Alto Shaam RH Installation Manual

Recirculating Hood

Installation, Operation, and Maintenance Manual

Save these instructions

RECEIVING AND INSPECTION

WARNING!!

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free.

Installation of this unit should only be performed by a qualified professional who has read and

understands these instructions and is familiar with proper safety precautions. Read this

manual thoroughly before installing or servicing this equipment.

. This document is the property of the owner of this equipment and is

required for future maintenance. Leave this document with the owner when installation or

service is complete.

November 2008 Rev. 1

2

TABLE OF CONTENTS

WARRANTY ............................................................................................................................................ 3

LISTINGS ................................................................................................................................................ 4

INSTALLATION ....................................................................................................................................... 4

Site Preparation .................................................................................................................................. 4

Mechanical Installation ........................................................................................................................ 5

Table 1 – Clearances ...................................................................................................................... 5

Hanging Dimensions ....................................................................................................................... 6

Hanging Details ............................................................................................................................... 6

Electrical ............................................................................................................................................. 7

Electrical Connections ..................................................................................................................... 7

Copper Wire Ampacity .................................................................................................................... 7

OPERATION ........................................................................................................................................... 8

Start Up Procedure .............................................................................................................................. 8

Components ........................................................................................................................................ 8

Hood Switch Plate ........................................................................................................................... 8

Electrical Board ............................................................................................................................. 10

On-Delay Timer ............................................................................................................................. 11

Off-Delay Timer ............................................................................................................................. 11

Airflow Switch ................................................................................................................................ 11

High Temperature Limit ................................................................................................................. 12

Filters ............................................................................................................................................ 12

Filter Stages .................................................................................................................................. 12

Filter Part Numbers ....................................................................................................................... 12

Stage 1 – High Efficiency Baffle Filter ............................................................................................ 13

Stage 1 – Captrate Solo Baffle Filter .............................................................................................. 13

Stage 2 – HEPA Filter ................................................................................................................... 13

Stage 3 – Charcoal Filter ............................................................................................................... 13

Troubleshooting ................................................................................................................................ 14

Troubleshooting Chart ................................................................................................................... 14

MAINTENANCE .................................................................................................................................... 15

General Maintenance ........................................................................................................................ 15

Weekly Maintenance ......................................................................................................................... 15

Quarterly Maintenance ...................................................................................................................... 15

Start-Up and Maintenance Documentation ........................................................................................ 16

Job Information ............................................................................................................................. 16

Hood Information ........................................................................................................................... 16

Maintenance Record ..................................................................................................................... 16

Factory Service Department .......................................................................................................... 16

3

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 12 months from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation

instructions shipped with the product,

2. The equipment is not installed in accordance with federal, state and local codes and regulations,

3. The equipment is misused or neglected,

4. The equipment is not operated within its published capacity,

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization, and all returned equipment shall be

shipped by the BUYER; freight prepaid to a destination determined by the MANUFACTURER.

4

LISTINGS

FOLLOW SMACNA GUIDES AND RECOMMENDATIONS FOR THE HANGING AND

This hood is ETL listed to standard UL-710B and EPA test method 202 when installed in accordance with

these installation instructions and National Fire Protection Association Standard “NFPA 96, Standard for

Ventilation Control and Fire Protection of Commercial Cooking Operations.”

INSTALLATION

It is imperative that this unit is installed and operated with the designed airflow, filters and construction in

accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE

OR MAINTAINANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

WARNING: THIS PRODUCT IS NOT PROVIDED WITH AN INTEGRAL FIRE

EXTINGUISHING SYSTEM. AUTHORITIES HAVING JURISDICTION SHOULD BE

CONSULTED AS TO THE REQUIREMENTSFOR THIS EQUIPMENT WITH RESPECT

TO FIRE EXTINGUISHING SYSTEMS, SUCH AS THE NEED FOR FIELD

INSTALLED SYSTEMS IN ACCORDANCE WITH NFPA 96.

Site Preparation

1. Provide clearance around installation site to safely rig and lift equipment into its final position.

Consider general service and installation space when locating unit.

2. Thoroughly review the plans and specifications of the project.

3. Determine the exact location in which the cooking hood will be installed and verify that there are

no interferences, which will prevent proper installation.

4. Verify that all overhead beams and angles are structurally strong enough to support the weight of

the hood and hanging system. It is often necessary to strengthen existing structural beams, as

they are not designed to carry the weight of a stainless steel hood. Refer to the project submittal

drawing for hood weight(s). It may also be necessary to create a support structure suspended

from the ceiling joists to better align with the desired hood location.

5. Determine if adequate room is available to install the hood with proper clearances from

combustible material. IMC, NFPA96 and local authorities having jurisdiction call for a minimum

clearance (typically 18 inches) between the cooking hood(s) and building materials, which are

combustible. However, IMC and NFPA96 outline acceptable clearance reduction methods. It is

important to check with the local authority having jurisdiction to determine that the installation

method is satisfactory to meet their requirements prior to installing the equipment.

INSTALLATION OF HOODS.

5

Mechanical Installation

The following is a step-by-step procedure for installation of the Recirculating Hood:

1. Uncrate the hood, being very careful not to dent or scratch the outer surface. NOTE: Report any

damage to the delivering freight carrier and file a claim if appropriate. Refer to the

installation drawing for typical details of the ventilation system prior to hanging the hood. Check

the nameplate on the equipment to make certain it meets the specifications provided by the

architect and/or engineer. If discrepancies exist, notify the manufacturer immediately.

2. It’s important that you have read and understand “Site Preparation” before continuing with the

installation of the hood. See Table 1 “Clearances.”

3. Determine the exact location of the hood. Ensure support beams are structurally strong enough to

support the weight of the hood. The structural integrity of the structural support system is

the responsibility of the contractor and the structural engineer

4. Use 5/16-18 threaded rod to hang the hood. Drill 3/8” holes in the structural support system or

use Unistrut® to line up with the pre-punched holes on the hood. See Figure 1 for details.

5. Each corner of the hood has a pre-punched hole. It is important that the 5/16-18 threaded rod

that will be used to suspend the hood is secured at these locations. Each hole has a 14 gauge

steel support plate that is riveted to the inside of the lid to strengthen the hood corners. Do not

remove or relocate these plates.

6. Raise the hood into position using high lifts or equipment jacks at each end of the hood to ensure

the hood is level. When the hood is elevated to the proper height, install 5/16-18 threaded rod

between the hood support plates and the modified supports in the ceiling. Secure the threaded

rod with 5/16-18 large flanged nuts and appropriate sized fender washers above and below

hanging angles and hood support plates.

7. Make final adjustments as needed to ensure that the hood is level. Maintain tension on all the

rods to ensure hood weight is evenly distributed. Make fine adjustments to the height of the hood

by simply moving the hardware up and down the threaded rod.

8. For further information detailing installation and dimensional data. See Figure 1 & 1A.

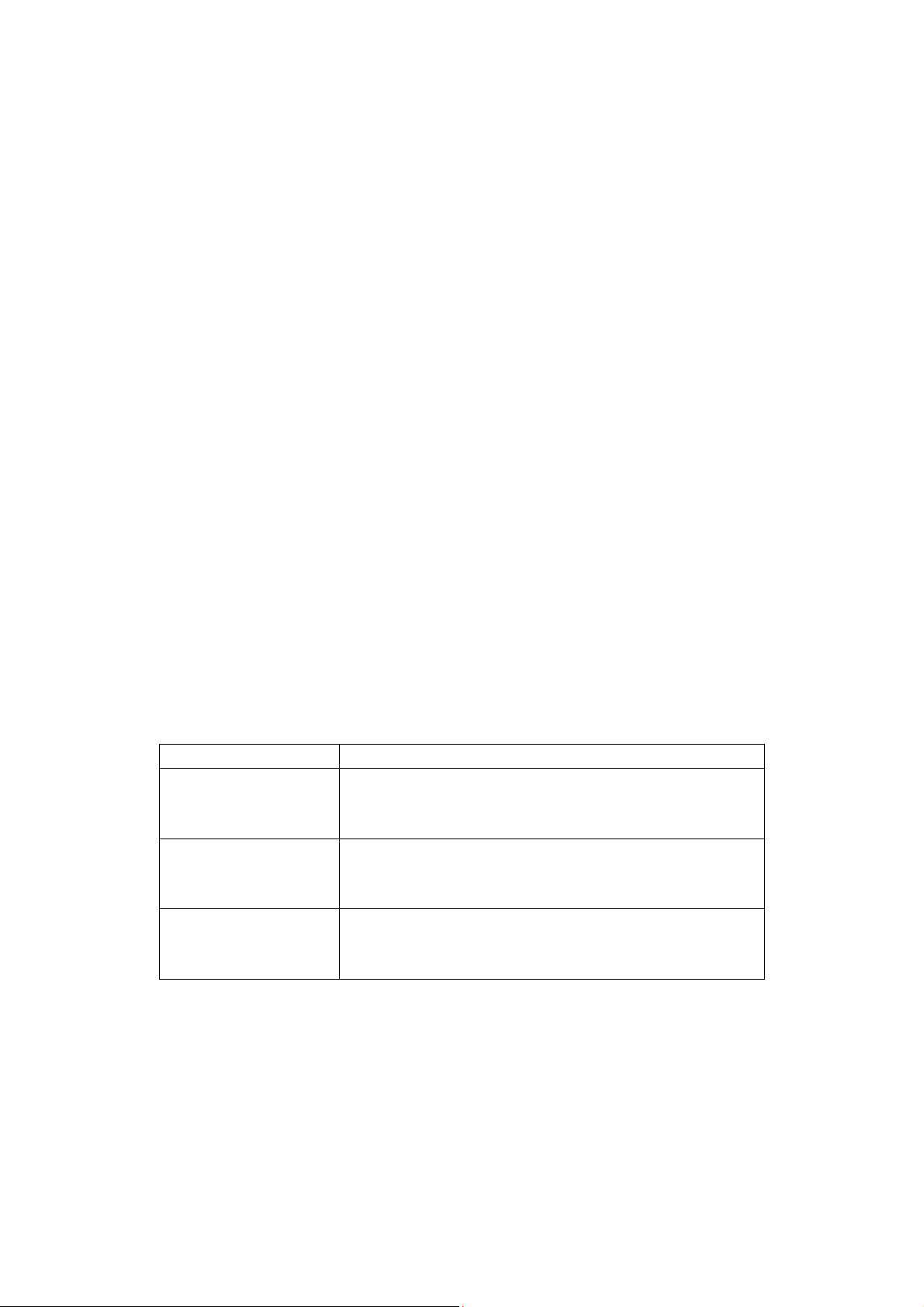

Table 1 – Clearances

Equipment Type Clearances

Ovens

Conveyor Ovens

Rotisseries

6" maximum from hood skirt bottom to door top.

1" minimum from hood skirt bottom to oven top.

6" minimum hood skirt over hang to heated oven door.

30" maximum from hood skirt bottom to top of conveyor belt.

1" minimum from hood skirt bottom to oven top.

6" minimum hood skirt over hang to heated oven door.

6" maximum from hood skirt bottom to door top.

1" minimum from hood skirt bottom to oven top.

6" minimum hood skirt over hang to heated oven door.

Loading...

Loading...