Page 1

◆

PowerBlade

Chassis

®

AT-PBC18

Installation

Guide

PN 613-50144-00 Rev C

Page 2

Copyright 2002 Allied Telesyn, Inc.

960 Stewart Drive Suite B, Sunnyvale, CA 94085 USA

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesyn, Inc.

Netscape Navigator is a regist ered trademark of Netscape Communications Corporation. All other product names, company

names, logos or other designations mentioned herein are trademarks or registered trademarks of their respective owners.

Allied Telesy n, Inc. rese rves t he r ight t o mak e chan ges i n spec ifica tion s and ot her i nform ation c ont ained i n this doc ument w ithout

prior written notice. The information provided herein is subject to change without notice. In no event shall Allied Telesyn, Inc. be

liable for any incidental, special, indirect, or consequential damages whatsoever, including but not limited to lost profits, arising

out of or related to this manual or the information contained herein, even if Allied Telesyn, Inc. has been advised of, known, or

should have known, the possibility of such damages.

Page 3

Electrical Safety and Emission Compliance

Statement

Standards: This product meets the following standards:

U.S. Federal Communications Commission

Radiated Energy

Note: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with this instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a res identia l area is li kely to caus e harmful inte rference in which case t he user will be required t o

correct the interference at his own expense.

Note: Modifications or changes not expressly approved by the manufacturer or the FCC can void your right to operate this

equipment.

Industry Canada

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

RFI Emission EN55022 Class A, EN61000-3-2, EN61000-3-3

Warning: In a domestic environment this product may cause radio interference in which case the user may be required to take

adequate measures.

Immunity EN55024

Electrical Safety EN60950, UL 1950 (UL/cUL)

Laser EN60825

Important: Appendix A contains translated safety statements for installing this equipment. When you see the

A for the translated safety statement in your language.

Wichtig: Anhang A enthält übersetzte Sicherheitshinweise für die Installation dieses Geräts. Wenn Sie

Anhang A den übersetzten Sicherheitshinweis in Ihrer Sprache nach.

Vigtigt: Tillæg A indeholder oversatte sikkerhedsadvarsler, der vedrører installation af dette udstyr. Når De ser symbolet

De slå op i tillæg A og finde de oversatte sikkerhedsadvarsler i Deres eget sprog.

Belangrijk: Appendix A bevat vertaalde veiligheidsopmerkingen voor het installeren van deze apparatuur. Wanneer u de

raadpleeg Appendix A voor vertaalde veiligheidsinstructies in uw taal.

Important: L'annexe A contient les instructions de sécurité relatives à l'installation de cet équipement. Lorsque vous voyez le

symbole

Tärkeää: Liite A sisältää tämän laitteen asentamiseen liittyvät käännetyt turvaohjeet. Kun näet

turvaohjetta liitteestä A.

Importante: l’Appendice A contiene avvisi di sicurezza tradotti per l’installazione di questa apparecchiatura. Il simbolo

di consultare l’Appendice A per l’avviso di sicurezza nella propria lingua.

Viktig: Tillegg A inneholder oversatt sikkerhetsinformasjon for installering av dette utstyret. Når du ser

for å finne den oversatte sikkerhetsinformasjonen på ønsket språk.

Importante: O Anexo A contém advertências de segurança traduzidas para instalar este equipamento. Quando vir o símbolo

leia a advertência de segurança traduzida no seu idioma no Anexo A.

Importante: El Apéndice A contiene mensajes de seguridad traducidos para la instalación de este equipo. Cuando vea el símbolo

!, reportez-vous à l'annexe A pour consulter la traduction de ces instructions dans votre langue.

! 2

! 3

! 4

! 5

!-symbolin, katso käännettyä

! 1

!, go to Appendix

! sehen, schlagen Sie in

!, skal

! ziet,

!, indica

!, åpner du til Tillegg A

!,

!, vaya al Apéndice A para ver el mensaje de seguridad traducido a su idioma.

Obs! Bilaga A innehåller översatta säkerhetsmeddelanden avseende installationen av denna utrustning. När du ser

till Bilaga A för att läsa det översatta säkerhetsmeddelandet på ditt språk.

!, skall du gå

3

Page 4

Page 5

Table of Contents

Preface ......................................................................................................................................................................................................................9

How This Guide is Organiz ed .............................................................................................................................................................................9

Where to Find Related Guides .........................................................................................................................................................................11

Document Conventions ................................................ ....................................................................................................................................12

Contacting Allied Telesyn Technical Support ................ ............................................................................................................................13

Online Support..............................................................................................................................................................................................13

Telephone Suppor t........ ......................... .....................................................................................................................................................13

E-mail Support..... ..........................................................................................................................................................................................13

Returning Products .............................................................................................................................................................................................14

FTP Server ...............................................................................................................................................................................................................15

For Sales or Corporate Information ...... .........................................................................................................................................................16

Tell Us What You Think ......................................................................................................................................................................................17

Chapter 1

Overview ................................................................................................................................................................................................................19

PowerBlade PBC18 Chassis ...............................................................................................................................................................................19

Key Features...................................................................................................................................................................................................20

Status LEDs .....................................................................................................................................................................................................21

Power Supply.................................................................................................................................................................................................22

Optional Management Module...............................................................................................................................................................23

Chapter 2

Installing the Chassis on a Desktop or in a Rack .................................................................................................................................25

Overview .................................................................................................................................................................................................................25

Verifying Package Contents......................................................................................................................................................................25

Preparing the Site......................................................... .................................................... ............................................................................26

Reviewing Safety Precaut io ns............. .....................................................................................................................................................26

Installing the Chassis on a Desktop ............................................................................. ..................................................................................28

Installing the Chassis in a Rack ................................................................................. .......................................................................................29

Warranty Registration .........................................................................................................................................................................................31

Chapter 3

Installing a Power Supply Module .............................................................................................................................................................33

Overview .................................................................................................................................................................................................................33

Installing a Main Power Supply ............................... ........................................................................................................................................35

Installing an Optional Power Su pply .................................................................................. ..........................................................................40

Hot Swapping a Power Supply ................... .....................................................................................................................................................42

5

Page 6

Table of Contents

Chapter 4

Installing a Media Converter Module ......................................................................................................................................................43

Overview ................ ............ ............ ................. ............ ............. ................ ............. ..................................................................................................44

Common Features ...............................................................................................................................................................................................45

MDI/MDI-X......................................................................................................................................................................................................45

Link Test/MissingLink......................... ........................................................................................................................................................46

Half-duplex and Full-duplex Mode .......................................................................................................................................................48

Network Topologies ....................... ............................................................................................................................................................49

AT-PB10 Series Modules ...................................................................................................................................................................................51

Status LEDs.................... .................................................................................................................................................................................52

BNC Termination Switch (AT-PB15 only).............................................................................................................................................53

J5 Jumper (AT-PB15 only).........................................................................................................................................................................54

Cable Specifications....................................................................................................................................................................................55

AT-PB100 Series Modules ............................. ...................................................... ..............................................................................................56

Status LEDs.................... .................................................................................................................................................................................58

Cable Specifications....................................................................................................................................................................................58

100Base-FX Fiber Optic Port Specifications.......................................................................................................................................61

Auto-negotiation Swit ch........... ................................................................................................................................................................63

AT-PB300 Series Modules ............................. ...................................................... ..............................................................................................65

Status LEDs.................... .................................................................................................................................................................................66

Cable Specifications....................................................................................................................................................................................67

Auto-negotiation Swit ch........... ................................................................................................................................................................68

AT-PB1000 Series Module ....................................................................................................... .........................................................................69

Status LEDs.................... .................................................................................................................................................................................70

Link Test Back-to-back/ St andalone Button.................... ...................................................................................................................71

Cable Specifications....................................................................................................................................................................................71

Installing a Media Converter ...........................................................................................................................................................................73

Hot Swapping a Media Converte r ............. ....................................................................................................................................................76

Chapter 5

Installing a Switch Module ...........................................................................................................................................................................77

Overview ................ ............ ............ ................. ............ ............. ................ ............. ..................................................................................................77

Features...........................................................................................................................................................................................................79

Switch Performance....................................................................................................................................................................................80

Frame Processing .........................................................................................................................................................................................80

Address Recognition and Filte ring........................................................................................................................................................80

Status LEDs.................... .................................................................................................................................................................................81

MDI/MDI-X......................................................................................................................................................................................................81

DIP Switches............. .....................................................................................................................................................................................82

J6 Jumper........................................................................................................................................................................................................83

Network Topologies ....................... ............................................................................................................................................................84

Cable Specifications....................................................................................................................................................................................85

Installing a Switch ...............................................................................................................................................................................................89

Hot Swapping a Switch .....................................................................................................................................................................................92

Chapter 6

Installing an Optional Management Module ......................................................................................................................................93

Overview ................ ............ ............ ................. ............ ............. ................ ............. ..................................................................................................93

Features...........................................................................................................................................................................................................94

Status LEDs.................... .................................................................................................................................................................................95

Reset Button..................................................................................................................................................................................................95

Cable Specifications....................................................................................................................................................................................95

Installing an Optional Managem ent Module ............................. ...............................................................................................................96

6

Page 7

PowerBlade PBC18 Installatio n Guid e

Chapter 7

Troubleshooting ................................................................................................................................................................................................99

Chassis .................... .................... ................. ..................... ................ ..................... ...................................................................................................99

Media Converter or Switch Module ....................... .....................................................................................................................................100

Optional Management Module ..................... ..............................................................................................................................................101

Appendix A

Technical Specifications ..............................................................................................................................................................................103

Physical Characteristics .... ...............................................................................................................................................................................103

Power Requirements .......................................................................................................................................................................................103

Agency Certifications .......................................................................................................................................................................................103

Appendix B

Translated Safety Information .................................................................................................................................................................105

7

Page 8

Page 9

Preface

This installation guide contains instructions on how to install a

PowerBlade PBC18 on a desktop or in a 19-, 23- or 25-inch rack and how

to install the PowerBlade Series Modules.

How This Guide is Organized

This guide contains the following chapters and appendices:

Chapter 1, Overview, describes the features and functions of the

PowerBlade PBC18 Chassis.

Chapter 2, Installing the Chassis on a Desktop or in a Rack, explains how

to install the chassis on a desktop or in a rack.

Chapter 3, Installing a Power Supply Module, explains how to install a

main and optional power supply module into the chassis.

Chapter 4, Installing a Media Converter Module

and functions of the PowerBlade Media Converter modules and contains

installation instructions.

Chapter 5, Installing a Switch Module

functions of the PowerBlade Switch modules and contains installation

instructions.

Chapter 6, Installing an Optional Management Module, contains

instructions on how to install an optional management module.

Chapter 7, Troubleshooting, provides troubleshooting information for

the chassis and modules.

, describes the features and

, describes the features

Appendix A, Technical Specifications, provides technical specifications

for the chassis.

9

Page 10

Preface

Appendix B, Translated Safety Information, contains multi-language

translations of the safety and emission statements in this guide.

10

Page 11

Where to Find Related Guides

The Allied Telesyn web site at www.alliedtelesyn.com offers you an easy

way to access the most recent documentation, software, and technical

information for all of our products.

The following guides are shipped with their respective products and

contain abbreviated versions of the installation procedures:

❑ AT-PBC18 Quick Install Guide,

PN 613-50145-00

❑ AT-PB10 Seri es Quick Install Guide

PN 613-50146-00

❑ AT-PB100 Series Quick install Guide

PN 613-50147-00

❑ AT-PB200 Series Quick Install Guide

PN 613-50148-00

PowerBlade PBC18 Installation Guide

❑ AT-PB300 Series Quick Install Guide

PN 613-50198-00

❑ AT-PB1000 Ser ies Quick Install Guide

PN 613-50149-00

❑ AT-PBM02 Quick Install Guide

PN 613-50172-00

❑ AT-PBPWRAC Quick Install Guide

PN 613-50166-00

❑ AT-PBPWRDC Quick Install Guide

PN 613-50189-00

❑ PowerBlade Rackmount Brackets Quick Install Guide,

PN 613-50230-00

If you purchased a PowerBlade Optional Management module, you will

need the following guide:

❑ AT-S31 User’s Guide

PN 613-50205-00

The AT-S31 User’s Guides provides information and instructions for

managing the chassis and modules. This guide can be downloaded from

Allied Telesyn’s web site.

11

Page 12

Preface

Document Conven tions

This guide uses the following conventions:

Note

Notes provide additional information.

Warning

Warnings inform that performing or omitting a specific action may

result in bodily injury.

Caution

Cautions inform you that performing or omitting a specific action

may result in equipment damage or loss of data.

12

Page 13

PowerBlade PBC18 Installation Guide

Contacting Allied Telesyn Technical Support

You can contact Allied Telesyn technical support online or by telephone

or e-mail.

Online Support You can request technical support online by accessing the Knowledge

Base from our web site at http:\\kb.alliedtelesyn.com. You can use the

Knowledge Base to submit questions to our technical support staff and

review answers to previously asked questions.

Telephone

Support

For Technical Support by telephone, contact Allied Telesyn at one of the

following locations:

Americas

United States, Canada, Mexico,

Central America, South America

Tel: 1 (800) 428-4835

Asia

Singapore, Taiwan, Thailand,

Malaysia, Indonesia, Korea,

Philippines, China,

India, Hong Kong

Tel: (+65) 3815-612

Australia

New Zealand

Tel: 1 (800) 000-880

France

Belgium, Luxembourg, The

Netherlands, Middle East, Africa

Tel: (+33) 1-60-92-15-25

Germany

Switzerland, Austria, Eastern Europe

Tel: (+49) 30-435-900-126

Italy

Spain, Portugal, Greece, Turkey,

Israel

Tel: (+39) 02-41-30-41

Japan

Tel: (+81) 3-3443-5640

United Kingdom

Denmark, Norway, Sweden, Fi nland,

Iceland

Tel: (+44) 1-235-442560

E-mail Support Latin America, Mexico, Puerto Rico, Caribbean, and Virgin Islands

latin_america@alliedtelesyn.com

Europe

support_europe@alliedtelesyn.com

13

Page 14

Preface

Returning Products

Products for return or repair must first be assigned a Return Materials

Authorization (RMA) number. A product sent to Allied Telesyn without a

RMA number will be returned to the sender at the sender’s expense.

To obtain an RMA number, contact Allied Telesyn’s Technical Support at

one of the following locations:

❑ North America

Toll-free: 1-800-762-1664

Fax: 1-425-806-1050

❑ Europe, Africa, and the Middle East

Tel: +44-1793-501401

Fax: +44-1793-431099

❑ Latin America, the Caribbean, an d Virgin Islands

Tel: International code + 425-481-3852

Fax: International code + 425-481-3895

❑ Puerto Rico

Toll-free: 1-800-424-5012, ext 3852

or 1-800-424-4284, ext 3852

❑ Mexico

Toll-free: 800-424-5012, ext 3852

Fax: International code + 425-481-3895

❑ Asia and Southeast Asia

Tel: +65 381-5612

Fax: +65 383-3830

❑ Australia

Toll-free: 1-800-000-880

Fax: 2-9438-4966

❑ New Zealand

Toll-free: 0800-45-5782

14

Page 15

FTP Server

PowerBlade PBC18 Installation Guide

If you need management software for an Allied Telesyn managed device

and you know the file name of the software, you can download the

software by connecting directly to our FTP server at

ftp.alliedtelesyn.com. At login, enter ‘anonymous’ as the user name and

your e-mail address for the password.

15

Page 16

Preface

For Sales or Corporate Information

You can contact Allied Telesyn for sales or corporate information at the

location listed below:

Allied Telesyn, Inc.

19800 North Creek Parkway, Suite 200

Bothell, WA 98011

Tel: 1 (425) 487-8880

Fax: 1 (425) 489-9191

16

Page 17

Tell Us What You Think

If you have any comments or suggestions on how w e might improve this

or other Allied Telesyn documents, please fill out the General Enquiry

Form online. This form can be accessed by selecting “Contact Us” from

www.alliedtelesyn.com.

PowerBlade PBC18 Installation Guide

17

Page 18

Page 19

Chapter 1

Overview

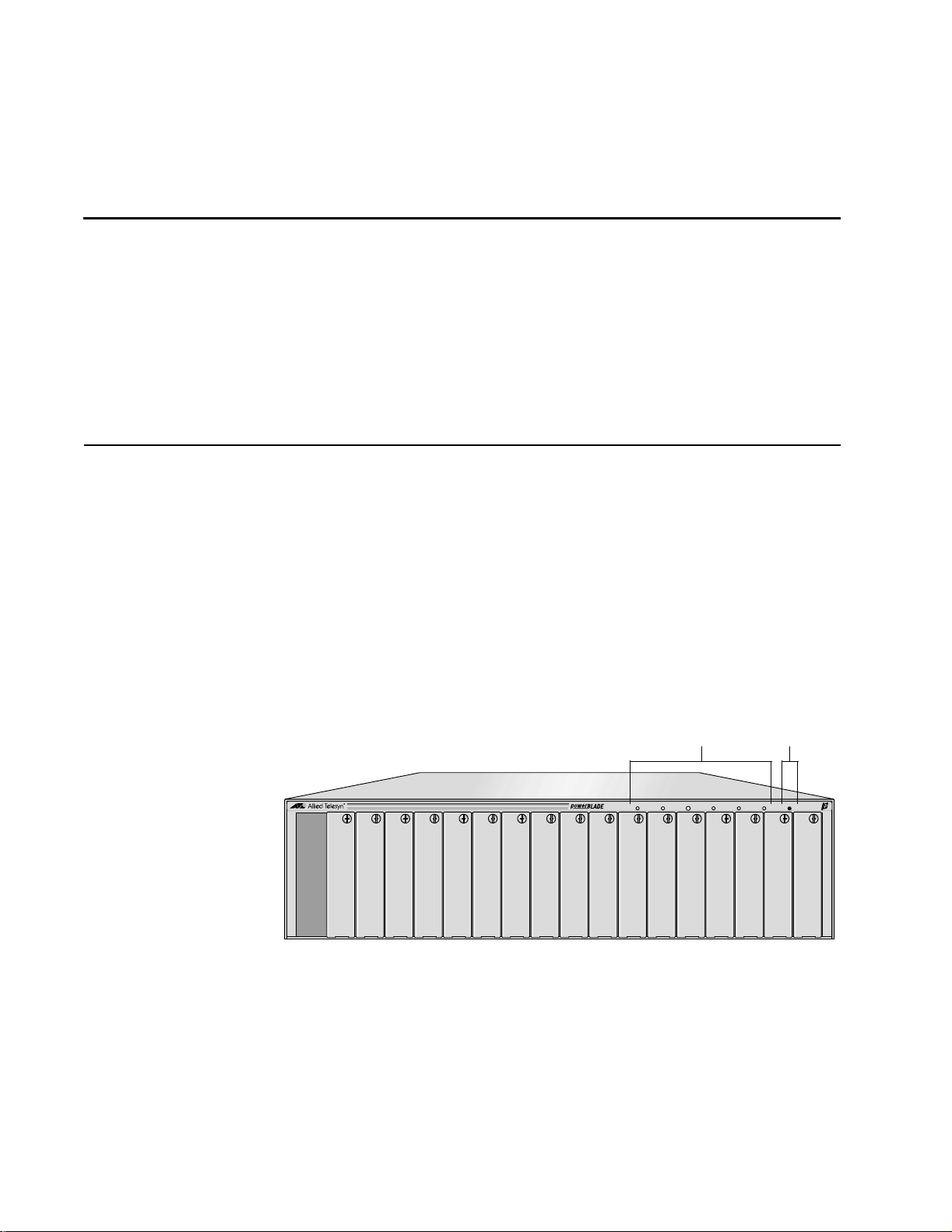

PowerBlade PBC18 Chassis

The PowerBlade PBC18 is an 18-slot chassis that is designed to hold up

to 18 PowerBlade Media Converter modules and Switch modules. The

chassis can be used on a desktop or in a 19-, 23- or 25-inch rack.

The front of the chassis has 18-slots for the PowerBlade modules along

with six LEDs to notify you of power and management status. The

chassis also has a Reset button that allows you to reset the optional

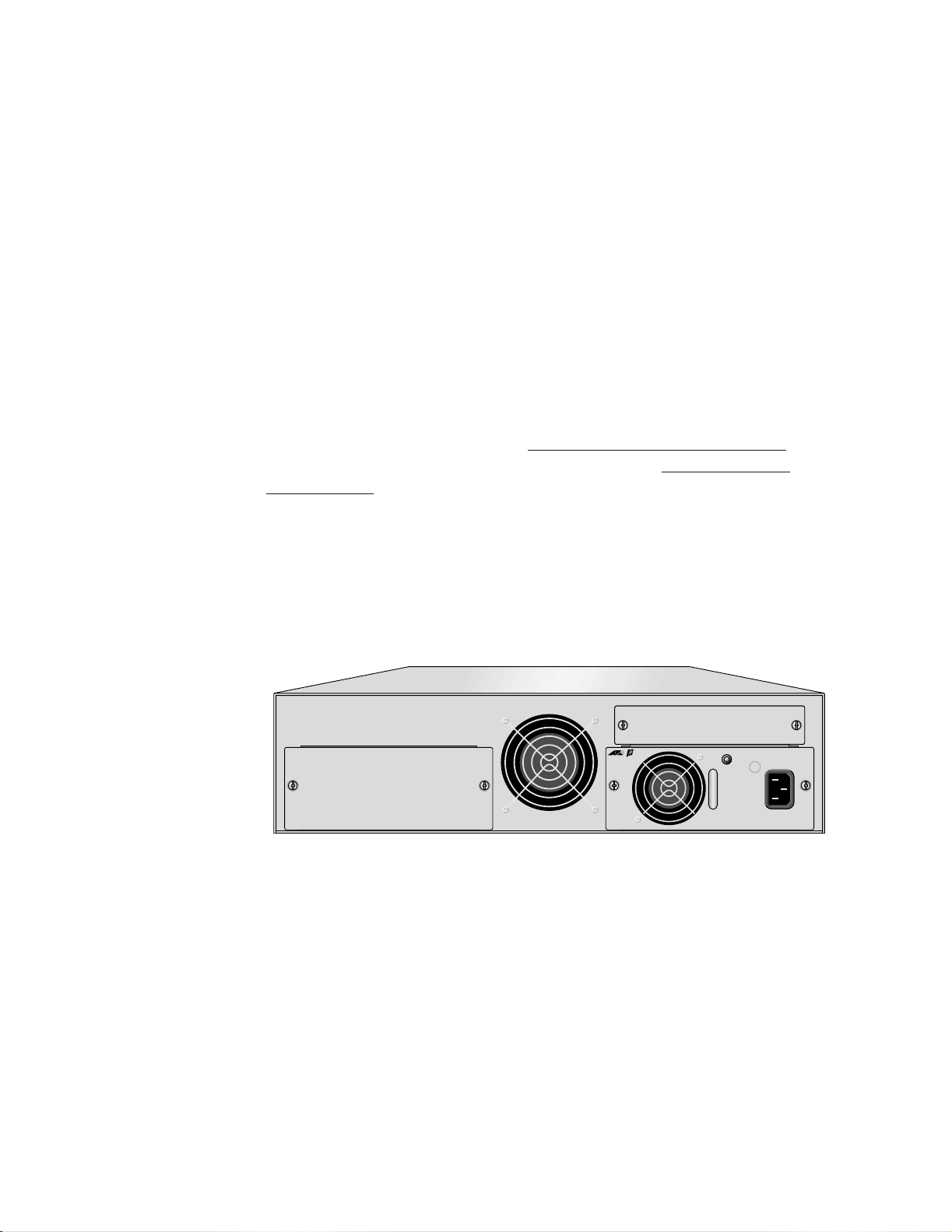

management module. (See Figure 1.) The back of the chassis features a

PWR 1 expansion slot for the main power supply, a PWR 2 expansion slot

for an optional redundant power supply module, and an optional

management module expansion slot. (See Figure 2.)

Status LEDs

PWR 1 PWR 2 STATUS LINK 100M FDX RESET

PBC18

Figure 1 PowerBlade PBC18 Front View

Reset Button

19

Page 20

Overview

Optional Management

Module Expansion Slot

PBM02

Management

PWR

RESET

LNK

STATUS

PWR 2 PWR 1

RS-232 Terminal 10Base-T

MDI

MDI-X

Main Power SupplyOptional Power Supply

Expansion Slot (PWR 2) Expansion Slot (PWR 1)

Figure 2 PowerBlade PBC18 Back View

Key Features ❑ 18-slots to “mix and match” hot swappable PowerBlade modules

❑ LEDs on the front of the chassis for power and management

status

❑ Desktop or rackmount installation

❑ Front mounted Reset button (for use with the management

module only)

20

❑ Hot swappable AC or DC power supplies

❑ An expansion slot for the main power supply and an optional

redundant power supply

❑ One expansion slot for an optional management module

Page 21

PowerBlade PBC18 Installation Guide

Status LEDs Table 1 defines the power and management LEDs.

Table 1 Status LEDs

LED Color Description

Power Modules

PWR1 Green The main power supply is functioning

normally.

PWR2 Green The optional redundant power supply, if

installed, is functioning normally.

Management Module

Status Amber The module is performing a self-test.

Flashing

Amber

The module is d ownloa ding t he f irmwar e from

a host PC.

Red The module or management software is

malfunctioning.

Green The module is installed and online.

LINK Green A valid link has been detected on the RJ-45

port.

100M Not used at this time.

FDX Not used at this time.

21

Page 22

Overview

Power Supply The PowerBlade PBC18 can be either an AC or DC powered chassis. The

expansion slot for the main power supply and the optional redundant

power supply are located on the back of the chassis. Refer to Figure 2 on

page 20.

The main and redundant power supplies can be “hot swapped,”

meaning that should either power supply fail, the failed power supply

can be removed and replaced with a new power module while the

chassis is operating. Network operations will not be interrupted. The

power modules to be hot swapped must be the same type. For example,

both power supplies must be AC or both must be DC.

Powering ON or OFF the chassis depends on the type of power supply

installed. For an AC model, you connect or disconnect the power cord.

For a DC model, you connect or disconnect the DC power cables or

power OFF the DC circuit to which the power supply is connected.

To install a power supp l y , refer to Installing a P ower Supply Modu le on

page 33. For instructions on hot swapping, refer to Hot Swapping a

Power Supply on page 42.

AC Power Supply

The AC power supply operates at 100-120/200-240 V AC with an input

frequency of 50/60 Hz at ± 3%. Figure 3 shows an PowerBlade PBC18

with an AC power supply.

LNK

AC INPUT

100-240AC

50-60Hz

3A MAX.

150W

PBM02

Management

PWR

RESET

STATUS

RS-232 Terminal 10Base-T

MDI

MDI-X

PBPWRAC

PWR 2 PWR 1

Figure 3 PowerBlade PBC18 with an AC Power Supply

22

Page 23

PowerBlade PBC18 Installation Guide

DC Power Supply

The DC power supply has a 48 V DC terminal block connector. Figure 4

shows an PowerBlade PBC18 with a DC power supply.

Optional

Management

Module

PWR

LNK

STATUS

DC INPUT

36-60VDC , 1.0A

PBM02

Management

RESET

PWR 2 PWR 1

PBPWRDC

RS-232 Terminal 10Base-T

MDI

MDI-X

FOR CENTRALIZED DC

POWER CONNECTION,

INSTALL ONLY IN A

RESTRICTED AREA

Figure 4 PowerBlade PBC18 with a DC Power Supply

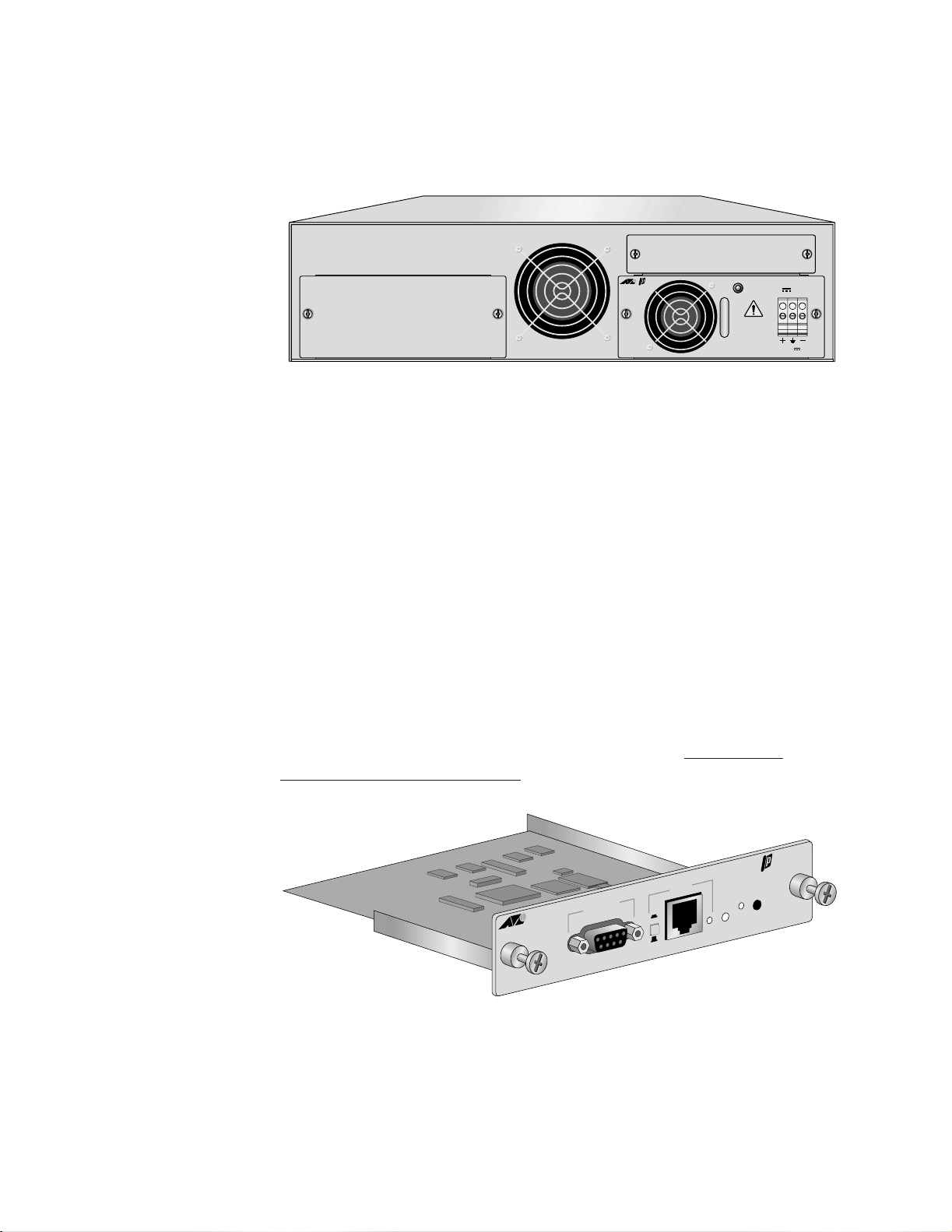

The management module is an optional module used to monitor the

operating status of the media converters and switches installed the

PowerBlade PBC18. Refer to Figure 2 on page 20 for the location of the

expansion slot. The management module is not required for the chassis

to operate, but it is necessary if you want to locally or remotely monitor

and configure the modules and ports.

The management module features a Link, Power, and Status LEDs, as

well as a Reset button. (See Figure 5.) The LEDs and the Reset button are

duplicated on the front of the chassis for easy monitoring or to reset the

management module. You may need to reset the module after

completing the installation, adding or hot swapping a power supply, or

after upgrading the module’s firmware.

To install an optional management module, ref er to Ins tall in g an

Optional Management Module on page 93.

M

10Base-T

RS-232 Terminal

I

D

M

X

-

I

D

M

R

T

E

W

S

P

E

R

S

U

T

A

T

S

K

N

L

Figure 5 Optional Management Module (AT-PBM02 Model)

PBM02

ent

anagem

23

Page 24

Page 25

Chapter 2

Installing the Chassis on a Desktop

or in a Rack

This chapter contains the following procedures:

❑ Installing the Chassis on a Desktop on page 28

❑ Installing the Chassis in a Rack on page 29

Overview

Verifying Package

Contents

Make sure the following items are included in your package. If items are

missing or damaged, contact your Allied Telesyn sales representative for

assistance.

❑ One PowerBlade PBC18 Chassis

❑ One rackmounting kit

❑ Four protective rubber feet (for desktop installation only)

❑ PowerBlade PBC18 Quick Install Guide

❑ Warranty card

25

Page 26

Installing the Chassis on a Desktop or in a Rack

Preparing the Site Be sure to observe the following guidelines when planning the

installation of your chassis.

❑ Make sure that the chassis’ power is accessible and cables can be

easily connected.

❑ Cables must be away from sources of electrical noise such as

radios, transmitters, broadband amplifiers, power lines,

fluorescent or halogen light fixtures.

❑ Air flow around the chassis and through its vents on the side and

rear should not be restricted.

❑ If you are using the chassis on a desktop, make sure it is placed on

a level, secure surface.

❑ Do not place objects on top of the chassis.

❑ Do not expose the chassis to moisture or water.

❑ Make sure the chassis is in a dust-free environment.

Reviewing Safety

Precautions

❑ Use dedicated power circuits or power conditioners to supply

reliable electrical power to the network devices.

Please review the following safety precautions before you install the

chassis and the PowerBlade modules. (The first warning applies only if

you purchased a module with a fiber optic port.)

Warning

Do not stare into the laser beam. ! 7

Warning

Electric Shock Hazard: To prevent electric shock, do not remove

the cover. There are no user-serviceable parts inside. The unit

contains hazardous voltages and should only be opened by a

trained and qualified technician. ! 8

Warning

Lightning Danger: Do not work on this equipment or cables

during periods of lightning activity. ! 9

26

Caution

Power cord is used as a disconnection device: To de-energize

equipment, disconnect the power cord. ! 10

Page 27

PowerBlade PBC18 Installation Guide

Warning

Electrical-Type Class 1 Equipment: This equipment must be

earthed. The power plug must be connected to a properly wired

earth ground socket outlet. An improperly wired socket outlet

could place hazardous voltages on accessible metal parts. ! 11

Caution

Pluggable Equipment: The socket outlet should be installed near

the equipment and should be easily accessible. ! 12

Caution

Air vents: The air vents must not be blocked on the unit and must

have free access to the room ambient air for cooling. ! 13

Caution

Operating Temperature: This product is designed for a maximum

ambient temperature of 40°C. ! 14

Caution

All Countries: Install this product in accordance with local and

National Electric Codes. ! 15

Caution

Lithium Battery - Should only be changed by trained and qualified

technician.

Danger of explosion if battery incorrectly replaced. Replace only

with the same or equivalent type recommended by the

manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

Attention: IL y a danger d’explosion s’ily y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du même

type ou d’un type recommandé par le constructeur. Mettre au rébut

les batteries usagés conformement aux instructions du fabricant.

! 21

27

Page 28

Installing the Chassis on a Desktop or in a Rack

Installing the Chassis on a Desktop

This section explains how to install the chassis on a desktop. To install

the chassis in a rack, refer to Installing the Chassis in a Rack on page 29.

For desktop installation, perform the following procedure:

1. Remove all the items from the shipping package and store the

packaging material in a safe location. In case you need to return the

chassis to Allied Telesyn, you will need to ship the unit back using as

much of the original packaging material as possible.

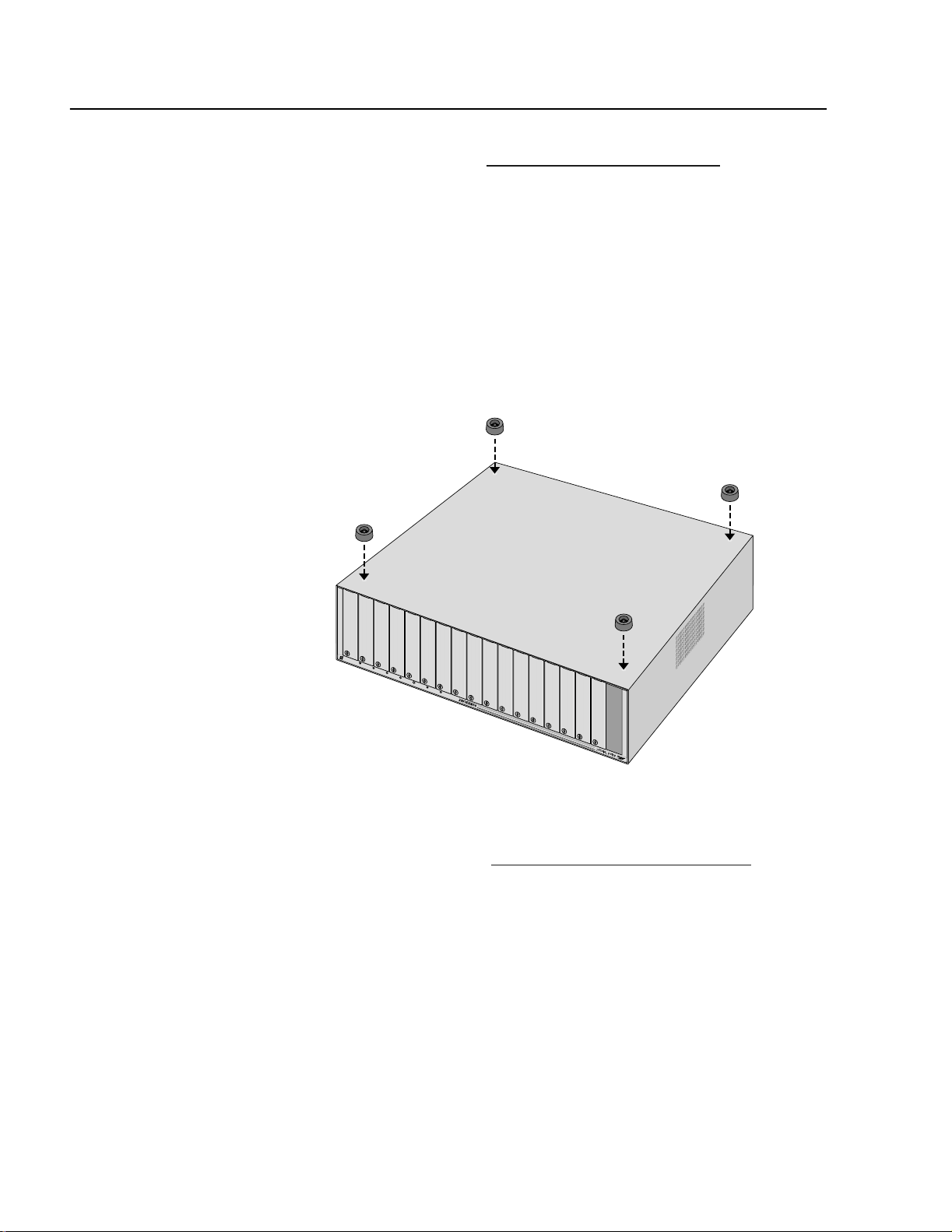

2. Place the chassis upside down on a level, secure surface.

3. Attach one of the protective rubber feet to each corner of the

chassis, then turn the unit right side up. See Figure 6.

T

E

S

E

R

X

D

MF

0

0

1

K

IN

L

S

U

T

A

T

S

2

R

W

P

1

R

W

P

8

1

C

B

P

Figure 6 Attaching the Protective Rubber Feet

4. Apply power to the chassis by connecting the AC power cord or DC

wires. Refer to Chapter 3, Install ing a Power Supply Module

on page

33 for instructions.

28

Page 29

Installing the Chassis in a Rack

The chassis can be installed in a 19-, 23-, or 25-inch rack. It is

recommended that you install the chassis in the rack before installing

the PowerBlade modules.

For rackmount installation, perform the following procedure:

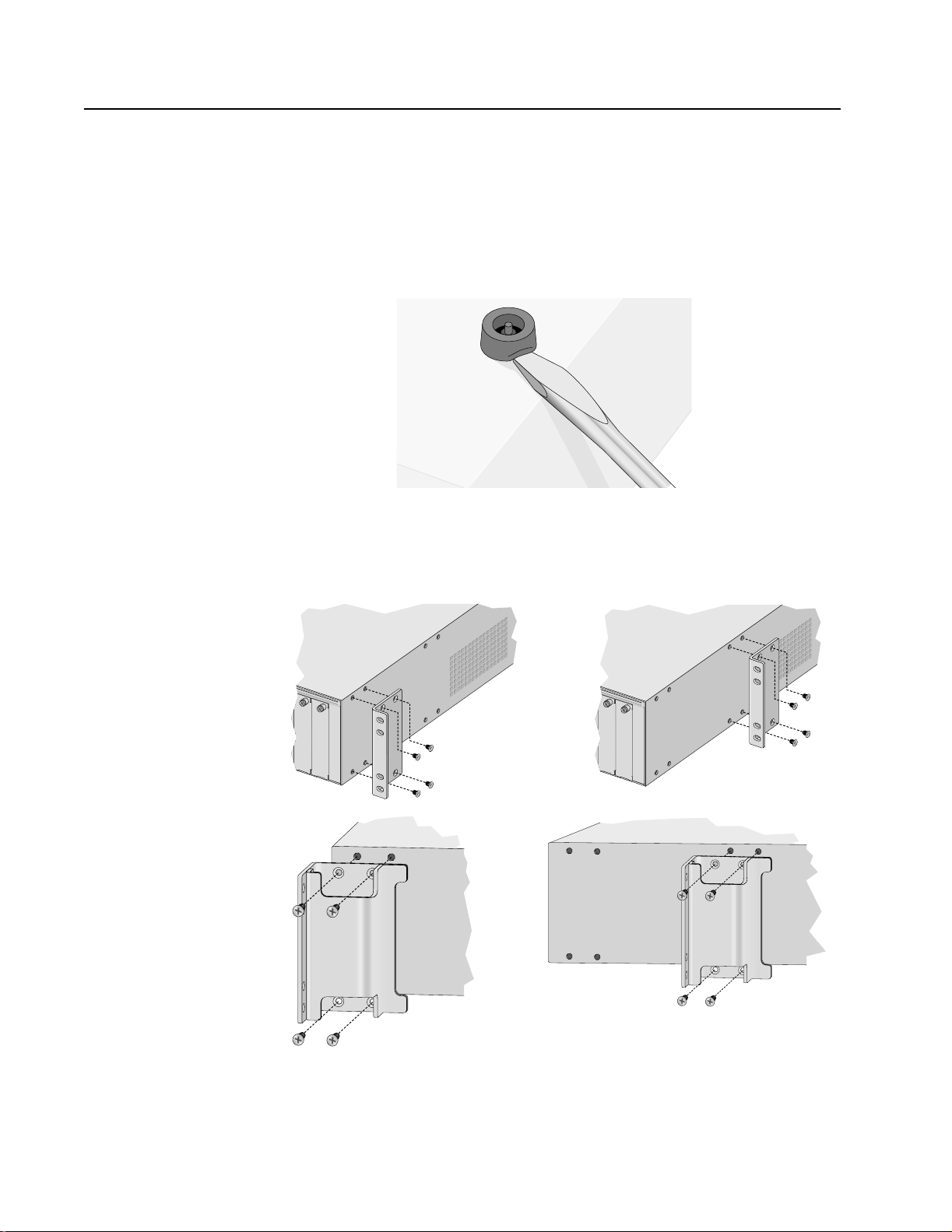

1. Remove the protective rubber feet from the bottom of the chassis, if

attached, as shown in Figure 7.

PowerBlade PBC18 Installation Guide

Figure 7 Removing the Protective Rubber Feet

2. Attach the brackets to either the front or middle of the side of the

chassis, as shown in Figure 8.

19-inch Bracket

Installation A

19-inch Bracket

Installation B

23- and 25-inch

Bracket Installation B

23- and 25-inch

Bracket Installation A

Figure 8 Attaching the Brackets to the PowerBlade PBC18

29

Page 30

Installing the Chassis on a Desktop or in a Rack

Note

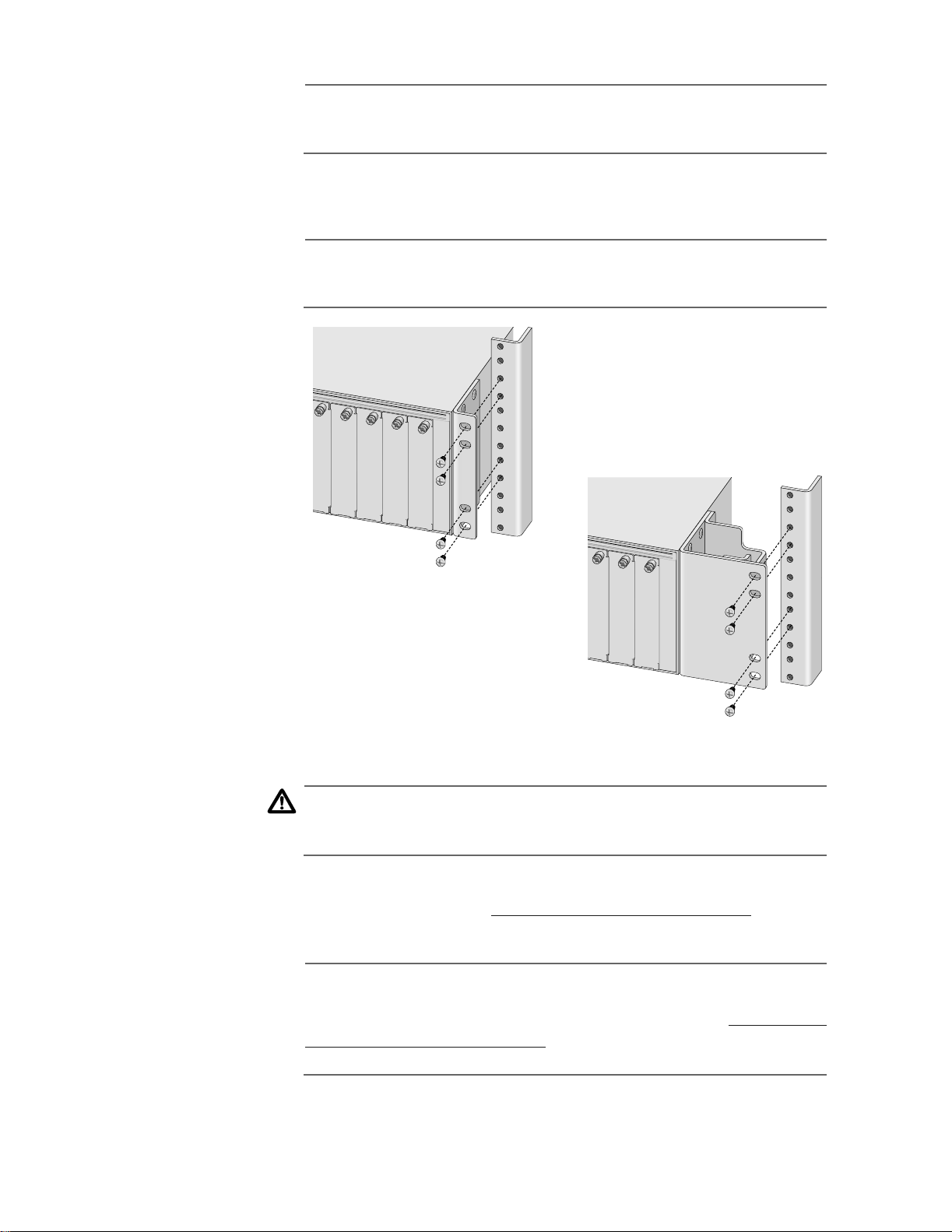

The chassis may be heavy and awkward to lift. It is recommended

that you get assistance with the next step.

3. Attach the chassis to the rack with 4 screws (not provided) for each

side. Refer to Figure 9.

Note

The brackets are designed to be installed in the center of a 3U high

opening on a standard rack.

19-inch Version

23- and 25-inch Version

Figure 9 Installing the Chassis in a Rack

Caution

Power cord is used as a disconnection device. To de-energize

equipment, disconnect the power cord. ! 10

4. Apply power to the chassis by connecting the AC power cord or DC

wires. Refer to Chapter 3, Install ing a Power Supply Module on page

33 for instructions.

Note

If you purchased an optional management module, install the

module before applying power to the chassis. Refer to Installing an

Optional Management Module on page 93 for installation

instructions.

30

Page 31

Warranty Registration

When you have finished installing the product, you should register your

product by completing the enclosed warranty card and sending it in.

PowerBlade PBC18 Installation Guide

31

Page 32

Page 33

Chapter 3

Installing a Power Supply Module

This chapter describes of the features and functions of the PowerBlade

Power Supply modules. This chapter also contains the following

procedures:

❑ Installing a Main Power Supply on page 35

❑ Installing an Optional Power Supply on page 40

❑ Hot Swapping a Power Supply on page 42

Overview

There are two types of power modules available for the PowerBlade

PBC18: an AT-PBPWRAC and an AT-PBPWRDC. The AT-PBPWRAC is an AC

power supply module and the AT-PBPWRDC is a DC power supply

module.

Figure 10 illustrates an AC power supply module.

Power LED

PBPWRAC

AC INPUT

100-240AC

50-60Hz

3A MAX.

150W

AC Connector

Figure 10 AT-PBPWRAC Power Supply Module

33

Page 34

Installing a Power Supply Module

Figure 11 illustrates a DC power supply module.

Power LED

PBPWRDC

FOR CENTRALIZED DC

POWER CONNECTION,

INSTALL ONLY IN A

RESTRICTED AREA

DC INPUT

DC Terminal

Block

36-60VDC , 1.0A

Figure 11 AT-PBPWRDC Power Supply

An optional power supply share the load of powering the chassis with

the main power supply. This is known as “load-sharing.” In the event the

main power supply fails, the optional power supply will provide full

power to the chassis, thereby preventing a system failure.

The main and optional power supplies can be “hot swapped,” meaning

that should either power supply fail, the failed power supply can be

removed and replaced with a new power module while the chassis is

operating. Network operation will not be interrupted. The power

modules to be hot swapped must be the same type. You cannot install

an AC power supply and a DC power supply in the same chassis.

The back of the PowerBlade PBC18 has two expansion slots: one for the

main power supply and one for the optional power supply. The power

module installed in the PWR 1 expansion slot is for the main power

supply. The power module installed in the PWR 2 expansion slot is for

the optional power supply.

34

Powering ON or OFF the chassis depends on the type of power supply

installed. For an AC model, you connect or disconnect the power cord.

For a DC model, you connect or disconnect the DC power cables or

power OFF the DC circuit to which the power supply is connected.

Page 35

Installing a Main Power Supply

To install a main power supply, perform the following procedure:

1. Remove the PWR 1 blank faceplate from the back of the chassis by

loosening the two thumbscrews, as shown in Figure 12.

PowerBlade PBC18 Installation Guide

t

PBM02

n

e

m

e

g

a

n

a

M

-T

se

a

B

0

1

l

a

in

m

r

e

T

2

3

2

S-

R

R

PW

ESET

R

I

D

M

S

U

T

A

ST

K

N

L

I-X

D

M

Figure 12 Removing the Main Power Supply Blank Faceplate

2. Remove the power supply from the shipping package and store the

packaging material in a safe location.

3. Slide the power supply into the expansion slot, gently seating the

power supply’s connector into the chassis’ backplane. See Figure 13.

t

PBM02

n

e

m

e

g

a

n

a

M

-T

se

a

B

0

1

l

a

n

i

m

r

e

T

2

3

2

S-

R

R

PW

ESET

R

I

D

M

S

U

T

A

ST

K

N

L

I-X

D

M

Figure 13 Installing the Main Power Supply

4. Secure the power supply to the chassis by tightening the two

thumbscrews.

35

Page 36

Installing a Power Supply Module

Caution

Power cord is used as a disconnection device: To de-energize

equipment, disconnect the power cord. (AC model only.) ! 10

5. For an AC powered chassis, plug one end of the power cord to the

back of the power supply and plug the other end to a power outlet.

Proceed to Step 7 on page 39 for further instructions.

Note

If you purchased an optional management module, install the

module before applying power to the chassis. Refer to Installing an

Optional Management Module on page 93 for installation

instructions.

6. For a DC powered chassis, perform the following steps:

a. Before attaching wires to the DC terminal block on the power

supply module, review the following warning:

Warning

As a safety precaution, a 10 Amp circuit breaker should be installed

at the supply end of the cable to be used with this LAN equipment.

Always connect the wiring to the LAN equipment first before

connecting the wiring to the breaker. To avoid the danger of

physical injury from electrical shock, do not work with HOT feeds.

Always be sure that the breaker is in the OFF position before

connecting the wiring to the breaker. ! 16

36

Page 37

PowerBlade PBC18 Installation Guide

TRALIZED DC

L ONLY IN A

CTED AREA

36-60VDC , 1.0A

DC INPUT

b. Identify the positive, frame ground and negative terminals

using the positive (+), ground ( ), and negative (-) symbols on

the DC power supply. See Figure 14.

PBM02

Management

PWR

RESET

LNK

STATUS

DC INPUT

36-60VDC , 1.0A

Negative

PWR 2 PWR 1

Positive

PBPWRDC

RS-232 Terminal 10Base-T

MDI

MDI-X

FOR CENTRALIZED DC

POWER CONNECTION,

INSTALL ONLY IN A

RESTRICTED AREA

Ground

Figure 14 Positive, Ground, and Negative Symbols

c. Strip the three wires in the cable tray coming from the DC input

power source to 8 millimeters ± 1 millimeters (0.31 inches ±

0.039 inches) using a 14-gauge wire-stripping tool. See Figure

15.

Warning

Do not strip more than the recommended amount of wire.

Stripping more than the recommended amount can create a safety

hazard by leaving exposed wire on the terminal block after

installation. ! 17

8 mm ± 1 mm

(0.31 in ± 0.039 in)

Figure 15 Stripped Wire

d. Connect the frame ground wire to the terminal marked with the

ground symbol by inserting the wire into the terminal block and

tightening the connection with a flathead screwdriver. See

Figure 16.

37

Page 38

Installing a Power Supply Module

36-60VDC , 1.0A

DC INPUT

Warning

When installing this equipment, always ensure that the frame

ground connection is installed first and disconnected last. ! 18

LNK

STATUS

PBM02

Management

PWR

RESET

DC INPUT

36-60VDC , 1.0A

PWR 2 PWR 1

PBPWRDC

RS-232 Terminal 10Base-T

MDI

MDI-X

FOR CENTRALIZED DC

POWER CONNECTION,

INSTALL ONLY IN A

RESTRICTED AREA

Figure 16 Connecting the Stripped Wire

e. Connect the positive feed wire to the terminal block marked +

(positive).

f. Connect the negative feed wire to the terminal block marked -

(negative).

38

Warning

Safety Hazard - Check to see if there are any exposed copper

strands coming from the installed wires. When this installation is

done correctly there should be no exposed copper wire strands

extending from the terminal block. Any exposed wiring can

conduct harmful levels of electricity to persons touching the wires.

! 19

g. Secure the tray supply cable near the rack using multiple cable

ties (not provided). This will help minimize the chance of the

connections being disturbed by casual contact with the wiring.

It is recommended that you use at least four cable ties 10

centimeters (4 inches) apart with the first one located within 15

centimeters (6 inches) of the terminal block.

Page 39

PowerBlade PBC18 Installation Guide

Note

This system will work with a positive grounded or negative

grounded DC system. ! 20

h. Connect the three DC wires to a DC power source.

7. Check that the PWR1 LED on the front of the chassis is green. If the

LED is OFF, refer to Troubleshooting on page 99 for assistance.

The PowerBlade PBC18 is now ready for use. Proceed to Installing a

Media Converter Module on page 43 or Installing a Switch Module on

page 77 for further instructions.

39

Page 40

Installing a Power Supply Module

Installing an Optional Power Supply

To install an optional power supply, perform the following procedure:

Note

It is recommended that you connect the main and optional power

supplies to power outlets on separate power circuits to protect

your chassis from a loss of power due to a power circuit failure.

1. Remove the PWR 2 blank faceplate from the back of the chassis by

loosening the two thumbscrews, as shown in Figure 17.

PBPWRAC

02

M

B

t

P

n

e

m

e

g

na

a

M

T

-

e

s

a

B

0

1

l

a

n

i

m

r

e

T

2

3

2

-

S

R

R

T

E

W

S

P

E

R

I

D

M

S

U

T

A

T

S

K

N

L

X

-

I

D

M

T

U

P

N

I

C

A

C

A

0

4

-2

0

0

1

z

H

0

-6

0

5

.

X

A

M

A

3

W

0

5

1

PWR 1

PWR 2

Figure 17 Removing the Optional Power Supply Blank Faceplate

2. Remove the power supply from the shipping package and store the

packaging material in a safe location.

3. Slide the optional power supply into the expansion slot, gently

seating the power supply’s connector into the chassis’ backplane.

See Figure 18.

PBM02

Management

T

-

e

s

a

B

0

1

l

a

n

i

m

r

e

T

2

3

2

-

S

R

C

A

R

W

P

B

P

R

T

E

W

S

P

E

R

I

D

M

S

U

T

A

T

S

K

N

L

I-X

D

M

T

U

P

N

I

C

A

C

A

0

4

2

-

0

0

1

z

H

0

6

-

0

5

.

X

A

M

A

3

W

0

5

1

40

PWR 2

PWR 1

T

U

P

N

I

C

A

R

W

P

B

P

C

A

C

A

0

4

2

-

0

0

1

z

H

0

6

-

0

5

.

X

A

M

A

3

W

0

5

1

Figure 18 Installing an Optional Power Supply

Page 41

PowerBlade PBC18 Installation Guide

4. Secure the optional power supply to the chassis by tightening the

two thumbscrews.

Note

It is recommended that you connect the main and optional power

supplies to power outlets on separate power circuits to protect

your chassis from a loss of power due to a power circuit failure.

5. Apply power to the module by connecting the appropriate power

cord or wires. Refer to , Step 5 on page 36 for an AC unit or Step 6 on

page 36 for a DC unit.

6. Check that the PWR LED on the front of the chassis is green. If the

LED is OFF, refer to Troubleshooting on page 99.

The PowerBlade PBC18 is now ready for use. Proceed to Installing a

Media Converter Module on page 43 or Installing a Switch Module on

page 77 for further instructions.

41

Page 42

Installing a Power Supply Module

Hot Swapping a Power Supply

Both the main and optional power supplies are hot swappable. The

power modules to be hot swapped must be the same type. You cannot

install an AC power supply and a DC power supply in the same chassis.

1. To remove a failed power supply, you must power OFF the

appropriate power source. To do this, perform one of the following:

❑ For an AC model, unplug the power cord from the power outlet

and then unplug the power cord from the failed module.

❑ For a DC model, follow the steps below:

Warning

When installing this equipment, always ensure that the frame

ground connection is installed first and disconnected last. ! 18

a. Remove the positive and negative feed wires from the terminal

block by loosening the screws to the wire connections with a

flathead screwdriver.

b. Remove the frame ground wire from the terminal block by

loosening the screw to the wire connection with a flathead

screwdriver.

2. Loosen the two thumbscrews and slide out the failed power supply.

3. Remove the new power supply from the shipping package and

store the packaging material in a safe location.

4. Slide the new power supply into the expansion slot, gently seating

the power supply’s connector into the chassis’ backplane.

5. Secure the new power supply to the chassis by tightening the two

thumbscrews.

Note

It is recommended that you connect the main and optional power

supplies to power outlets on separate circuits to protect your

chassis from loss of power due to a power circuit failure.

6. Apply power to the new module by connecting the AC power cord

or DC wires. Refer to Step 5 on page 36 for an AC unit or Step 6 on

page 36 for a DC unit.

42

7. Check that the PWR LED on the font of the chassis is green. If the

LED is OFF, refer to Troubleshooting on page 99.

The new power supply is now ready for use.

Page 43

Chapter 4

Installing a Media Converter Module

This chapter describes the features and functions of the following

PowerBlade Media Converter modules:

❑ AT-PB10 Series Modules on page 51

❑ AT-PB100 Series Modules on page 56

❑ AT-PB300 Series Modules on page 65

❑ AT-PB1000 Series Module on page 69

This chapter also contains the following procedures:

❑ Installing a Media Converter on page 73

❑ Hot Swapping a Media Converter on page 76

43

Page 44

Installing a Media Converter Module

Overview

The PowerBlade Media Converters are designed to extend the distance

of your network by interconnecting LAN devices that are physically

separated by large distances.

There are several different PowerBlade modules that you can “mix and

match” in a chassis. The media converter modules come in a variety of

port configurations, connectors types, and operating distances.

PowerBlade Media Converters are available with an RJ-45 twisted pair

connector and either an BNC standard thin Ethernet connector or a FJ,

LC, MT-RJ, SC, ST, or VF-45 fiber optic connector. Depending on the

model, the media converters feature a maximum operating distance of

100 meters (328 feet) to 100 kilometers (62 miles).

44

Page 45

PowerBlade PBC18 Installation Guide

Common Features

The following is a list of features common to most PowerBlade Media

Converter modules:

❑ LEDs for unit and port status

❑ MDI/MDI-X feature that eliminates the need for a crossover cable

(except for the AT-PB1000 Series)

❑ Link Test feature performs a link test on the module’s port

❑ MissingLink™ notifies end-nodes of link failures

❑ Half-duplex or full-duplex operation

MDI/MDI-X An RJ-45 port on a 10 Mbps or 100 Mbps Ethernet network device can

have one of two possible wiring configurations: MDI or MD I-X. The RJ- 45

port on a PC, router or bridge is typically wired as MDI, while the twisted

pair port on a switch or hub is usually MDI-X.

Note

This feature is available for all PowerBlade modules except for the

AT-PB1000 Series.

To connect two 10 Mbps or 100 Mbps network devices together that

have dissim ilar p ort wiri ng configu rati ons, such as MDI t o MDI-X , you use

a straight-through cable. To connect two network devices that have an

RJ-45 port with the same wiring configuration, such as MDI to MDI, you

use a crossover cable.

The PowerBlade 10 Mbps and 100 Mbps media converters that have an

RJ-45 port feature an MDI/MDI-X button. You can use this button to

configure the twisted pair port on the media converter as either MDI or

MDI-X, thus eliminating the need for a crossover cable regardless of the

type of network device you are connecting to the unit.

45

Page 46

Installing a Media Converter Module

Table 2 lists the pinouts of the RJ-45 ports for both MDI and MDI-X wiring

configurations.

Table 2 RJ-45 Pinout

MDI MDI-X

Pin Signal Pin Signal

1TD +1RD+

2TD-2RD3RD+3TD+

6RD-6TD4, 5, 7, 8 N/A 4, 5, 7, 8 N/A

Link Test/

MissingLink

The Link Test/MissingLink (LT/ML) button or switch, depending on your

module, allows you to perform a link test on the media converter ports

and to activate the MissingLink feature on the unit. Both features are

describe in the following section.

Link Test

The link test is a fast and easy way for you to test the connections

between the media converter ports and the end-nodes that are

connected to the ports. If a network problem occurs, you can perform a

link test to determine which port is experiencing a problem, and be able

to focus your troubleshooting efforts on the cable and end-node where

the problem resides.

A link test is performed when the LT/ML button or switch is in LT

position. For instructions on performing a link test, refer to

Troubleshooting on page 99.

Note

Performing a link test does not interfere with a media converter’s

ability to pass network traffic, except for the AT-PB1000 Series

modules.

46

Page 47

PowerBlade PBC18 Installation Guide

MissingLink

The MissingLink feature enables the ports on the media converter to

pass the “Link” status of their connections to each other. When the

media converter detects a problem with one of the ports, such as the

loss of connection to a end-node, the media converter shuts down the

connection to the other port, thus notifying the end-node that the

connection has been lost.

For example, if the network twisted pair cable on a AT-PB101 were to fail,

the module would respond by dropping the link on the fiber optic port.

In this way, the AT-PB101 notifies the end-node connected to the fiber

optic port that the connection on the twisted pair port has been lost. If

the failure had started with the fiber optic cabling, the unit would drop

the link to the twisted pair port.

The value to this type of network monitoring and fault notification is that

some hubs and switches can be configured to take a specific action in

the event of the loss of connection on a port. In some cases, the unit can

be configured to seek a redundant path to a disconnected end-node or

send out a trap to a network management station, alerting the network

administrator of the problem.

Note

MissingLink is disabled when you perform a link test with the

MissingLink/Link Test feature. Consequently, to ensure that the

MissingLink is enabled on the media converter, always set the

ML/LT to the ML position during normal network operations.

47

Page 48

Installing a Media Converter Module

Half-duplex and

Full-duplex Mode

Duplex mode refers to the way an end-node sends and receives data on

the network. An end-node that is operating in half-duplex mode can

either send data or receive data, but it cannot do both at the same time.

An end-node that is operating in full-duplex mode can send and receive

data simultaneously. The best network performance is achieved when

an end-node can operate at full-duplex, since the end-node is able to

both send and receive data simultaneously.

All of the PowerBlade Media Converters are transparent to the duplex

mode of the end-nodes that are connected to their two ports. That is, a

PowerBlade Media Converter can operate with end-nodes operating at

either half-duplex or full-duplex mode. However, the two end-nodes

connected to the ports on a PowerBlade Media Converter must operate

with the same duplex mode.

For example, assume that the 100Base-TX port on an AT-PB102 is

connected to a port on an AT-FH705E hub configured for half-duplex

operation, while the 100Base-FX port is connected to a port on an

AT-8224XL switch configured for full-duplex operation. This would be an

invalid configuration and could adversely impact the performance of the

network. Either the port on the AT-FH705E hub connected to the

100Base-TX port would have to be changed to full-duplex (if it supports

that capability), or the port on the AT-8224XL switch connected to the

100Base-FX port would need to be changed to half-duplex.

48

Page 49

PowerBlade PBC18 Installation Guide

Network

Topologies

The PowerBlade Media Converters can be used in two different

topologies: standalone and back-to-back. Both types of topologies are

described below.

Standalone Topology

A standalone topology is when one media converter is used to

interconnected two end-nodes. Figure 19 illustrates a standalone

topology that uses one AT-PB1001/1 module to interconnect two

remote campuses. Campus 1 has an AT-8224XL switch with an

AT-A15/LX expansion module connected to the 1000Base-LX port on the

AT-PB1001/1. Campus 2 has an AT-8216FXL switch with an AT-A15/SX

expansion module connected to the 1000Base-SX port on the

AT-PB1001/1.

Campus 1: AT-8224XL with one

AT-A15/LX Expansion Modules

10BASE-T / 100BASE-TX

AT-A15

FAST ETHERNET SWITCH

ACTIVITY

LINK

A

1X 3X 5X 7X

FULL

1000BASE-X

HALF

AT-A15

ACTIVITY

LINK

B

FULL

2X 4X 6X 8X

1000BASE-X

HALF

10BASE-T / 100BASE-TX

9X 11X 13X 15X

10X 12X 14X 16X

17X 19X 21X 23X

18X 20X 22X 24X

PORT ACTIVITY

L/A

100M LINK / ACTIVITY 10M LINK / ACTIVITY

D/C

FULL DUP

1234567891011121314151617181920212223

L/A

D/C

L/A

D/C

STATUS

RS-232

TERMINAL PORT

HALF DUP/

COL

FAULT

RPS

PWR

24

RESET

10 km (6.2 mi) maximum

PB102

PB1001/1

100Mbps

100Mbps

LKAT

LK

T

X

L

S

M

X

F

X

R

X

LT

ML

LT

LT SALT BB

T

X

M

S

M

T

X

X

R

X

LKAT FD

LK

MLPR

MLPR

CLASS 1

LASER PRODUCT

DO NOT STARE

INTO BEAM

PB103/1

PB13

PB13

PB1001/1

PB102

100Mbps

10Mbps

10Mbps

100Mbps

100Mbps

LKAT

LKRX

LKRX

LK

LKAT

T

T

T

X

X

F

F

M

M

M

M

L

L

R

R

X

X

LT

ML

ML

MDIMDI-X

MDIMDI-X

T

T

LKRX

MLPR

X

T

T

X

X

L

S

M

X

F

F

M

M

M

M

X

X

R

X

R

R

X

X

LT

ML

LT

LT

LKRX

MLPR

LT

ML

ML

LT SALT BB

MDIMDI-X

MDIMDI-X

T

X

M

S

M

T

T

X

X

X

R

X

LKAT FD

LKAT FD

LK

MLPR

MLPR

MLPR

CLASS 1

LASER PRODUCT

DO NOT STARE

INTO BEAM

AT-PB1001/1 Module

550 m (1,804 ft) maximum

100BASE-FX FAST ETHERNET SWITCH

AT-A15

ACTIVITY

LINK

A

FULL

1000BASE-X

HALF

L/A

L/A

L/A

D/C

D/C

B

1234 5678 9101112 13141516

100BASE-FX

L/A

L/A

L/A

L/A

L/A

L/A

D/C

D/C

D/C

D/C

D/C

D/C

D/C

L/A

L/A

L/A

L/A

L/A

L/A

D/C

D/C

D/C

D/C

D/C

Campus 2: AT-8216FXL with one

AT-A15/SX Expansion Module

PWR 1 PWR 2 STATUS LINK 100M FDX RESET

PB102

100Mbps

LKAT

T

T

X

X

F

M

M

M

M

X

R

R

X

X

LT

ML

ML

MDIMDI-X

MDIMDI-X

T

X

LKAT FD

MLPR

PORT ACTIVITY

L/A

100M LINK

D/C

FULL DUP

HALF DUP/ COL

L/A

D/C

D/C

PBC18

PB103/1

PB13

PB13

100Mbps

10Mbps

10Mbps

LKAT

LKRX

LKRX

T

T

X

X

F

F

F

M

M

M

M

X

L

L

R

R

X

X

LT

LT

LT

ML

ML

MDIMDI-X

MDIMDI-X

T

T

T

X

LKAT FD

LKRX

LKRX

MLPR

MLPR

MLPR

STATUS

RS-232

TERMINAL PORT

ACTIVITY

FAULT

RPS

PWR

RESET

PB102

PB13

PB1001/1

100Mbps

10Mbps

100Mbps

LKAT

LKRX

LK

T

X

T

T

X

X

L

S

M

X

F

F

M

M

M

M

X

L

R

X

R

R

X

X

LT

ML

LT

LT

ML

ML

LT SALT BB

MDIMDI-X

MDIMDI-X

T

X

M

S

M

T

X

T

X

R

X

LKAT FD

LKRX

LK

MLPR

MLPR

MLPR

CLASS 1

LASER PRODUCT

DO NOT STARE

INTO BEAM

PB103/1

PB13

PB13

PB1001/1

100Mbps

10Mbps

10Mbps

100Mbps

LKAT

LKRX

LKRX

LK

T

T

T

X

X

F

F

M

M

M

M

L

L

R

R

X

X

LT

ML

ML

MDIMDI-X

MDIMDI-X

T

T

LKRX

MLPR

X

T

T

X

X

L

S

M

X

F

M

M

M

M

X

R

X

R

R

X

X

LT

ML

LT

LT

ML

ML

LT SALT BB

MDIMDI-X

MDIMDI-X

T

X

M

S

M

T

X

X

R

X

LKAT FD

LKRX

LK

MLPR

MLPR

MLPR

CLASS 1

LASER PRODUCT

DO NOT STARE

INTO BEAM

Cable Legend

Single-mode Fiber

Multimode Fiber

Figure 19 Standalone Topology

49

Page 50

Installing a Media Converter Module

Back-to-back Topology

A back-to-back topology is when two media converters are used to

interconnect the end-nodes. Figure 20 illustrates a back-to-back

topology that uses an AT-PB1001/4 and an AT-MC1001 media converter

to connect two remote campuses. Campus 1 has an AT-8224XL switch

with an AT-A15/SX expansion module connected to the 1000Base-SX

port on the AT-PB1001/4. The 1000Base-LX port on the AT-PB1001/4 is

connected to the 1000Base-LX port on the AT-MC1001. The 1000Base-SX

port on the AT-MC1001 is connected to the AT-8224XL switch at Campus

2.

In this example, the two media converters are used both to extend the

distance of your network and also convert the fiber optic cable from

multimode to single-mode and back again.

Campus 1: AT-8224XL with one

AT-A15/SX Expansion Module

10BASE-T / 100BASE-TX

AT-A15

ACTIVITY

FAST ETHERNET SWITCH

LINK

A

FULL

1X 3X 5X 7X

1000BASE-X

HALF

B

2X 4X 6X 8X

10BASE-T / 100BASE-TX

9X 11X 13X 15X

10X 12X 14X 16X

17X 19X 21X 23X

18X 20X 22X 24X

L/A

100M LINK / ACTIVITY 10M LINK / ACTIVITY

D/C

FULL DUP

1234567891011121314151617181920212223

L/A

D/C

L/A

D/C

STATUS

RS-232

PORT ACTIVITY

TERMINAL PORT

HALF DUP/

COL

FAULT

RPS

PWR

24

RESET

550 m (1,804 ft) maximum

PB102

PB1001/1

100Mbps

100Mbps

LKAT

LK

T

X

L

S

M

X

F

X

R

X

LT

ML

LT

LT SALT BB

T

X

M

S

M

T

X

X

R

X

LKAT FD

LK

MLPR

MLPR

CLASS 1

LASER PRODUCT

DO NOT STARE

INTO BEAM

PB103/1

PB13

PB13

PB1001/1

100Mbps

10Mbps

10Mbps

100Mbps

LKAT

LKRX

LKRX

LK

T

T

T

X

X

F

F

M

M

M

M

L

L

R

R

X

X

LT

LT

ML

ML

MDIMDI-X

MDIMDI-X

T

T

LKRX

MLPR

X

T

T

X

X

L

S

M

X

F

M

M

M

M

X

R

X

R

R

X

X

LT

ML

LT

ML

ML

LT SALT BB

MDIMDI-X

MDIMDI-X

T

X

M

S

M

T

X

X

R

X

LKAT FD

LKRX

LK

MLPR

MLPR

MLPR

CLASS 1

LASER PRODUCT

DO NOT STARE

INTO BEAM

AT-PB1001/4 Module

70 km (43.4 mi) ma ximum

TX RX

CLASS 1

LASER LIGHT

DO NOT STARE

INTO BEAM

SINGLE MODE MULTI MODE

MC1001 GIGABIT ETHERNET MEDIA CONVERTER

1000Base-LX

LNK

LNK TST

M/L ON

TX RX

1000Base-SX

550 m (1,804 ft) maximum

10BASE-T / 100BASE-TX

AT-A15

ACTIVITY

FAST ETHERNET SWITCH

LINK

A

FULL

1X 3X 5X 7X

1000BASE-X

HALF

B

2X 4X 6X 8X

10BASE-T / 100BASE-TX

9X 11X 13X 15X

10X 12X 14X 16X

Campus 2: AT-8224XL with one

AT-A15/SX Expansion Module

PB102

PB102

PB13

PB13

100Mbps

100Mbps

10Mbps

10Mbps

LKAT

LKAT

LKRX

T

T

T

X

X

X

F

F

F

F

M

M

M

M

M

M

X

X

L

L

R

R

R

X

X

X

LT

LT

LT

LT

ML

ML

ML

MDIMDI-X

MDIMDI-X

MDIMDI-X

T

T

T

T

X

X

LKAT FD

LKAT FD

LKRX

MLPR

MLPR

MLPR

MLPR

PWR

AT-MC1001

LNK

M/L ON

Media Converter

17X 19X 21X 23X

18X 20X 22X 24X

PORT ACTIVITY

L/A

100M LINK / ACTIVITY 10M LINK / ACTIVITY

D/C

FULL DUP

1234567891011121314151617181920212223

L/A

D/C

L/A

D/C

HALF DUP/

PWR 1 PWR 2 STATUS LINK 100M FDX RESET

PBC18

PB103/1

PB1001/1

100Mbps

100Mbps

LKAT

LKRX

LK

T

X

T

T

X

X

L

S

M

X

F

M

M

M

M

X

R

X

R

R

X

X

LT

ML

LT

ML

ML

LT SALT BB

MDIMDI-X

MDIMDI-X

T

X

M

S

M

T

X

X

R

X

LKAT FD

LKRX

LK

MLPR

MLPR

CLASS 1

LASER PRODUCT

DO NOT STARE

INTO BEAM

STATUS

RS-232