Alto-Shaam Quickchiller User Manual

uickchiller

™

Q

Imagine how much easier and more efficient food

production would be if you could remove a

number of items from your daily production

schedule and reschedule production of those

products to once or twice a week. That's just one

of the many benefits derived from chill processing

with the use of an Alto-Shaam Quickchiller.

Chill processing not only provides an improved

production schedule, it also gives you better

control over the number of portions you use and

that results in less product waste. You gain a

five-day refrigerated storage life for the foods

processed in a Quickchiller. Five days of

production inventory, including the day of

preparation and the day of service, would be a

big advantage to any food service operation.

A variety of fully cooked foods, made from fresh

ingredients, chilled, and held under refrigeration

takes only minutes to rethermalize back to a

serving temperature. After reheating, chilled foods

are just as tasty as their freshly prepared

counterparts. Many foods often improve in quality

when seasonings are allowed to cure and natural

flavors combine to enhance the taste of a product.

Whether chill processing is used for several of

your more labor-intensive menu items; a number

of items cooked fresh and used on a daily basis;

or where all items are prepared, chilled, and

rethermalized in bulk or portion sizes; the

benefits provide you with significant advantages.

Chill processing has grown far beyond the needs

of institutional markets and large banqueting

facilities to encompass all areas of food

preparation that are faced with labor shortages

and rising costs. With a variety of sizes and

product chilling capacities, there is a

Quickchiller available to handle any productionprocessing requirement to ease hectic

production schedules.

Why

Cook

Chill?

Production Efficiency

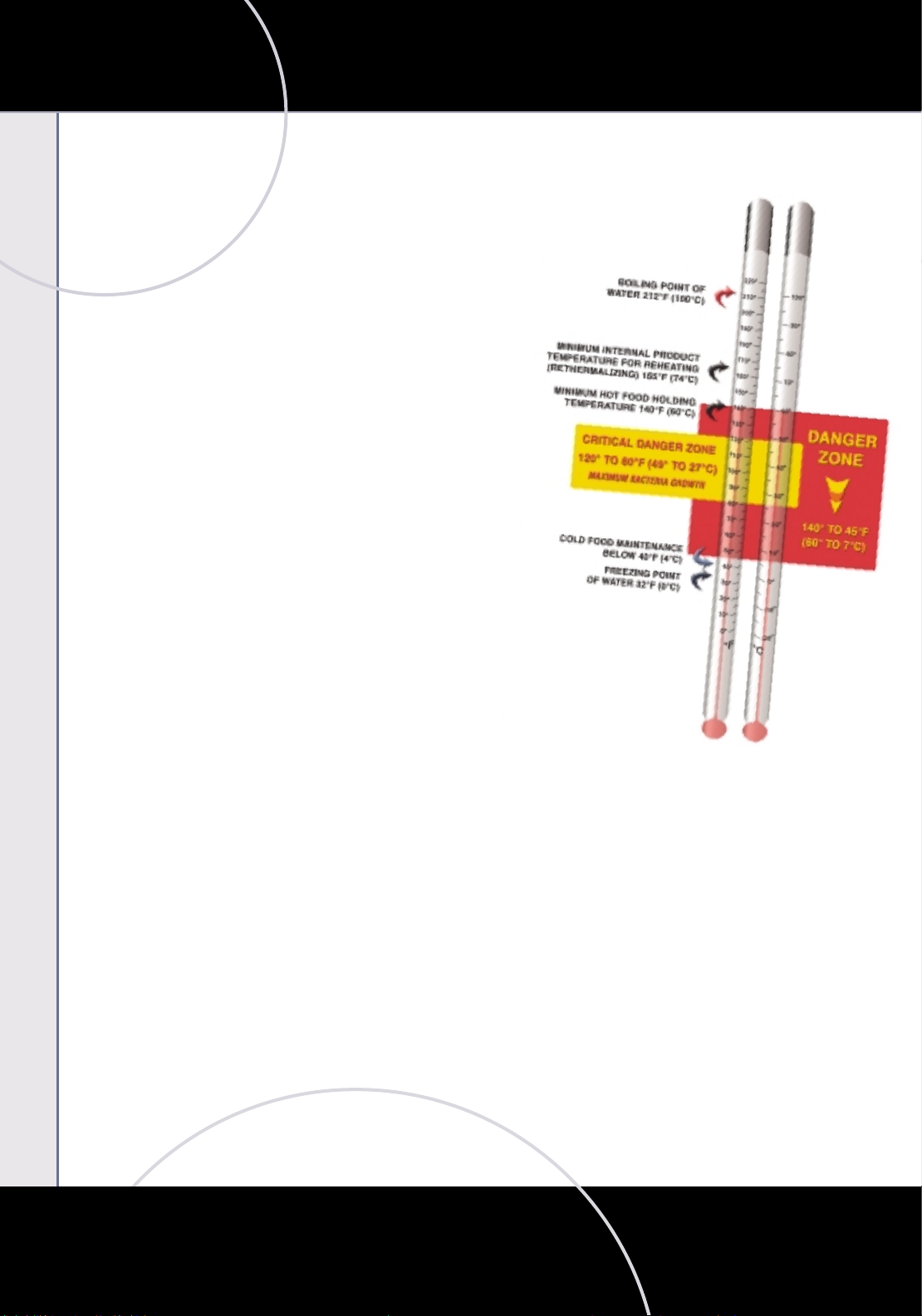

A single incident of a food borne outbreak

can have a devastating effect on any food

service operation. Food borne illness

causes an estimated 10,000 or more

preventable deaths every year. It has also

been estimated that more than half of all

food borne illnesses within the United

States is directly related to improper hot

food cooling methods. Outside of

sterilization, it would be virtually

impossible to eliminate all microbiologic

contamination from food. Sterilization

would also destroy all sensory aspects of

food such as taste, color, and texture, along

with most of the nutrients.

Conventional storage refrigerators are

not engineered nor equipped to rapidly

remove heat from large loads of hot food.

Consequently, hot foods take much longer

to cool, remain within the danger zone for

a longer period of time, and are at greater

risk of becoming contaminated. This

situation can result in loss of sanitation

and loss of product.

The rapid reduction of hot food

temperatures reduces the opportunity for

bacterial growth. Chilling specific foods

directly from the cooking process within

a prescribed amount of time is also a

general requirement of state and local

health (hygiene) organizations and falls

under HACCP guidelines.

Quick chilling is the process of rapidly

reducing food temperature by directing

high velocity cold air above and below each

pan of food. This balanced heat removal

process transfers food temperature quickly

through the danger zone, greatly reducing

bacterial growth. Reduction of bacterial

growth and associated toxins provides an

extended refrigerated holding life and a

much greater measure of safety. Studies

have shown that properly processed

cook/chill products show no appreciable

bacterial growth for a full five days,

including the day the product was cooked.

Enhanced

Food Safety

Loading...

Loading...