Page 1

48V

A / B

LINE

/MIC

TRIM

RECORD

/EDIT

SELECT

ASSIGN

SELECT

INPUT 1

ON OFF

234567891011121

A BA BA BA BA BA BA BA BA BA BA B

123456789101112

0

+60

+600+600+600+600+600+600+600+600+600+600+60

+45

+45

+45

+45

+45

+45

+45

-15

-15

-15

-15

-15

SIGNAL / CLIP

SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP

23

1

123456789101112

567

13 14 15 16 17 18 19 20 21 22 23 24

-15

4567

8123

L / R 1 / 2 3 / 4 5 / 6 7 / 8

Q-CHANNEL

20Hz

L R

PAN

ON

SOLO SOLO SOLO SOLO SOLO SOLO SOLO SOLO SOLO SOLO SOLO SOLO

TRACK 1 / 13

2 / 14 3 / 15 4 / 16 5 / 17 6 / 18 7 / 19 8 / 20 9 / 21 10 / 22 11 / 23 12 / 24

20Hz

20kHz

20kHz

-

24dB

LOW

-

24dB

+

24dB

+

24dB

Q

SWEEP

23456789101112

GROUP 1 GROUP 2 GROUP 3 GROUP 4 GROUP 5 GROUP 6 GROUP 7 GROUP 8

-15

Q-STRIP

FUNCTION

20Hz

20kHz

-

HIGH

+45

-15

-15

812

456

FX / AUX 1 FX / AUX 2 FX / AUX 3 FX / AUX 4

PAN

PRE PRE PRE PRE EQ ON

FX / AUX 1 FX / AUX 2 FX / AUX 3 FX / AUX 4

24dB

+

24dB

FX RTN 1 FX RTN 2 FX RTN 3 FX RTN 4 L / R

LINE MICLINE MICLINE MICLINE MICLINE MICLINE MICLINE MICLINE MICLINE MICLINE MICLINE MIC

+45

+45

-15

-15

EFFECT / AUX SENDS

A B

LINE MIC

0

+45

+45

-15

34

78

MONITOR

LEVEL

MIN

!!SOLO!!

2-TRACK

MONO

NEAR

STUDIO CR

SELECT

TALK BACK

MASTER

MAX

CLIP

0

2

4

6

8

10

15

20

25

30

35

40

50

60

LR

TB

LEVEL

EXT

MAIN

SYNC

SCREEN

OFFSET

SHIFT

UNDO REDO PRE-ROLL AUTO

FADER BANK

INP

TRACKS

TRACKS

1-12

1-12

13-24

TO FROM IN OUT

OVER

REWIND FAST FORWARD STOP

5

5

F 1 F 2 F 3 F 4 F 5 F 6

HOURS MINS SECS FRAMES

BARS BEATS CLOCKS

SET

GROUP

USER

FX

BANK

AUTO LOCATE

GO TO

LOOP

MEMORY

ABORT

MIX SCENE

DISPLAY

SELECT

V

.

TRACK CD-RDSP PATCHGRID

RECALLSTORE

ENTERCANCEL

WHEELININP MON

LOCK

RELEASE

CONTRAST

SETUPPROJECTFXAUTOMATEMIXEREDIT

789

456

123

-

JOG SHUTTLE

Q 1

Q 2

Q 3

Q 4

Q 5

Q 6

CURSOR

ZOOM

+

0

OUT

DIGITAL PERSONAL STUDIO

SERVICE MANUAL

1

Page 2

##

#

SAFETY INSTRUCTIONS

##

##

# INFORMATIONS

##

1. Parts identified by the } symbol are critical for saf ety.

Replace them only with the parts number specified.

2. In addition to safety, other par ts and assemblies are

specified for conformance with such regulations as those

applying to spurious radiation.

These must also be replaced only with the specified

replacements.

Examples : Noise blocking capacitors, noise blocking filters ,

etc.

3. Use specified internal wiring. Note especially :

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

4. Use specified insulating materials for hazardous live parts.

Note especially :

1) Insulation Tape

2) PVC tubing

3) Spacers (insulating barriers)

4) Insulation sheets for transistors

5) Plastic screws for fixing micro switches

5. When replacing AC primary side components (transformers, power cords, noise b locking capacitors , etc.), wrap

the ends of the wires securely around the terminals before

soldering.

SYMBOLS FOR PRIMARY DESTINATION

Unit destinations are indicated with letters as shown below.

Symbols Principal Destinations

A U.S.A

B England

E Europe

J Japan

V

X1

X4

MAKE YOUR CONTRIBUTION TO PROTECT THE

ENVIRONMENT

Used batteries with the ISO symbol for recycling as

well as small accumulators (rechargeable batteries),

mini-batteries (cells) and starter batteries should not

be thrown into the garbage can.

Please leave them at an appropriate depot.

PRECAUTIONS FOR LITHIUM BATTERY

The lithium battery may explode when

[OBSERVE THE FOLLOEING WHEN REPLACING]

Germany

Japan

Universal Area

incorrectly replaced.

6. Make sure that wires do not contact heat producing parts

(heat sinks, oxide metal film resistors, fusible resistors,

etc.).

7. Check that replaced wires do not contact sharp edged or

pointed parts.

8. Also check areas surrounding repaired locations.

9. Make sure that foreign objects (screws, solder droplets,

etc.) do not remain inside the set.

SAFETY CHECK AFTER SERVICING

After servicing, make measurements of leakage-current or

resistance in order to determine that exposed parts are

acceptably insulated from the supply circuit. The leakagecurrent measurement should be done between accessible

metal parts (such as chassis, ground terminal, microphone

jacks, signal input/output connectors, etc.) and the earth ground

through a resistor of 1500 ohms paralleled with a 0.15 µF

capacitor, under the unit’s normal working conditions.

The leakage-current should be less than 0.5 mA rms AC. The

resistance measurement should be done between accessible

exposed metal parts and power cord plug prongs with the

power switch (if included) “ON”. The resistance should be

more than 2.2 M ohms.

• Replace with the same make and type or equivalent recom

mended by manufacturer.

• Place battery in correct polarity.

• Do not short the terminals.

• Do not charge battery.

• Do not dispose of battery in fire.

SERVICE MANUAL

2

Page 3

I. SPECIFICATIONS

Specifications

Power Supply AC 120V 60Hz (US, Canada), 220-240V 50Hz (Europe) 110W

Operating Temperature 10 - 35° C

Operating Humidity 10% - 60% (without condensation)

Dimensions (mm) 726 (W) x 190 (H) x 579 (D) max. (with LCD tilted down)

Weight 17.8kg (without drive)

Display 320 x 240 dots STN graphic LCD with back light

Sampling Rate 96kHz, 48kHz, 44.1kHz, 32kHz

Quantization Bit 24 bit/16 bit Linear

Recording Media Internal IDE Harddisk

Recording Time With 10Gbyte Harddisk drive (24bit)

FS=96kHz Approx. 9 hrs. 55 min. (12 tracks x 49 min. 45 sec.)

FS=48kHz Approx. 19 hrs. 50 min. (24 tracks x 49 min. 45 sec.)

FS=44.1kHz Approx. 21 hrs. 35 min. (24 tracks x 54 min. 10 sec.)

FS=32kHz Approx. 29 hrs. 50 min. (24 tracks x 1 hour 14 min.)

Frequency Response

FS=96kHz 10Hz - 44kHz +0/-2dB

FS=48kHz 10Hz - 22kHz +0/-2dB

FS=44.1kHz 10Hz - 20kHz +0/-2dB

FS=32kHz 10Hz - 15kHz +0/-2dB

ADC 24bit 128-times oversampling, enhanced dual bit delta/sigma modulation

DAC 24bit 8-times oversampling, advanced segment delta/sigma modulation

Dynamic Range 104dB or more (30kHz LPF, FS=44.1kHz)

Distortion Ratio 0.003% or less (1kHz, 44.1kHz)

Channel Crosstalk 80dB or less (10kHz referenced, 100 ohms terminated)

Wow & Flutter Below measurable level

Analog Audio Input Inputs A

1 - 4ch 6.3mm Stereo Phone/XLR Combo Jack - balanced

Phantom Power provided (switchable) for XLR connection

5 - 12ch 6.3mm Stereo Phone/XLR Combo Jack - balanced

Inputs B

1 - 12ch 6.3mm Stereo Phone Jack - balanced

Hi-Z 12ch 6.3mm Phone Jack - unbalanced

ADC In 6.3mm Stereo Phone Jack - balanced

AUX In 6.3mm Stereo Phone Jack - balanced

2-Track RCA - unbalanced

Input Level Mic mode -62 - -2dBu (+16dBu max. balanced, 1kHz)

Line mode -47 - +13dBu (+31dBu max. balanced, 1kHz)

Hi-Z -68 - -8dBu (+10dBu max. unbalanced, 1kHz)

ADC In +4dBu (+22dBu max. balanced, 1kHz)

AUX In +4dBu (+22dBu max. balanced, 1kHz)

2-Track -14dBu (+4dBu max. unbalanced, 1kHz)

Impedance Mic mode 3k ohms (1 - 12ch)

Line mode 12k ohms (1 - 12ch)

Hi-Z 1M ohms

ADC In 10k ohms

AUX In 10k ohms

2-Track 15k ohms

Analog Audio Output Stereo Out 6.3mm Stereo Phone - balanced

Main (monitor) 6.3mm Stereo Phone - balanced

Nearfield (monitor) 6.3mm Stereo Phone - balanced

Studio Out 6.3mm Stereo Phone - balanced

Direct Out 6.3mm Stereo Phone - balanced

AUX Sends 1 - 4 6.3mm Stereo Phone - balanced

SERVICE MANUAL

3

Page 4

Output Level Stereo Out +4dBu (+22dBu balanced max., 20k ohms load)

Main (monitor) +4dBu (+22dBu balanced max., 20k ohms load)

Nearfield (monitor) +4dBu (+22dBu balanced max., 20k ohms load)

Studio Out +4dBu (+22dBu balanced max., 20k ohms load)

Direct Out +4dBu (+22dBu balanced max., 20k ohms load)

AUX Sends 1 - 4 +4dBu (+22dBu balanced max., 20k ohms load)

Impedance Stereo Out 1k ohms - balanced

Main (monitor) 1k ohms - balanced

Nearfield (monitor) 1k ohms - balanced

Studio Out 1k ohms - balanced

Direct Out 1k ohms - balanced

AUX Sends 1 - 4 1k ohms - balanced

Stereo Phones Output x 2, 6.3mm Stereo Phone Jack - adjustable

Max. Output 155mW/32 ohms

Digital Audio Input x 1, RCA (SPDIF) 2-channels assignable

x 1, MP Light Pipe (adat/SPDIF) 8-channels/2-channel assignable

Digital Audio Output x 1, RCA (SPDIF) Master Output

x 1, MP Light Pipe (adat/SPDIF) 8-channels assignable/Master Output

Wordclock x 1, BNC - In/Out

Foot switch x 1, 6.3mm Phone Jack

MIDI x 3, 5 pin DIN - IN, OUT, THRU

ASCII Keyboard x 1, 6 pin Mini-DIN

Accessories 3-prong Power Cable

Internal Disk Mounting Kit

Operator’s Manual

Options IB-24LTC - SMPTE/EBU LTC Interface Board

IB-24ADT - 16-channel adat Interface Board w/adat Sync

IB-24SCSI - SCSI Interface Board

*0dBu = 0.775Vrms

The specifications are subject to change without prior notice.

SERVICE MANUAL

4

Page 5

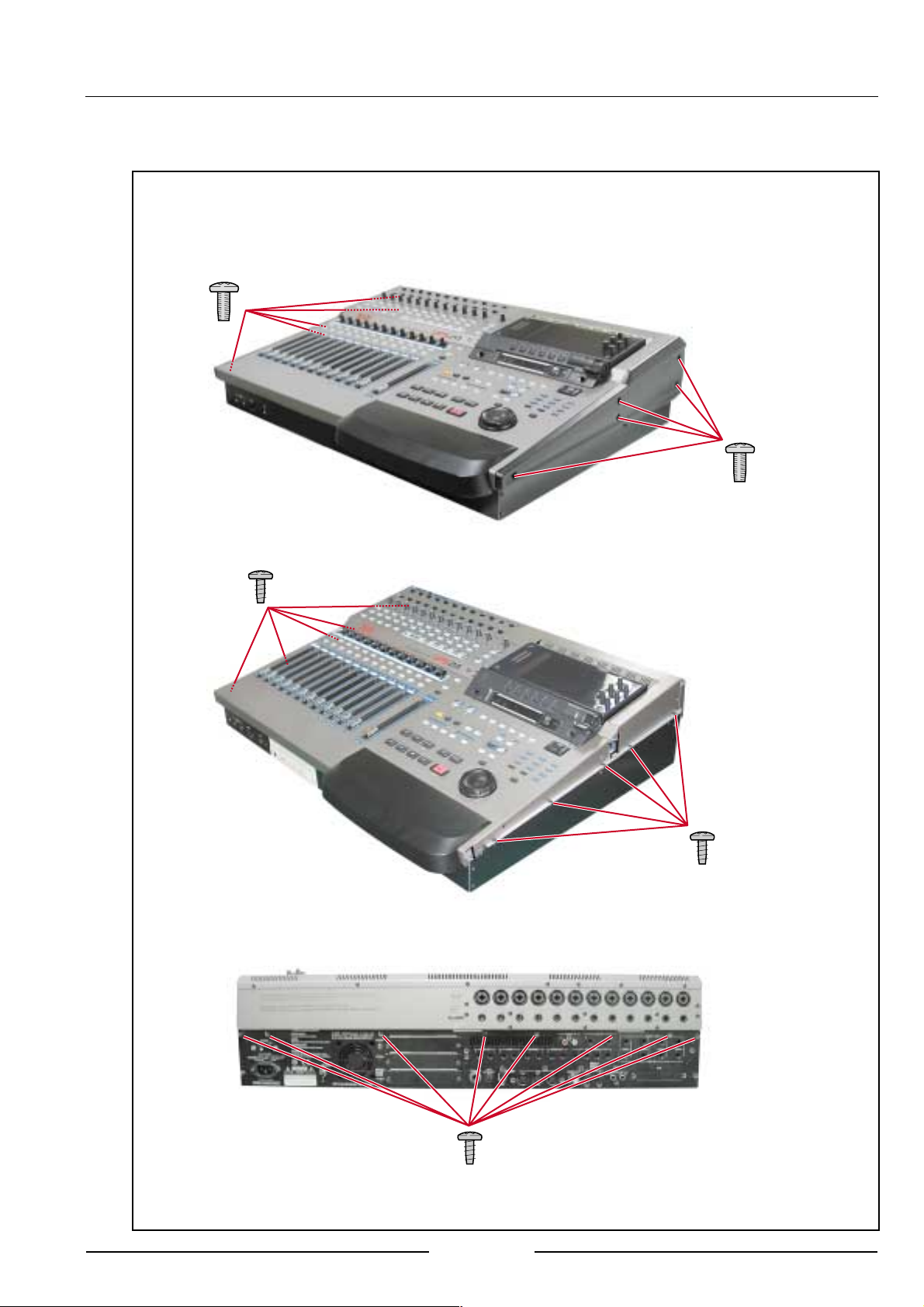

II. DISASSEMBLY

In case of trouble, etc., necessitating dismantling, please dismantle in the order shown in the illustrations . Reassemb le in the

reverse order.

1. Removal of the FRONT PANEL BLOCK

ZS-378447

ST BID40X10STL BNI

ZS-378447

ST BID40X10STL BNI

ZS-331182

BT BID30X08STL BNI

ZS-331182

BT BID30X08STL BNI

ZS-331182

BT BID30X08STL BNI

SERVICE MANUAL

5

Page 6

ZS-331182

BT BID30X08STL BNI

ZS-331182

BT BID30X08STL BNI

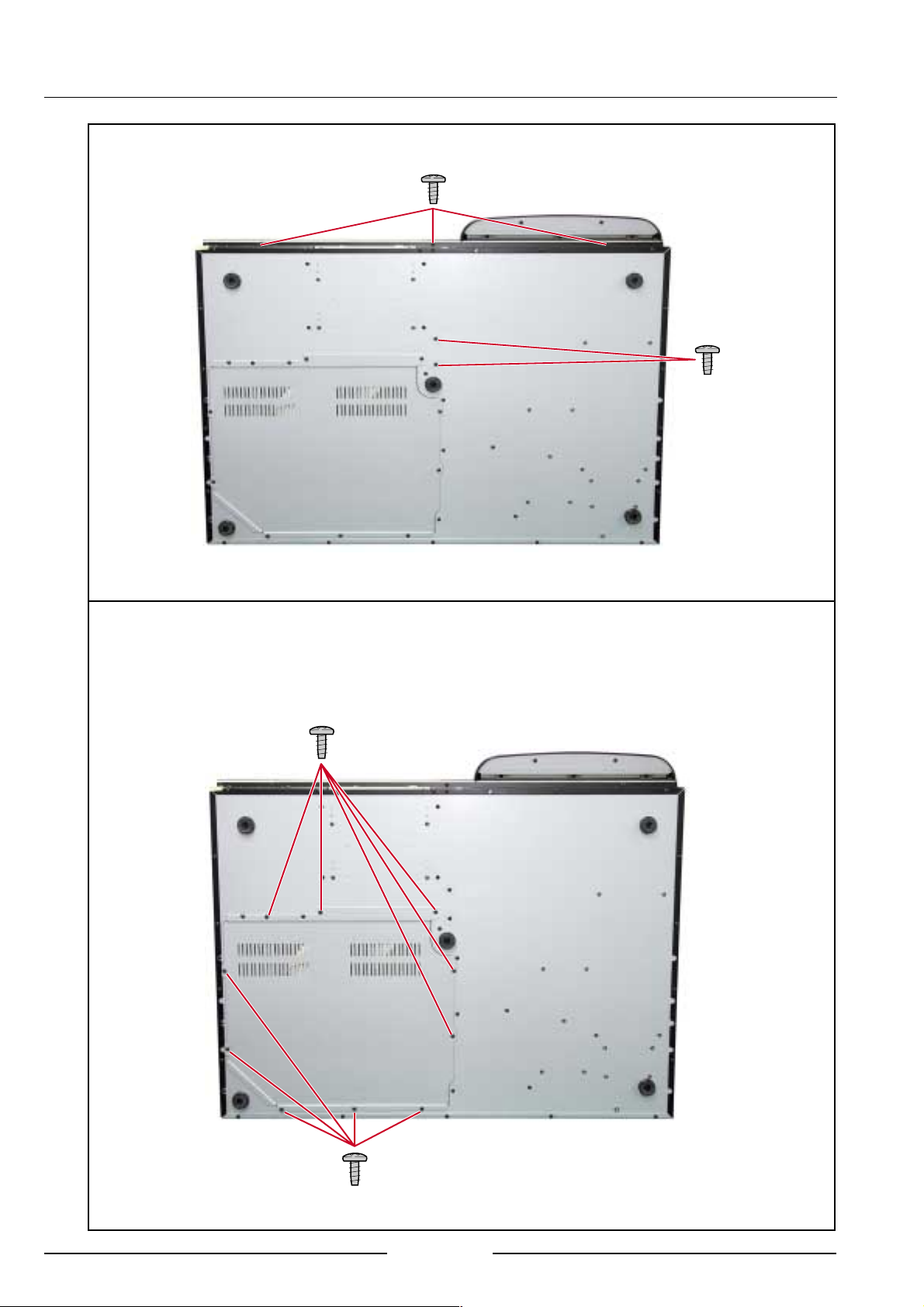

2. Removal of the BOTTOM COVER

ZS-331182

BT BID30X08STL BNI

ZS-331182

BT BID30X08STL BNI

SERVICE MANUAL

6

Page 7

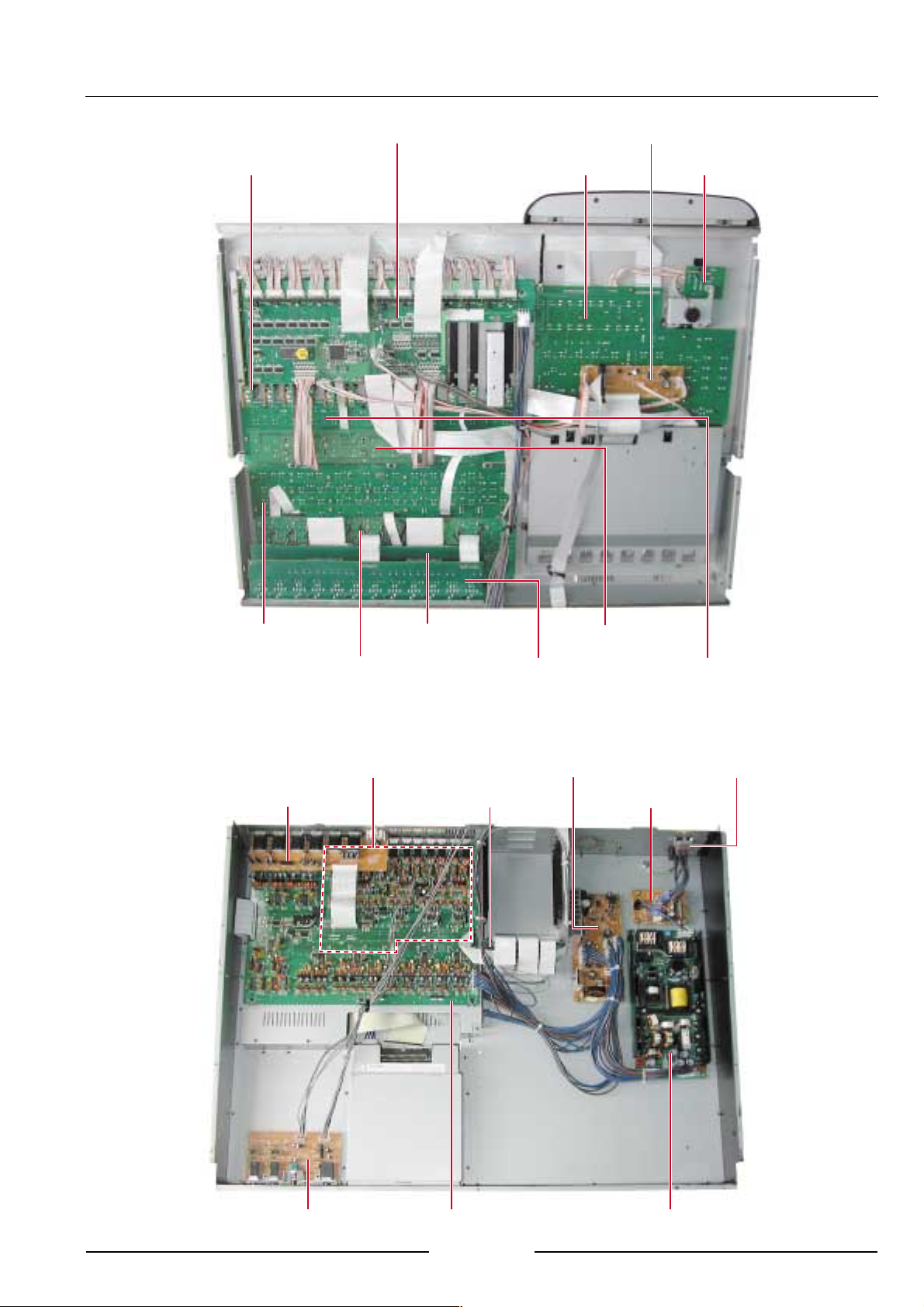

III. PRINCIPAL PARTS LOCATION

PC CONTROL BLK

PC OPERATION R BLKPC FADER BLK

PC OPE-DIST BLK

PC JOG BLK

PC OPERATION L BLK

PC PRE-AMP BLK PC INPUT B BLK

PC CPU BLK

PC AUX IN

PC INPUT A BLK

PC MOTHER BLK

PC LED PAN BLK

PC POWER BLK

PC FILTER BLK

PC PAN ENC BLK

POWER SW BLK

PC HP-HIZ BLK

PC ADDA BLK

SERVICE MANUAL

SW POWER BLK

7

Page 8

IV. SUPPLEMENTARY INFORMATION

1. Test Mode

While pressing the SHIFT button, press the CANCEL button to enter the DEBUG PAGE. To leave the DEBUG

page, press the MAIN SCREEN button. Return to the DEBUG PAGE from any TEST MODE by pressing the

CANCEL button while the SHIFT button is being pressed.

1-1. F1 (BUFFERS)

For confirmation of DISK BUFFERS LEVEL.

1-2. F3 (PANEL)

For confirmation of FADER TOUCH SENSE operation.

F1/F2 (RED TRACK LEDS)

To check whether red LED operation is correct or not.

The RECORD/EDIT SELECT LED, SIGNAL CLIP LED will light up in red.

All other LEDs will light.

F3/F4 (GREEN TRACK LEDS)

To check whether green LED operation is correct or not.

The RECORD/EDIT SELECT LED, SIGNAL CLIP LED will light up in green.

NOTE: After LED CHECK, even when the DEBUG mode has been escaped from, all LED indicators will go

out and only renewed modes will light up in order.

1-3. F4 (AUDIO)

The input AUDIO signal will be output to dircet according to display indicator specification. The main

purpose of this function is for factory testing.

1-4. F2 (MIX DSP) F6 (PATCH)

Not operational at V1.0.

2. PANEL OPERATION TEST MODE

This mode is operated by the OPERATION CPU and is not affected by the CPU circuit of the CPU PCB. This test

mode will operate even if the CPU PCB is not operating properly. Turn the power on while pressing down the

REWIND, FAST FORWARD, STOP and PLAY buttons.

This mode can be used to confirm correct operation of the SWITCH, FADER VR, MONITOR VR, JOG, SHUTTLE

and ENCODER. However, A/B SW, LINE/MIC SW, TRIM, TB LEVEL, PHONE LEVEL are omitted.

NOTE: FADER operation directly after power has been input cannot be tested.

3. OTHER HIDDEN MODES

3-1 With the SHUTTLE knob turned fully to the right, turning the power on will immediately access the VERSION

UP mode via the USB.

3-2 With the SHUTTLE knob turned fully to the left, turning the power on will boot up the system without

running a hard disc check.

This mode is convenient when the system will not startup because of hard disc data.

3-3 With the SHUTTLE knob turned 1/4 to the left, turning the power on will check hard disc content and start up

the system in PROJECT initial settings. Normally the DPS24 starts up in the last PROJECT created. This

mode is convenient when there is a problem with the last PROJECT data and the system won't start up.

SERVICE MANUAL

8

Page 9

4. JIG PC BOOT DPS24 (PART No. BA-771030J)

JIG PC BOOT is used for BOOT BLOCK recovery and for CPU circuit testing etc.

Insert in SLOT 1 on the OPTION BOARD. Make sure the power is off before inserting. The JIG PC BOOT will not

work in any other slot besides SLOT 1.

When the DPS24 power is turned on, the SELF CHECK function will operate to check each CHIP. If a fault is found

somewhere, FAILED will appear and operation will stop.

FAILED will appear when nothing after MIDI SPDIF, WCLK, ASCII are connected, but this is not an indication of

faulty operation.

5. OS BOOT BLOCK RECOVERY PROCEDURE

Insert the PC JIG BOOT into SLOT 1. Make sure the power is off before inserting. The JIG PC BOOT will not w ork

in any other slot besides SLOT 1.

1. When the DPS24 power is turned on, the SELF CHECK function will operate to check each CHIP. After confir-

mation, the screen will normally be returned to.

2. Press the SETUP button, then the F6(OS) button.

3. Press the F2/F3/F4 (upgrade from EPROM) button.

4. Press the F6(YES) button.

5. Press the F6(OK) button.

6. OS UPDATE PROCEDURE

• OS UPDATE FROM CD-ROM

You can update the OS from the built-in CD-ROM drive. Please use a CD-ROM that contains the OS for the

DPS24.

You can create the OS disc by using your PC's CD-R/W function to write the “DPS24.bin file” onto an ISO 9660

CD-ROM disc.

1. Turn the DPS24 on and insert the OS disc

2. Press the SETUP button, then the F6(OS) button.

3. Set “Update from” to “CD” with Q1 knob.

4. Press the F5/F6 (UPGRADE) button.

5. Confirm the displayed OS version. If not displayed, repeat the procedure.

6. If the correct version is displayed, press the F6(YES) button.

7. Press the F6 (OK) button.

8. Reboot the DPS24.

• OS UPDATE FROM USB

The OS update can be made from the PC via the USB port.

You must have the "OS Loader software for DPS24".

The following files are required for the update:

dps24usb.sys (USB set up file)

dps24usb.inf (USB set up file)

usbrom.exe (USB transmission software)

dps24.bin (OS file for DPS24)

These files must be placed in the same folder. (eg. c:\DPS24)

Installing the USB drivers:

1. Connect USB cable between DPS24 and PC.

2. Power up the PC and let it complete the boot up process.

3. Power up the DPS24.

SERVICE MANUAL

9

Page 10

4. Yous PC should automatically detect the DPS24 and open the New Hardware Wizard.

5. Choose the option in the New Hardware Wizard that allows you to specify the location of the driver files.

6. Ues the BROWSE function to locate the files expanded into the folder you created.

7. Click OK and next to install the drivers.

OS UPDATE FROM USB

1. Connect the DPS24 and PC with the USB cable.

2. Turn on the DPS24 and PC.

3. Press the DPS24's SETUP button, then the F6(OS) button.

4. Set “Upgrade from” to the USB port with Q1 knob.

5. Press the F5/F6(upgrade) button, then the F6(YES) button.

6. Wait for the OS to be loaded from the PC.

7. The OS Loader runs only using the MS-DOS Command prompt.

8. In the Command prompt window, switch to the folder you created. (eg. c:\DPS24)

9. Select the update type from the following. Normally select usbrom /v dps24.bin

#1. usbrom dps24.bin ------ (normal)

#2. usbrom /v dps24.bin ------ (update and checksum)

#3. usbrom /bootblock dps24.bin ------ (overwrite boot block)

Type in either of the above to execute the program.

10. Reboot the DPS24.

10

SERVICE MANUAL

Page 11

Installation of Options

IB-24LTC/IB-24ADT

1. Remove the screws for the cover of expansion slot and remove the cover. Save the screws.

2. Slide the Option Board in along the guide groove and press it firmly to ensure secure connection.

3. Tighten the screws back that have been removed in the previous step.

IB-24SCSI

1. From the bottom of the unit, remove the screws for the bottom cover and open the bottom.

2. Remove the screws for the cover of SCSI option slot on the Rear Panel and remove the cover. Save the

screws.

3. Place the board as illustrated, making sure that connectors are securely connected.

4. Mount the board with the screw included in the option board and with those screws removed previously.

5. Place the bottom cover back and tighten all screws.

SERVICE MANUAL

11

Page 12

Hard Disk Drive

1. From the bottom of the unit, remove the screws for the bottom cover and open the bottom.

2. Jumper setting of the hard disk has to be in MASTER mode with the short pin on the hard disk.

3. Referring to the illustration, slide the Hard Disk Drive in the disk holder and mount it with the screws inside

the Internal Disk Mounting Kit. There are inch-threaded screws and millimeter-threaded screws inside. Be

sure to use the appropriate type.

4. Connect the 4-pin Power Cable and 40-pin Disk Drive Cable as illustrated.

On the Disk Drive Cable, BLUE connector has to be connected to the CPU board on DPS24.

ZS-418538J

PAN N06-32UNCXSMM

STL CMT

5. Place the bottom cover back and tighten all screws.

12

SERVICE MANUAL

Page 13

CD-R/CD-RW Drive

1. From the bottom of the unit, remove the screws for the bottom cover and open the bottom.

2. Remove the cover for the CD-R/RW Drive on the Front Panel.

3. Jumper settingof the CD-R/RW has to be in SLAVE mode with short pin on the CD-R/RW.

4. Referring to the illustration, slide the CD-R/RW Drive from the front and mount it on the bottom chassis with

the screws inside the Internal Disk Mounting Kit. There are inch-threaded screws and millimeter-threaded

screws inside. Be sure to use the appropriate type.

5. Connect the 4-pin Power Cable and 40-pin Disk Drive Cable as illustrated.

On the Disk Drive Cable, BLUE connector has to be connect to the CPU board on DPS24.

6. Place the bottom cover back and tighten all screws.

SERVICE MANUAL

13

Page 14

V. PARTS LIST

ATTENTION

1. When placing an order for parts, be sure to list the Part No., Model No. and the description of each part.

Otherwise, the non-delivery of the part or the delivery of a wrong part may result.

2. Please make sure that Part No. is correct when ordering.

If not, a part different from the one you ordered may be delivered.

3. Since the parts shown in Parts List or Preliminary Service Manual may have been the subject of changes,

please use this Parts List for all future reference.

HOW TO USE THIS PARTS LIST

1. This Parts List lists those parts which are considered necessary for repairs.

2. Parts not shown in the Parts List will not in principle be supplied.

3. How to read the Parts List.

1. PC MAIN BOARD BLK

Ref. No. Part No. Description

D5 ED-431276C D SCHOT 1S30-J T05

D110 ED-431276C D SCHOT 1S30-J T05

:

:

IC5 EI-811073J ICTRC-6593

IC10 EI-811068J IC HD74HC157FP

Service parts classification

These reference symbols correspond with component

symbols in the Schematic Diagrams.

2. FINAL ASSEMBLY BLK

Ref. No. Part No. Description

1. SA-349332 FOOT

2. ZS-344754C ST PAN30x06STL CMT

:

:

44. SP-417333J COVER TOP

45. ZS-418385J BT BID30X06STL BNI EATRH LOCK

46-A EW-380905J AC CORD 250S KP300 KS16A

H B J [J]

46-B EW-368420J1 AC CORD 200SKP30KS B AC [A]

46-C EW-410608J AC CORD 250 KP4819D KS31A B E

[E,V]

Symbols for primary destination

[A] U.S.A. [J] Japan

[B] England [V] Germany

[E] Europe [x1] Japan

[X4] Universal Area

Safety critical component

This number corresponds with the individual parts index number

in the figure.

WARNING

}}

} INDICATES SAFETY CRITICAL COMPONENTS. FOR CONTINUED SAFETY, REPLACE SAFETY CRITICAL

}}

COMPONENTS ONLY WITH MANUFACTURER'S RECOMMENDED PARTS.

AVERTISSEMENT

}}

} IL INDIQUE LES COMPOSANTS CRITIQUES DE SÉCURITÉ. POUR MAINTENIR LE DEGRÉ DE SÉCURITÉDE

}}

L'APPAREIL, NE REMPLACER QUE DES PIÉCES RECOMMANDEES PAR LÉ FABRICANT.

SERVICE MANUAL

14

Page 15

PC BOARD BLK

The PC Board Block may contain se veral PC Boards. The y appear

under its block name with their individual part number.

1. P.C.BOARD BLK

Ref.No Part No. Description

1 BA-L3056A020A PC CPU BLK DPS24

2 BA-L3056A030A PC(#)ADDA BLK DPS24

3 BA-L3056A040A PC(#)CONTROL BLK DPS24

4 BA-L3056A050A PC(#)OPE R BLK DPS24

5 BA-L3056A060A PC(#)OPE L BLK DPS24

6 BA-L3056A070A PC(#)IO BLK DPS24

7 BA-L3056A080A PC(#)FADER BLK DPS24

PC(#)ADDA BLK DPS24 CONSISTIS OF FOLLOWING P.C.BOARD

Part No. Description

BA-L3056A502A PC ADDA BLK

BA-L3056A502B PC PAN ENC BLK

PC(#)CONTROL BLK DPS24 CONSISTIS OF FOLLOWING P.C.BOARDS

Part No. Description

BA-L3056A503A PC CONTROL BLK

BA-L3056A503B PC PRE-AMP BLK

BA-L3056A503C PC MOTHER BLK

PC(#)OPE R BLK DPS24 CONSISTIS OF FOLLOWING P.C.BOARDS

Part No. Description

BA-L3056A504A PC OPERATION R BLK

BA-L3056A504B PC 7 SEG BLK

BA-L3056A504C PC LCD-DIST BLK

BA-L3056A504D PC FILTER BLK

BA-L3056A504E PC Q-LINK BLK

BA-L3056A504F PC METER BLK

BA-L3056A504G PC MIC BLK

PC(#)OPE L BLK DPS24 CONSISTIS OF FOLLOWING P.C.BOARDS

Part No. Description

BA-L3056A505A PC LED PAN BLK

BA-L3056A505B PC OPERATION L BLK

BA-L3056A505C PC AUX-IN BLK

BA-L3056A505D PC OPE-DIST BLK

BA-L3056A505E PC JOG BLK

PC(#)IO BLK DPS24 CONSISTIS OF FOLLOWING P.C.BOARDS

Part No. Description

BA-L3056A506A PC INPUT A BLK

BA-L3056A506B PC INPUT B BLK

BA-L3056A506C PC POWER BLK

BA-L3056A506D PC HP-HIZ BLK

PC(#)FADER BLK DPS24 CONSISTIS OF FOLLOWING P.C.BOARDS

Part No. Description

BA-L3056A507A PC FADER BLK

2. P.C. CPU BLK

Ref.No Part No. Description

J1 EJ-821219X PHONE J YKB22-5244 NUT 6.3

J2 EJ-403478J DIN J YKF51-5040 5P

J3 EJ-821236X SOCKET CONNECTER YKF45-0020 4P

J4 EJ-810323J SOCKET TCS7927-56

J5 EJ-820150J SOCKET COAX. BNC-LNRD-BPAA

J6 EJ-394490J SOCKET OPTICAL GP1F32T

J7 EJ-394459J SOCKET OPTICAL GP1F32R

J8 EJ-820754X PIN J YKC21-3079 P2P

J9 EJ-820493X SOCKET BATTERY BH25TN

BT1

J201 EJ-821170X SOCKET 20FMZ-BT 20P

J202 EJ-812021J SOCKET 26FMZ-BT 26P

J203 EJ-821171X SOCKET 28FMZ-BT 28P

J301 EJ-820809X SOCKET 40FE-BT-VK-N 40P

P11 EJ-820807X PLUG 128A-050P2A-L14A 50P

P101 EJ-821378X PLUG 302-40GSB-ATA 40P

P102 EJ-811058J PLUG 302-16GSB 16P

SF9 EF-811099J FUSE RXE030 60V 0.30A

D1 ED-428998J D SILICON C.1SS355TE-17 T08E

D2 ED-428998J D SILICON C.1SS355TE-17 T08E

D3 ED-428998J D SILICON C.1SS355TE-17 T08E

D5 ED-812338J D ZENER C.UDZ4.7BTE-17 T08E

D6 ED-428998J D SILICON C.1SS355TE-17 T08E

D7 ED-428998J D SILICON C.1SS355TE-17 T08E

IC1 EI-820788X IC GDS1110BD-206MHZ MBGA [unavailable]

IC2 EI-820802X IC XC2S150-5FG256C MBGA [unavailable]

IC3 EI-812794J IC XCB56362PV100 TQFP

IC4 EI-812794J IC XCB56362PV100 TQFP

IC5 EI-812794J IC XCB56362PV100 TQFP

IC6 EI-821487X IC HY57V641620HGT-P

IC7 EI-821487X IC HY57V641620HGT-P

IC8 EI-821487X IC HY57V641620HGT-P

IC9 EI-821487X IC HY57V641620HGT-P

IC10 EI-812979J IC HD74LVC245ATELL FPELT16E

IC11 EI-812979J IC HD74LVC245ATELL FPELT16E

IC12 EI-812978J IC HD74LVC541ATELL FPELT16E

IC13 EI-812978J IC HD74LVC541ATELL FPELT16E

IC14 EI-820787X IC GAL16V8D-15QP L3056

IC15 EI-820062J IC HD74HCT541FP FPELT24

IC16 EI-812979J IC HD74LVC245ATELL FPELT16E

IC17 EI-812979J IC HD74LVC245ATELL FPELT16E

IC18 EI-820795X IC HD74LVC14TELL FPELT12E

IC19 EI-820794X IC HD74LVC138TELL FPELT12E

IC20 EI-820792X IC HD74LS08FP FPELT16E

IC21 EI-811096J IC HD74HC4053FP

IC22 EI-438820J IC TC74HCU04AF FPEL T16E

IC23 EI-820154J IC CS8420-CS FP

IC24 EI-810887J IC AV9173-01CS08 FP T12E

IC25 EI-810574J IC M51957BFP FP73AT12

IC26 EI-820800X IC RS5C313

IC28 EI-821406X IC AIC1117CE FP T16E

IC29 EI-821406X IC AIC1117CE FP T16E

IC30 EI-820801X IC TE28F160C3BA90

IC31 EI-812978J IC HD74LVC541ATELL FPELT16E

IC32 EI-812978J IC HD74LVC541ATELL FPELT16E

IC33 EI-812978J IC HD74LVC541ATELL FPELT16E

IC34 EI-812978J IC HD74LVC541ATELL FPELT16E

IC35 EI-812978J IC HD74LVC541ATELL FPELT16E

IC36 EI-820793X IC HD74LVC125ATELL FPELT12E

IC37 EI-820955X IC NET2890

IC51 EI-812794J IC XCB56362PV100 TQFP

IC52 EI-812852J IC TC55V16256J-15

IC53 EI-812852J IC TC55V16256J-15

IC54 EI-820459X IC GM71VS65163CLT-5

IC55 EI-820459X IC GM71VS65163CLT-5

PH1 ET-431258J DETECTOR C.PC400T T12E

EZ-811066J BATTERY LITHIUM CR2025

SERVICE MANUAL

15

Page 16

Ref.No Part No. Description

T1 BT-810651J TRANS PULSE CIT0705S-35101TFP

TR1 ET-820772X TR CHIP DTB122JKT146 T08E

TR2 ET-821162X TR CHIP DTC343TKT146 T08E

TR3 ET-433976J TR C.DTA114TKA T146T08E

X1 EI-820769X OSC X’TAL C.SMD-49 3.6864MHZ

X2 EI-820827X OSC X’TAL C.SG8002JAPCB 50MHZ

X3 EI-427850J OSC X’TAL MC306 32.768KHZ

X4 EI-821163X OSC X’TAL C.SG8002JAPCB 48MHZ

3. P.C. (#)ADDA BLK

P.C. ADDA BLK

Ref.No Part No. Description

D601 ED-811455J D SILICON H 1SS133T-77 T26

D602 ED-811455J D SILICON H 1SS133T-77 T26

D603 ED-811455J D SILICON H 1SS133T-77 T26

D604 ED-811455J D SILICON H 1SS133T-77 T26

D605 ED-811455J D SILICON H 1SS133T-77 T26

D606 ED-811455J D SILICON H 1SS133T-77 T26

D607 ED-811455J D SILICON H 1SS133T-77 T26

D608 ED-811455J D SILICON H 1SS133T-77 T26

D609 ED-811455J D SILICON H 1SS133T-77 T26

D610 ED-811455J D SILICON H 1SS133T-77 T26

D611 ED-811455J D SILICON H 1SS133T-77 T26

D612 ED-811455J D SILICON H 1SS133T-77 T26

IC11 EI-810591J IC NJM5532L

IC12 EI-810591J IC NJM5532L

IC31 EI-810591J IC NJM5532L

IC32 EI-810591J IC NJM5532L

IC33 EI-812318J IC AK5393-VS

IC51 EI-810591J IC NJM5532L

IC52 EI-810591J IC NJM5532L

IC71 EI-810591J IC NJM5532L

IC72 EI-810591J IC NJM5532L

IC73 EI-812318J IC AK5393-VS

IC91 EI-810591J IC NJM5532L

IC92 EI-810591J IC NJM5532L

IC111 EI-810591J IC NJM5532L

IC112 EI-810591J IC NJM5532L

IC113 EI-812318J IC AK5393-VS

IC131 EI-810591J IC NJM5532L

IC132 EI-810591J IC NJM5532L

IC134 EI-384806J IC TC74HC4053AP

IC151 EI-810591J IC NJM5532L

IC152 EI-810591J IC NJM5532L

IC153 EI-812318J IC AK5393-VS

IC154 EI-384806J IC TC74HC4053AP

IC171 EI-810591J IC NJM5532L

IC172 EI-810591J IC NJM5532L

IC191 EI-810591J IC NJM5532L

IC192 EI-810591J IC NJM5532L

IC193 EI-812318J IC AK5393-VS

IC211 EI-810591J IC NJM5532L

IC212 EI-810591J IC NJM5532L

IC231 EI-810591J IC NJM5532L

IC232 EI-810591J IC NJM5532L

IC233 EI-812318J IC AK5393-VS

IC251 EI-810591J IC NJM5532L

IC252 EI-810591J IC NJM5532L

IC271 EI-810591J IC NJM5532L

IC272 EI-810591J IC NJM5532L

IC273 EI-812318J IC AK5393-VS

IC291 EI-810591J IC NJM5532L

IC292 EI-810591J IC NJM5532L

IC311 EI-810591J IC NJM5532L

IC312 EI-810591J IC NJM5532L

IC313 EI-812318J IC AK5393-VS

Ref.No Part No. Description

IC331 EI-810591J IC NJM5532L

IC332 EI-810591J IC NJM5532L

IC333 EI-821226X IC OPA2134UA FPT12E

IC345 EI-820799X IC PCM1738E FPT16E

IC352 EI-810591J IC NJM5532L

IC353 EI-821226X IC OPA2134UA FPT12E

IC371 EI-810591J IC NJM5532L

IC372 EI-810591J IC NJM5532L

IC373 EI-821226X IC OPA2134UA FPT12E

IC385 EI-820799X IC PCM1738E FPT16E

IC392 EI-810591J IC NJM5532L

IC393 EI-821226X IC OPA2134UA FPT12E

IC411 EI-810591J IC NJM5532L

IC412 EI-810591J IC NJM5532L

IC413 EI-821226X IC OPA2134UA FPT12E

IC425 EI-820799X IC PCM1738E FPT16E

IC432 EI-810591J IC NJM5532L

IC433 EI-821226X IC OPA2134UA FPT12E

IC451 EI-810591J IC NJM5532L

IC452 EI-810591J IC NJM5532L

IC453 EI-821226X IC OPA2134UA FPT12E

IC465 EI-820799X IC PCM1738E FPT16E

IC472 EI-810591J IC NJM5532L

IC473 EI-821226X IC OPA2134UA FPT12E

IC491 EI-810591J IC NJM5532L

IC492 EI-810591J IC NJM5532L

IC493 EI-821226X IC OPA2134UA FPT12E

IC505 EI-820799X IC PCM1738E FPT16E

IC512 EI-810591J IC NJM5532L

IC513 EI-821226X IC OPA2134UA FPT12E

IC531 EI-431241J IC HD74HC4052FP FPELT16E

IC532 EI-810591J IC NJM5532L

IC551 EI-403306J IC NJM4558L

IC552 EI-810591J IC NJM5532L

IC601 EI-820951X IC HD74LVC244AT FPELT16E

IC602 EI-810589J IC M51957BL

IC603 EI-431115J IC HD74HC595FP FPELT16E

IC604 EI-431115J IC HD74HC595FP FPELT16E

IC605 EI-413206J IC NJM7905FA

IC606 EI-820780X IC AIC1117-33CE

IC607 EI-812977J IC HD74LVC08TELL FPELT16E

IC608 EI-431241J IC HD74HC4052FP FPELT16E

IC609 EI-810591J IC NJM5532L

IC610 EI-820793X IC HD74LVC125ATELL FPELT12E

J1 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J2 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J3 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J4 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J203 EJ-821170X SOCKET 20FMZ-BT 20P

J301 EJ-820809X SOCKET 40FE-BT-VK-N 40P

J303 EJ-821169X SOCKET 13FMZ-BT 13P

J304 EJ-821169X SOCKET 13FMZ-BT 13P

J306 EJ-427802J SOCKET 26FE-BT 26P

J331 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

J351 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

J371 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

J391 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

J411 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

J431 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

J451 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

J471 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

J491 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

J511 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

J531 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

J551 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

RP601 ER-386637J COMP R RGLE8X 103J

SF7

EF-376821 FUSE ICP-N15 50V 0.6A

16

SERVICE MANUAL

Page 17

Ref.No Part No. Description

TR131 ET-362847 TR 2SA1317 S,T,U T05

TR132 ET-362209 TR 2SC3330 S,T,U T05

TR151 ET-362847 TR 2SA1317 S,T,U T05

TR152 ET-362209 TR 2SC3330 S,T,U T05

TR331 ET-820770X TR 2SD2227S T05

TR332 ET-820770X TR 2SD2227S T05

TR351 ET-820770X TR 2SD2227S T05

TR352 ET-820770X TR 2SD2227S T05

TR371 ET-820770X TR 2SD2227S T05

TR372 ET-820770X TR 2SD2227S T05

TR391 ET-820770X TR 2SD2227S T05

TR392 ET-820770X TR 2SD2227S T05

TR411 ET-820770X TR 2SD2227S T05

TR412 ET-820770X TR 2SD2227S T05

TR431 ET-820770X TR 2SD2227S T05

TR432 ET-820770X TR 2SD2227S T05

TR451 ET-820770X TR 2SD2227S T05

TR452 ET-820770X TR 2SD2227S T05

TR471 ET-820770X TR 2SD2227S T05

TR472 ET-820770X TR 2SD2227S T05

TR491 ET-820770X TR 2SD2227S T05

TR492 ET-820770X TR 2SD2227S T05

TR511 ET-820770X TR 2SD2227S T05

TR512 ET-820770X TR 2SD2227S T05

TR531 ET-820770X TR 2SD2227S T05

TR532 ET-820770X TR 2SD2227S T05

TR551 ET-820770X TR 2SD2227S T05

TR552 ET-820770X TR 2SD2227S T05

TR601 ET-389684J TR DTA113ZS T05

TR602 ET-389684J TR DTA113ZS T05

TR603 ET-389684J TR DTA113ZS T05

TR604 ET-820770X TR 2SD2227S T05

TR605 ET-820770X TR 2SD2227S T05

TR606 ET-389684J TR DTA113ZS T05

TR607 ET-389684J TR DTA113ZS T05

TR608 ET-820770X TR 2SD2227S T05

TR609 ET-820770X TR 2SD2227S T05

TR610 ET-820770X TR 2SD2227S T05

TR611 ET-820770X TR 2SD2227S T05

TR612 ET-364023 TR DTC114ES T05

TR613 ET-389684J TR DTA113ZS T05

TR614 ET-364023 TR DTC114ES T05

TR615 ET-389684J TR DTA113ZS T05

W313 EW-820715X WIRE ASSY L3056 W313 6P

P.C. PAN ENC BLK

IC801 EI-820790X IC HD74HC253FP FPELT16E

IC802 EI-820790X IC HD74HC253FP FPELT16E

IC803 EI-820790X IC HD74HC253FP FPELT16E

J409 EJ-438452J SOCKET 10-FMZ-ST 10P

SW801 ES-812749J SW ROTARY ENCORDER EC12E24204

SW802 ES-812749J SW ROTARY ENCORDER EC12E24204

SW803 ES-812749J SW ROTARY ENCORDER EC12E24204

SW804 ES-812749J SW ROTARY ENCORDER EC12E24204

SW805 ES-812749J SW ROTARY ENCORDER EC12E24204

SW806 ES-812749J SW ROTARY ENCORDER EC12E24204

SW807 ES-812749J SW ROTARY ENCORDER EC12E24204

SW808 ES-812749J SW ROTARY ENCORDER EC12E24204

SW809 ES-812749J SW ROTARY ENCORDER EC12E24204

SW810 ES-812749J SW ROTARY ENCORDER EC12E24204

SW811 ES-812749J SW ROTARY ENCORDER EC12E24204

SW812 ES-812749J SW ROTARY ENCORDER EC12E24204

4. P.C. (#)CONTROL BLK

P.C. CONTROL BLK

Ref.No Part No. Description

D701 ED-821003X D SILICON C. DAN217 T146T08

D702 ED-428998J D SILICON C.1SS355TE-17 T08E

D703 ED-821003X D SILICON C. DAN217 T146T08

IB701 ER-813231J COMP R C.MNR14 472J T08P

IB702 ER-813231J COMP R C.MNR14 472J T08P

IB703 ER-813231J COMP R C.MNR14 472J T08P

IB704 ER-813231J COMP R C.MNR14 472J T08P

IB705 ER-813231J COMP R C.MNR14 472J T08P

IC701 EI-820798X IC MB91110PMT2-G-BND QFTY

IC702 EI-811086J IC HD74HC541FP

IC703 EI-401216J IC HD74HC138FP

IC704 EI-820789X IC HD74HC238FP FPELT16E

IC705 EI-820789X IC HD74HC238FP FPELT16E

IC706 EI-812482J IC HD74HC4051FP

IC707 EI-431253J IC HD74HC14FP FPELT16E

IC708 EI-811577J IC HD74HC175FP FPELT16E

IC709 EI-820796X IC LMC555CMX FP T12E

IC710 EI-401216J IC HD74HC138FP

IC711 EI-401216J IC HD74HC138FP

IC712 EI-401216J IC HD74HC138FP

IC713 EI-401216J IC HD74HC138FP

IC714 EI-810268J IC HD74HC273FP

IC715 EI-810268J IC HD74HC273FP

IC716 EI-810268J IC HD74HC273FP

IC717 EI-811577J IC HD74HC175FP FPELT16E

IC718 EI-811577J IC HD74HC175FP FPELT16E

IC719 EI-812482J IC HD74HC4051FP

IC720 EI-812482J IC HD74HC4051FP

IC721 EI-820786X IC TLC2272CDR FP T16E

IC722 EI-820791X IC HD74HC86FP FPELT16E

IC723 EI-821405X IC AIC1117-33CE FP T16E

IC724 EI-431115J IC HD74HC595FP FPELT16E

IC725 EI-431115J IC HD74HC595FP FPELT16E

IC726 EI-431115J IC HD74HC595FP FPELT16E

IC727 EI-821440X IC M27C256B45XF1 DPS24 V1.0-OP

IC801 EI-820782X IC BA6286N

IC802 EI-820782X IC BA6286N

IC803 EI-820782X IC BA6286N

IC804 EI-820782X IC BA6286N

IC805 EI-820782X IC BA6286N

IC806 EI-820782X IC BA6286N

IC807 EI-820782X IC BA6286N

IC808 EI-820782X IC BA6286N

IC809 EI-820782X IC BA6286N

IC810 EI-820782X IC BA6286N

IC811 EI-820782X IC BA6286N

IC812 EI-820782X IC BA6286N

IC813 EI-820782X IC BA6286N

J401 EJ-821389X SOCKET 26FE-BT-VK-N 26P

J402 EJ-820808X SOCKET 20FE-BT-VK-N 20P

J403 EJ-821389X SOCKET 26FE-BT-VK-N 26P

J409 EJ-820815X SOCKET 10FMZ-BT 10P

J410 EJ-821389X SOCKET 26FE-BT-VK-N 26P

SF10 EF-376821 FUSE ICP-N25 50V 0.6A

TR701 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR702 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR703 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR704 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR705 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR706 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR707 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR708 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR709 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR710 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR711 ET-820771X TR FET CHIP 2SK2103T100 T12E

SERVICE MANUAL

17

Page 18

Ref.No Part No. Description

TR712 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR713 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR714 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR715 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR716 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR717 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR718 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR719 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR720 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR721 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR722 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR723 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR724 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR725 ET-820771X TR FET CHIP 2SK2103T100 T12E

TR726 ET-439329J TR C.DTA143ZKA T146T08E

TR727 ET-439329J TR C.DTA143ZKA T146T08E

TR728 ET-439329J TR C.DTA143ZKA T146T08E

TR729 ET-439329J TR C.DTA143ZKA T146T08E

TR730 ET-439329J TR C.DTA143ZKA T146T08E

TR731 ET-439329J TR C.DTA143ZKA T146T08E

TR732 ET-439329J TR C.DTA143ZKA T146T08E

TR733 ET-439329J TR C.DTA143ZKA T146T08E

TR734 ET-439329J TR C.DTA143ZKA T146T08E

TR735 ET-439329J TR C.DTA143ZKA T146T08E

TR736 ET-439329J TR C.DTA143ZKA T146T08E

TR737 ET-439329J TR C.DTA143ZKA T146T08E

TR738 ET-439329J TR C.DTA143ZKA T146T08E

TR739 ET-439329J TR C.DTA143ZKA T146T08E

TR740 ET-439329J TR C.DTA143ZKA T146T08E

TR741 ET-439329J TR C.DTA143ZKA T146T08E

TR742 ET-439329J TR C.DTA143ZKA T146T08E

TR743 ET-439329J TR C.DTA143ZKA T146T08E

TR744 ET-439329J TR C.DTA143ZKA T146T08E

TR745 ET-439329J TR C.DTA143ZKA T146T08E

TR746 ET-439329J TR C.DTA143ZKA T146T08E

TR747 ET-439329J TR C.DTA143ZKA T146T08E

TR748 ET-439329J TR C.DTA143ZKA T146T08E

TR749 ET-439329J TR C.DTA143ZKA T146T08E

TR750 ET-439329J TR C.DTA143ZKA T146T08E

TR751 ET-439329J TR C.DTA143ZKA T146T08E

TR752 ET-439329J TR C.DTA143ZKA T146T08E

TR753 ET-439329J TR C.DTA143ZKA T146T08E

TR754 ET-439329J TR C.DTA143ZKA T146T08E

TR755 ET-439329J TR C.DTA143ZKA T146T08E

TR756 ET-439329J TR C.DTA143ZKA T146T08E

TR757 ET-439329J TR C.DTA143ZKA T146T08E

TR758 ET-439329J TR C.DTA143ZKA T146T08E

TR759 ET-439329J TR C.DTA143ZKA T146T08E

X701 EI-820768X OSC X’TAL C.SMD-49 12.500MHZ

P.C. PRE-AMP BLK

D1 ED-811455J D SILICON H 1SS133T-77 T26

D2 ED-811455J D SILICON H 1SS133T-77 T26

D3 ED-811455J D SILICON H 1SS133T-77 T26

D4 ED-811455J D SILICON H 1SS133T-77 T26

D5 ED-811455J D SILICON H 1SS133T-77 T26

D6 ED-811455J D SILICON H 1SS133T-77 T26

D51 ED-811455J D SILICON H 1SS133T-77 T26

D52 ED-811455J D SILICON H 1SS133T-77 T26

D53 ED-811455J D SILICON H 1SS133T-77 T26

D54 ED-811455J D SILICON H 1SS133T-77 T26

D55 ED-811455J D SILICON H 1SS133T-77 T26

D56 ED-811455J D SILICON H 1SS133T-77 T26

D101 ED-811455J D SILICON H 1SS133T-77 T26

D102 ED-811455J D SILICON H 1SS133T-77 T26

D103 ED-811455J D SILICON H 1SS133T-77 T26

D104 ED-811455J D SILICON H 1SS133T-77 T26

Ref.No Part No. Description

D105 ED-811455J D SILICON H 1SS133T-77 T26

D106 ED-811455J D SILICON H 1SS133T-77 T26

D151 ED-811455J D SILICON H 1SS133T-77 T26

D152 ED-811455J D SILICON H 1SS133T-77 T26

D153 ED-811455J D SILICON H 1SS133T-77 T26

D154 ED-811455J D SILICON H 1SS133T-77 T26

D155 ED-811455J D SILICON H 1SS133T-77 T26

D156 ED-811455J D SILICON H 1SS133T-77 T26

D201 ED-811455J D SILICON H 1SS133T-77 T26

D202 ED-811455J D SILICON H 1SS133T-77 T26

D203 ED-811455J D SILICON H 1SS133T-77 T26

D204 ED-811455J D SILICON H 1SS133T-77 T26

D205 ED-811455J D SILICON H 1SS133T-77 T26

D206 ED-811455J D SILICON H 1SS133T-77 T26

D251 ED-811455J D SILICON H 1SS133T-77 T26

D252 ED-811455J D SILICON H 1SS133T-77 T26

D253 ED-811455J D SILICON H 1SS133T-77 T26

D254 ED-811455J D SILICON H 1SS133T-77 T26

D255 ED-811455J D SILICON H 1SS133T-77 T26

D256 ED-811455J D SILICON H 1SS133T-77 T26

D301 ED-811455J D SILICON H 1SS133T-77 T26

D302 ED-811455J D SILICON H 1SS133T-77 T26

D303 ED-811455J D SILICON H 1SS133T-77 T26

D304 ED-811455J D SILICON H 1SS133T-77 T26

D305 ED-811455J D SILICON H 1SS133T-77 T26

D306 ED-811455J D SILICON H 1SS133T-77 T26

D351 ED-811455J D SILICON H 1SS133T-77 T26

D352 ED-811455J D SILICON H 1SS133T-77 T26

D353 ED-811455J D SILICON H 1SS133T-77 T26

D354 ED-811455J D SILICON H 1SS133T-77 T26

D355 ED-811455J D SILICON H 1SS133T-77 T26

D356 ED-811455J D SILICON H 1SS133T-77 T26

D401 ED-811455J D SILICON H 1SS133T-77 T26

D402 ED-811455J D SILICON H 1SS133T-77 T26

D403 ED-811455J D SILICON H 1SS133T-77 T26

D404 ED-811455J D SILICON H 1SS133T-77 T26

D405 ED-811455J D SILICON H 1SS133T-77 T26

D406 ED-811455J D SILICON H 1SS133T-77 T26

D451 ED-811455J D SILICON H 1SS133T-77 T26

D452 ED-811455J D SILICON H 1SS133T-77 T26

D453 ED-811455J D SILICON H 1SS133T-77 T26

D454 ED-811455J D SILICON H 1SS133T-77 T26

D455 ED-811455J D SILICON H 1SS133T-77 T26

D456 ED-811455J D SILICON H 1SS133T-77 T26

D501 ED-811455J D SILICON H 1SS133T-77 T26

D502 ED-811455J D SILICON H 1SS133T-77 T26

D503 ED-811455J D SILICON H 1SS133T-77 T26

D504 ED-811455J D SILICON H 1SS133T-77 T26

D505 ED-811455J D SILICON H 1SS133T-77 T26

D506 ED-811455J D SILICON H 1SS133T-77 T26

D551 ED-811455J D SILICON H 1SS133T-77 T26

D552 ED-811455J D SILICON H 1SS133T-77 T26

D553 ED-811455J D SILICON H 1SS133T-77 T26

D554 ED-811455J D SILICON H 1SS133T-77 T26

D555 ED-811455J D SILICON H 1SS133T-77 T26

D556 ED-811455J D SILICON H 1SS133T-77 T26

D557 ED-811455J D SILICON H 1SS133T-77 T26

D558 ED-811455J D SILICON H 1SS133T-77 T26

D601 ED-811455J D SILICON H 1SS133T-77 T26

D602 ED-811455J D SILICON H 1SS133T-77 T26

D603 ED-820776X D LED MAA3372X ORANGE

IC1 EI-810591J IC NJM5532L

IC51 EI-810591J IC NJM5532L

IC101 EI-810591J IC NJM5532L

IC151 EI-810591J IC NJM5532L

IC201 EI-810591J IC NJM5532L

IC251 EI-810591J IC NJM5532L

18

SERVICE MANUAL

Page 19

Ref.No Part No. Description

IC301 EI-810591J IC NJM5532L

IC351 EI-810591J IC NJM5532L

IC401 EI-810591J IC NJM5532L

IC451 EI-810591J IC NJM5532L

IC501 EI-810591J IC NJM5532L

IC551 EI-810591J IC NJM5532L

J303 EJ-821172X SOCKET 13FMZ-ST 13P

J304 EJ-821172X SOCKET 13FMZ-ST 13P

J305 EJ-821172X SOCKET 13FMZ-ST 13P

J308 EJ-820809X SOCKET 40FE-BT-VK-N 40P

J309 EJ-820809X SOCKET 40FE-BT-VK-N 40P

SW1 ES-820707X SW PUSH SPPH43-W

SW2 ES-820707X SW PUSH SPPH43-W

SW51 ES-820707X SW PUSH SPPH43-W

SW52 ES-820707X SW PUSH SPPH43-W

SW101 ES-820707X SW PUSH SPPH43-W

SW102 ES-820707X SW PUSH SPPH43-W

SW151 ES-820707X SW PUSH SPPH43-W

SW152 ES-820707X SW PUSH SPPH43-W

SW201 ES-820707X SW PUSH SPPH43-W

SW202 ES-820707X SW PUSH SPPH43-W

SW251 ES-820707X SW PUSH SPPH43-W

SW252 ES-820707X SW PUSH SPPH43-W

SW301 ES-820707X SW PUSH SPPH43-W

SW302 ES-820707X SW PUSH SPPH43-W

SW351 ES-820707X SW PUSH SPPH43-W

SW352 ES-820707X SW PUSH SPPH43-W

SW401 ES-820707X SW PUSH SPPH43-W

SW402 ES-820707X SW PUSH SPPH43-W

SW451 ES-820707X SW PUSH SPPH43-W

SW452 ES-820707X SW PUSH SPPH43-W

SW501 ES-820707X SW PUSH SPPH43-W

SW502 ES-820707X SW PUSH SPPH43-W

SW551 ES-820707X SW PUSH SPPH43-W

SW552 ES-820707X SW PUSH SPPH43-W

SW601 ES-821228X SW SLIDE SSSB041600

TR1 ET-821232X TR 2SC3329 GR,BL T05

TR2 ET-821232X TR 2SC3329 GR,BL T05

TR3 ET-821232X TR 2SC3329 GR,BL T05

TR4 ET-821232X TR 2SC3329 GR,BL T05

TR51 ET-821232X TR 2SC3329 GR,BL T05

TR52 ET-821232X TR 2SC3329 GR,BL T05

TR53 ET-821232X TR 2SC3329 GR,BL T05

TR54 ET-821232X TR 2SC3329 GR,BL T05

TR101 ET-821232X TR 2SC3329 GR,BL T05

TR102 ET-821232X TR 2SC3329 GR,BL T05

TR103 ET-821232X TR 2SC3329 GR,BL T05

TR104 ET-821232X TR 2SC3329 GR,BL T05

TR151 ET-821232X TR 2SC3329 GR,BL T05

TR152 ET-821232X TR 2SC3329 GR,BL T05

TR153 ET-821232X TR 2SC3329 GR,BL T05

TR154 ET-821232X TR 2SC3329 GR,BL T05

TR201 ET-821232X TR 2SC3329 GR,BL T05

TR202 ET-821232X TR 2SC3329 GR,BL T05

TR203 ET-821232X TR 2SC3329 GR,BL T05

TR204 ET-821232X TR 2SC3329 GR,BL T05

TR251 ET-821232X TR 2SC3329 GR,BL T05

TR252 ET-821232X TR 2SC3329 GR,BL T05

TR253 ET-821232X TR 2SC3329 GR,BL T05

TR254 ET-821232X TR 2SC3329 GR,BL T05

TR301 ET-821232X TR 2SC3329 GR,BL T05

TR302 ET-821232X TR 2SC3329 GR,BL T05

TR303 ET-821232X TR 2SC3329 GR,BL T05

TR304 ET-821232X TR 2SC3329 GR,BL T05

TR351 ET-821232X TR 2SC3329 GR,BL T05

TR352 ET-821232X TR 2SC3329 GR,BL T05

TR353 ET-821232X TR 2SC3329 GR,BL T05

Ref.No Part No. Description

TR354 ET-821232X TR 2SC3329 GR,BL T05

TR401 ET-821232X TR 2SC3329 GR,BL T05

TR402 ET-821232X TR 2SC3329 GR,BL T05

TR403 ET-821232X TR 2SC3329 GR,BL T05

TR404 ET-821232X TR 2SC3329 GR,BL T05

TR451 ET-821232X TR 2SC3329 GR,BL T05

TR452 ET-821232X TR 2SC3329 GR,BL T05

TR453 ET-821232X TR 2SC3329 GR,BL T05

TR454 ET-821232X TR 2SC3329 GR,BL T05

TR501 ET-821232X TR 2SC3329 GR,BL T05

TR502 ET-821232X TR 2SC3329 GR,BL T05

TR503 ET-821232X TR 2SC3329 GR,BL T05

TR504 ET-821232X TR 2SC3329 GR,BL T05

TR551 ET-821232X TR 2SC3329 GR,BL T05

TR552 ET-821232X TR 2SC3329 GR,BL T05

TR553 ET-821232X TR 2SC3329 GR,BL T05

TR554 ET-821232X TR 2SC3329 GR,BL T05

TR555 ET-365191 TR FET 2SK363 GR T05

TR556 ET-365191 TR FET 2SK363 GR T05

TR601 ET-365191 TR FET 2SK363 GR T05

TR602 ET-365191 TR FET 2SK363 GR T05

TR603 ET-362209 TR 2SC3330 S,T,U T05

TR604 ET-362209 TR 2SC3330 S,T,U T05

TR610 ET-362847 TR 2SA1317 S,T,U T05

TR611 ET-362209 TR 2SC3330 S,T,U T05

VR1 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR51 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR101 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR151 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR201 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR251 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR301 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR351 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR401 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR451 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR501 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR551 EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

VR651 EV-820765X VR ROTARY RK09K113 L30 DCUT B103

W307 EW-820713X WIRE ASSY L3056 W307 3P

W312 EW-820714X WIRE ASSY L3056 W312 7P

P.C. MOTHER BLK

J201 EJ-821170X SOCKET 20FMZ-BT 20P

J202 EJ-812021J SOCKET 26FMZ-BT 26P

J203 EJ-821171X SOCKET 28FMZ-BT 28P

J204 EJ-821170X SOCKET 20FMZ-BT 20P

P204 EJ-413148J PLUG 128D-064P2C-S14A 64P

P205 EJ-413148J PLUG 128D-064P2C-S14A 64P

P206 EJ-413148J PLUG 128D-064P2C-S14A 64P

5. P.C. (#)OPE R BLK

P.C. OPERATION R BLK

Ref.No Part No. Description

D201 ED-820636X D LED SEL5755C YELLOW

D202 ED-820665X D LED SEL5955A ORANGE

D203 ED-820636X D LED SEL5755C YELLOW

D204 ED-820636X D LED SEL5755C YELLOW

D205 ED-820636X D LED SEL5755C YELLOW

D206 ED-820636X D LED SEL5755C YELLOW

D207 ED-820636X D LED SEL5755C YELLOW

D208 ED-820636X D LED SEL5755C YELLOW

D212 ED-820636X D LED SEL5755C YELLOW

D213 ED-820636X D LED SEL5755C YELLOW

D214 ED-820636X D LED SEL5755C YELLOW

D215 ED-820636X D LED SEL5755C YELLOW

D216 ED-820636X D LED SEL5755C YELLOW

SERVICE MANUAL

19

Page 20

Ref.No Part No. Description

D217 ED-820636X D LED SEL5755C YELLOW

D218 ED-820636X D LED SEL5755C YELLOW

D221 ED-820665X D LED SEL5955A ORANGE

D222 ED-820665X D LED SEL5955A ORANGE

D224 ED-820665X D LED SEL5955A ORANGE

D225 ED-820665X D LED SEL5955A ORANGE

D226 ED-820665X D LED SEL5955A ORANGE

D239 ED-820777X D LED MPG3372X GREEN

D240 ED-821292X D LED BR3372X RED

J403 EJ-820812X SOCKET 26FE-ST-VK-N 26P

J410 EJ-820812X SOCKET 26FE-ST-VK-N 26P

J411 EJ-820812X SOCKET 26FE-ST-VK-N 26P

SW201 ES-410552J SW TACT SKHVBE T05

SW202 ES-410552J SW TACT SKHVBE T05

SW203 ES-410552J SW TACT SKHVBE T05

SW204 ES-410552J SW TACT SKHVBE T05

SW205 ES-410552J SW TACT SKHVBE T05

SW206 ES-410552J SW TACT SKHVBE T05

SW207 ES-410552J SW TACT SKHVBE T05

SW208 ES-410552J SW TACT SKHVBE T05

SW209 ES-410552J SW TACT SKHVBE T05

SW210 ES-410552J SW TACT SKHVBE T05

SW211 ES-410552J SW TACT SKHVBE T05

SW212 ES-410552J SW TACT SKHVBE T05

SW213 ES-410552J SW TACT SKHVBE T05

SW214 ES-410552J SW TACT SKHVBE T05

SW215 ES-410552J SW TACT SKHVBE T05

SW216 ES-410552J SW TACT SKHVBE T05

SW217 ES-410552J SW TACT SKHVBE T05

SW218 ES-410552J SW TACT SKHVBE T05

SW221 ES-410552J SW TACT SKHVBE T05

SW222 ES-410552J SW TACT SKHVBE T05

SW223 ES-410552J SW TACT SKHVBE T05

SW224 ES-410552J SW TACT SKHVBE T05

SW225 ES-410552J SW TACT SKHVBE T05

SW226 ES-410552J SW TACT SKHVBE T05

SW227 ES-410552J SW TACT SKHVBE T05

SW228 ES-410552J SW TACT SKHVBE T05

SW231 ES-415015J SW TACT SKQEAD

SW232 ES-415015J SW TACT SKQEAD

SW233 ES-415015J SW TACT SKQEAD

SW234 ES-415015J SW TACT SKQEAD

SW235 ES-415015J SW TACT SKQEAD

SW236 ES-415015J SW TACT SKQEAD

SW237 ES-415015J SW TACT SKQEAD

SW238 ES-415015J SW TACT SKQEAD

SW239 ES-415015J SW TACT SKQEAD

SW240 ES-415015J SW TACT SKQEAD

SW241 ES-410552J SW TACT SKHVBE T05

SW242 ES-410552J SW TACT SKHVBE T05

SW243 ES-410552J SW TACT SKHVBE T05

SW244 ES-410552J SW TACT SKHVBE T05

SW251 ES-410552J SW TACT SKHVBE T05

SW252 ES-410552J SW TACT SKHVBE T05

SW253 ES-410552J SW TACT SKHVBE T05

SW254 ES-410552J SW TACT SKHVBE T05

SW255 ES-410552J SW TACT SKHVBE T05

SW256 ES-410552J SW TACT SKHVBE T05

SW257 ES-410552J SW TACT SKHVBE T05

SW258 ES-410552J SW TACT SKHVBE T05

SW259 ES-410552J SW TACT SKHVBE T05

SW260 ES-410552J SW TACT SKHVBE T05

SW261 ES-410552J SW TACT SKHVBE T05

SW262 ES-410552J SW TACT SKHVBE T05

P.C. 7 SEG BLK

D701 ED-812445J IND LE SA04-21IDB

Ref.No Part No. Description

D702 ED-812445J IND LE SA04-21IDB

D703 ED-812445J IND LE SA04-21IDB

D704 ED-812445J IND LE SA04-21IDB

D705 ED-812445J IND LE SA04-21IDB

D706 ED-812445J IND LE SA04-21IDB

D707 ED-812445J IND LE SA04-21IDB

D708 ED-812445J IND LE SA04-21IDB

D709 ED-820665X D LED SEL5955A ORANGE

D710 ED-820665X D LED SEL5955A ORANGE

IC721 EI-403306J IC NJM4558L

J411 EJ-820812X SOCKET 26FE-ST-VK-N 26P

SW711 ES-410552J SW T A CT SKHVBE T05

SW712 ES-410552J SW T A CT SKHVBE T05

SW713 ES-410552J SW T A CT SKHVBE T05

SW714 ES-410552J SW T A CT SKHVBE T05

SW715 ES-410552J SW T A CT SKHVBE T05

SW716 ES-410552J SW T A CT SKHVBE T05

SW717 ES-410552J SW T A CT SKHVBE T05

TR711 ET-362209 TR 2SC3330 S,T,U T05

TR712 ET-362847 TR 2SA1317 S,T,U T05

W414 EW-820720X WIRE ASSY L3056 W414 2P

P.C. LCD-DIST BLK

IC551 EI-382537J1 IC TC74HC253AP

IC552 EI-382537J1 IC TC74HC253AP

J418 EJ-811062J SOCKET 12FMZ-ST 12P

J419 EJ-820813X SOCKET 34FE-ST-VK-N 34P

J420 EJ-812764J SOCKET 13FE-ST-VK-N 13P

J421 EJ-820810X SOCKET 12FE-ST-VK-N 12P

RP551 ER-820824X COMP R RKC1/8B12 223J

P.C. FILTER BLK

C551

C556

C557

L551

P.C. Q-LINK BLK

J420 EJ-812764J SOCKET 13FE-ST-VK-N 13P

SW601 ES-812749J SW ROTARY ENCORDER EC12E24204

SW602 ES-812749J SW ROTARY ENCORDER EC12E24204

SW603 ES-812749J SW ROTARY ENCORDER EC12E24204

SW604 ES-812749J SW ROTARY ENCORDER EC12E24204

SW605 ES-812749J SW ROTARY ENCORDER EC12E24204

SW606 ES-812749J SW ROTARY ENCORDER EC12E24204

P.C. METER BLK

D631 ED-820752X IND LE TOA-B10AA2MRMYMG6-B4-LC

D632 ED-820753X IND LE TOA-B10AAMG8-B4-LC

D633 ED-820752X IND LE TOA-B10AA2MRMYMG6-B4-LC

D634 ED-820753X IND LE TOA-B10AAMG8-B4-LC

J421 EJ-820810X SOCKET 12FE-ST-VK-N 12P

P.C. MIC BLK

MC741 EY-820803X MIC KUC4023-040235

EC-430824J C MMY V CUT MKP3362 683M 275AC

EC-427562J C MMY V CUT MKP3362 103M 275AC

EC-427562J C MMY V CUT MKP3362 103M 275AC

EO-427223J COIL LF HR-24-562

6. P.C. (#) OPERATION L BLK

P.C. LED PAN BLK

Ref.No Part No. Description

D401 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

D402 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

D403 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

D404 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

D405 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

D406 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

D407 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

20

SERVICE MANUAL

Page 21

Ref.No Part No. Description

D408 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

D409 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

D410 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

D411 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

D412 ED-820751X IND LE TOA-L23ZMYMR-91B-LC

D421 ED-820665X D LED SEL5955A ORANGE

D422 ED-820665X D LED SEL5955A ORANGE

D423 ED-820665X D LED SEL5955A ORANGE

D424 ED-820665X D LED SEL5955A ORANGE

D425 ED-820665X D LED SEL5955A ORANGE

D426 ED-820665X D LED SEL5955A ORANGE

D427 ED-820665X D LED SEL5955A ORANGE

D428 ED-820665X D LED SEL5955A ORANGE

D429 ED-820665X D LED SEL5955A ORANGE

D430 ED-820665X D LED SEL5955A ORANGE

D431 ED-820665X D LED SEL5955A ORANGE

D432 ED-820665X D LED SEL5955A ORANGE

D435 ED-820636X D LED SEL5755C YELLOW

D441 ED-820636X D LED SEL5755C YELLOW

D442 ED-820636X D LED SEL5755C YELLOW

D443 ED-820636X D LED SEL5755C YELLOW

D444 ED-820636X D LED SEL5755C YELLOW

D445 ED-820636X D LED SEL5755C YELLOW

D446 ED-820636X D LED SEL5755C YELLOW

D447 ED-820636X D LED SEL5755C YELLOW

D448 ED-820636X D LED SEL5755C YELLOW

D449 ED-820636X D LED SEL5755C YELLOW

D450 ED-820636X D LED SEL5755C YELLOW

D451 ED-820636X D LED SEL5755C YELLOW

D452 ED-820636X D LED SEL5755C YELLOW

D455 ED-820665X D LED SEL5955A ORANGE

J401 EJ-820812X SOCKET 26FE-ST-VK-N 26P

SW415 ES-410552J SW TACT SKHVBE T05

SW421 ES-410552J SW TACT SKHVBE T05

SW422 ES-410552J SW TACT SKHVBE T05

SW423 ES-410552J SW TACT SKHVBE T05

SW424 ES-410552J SW TACT SKHVBE T05

SW425 ES-410552J SW TACT SKHVBE T05

SW426 ES-410552J SW TACT SKHVBE T05

SW427 ES-410552J SW TACT SKHVBE T05

SW428 ES-410552J SW TACT SKHVBE T05

SW429 ES-410552J SW TACT SKHVBE T05

SW430 ES-410552J SW TACT SKHVBE T05

SW431 ES-410552J SW TACT SKHVBE T05

SW432 ES-410552J SW TACT SKHVBE T05

SW435 ES-410552J SW TACT SKHVBE T05

SW441 ES-410552J SW TACT SKHVBE T05

SW442 ES-410552J SW TACT SKHVBE T05

SW443 ES-410552J SW TACT SKHVBE T05

SW444 ES-410552J SW TACT SKHVBE T05

SW445 ES-410552J SW TACT SKHVBE T05

SW446 ES-410552J SW TACT SKHVBE T05

SW447 ES-410552J SW TACT SKHVBE T05

SW448 ES-410552J SW TACT SKHVBE T05

SW449 ES-410552J SW TACT SKHVBE T05

SW450 ES-410552J SW TACT SKHVBE T05

SW451 ES-410552J SW TACT SKHVBE T05

SW452 ES-410552J SW TACT SKHVBE T05

SW455 ES-410552J SW TACT SKHVBE T05

P.C OPERATION L BLK

D301 ED-820779X D LED VRPG3312X RED/GREEN

D302 ED-820779X D LED VRPG3312X RED/GREEN

D303 ED-820779X D LED VRPG3312X RED/GREEN

D304 ED-820779X D LED VRPG3312X RED/GREEN

D305 ED-820779X D LED VRPG3312X RED/GREEN

D306 ED-820779X D LED VRPG3312X RED/GREEN

Ref.No Part No. Description

D307 ED-820779X D LED VRPG3312X RED/GREEN

D308 ED-820779X D LED VRPG3312X RED/GREEN

D309 ED-820779X D LED VRPG3312X RED/GREEN

D310 ED-820779X D LED VRPG3312X RED/GREEN

D311 ED-820779X D LED VRPG3312X RED/GREEN

D312 ED-820779X D LED VRPG3312X RED/GREEN

D315 ED-820776X D LED MAA3372X ORANGE

D321 ED-820778X D LED SML72755C YELLOW/RED

D322 ED-820778X D LED SML72755C YELLOW/RED

D323 ED-820778X D LED SML72755C YELLOW/RED

D324 ED-820778X D LED SML72755C YELLOW/RED

D325 ED-820778X D LED SML72755C YELLOW/RED

D326 ED-820778X D LED SML72755C YELLOW/RED

D327 ED-820778X D LED SML72755C YELLOW/RED

D328 ED-820778X D LED SML72755C YELLOW/RED

D329 ED-820778X D LED SML72755C YELLOW/RED

D330 ED-820778X D LED SML72755C YELLOW/RED

D331 ED-820778X D LED SML72755C YELLOW/RED

D332 ED-820778X D LED SML72755C YELLOW/RED

D335 ED-820636X D LED SEL5755C YELLOW

D341 ED-820778X D LED SML72755C YELLOW/RED

D342 ED-820778X D LED SML72755C YELLOW/RED

D343 ED-820778X D LED SML72755C YELLOW/RED

D344 ED-820778X D LED SML72755C YELLOW/RED

D345 ED-820778X D LED SML72755C YELLOW/RED

D346 ED-820778X D LED SML72755C YELLOW/RED

D347 ED-820778X D LED SML72755C YELLOW/RED

D348 ED-820778X D LED SML72755C YELLOW/RED

D349 ED-820778X D LED SML72755C YELLOW/RED

D350 ED-820778X D LED SML72755C YELLOW/RED

D351 ED-820778X D LED SML72755C YELLOW/RED

D352 ED-820778X D LED SML72755C YELLOW/RED

D355 ED-820636X D LED SEL5755C YELLOW

D361 ED-820636X D LED SEL5755C YELLOW

D362 ED-820636X D LED SEL5755C YELLOW

D363 ED-820636X D LED SEL5755C YELLOW

D364 ED-820636X D LED SEL5755C YELLOW

D365 ED-820636X D LED SEL5755C YELLOW

D366 ED-820665X D LED SEL5955A ORANGE

D368 ED-820636X D LED SEL5755C YELLOW

D369 ED-820636X D LED SEL5755C YELLOW

D370 ED-820636X D LED SEL5755C YELLOW

D371 ED-820636X D LED SEL5755C YELLOW

D372 ED-820636X D LED SEL5755C YELLOW

D375 ED-820636X D LED SEL5755C YELLOW

J402 EJ-820811X SOCKET 20FE-ST-VK-N 20P

SW321 ES-410552J SW T A CT SKHVBE T05

SW322 ES-410552J SW T A CT SKHVBE T05

SW323 ES-410552J SW T A CT SKHVBE T05

SW324 ES-410552J SW T A CT SKHVBE T05

SW325 ES-410552J SW T A CT SKHVBE T05

SW326 ES-410552J SW T A CT SKHVBE T05

SW327 ES-410552J SW T A CT SKHVBE T05

SW328 ES-410552J SW T A CT SKHVBE T05

SW329 ES-410552J SW T A CT SKHVBE T05

SW330 ES-410552J SW T A CT SKHVBE T05

SW331 ES-410552J SW T A CT SKHVBE T05

SW332 ES-410552J SW T A CT SKHVBE T05

SW335 ES-410552J SW T A CT SKHVBE T05

SW341 ES-410552J SW T A CT SKHVBE T05

SW342 ES-410552J SW T A CT SKHVBE T05

SW343 ES-410552J SW T A CT SKHVBE T05

SW344 ES-410552J SW T A CT SKHVBE T05

SW345 ES410552J SW TACT SKHVBE T05

SW346 ES-410552J SW T A CT SKHVBE T05

SW347 ES-410552J SW T A CT SKHVBE T05

SW348 ES-410552J SW T A CT SKHVBE T05

SERVICE MANUAL

21

Page 22

Ref.No Part No. Description

SW349 ES-410552J SW TACT SKHVBE T05

SW350 ES-410552J SW TACT SKHVBE T05

SW351 ES-410552J SW TACT SKHVBE T05

SW352 ES-410552J SW TACT SKHVBE T05

SW355 ES-410552J SW TACT SKHVBE T05

SW361 ES-410552J SW TACT SKHVBE T05

SW362 ES-410552J SW TACT SKHVBE T05

SW363 ES-410552J SW TACT SKHVBE T05

SW364 ES-410552J SW TACT SKHVBE T05

SW365 ES-410552J SW TACT SKHVBE T05

SW366 ES-410552J SW TACT SKHVBE T05

SW368 ES-410552J SW TACT SKHVBE T05

SW369 ES-410552J SW TACT SKHVBE T05

SW370 ES-410552J SW TACT SKHVBE T05

SW371 ES-410552J SW TACT SKHVBE T05

SW372 ES-410552J SW TACT SKHVBE T05

SW375 ES-410552J SW TACT SKHVBE T05

P.C. AUX-IN BLK

J1 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J2 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J3 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J4 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J5 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J6 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J7 EJ-821484X PIN J YKC21-4133 2P

J305 EJ-821169X SOCKET 13FMZ-BT 13P

J306 EJ-820812X SOCKET 26FE-ST-VK-N 26P

P.C. OPE-DIST BLK

D451 ED-820774X D SCHOT.H EK16 V0 T26 60/1.5A

IC451 EI-821215X IC NJM2360AD

J419 EJ-820813X SOCKET 34FE-ST-VK-N 34P

L451 EO-820705X COIL FIX 1 LHL10NB 102J

SE8

TR451 ET-362209 TR 2SC3330 S,T,U T05

TR452 ET-364291 TR DTA144ES T05

TR453 ET-361961 TR DTC144ES T05

W408 EW-820717X WIRE ASSY L3056 W408 8P

EF-376821 FUSE ICP-N15 50V 0.6A

Ref.No Part No. Description

J102 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J103 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J104 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J105 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J106 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J107 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J108 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J109 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J110 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J111 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J112 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

J310 EJ-820808X SOCKET 20FE-BT-VK-N 20P

J311 EJ-820808X SOCKET 20FE-BT-VK-N 20P

P.C. POWER BLK

D901 ED-820774X D SCHOT.H EK16 V0 T26 60/1.5A

D902 ED-811455J D SILICON H 1SS133T-77 T26

D903 ED-379309 D ZENER H HZ9A2 T26

D904 ED-379309 D ZENER H HZ9A2 T26

D905 ED-820773X D SCHOT. FMB-G14L 40/5.0A

IC901 EI-396659J IC NJM2360D

IC902 EI-820785X IC NJM2367TLA2050

IC903 EI-820783X IC EZ1587CT-3.3

IC904 EI-821227X IC SI-3051N

L901 EO-812744J COIL FIX 1 LHL13NB 221K

L902

SF1

SF2

SF3

SF4

SF5

SF6

TH901 812845J THERMISTOR M5R107CS CUT

TR901 ET-812777J TR 2SC3255

TR902 ET-368834 TR DTA144TS T05

TR903 ET-416589J TR 2SB1375

TR904 ET-364023 TR DTC114ES T05

TR905 ET-362209 TR 2SC3330 S,T,U T05

TR906 ET-362209 TR 2SC3330 S,T,U T05

EO-820704X COIL FIX 1 GLA-05-0140 141X

EF-373143 FUSE ICP-N38 50V 1.5A

EF-373142 FUSE ICP-N25 50V 1.0A

EF-373143 FUSE ICP-N38 50V 1.5A

EF-373143 FUSE ICP-N38 50V 1.5A

EF-373143 FUSE ICP-N38 50V 1.5A

EF-373143 FUSE ICP-N38 50V 1.5A

P.C. JOG BLK

IC201 EI-386315J IC HD74HC14P

W412 EW-820718X WIRE ASSY L3056 W412 8P

7. P.C. (#) IO BLK

P.C. INPUT A BLK

Ref.No Part No. Description

J1 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J2 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J3 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J4 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J5 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J6 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J7 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J8 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J9 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J10 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J11 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J12 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J308 EJ-820809X SOCKET 40FE-BT-VK-N 40P

J309 EJ-820809X SOCKET 40FE-BT-VK-N 40P

J310 EJ-820808X SOCKET 20FE-BT-VK-N 20P

J311 EJ-820808X SOCKET 20FE-BT-VK-N 20P

P.C. INPUT B BLK

J101 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

P.C. HP-HIZ BLK

IC401 EI-812779J IC.NJM4556AD

IC411 EI-812779J IC.NJM4556AD

IC501 EI-820784X IC NJM2082L

J401 EJ-821000X PHONE J YKB26-5264 S.NUT 6.3

J402 EJ-821000X PHONE J YKB26-5264 S.NUT 6.3

J501 EJ-821392X PHONE J YKB26-5328 S.NUT 6.3

VR401 EV-810500J VR ROTARY RK0971220 L=20 B203X

8. P.C. FADER BLK

Ref.No Part No. Description

D802 ED-439573J D SILI.H 1SS244T-77T26 250/0.2

D803 ED-402189J D ZENER H HZS5B1

TR801 ET-363953 TR DTA114TS

VR801 EV-820767X VR SLIDE RSA0N11J9

9. IB-24ADT (OPTION P. C. BOARD)

Ref.No Part No. Description

100 EJ-820568X SOCKET IC IC110-99-320 20P

IC1 EI-820941X IC XC2S50-5TQ144C

IC2 EI-821193X IC GAL16V8D-15QP L5266

IC3 EI-820780X IC AIC1117-33CE

22

SERVICE MANUAL

Page 23

Ref.No Part No. Description

IC4 EI-820781X IC AIC1117CE

IC5 EI-355888 IC HD74LS08P

J1 EJ-413146J SOCKET 128D-064S2C-L14A 64P

J2 EJ-427870J SOCKET DELC-J9SAF-10L9 9P

J3 EJ-394459J SOCKET OPTICAL GP1F32R

J4 EJ-394459J SOCKET OPTICAL GP1F32R

J5 EJ-394490J SOCKET OPTICAL GP1F32T

J6 EJ-394490J SOCKET OPTICAL GP1F32T

PH1 ET-821189X DETECTOR HCPL2601N

X1 EI-820827X OSC X’TAL C.SG8002JAPCB 50MHZ

10. IB-24SCSI (OPTION P. C. BOARD)

Ref.No Part No. Description

D1 ED-353374 D SILICON DS135E-FA3 100/1.0A

J1 EJ-821194X SOCKET 128A-050S2C-L14A 50P

J2 EJ-821198X SOCKET FCN-235D068-G/HA 68P

J3 EJ-413156J SOCKET FCN-234J068-G/0 68P

SF1

EF-811786J FUSE RUE110 30V 1.10A

Ref.No Part No. Description

27 ZW-270101 RING E 300SUP CMT

28 ML-820895X LEVER LOCK LCD

29 ZS-411232 BID40X10STL BNI

30 SP-820891X PANEL FUNCTION

31 SE-820804X MIC ACC.KCU2011-50-0010

32 EW-820748X CORD FFC P1.25 L350 26P

33 SP-820900X WINDOW SEGMENT

34 ZS-821449X 6RB30X080STL BNI

35 SK-820594X KNOB ENCODER (B) YELLOW

SW ES-812749J SW ROTARY ENCORDER EC12E24204

36 SE-820871X COVER LCD BOTTOM

37 SB-820588X BUTTON PUSH LED (B) [BLACK]

SW ES-410552J SW TA CT SKHVBE T05

39 ZS-321298 BID30X08STL CMT

40 EV-820764X VR ROTARY RK09K113 L20 B203

[CONTRAST]

41 EV-820763X VR ROTARY RK09K113 L20 B103

[TB-LEVEL]

42 BA-L3056A504E PC Q-LINK BLK

43 BA-L3056A504F PC METER BLK

44 BA-L3056A504C PC LCD-DIST BLK

45 BA-L3056A504B PC 7 SEG BLK

11. IB-24LTC (OPTION P. C. BOARD)

Ref.No Part No. Description

200 EJ-429984J SOCKET IC113-0444-004 44P

IC1 EI-430810J IC ICS2008AV

IC2 EI-812954J IC.TC74HCT139AP

IC3 EI-821190X IC AIC1660CN

IC4 EI-380145J IC LF353

J1 EJ-413146J SOCKET 128D-064S2C-L14A 64P

J2 EJ-821221X PHONE J YKB22-5312 NUT 6.3

J3 EJ-821220X PHONE J YKB22-5257 NUT 6.3

X1 EI-410263J OSC X’TAL HC-49/U 14.318180MHZ

12. JOG BLK (Refer to 25 pages)

13. LCD BLK

Ref.No Part No. Description

1 SP-820887X PANEL LCD FRONT

2 MH-821456X PROP F.SCREW PANEL LCD

3 EM-811115J IND LCD GMF32024HFTW

4 ZS-331182 BT BID30X08STL BNI

5 EW-820744X CORD FFC P1.25 L140 12P

6 EW-820747X CORD FFC P1.25 L210 34P

7 EW-820745X CORD FFC P1.25 L160 13P

8 BA-810408J INVERTER 13585A-CFL-INV

9 SE-820890X WINDOW LCD

10 EW-820736X CORD FFC P1.00 L 90 12P

11 MB-820882X CUSHION PANEL LCD

12 ZS-428277J PAN30X06STL CMT POLY WAVE

13 MH-820879X PROP F.SCREW SUPPORT

14 SP-820888X PANEL LCD BOTTOM

15 GH-820873X HOLDER PANEL ( R )

16 MS-821026X CHUCK BOTTOM

17 BL-820877X CHUCK LCD LEVER PART

18 MS-821025X SPACER CHUCK

19 ZG-820880X SP PUSH LCD LEVER

20 BL-820878X CAM LCD LEVER

21 ZS-821482X PAN20X06STL CMT SW

22 BL-820875X COLLAR LCD LEVER

23 BL-820874X SHAFT LCD LEVER

24 ZG-820881X SP TORSION PANEL LCD

25 ZW-259694 PW41X130X050STL CMT

26 ZW-270123 RING E 400SUP CMT

14. FINAL ASSEMBLY BLK

Ref.No Part No. Description

1 SP-820883X PANEL MAIN (F) DPS24

2 SP-820884X PANEL MAIN (R) DPS24

3 SE-820912X ESCUTCHEON REC

4 KNOB SB-820587X BUTTON PUSH LED (A) [WHITE]

SW ES-410552J SW TA CT SKHVBE T05

5 KNOB SB-820588X BUTTON PUSH LED (B) [BLACK]

SW ES-410552J SW TA CT SKHVBE T05

6 KNOB SB-820589X BUTTON PUSH LED (C) [ORANGE]

S W ES-410552J SW TA CT SKHVBE T05

7 KNOB SB-820590X BUTTON PUSH SMALL (A) [BLUE]

SW ES-410552J SW TA CT SKHVBE T05

8 KNOB SB-820591X BUTTON PUSH SMALL (B) [BLACK]

SW ES-410552J SW TA CT SKHVBE T05

9 KNOB SB-820902X BUTTON PUSH TRA PLAY [PLAY]

SW ES-415015J SW TA CT SKQEAD

10 KNOB SB-820903X BUTTON PUSH TRA STOP [STOP]

SW ES-415015J SW TA CT SKQEAD

11 KNOB SB-820904X BUTTON PUSH TRA FF [FF]

SW ES-415015J SW TA CT SKQEAD

12 KNOB SB-820905X BUTTON PUSH TRA REW[REW]

SW ES-415015J SW TA CT SKQEAD

13 KNOB SB-820906X BUTTON PUSH TRA GOTO [GOTO]

SW ES-415015J SW TA CT SKQEAD

14 KNOB SB-820907X BUTTON PUSH TRA MEM[MEMORY]

SW ES-415015J SW TA CT SKQEAD

15 KNOB SB-820908X BUTTON PUSH TRA TO [TO]

SW ES-415015J SW TA CT SKQEAD

16 KNOB SB-820909X BUTTON PUSH TRA FROM [FROM]

SW ES-415015J SW TA CT SKQEAD

17 KNOB SB-820910X BUTTON PUSH TRA I/O [IN/OUT]

SW ES-415015J SW TA CT SKQEAD

18 KNOB SB-820911X BUTTON PUSH TRA REC [REC]

SW ES-415015J SW TA CT SKQEAD

19 KNOB SB-811562J BUTTON CURSOR(3) [CURSOR]

SW ES-410552J SW TA CT SKHVBE T05

20 SE-820892X ESCUTCHEON FADER

21 ZS-377929 BID30X03STL BNI

22 SP-820886X PANEL SIDE

23 KNOB SK-820595X KNOB VOL. [BLUE]

VR EV-820766X VR ROTARY RK09K113 L30 DCUT RD203

[TRIM]

SERVICE MANUAL

23

Page 24

Ref.No Part No. Description

VR EV-820765J VR ROTARY RK09K113 L30 DCUT B103

[MONITOR]

24 KNOB SK-820593X KNOB ENCODER (A) [ORANGE]

SW ES-812749J SW ROTARY ENCORDER EC12E24204

25 SE-820899X WINDOW PAN

26 KNOB SB-820901X BUTTON P PUSH-2 [BLACK]

SW ES-820707X SW PUSH SPPH43-W

27 SC-821040X COVER REST

28 SC-820918X COVER 5 INCH BLANK

29 SP-820885X PANEL REAR DPS24

30

31 EJ-358632J2 SOCKET INLET SOT-16 3P [AC INLET]

32 EJ-329610 TERMINAL W/SCREW UB-0067 L 1P

33 KNOB SK-377733 KNOB VOL B

34 ZS-331182 BT BID30X08STL BNI

35 ZS-355511 BID30X06STL BNI

36 ZS-820481X BT PAN30X08STL BZN C080

37 BA-821441X SW POW ZWQ130-5222/AP

38 EW-820741X CORD FFC P1.00 L340 20P

39 EW-821180X CORD FFC P1.00 L340 26P

40 EW-821181X CORD FFC P1.00 L340 28P

41 EW-820740X CORD FFC P1.00 L150 20P

42 EW-820743X CORD FFC P1.25 L110 26P

43 EW-820749X CORD FFC P1.25 L400 20P

44 EW-820739X CORD FFC P1.00 L290 13P

45 EW-820738X CORD FFC P1.00 L180 13P

46 EW-820746X CORD FFC P1.25 L190 40P

47 EW-820742X CORD FFC P1.25 L100 20P

48 EW-820748X CORD FFC P1.25 L350 26P

49 EW-821418X CORD FFC P1.00 L110 10P

50 EW-820750X CORD FFC P1.25 L490 26P

51 EW-820747X CORD FFC P1.25 L210 34P

52 EW-820714X WIRE ASSY L3056 W312 7P

53 EW-820715X WIRE ASSY L3056 W313 6P

54 SK-820896X KNOB FADER

55 SK-820897X INDEX FADER (A) [BLUE]

56 SK-820898X INDEX FADER (B) [ORANGE]

57

58-A

58-B

58-C

58-D

59 EW-820710X WIRE ASSY L3056 W101 40P [ATA40pin]

60 EW-820735X WIRE ASSY L3056 W911 4P [HD-Power]

61

62 HM-820925X PROP6 M.SCREW L=10

63 MH-384700J1 PROP 2 F.SCREW L=10

64 MH-820655X PROP 1 F.SCREW L=27

65 SA-311742 FOOT ROUND SHAPED

66 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

67 EJ-821223X PHONE J YKB26-5312 S.NUT 6.3

68 EJ-821392X PHONE J YKB26-5328 S.NUT 6.3 [HI-Z]

69 EJ-821000X PHONE J YKB26-5264 S.NUT 6.3

70 EJ-821484X PIN J YKC21-4133 2P [2TRACK IN]

71 EJ-821222X PHONE J YKB26-5257 S.NUT 6.3

72 EJ-821219X PHONE J YKB22-5244 NUT 6.3

73 EJ-403478J DIN J YKF51-5040 5P

ES-405438J SW SEESAW SDDTA3 TV5 01-1

[POWER SW]

VR EV-810500J VR ROTARY RK0971220 L=20 B203X

[H.Phone]

VR EV-820767X VR SLIDE RSA0N11J9

EJ-405424J PLUG ADAPTOR KPR-25 (J)

EW-380905J AC CORD 250S KP300 KS16A H B J (J)

EW-403993J AC CORD200SKP4819DKS31A B E (E,V)

EW-419170J AC CORD200S KP610 KS31A B (B)

EW-821485X AC CORD200SKP30KS31 B AC (A)

EF-821407X FUSE ET T 250V 6.30A

[INPUT1]

[INPUT2/AUX IN etc]

[H-Phone]

[STEREO OUT etc]

[FOOT SW]

[MIDI IN/OUT/THRU]

Ref.No Part No. Description

74 EJ-821236X SOCKET CONNECTER YKF45-0020 4P

[USB-B]

75 EJ-810323J SOCKET TCS7927-56 [ASCII-KEYBOARD]

76 EJ-820150J SOCKET COAX. BNC-LNRD-BPAA

[WORD CLOCK]

77 EJ-394490J SOCKET OPTICAL GP1F32T [DIGI OUT]

78 EJ-394459J SOCKET OPTICAL GP1F32R [DIGI IN]

79 EJ-820754X PIN J YKC21-3079 P2P [DIGI I/O]

81 ZS-322570 ST BID40X08STL NI3

80 ZS-378447 ST BID40X10STL BNI

82 ZW-413267 N FRANGE 40STL CMT

24

SERVICE MANUAL

Page 25

JOG BLK

1

2

3

4

5

8

JOG BLK

Ref.No Part No. Description

1 SK-820893X KNOB JOG

2 ZS-821450X 6SET30X040SCM PKR WP

3 SK-820894X KNOB SHUTTLE

4 ZS-331182 BT BID30X08STL BNI

5 ZW-820709X SW SHUTTLE SRGPVJ

6 ZW-812440J PW122X160X050STL NI3

7 ES-820708X SW R.ENCORDER RES20D-50-201-1

8 BA-L3056A505E PC JOG BLK

6

7

SERVICE MANUAL

25

Page 26

LCD BLK DPS24

34

9

1

2

33

30

31

4

A'

A'

37

43

5

2

3

35

35

34

2

2

4

7

42

44

41

45

32

12

4

40

C

B'

B'

B'

4

13

24

26

15

A

11

A

10

6

C'

27

25

24

4

22

B

B

B

21

4

4

8

4

4

4

16

17

18

19

20

23

28

29

39

14

4

26

4

36

SERVICE MANUAL

Page 27

FINAL ASSEMBLY BLK DPS24

ON OFF

48V

2 3 4 5 6 7 8 9 10 11 121

A / B

26

23

4

24

25

4

21

54

55

56

20

22

LINE

/MIC

1 2 3 4 5 6 7 8 9 10 11 12

TRIM

0

+60

+600+600+600+600+600+600+600+600+600+600+60

+45

+45

+45

+45

+45

-15

-15

-15

SIGNAL / CLIP

SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP SIGNAL / CLIP

1

1 2 3 4 5 6 7 8 9 10 11 12

RECORD

/EDIT

SELECT

567

13 14 15 16 17 18 19 20 21 22 23 24

L / R 1 / 2 3 / 4 5 / 6 7 / 8

ASSIGN

20Hz

L R

PAN

SELECT

ON

SOLO SOLO SOLO SOLO SOLO SOLO SOLO SOLO SOLO SOLO SOLO SOLO

INPUT 1

TRACK 1 / 13

GROUP 1 GROUP 2 GROUP 3 GROUP 4 GROUP 5 GROUP 6 GROUP 7 GROUP 8

-15

23

20Hz

20kHz

23456789101112

2 / 14 3 / 15 4 / 16 5 / 17 6 / 18 7 / 19 8 / 20 9 / 21 10 / 22 11 / 23 12 / 24

20kHz

-

24dB

+

24dB

LOW

+45

-15

-15