Ametek CBA-1G-600B, CBA-1G-070B, CBA-3G-050B, CBA-1G-1200B, CBA-1G-300B Operation Manual

...Page 1

CBA POWER AMPLIFIER

Operation Manual

Manual number H012161

Revision: 3

First edition published 26th July 2017

Page 2

China

AMETEK Commercial Enterprise

(Shanghai) Co. Ltd

Beijing Branch

Western Section, 2nd Floor

Jing Dong Fang Building (B10)

Chaoyang District

Beijing,

T +86 10 8526 2111

chinasales@teseq.com

Japan

AMETEK Co. L

td.

Tokyo office

3rd floor, Shiba NBF Tower,

1-1-30 Shiba-Daimo n, Minat o- ku

Tokyo, 105-0012, Japan

T +81 3 6809 2401

cts-japan.sales@ametek.com

Shanghai Office:

Part A1, A4, 2nd

No. 526 Fute 3rd Road East

Pilot Free Trade Zone, Shanghai 200131,

China

T +86 21 5868 5111

Nagoya Office

1

Aichi

T +81 52 709 5501

Guangzhou Office:

Room 1410

33 J

Guangzhou, China

T +86 20 8363 4768

Poland

AMETEK CTS Germany GmbH

Biuro w Polsce

ul. Ogrodowa 31/35

00

T +48 518 643 512

infopolska.cts@ametek.com

Germany

AMETEK CTS Germany GmbH

Lünener S

59174 Kamen, Deutschland

T +49 2307 26070

sales.cts.de@am

service.rf.cts@ametek.com

Singapore

AMETEK Singapore Pte.

No. 43 Changi South Avenue 2

#04

T +65 6484 2388

singaporesales.cts@ametek.com

Great Britain

AMETEK (GB) Ltd. trading as Teseq

5 Ashville Way, Molly Millars Lane

Wokingham

Berkshire RG41 2PL

Great Britain

T +44 845 074 0660

teseq-uk.service@ametek.com

Taiwan

AMETEK Taiwan Corp. Ltd.

10F

GongDaoWu Rd.,

Hsinchu City 30072, Taiwan

T +886

taiwan.sales.cts@ametek.com

USA

Teseq Inc. / AMETEK

52 Mayfield Avenue

Edison, New Jersey 08837, USA

T +1 732 417 0501

Toll free: +1 888 417 0501

usasales.cts@ametek.com

usasupport.cts@ametek.com

Any disclosure to third parties, or reproduction by any

means of any part of this manual without the written

consent of Teseq, is prohibited.

For Sales

.

China, 100015

floor, Building No. 1

-12, Yian Plaza

ian She Liu Ma Road

traße 211

-0

etek.com

-329 Kifune Meito-ku Nagoya-shi

-ken, 465-0058, Japan

-893 Warszawa, Polen

Ltd.

-01 Singapore 486164

-5, No. 120, Sec 2,

3 57 5099

CBA Manual: H012161 Rev: 3 2

CTS

Page 3

Table of Contents

1 INTRODUCTION 5

1.1 About this manual 5

1.2 Amplifier description 5

SAFETY 6

2

2.1 General 6

2.2 Safety symbols and terms 6

2.3 Safety precautions 7

INSTALLATION 9

3

3.1 General 9

3.2 Connecting the line cord 10

3.3 Connecting the chassis ground cable 10

3.4 Connecting the RF cables 10

3.5 Connecting the Safety interlock 10

PROTECTION CIRCUITS 11

4

4.1 Over Heat Protection 11

4.2 Input Protection 11

4.3 Power Supply Faults 11

4.4 Mismatch Protection 11

AMPLIFIER OPERATION 12

5

5.1 Safety interlock Operation 12

5.2 Switching on line supply 12

5.3 Cooling Fan Operation 13

5.4 General 13

5.5 OPRT/STBY 13

5.6 FLT/RST 14

5.7 LOC/RMT 14

5.8 Gain Control 14

5.9 GPIB 15

INDICATORS & FUNCTIONS 15

6

6.1 General 15

6.2 Touch Screen Indication 15

CONNECTIONS 16

7

7.1 General 16

7.2 RF input, N Type connector 16

7.3 RF output N-Type or 7/16 (Model Dependent) 17

7.4 Sample Ports, N-TYPE Female 17

7.5 Line supply input connector 17

7.6 Safety interlock 18

7.7 IEEE-488 Convector 18

7.8 Ethernet 18

7.9 RS232 Connection 19

7.10 USB Connection 19

7.11 Ground post (8-32 thread) 19

CBA Manual: H012161 Rev: 3 3

Page 4

8 REMOTE CONTROL CONNECTIONS & OPERATIONS. 20

8.1 Connectors 20

8.2 IEEE 488 Operation 20

8.3 RS-232 Operation 20

8.4 Ethernet Connection 21

8.5 USB Connection 21

8.6 Remote Command Set 22

ROUTINE MAINTENANCE 24

9

9.1 General cleaning 24

9.2 RF connectors 24

9.3 Air-filter cleaning. 24

FAULT FINDING 25

10

10.1 General checks 25

10.2 Fault indications 26

WARRANTY 28

11

11.1 Definitions 28

11.2 Scope 28

11.3 Terms and conditions 28

11.4 Transfer of Warranty 29

11.5 Protection of Warranty 29

11.6 Repair form 30

13.1 Fig 1, 3U front Panel & Outline Drawing 31

13.2 Fig 2, 4U Front Panel & Outline Drawing 32

13.3 Fig 3, 6U Front Panel & Outline Drawing 33

13.4 Fig 4, 10U Front Panel Drawing 34

14

DATASHEET SPECIFICATIONS 36

CBA Manual: H012161 Rev: 3 4

Page 5

iCAUTION! This Operation Manual contains important information for

the user of the amplifier. It details important safety information and

hazards that can be encountered by the user, and recommends

precautions that should be taken to prevent damage to the amplifier or

associated equipment. It is important that this Operation Manual

(including any information in the Appendices) is read before attempting

to install or operate the amplifier.

1 INTRODUCTION

1.1 About this manual

This operation manual contains information that details installation, routine

maintenance and amplifier operation. It does not contain information needed for

servicing or calibration.

1.2 Amplifier description

The TESEQ CBA amplifier series is designed for laboratory use. The form factor

ranges from 3U, 4U & 6U bench top units up to rack mountable 10U amplifiers

consisting of a 7U power amplifier drawer and separate 3U power supply draw.

A CBA amplifier can be remotely controlled via the built in RS232, IEEE 488, USB or

Ethernet amplifier controller. Local control is via a front panel touch screen. This also

shows the amplifier status when controlled remotely.

A comprehensive performance and status indicating system is included. These

circuits monitor:

x Interlock circuit status

x Forward power indication

x Reflected power indication

x High VSWR indication

x RF baseplate temperature

x Ambient temperature

x Power supply DC voltage

x Power supply DC current

x Overall status of the amplifier

Visual indications are given. If a fault is detected, the amplifier automatically reverts

into a latched STANDBY condition. It remains in this condition unti l the fault has been

cleared and the fault latch is reset via the front panel touch screen.

The design of the amplifier is subject to continuous improvement. Consequently, the

amplifier may incorporate minor changes in detail from the information contained in

this manual.

CBA Manual: H012161 Rev: 3 5

Page 6

2 SAFETY

i

i

When used on the amplifier, warns the user of a non-ionising radiation

hazard. When used in this operation manual, alerts the user to the part of the

manual that deals with a non-ionising radiation hazard.

When used on the amplifier, directs the user to refer to the operation manual.

When used in this operation manual, alerts the user to

iWARNING! and

iCAUTION! statements.

or

Warns personnel to observe correct lifting practices.

Ground terminal. Connect this terminal to a clean ground to improve EMC

immunity. Although it provides an extra measure of safety, this is

protective earth

is the pin on the line

inlet connector.

2.1 General

The amplifier described in this manual is designed to be used only by qualified

personnel. Use of the amplifier in a manner not specified in this manual may impair

the protection provided by the amplifier. Before use, inspect the amplifier for damage

which may impair safety.

There are no user-serviceable parts inside the amplifier, and any warranty is rendered

void if the seals on any covers are broken.

The following safety information is intended to protect all installers and operators, and

to prevent damage to the amplifier. It should be read and understood before installing

and operating the amplifier

2.2 Safety symbols and terms

iCAUTION! statements identify conditions or practices that could result in damage to

the amplifier or other property.

iWARNING! statements identify conditions or practices that could result in personal

injury or loss of life.

Note statements inform the user of important general information.

i

Hints and tips statements inform the user of useful information and operational

short cuts.

The following symbols appear on the amplifier and in this manual:

ground. The protective earth ground

CBA Manual: H012161 Rev: 3 6

not a

Page 7

i

i

i

i

i

i

2.3 Safety precautions

Observe all the following precautions to ensure personal safety and prevent damage

to the amplifier or equipment connected to it.

iWARNING! Properly dispose of the amplifier.

The RF amplifier modules in this equipment contain Beryllium Oxide, and other

components contain PTFE. The appropriate precautions and regulations must be

observed concerning the disposal of this amplifier and certain internal components.

Do not crush or incinerate.

Note: Beryllium Oxide is a material used in the manufacture of RF devices. Toxic

i

dust is given off when crushed.

Note: PTFE is a material used in the manufacture of certain components within the

amplifier. PTFE gives off toxic gasses when incinerated.

iWARNING! Do not touch the inner conductor of the RF-output connector.

High voltages can occur on the inner conductor of the RF output connector, or on

cables or antennas connected to it. These can cause RF burns if touched.

WARNING! Ground the amplifier.

The amplifier conforms with IEC Safety class 1, meaning that it is provided with a

protective grounding terminal. This is through the line supply cord to the centre pin of

the power inlet connector. To maintain this protection, the line supply cord must

always be connected to the source of line supply via a socket with a grounded contact.

Do this before making connections to the RF-input or RF-output connectors of the

amplifier.

Without the protective ground connection, all parts of the amplifier constitute a

potential shock hazard.

WARNING! Use the correct power cord.

Use only the line supply cord and connector specified for the amplifier. Use only a line

supply cord that is in good condition.

WARNING! Do not remove covers or panels.

To avoid personal injury, do not operate the amplifier without the panels or covers in

place.

WARNING! Do not operate in explosive atmospheres.

The amplifier provides no explosive protection from static discharges or arcing

components. Do not operate the amplifier in an atmosphere of explosive gasses.

CBA Manual: H012161 Rev: 3 7

Page 8

i

i

i

i

i

i

or

iCAUTION!

Exercise caution when lifting.

iWARNING!

Use the safety interlock facility within danger areas.

i

CAUTION! Avoid static discharges

The RF input and output connections are static-sensitive and should not be subjected

to static discharge.

CAUTION! Use the correct line supply source

It is essential that the amplifier operates from a line supply source that does not apply

voltages and frequencies between the line supply conductors (or between either line

supply conductor and ground) that are outside the range detailed in the specification

sheet.

CAUTION! Do not obstruct the circuit breaker.

Ensure that there are no obstructions that impair the operation of the front panel linesupply circuit breaker(s).

CAUTION! Do not obstruct the airflow through the amplifier.

The cooling airflow is drawn in through the front and exhausted at the rear. If this

airflow is obstructed, overheating of the amplifier may occur.

CAUTION! Do not operate the amplifier outside its specification.

This may cause the amplifier to malfunction or be damaged.

iWARNING! Do not touch the exterior of the amplifier (rack mount version)

when in use.

The top and side panels of the amplifier can get hot during use, especially on high

power models.

CAUTION! Periodically replace the air-intake filters.

Operating the amplifier with the air filters dirty may cause the amplifier to overheat.

The appropriate lifting practices should be observed during transportation, installation,

or removal of the amplifier from its mounting position.

Any area where personnel may come into direct contact with high power RF, or be

exposed to non-ionising radiation, should be designated as a danger area. A barrier

should be established around any such area, with a switch in place when the barrier is

broken. This switch can be linked to the safety interlock BNC connector on the

amplifier, thus disabling the amplifier when the barrier is breached.

It is the responsibility of the operator to ensure that the working environment is safe.

The ‘safety interlock’ feature is provided to assist the purchaser in establishing such a

‘safe’ area.

CBA Manual: H012161 Rev: 3 8

Page 9

3 INSTALLATION

or

iiCAUTION!

Exercise care when lifting.

iiCAUTION!

Do not support the whole weight of the a

handles

(See Section 12)

i

iCAUTION!

Do not obstruct the airflow through the amplifi er.

iCAUTION!

Even though the ambient air temperature may be within the amplifier’s

specification, the internal temperature may rise above operational limits if it

is operated in direct sunlight.

3.1 General

Amplifier models that are very heavy have a caution label on the top cover.

Appropriate lifting practices should be observed during transportation, installation, or

removal of the amplifier from its mounting posit ion. When mounted in a rack, the

amplifier must not be supported by the front panel fixing holes alone. For easier

installation and removal, we recommend that the amplifier is positioned with its top no

more than 1.4 metres above ground level.

These should only be used for sliding the amplifier in and out on the rack.

i

Note: The amplifier may be lifted using the rear protection handles.

(See Section 12).

The amplifier is designed to be mounted in a 19” fixed rack installation. When mounted

in a rack, use a support tray-slider-assembly, especially for heavy amplifier models.

See the section 12 of this manual for details of amplifier dimensions.

mplifier with the front panel

At least 200mm clearance should be allowed behind the amplifier, so that air flow and

connecting cables are not obstructed. An unobstructed area of at least 200mm should

be allowed in front of the amplifier front panel air-intakes.

The cooling airflow is drawn in through the front and exhausted at the rear. If this

airflow is obstructed, overheating of the amplifier may occur. For correct amplifier

operation, airflow through the unit must be maintained.

CBA Manual: H012161 Rev: 3 9

Page 10

iiCAUTION!

It is e

ssential that the amplifier operates from a line source that does not

apply voltages and frequencies between the line conductors (or between

either line conductor and ground) that are outside the range detailed in the

specification sheet.

iiCAUTION!

Ensure that the line cord does not interfere with the operation of the rear

panel line-input circuit breaker(s).

To improve EMC immunity, bond the amplifier to a good ground with a

conductor of 4 sq.mm or the equivalent earth braid, a ground post being

provided for this purpose on the rear panel. Although it provides an extra

measure of safety, this is

NOT a protective earth. The protective earth is the

ground pin on the line supply connector(s).

iiCAUTION!

Ensure that the RF source is OFF when making connections.

iiCAUTION!

Ensure any cables and connectors mating with the RF input and RF output

connectors are of

50-ohm impedance, and are designed to handle the power

at the frequencies generated by the amplifier. Although very similar,

75-ohm

connectors must not be used.

iiWARNING!

Use the safety interlock facility within danger areas.

3.2 Connecting the line cord

3.3 Connecting the chassis ground cable

3.4 Connecting the RF cables

Use cable with the lowest loss that is practical. The connectors should not be overtightened, and any tightening instructions for the connector should be observed.

Ensure that any bends in cables conform to the recommended minimum-bend-radius

of those cables, especially where the cables enter the RF connectors.

3.5 Connecting the Safety interlock

If the amplifier is to be connected to an antenna, personnel may be exposed to nonionising radiation. In such systems, the safety interlock function should be used.

Connection (via the rear panel) is with a BNC-type connector. We recommend that

shielded cable is used for all interlock connections to ensure EMC immunity.

The current in the safety-interlock circuit is less than 1mA, so cable with a low current

capacity is suitable.

CBA Manual: H012161 Rev: 3 10

Page 11

If you do not need this function, fit the supplied BNC shorting-link in place. Failure to

do this will result in the amplifier latching in an “Interlock Open” status which switches

the amplifier into standby mode.

4 PROTECTION CIRCUITS

4.1 Over Heat Protection

The CBA RF components produce heat and are air cooled by fans. Should an over

heat condition occur for any reason, the CBA contains heat sensors that will shut

down the system via the amplifier control system. If the inlet and outlet openings are

obstructed, clear the obstruction and allow the amplifier to remain in standby so that

the internal fans can cool the amplifier down. Once the amplifier has reached an

acceptable temperature, depress the ”Fault Reset” soft key on the touchscreen and

the amplifier will operate normally.

4.2 Input Protection

The CBA series is designed to achieve the specified output power level (see

applicable datasheet) for an input level of 0 dBm or less (1.0mW) however, to prevent

overdriving the amplifier, the Input Protection circuit will activate if the input signal

exceeds 10 dBm and will automatically compensate for the increased input signal by

reducing the gain of the preamplifier. Even though the amplifier has an Input

Protection Circuit, overdriving the amplifier is not recommended.

IMPORTANT NOTE:

The CBA Sample Port connectors must be either connected to a 50Ω measurement

system or terminated with the supplied 50Ω load. If the CBA is operated without 50Ω

impedance on the Sample ports, the metering and output protection may be

inaccurate, which may result in damaging the amplifier and voiding the unit’s warranty.

4.3 Power Supply Faults

The Power Supply Fault circuit monitors the voltage and current of system power

supplies and produces a fault indication should any voltage or current level deviate

from normal operating parameters. Each power supply voltage output is monitored

and displayed to indicate the power supplies are operating within design parameters.

4.4 Mismatch Protection

The amplifier is not damaged by using it into a load that has a poor VSWR. While

operating into a load that has poor VSWR, the amplifier may not deliver specified

output power. In extreme cases, the amplifier folds back to protect internal circuitry.

CBA Manual: H012161 Rev: 3 11

Page 12

iiCAUTION!

Ensure that all the installation procedures detailed in Section 3 are complete

before operating the amplifier.

iiCAUTION!

Ensure that before connecting or turning the RF source ON, the

source

peak output level is set to less than the maximum level detailed adjacent to the

RF input connector(s).

ii

WARNING!

Use the safety interlock f

unction within danger areas.

Any area where personnel may come into direct contact with high power RF, or

be exposed to non

-ionising radiation, should be designated as a danger area.

A barrier should be established around this area, with a switch

opening when

the barrier is broken.

This should be linked to the safety interlock connector,

disabling the amplifier when the barrier is breached. (It is the responsibility of

the operator to ensure a safe working environment).

i

5 AMPLIFIER OPERATION

5.1 Safety interlock Operation

input-

Safety interlock connections are via a BNC connector on the rear panel. This should

be used with an appropriate switching or control arrangement so that the amplifier is

disabled when any barrier to a dangerous area is broken. Once the interlock

connection is broken the amplifier will default to standby mode. Once the interlock

connection is remade the amplifier will automatically resume operation in “Operate

Mode”

5.2 Switching on line supply

After ensuring that the amplifier front panel rocker switch is in the down position (off)

ensure the mains lead is connected to the correct AC line source. Depending on the

model of CBA,

1 Switch the rear panel 3 phase circuit breaker to the “On” position. The rear

panel circuit breaker provides AC overcurrent protection. There will be no

amplifier indication as a result of this step.

2 Switch the front panel rocker switch to the Up (On) position. The touchscreen

will indicate that the boot up process has begun.

i

Hints and tips: This switch can remain in the ON position all the time, but it is best

set to OFF when the amplifier is not being used for long periods.

CBA Manual: H012161 Rev: 3 12

Page 13

i

5.3 Cooling Fan Operation

Once the amplifier has been turned on, the power supply fan will start along with the

rear panel cooling fans. The CBA B series uses a forced air cooling system where air

is drawn in to the front grill and exhausted out of the rear of the amplifier. Temperature

sensitive fan circuits are used for optimal audible noise when the amplifier is in use.

When in standby mode the fans will operate at their s lowest speed, once the amplifier

is set to, “Operate” mode, the RF modules will be enabled and start to generate heat.

The fans will slowly increase in speed until the amplifier has reached thermal

equilibrium.

Hints and tips: The air intake/exhaust should be kept clear at all times. If they are

i

blocked for any reason the amplifier will overheat and fault latch. Once the internal

amplifier temperature has cooled to within normal operating conditions the fault can be

reset and normal operation resumed.

5.4 General

When the front panel rocker switch is

switched Up to the, “ON” position the

Teseq splash screen will appear on the

touch screen display. The amplifier will

remain in this state for a maximum of 45

seconds while the amplifier controller

completes its boot sequence.

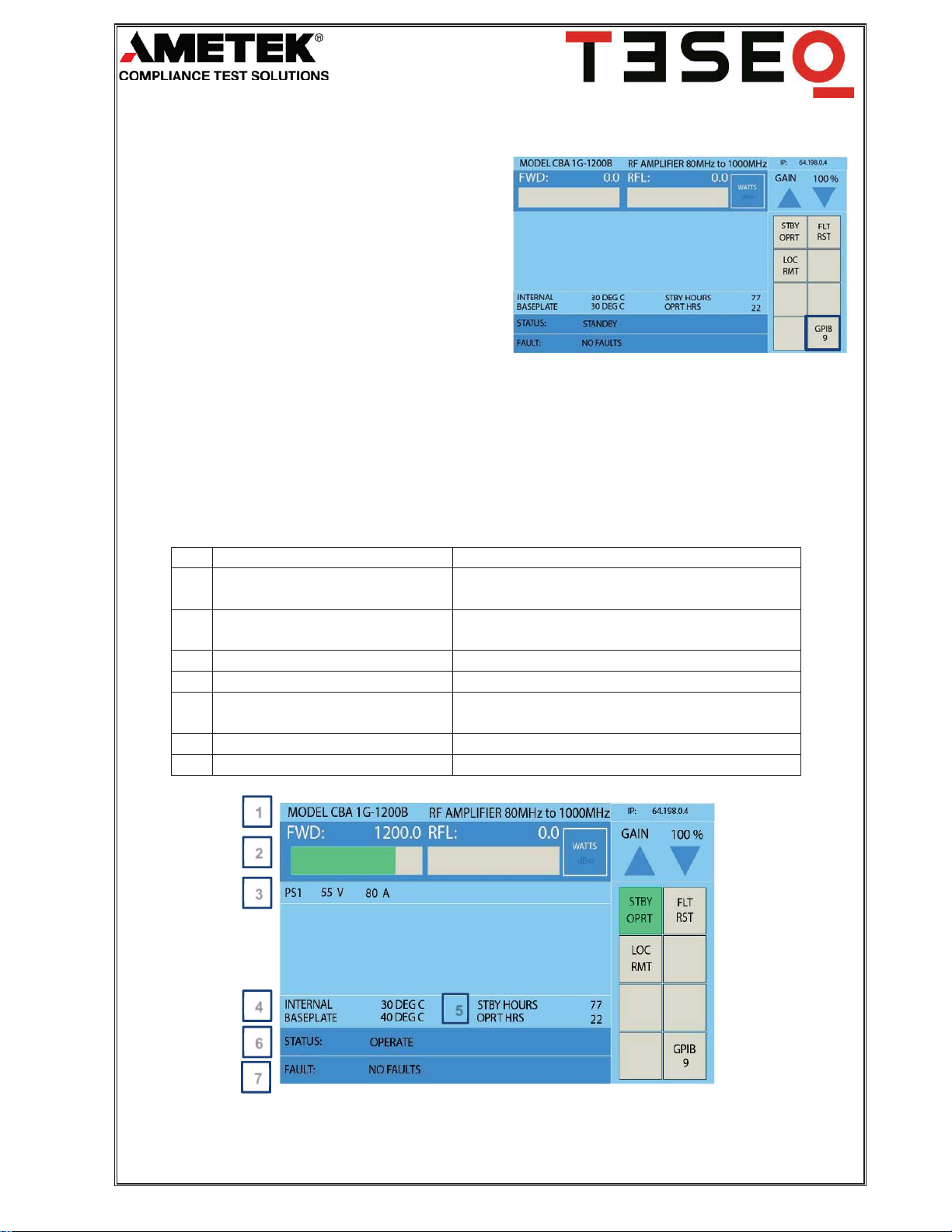

5.5 OPRT/STBY

The operate/standby button controls the

RF On/Off function of the amplifier. In

standby the DC power supply is in the,

“Off” state and the amplifier is in standby

mode (RF Off).

CBA Manual: H012161 Rev: 3 13

Page 14

Once pressed the OPRT/STBY button

will illuminate green. This will indicate the

DC power supply has energised

supplying voltage to the power modules

and the amplifier is in, Operate mode

(RF On)

5.6 FLT/RST

The Fault/Reset (FLT/RST) will illuminate

red when a fault is detected. Once the

fault is removed/fixed depressing the

FLT/RST will clear the fault indication so

that normal operation of the amplifier can

resumed.

5.7 LOC/RMT

When the amplifier recei ves a remote

command the LOC/RMT will illuminate

green. Depressed the button will restore

the amplifier to local operation

5.8 Gain Control

The gain control button allows for gain

adjustments over the entire operating

frequency of the amplifier over a range of

30dB in 100 steps via the touch screen.

255 steps via the remote command

function.

CBA Manual: H012161 Rev: 3 14

Page 15

i

Display Indication

Display Function

1

Amplifier model number and

frequency range of operation

Amplifier model number and frequency

range of operation identification

2

Forward and reflected power

indication

Mismatch load conditions as forward and

reflected power in watts

3

PSU voltage and current

VDC PSU in Amps & Volts status

4

Internal Temperatures

Internal and baseplate temperature status

5

Hours of operation

Elapsed time indication of STBY/OPRT

hours

6

Status. Operate/Standby

Operate and standby indication

7

Fault status.

Thermal, PSU or Interlock fault status

1

4

2

3

5

6

7

5.9 GPIB

The GPIB address can be changed by

pressing the GPIB button. Pressing the

button will cycle through the available

addresses.

6 INDICATORS & FUNCTIONS

6.1 General

Note: The front panel touch screen shows the amplifier status for both local and

i

remote-control conditions.

6.2 Touch Screen Indication

CBA Manual: H012161 Rev: 3 15

Page 16

7 CONNECTIONS

Front Panel

Rear Panel

Function

Comment

Function

Comment

Amplifier Mains

Breaker

3 Phase Main

Breaker

Model Dependent

Local/Remote Switch

Touch Screen

Amplifier Tray &

PSU Tray DC

Power

interconnect.

Model Dependent

RF On/Off Switch

Touch Screen

AC Power Connector

Fault/Reset Switch

Touch Screen

Interlock, BNC

Colour Touch Screen

Display Status

Touch Screen

IEEE 488, Connector

Gain Control,

Touch Screen

Ethernet

RS232

USB

Ground Post

Front or Rear Panel RF Connectors

Function

Comment

RF Input & Output

Configuration Dependent

FWD/RFL Sample Ports

Configuration Dependent

iiCAUTION!

The maximum input level detailed in the specification sheet and on the

amplifier front panel must not be exceeded. Do not expose the centre pin of

the RF

input connector to static discharge. The signal source must be at DC

zero.

i

7.1 General

The CBA series has an RF In, RF Out and a built in dual directional coupler with NType forward and reflected connections. These are available in two configurations,

either all on the front or all on the rear of the amplifier. The CBA series are equipped

with either a N-Type or a 7/16

datasheet) but the same standard shall still apply; all RF connections are either on the

rear or on the front of the amplifier. The interlock, remote connections, AC connector,

and interconnecting cables are always located on the rear panel.

Summary

th

RF output connecter (model dependent, see applicable

7.2 RF input, N Type connector

-

Refer to the specification sheet for details of RF input levels. The nominal input

impedance is 50 ohms.

Hints and tips: Don’t forget that modulated or complex signals may have a peak

i

power that may not be indicated on the signal source. Always ensure that the peak

level of the input signal is within the limits specified in the applicable datasheet.

CBA Manual: H012161 Rev: 3 16

Page 17

iiWARNING!

High RF voltages can occur on the inn er conductor of the RF

connector, which could cause RF burns if touched. Do not expose

the centre pin to static discharge.

Nominal Output

Impedance (ohms)

Amplifier Power

Level (Watts)

Nominal Output

Level (dBc)

Flatness

(dB)

50

<700

40

+/- 3

50

> 700

50

+/- 3

i

Rear Panel Single Phase

Neutrik ‘Powercon’

3 Phase 5 Wire MS Connector

Rear Panel Single Phase

IEC

7.3 RF output N-Type or 7/16 (Model Dependent)

-out

The nominal RF output impedance of the amplifier is 50 ohms, but it will safely drive a

load with an input impedance other than 50 ohms (resistive or reactive), but will deliver

less power. Refer to the specification sheet for details of RF output power.

7.4 Sample Ports, N-TYPE Female

These allow monitoring of both the incident power (P

) and the reflected power (Pr) at

i

low level.

The nominal output impedance is 50 ohms, and each output should be connected to a

50Ω test system or terminated with 50Ω load supplied with the amplifier.

The above parts can be supplied as spares or replacement items. The part number

must be quoted when ordering.

7.5 Line supply input connector

The CBA series power supply is equipped with a IEC or Neutrik Powercon inlet for

single phase models and a high current 3 phase / 5 wire MS connector for high power

models. The amplifier systems are supplied with mating power cords.

i

Note: Mains inlet connectors are model dependent.

CBA Manual: H012161 Rev: 3 17

Page 18

Pin

Signal

Pin

Signal

1

Data IO1

13

Data IO5

2

Data IO2

14

Data IO6

3

Data IO3

15

Data IO7

4

Data IO4

16

Data IO8

5

End or Identify

17

Remote Enable

6

Data Valid

18

GND

7

Not Ready for Data

19

GND

8

No Data Accepted

20

GND

9

Interface Clear

21

GND

10

Service Request

22

GND

11

Attention

23

GND

12

Shield

24

GND Logic

Pin

Signal

1

Transmit (TX+)

2

Transmit (TX-)

3

Receive (RX+)

4

NC

5

NC 6 Receive (RX-)

7

NC

8

NC

7.6 Safety interlock

Rear Panel mounted BNC jack receptacle.

50Ω impedance.

+5 Volts (current limited)

This connector is supplied with a shorting-link for use when

the safety interlock function is not required.

7.7 IEEE-488 Convector

24 Way IEEE Bulkhead Connector.

7.8 Ethernet

RJ45 remote interface with signalling LED’s

CBA Manual: H012161 Rev: 3 18

Page 19

7.9 RS232 Connection

Pin

Signal

1

Data Carrier Detected

2

Receive (RX)

3

Transmit (TX)

4

Data Terminal Ready

5

Signal Ground

6

Data Set Ready

7

Request to Send

8

Clear to send

9

Ring Indicator

Pin

Signal

1

VDC (5V)

2

Receive (RX)

3

Transmit (TX)

4

Data Terminal Ready

To improve EMC immunity, bond the amplifier to a clean ground with a

conductor of 4 sq.mm or the equivalent braid, to

provides an extra measure of safety, this is not a protective earth. The

protective earth is the ground pin on the line inlet connector.

Pin Female D-Type

7.10 USB Connection

USB-B device connector

7.11 Ground post (8-32 thread)

this post. Although it

CBA Manual: H012161 Rev: 3 19

Page 20

i

i

i

8 REMOTE CONTROL CONNECTIONS & OPERATIONS.

8.1 Connectors

IEEE 488.2 24 Way IEEE connector

RS232 9 pin female D-type

LAN RJ45 with signalling LED’s

USB USB-B device connector

8.2 IEEE 488 Operation

The Teseq Amplifiers can be operated remotely from a computer having an IEEE-488

interface. This interface allows the amplifier to be remotely controlled over the

General-Purpose Interface Bus (GPIB) by sending commands to the amplifier.

Additionally, amplifier status and forward and reverse power readings may be read

over the GPIB. All functions can be controlled by coded messages sent over the

interface bus via the 24-pin socket connector on the rear panel of the unit. The GPIB

command codes for the TESEQ Amplifier series are discussed on subsequent pages

and, for ease of identification; the command codes are identified within the text by bold

capital characters. For full information on the IEEE protocols and syntax the IEEE-

488.2 Standard should be consulted

.

When the amplifier receives a command over the GPIB, it automatically switches to

REMOTE operation, pressing the LOCAL key on the front panel returns the unit to

normal manual local operation. The initial state of the amplifier after power-on is the

full attenuation condition.

Note: The ZEROATT command must be set in order for the amplifier to be able to

i

generate output power.

The GPIB address of the amplifier is set by via the Front panel using the touch screen

control button.

8.3 RS-232 Operation

For operation of the serial port a terminal application is required to be configured with

the following port configuration. Connect the RS232 cable and power the amplifier up.

Note: To determine which COM port is being used for a specific protocol, navigate to

CONTROL PANEL and double-click on the SYSTEM icon. Once under System

Properties, navigate to the HARDWARE tab and select DEVICE MANAGER. Scroll

down until you see PORTS (COM & LPT) and expand the drop-down menu. The

associated port should be listed.

Note: Teseq doesn’t recommend the use o f USB to serial ada ptors unless the ad aptor

contains an FTDI chip set.

CBA Manual: H012161 Rev: 3 20

Page 21

RS-232 / USB Configuration Settings

RS-232

USB

Bits per second

9600

9600

Data Bits

8

8

Parity

None

None

Stop Bits

1

1

Flow Control

None

None

i

STATIC IP

Y/N

STATIC IP Value

XXX.XXX.X.XX

SAVE SETTINGS

Y/N

i

Configure the selected Port as per the below settings.

To place the amplifier in remote operation type in a valid command such as

“STATUS”. The amplifier will then go into remote operation and the status will be

displayed on the computer.

8.4 Ethernet Connection

With the amplifier powered down connect via an Ethernet cable to the network. Power

the amp up and wait (5/10 seconds) for the amplifier to acquire an IP address

dynamically. The acquired IP address will then be displayed on the touch screen in the

top right-hand corner.

i

Note: The port number is 10001 and a DCHP server is required to address the

amplifier.

To assign a static IP to the ampli fier, you must first esta blish a re mote conn ection. Once

connected, type the command Settings to enter the User Settings Mode. Once in this

mode, you can enter the command Edit to begin configuring the static IP settings. The

Edit Settings Values are as follows:

CBA Manual: H012161 Rev: 3 21

8.5 USB Connection

Note: A USB cable with an FTDI chip set is required for this form of communication.

FTDI drivers are required to assign the USB interface a virtual com port. If these are

not installed on the PC in use they can be downloaded from,

http://www.ftdichip.com/FTDrivers.htm

Ensure the drivers are loaded and installed on the PC in use before connecting via

USB. With the amplifier powered down connect to the USB interface. Power the

amplifier up and the interface will be assigned a virtual com port. The COM Port

number can be discovered as per the RS232 method (8.3). Again, a terminal

application will be required to communicate with the amplifier using the same setting

as per the RS232 method (8.3)

Page 22

Amplifier Status Commands

MODEL

Display Unit Model

SN

Display Unit Serial Number

*IDN?

Model, S/N, Firmware Version

*RST

Restarts the Amplifier

STATUS

Display Amplifier Status Message

FAULT

Display Amplifier Fault

RESET, RE

Reset Amplifier Fault

*SCREENSHOT

Takes a screenshot of the display

Amplifier Operate Commands

ON, OP, OPRT, RFOP, RFON

Turns the Amplifier On

OFF, STBY, OF, STB, RFOF

Turns the Amplifier Off

BAND_STAT US

Query Current Amplifier Band

BAND1

Switch to Band 1

BAND2

Switch to Band 2

Amplifier Pulse Commands

PULSEW

Display Pulse Width

DUTYCYC

Display Duty Cycle

FRQNCY

PERIOD

CW_ON

Switch to CW Operation

PLS_ON

Switch to Pulse Operation

PLS/CW_STATUS

Query current mode

Amplifier Temperature Metering Commands

TEMP-BASE

Query the Amplifiers Base Plate

Temperature

TEMP-AMB

Query the Amplifiers Ambient

Temperature

Amplifier Elapsed Time Metering Commands

TOTALH

Total Amplifier ON Hours

OPERATEH

Total Amplifier OPERATE Hours

8.6 Remote Command Set

CBA Manual: H012161 Rev: 3 22

Page 23

Amplifier RF Power Metering Commands

POWERFWD

Report FWD Power (Watts)

POWERFWDDB

Report FWD Power (dBm)

POWERRFL

Report RFL Power (Watts)

POWERRFLDB

Report RFL Power (dBm)

RP

Report Power (FWD, RFL)

Amplifier Gain Control

GAIN

Display Gain Level

SETGAINxxx

Set specific gain level

ZEROATTN

Set Gain to 100%

FULLATTN

Set Gain to 0%

ATTUxxx

Attenuation Up

ATTDxxx

Attenuation

Amplifier Power Supply Metering Commands

PS1V

Power Supply 1 Voltage

PS1I

Power Supply 1 Current

PS2V

Power Supply 2 Voltage

PS2I

Power Supply 2 Current

PS3V

Power Supply 3 Voltage

PS3I

Power Supply 3 Current

PS4V

Power Supply 4 Voltage

PS4I

Power Supply 4 Current

Amplifier Power Supply Metering Commands

PAIALL

Display all PA Currents

PA1I

Module 1 Current

PA2I

Module 2 Current

PA3I

Module 3 Current

PA4I

Module 4 Current

PA5I

Module 5 Current

PA6I

Module 6 Current

PA7I

Module 7 Current

PA8I

Module 8 Current

IPAIALL

Display all IPA Currents

IPA1I

Intermediate Power Module 1 Current

IPA2I

Intermediate Power Module 2 Current

CBA Manual: H012161 Rev: 3 23

Page 24

iiCAUTION!

Do not use cleaning materials that leave a residue or that are abrasive for

cleaning the RF connectors, as this seriously degrades their performance.

iiCAUTION!

Operating the ampl

to overheat.

9 ROUTINE MAINTENANCE

9.1 General cleaning

For cleaning the front panel, use an anti-static foam cleaner and a soft lint-free cloth or

tissue. Using abrasive materials or strong solvents may damage the surface finish or

the front panel overlay.

9.2 RF connectors

If the RF connectors are used frequently, or left disconnected for long periods, there is

a tendency for dirt and oxide deposits to build up. This increases the contact

resistance and creates localised heating of the RF OUT connector pin, which may

cause damage on high power models. Periodically inspect the inner pins of the RF

connectors for damage or deposits, and carefully clean if required.

When storin g the amplifier for long periods, the RF connectors should be pr otected

with the plastic covers provided.

9.3 Air-filter cleaning.

ifier with the air-filter clogged, may cause the amplifier

The air-intake-filter on the amplifier front panel should periodically be checked for

cleanliness. If it is seen to be obstructed with any dust or debris this should be cleaned

away before the amplifier is operated.

CBA Manual: H012161 Rev: 3 24

Page 25

10 FAULT FINDING

i

i

10.1 General checks

These are simple checks the user can perform to establish the cause of any amplifier

malfunction. The following procedures are by no means comprehensive, and do not

disclose any obscure fault with the amplifier or any system it may form a part of.

Amplifier Won’t Power Up at Mains Switch on.

x Ensure that the line cord is properly installed.

x Ensure that the line cord or connector is not damaged.

x Ensure that the 3-phase line circuit-breaker (model dependent) and front panel

rocker switch is switched on.

x Ensure that the line circuit-breaker is not in the tripped condition.

i

Note: If the line circuit-breaker trips, there is a fault with the power supply and the

amplifier must be returned to TESEQ for repair. There are no user-replaceable fuses

in the amplifier.

No RF Output

x Ensure that the correct safety interlock signal is present. If the Interlock facility is

not used, ensure that the Interlock shorting-link (rear panel) is inserted.

x Ensure that the touch screen Operate/Standby button is illuminated green.

x Ensure that the RF cables and connectors are mated correctly.

x Ensure that there is no damage to any of the RF connectors or cables, especially

where the cable enters the connector.

x Ensure that the touch screen FLT/RST fault light is not illuminated red.

x Ensure that the RF input level is within specification.

RF present but at reduced level

x Ensure that the gain control is set to 100%

x Ensure that the RF cables and connectors are mated correctly.

x Ensure that the inner pins of the RF connectors are clean.

x Ensure that the RF load is 50 ohms.

x Ensure that there is no damage to any of the RF connectors or cables, especially

where the cable enters the connector.

x Ensure that the RF input level is within specification and that the gain adjustment is

set as expected.

Note: If the above checks have been done and the RF output is still at reduced level,

there is probably a fault with the RF modules, in which case the amplifier must be

returned to TESEQ for repair.

CBA Manual: H012161 Rev: 3 25

Page 26

i

i

Amplifier not responding to remote commands

x Ensure that the remote connector is mated properly.

x Ensure that the ‘REMOTE’ indicator is illuminated on the touch screen. If not, send

a, “OPRT” command.

x Ensure that there is no damage to the remote connector or cable, especially

around where the cable enters the connector.

10.2 Fault indications

HIGH VSWR

High VSWR is seen when high levels of output power are reflected into the amplifier.

The internal diagnostics determine if this state exists.

Note: The amplifier will not be damaged by using it with a high VSWR. It might be

i

that the load naturally has a poor VSWR – this just means that the full output power of

the amplifier cannot be delivered to the load. The function of the indication is not to

protect the amplifier. It is there to alert the operator that there has been a change in

the system operating conditions.

x Ensure that the RF cables and connectors are mated correctly.

x Ensure that the RF load is 50 ohms.

x Ensure that the inner pins of the RF connectors are clean.

x Ensure that there is no damage to any of the RF connectors or cables, especially

around where the cable enters the connector.

Interlock

Is indicated on the display in the amplifier status section when the continuity of the

safety interlock circuit is broken, or the interlock control signal is not present.

x Ensure that there is continuity through the safety interlock switch and wiring (if

used).

x Ensure that the safety interlock connector or shorting-link is properly mated.

x Ensure that the safety interlock control signal is present.

Note: If no external safety interlock switch or control signal is used, connect the

safety interlock shorting-link (rear panel).

Power Supply fault

When the power supply voltage or current is outside operational limits, a power supply

fault is illuminated and the system enters standby mode.

x Ensure that the power supply air-filter insert is not clogged or obstructed. Clean as

necessary.

x Ensure that the ambient temperature is within the amplifier specification.

x Ensure that there is at least the recommended clearance around the front and rear

panel air vents.

CBA Manual: H012161 Rev: 3 26

Page 27

i

i

x Ensure that for amplifier models with multiple line-input connectors, all connectors

are connected to the line supply.

x Ensure that for models with more than one power supply, that all the rear panel

circuit breakers are set to the ON position.

i

Note: If the supply fault indicator is due to a high-temperature condition, cool the

power-supply by leaving the amplifier in, “STANDBY” mode. The power-supply

cooling fan (internal to the power-supply) can then reduce the power-supply

temperature. If the supply fault indicator remains illuminated when the power-supply

has cooled down, return the amplifier to TESEQ for repair.

Thermal Fault

A thermal fault is indicated on the display in the amplifier fault section when the

temperature of the modules has risen above operational limits.

x Ensure that both rear panel fans are operating and not obstructed.

x Ensure that the air-filter inserts are not clogged or obstructed. Clean or replace if

necessary.

x Ensure that the amplifier is not operating in direct sunlight.

x Ensure that the ambient temperature is within the amplifier specification.

x Ensure that there is at least the recommended clearance around the front and rear

panel air vents.

Note: To cool the RF modules down, leave the amplifier in the RF STANDBY

condition so the cooling fans can reduce the RF module temperature. If the fans are

not operating, or this indicator remains illuminated when the RF modules have cooled

down, return the amplifier to TESEQ for repair.

If, after fault-finding, problems persist, contact TESEQ by telephone, fax or E-mail. It

may be necessary to return the equipment to TESEQ for repair. See the Appendix 2

for details on how to do this.

CBA Manual: H012161 Rev: 3 27

Page 28

11 WARRANTY

Teseq Ltd. Warrants that this product is free from defects in materials and

workmanship for a period of:

x Three years on standard products

x one year on specifically designed products

11.1 Definitions

“Standard” means TESEQ commercial product which, from time to time, appears in its

official marketing literature. It precludes product specifically designed to a Customer

requirement.

11.2 Scope

TESEQ warrants to the owner of any standard, CBA-B, power amplifier product,

purchased from TESEQ, its authorised dealers or resellers, that it will be free from

defects in material and workmanship for a period of 3 years from the date of original

shipment.

Should you encounter a problem within your first 3 years of ownership, we will have

the unit collected and guarantee to apply our reasonable endeavours to have it

repaired, and available for return, within 48 hours (6 working days) following receipt at

our facility. All costs associated with the activity will be borne by TESEQ Ltd.

It is necessary for Customers to comply with the terms and conditions laid out below

so that they may enjoy the benefits of the warranty.

In order to obtain service under this warranty, the Customer must notify TESEQ. (or

one of its agents) of the defect before the expiration of the warranty period, using the

‘Returns Form’ from this handbook (or a photocopy of it).

11.3 Terms and conditions

TESEQ, or one of its authorised service centres, will, at its option, repair or replace

any unit or component covered by this warranty which becomes defective, or

malfunctions, under normal use / service during the period of this warranty, at no

charge for parts, labour or shipping to the owner.

Components, or units, replaced under the terms of the warranty shall continue to have

the benefit of the unexpired portion of the warranty only.

CBA Manual: H012161 Rev: 3 28

Page 29

This warranty does not cover damage from customer accidents, misuse, abuse,

misapplication, operation with incorrect AC voltage, operation with faulty associated

equipment, unauthorised use by third parties other than the original customer,

modification or alteration without prior factory approval, service by an unauthorised

Service Centre and performance deterioration which will occur due to normal usage.

Units on which the serial number, or anti-tamper labels, has been removed or defaced

are not eligible for warranty service. Evidence of alteration, erasing, or forgery of

proof-of-purchase documents will be cause to void the warranty.

Units damaged due to the absence of routine maintenance, as defined by TESEQ in

the product handbook, are not eligible for warranty service.

When product is to be returned for warranty service a return authorisation number

must first be obtained from TESEQ. A description of the problem, as specific as

possible, should be attached to the request for the return authorisation number.

11.4 Transfer of Warranty

This warranty can be transferred to any new owner by informing TESEQ within 30

days of ownership transfer.

TESEQ may, at its discretion, request that the amplifier is first returned to the factory,

freight prepaid, to establish the condition of the amplifier and suitability for continuing

warranty cover. Failure to notify TESEQ Ltd within 30 days will be cause to void the

warranty.

11.5 Protection of Warranty

To protect your warranty, we recommend you:

x Ensure the product is serviced in accordance with the guidance laid out in the

product handbook.

x Avoid unauthorised modifications to the product

Report any faults to TESEQ, or the nearest authorised dealer, as soon as they

occur.

CBA Manual: H012161 Rev: 3 29

Page 30

11.6 Repair form

NAME OF DISTRIBUTOR:

AMPLIFIER BEING RETURNED FROM:

MODEL No:

SERIAL No:

PART No:

SHIPPING AGENT BEING USED:

EXPECTED DATE OF ARRIVAL AT TESEQ:

NATURE OF FAULT:

WHEN DID THE FAILURE OCCUR:

For TESEQ Use Only:

Teseq GmbH

Teseq Inc / AMETEK CTS

Landsberger Straße 255

52 Mayfield Avenue

12623 Berlin

Edison, New Jersey, 08837, USA

Telephone: +49 30 5659 880

Telephone: +1 732 417 0501

mailto:service.rf.cts@ametek.com

usasupport.cts@ametek.com

RETURN OF EQUIPMENT TO TESEQ

REPAIR DETAIL

Works Order No:

Please use this form for ALL amplifiers being returned for repair. Please give as many

details as possible.

CBA Manual: H012161 Rev: 3 30

Returns No:

Page 31

3 DRAWING SPECIFICATIONS

13.1 Fig 1, 3U front Panel & Outline Drawing

CBA Manual: H012161 Rev: 3 31

Page 32

13.2 Fig 2, 4U Front Panel & Outline Drawing

CBA Manual: H012161 Rev: 3 32

Page 33

13.3 Fig 3, 6U Front Panel & Outline Drawing

CBA Manual: H012161 Rev: 3 33

Page 34

13.4 Fig 4, 10U Front Panel Drawing

This configuration consists of a 7U power amplifier draw & 3U power supply draw

CBA Manual: H012161 Rev: 3 34

Page 35

CBA Manual: H012161 Rev: 3 35

Page 36

14 DATASHEET SPECIFICATIONS

http://www.teseq.co.uk/products/CBA-1G-030B.php

http://www.teseq.co.uk/products/CBA-1G-070B.php

http://www.teseq.co.uk/products/CBA-1G-150B.php

http://www.teseq.co.uk/products/CBA-1G-300B.php

http://www.teseq.co.uk/products/CBA-1G-600B.php

http://www.teseq.co.uk/products/CBA-1G-1200B.php

http://www.teseq.co.uk/products/CBA-3G-050B.php

http://www.teseq.co.uk/products/CBA-3G-100B.php

http://www.teseq.co.uk/products/CBA-3G-300B.php

http://www.teseq.co.uk/products/CBA-3G-500B.php

http://www.teseq.co.uk/products/CBA-6G-035C.php

http://www.teseq.co.uk/products/CBA-6G-075C.php

http://www.teseq.co.uk/products/CBA-6G-040B.php

http://www.teseq.co.uk/products/CBA-6G-080B.php

http://www.teseq.co.uk/products/CBA-6G-120B.php

CBA Manual: H012161 Rev: 3 36

Loading...

Loading...