Page 1

5

to

21

I,

m

SO,

3

/h

C

PASCAL

1,

C2

Series

Series

I

ROTARY

VANE

User's

PUMPS

manual

II

I

I

!

I

I

I

Ii

I r

High Vacuum Technology

Page 2

Since it was founded in

1962,

Alcatel High Vacuum

Technology has been devoted to supplying industries

using vacuum

Its

vane rotary pumps, designed

reliability are the basis

technologies with high quality equipment.

to

offer maximum

of

its

success

and world-wide

reputation.

In

order to provide constant improvements

and satisfy very diverse customer requirements,

of

its

products

Alcatel

has invested in an ultra-modern flexible manufacturing

facility.

equipment has

leaders in the manufacture

This

set

of

adapted

and

automated machining

placed Alcatel among the world-wide

of

rotary vane pumps.

In a world

quality, quick response

where

adapting

and

to customer requirements,

service are operational

standards, Alcatel has equipped itself with exceptional

resources in

to be

Vacuum

since

R&D,

manufacturing and quality, in order

able to reach

its

goal: total quality. Alcatel High

Technology has been ISO

1993.

9001

certified

Alcatel's commitment to supplying high quality

products, has contributed to improving

performance and reliability

of

the equipment

the

in

which they are used.

With

our experienced personal, our knowledge

of

vacuum technologies and our range

performance products,

us

as

an integral

to

help define improved answers to

your needs.

part

we

invite you

of

your development team,

Our

international Sales

and Support network

assist you

in

this way.

to

is

ready

of

high

consider

to

Page 3

Rotary vane pumps

Welcome

Dear customer,

You

have

just

bought an

Alcatel rotary vane pump.

We

would like

and are proud

among our customers.

This

product

experience acquired over

many years

design

of

to

thank you

to

count you

is a result

by

Alcatel

rotary vane pumps.

of

in

the

'!

:1

'.

:1

i

ApPLICATIONS:

•

RESEARCH

Physics

•

INDUSTRY

Foodstuffs

Electronic

AND

DEVELOPMENT

and chemistry laboratories,

etc.

(freeze-dryingL Pharmaceuticals,

tube manufacture,

Metallurgy, Drying systems,

Refrigeration systems, Chemical industry,

•

INSTRUMENTATION

Mass spectrometetry, Centrifuges,

Electronic

•

VARIOUS

microscopes,

SEMICONDUCTOR

Leak

detection

PROCESSES

systems,

etc.

etc.

£

;.1:_t1i.,

particularly the chapter

installation and operation,

before you start

pump

obtain optimum levels of

performance and complete

satisfaction from

equipment.

We

sug.gest

read

so

that you

this

that you

manual,

to

use

can

this

on

this

Contents

51

Page 4

\

...

j

Page 5

Contents

The

PASCAL

series 5 to

21

m3/h

Presentation

Operating principle

a rotary vane pump

Technical characteristics

Pump

Accessories

Installation and connections

Safety instructions

Table

Filling with oil

Mechanical connections

Electrical connections

Motor

Operation

Precautions . . . . . . . . . . . .

Operating temperature

Before starting up

Start-up

Operation

Particular

Oxygen pumping

High pressure pumping and cycling

dimensions

of

protection . . . . . . . . . . . . . . . . . . . . . . .

of

the

product range

of

......................

.......................

..........................

......

recommended oils

........

....................

.....

the

pump

..........

of

gas ballast

uses

.....

.

.

...................

...................

.............

.

54

59

62

.63

.

.65

..

..

.72

.75

.75

.75

.76

.77

.79

.81

.82

56

67

68

69

71

Maintenance

Precautions

Troubleshooting and corrective actions

Maintenance frequency.

Draining the

Flushing

Change of type of oil

Replacement

Tools

Disassembling the pump

Cleaning components

Replacement

Reassembling the pump

Spare parts

and consumable products.

................

oil

the

pump

of

of

lists.

...

.

...

.

..

front shaft seal .

...

.

.....

all shaft seals.

....

.

..................

.

.

.

.83

.84

.87

.87

.88

.88

.89

.90

.

91

.94

.95

.96

149

.

53

Page 6

Presentation

of

the

product

range

A wide range

Specific solutions adapted

to

various

applications

SO

series

.

series

C 1

series

C2

series

Alcatel oil

applications.

They

(10-3 mbar), or

turbomolecular pump.

or

Standard pumps for several purposes (non-corrosive applications).

Manufacture of light bulbs, production of

tubes,

Pumps designed

seal

rotary vane

can

be

used

on

their own

in

pumping assemblies, e.g. at

metallurgy, centrifuges,

to

meet the requirements of analytical instrumentation and

pumps

are

used

in

all vacuum technology

to

achieve a maximum vacuum of 10.3 Torr

the

exhaust of a diffusion pump

TV

tubes,

manufacture of electronic

etc

.

R&D.

Mass spectrometer, electronic microscopes,

leak

detectors, sterilizers,

Pumps suited to the pumping

R&O,

laboratories, freeze-drying, pumping of

Pumps with increased resistance

aggressive processes

Ion

implantation, sputtering,

etc.

of

corrosive gases.

to

meet the requirements

of

the semiconductor industry.

etc.

GC/MS,

solvents,

LC/MS, gas analyzers,

etc.

of

the more

./

i

Hl

series

Sealed pumps offering maximum tightness.

Pumping

Nom.

I

SO

C1

C2

H 1

of pure or precious

flo

rate

series

series

series

series 2 stages

series

2

1 stage

2

1 stage 1005C1

2

2 stages 2005H1

3

m

/h

stages

stages

stages

gases.

5

20051 20101

1005S0

2005S0

2005C1

1010S0

2010S0

1010C1

2010C1

2010C2

10

15

20151 20211

1015S0 1021S0

2015S0 2021S0

1015C1

2015C1 2021C1

2015C2

2015H1

21

1021C1

2021C2

54

Page 7

Precautions

5

I,

to

21

SO,

m

C1,

3

/h

C2

rotary

Pascal

vane

series

pumps.

"'1

'I

]

Four 5 to

the

- A

very compact.

- An electrically insulated

handle

- An

the tightness of the pump during

accidental or voluntary shutdowns.

- A

of condensable vapours (except for

C2

The

phase

independently

pump, without the need to drain

the

On

-

glass

level easily when filling

during the operation of

- A

degas oil and dilute pumped gases

on

21

m3/h

pump

models

following main characteristics:

direct

drive

motor,

making

fold-away

is

used for easy carrying.

anti-suckback

gas

ballast

series).

universal three-phase or single-

motor

oil case.

the oil case, a

can be

neutral

C2

gas

series models.

system

enables the pumping

can be disassembled

of the

used

to

purge

rest

of the

vertical

inspect

the

the

is

used

ensures

sight

the

tank and

pump.

with

them

oil

to

1.

Oil

case

2. Gas ballast control

Base

3.

4.

Oil

level sight glass 10. Fold-away handle

5.

Filling plugs 11. Electric motor

6. Draining plug 12.

The

inlet and exhaust end fittings are

They are fitted vertically on the pump at delivery but can be positioned on

if

the horizontal openings

They can also be

The

main remplacement parts are interchangeable:

disassembly-assembly operations and replacement without changing the

pump's performance.

used

required

to connect many of our accessories

7.

Frame

Inlet end fitting

8.

9.

Exhaust end fitting

IEC

electric socket

PNEUROP

by

operating conditions.

ISO-KF

standardized.

This

enables easier

(see

page

63).

used

to

adapt

the

Various accessories can be

of your application.

The

moulded aluminium pump frame supports the pumping module and

motor. All the parts of the pumping module

zinc, copper and cadmium.

The

other construction materials include cast iron, aluminium alloy, stainless

steel, fluorocarbons

(FPM),

nitril

(NBR)

and chemically resistant polymers.

pump to meet the requirements

in

contact with gases are free of

the

55

Page 8

Operating principle of

the

rotary vane pump

rotary

The

Single-stage

vane

pumping

given

pump

cycle

below:

Inlet

Transfer

This

is

a volumetric pump, with a functional

hollow

- A

- A rotor mounted eccentrically inside the stator for pumping.

- Two vanes

and springs.

cylindrical stator with inlet

sliding

in

the rotor, forced against the stator

part

and

exhaust valves.

is

As the vane passes in front

inlet orifice, an increasing space

formed into which the gas from the

chamber

When

the second vane passes, the

space

is

The gas trapped in the space

between the

to the exhaust orifice

rotates.

composed of:

by

centrifugal force

to

be evacuated expands.

closed.

two

vanes

is

as

the rotor

of

the

is

transferred

Compression

Exhaust

Application

56

In.

Single stage rotary vane pumps

1.0

above

condensable gases

Torr (1,3 mbar),

~Exh.

as

are

present.

The space communicates with the

is

exhaust, which

the gas

valve

The

casing when the pressure

to open the

are

the best choice for continuous pressures

well

as

applications where large amounts

is

gas

is

opened.

is

fitted with a valve:

compressed until the safety

expelled into the oil

valve.

is

sufficient

of

Page 9

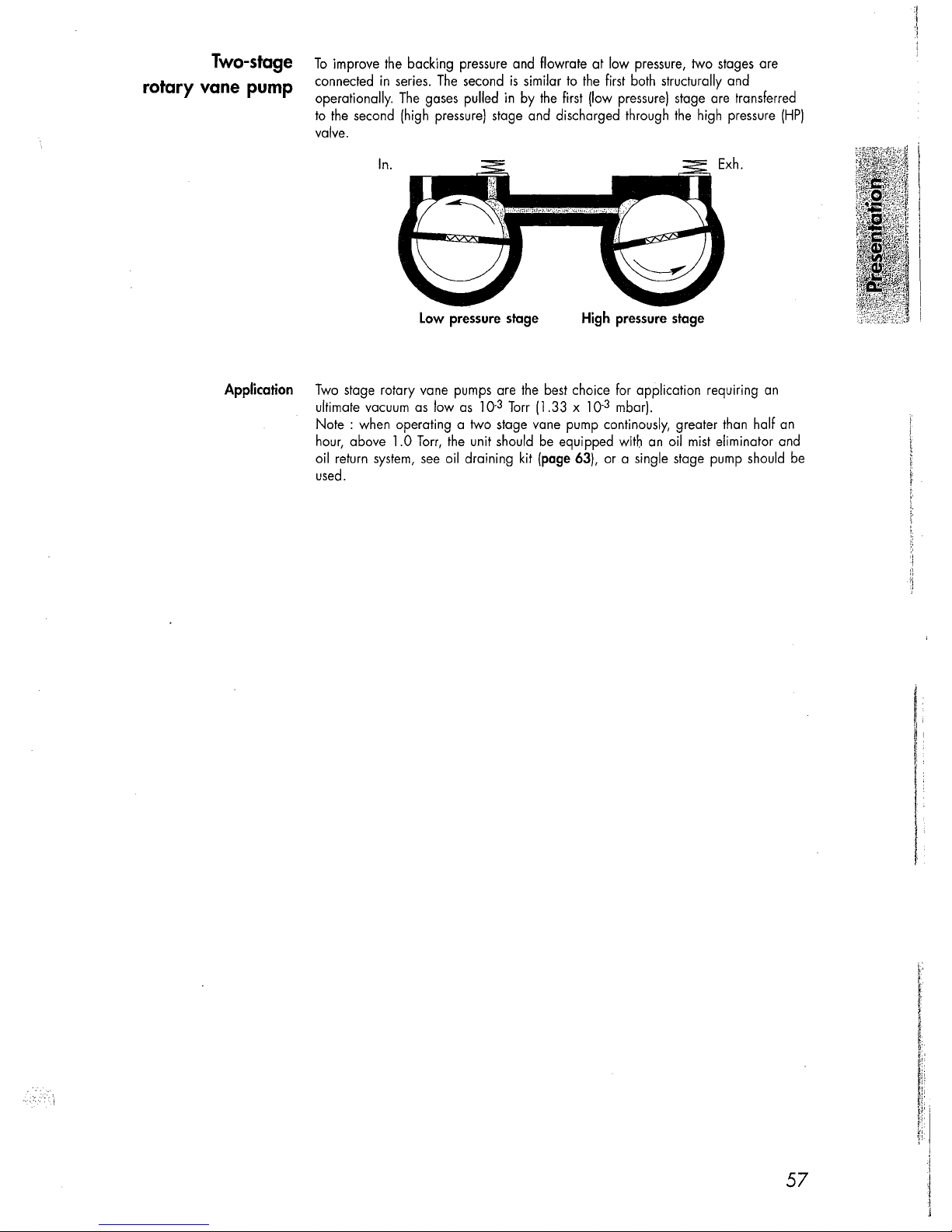

Two-stage

rotary vane pump

To

improve

connected

operationally.

to

the

valve.

in

second (high

In.

the

backing pressure and flowrate at low

series.

The

The

gases

pressure)

Low

second

pulled

pressure

is

similar

to

in

by

the

first (low

stage and discharged through

stage

pressure,

the

first both structurally and

High

pressure)

pressure

stage are transferred

the

stage

two

stages

high pressure

are

(HP)

Application

Two

stage rotary vane pumps are

ultimate vacuum

Note:

when operating a two stage vane pump continously, greater

hour,

above 1.0

oil return

used.

system,

as

low

as

Torr,

the

see

oil draining kit

unit should

10.3 Torr

the

best

choice for application requiring

(1.33 x 10.3 mbar).

be

equipped with

(page

63), or a single stage pump should

an

oil

mist

an

than

half

an

eliminator and

be

57

Page 10

Choosing

Its

the

function

right

oil

Oil

Oil

has

several important functions

-

It

lubricates mechanical components (bearings,

It

makes

It

-

Not

depends

dissolve gases.

Good pumping conditions are

The

- Expected pump performance.

Chemical aggression and corrosion

-

- Accessories

- Desired maintenance intervals and total operating

ALCATEL

moving parts relatively tight by limiting internal leakage.

carries away

all oils produce

choice depends on:

the

heat produced by

the

same

on

the

saturated vapour pressure of

used.

has

selected various

in

the

pump:

the

compressed

ultimate pressure

related

to

the

of

pumped gases.

types

of oil for

the

type

its

seals,

in

pumps

rotor, vanes, etc.).

gases.

a given pump. Ultimate pressure

oil,

its

of

oil

cost.

viscosity and

used.

(see

page

67).

its

ability

to

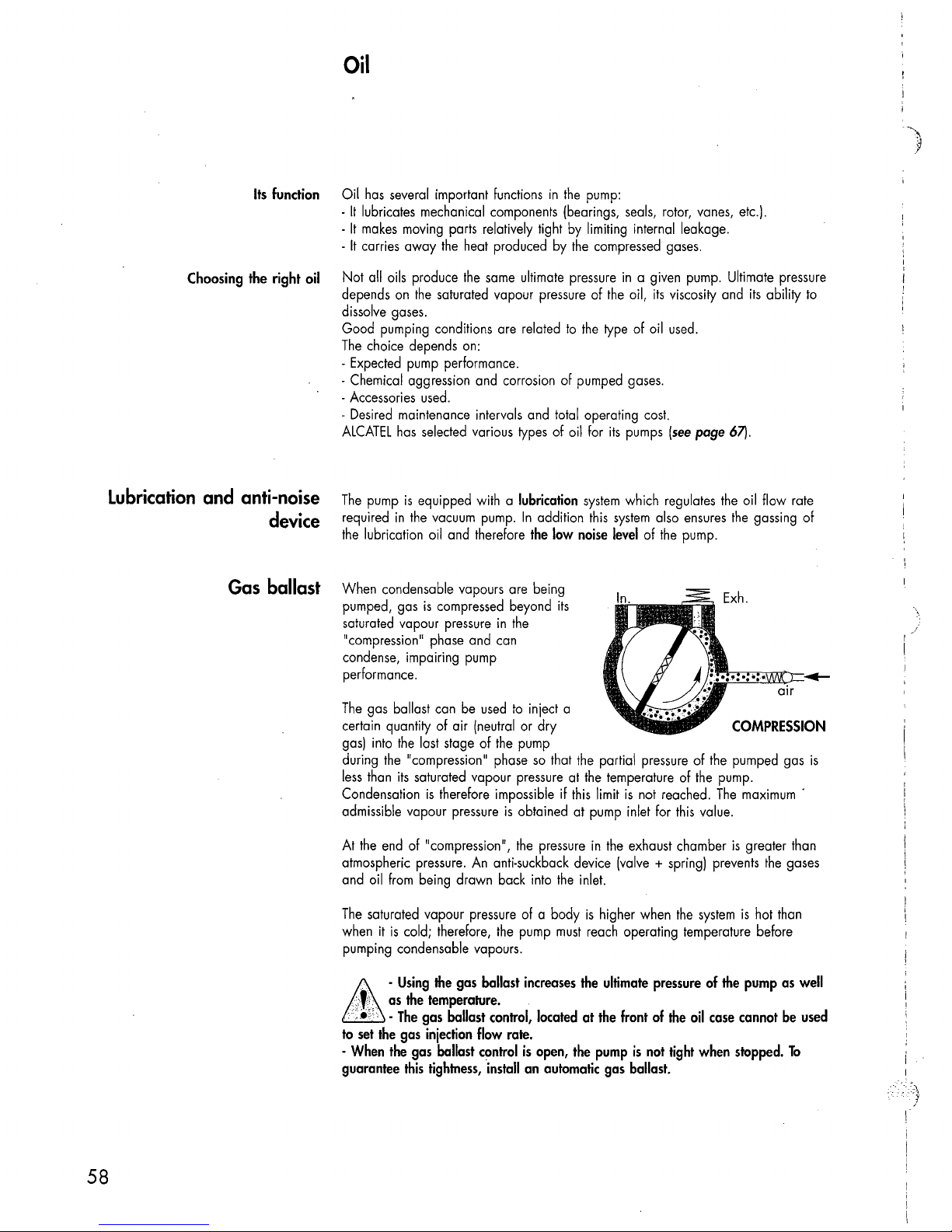

Lubrication

and

Gas

anti-noise

device

The

pump

is

equipped with a

required

the

in

the

vacuum pump.

lubrication oil and therefore

ballast When condensable vapours are being

is

pumped, gas

saturated vapour pressure

"compression" phase and can

condense, impairing pump

performance.

The

gas ballast can

certain quantity of air (neutral or dry

gas)

into

the

during

less

than

Condensation

admissible vapour pressure

At

the

end

atmospheric pressure.

and

oil

from

The

saturated vapour pressure of a body

when it

pumping condensable vapours.

compressed beyond

in

be

used

the

last stage of

"compression" phase

its

saturated vapour pressure at

is

therefore impossible if

of "compression",

being drawn back into

is

cold; therefore,

the

An

anti-suckback device (valve + spring) prevents

the

lubrication

In

the

the

to

inject a

pump

so

is

obtained at pump inlet for

the

pump

addition

low

its

that

this

pressure

the

must

system

which regulates

this

system

noise

level

the

partial pressure of

the

temperature of

limit

is

in

the

exhaust chamber

inlet.

is

higher when

reach operating temperature before

also

ensures

of

the

pump.

the

not reached.

this

value.

the

system

the

oil flow rate

the

gassing

COMPRESSION

the

pumped gas

pump.

The

maximum'

is

greater than

the

is

hot than

of

\

is

gases

58

'"

-

..

>,ci,

as

,;

, •.

'. -The

&

to

set

the

-

When

the

guarantee

Using

the

temperature.

gas

gas

injection

gas

this

tightness,

the

gas

ballast

ballast

ballast

control,

flow

rate.

control

install

increases

located

is

open,

an

automatic

the

at

the

ultimate

the

front

pump

gas

pressure

of

is

not

ballast.

the

tight

of

oil

when

the

case

pump

cannot

stopped.

as

be

To

well

used

Page 11

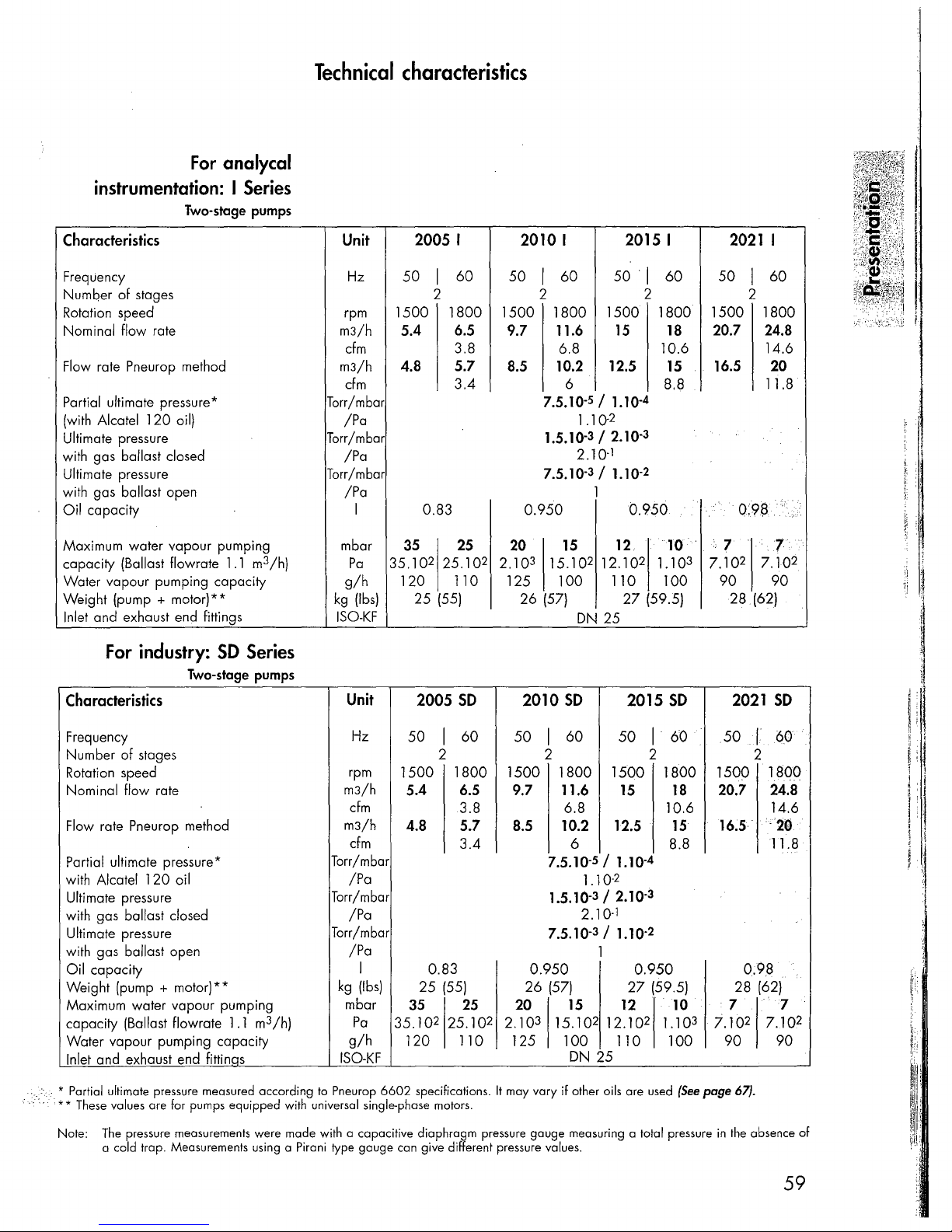

For

analycal

instrumentation: I Series

Two-stage pumps

Technical

characteristics

Characteristics

Frequency

Number of stages

Rotation speed

Nominal

Flow rate Pneurop method

Portia

(with Aleatel 120 oil)

Ultimate pressure

with gas

Ultimate pressure

with gas

Oil

Maximum water vapour pumping

capacity

Water vapour pumping capacity

Weight (pump

Inlet and exhaust end fittings

flow rate

I ultimate pressure *

ballast closed

ballast open

capacity

(Ballast flowrate

+

motor)**

For industry:

1.1

m3/h)

SO

Series

Two-stage pumps

Characteristics

Unit

Hz 50

2005 I

60 50 I 60

I

2010 I

2 2

rpm

m3/h

cfm

m3/h

cfm 3.4 6

Torr/mbor

/Pa

Torr/mbor

/Pa

Torr/mbor

/Pa

mbor

g/h

kg

ISO-KF

Unit

1500 1800 1500 1800 1500 1800

5.4

6.5

9.7

3.8

4.8 5.7

I 0.83 0.950

35

Po

35.102 25.102 2.103 15.102 12.102 1.10

25

8.5

20

120 110 125 100 110 100

25

(Ibs)

(55)

2005

SO

26

2010

2015 I

50

11.6

15

6.8

5

1.10-

/

12.5

1.1

2

10.2

7.5.10-

1.5.10-3/ 2.10.

1

2.10-

7.5.10-3/

1.10-

1

DN

12

27 (59.5)

25

15

(57)

SO

1

2

4

0-

3

2

0.950

2015

60

18

10.6

15

8.8

10

SO

2021

50

1500 1800

20.7

16.5

7

3

7.10

90 90

28

2021

1

2

0:9$

2

(62)

I

60

24.8

14.6

20

11.8

.7

7.10

SO

i

, ,

'.

~l

:

'.

I

2

Frequency

Number of stages

Rotation speed

Nominal flow rate

Flow rate Pneurop method

Portial ultimate pressure*

with

Alcatel 120 oil

Ultimate pressure

with gas

Ultimate pressure

with gas

Oil

Weight (pump

Maximum water vapour pumping

capacity (Ballast flowrate

Water vapour pumping capacity

Inlet and exhaust end fittinqs

:'

..

• Partial ultimate pressure measured according

••

These values are for pumps equipped with universal single-phase motors.

Note: The pressure measurements were made with a capacitive

ballast closed

ballast open

capacity

+

motor)**

1.1

m3 fh)

a cold trap. Measurements using a Pirani type

Hz

rpm

m3/h

cfm

m3fh

cfm

Torr/mbor

fPa

Torr/mbor

fPa

Torr/mbor

/Pa

kg

mbor

Po

g/h

ISO-KF

to

Pneurop

I

(Ibs)

6602

gauge

50

60 50

1

60 50 1 60

1

2 2 2

1500 1800 1500 1800 1500 1800

5.4

6.5

9.7

11.6

15

18

3.8 6.8 10.6

4.8 5.7

8.5

10.2 12.5

15

3.4 6 8.8

/

1.10-

2

/ 2.10-

1

1.10-

4

3

2

5

7.5.10-

1.10-

1.5.10-3

2.10-

7.5.10-3/

1

0.83

25

(55)

35

25

35.102 25.102 2.103 15.10

120 110 125

specifications.

diaphragm

can give different pressure values.

pressure

0.950 0.950

26

(57)

20

15

2

100 110 100

DN

It

may

vary

if

other oils are used

gauge

measuring a total pressure

27 (59.5)

12

12.102 1.10

25

10

(See

3

1500

7.10

page

in

50

.1

2

1aOO

20.7

24.8

14.6

16.5'

-20

11.8

0.98

28

(62)

7

2

7.10

90 90

67) .

the absence

60

7

2

of

59

Page 12

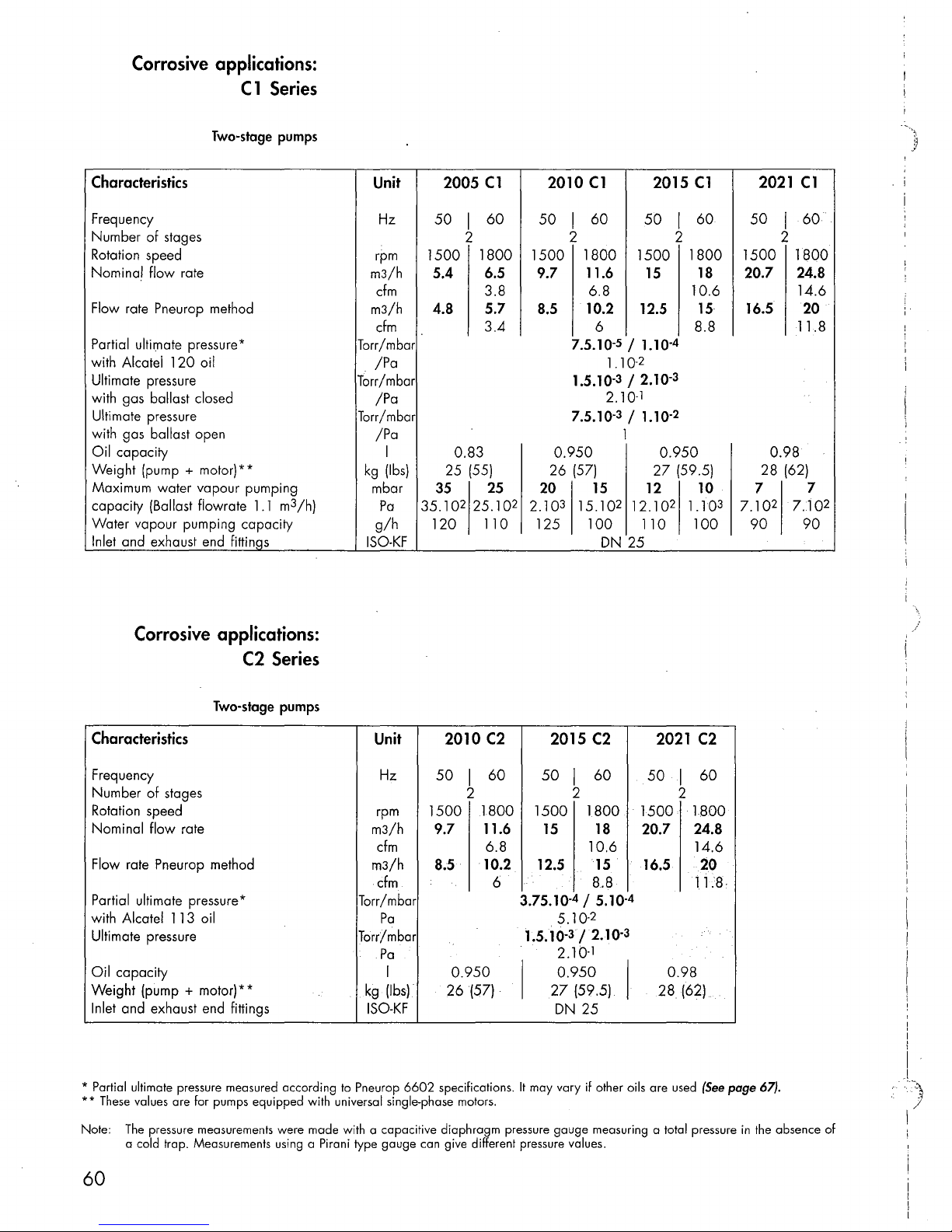

Corrosive

applications:

C1

Series

Two-stage

pumps

Characteristics

Frequency

Number of stages

Rotation speed

Nominal flow rate

Flow rate Pneurop method

Partial ultimate pressure *

with

Alcatel 1 20 oil

Ultimate pressure

with gas ballast closed

Ultimate pressure

with gas ballast open

Oil

capacity

Weight (pump + motor) * *

Maximum water vapour pumping

1.1

capacity (Ballast flowrate

Water vapour pumping capacity

Inlet and exhaust end

fittin~s

m3/h)

Unit

Hz

rpm

m3/h

cfm

m3/h

cfm

Torr/mbar

/Pa

Torr/mbar

/Pa

Torr/mbar

/Pa

I

kg

(Ibs)

mbar

Pa

g/h

ISO-KF

2005

50

I

2

1500

5.4 6.5

4.8

0.83

25

(55)

35

2

35.10

120

C1

60

1800

3.8

5.7

3.4

25

25.10

110

2010

C1

I

60

50

2 2

9.7

1800

11.6

1500

6.8 10.6

8.5

10.2

6

7.5.10-

1.5.10-3 / 2.10-

2.10-

7.5.10-3 / 1.10-

0.950 0.950

26

(57)

2

20

2.10

3

15.10

15 12

125 100

DN

2015

50

1500

15

12.5

5

1.10-

/

2

1.10-

1

1

27

2

12.102 1.10

110 100

25

I

1800

8.8

4

3

2

(59.5)

C1

60

18

15

10

2021

50 I 60

1500 1800

20.7 24.8

16.5 20

0.98

28

7

3

7.10

90

2

2

(62)

C1

14.6

11.8

7

7010

90

2

Corrosive

applications:

C2

Series

Two-stage

pumps

Characteristics

Frequency

of

Number

Rotation speed

Nominal flow rate

Flow rate Pneurop method

Partial ultimate pressure *

with

Ultimate pressure

Oil

capacity

Weight (pump

Inlet and exhaust end fittings

* Partial ultimate pressure measured according

**

These

Note:

stages

Alcatel 113 oil

+

motor)**

values are for pumps equipped with universal single-phase motors.

The

pressure measurements were made with a capacitive

a cold trap. Measurements using a Pirani type

m3/h

m3/h

Torr/mbar

Torr/mbar

kg

ISO-KF

to

Pneurop

Unit

Hz

2010

C2

50 I 60

2

rpm

cfm

cfm

Pa

Pa

gauge

1500 1800

9.7 11.6

6.8

8.5 10.2

6

I

(Ibs)

6602

0.950

26(57)

specifications.

diaphragm

can give different pressure values.

2015

50

1500 1800

15

12.5

3.75.10-

5.10.

1.5.10-3 / 2.10-

2.10-

0.950

27

I

DN

It

may

vary

pressure

gauge

I

2

C2

60

2021

50 I 60

2

1500 1800

18

20.7 24.8

10.6

15

16.5 20

8.8

4

(59.5)

/

5.10-

2

1

4

3

0.98

I

28

(62)

25

if other oils are used

measuring a total pressure

C2

14.6

11.8

(See

page 67).

in

the absence

of

..

!

I

i

I

.!

..

~'i.

)

I

60

Page 13

For

industry:

Single-stage pumps

SO

Series

Characteristics

Precautions

Frequency

Number

Rotation speed rpm

Nominal flow rate

Flow rate Pneurop method

Ultimate' pres'sure*

with gas ballast closed

Ultimate pressure'"

.yvith

Oil

WE~ight

Maximum water vapour pumping

capacity (Ballast flowrate

Water

Inlet and exhaust end fittings

of

stages

gas, balla,st open

capacity

(pump.+.

vapour

niofor)**

pumping

.

1.1

m3/h)

capaCity

Unit

Hz

m3/h

cfm

m3/h

cfm

Torr/mbar

/Pa

Torr/mbar

/Pa

kg

mbar

Pa

g/h

ISO-KF

Corrosive applications:

C1

Series

1005

SO

50

60

I I

1

5.4

1800

6.5

1500

1010

50

1

1500 1800 1500 1800

9.7

3.8

5.5

4.8

'

8.5

3.2 5.8

3.75.10-

3/4

2

4.10

30

21

1.1

(46)

25

I

(Ibs)

3.103 25.102 4.103 35.102 35.10

120

130"

22

40

260

1.0

(48)

SO

60

11.6

6.8

10

12.5

2

/

5

35 35

280

DN 25 ISO

330 370

1015

SO

50 I 60

1

15

18

10.6 14.6

15

8.8

2

5.10-

5.25/7

7.10

1.0 1.0

24.5

(54)

30

2

KF

3.10

3

1021

50 I 60

1

1500

20.7

16.5

2

25

(55)

25

2

25.10

340

SO

1800

24.8

20

11.8

22

22.10

340

2

Single-stage pumps

Characteristics

l,i~qiiehcy

Number

'R9ia.ti9~,

Nominal flow rate

FI9f

'Uiti~~t~'pr~s~~re

with gas ballast closed

'Uiti

Witbgos,

Oil

.:\§iejghUp~hlp~

Maximum water vapour pumping

capacity (Ballast flowrate

\Y:{9:t~~~9FiR1~(p~mpihgcOpacHy,

Inlet and exhaust end fittings

*

Pressure

**

Note:

of

~tages

~pe~9

rati!'

PneQtop,'

n1ate'prd~sure

pqllast.,open

capacity

measured according

These

values are for pumps equipped with universal single-phase motors.

The

pressure measurements were made with a capacitive diaphragm pressure gauge measuring a total pressure

a cold trap. Measurements using a Pirani type gauge can give different pressure values.

:,;

*

}:,mot

method

cir

)

**

1.1

to

Pneurop

m3/h)

.•

,

,

..

' "

,.

6602

Unit

Hz

rpm

m3/h

cfm

m3/h,.

cfm

Torr/mbar

/Pa

Torr/mbar

/Pa

I

kg

(Ibs)

mbar

Pa

g/h

ISO-KF

specifications with Alcatel

1005 Cl

50

I

60

1

1500 1800

5.4

6.5

3.8

4.8

5.5

3.2 5.8 8.8

1.1

21(46)

30

3.10

120

25

3

25.102 4.103 35.102 35.10

'130'

120

·1500

3/4

4.10

oil charge.

1010

50'

9.7

8.5

2

1.0 1.0

.22(48)

40

260

Cl 1015 Cl

I'

60

50

1

iSOO

11.6

1500 1800

15

6.8

.10

3.75.10-

12.5

2

/

5.10-

5

'24.5

DN

, .

25

..

330

35

if

other oils are

35

280

It

may vary

2

1

1

2

'{54)

3.10

60

18

10.6

15

5.25/7

7.10

30

3

370

1021 Cl

50 I 60

1

1500

1800

20.7 24.8

14.6

16.5

2

25

25.102 22.10

,340

used

in

20

11.8

1.0

5

Z5(5

J'

22

'340

(See

page

the absence

.'

,",-,

2

67).

of

61

Page 14

Pump

dimensions

Filling

3/8G

!

\

Inlet

C2

Bubbler

A

63

45

192 96,5

Series

DN25

ISO

\

1\

KF

113,5

37

I Exhaust

DN25

915

ISO

KF

/

37/

. ',..;

,\t

r,-

£

1/

If wei

\

ir

[I-

II")

~

\

-r--=-

N

~

~~

r-

\

95,5

226

259

B

~

237

1\

II")

2:

0

'<t

c:;

N

N

II")

'<t'

~.

~

-I

-

-

\

I I

1r'

-

1

c=J

1

ffi

101

98

J

141

164

-

~~

-0

c:;

0

:=

\

:\

)"

!

Drain

3/8

G

Dim.

inch/(mm)

A

B

C

62

1005

4.55

(115.5)15.4

1

1010

9

(229)

(183)

7

(136.5)

2005 1015

1

14.55

(115.5)

\ 4 x 8

Pump

6.2

(157.5)

mm

9.8

(249)

8 (204)

diam. holes

type

2010

1

15.4

(136.5)

1021

7.03 (178.5)16.2

10.6

8.9

1

(270)

(225)

2015

(157.5)

2021

11.5 (291)

9.7 (246)

7.03

(178.5)

.~

J

Page 15

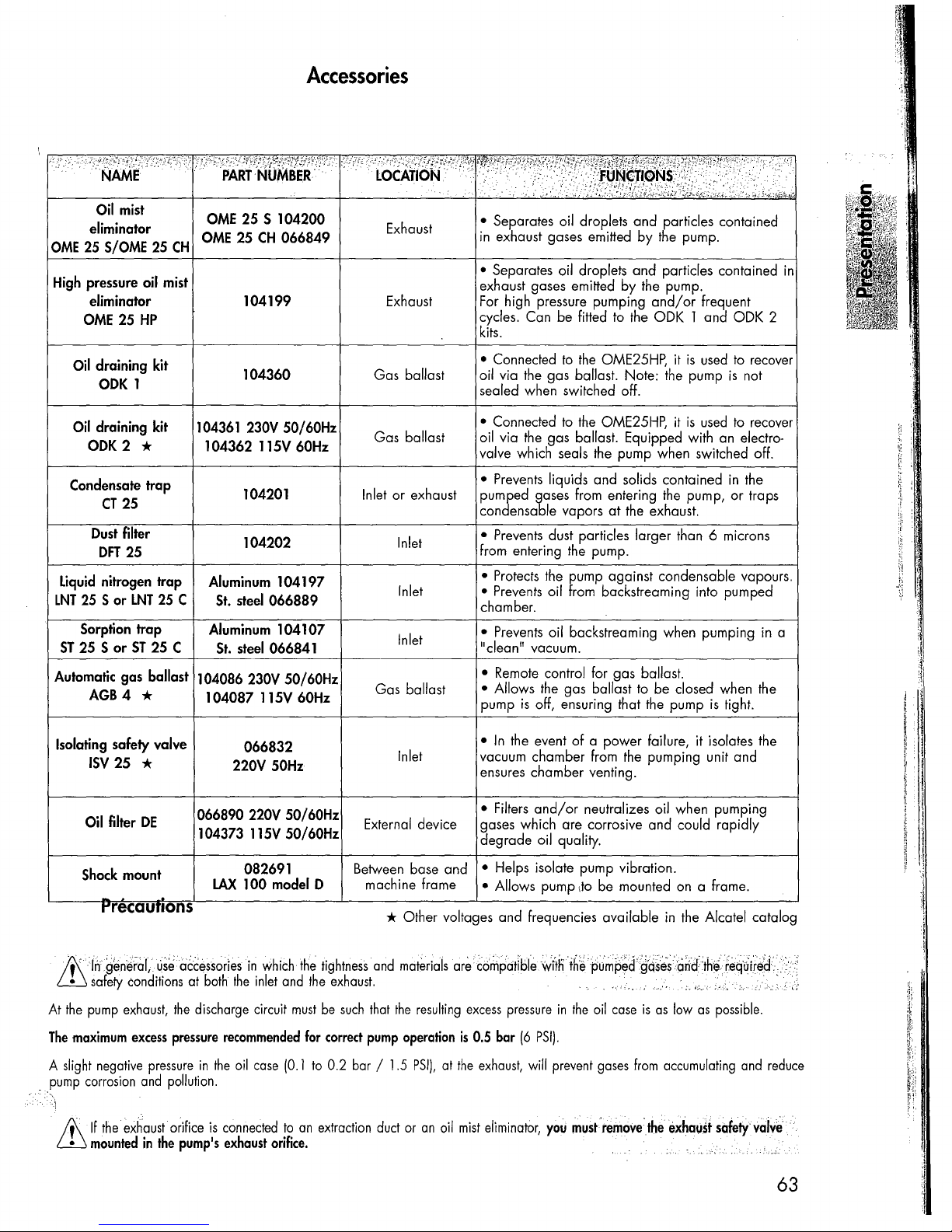

OME

Oil

mist

eliminator

25 S/OME

25

CH

OME

OME

25

5 104200

25

CH

Accessories

066849

Exhaust

• Separates oil droplets and particles contained

in

exhaust gases emitted

by

the

pump.

High pressure oil mist

eliminator

OME

25

HP

Oil draining

OOK

Oil draining

OOK

Condensate trap

CT

Dust filter

OFT

Liquid nitrogen trap

LNT

25 S

Sorption trap

51

25 5

Automatic gas ballast 104086 230V SO/60Hz

AGB 4 *

2 *

25

25

or

or

1

LNT

ST

kit

kit

25 C

25 C

104199

104360

104361 230V 50/60Hz

104362 115V 60Hz

104201

104202

Aluminum

St.

Aluminum

St.

104087

steel

steel

104197

066889

104107

066841

11SV

60Hz

Exhaust

Gas ballast

Gas ballast

Inlet or exhaust

Inlet

Inlet

Inlet

Gas ballast

• Separates oil droplets and particles contained

exhaust gases emitted by

For

high pressure pumping

Can be fitted to

cycles.

kits.

• Connected

oil via

sealed when switched off.

• Connected

oil via

valve which seals

•

Prevents

pumped gases from entering

condensable vapors

•

Prevents

from entering

•

Protects

•

Prevents

chamber.

•

Prevents

"clean" vacuum.

•

Remote

• Allows

pump

to

the

the

is

the

gas ballast. Note:

to

the

gas ballast. Equipped with

the

oil from backstreaming into pumped

control for gas ballast.

the

off, ensuring that

the

liquids and solids contained

dust particles larger than 6 microns

the

pump.

pump against condensable vapours.

oil backstreaming when pumping in a

gas ballast to be closed when

the

pump.

and/or

the

ODK 1 and ODK 2

OME25HP, it

OME25HP, it

pump when switched off.

at

the

exhaust.

the

the

the

pump

frequent

is

used

pump

is

used

pump,

is

is

an

in

or

tight.

to

recover

not

to

recover

electro-

the

traps

the

in

Isolating

safety valve

ISV

25

*

Oil filter

Shock mount

DE

066832

220V

066890 220V 50/60Hz

104373 115V 50/60Hz

082691

LAX

100 model 0

t"recaunons

!f\rngen~rar,

ill

safety

At

the

pump

The

maximum

A

slight

negative

pump

corrosion

i

If\

If

the

ill

mounted

.U.S~

conditions

exhaust,

excess

exhaustorifice

a~cessorles

at

the

pressure

pressure

and

pollution.

in

the

pump's

in.

both

discharge circuit

in

the

is

which

the

Inlet

recommended

oil

case

connected

exhaust

•

In

the

event

of

a power failure, it isolates the

neutralizes oil when pumping

be

50Hz

Inlet

External device

Between base and

machine frame

vacuum chamber from

ensures chamber venting.

• Filters

gases which are corrosive and could rapidly

degrade oil quality.

• Helps isolate pump vibration.

• Allows pump Ito

and/or

* Other voltages and frequencies available

the

tightness

and

the

must

be

for

correct

(0.1

to

to

an

extraction

orifice. ,

exhaust.

such

that

pump

0.2 bar /

and

duct

materials

the

resulting

operation

1.5

PSI),

or

an

are

C6n,pcitiblewftfiih~pumpe.d'.gQs.

excess

pressure

is

at

oil

0.5 bar

the

mist

(6

exhaust,

eliminator,

will

". . ""

in

the

PSI).

prevent

you

must'remove:the

oil

gases

the

pumping unit and

mounted

on

In

e~Cind.

;"

case

is

as

low

from

accumulating

exha\Jst

,'.

,.'

a frame.

the

Alcatel catalog

:th.e

.• · .....

feq

..

>.

as

possible.

lii;ed."

'..

and

"

reduce

. c,

'0.,

safetyvalv~

d

•• ' ,.

",i,

63

Page 16

I

I

I

'")

)

I

\

)

64

.-.

i

:\

1

I

)

Page 17

Safety instructions concerning the installation and

Unpacking

Storage

operation

When

you receive the equipment, unpack it carefully. Do not discard the

packaging

during transport. Otherwise, take the necessary measures with the transporting

company and,

For all handling, only

handle, etc.).

The

pump

bottles. Similarly, it

of

pumping

until you have ensured that the pump

if

necessary, notify

use

the devices provided for this purpose (lifting rings,

is

not supplied filled with oil.

is

recommended to drain the pump before redispatching

systems

ALCATEL.

The

oil

has

not been damaged

is

contained

in

separate

the equipment.

• if the pump

without

temperature between 41°F and 149°F or 5 and

is

to be stored,

particular storage precautions for up to 3 months (ambient

we

guarantee the reliability of our equipment

6SOC).

•

For

storage periods

oil during storage.

orifice blocked) for approximately 1 hour in order to lubricate all

the functional block (see

Then,

stop

the

pump and store it with the inlet and exhaust orifices sealed:

clamping ring, centring ring, plug, etc.

The

shaft should be rotated

following this storage procedure.

• After 6 months storage without oil, factors

humidity,

particularly

and the gumming

particularly oil leaks. Before any start-up (new pump

pump

Note

The

light (sunlight and ultraviolet light)

hardening (AFNOR standard

salt air, etc. may cause the deterioration

the

must

be disassembled (see

1:

seal

kits

must

of

over 3 months,

For

this, fill the pump and

page

76).

by

hand or

hardening

of

be stored with caution. Keep

of

O-rings and the "sticking"

oil.

in

this state, a pump may have operational problems,

FD T 46.022).

by

page

91), and all the

in

order

we

recommend to fill the pump with

run

it at ultimate vacuum (inlet

starting the pump every six months

such

as

temperature, degree of

of

the pump components,

of

lip seals on shafts

as

well

as

seals

changed.

them

away

from heat and

to

prevent the elostomers from

the

parts

used), the

of

65

Page 18

Installation and

start-up

•

The

machines

with decree

electrical codes that apply.

•

It

is

important to isolate the machine from the power source before any

intervention on

• When switching off the power of equipment containing capacitors loaded

with over

pins (single-phase motors, equipment with mains filter, frequency converter,

monitor, etc.).

88-1056

60

VDC or

must

be connected to an electrical installation

dated 14th November

the

equipment (for maintenance purposes).

25

VAC, take precautions when accessing the connector

1988,

in

as

well as any local

compliance

,

')

j

• Vane roughing pumps

information from the manufacturer on

product used.

•

Our

pumps are tested

for the USA (Alcatel

same oil during operation.

If

changing the type of oil, refer

of

and the type

•

Our

pumps are designed to prevent any thermal risk for user safety.

However, specific operating conditions may generate temperatures which may

justify particular attention on the part of the user (outer

lubricant required.

use

lubricants, it

in

the factory with

113

oil for the C2series).

to

the

is

recommended to request

the

safety data

ALCATEL

chapter concerned for the procedure

sheets

120

oil or Alcatel

It

is

recommended to

surfaces>

concerning the

use

70°e).

119

the

66

Page 19

Vapor

Assembly

pumping

(continued)

procedure

-

we

do not recommend an oil mist

eliminator when pumping condensable

vapors:

it

it outside the condensation zone.

- remove the stop

exhaust;

mechanical device creating a negative

pressure from

- Valve off the pump from the

30

- Start pumping and check

- After pumping, regenerate the oil using gas ballast if it

discoloured.

- Change the

improved

if

it

is

essential,

directly to the pump exhaust but place

if

possible, connect the exhaust

0.1

minutes with gas ballast

the

level drops, oil

•

the

level rises, condensates have been added to the oil.

•

•

if

the level

oil

by

regeneration.

do

not connect

valve from the pump

to

to

0.2

bar.

system

(see

page

the

oil level:

is

being lost;

is

too high, change

as

soon

as

inlet pressure characteristics

a

and increase the pump temperature,

76).

In.

the

oil and regenerate.

is

cloudy

drop

Exh. •

Condensate

trap

or

and are not

78

Page 20

Operation of gas ballast

Regeneration

Pumping

Choice

of

pump

condensable

vapours

pump

and

system

of

In

a pump stored with the same oil for a long time, condensed vapours may

contaminate the oil bath and affect performance.

oil

pumping vapours and when

sight glass.

-

Run

the

pump, shutting it off from the

plug.

- Open the gas ballast and

1 hour, or longer

temperature rise

the oil bath.

To

pump with condensable products, it

pump. For this,

1/2

hour with the gas ballast open, or 1 hour (if possible) with the gas

ballast closed. When the oil bath

the pump

The

the pump temperature and the quantity

Thus,

suitable. However, when not pumping vapours,

Care

admissible water vapor pressure with the pumped product.

by

The

of

vapours are

cause the products condensed

is

pump's capacity to eliminate condensable vapours

for high vapour levels

should be taken

reading the pump characteristic table for water vapour.

use

of

if

the oil remains cloudy.

of

the pump while eliminating residual va pours present

isolate the pump from the

reduced

cold traps or condensers are recommended when large quantities

to

be extracted. Excessively intense or prolonged pumping may

the

oil appears cloudy or discolored through the

allow

the pump

is

hot, the condensation

or

prevented.

in a system,

to

limit the inlet pressure

in

the trap to be evaporated a second time.

system

is

necessary to operate with a hot

system

of

air

the single-stage pump

This

is

also the case after

at the inlet

to

operate for

This

operation accelerates the

and

introduced

its

of

the pump to

by

a valve or a

1/2

allow

it

of

vapours

is

related

by

the gas ballast.

ultimate pressure

This

hour

to

to

operate for

to

their type,

is

more

is

its

maximum

is

obtained

in

in

higher.

Choice

Assembly

of

oil

Choose an

be condensed

etc.)

The

- the pump and

- the pressure at the exhaust

as possible (removal of the oil mist

eliminator ...

- the condensates are collected

separately from the oil bath and

block

For this:

- avoid using any

promotes the condensation

and the return of

pump.

-

use

oil which facilitates

in

the

oil bath (anti-emulsion oil for water-based compounds,

(see

page 67).

condensation

the

exhaust duct.

a condensate collector;

of

vapours at the pump exhaust

oil temperature are high;

);

vertical ducting which

these

the

is

as

of

products

products to

separation

low

do

not

the

of

pumped products which may

is

reduced if:

•

Exh.

77

Page 21

Start-up

• When using a three phase motor,

(see

motor.

electrical connections start-up

check

the direction of rotation of the

chap.

page 71).

• Check the oil level

• Start-up the pump.

• Allow the pump

vacuum:

During this operation, make sure that the oil circuit

of

the oil fill plugs to listen

At

start-up, the oil enters the lubrication circuit

result, noises

as

the oil heats up.

has been replaced.

Under normal temperature conditions, the oil circuit should start

1 minute after start-up

of

contamination).

•

Using

- to decontaminate the pump's oil;

- to accelerate heating.

through the oil sight glass) when the pump

starting

sure). If necessary, stop the pump and adjust the oil level between the

and"

min" levels on the sight glass.

will be heard (first irregularly, then regularly) which .will reduce

the gas ballast:

of

the oil circuit and the operating conditions

(See

page 68).

to

run for one hour with the inlet blocked

is

to

the pump.

of

the vacuum pump.

These

noises will no longer be heard when the fill plug

(this

time may

It

is

normal for the oil level to change

vary

with the type

is

hot, due to expansion

at

ultimate

operating. Remove one

less

of

oil and

of

the pump (inlet pres-

(as

its

can be

As

a

than

degree

of

the oil,

"max"

seen

, I

I

I

In

the event

actions" table

of

a malfunction, refer

(page 84).

to

the "Troubleshooting and corrective

76

Page 22

Operation

Preliminary precautions

Operating

temperature

•

The

be

use.

•

The

vacuum

dangerous.

•

The

pumps

However,

performance

guaranteed

pump

Study

the

are

designed

specific

operating

and

if it

is

is

also a compressor:

user

manual

to

may justify partic"laraftention:

•

Product

product

of

pumps).

Be

sure

-

At

temperature

-

The

(12°C)

- Under

case)

operating conditions).

tightness

leaves

the

tightness

start-up,

particularly when

to

fill

the

before switching

is

greater than 53°F

ambient

will

operating

and 113°F (45°C).

these

conditions,

be

between 140°F and 158°F (60 and

is

gu(jfant~d

factory.

pump

It

with

temperature

the

operating

operated

before

prevent

conditions

on

the

for

is

the

users

pumping

oil

(see

page

on

the

(12°q.

for the pump

stabilized

safety

of

this

prod~ctcan

according

tonornl'al.i:onditiorisof

incorrectoperatio~

any

may·

part

skirting

thermal

generate

of

the

user>

up

the pump.

risk

for

IJser

. temperatures

lqoC)..

normciloperatin9>conditions~hen)he

responsibilitY

dangerous.

to

maintairi:theleY~I

produds(onCseries

may

safety.

only

be.

which

...

..

...

68).

motor, check that the oil bath

must

be between 53°F

pump

temperature

700q (depending on

(at

the

front of

the

oil

Before starting-up

the pump

Special

Synthetic oils are much more viscous when cold than mineral oils.

Do not start up

For

drops of oil

In

with slightly contaminated oil,

the oil

internal thermal protection

pages

case -Synthetic

the

the

same

reason and

(I

to 2

&

Check

that

certain cases, when the pump

in

the

pump

72

& 73).

oils

pump at ambient temperatures below 59°F

to

3

)

cm

through

the

exhciust

is

heated up.

to

(1

facilitate lubrication

the

inlet orifice before starting.

orifice

is

not blocked.

is

started up

the

current after start-up may remain high until

These

conditions are sufficient for

be activated, making start-up impossible

of

the pump, pour a few

in

cold ambient conditions, or

YC).

the

(see

75

Page 23

Incidents

The

vacuum pump does not

produce a vacuum (continued)

Causes

Corrective

actions

Noisy pump

Pump too hot

•

At

the pump exhaust, the

installation produces an exhaust

pressure of

-.-Oil

[~

r---~--~.~,_----_._.-------

-.-Incc)rrect

mi;t eliminator cartridge

clogged.

• Oil

level

-.

OXcont~;;inateJlPr~senc;-;r---

particles) .

•

Pump

used.

~~~;C6~~~~~:s~;~g~~*pl.t~--

• Motor coupling incorrectly set or

damaged.

• Incorrect

assembly

• Vanes

1,1

25

Torr

(1.5

too high.

not

p;~pared

-----------~-~

fan

anti-suckbactdeviCe-

---.,----c-------

damaged

for

assembly.

or stuck.

the

bar).

oil

Check the installation.

~

...

:--!

--"'j

i

!

I

1

1-;::--......,.-------------------------------1

--

Replace.

Drain

and

fill

with

-D~~-i·n:-1T~-s·h--~~-(r·~-e1i

oil. j

Check the

the type of oil.

Check

-R;pla~;-ihe--~-otor-cjjter-in-;-pectiori

Check

Check

-Repeat the-Ci-ssem5ry.------------_·--!

pump

the--power

the

-setting.

theassembly.------------j

a new oil.

n-~ith-~

configuration or .

-SUpply.

r~~

--------1

--------------.-j

i

R;;pi~~-------'====-J

• Ambient temperature too high.

--

•

Pump

ventilated place or vents

blocked.

•

Operation at high pressure

P >

-

-~--oiT~ont~;;T

-;~p

--_._---_._----_

22

• Excess pressure at exhaust.

• Motor

Motor

-not prepared

used or

.

placed

In

Torr

(30 mbar).

i~

over-voltage or

in

short-circuit.

nated-.----------

oil

unsuitable.

..

a poorly

for

__

...

_--

Check the installation_

------.---~---

Check

------

-----

the

Oi-I~I

--

Check the

~-k

~~tor·----------------------I

Drain,

oil.

Check pump configuration or type I

of oil. I

------_.---------------_.

._---_.

for

system leaks.

exh~~st-line;~---------I

the-voltage,

flush

and

replace--~i

refill

------~

i

j

I

I

with

clean !

______

__

._-

______

.-1

1

85

Page 24

\

Incidents

Considerable

Poor

pump

off.

___

Oil

in

oil

losses.

tightness

.

_______

base. I •

when

switched

.

________________

I

I

Causes"······

Drain

and

fill

with

new

•

0;1

le'el

tao

h;gh.

• Operation at

-.-GasbaTlastopen:··-

1 - accidentally,

2 - pumping

___

vapours.

•

Leak

at

seal.

~~~

l-·

Safety va!:,!_

high

p~:_~~~r~.

of

condensable

oil

case seal or at

open~______

da~_<:J.ged.

I~~~;:~;~;;;~,kb:~::em~~_

..

___

1

::_;r_I;_o~~;~~~c_._-_-_--._.··

-.

Oil

case and frame cleaned I

poorly during reassembly.

;.

-OiT.

case--seaTPi~~hecr-

-;F~onTseaida-maged---orfelt

saturated.

-----------------_._--.------

- -

J

Use

an

HP

type

__

_

___

front

with

oil

e-------.---.-.-.-

1 - Close.

2 .

._

~-----.~~-~------

Check the assembly and replace

the seals

S-Relopslaec·-

recovery.

..

----------------

Use

a condensate collector.

-e-.--------------=l

f::~:~e

oil

if

necessary.

a"embly.

·~;~:~~"~a~;~;;I;,;h~~O;1

--1--+------------------··---·----1

~'

..... ----.-.

---

-.---

Remove

I I

-Disassemble the

I

faces and

l~~~~~:~-~~~

the

base and clean. !

refit

a new seal.

__

~=~~~~_-_

oil.

mist

eliminator

___~

oil

case, clean -the

..

---.-

...

-----

:==-~

-

I

_I

~~

j

I

I

86

I

.1

.,

)'

Page 25

Maintenance frequency

Maintenance

An

incorrect ultimate vacuum or a reduction in pumping

oil

has

deteriorated.

The

periodic inspection of

a

sample

of new oil

the

lubricant.

of

The

frequency at which oil

the

oil

is

the

cloudy,

The

the

pump

oil

- if

pumping.

- a thickening of

indicate that

Drain

can

the

oil

and

the

state

of

the

oil

is

in

order

to

check

the

level

is

renewed

this

indicates that condensables

be

regenerated

oil, together with a blackish color and a "burnt"

has

deteriorated.

flush

it.

is

adapted

using

the

speed

are

signs

that

the

performed by comparison with

of contamination or deterioration

to

the

type of operation:

have

been

absorbed during

gas

ballast

(see

page

77].

smell

I

i

I!

I

!

,

,

i

I

!

!.

,

~

j

i

Draining

Normally, for a pump operating continuously at a pressure lower than 0.75

(1

mbar) with a

This

value

vacuum

Similarly,

changed at intervals of 6 months to a maximum

sticky).

Note:

intervals adapted

page

required

Every

63)

/'\

•

.Thedraj~in~ope~ation

mcomr1umcatioi1.'wlth,t~"r

ensur~

perst>;ral,

The

pump

atmospheric

-

switch

off

isolate

-

installation;

- tilt

the

- unscrew

the

oil

case

of

the

oil

When all

two

plugs

for about 10

Take

open.

may

appear at

removes

- drain

this

plug;

- replace

of

the

oil

clean

is

given

as

is

sufficient (for primary

if

the

pump

pumping operation

to

each

can

reduce

safety.

must

be

drained

pressure.

the

pump;

the

pump

or disconnect

pump;

the

draining

and

the

filling

case.

the

oil

has

temporarily and

seconds

care with

the

exhaust.

the

oil

from

oil

by

removing

the

draining

case

oil sight

gas (dry air),

a guide only.

is

stopped frequently for long periods,

specific application.

the

frequency of

the

oil should

It

may

vacuum

is

different.

these

plac~s;

~e

.con~~in~ted,

be

be

extended

pumps).

of

This

oil

The

use

maintenance operations.

1 year

must

oli~ldeah,nosphere,~Takealll')ecessc;lry,

:':

.'

.,"

;.

'.

; , ' ,

when

hot

and

after

the

oil

For

this:

from

the

plug

on

the

side of

plug

on

the

top

drained, replace

run

leaving

the

the

the

oil

mist

This

functional block;

the

plug

and fill with

glass

through

the

pump

intake

which

operation

draining

the

fresh

the

filling orifice

oil

to

the

changed every 6

to

1 year if

the

(oil

therefore

of certain

pumping, circuit in,

",

case

has

appropriate

(see

page

the

oil should

may

become

be

accessories

. • : .

been

:.:'".

maximum

69).

months.

ultimate

changed at

steRs.

vented

be

.','

Torr

(see

,

to,

to

87

Page 26

Flushing

The

draining operation

particularly dirty.

the

pump.

can

be

followed by a flushing operation if the oil

This

operation requires a volume of oil equal to

the

capacity of

is

Change

Compatible

Incompatible

of

type

of

oil

oils

oils

After draining

intake filter, clean it and replace it.

the

flushing oil very slowly through

develop at

may

draining plug. Replace

ALCATEL 5 to

120

oil or Alcatel 119 for

specified otherwise

quantity of

Thus,

if

Mineral oil

pump

(see

Mineral oils are also compatible with mineral-based synthetic oils

(see

page 67).

This

is

(e.g.

ALCATEL

Synthetic oils are considered

reasons:

resulting mixture, which could

contamination or deterioration.

For

the

are

also expensive, are treated

the

oil

case

(see

page 87), replace

Run

the

the

exhaust.

21

m3/h

in

oil remains

you wish

the

they are expensive. A mixture may

same

to

use

can

be

replaced by another type

above)

case

using

when, for example, a mineral oil

120

by

reasons,

Stop

the

pump and drain

the

plug and fill with

series

pumps

are

USA

(ALCATEL

the

order. When

in

the

functional block

another type of oil, proceed

the

new oil and fill

ALCATEL

clear synthetic and mineral oils

113).

to

be

incompatible with each other for practical

be

interpreted mistakenly

as

synthetic oils.

the

draining plug.

the

pump at atmospheric pressure, pour

inlet orifice.

tested

113 for C2

the

Take

care with oil

the

fresh

oil

(see

in

the

factory with

series

pump

is

delivered, a certain

as

of

mineral oil. Simply

the

pump

(see

is

replaced by a synthetic oil

cause

slight cloudiness of

as a sign

(ALCATEL

flushing oil via

page 68).

pumps)

follows:

page 68).

Remove

mist

which

the

ALCATEL

unless

flush

the

the

of

300), which

the

These

remarks apply

Alcatel 111,

Proceed

- Disassemble

-

Reassemble

- Connect an oil

-

Fill

the

NOTE:

oils.

113 and

as

follows:

the

it.

pump with

to

replace a synthetic oil by a mineral oil, proceed

to

ester

or fluorocarbon type synthetic oils and

300

(see

page 67).

pump completely and clean it

mist

eliminator to

the

new oil

the

(see

page 68).

pump exhaust.

(see

page 91).

as

the

oils

for compatible

88

Page 27

Replacement of front seal

In

the event

on the pump, it

the shaft

You

will need:

- a front

(see

page 90),

- a screwdriver,

3, 4 and 5

- a

• Stop the pump and disconnect the

power

• Disconnect the pump from

installation to which it

• If possible, position the pump

vertically, with the motor

resting on the front side

drain the

resting it on

• Disconnect the motor by unscrewing the 4 fastening screws, simultaneously

and alternately.

Remove the motor vertically.

•

Unscrew

•

washer.

•

With

• Unscrew the two seal-holder fastening screws and remove the seal-holder.

Remove the seal from the seal-holder

•

it.

• Clean the metal parts. Inspect the wearing side

cleaning, the

polishing). Should the sleeve show any signs

replaced.

be

• Preferably

• Reassemble

• Reinsert the new O-ring on the seal-holder.

• Insert

Engage

•

• Insert the O-ring

the

key,

• Immediately order a replacement maintenance

of

an external oil leak

is

necessary to change

seal on the motor side.

seal replacement kit

mm

Allen wrench.

cord motor.

the

is

connected.

at

the

top,

of

the

oil case; in this position, it

oil case. Otherwise, disassemble the pump

its

base, after it has been drained.

the

fan fastening screw. Remove the fan,

a screwdriver, remove

sleeve may show a perfectly normal trace

use

new parts from the seal kit

the lip seal in

the shaft sleeve inside the seal-holder.

the

reassembled seal-holder on

in

the shaft sleeve. Position the support washer. Then, install

reassemble

the

the

shaft sleeve and

as

its

housing

fan and the motor

as

described on page 95 and discard

or

described

its

axis and screw onto the frame.

in

is

not necessary to

in

the horizontal position,

the

key and

its

O-ring.

of

the shaft sleeve: after

of

of

indentation or grooves, it must

set

of

seals.

on

page 95.

the reverse order

set

or

kit

the

support

rubbing (caused

of

disassembly.

(see

page 90).

by

89

Page 28

Tools

and

consumable

products

Special precautions

Spare

parts

Minor

Major

kit

kit

•

Read

the warning at

• Before disassembling the pump, drain it

• All the seals and faulty parts should be replaced, provide for a seal kit or

a maintenance kit.

This

contains all the seals on the

pump which

each

Keep this kit in a

light),

standards: "storage conditions for vulcanized elastomer based products" -

FD

T.46

In

addition to the seal kit, this kit contains a

maintenance operations on the pump for a two year period, under

operating conditions.

PU!'lP:

2010

2015

2021

1005

1010

1015

1021

1005

1010

1015

1021

must

complete disassembly.

in

order to prevent any hardening

022).

modtlls'"

C2

C2

C2

Cl

Cl

Cl

Cl

SO

SO

SO

SO

the

beginning

be replaced at

dry

place,

away

"

' "

, ;

Part,Nc).

104614

104615

104616 2015

104617

104618 2005 I

104619 2010 I

104620 2015 I

104622

104623

104643

104644 2015

of

the' maintenance chapter.

(see

page 87).

pumpm.odels

SO

1/

Cl / C2

from heat and light (sunlight and ultraviolet

of

the elastomers

set

of

spare parts to perform

Pump

models

SO

2005

SO

2010

(see

SO

2021

SO

' PartNo.

103911

103912

AFNOR

normal

Part

103902

103903

103904

103905

No.

103906

103907

103908

2021

I 103909

2005

2010

2021

Cl

Cl

Cl

Cl

104976

104977

104978

104979

Front

seal

replacement

(parts for shaft passage tightness on

motor side)

Screw

Specific

Recommended

kit

kit

tools

tools

90

This

kit contains all the parts which

must

be replaced in the event

leak

on

the

shaft on the motor side.

This

kit contains all screws and

washers for

Lip

seal assembly mandrel.

•

Two

• Thin spanner:

• Allen wrenches:

• 1 2

all pump models.

5

,5

x

100

mm

box wrench

flat screwdrivers

10

mm

2.5

- 3 - 4 - 5

~

of

on face

a

l5":I!

~

~]

mm

~

Pump

SO

I /Cl /

Screw

All

pumps

Pump

All

models

kD

models

C2

kit

models

kTI

m

Part

No.

065875

065612

Part

No.

104919

Part

No.

052993

Page 29

Disassembling

the

pump

Disassembling

Disassembling

Replacing

the

Disassembling

the

motor

block

the

front

the

6allast

fan

seal

gas

(1)

(;:fl

Remove the motor cover.

t:[l Remove the motor attachment

screws.

(4J

Remove the fan fastening screw

and the support washer.

Remove the

See

page

key.

89.

Il] Remove the gas ballast cover

(2

screws), the adjustment button,

the spring and the

Remove the tank feed-through

(2

screws) and

its

sleeve.

seal.

Disassembling

Removing

Disassembling

the

the

oil

the

(C2

oil

sight

glass

(2)

case

(3)

bubbler

pump)

I:JJ

Remove the

the

rn

O-ring after removing the 4 fastening

screws.

rg.!)

Remove the nitrogen inlet

disconnect the connector

Disconnect the nut which secures the

tube on the

the tube

frame. .

Remove the sight glass cover.

plate, the sight glass and

O-ring.

Remove the oil case and

Disconnect the nitrogen inlet.

functional block and pull

(5)

to

release it

and

(4).

fr.om

its

the

91

Page 30

Oisassembling the

exhaust

valve cover

~J

Remove

(6)

exhaust valves and their springs.

the coverts), the

~

-~

y

/\

r

(

I

I

I

I

I

I

Oisassembling the

(except

1015

SO,

Oisassembling the

pump

also 1015

SO,

SO

oil

1021

I,

oil

1021

pump

system

SO)

C 1,

C2

system

SO

The

oil system

must be reset in the event

disassembly

the

rear flange

without modifying the setting.

Remove

the

circlip.

Do

not disassemble

it. During

not blocked

compressed

m

Remove

pump (9).

equipped with the washer, piston and

spring.

Release

housing.

-;.:'1

[

i

1<.1

Unscrew

(11) and remove

Then

remove the vane (12),

pump rotor (13) and the

coupling (14).

is

set in the factory,

(see

reassembly). However,

(7)

can be disassembled

the

spinner-cam

the

reassembly, check that it

by

sending a jet of

air

through

the cover from

Release

the

stop valve (10) from

the

the

(8)

the

nozzle

it.

the cylinder (15)

seat of

O-ring.

Oldham

of

by removing

to

the

oil

the

stop valve

the

oil

it

clean

its

is

o

fJ

I

I

I

I

I

i

I

I

I

I

I

I

I

\

!

I

I

I

92

Page 31

Disassembling the

rear flange

@)

Remove the 4

nuts

(and washers). Release the flange

in

the axis.

Disassembling the Remove the stator

HP

stator and the rotor rotor.

(two-stage pumps)

Release the rotor

and the vanes.

Disassembling the

intermediate flange

Insert two screwdrivers

and

(two-stage pumps)

Disassembling the

LP

stator and the rotor

Remove the

Remove the rotor and the vanes

equipped with the springs.

by

release the flange

LP

stator.

sliding it along the

in

the notches

in

the axis.

I

I

I

I

"

I

I

J_'_/

__

I_I_~

93

Page 32

Cleaning

components

Cleaning

metal

componeonts

Solvents are required

Standard precautions

instructions.

After

use

in

mineral

mineral products based solvent

PREMACLEANI3),

The

component

use

use

such

when cold

dry

in

(perfluorinate)

as

when cold by

in

(non-perfluorinate)

when cold

• Clean

• Vacuum

•

After

solvent

• Clean

• Dry the components in the air

After

components with a solvent

• Clean

• Dry the components in the

• )ndustrial washing solutions can also be used.

should be followed

to

clean components.

should be taken

or

synthetic

NAPHTEOLl4).

or

hot (max.

in a ventilated oven

must

be

oil,

such

Proceed

cleaned a second

synthetic

GALDEN

S

90™15)

dipping

or

or

synthetic

such

as

by

dipping

by

vacuum drying.

or

air

in

compliance with the manufacturer's

clean the metal components with a

as

AXARELil) , CARECLEANI2),

as

follows:

45°q

by

dipping

time

oil,

clean the metal components

and proceed as follows:

using a cloth

with compressed

or

mineral

alcohol and proceed

using a cloth

or

using a cloth

with

alcohol.

air

oil,

clean the metal

as

follows:

The

cleaning operation

in

a

,

,

Cleaning

the

I,

SO,

oil

C2

C1

level

series

series

sight

glass

pumps

pumps