available, the

configurations listed in paragraph 2.1.1 are possible.

3.5 Output Power Connections – TB2

The output terminal block, TB2, is located at the rear of the unit. Refer to Figure 3-3 for an illustration of

the power source rear panel and all terminal strips and connectors. The external sense inputs allow the

power system output voltages to be monitored directly at the load and must be connected either at TB2

or the load when the sense is programmed for external. The external sense input does not have to be

connected when Internal Sense is programmed. The external sense wires are to be connected to TB3

on the rear panel and should be run as a twisted pair for short lengths. Sense leads over three (3) feet

long should be run as a twisted shielded pair. Refer to Figure 3-4 for all connections. Included in the

power source ship-kit is a safety cover. This cover is used to cover the AC Line input, TB1, the Power

Output terminal block, TB2, and the External Sense terminal block, TB3. Strain reliefs are included with

the safety cover.

Note: The output of the power source is isolated from the input line and floating from

chassis ground. The Output Neutral must not float more than 20 volts or an error

will be reported and the output will shut down.

3.5.1 Wire Gauge Selection

The following guidelines assist in determining the optimum cable specification for

your power applications. These guidelines are equally applicable to both DC and low frequency AC (up

to 450 Hz) power cabling. The same engineering rules apply whether going into or out of an electrical

device. Thus, this guide applies equally to the input cable and output cable for this California Instrument

power source and application loads.

Power cables must be able to safely carry maximum load current without overheating or causing

insulation destruction. It is important to everyday performance to minimize IR (voltage drop) loss within

the cable. These losses have a direct effect on the quality of power delivered to and from instruments

and corresponding loads.

When specifying wire gauge, the operating temperature needs to be considered. Wire gauge current

capability and insulation performance drops with the increased temperature developed within a cable

bundle and with increased environmental temperature. Thus, short cables with generously derated

gauge and insulation properties are recommended for power source applications.

Avoid using published commercial utility wiring codes. These codes are designed for the internal wiring

of homes and buildings and accommodate the safety factors of wiring loss, heat, breakdown insulation,

aging, etc. However, these codes consider that up to 5% voltage drop is acceptable.

Such a loss directly detracts from the quality performance specifications of this power source.

Frequently, these codes do not consider bundles of wire within a cable arrangement.

In high performance applications, as in motor start-up and associated inrush/ transient currents,

additional consideration is required. The cable wire gauge must consider peak voltages and currents,

which may be up to ten times the average values. An underrated wire gauge adds losses, which alter

the inrush characteristics of the application and thus the expected performance. The following table

identifies popular ratings for DC and AC power source cable wire gauges.

30 CSW Series

Page 31

User Manual California Instruments

COLUMN 1:

SIZE

(AWG)

COLUMN 2:

AMPERES

(MAXIMUM)

COLUMN 3:

OHMS/100 FEET

(ONE WAY)

COLUMN 4:

IR DROP/100 FEET

(COL. 2 X COL. 3)

14 15 0.257 3.85

12 20 0.162 3.24

10 30 0.102 3.06

8 40 0.064 2.56

6 55 0.043 2.36

4 70 0.025 1.75

2 95 0.015 1.42

1/0 125 0.010 1.25

3/0 165 0.006 1.04

Recommended Wire Gauge Selection Guide

The output power cables must be large enough to prevent a total voltage drop exceeding 1% of

the rated output voltage between the power source and the load. Table 3-1 shows the AWG size

of the cables that may be used. Cable lengths must not exceed twenty-five (25) feet. For lengths

greater than 25 feet, calculate the voltage drop from the following formul a:

2 X DISTANCE X CABLE RESISTANCE PER FT. X CURRENT = VOLT DROP

LOAD CURRENT WIRE GAGE

22 AMPS 10 AWG

37 AMPS 8 AWG

74 AMPS 4 AWG

111 AMPS 2 AWG

Table 3-1: Wire Sizes

CSW Series 31

Page 32

User Manual California Instruments

3.6 Connectors - Rear Panel

A number of connectors are located on the rear panel of the power source. The connectors are

identified by J numbers. The terminal strips are identified by TB numbers.

3.6.1 System Interface, Clock and Lock Connectors, J33 and J34

J33 and J34 are the Clock and Lock connectors. These connectors are only available with the

LK option. The LK option is used to synchronize and control the phase shift between the Phase

A output of the Master power source and the Phase A output of additional auxiliary power

sources. The frequency of the auxiliary power sources is determined by the frequency of the

master source. Refer to Figure 3-6 for the Clock and Lock connections to three power sources.

The System Interface connectors, J28A and J28B, are used to connect the Auxiliary power

sources to the Master power source in multiple source systems. The power that is to be the

Master source will have the System Interface cable plugged into its connector labeled “To

Auxiliary”, J28B. The other end of the System Interface cable will plug into J28A, labeled “To

Master”, of the first Auxiliary power source. Additional Auxiliary power sources will be chained

together with additional System Interface cables. Refer to Figure 3-4 for the System

Interconnect.

3.6.2 External Input/ Output Signal Connector

The External Input/ Output Connector is J32 on the rear panel. Table 3-2 shows the function for

each pin of this connector.

J32 Description

1 External Signal A: The input for an external signal or RPV for Phase A referenced to pin 10

2 External Signal C: The input for an external signal or RPV for Phase C referenced to pin 10

3 MOD A: The input for an amplitude modulation for Phase A referenced to pin 12

4 MOD C: The input for an amplitude modulation for Phase C referenced to pin 12

5 SYNC-HI: The Hi input for the TTL External Sync input.

6 ISOCOM: The common for the RTIN and /INHIBIT functions

7 /INHIBIT: A logic Lo or contact input to inhibit the outputs referenced to pin 6

8 DFI: Pins 8 and 15 are the two pins for the isolated DFI function

9 External Signal B: The input for an external signal or RPV for Phase B referenced to pin 10

10 External Signal Common: The common for all external signal or RPV inputs

11 MOD B: The input for an amplitude modulation for Phase B referenced to pin 12

12 MOD-COM: The common for all amplitude modulation inputs

13 SYNC-LO: The Lo input for the TTL External Sync input

14 RTIN: An input to trigger a function, referenced to pin 6

15 DFI: Pins 8 and 15 are the two pins for the isolated DFI function

32 CSW Series

Table 3-2: System Interface Connector (J32)

Page 33

User Manual California Instruments

3.6.2.1 /Inhibit (Remote Inhibit)

The /Inhibit input J32 pin 7 can be used to open and close the output relay of the power source.

This input overrides the state of the output relay programmed from the front panel or the bus. It

may be used for safety interlock purposes.

The default level for remote inhibit is a logic low or contact closure between pin J32-7 and pin J23-6

(ISOCON). This will cause the output voltage to be programmed to 0.0 volts and the output relays

to open. Alternative, the level can be reversed using the “output:ri:level high” command over the

bus.

The mode of operation of the remote inhibit can be changed using the Output mode bus command.

This command selects the mode of operation of the Remote Inhibit protection. The following

modes can be selected:

LATChing A TTL low at the RI input latches the output in the protection shutdown state,

which can only be cleared by OUTPut:PROTection:CLEar.

LIVE The output state follows the state of the RI input. A TTL low at the RI input turns

the output off; a TTL high turns the output on.

OFF The instrument ignores the RI input.

The RI output state is saved at power down. The factory default state is LIVE.

For details on programming the remote inhibit function, refer to the CSW programming manual

3.6.2.2 External Signal Inputs

The External Signal Inputs are for either a DC or Direct waveform inputs. The DC input is

programmed by enabling the RPV function. This function is also called the External Gain

Control. A 0 to 7.07 volt DC input will adjust the output voltage from 0 to a full-scale output.

3.6.2.3 Remote Sense Connector TB3

It is important that the remote sense connections are hooked up at the load for the programmed

voltage to be correct at a load with high load currents. For single-phase systems, connect Phase

A to phase A and neutral to neutral. For three-phase system configurations, connect all three

phase and neutral.

If the sense lines are not connected the power source has internal resistors that will connect the

sense lines to the Master power source output terminals.

NOTE: Do not reverse or swap sense connection phasing or damage to the unit may

result.

For systems consisting of multiple CSW5550 chassis, the end user has to connect the external

sense inputs of the Master power source for the correct External sense function. The Auxiliary

power sources will have no control of the output voltage. Refer to Figure 3-3 for an illustration of

the power source rear panel and the Remote Sense terminal strip. Note that there are multiple

Neutral terminals for TB3. The terminals are all connected in parallel in the power source. Only

one terminal needs to be connected to the sense point.

CSW Series 33

Page 34

User Manual California Instruments

3.6.3 RS232C Serial Interface Connector

Pin Name Direction

1 N/C

2 TxD Output

3 RxD Input

4 N/C

5 Common Common

6 N/C

7 CTS Input

8 RTS Output

9 N/C

Table 3-3: RS232 Connector pin out

The CSW series power sources use a regular straight-through DB9 male to DB9 female serial

cable for the RS232 interface.

3.6.4 USB Interface

A standard USB Series B device connector is located on the rear panel for remote control. A

standard USB cable between the AC Source and a PC or USB Hub may be used.

Note: Use of the USB port to control more than one power source from a single PC is not

recommended, as communication may not be reliable. Use GPIB interface for

multiple power source control.

Figure 3-2:USB Connector pin orientation

Pin Name Description

1 VBUS +5 VDC

2 D- Data 3 D+ Data +

4 GND Ground

Table 3-4: USB Connector pin out.

34 CSW Series

Page 35

User Manual California Instruments

A

3.6.5 LAN Interface – RJ45

An optional RJ45 Ethernet 10BaseT connector is located on the rear panel for remote control. A

standard RJ45 UTP patch cord between the AC Source and a network Hub may be used to

connect the AC source to a LAN. For direct connection to a PC LAN card, a crossover RJ45

cable is required. Consult your network administrator for directions on connecting the AC source

to any corporate LAN.

If the –LAN Ethernet interface option is present, the MAC Address (Media Access Control) of the

Ethernet port is printed on the serial tag of the power source. The serial tag is located on the

rear panel of the unit.

For information on how to set up a network connection or a direct PC connection using the LAN

interface, refer to the CSW Series Programming Manual P/N M162084-03 distributed in Adobe

PDF format on CD ROM CIC496.

LAN

Pin Ethernet TPE

10BaseT/100BastT/1000BaseT

1 Transmit/Receive Data 0 + White with green stripe White with orange stripe

2 Transmit/Receive Data 0 - Green with white stripe or

3 Transmit/Receive Data 1 + White with orange stripe White with green stripe

4 Transmit/Receive Data 2 + Blue with white stripe or

5 Transmit/Receive Data 2 - White with blue stripe White with blue stripe

6 Transmit/Receive Data 1 - Orange with white stripe

7 Transmit/Receive Data 3 + White with brown stripe or

8 Transmit/Receive Data 3 - Brown with white stripe or

Table 3-5: RJ45 LAN Connector pin out.

EIA/TIA 568

solid green

solid blue

or solid orange

solid brown

solid brown.

EIA/TIA 568B

Crossover

Orange with white stripe or

solid orange

Blue with white stripe or

solid blue

Green with white stripe or

solid

White with brown stripe or

solid brown

Brown with white stripe or

solid brown

CSW Series 35

Page 36

User Manual California Instruments

Figure 3-3: Rear Panel View for the CSW5550)

3.7 Single-Phase and Three Phase Multiple Box System Configurations

Three Phase System:

Refer to Figure 3-4 for the output power connections for a 3-phase power system. For

connections to a single power source disregard the connections to the Auxiliary power sources

shown in Figure 3-4.

All multi-source systems must be interconnected using the system Interface cable. All of the

respective outputs from the power sources must be connected at an external terminal block as

shown in Figure 3-4. The connections to the Output Sense terminal block of the Master power

sources should be connected to the point where the voltage is to be regulated. If the sense lines

are not connected the programmed output voltage will be regulated and the output of the Master

Power source.

For all multi-source power systems only the Master power source can control and report the

measured system output.

Single Phase System: