Page 1

HV-MC90

SIMPLE-2

KE

SERVICE MANUAL

VIDEO CASSETTE RECORDER

Apartofcontentsisadequate.

Re-issuing is under request.

BASIC VIDEO MECHANISM

: D33Y1-2HD/PAL(6721RF0412A)

S/M Code No. 09-019-358-4N1

DATA

Page 2

TABLE OF CONTENTS

SPECIFICATIONS ................................................................... 3

ACCESSORIES LIST .............................................................. 4

DISASSEMBLY INSTRUCTIONS............................................ 5

SERVICE POSITION ............................................................... 6

VCR TEST TAPE INTERCHANGEABILITY TABLE ............... 7

ELECTRICAL MAIN PARTS LIST................................... 8 ~ 15

TRANSISTOR ILLUSTRATION ............................................. 16

WIRE HARNESS DIAGRAM ................................................. 17

BLOCK DIAGRAM ........................................................ 18 ~ 21

SCHEMATIC DIAGRAM

1. POWER............................................................................. 22

2. AUDIO/VIDEO................................................................... 23

3. SYSTEM CONTROL ......................................................... 24

WIRING

1. MAIN C.B .......................................................................... 25

WAVEFORM

AUDIO/VIDEO SECTION ...................................................... 26

SYSTEM CONTROL SECTION ............................................ 27

VOLTAGE CHART

1. POWER/NICAM SECTION ............................................... 28

2. AUDIO/VIDEO SECTION.................................................. 28

3. SYSTEM CONTROL ......................................................... 29

ADJUSTMENT....................................................................... 30

IC BLOCK DIAGRAM............................................................ 31

IC DESCRIPTION .......................................................... 32 ~ 34

ELECTRICAL TROUBLESHOOTING ........................... 35 ~ 47

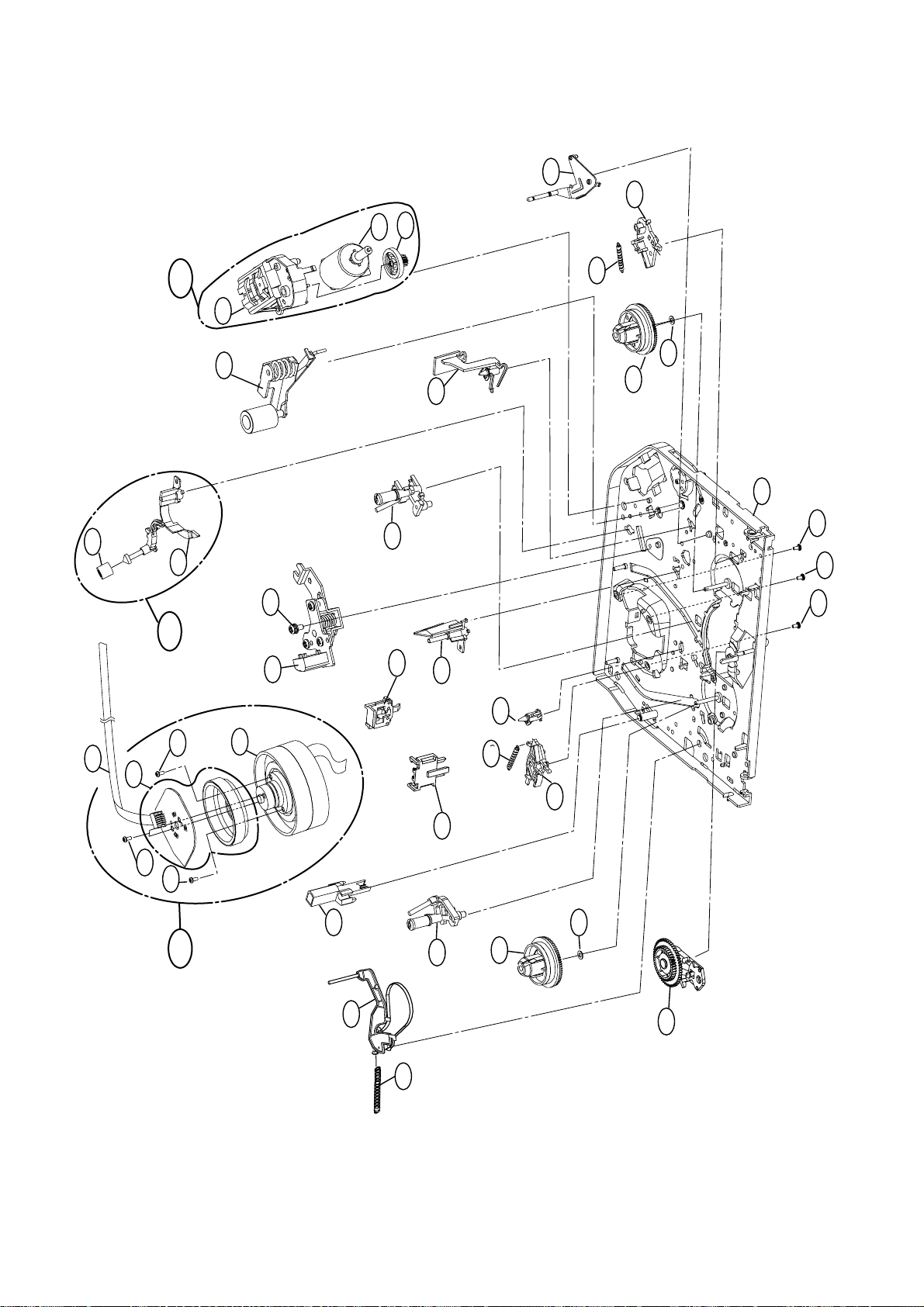

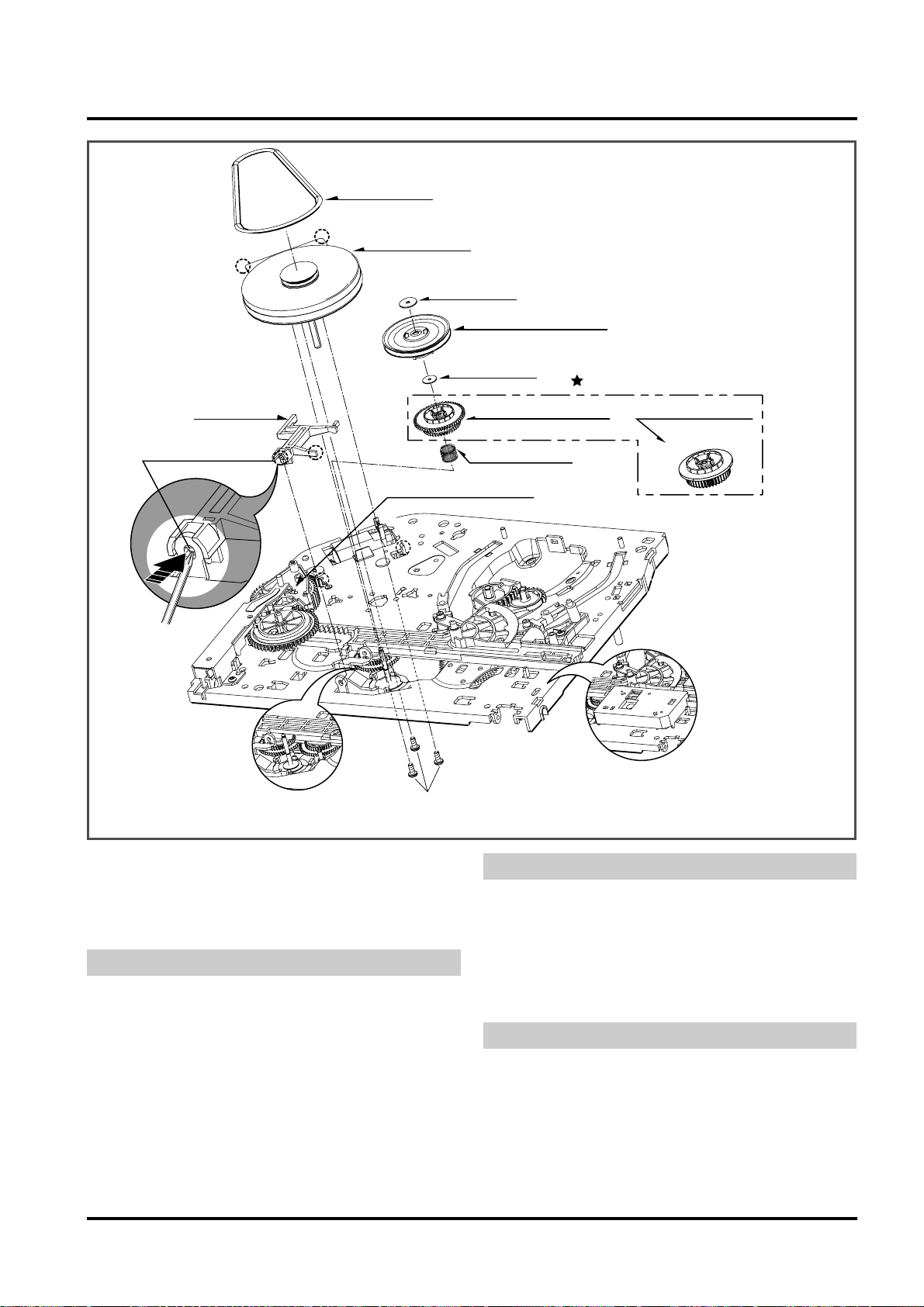

MECHANICAL EXPLODED VIEW 1/1 .................................. 48

MECHANICAL MAIN PARTS LIST 1/1 ........................... 49,50

MECHANISM EXPLODED VIEW 1/3 .................................... 51

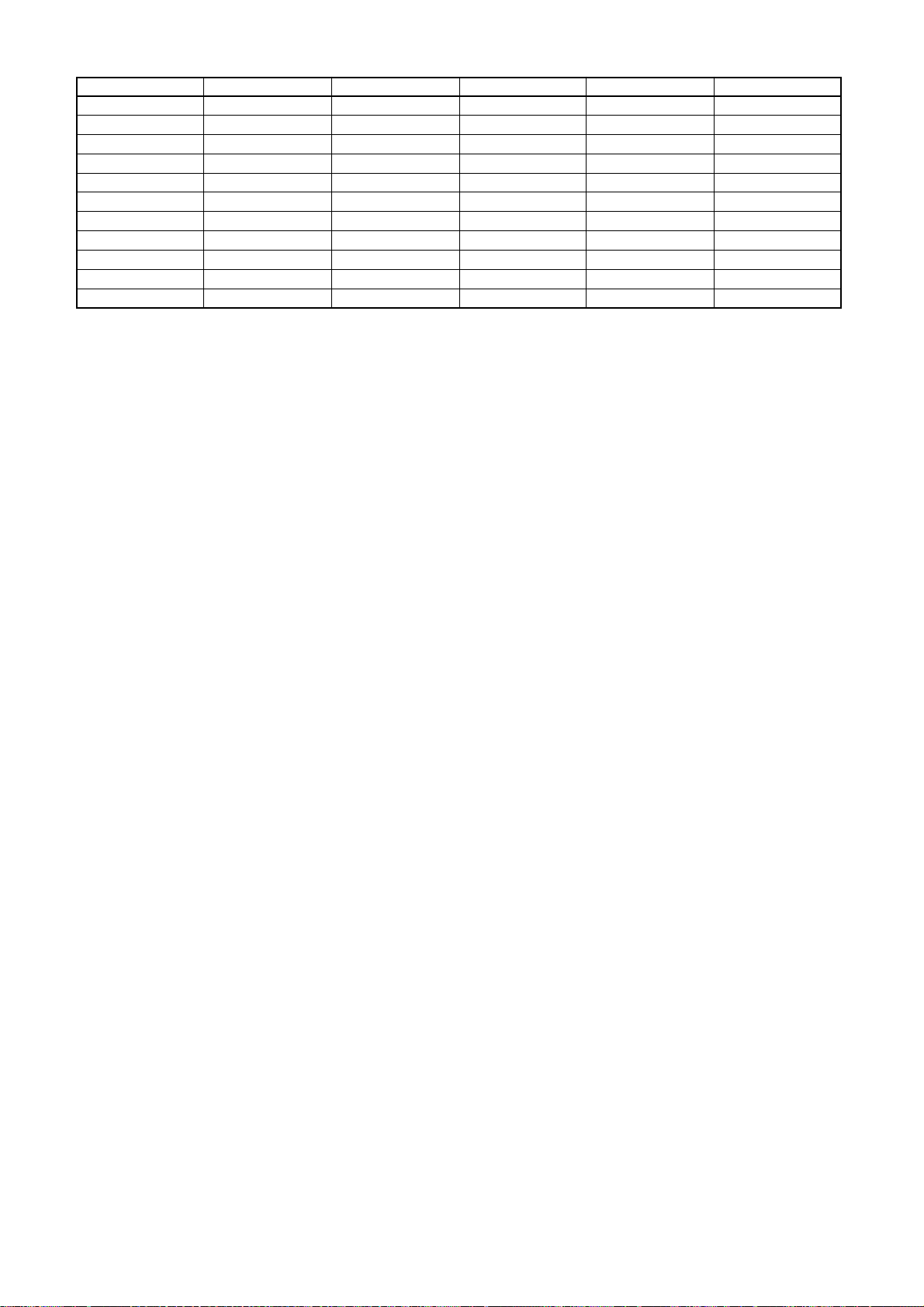

MECHANISM MAIN PARTS LIST 1/3 ................................... 52

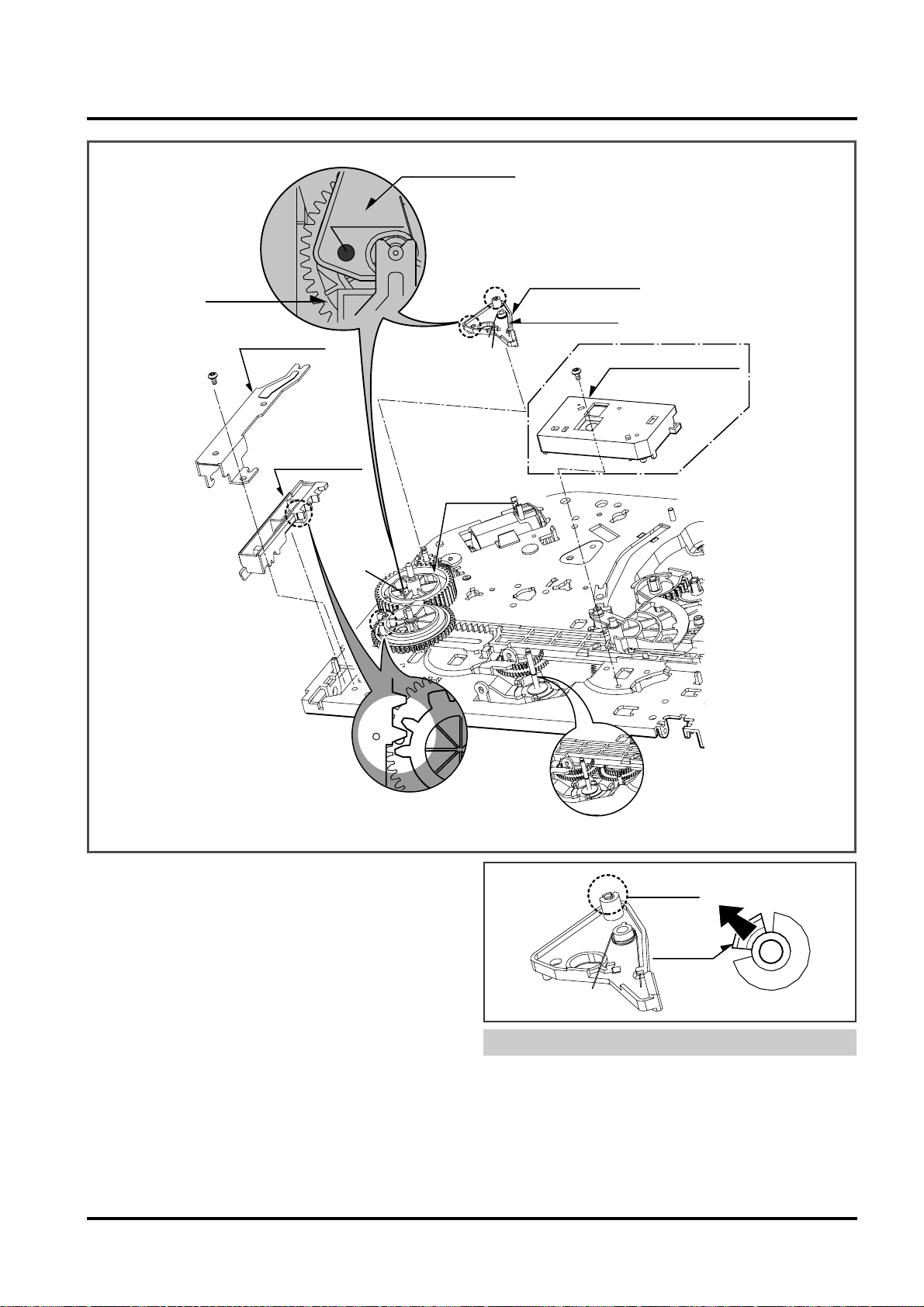

MECHANISM EXPLODED VIEW 2/3 .................................... 53

MECHANISM MAIN PARTS LIST 2/3 ................................... 54

MECHANISM EXPLODED VIEW 3/3 .................................... 55

MECHANISM MAIN PARTS LIST 3/3 ................................... 56

OTHER PARTS LIST ............................................................. 57

DECK MECHANISM PARTS LOCATIONS

Top View................................................................................. 58

Bottom View ........................................................................... 58

DECK MECHANISM DISASSEMBLY

1. Drum Assembly ................................................................ 59

2. Plate Assembly Top.......................................................... 61

3. Holder Assembly CST ...................................................... 61

4. Guide CST ....................................................................... 61

5. Bracket Side (L)/Bracket Assembly Door ......................... 61

6. Arm Assembly F/L ............................................................ 61

7. Lever Assembly S/W ........................................................ 61

8. Arm Assembly Cleaner ..................................................... 62

9. Head F/E .......................................................................... 62

10. Base Assembly A/C Head ............................................... 62

11. Brake Assembly S ........................................................... 63

12. Brake Assembly T ........................................................... 63

13. Arm Assembly Tension .................................................... 63

14. Reel S & Reel T .............................................................. 63

15. Support CST ................................................................... 64

16. Base Assembly P4 .......................................................... 64

17. Opener Lid ...................................................................... 64

18. Arm Assembly T/up ......................................................... 64

19. Arm Assembly Pinch ....................................................... 64

20. Belt Capstan/Motor Capstan ........................................... 65

21.Clutch Assembly D33-Y ................................................... 65

22. Lever F/R ........................................................................ 65

23. Gear H-Up/D-K or

Gear Up/D-K ................................................................... 65

24. Bracket Assembly Jog..................................................... 66

25. Guide Rack F/L, Gear Rack F/L ...................................... 66

26. Brake Assembly Capstan ................................................ 66

27. Gear Drive/Gear Cam/Gear Connector .......................... 67

28. Bracket Assembly L/D Motor........................................... 67

29. Gear Sector ..................................................................... 68

30. Base Tension/Plate Slider/Lever Tension ........................ 68

31. Gear Assembly P3/Gear Assembly P2 ........................... 69

32. Base Assembly P3/Base Assembly P2 ........................... 69

33. Arm Assembly Idler or Arm assembly Idler Jog............... 69

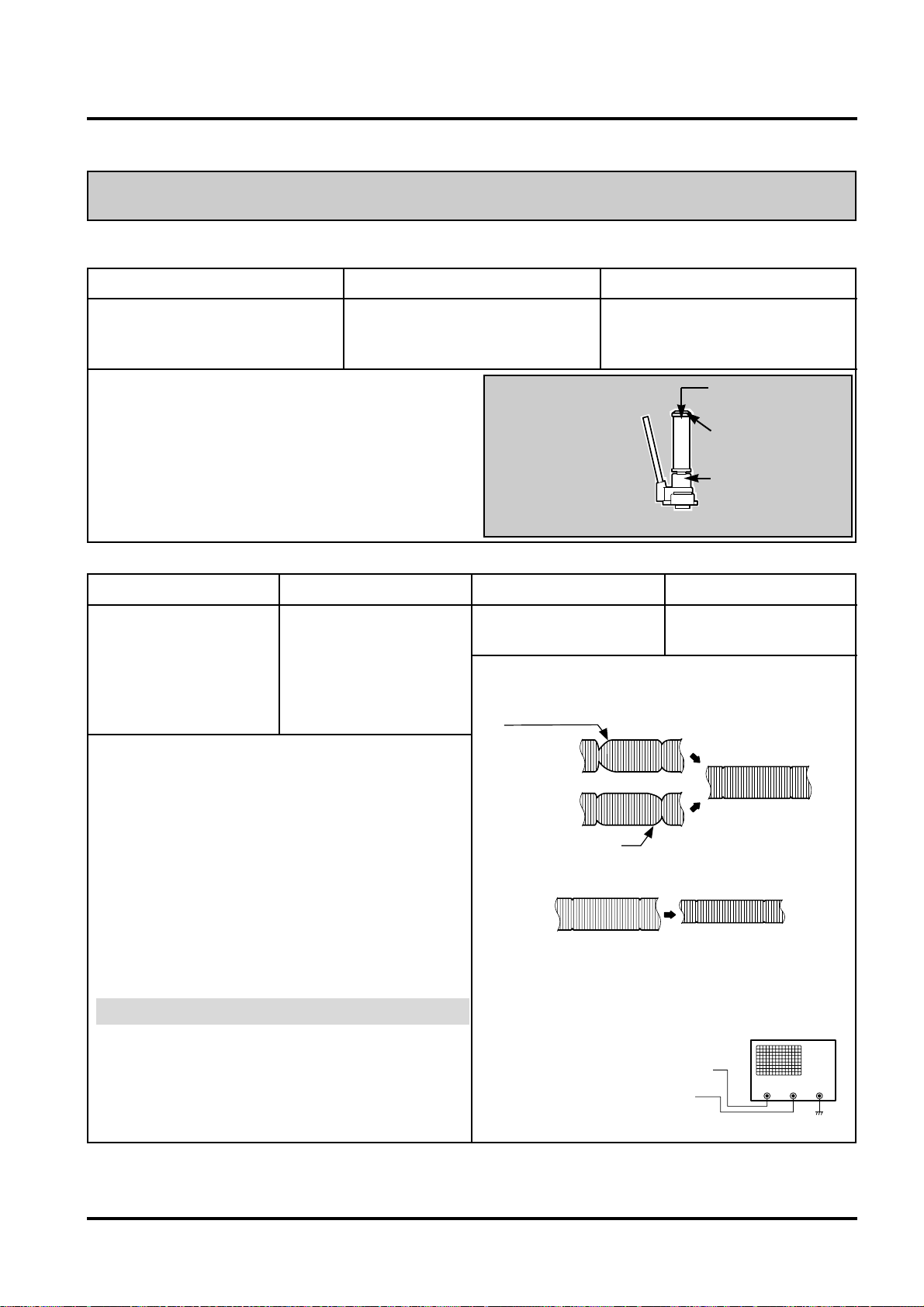

DECK MECHANISM ADJUSTMENT

Tools and Fixtures for Service ................................................ 70

1. Mechanism Alignment Position Check .............................. 71

2. Preparation for Adjustment ............................................... 72

3. Checking Torque ............................................................... 72

4. Guide Roller Height Adjustment ........................................ 73

4-1. Preliminary Adjustment ................................................. 73

4-2. Precise Adjustment ....................................................... 73

5. Audio/Control (A/C) Head Adjustment ............................... 74

5-1. Preliminary Adjustment ................................................. 74

5-2. Confirm that the Tape Passes smoothly between

the Take-up Guide and Pinch Roller ............................ 75

5-3. Precise Adjustment (Azimuth Adjustment) .................... 75

6. X-Value Adjustment ........................................................... 75

7. Adjustment after Replacing Drum Assembly

(Video Heads) .................................................................... 76

8. Check the Tape Travel after Reassembling

Deck Assembly................................................................... 76

8-1. Checking Audio and RF Locking Time

during Playback and after CUE or REV ....................... 76

8-2. Check for Tape Curling or Jamming.............................. 76

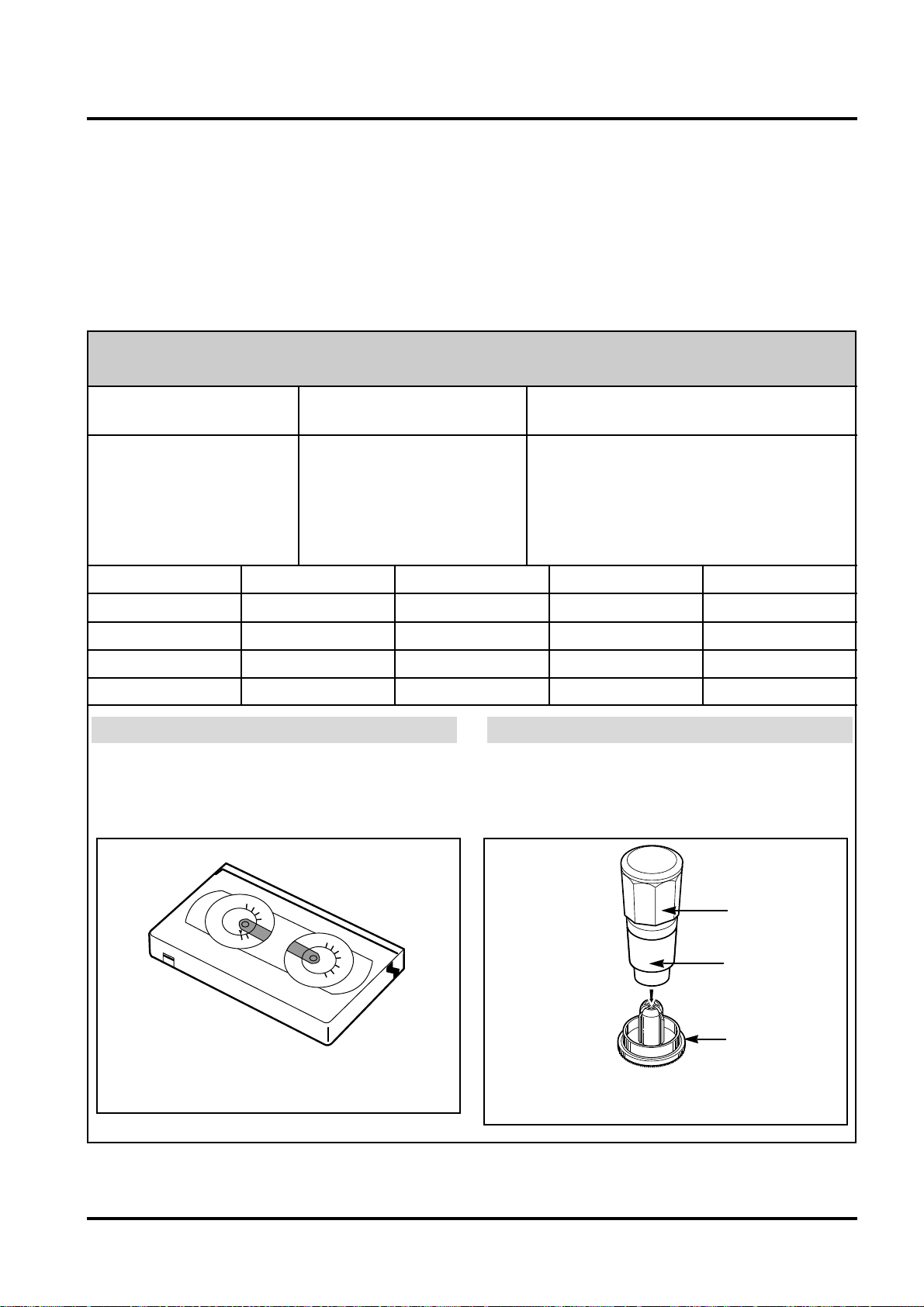

MAINTENANCE/INSPECTION PROCEDURE

1. Check before starting Repairs .......................................... 77

2. Required Maintenance ...................................................... 78

3. Scheduled Maintenance ................................................... 78

4. Supplies Required for Inspection and Maintenance ......... 78

5. Maintenance Procedure .................................................... 78

5-1. Cleaning ........................................................................ 78

5-2. Greasing ....................................................................... 79

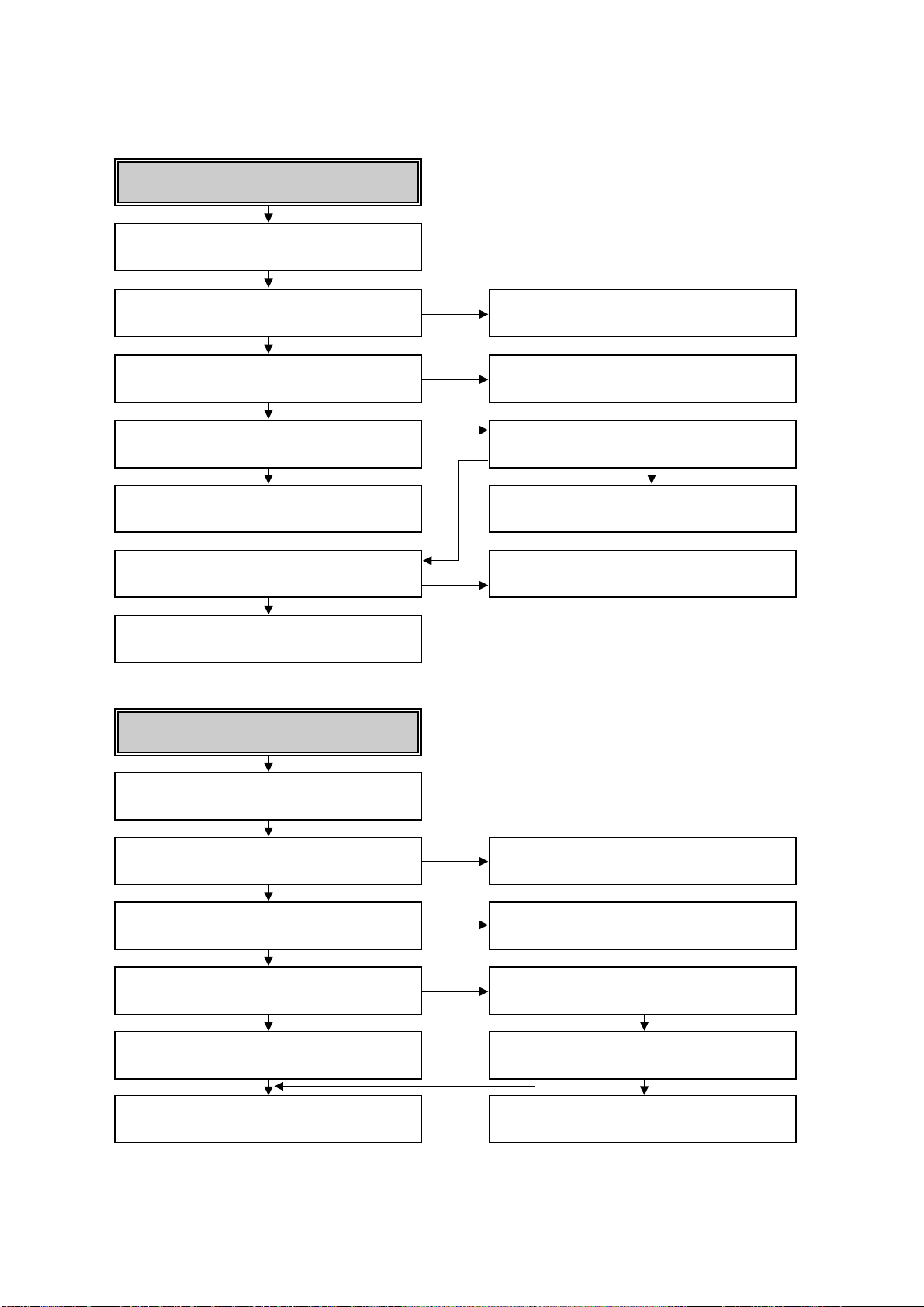

MECHANISM TROUBLESHOOTING GUIDE

1. Deck Mechanism ...................................................... 80 ~ 82

2. Front Loading Mechanism ........................................ 83 ~ 84

-2-

Page 3

SPECIFICATIONS

Video recording system Rotary 2 head helical scanning system

Video head 2 heads

Video signal system PAL/MESECAM color signal, 625 lines, 50 fields

NTSC color signal, 525 lines, 60 fields

Usable cssettes VHS video cassettes

Recording/playback time PAL/MESECAM

SP: 5 hours max. with E-300 tape.

LP: 10 hours max. with E-300 tape

NTSC

SP: 3 hours 30 minutes max. with T-210 tape (playback only)

LP: 7 hours max. with T-210 tape

EP: 10 hours 30 minutes max. with T-210 tape

Tape speed PAL/MESECAM

SP: 23.39 mm/s

LP: 11.69 mm/s

NTSC

SP: 33.35 mm/s

LP: 16.67 mm/s

EP: 11.12 mm/s

Rewind time: Approx. 3 min. with E-180 tspe

Video input 1.0 Vp-p, 75 ohm, unbalanced

Video output 1.0 Vp-p, 75 ohm, unbalanced

Horizontal resolution 240 lines (SP mode)

Video S/N 43 dB (SP mode)

Audio track 1 track (Normal sound)

Audio input -6 dBm, more than 47 k ohm

Audio output -6 dBms, less than 4.7 k ohm

Operating temperature: 5 °C to 35 °C

Power requirements 110 - 240 V AC, 50/60 Hz

Power consumption 10 watts

TYP 3 watts (power save mode.)

Dimensions 360 (W) x 270 (D) x 94.5 (H) mm

Weight (141 /4 x 103/

Approx. 3.2 kg (7.26 lbs)

x 33/4 in)

4

• Design and specifications are subject to change without notice.

-3-

Page 4

ACCESSORIES PARTS LIST -1/1

! = ! SAFTY PARTS

C = Components marked

UNIT-NAME ! C REF-NO PARTS-NO PARTS-NAME SUFFIX&MODEL

HV-MC90

KEJC

O 1 S8-35R-P00-66W INSTRUCTION ASSY A

O 2 S7-11R-2P0-36A RC UNIT,P8(CLA112TW HA7IA) A

O 3 S8-50R-CAA-260 CABLE,COAXIAL 1200M/M A

O 4 S8-51R-P00-03A CABLE ASSY,RF/SCART/RCA USI A

All components used on this model at the production line are shown in this service manual.

However, please note that not all components will be available as spare parts for after-sales service.

Components marked S and O are designated as spare parts for service and will be stocked at the spare parts centers.

Components marked X and R are not designated as spare parts for after sales service, and will not be stocked at the spare parts centers.

-4-

Page 5

DISASSEMBLY INSTRUCTIONS -1/1

1. Top Case Removal

1) Remove 4 screws holding the top case.

2. Panel Front Removal (see Fig. 1)

1) Release 7 tabs, and then remove the panel front.

4. Main C.B. Removal (see Fig. 3)

1) Remove 2 screws B holding the panel assy, distri-butor.

2) Release 5 tabs, and then simultaneously lift the panel assembly, distributor and Main C.B. to remove them.

B

TAB

TAB

PANEL

DISTRIBUTOR

TAB

TAB

TAB

PANEL

FRONT

TAB

Fig. 1

3. Mechanism Removal (see Fig. 2)

1) Disconnect the drum FF cable from the connector (PMD01)

on the Main C.B.

2) Disconnect the ACE head FF cable from the connector (P3D02)

on the Main C.B.

3) Remove 6 screws A .

FF CABLE

P3D02

A

PMD01

MAIN C.B

Fig. 3

A

FF CABLE

A

Fig. 2

-5-

Page 6

SERVICE POSITION -1/1

To set the mechanism to the service position in active status:

Insert a spacer as shown below: The service position can be set in the stable status without any defective contact.

MAIN C.B

D33

MECHA

SPARSER

60mm

MAIN C.B

D33 MECHANISM

Location

Install spacers at locations (A) and (B).

REAR PANEL

SPARSER

A

CYLINDER

HEAD CLEANER

Top View

-6-

B

Page 7

VCR TEST TAPE INTERCHANGEABILITY TABLE -1/1

There are two types of the new allgnment tape CH-1B (for NTSC) and CH-2 (for PAL). On each tape four signals (1)-(4) are

recorded for the times and in the order shown below.

(1) : 8min. → (2) : 2min. → (3) : 5min. → (4) : 5min.

The TTV-MP1 (for M-PAL), TTV-MS1 (for MESECAM) and TTV-S1 (for SECAM) allgnment tapes have the same

contents as the previous tapes.

Method

NTSC

Now in use TYPE

Model Contents *1

TTV-N1

TTV-NS1

TTV-N1E

TTV-NS6E

TTV-N2

TTV-N12

(SCV-1998)

TTV-N6

(TTV-N06T)

TTV-N7A

NTSC, Color bar,

1 kHz, SP

NTSC, Color bar,

1 kHz, SP

NTSC, Color bar,

1 kHz, EP

NTSC, Color bar,

No sound, EP

NTSC, Stairsteps,

7 kHz, SP

NTSC, Color bar,

1 kHz, SP

NTSC, Mono scope,

7 kHz, SP

NTSC, Stairsteps,

1 kHz, SP, HiFi 400 Hz

New TYPE

Model Contents *1

CH-1B(2)

CH-1B(4)

*2

CH-1B(1)

CH-1B(4)

CH-1B(3)

NTSC, Stairsteps,

1 kHz, SP

No Changed.

NTSC, Color bar,

1 kHz, EP

No Changed.

NTSC, Stairsteps,

7 kHz, SP

NTSC, Color bar,

1 kHz, EP

No Changed.

NTSC, Color bar,

No sound SP,

HiFi 400 Hz

Application

PB-Y Level/General electrical ADJ.

Head ACE Height/Tilt ADJ.

For S-VHS (SQPB) check

Switching position ADJ.

For S-VHS (SQPB) check

Head ACE Azimuth ADJ.

FM Envelope ADJ.

X-Value ADJ.

For total picture quality check (resolution, etc)

HiFi Audio PB Level ADJ.

Switching position ADJ.

PB-Y Level/General electrical ADJ.

Head ACE Height/Tilt ADJ.

Switching position. (LP Model)

FM Envelope ADJ. (LP Model)

X-Value ADJ. (LP Model)

HEAD ACE Azimuth ADJ.

FM Envelope ADJ. (SP Model)

X-Value ADJ. (SP Model)

For total picture quality check (resolution, etc)

HiFi Audio PB Level ADJ.

FM Filter ADJ.

PA L

TTV-P1

TTV-P1L

TTV-P2

TTV-P6

(TTV-N06T)

TTV-P7

TTV-P16

PAL, Color bar,

1 kHz, SP

PAL, Color bar,

1 kHz, LP

PAL, Stairsteps,

6 kHz, SP

PAL, Monoscope,

6 kHz, SP

PAL, Stairsteps,

1 kHz, SP,

HiFi 1 kHz

PAL, Color bar,

400 Hz,

SP, HiFi 1 kHz

CH-2 (2)

* 3

CH-2 (4)

CH-2 (1)

CH-2 (3)

PAL, Stairsteps,

1 kHz, SP

PAL, Color bar,

1 kHz, LP

PAL, Stairsteps,

6 kHz, SP

No Changed.

PAL, Color bar,

No sound

SP, HiFi400 Hz

No Changed.

* 1. Described in the order of color format. video signal. linear audio. tape speed and Hi-Fi audio.

* 2. Use CH-1B (1)-(3) with models used exclusively in the SP mode.

* 3. Use CH-2 (3) and (4) when it is necessary to observe the chroma signal.

-7-

Page 8

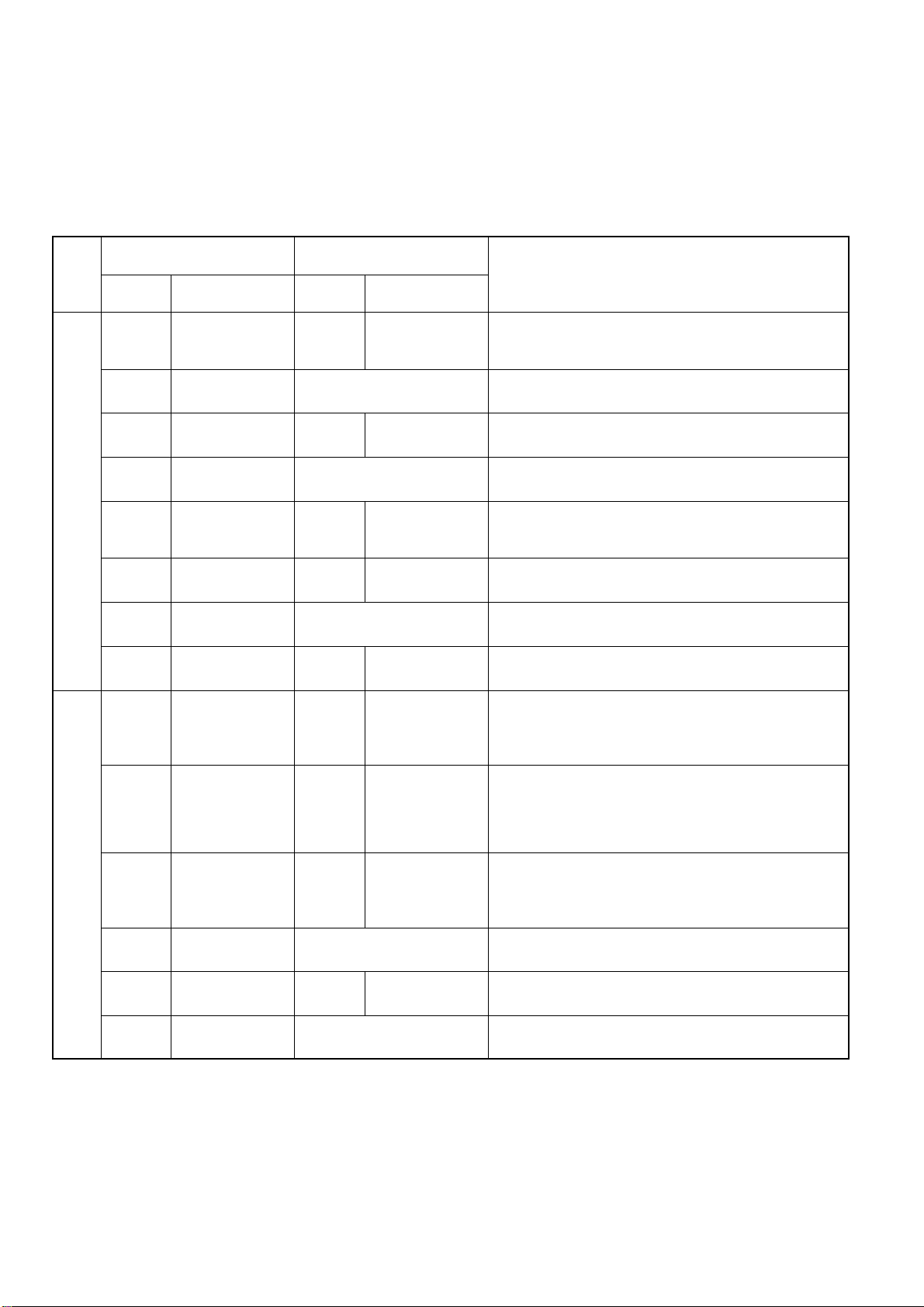

ELECTRICAL PARTS LIST - 1/8

! = ! SAFTY PARTS

C = Components marked

UNIT-NAME ! C REF-NO PARTS-NO PARTS-NAME SUFFIX&MODEL

HV-MC90

KEJC

MAIN S BD 101 87-070-173-010 DIODE,S1WBA60 A

MAIN O BD 3M1 S6-360-04C-000 COIL,BFS3550R2FD8 A

MAIN ! O C 101 S2-408-8L0-000 CAP,E 0.1UF-2 A

MAIN ! O C 102 S2-408-8L0-000 CAP,E 0.1UF-2 A

MAIN ! O C 103 SC-E68-6CV-610 CAP,E 68UF-450V A

MAIN ! O C 105 87-016-375-010 CAP,0.01UF-630V A

MAIN ! O C 106 S6-240-87A-000 HIGH VOL 150P-1KV A

MAIN O C 109 87-010-415-010 CAP,10M-50V A

MAIN X C 110 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN O C 112 87-012-379-010 CAP,3300PF-400V A

MAIN O C 113 SC-G33-10U-510 CAP,CER 330PF-400V A

MAIN X C 114 SC-Q47-32K-409 CAP,0.047UF-50V A

MAIN O C 116 SC-E10-86F-6CM CAP,E 1000UF-16V M FM5 BU A

MAIN O C 117 87-010-375-080 CAP,E 330-10V A

MAIN O C 120 87-016-134-080 CAP,E 470UF-25V M FM A

MAIN O C 121 SC-E33-7CH-618 CAP,E 330UF-25V A

MAIN X C 127 SC-N22-3AK-948 CAP,0.022UF 50V A

MAIN X C 129 SC-N22-3AK-948 CAP,0.022UF 50V A

MAIN X C 135 SC-N47-10K-518 CAP,470P-50V A

MAIN O C 153 87-015-681-080 CAP,E 10-16V A

HV-MC90

KEJC

MAIN O C 154 87-015-681-080 CAP,E 10-16V A

MAIN O C 156 87-015-698-080 CAP,E 4.7-50V A

MAIN X C 301 SC-N10-30F-678 CAP,0.01-16V A

MAIN O C 302 87-010-552-040 CAP,E 22-16V A

MAIN X C 303 SC-N12-20F-668 CAP,1200P-16V A

MAIN O C 304 87-015-698-080 CAP,E 4.7-50V A

MAIN X C 305 SC-N22-20F-668 CAP,2200P-16V A

MAIN O C 306 87-015-698-080 CAP,E 4.7-50V A

MAIN O C 307 87-015-681-080 CAP,E 10-16V A

MAIN X C 310 SC-K10-4AK-945 CAP,CER 0.1UF-50V A

MAIN O C 311 87-010-552-040 CAP,E 22-16V A

MAIN O C 312 87-015-681-080 CAP,E 10-16V A

MAIN X C 313 SC-Q10-32K-409 CAP,0.01UF-50V A

MAIN X C 314 SC-Q33-32K-409 CAP,0.033UF-50V A

MAIN O C 315 87-015-684-080 CAP,E 47-16V A

MAIN O C 317 87-016-088-040 CAP,E 220-6.3V A

MAIN X C 318 SC-N15-10K-518 CAP,150P-50V A

MAIN X C 319 SC-K10-4AK-945 CAP,CER 0.1UF-50V A

MAIN O C 320 87-015-681-080 CAP,E 10-16V A

MAIN X C 321 SC-X47-00K-408 CAP,47P-50V A

HV-MC90

KEJC

MAIN X C 322 SC-K10-4AK-945 CAP,CER 0.1UF-50V A

MAIN X C 323 SC-N10-40K-948 CAP,0.1UF-50V A

MAIN O C 324 87-015-681-080 CAP,E 10-16V A

MAIN X C 325 SC-N10-40K-948 CAP,0.1UF-50V A

MAIN X C 326 SC-K10-4AK-945 CAP,CER 0.1UF-50V A

MAIN O C 327 87-010-403-040 CAP,E 3.3-50V A

MAIN O C 328 87-015-681-080 CAP,E 10-16V A

MAIN O C 330 87-010-402-040 CAP,E 2.2-50V A

MAIN X C 333 SC-N33-10K-518 CAP,330P-50V A

MAIN X C 334 SC-N47-30K-948 CAP,0.047-50V A

MAIN O C 335 87-015-684-080 CAP,E 47-16V A

MAIN X C 336 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 337 SC-N10-40K-948 CAP,0.1UF-50V A

MAIN X C 338 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 339 SC-N10-40K-948 CAP,0.1UF-50V A

MAIN X C 340 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 341 SC-N10-30F-678 CAP,0.01-16V A

MAIN O C 342 87-016-088-040 CAP,E 220-6.3V A

MAIN X C 344 SC-N22-3AK-948 CAP,0.022UF 50V A

MAIN O C 345 87-015-698-080 CAP,E 4.7-50V A

HV-MC90

KEJC

MAIN X C 346 SC-C05-00K-015 CAP,5P-50V A

MAIN O C 347 87-015-698-080 CAP,E 4.7-50V A

MAIN X C 348 SC-K10-4AK-945 CAP,CER 0.1UF-50V A

MAIN X C 349 SC-N22-3AK-948 CAP,0.022UF 50V A

MAIN O C 350 87-015-695-080 CAP,E 1.0-50V A

MAIN X C 351 SC-K10-4AK-945 CAP,CER 0.1UF-50V A

MAIN O C 352 87-010-402-040 CAP,E 2.2-50V A

MAIN X C 353 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 354 SC-Q22-32L-559 CAP,0.022UF-63V A

MAIN O C 356 SC-E33-44K-638 CAP,E 0.33M-50V A

MAIN X C 357 SC-N33-30K-518 CAP,0.033UF-50V A

MAIN O C 358 87-010-403-040 CAP,E 3.3-50V A

MAIN O C 359 87-015-684-080 CAP,E 47-16V A

MAIN X C 360 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 361 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 362 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 363 SC-N10-30F-678 CAP,0.01-16V A

MAIN O C 365 87-015-684-080 CAP,E 47-16V A

MAIN O C 370 87-015-698-080 CAP,E 4.7-50V A

MAIN X C 371 SC-N68-10K-518 CAP,680P-50V A

All components used on this model at the production line are shown in this service manual.

However, please note that not all components will be available as spare parts for after-sales service.

Components marked S and O are designated as spare parts for service and will be stocked at the spare parts centers.

Components marked X and R are not designated as spare parts for after sales service, and will not be stocked at the spare parts centers.

-8-

Page 9

ELECTRICAL PARTS LIST - 2/8

! = ! SAFTY PARTS

C = Components marked

UNIT-NAME ! C REF-NO PARTS-NO PARTS-NAME SUFFIX&MODEL

HV-MC90

KEJC

MAIN X C 391 SC-N22-3AK-948 CAP,0.022UF 50V A

MAIN X C 3M1 SC-N10-20K-518 CAP,1000P-50V A

MAIN X C 3M2 SC-N10-20K-518 CAP,1000P-50V A

MAIN X C 3M3 SC-N10-30F-678 CAP,0.01-16V A

MAIN O C 3M5 87-015-681-080 CAP,E 10-16V A

MAIN O C 3M7 87-015-695-080 CAP,E 1.0-50V A

MAIN O C 3M8 SC-E47-7CD-638 CAP,E 470UF-10V A

MAIN X C 3N1 SC-N22-3AK-948 CAP,0.022UF 50V A

MAIN O C 3N2 87-015-681-080 CAP,E 10-16V A

MAIN O C 3N3 87-015-681-080 CAP,E 10-16V A

MAIN X C 3N4 SC-N22-3AK-948 CAP,0.022UF 50V A

MAIN O C 500 87-016-088-040 CAP,E 220-6.3V A

MAIN X C 501 SC-K10-4AK-945 CAP,CER 0.1UF-50V A

MAIN O C 502 87-010-078-080 CAP,E 47M-6.3V A

MAIN X C 503 SC-N10-30F-678 CAP,0.01-16V A

MAIN O C 505 87-016-088-040 CAP,E 220-6.3V A

MAIN X C 506 SC-N22-3AK-948 CAP,0.022UF 50V A

MAIN X C 507 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 508 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 509 SC-N22-3AK-948 CAP,0.022UF 50V A

HV-MC90

KEJC

MAIN O C 510 87-016-088-040 CAP,E 220-6.3V A

MAIN O C 525 87-016-088-040 CAP,E 220-6.3V A

MAIN O C 526 87-016-130-080 CAP,47-25V A

MAIN X C 530 SC-N10-30F-678 CAP,0.01-16V A

MAIN O C 531 87-016-088-040 CAP,E 220-6.3V A

MAIN X C 532 SC-N10-10K-518 CAP,100P-50V A

MAIN O C 533 87-010-402-040 CAP,E 2.2-50V A

MAIN O C 534 87-015-695-080 CAP,E 1.0-50V A

MAIN O C 535 87-015-695-080 CAP,E 1.0-50V A

MAIN O C 536 87-015-695-080 CAP,E 1.0-50V A

MAIN X C 537 SC-N10-40K-948 CAP,0.1UF-50V A

MAIN X C 538 SC-N10-20K-518 CAP,1000P-50V A

MAIN X C 540 SC-N33-30K-518 CAP,0.033UF-50V A

MAIN X C 542 SC-N68-10K-518 CAP,680P-50V A

MAIN X C 543 SC-N33-30K-518 CAP,0.033UF-50V A

MAIN X C 544 SC-Q47-32K-409 CAP,0.047UF-50V A

MAIN X C 545 SC-N33-30K-518 CAP,0.033UF-50V A

MAIN X C 551 SC-Q33-32K-409 CAP,0.033UF-50V A

MAIN X C 552 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 555 SC-K10-4AK-945 CAP,CER 0.1UF-50V A

HV-MC90

KEJC

MAIN X C 556 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 557 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 567 SC-N10-20K-518 CAP,1000P-50V A

MAIN X C 570 SC-C15-00K-415 CAP,15P-50V A

MAIN X C 571 SC-C15-00K-415 CAP,15P-50V A

MAIN X C 572 SC-K10-4AK-945 CAP,CER 0.1UF-50V A

MAIN X C 574 SC-N10-20K-518 CAP,1000P-50V A

MAIN X C 575 SC-N10-20K-518 CAP,1000P-50V A

MAIN X C 581 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 582 SC-N10-30F-678 CAP,0.01-16V A

MAIN X C 584 SC-K10-4AK-945 CAP,CER 0.1UF-50V A

MAIN O C 585 87-016-088-040 CAP,E 220-6.3V A

MAIN O C 586 87-010-544-010 CAP,E 0.1-50V A

MAIN O C 587 87-010-400-080 CAP,E 0.47-50V A

MAIN X C 588 SC-N22-3AK-948 CAP,0.022UF 50V A

MAIN X C 589 SC-N22-20F-668 CAP,2200P-16V A

MAIN X C 590 SC-N22-20F-668 CAP,2200P-16V A

MAIN O C 591 87-010-387-080 CAP,E 470UF-25V A

MAIN O C 5R1 87-015-681-080 CAP,E 10-16V A

MAIN O CS 501 S6-00R-DB0-04C SW,MPU10252MLB4 MIC A

HV-MC90

KEJC

MAIN O D 102 87-357-529-310 DIODE,ERA22-10 A

MAIN O D 103 SD-R18-020-9AA DIODE,ERA18-02KFRB A

MAIN O D 104 87-020-465-080 DIODE,1SS133 A

MAIN O D 106 SD-R15-822-0AA DIODE,1N5822 A

MAIN O D 109 SD-R20-200-0AB DIODE,HER202 BK A

MAIN O D 151 SD-R10-400-9AB DIODE,RL104 A

MAIN X D 152 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN O D 153 SD-R10-400-9AB DIODE,RL104 A

MAIN O D 157 87-020-465-080 DIODE,1SS133 A

MAIN X D 501 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN O ES 501 S9-31R-001-6C0 HOLDER ASSY END(DI-CKD)LOCAL A

MAIN O ES 502 S9-31R-001-6C0 HOLDER ASSY END(DI-CKD)LOCAL A

MAIN ! O F 101 S5-850-11T-000 FUSE,1600MA 250V A

MAIN ! O FH 01 S5-860-08B-000 HOLDER,FUSE CLIP A

MAIN ! O FH 02 S5-860-08B-000 HOLDER,FUSE CLIP A

MAIN O FL 301 S6-330-32N-000 COIL,BIAC OSC DEO-010 KSE A

MAIN ! S IC 101 SI-PMG-SK0-01A IC,STR-G6351L A

MAIN ! O IC 102 S5-00R-DB0-11A SENSOR,PHOTO KP1010 A

MAIN O IC 103 SI-KE4-310-00A IC,KIA431 3P A

MAIN S IC 301 SI-HI1-187-17B IC,HA118717F A

All components used on this model at the production line are shown in this service manual.

However, please note that not all components will be available as spare parts for after-sales service.

Components marked S and O are designated as spare parts for service and will be stocked at the spare parts centers.

Components marked X and R are not designated as spare parts for after sales service, and will not be stocked at the spare parts centers.

-9-

Page 10

ELECTRICAL PARTS LIST - 3/8

! = ! SAFTY PARTS

C = Components marked

UNIT-NAME ! C REF-NO PARTS-NO PARTS-NAME SUFFIX&MODEL

HV-MC90

KEJC

MAIN S IC 501 SI-MCR-NE0-07B IC,UPD784927GF-214-3BA A

MAIN S IC 502 SI-LNR-SA0-02A IC,LB11880 A

MAIN O IC 504 SI-KE7-031-00A IC,KIA7031P A

MAIN X J 301 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN O JK 3M1 S7-204-2A0-000 JACK,PIN (4PIN) A

MAIN ! O L 102 S6-161-45H-000 FILTER SHT LFS2020V4-04350 A

MAIN O L 103 S6-330-88G-000 COIL,CHOCK TP 5MM A

MAIN O L 104 S6-330-88G-000 COIL,CHOCK TP 5MM A

MAIN O L 301 87-005-208-080 COIL,100 A

MAIN O L 303 87-A50-002-080 COIL,270U 2.3-3.4-5 A

MAIN O L 304 SL-R10-00J-0N5 COIL,100UH A

MAIN O L 306 87-003-282-080 COIL,12 2.3-3.4-5 A

MAIN O L 310 SL-R10-00J-0N5 COIL,100UH A

MAIN O L 311 87-003-152-080 INDUCTOR,100M 2.3-3.4-5 A

MAIN O L 3M1 87-003-152-080 INDUCTOR,100M 2.3-3.4-5 A

MAIN O L 3M2 87-003-152-080 INDUCTOR,100M 2.3-3.4-5 A

MAIN O L 3M3 SL-R10-00J-0N5 COIL,100UH A

MAIN O L 3M4 SL-R10-00J-0N5 COIL,100UH A

MAIN O L 3M5 SL-R10-00J-0N5 COIL,100UH A

MAIN O L 501 87-005-208-080 COIL,100 A

HV-MC90

KEJC

MAIN X L 502 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN O L 503 SL-R56-00K-035 COIL,560M A

MAIN O LD 501 S9-31R-001-7C0 HOLDER ASSY LED(DI-CKD)LOCAL A

MAIN O LED502 S3-01R-2U0-01A LED ASSY,TOH-30M05G1 A

MAIN O MD 3M1 S7-04R-P00-2B0 MODULATOR,RUMP73655VL A

MAIN O MS 501 S6-00R-PY0-01B SW,MMS00420ZMBO MIC A

MAIN O P 3D01 S5-612-34Z-000 CONN,3P A

MAIN O P 3D02 S6-30R-5S0-10A CONN,6P A

MAIN O P 3D03 S5-612-51B-000 GB201-2P-TS-B(LGC) P A

MAIN O PMC01 S6-30R-2P0-05C CONN,TMC-J08P-A1 8PIN 2MM A

MAIN O PMD01 S5-612-34V-000 GF120-07S-TS LGC 7P SP A

MAIN O PML01 S6-30R-2S0-11A CONN,2P A

MAIN ! O PW 101 S5-612-92B-000 GP390 LGC 3P STRAIG P A

MAIN S Q 152 ST-R22-030-9AF TR,SRA2203 A

MAIN S Q 153 ST-R32-050-9AB TR,KTC3205-TP-Y A

MAIN O Q 155 ST-R12-730-9AA TR,KTA1273-TP-Y A

MAIN O Q 156 ST-R53-430-9BA TR,2SC5343-L A

MAIN O Q 301 ST-R53-440-9AA TR,2SC5344Y A

MAIN O Q 302 ST-R12-730-9AA TR,KTA1273-TP-Y A

MAIN S Q 303 ST-R12-030-9AE TR,SRC1203 A

HV-MC90

KEJC

MAIN O Q 304 ST-R19-800-9CA TR,2SA1980G A

MAIN O Q 305 ST-R53-430-9BA TR,2SC5343-L A

MAIN O Q 306 ST-R53-430-9BA TR,2SC5343-L A

MAIN S Q 307 ST-R22-030-9AF TR,SRA2203 A

MAIN O Q 3M1 ST-R19-800-9CA TR,2SA1980G A

MAIN S Q 514 ST-R12-030-9AE TR,SRC1203 A

MAIN S Q 515 ST-R12-030-9AE TR,SRC1203 A

MAIN ! O R 101 S6-140-07A-000 RES,CEM 2.7/2W A

MAIN X R 102 SR-D68-03F-608 RES,680K-1/6W A

MAIN X R 103 SR-D04-72F-608 RES,47-1/6W A

MAIN X R 104 SR-S56-02K-619 RES,56K-2W A

MAIN X R 106 SR-D68-03F-608 RES,680K-1/6W A

MAIN O R 109 SR-S03-50K-619 RES,0.35-2W A

MAIN X R 116 SR-D22-00F-608 RES,220-1/6W A

MAIN X R 117 SR-D39-01F-608 RES,3.9K-1/6W A

MAIN X R 118 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 119 SR-N33-01F-408 RES,3.3K-1/6W A

MAIN X R 120 SR-N27-01F-408 RES,2.70K-1/6W A

MAIN X R 121 SR-D18-00F-608 RES,180-1/6W A

MAIN X R 125 SR-D56-01F-608 RES,5.6K-1/6W A

HV-MC90

KEJC

MAIN X R 126 SR-D68-00F-608 RES,680-1/6W A

MAIN X R 153 SR-D18-01F-608 RES,1.8K-1/6W A

MAIN X R 156 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 157 SR-D47-00F-608 RES,470-1/6W A

MAIN X R 159 SR-D47-02F-608 RES,47K-1/6W A

MAIN X R 15T1 SR-D22-01F-608 RES,2.2K-1/6W A

MAIN X R 161 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 301 SR-D33-03F-608 RES,330K-1/6W A

MAIN X R 302 SR-D12-02F-608 RES,12K-1/6W A

MAIN X R 303 SR-D18-00F-608 RES,180-1/6W A

MAIN X R 304 SR-D27-02F-608 RES,27K-1/6W A

MAIN X R 305 SR-D18-02F-608 RES,18K-1/6W A

MAIN X R 306 SR-D22-01F-608 RES,2.2K-1/6W A

MAIN X R 308 SR-D04-72F-608 RES,47-1/6W A

MAIN X R 309 SR-D15-01F-608 RES,1.5K-1/6W A

MAIN X R 310 SR-D27-01F-608 RES,2.7K-1/6W A

MAIN X R 311 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 312 SR-D47-02F-608 RES,47K-1/6W A

MAIN X R 313 SR-D12-02F-608 RES,12K-1/6W A

MAIN X R 314 SR-D47-01F-608 RES,4.7K-1/6W A

All components used on this model at the production line are shown in this service manual.

However, please note that not all components will be available as spare parts for after-sales service.

Components marked S and O are designated as spare parts for service and will be stocked at the spare parts centers.

Components marked X and R are not designated as spare parts for after sales service, and will not be stocked at the spare parts centers.

-10-

Page 11

ELECTRICAL PARTS LIST - 4/8

! = ! SAFTY PARTS

C = Components marked

UNIT-NAME ! C REF-NO PARTS-NO PARTS-NAME SUFFIX&MODEL

HV-MC90

KEJC

MAIN X R 315 SR-D27-01F-608 RES,2.7K-1/6W A

MAIN X R 316 SR-D56-01F-608 RES,5.6K-1/6W A

MAIN X R 317 SR-D56-01F-608 RES,5.6K-1/6W A

MAIN X R 320 SR-D39-02F-608 RES,39K-1/6W A

MAIN X R 321 SR-D12-02F-608 RES,12K-1/6W A

MAIN X R 322 SR-D68-01F-608 RES,6.8K-1/6W A

MAIN X R 324 SR-D22-01F-608 RES,2.2K-1/6W A

MAIN X R 325 SR-D15-01F-608 RES,1.5K-1/6W A

MAIN X R 327 SR-D33-01F-608 RES,3.3K-1/6W A

MAIN X R 328 SR-D15-01F-608 RES,1.5K-1/6W A

MAIN X R 330 SR-D82-02F-608 RES,82K-1/6W A

MAIN X R 332 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 333 SR-D56-01F-608 RES,5.6K-1/6W A

MAIN X R 334 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 336 SR-D75-00F-608 RES,750-1/6W A

MAIN X R 338 SR-D27-00F-608 RES,270-1/6W A

MAIN X R 340 SR-D02-21F-608 RES,2.2-1/6W A

MAIN X R 341 SR-D02-21F-608 RES,2.2-1/6W A

MAIN X R 342 SR-D33-01F-608 RES,3.3K-1/6W A

MAIN X R 346 SR-D22-04F-608 RES,2.2M-1/6W A

HV-MC90

KEJC

MAIN X R 3M1 SR-D33-01F-608 RES,3.3K-1/6W A

MAIN X R 3M2 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 3M3 SR-D18-02F-608 RES,18K-1/6W A

MAIN X R 3M4 SR-D07-52F-608 RES,75-1/6W A

MAIN X R 3M5 SR-D56-00F-608 RES,560-1/6W A

MAIN X R 3M6 SR-D56-00F-608 RES,560-1/6W A

MAIN X R 3M7 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 3M8 SR-D08-22F-608 RES,82-1/6W A

MAIN X R 504 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 505 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 506 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 511 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 515 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X R 521 SR-D12-01F-608 RES,1.2K-1/6W A

MAIN X R 522 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 523 SR-D33-01F-608 RES,3.3K-1/6W A

MAIN X R 527 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 528 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 529 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 531 SR-D10-02F-608 RES,10K-1/6W A

HV-MC90

KEJC

MAIN X R 534 SR-D10-04F-608 RES,1.0-1/6W A

MAIN X R 536 SR-D47-00F-608 RES,470-1/6W A

MAIN X R 537 SR-D47-00F-608 RES,470-1/6W A

MAIN X R 544 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 546 SR-D56-01F-608 RES,5.6K-1/6W A

MAIN X R 547 SR-D12-02F-608 RES,12K-1/6W A

MAIN X R 548 SR-D10-03F-608 RES,100K-1/6W A

MAIN X R 550 SR-D22-00F-608 RES,220-1/6W A

MAIN X R 551 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 553 SR-D22-00F-608 RES,220-1/6W A

MAIN X R 555 SR-D22-00F-608 RES,220-1/6W A

MAIN X R 556 SR-D22-02F-608 RES,22K-1/6W A

MAIN X R 557 SR-D27-02F-608 RES,27K-1/6W A

MAIN X R 558 SR-D22-02F-608 RES,22K-1/6W A

MAIN X R 559 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 560 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 563 SR-D56-02F-608 RES,56K-1/6W A

MAIN X R 564 SR-D27-02F-608 RES,27K-1/6W A

MAIN X R 570 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 571 SR-D10-00F-608 RES,100-1/6W A

HV-MC90

KEJC

MAIN X R 572 SR-D56-02F-608 RES,56K-1/6W A

MAIN X R 573 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X R 575 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 576 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 577 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 578 SR-D47-01F-608 RES,4.7K-1/6W A

MAIN X R 579 SR-D56-02F-608 RES,56K-1/6W A

MAIN X R 580 SR-D02-22F-608 RES,22-1/6W A

MAIN X R 581 SR-D68-02F-608 RES,68K-1/6W A

MAIN X R 587 SR-D22-00F-608 RES,220-1/6W A

MAIN X R 588 SR-D56-01F-608 RES,5.6K-1/6W A

MAIN X R 589 SR-D56-01F-608 RES,5.6K-1/6W A

MAIN X R 590 SR-D22-01F-608 RES,2.2K-1/6W A

MAIN X R 591 SR-D47-00F-608 RES,470-1/6W A

MAIN X R 592 SR-D56-03F-608 RES,560K-1/6W A

MAIN O R 593 SR-S04-70K-619 RES,FIX O 0.47-2W A

MAIN X R 597 SR-D10-03F-608 RES,100K-1/6W A

MAIN X R 598 SR-D15-00F-608 RES,150-1/6W A

MAIN X R 5B1 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 5C5 SR-D10-01F-608 RES,1.0K-1/6W A

All components used on this model at the production line are shown in this service manual.

However, please note that not all components will be available as spare parts for after-sales service.

Components marked S and O are designated as spare parts for service and will be stocked at the spare parts centers.

Components marked X and R are not designated as spare parts for after sales service, and will not be stocked at the spare parts centers.

-11-

Page 12

ELECTRICAL PARTS LIST - 5/8

! = ! SAFTY PARTS

C = Components marked

UNIT-NAME ! C REF-NO PARTS-NO PARTS-NAME SUFFIX&MODEL

HV-MC90

KEJC

MAIN X R 5C6 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 5C7 SR-D10-01F-608 RES,1.0K-1/6W A

MAIN X R 5C9 SR-D10-02F-608 RES,10K-1/6W A

MAIN X R 5E7 SR-D10-02F-608 RES,10K-1/6W A

MAIN X R 5E8 SR-D10-02F-608 RES,10K-1/6W A

MAIN X R 5P1 SR-D47-00F-608 RES,470-1/6W A

MAIN X R 5P2 SR-D47-00F-608 RES,470-1/6W A

MAIN X R 5P3 SR-D47-00F-608 RES,470-1/6W A

MAIN X R 5P4 SR-D47-00F-608 RES,470-1/6W A

MAIN X R 5P5 SR-D47-00F-608 RES,470-1/6W A

MAIN X R 5P6 SR-D47-00F-608 RES,470-1/6W A

MAIN X R 5R1 SR-D33-00F-608 RES,330-1/6W A

MAIN X R 5T1 SR-D18-01F-608 RES,1.8K-1/6W A

MAIN X R 5T2 SR-D15-01F-608 RES,1.5K-1/6W A

MAIN X R 5T3 SR-D22-01F-608 RES,2.2K-1/6W A

MAIN X R 5T4 SR-D27-01F-608 RES,2.7K-1/6W A

MAIN X R 5T5 SR-D39-01F-608 RES,3.9K-1/6W A

MAIN X R 5T9 SR-D18-01F-608 RES,1.8K-1/6W A

MAIN X R0 5T1 SR-D15-01F-608 RES,1.5K-1/6W A

MAIN O RC 501 S7-12R-193-8GA REMOTE CONTROLLER RECEI A

HV-MC90

KEJC

MAIN O RS 501 S5-00R-AB0-03A SNSR,SG-260 A

MAIN O RS 502 S5-00R-AB0-03A SNSR,SG-260 A

MAIN O SW 5T1 S5-621-3C0-000 SW,DETECTOR THVV951BAA A

MAIN O SW 5T10 S5-621-3C0-000 SW,DETECTOR THVV951BAA A

MAIN O SW 5T11 S5-621-3C0-000 SW,DETECTOR THVV951BAA A

MAIN O SW 5T12 S5-621-3C0-000 SW,DETECTOR THVV951BAA A

MAIN O SW 5T13 S5-621-3C0-000 SW,DETECTOR THVV951BAA A

MAIN O SW 5T3 S5-621-3C0-000 SW,DETECTOR THVV951BAA A

MAIN O SW 5T4 S5-621-3C0-000 SW,DETECTOR THVV951BAA A

MAIN O SW 5T5 S5-621-3C0-000 SW,DETECTOR THVV951BAA A

MAIN O SW 5T6 S5-621-3C0-000 SW,DETECTOR THVV951BAA A

MAIN ! O T 101 S4-201-5G0-000 TRANSFORMER,SJE-015G/SHT-015G A

MAIN O VR 501 S6-130-32W-000 SFR,RH0638CJ5R(220K) A

MAIN X W 101 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 102 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 103 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 104 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 105 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 106 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 107 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

HV-MC90

KEJC

MAIN X W 108 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 109 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 110 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 111 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 112 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 113 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 114 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 115 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 116 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 117 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 118 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 119 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 120 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 121 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 122 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 123 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 124 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 125 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 126 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 127 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

HV-MC90

KEJC

MAIN X W 128 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 129 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 130 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 131 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 132 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 301 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 302 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 303 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 304 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 305 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 306 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 307 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 309 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 310 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 312 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 313 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 314 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 315 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 316 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 317 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

All components used on this model at the production line are shown in this service manual.

However, please note that not all components will be available as spare parts for after-sales service.

Components marked S and O are designated as spare parts for service and will be stocked at the spare parts centers.

Components marked X and R are not designated as spare parts for after sales service, and will not be stocked at the spare parts centers.

-12-

Page 13

ELECTRICAL PARTS LIST - 6/8

! = ! SAFTY PARTS

C = Components marked

UNIT-NAME ! C REF-NO PARTS-NO PARTS-NAME SUFFIX&MODEL

HV-MC90

KEJC

MAIN X W 318 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 319 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 320 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 321 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 322 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 323 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 324 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 325 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 326 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 327 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 328 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 329 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 330 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 331 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 332 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 333 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 334 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 335 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 336 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 337 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

HV-MC90

KEJC

MAIN X W 338 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 339 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 340 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 341 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 342 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 343 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 344 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 345 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 346 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 347 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 348 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 349 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 350 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 351 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 352 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 353 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 354 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 355 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 356 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 357 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

HV-MC90

KEJC

MAIN X W 358 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 359 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 360 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 361 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 362 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 363 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 364 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 365 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 366 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 367 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 368 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 369 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 370 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 371 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 372 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 373 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 374 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 375 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 376 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 377 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

HV-MC90

KEJC

MAIN X W 378 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 379 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 380 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 381 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 382 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 383 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 384 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 385 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 386 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 387 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 388 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 389 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 390 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 391 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 392 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 393 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 394 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 395 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 396 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 397 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

All components used on this model at the production line are shown in this service manual.

However, please note that not all components will be available as spare parts for after-sales service.

Components marked S and O are designated as spare parts for service and will be stocked at the spare parts centers.

Components marked X and R are not designated as spare parts for after sales service, and will not be stocked at the spare parts centers.

-13-

Page 14

ELECTRICAL PARTS LIST - 7/8

! = ! SAFTY PARTS

C = Components marked

UNIT-NAME ! C REF-NO PARTS-NO PARTS-NAME SUFFIX&MODEL

HV-MC90

KEJC

MAIN X W 3A1 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 501 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 502 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 503 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 504 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 505 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 506 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 507 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 508 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 509 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 510 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 511 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 512 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 513 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 514 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 515 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 516 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 517 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 518 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 519 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

HV-MC90

KEJC

MAIN X W 520 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 521 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 522 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 523 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 524 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 525 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 526 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 527 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 528 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 529 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 530 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 531 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 532 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 533 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 534 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 535 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 536 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 537 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 538 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 539 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

HV-MC90

KEJC

MAIN X W 540 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 541 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 542 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 543 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 544 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 545 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 546 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 547 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 548 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 549 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 550 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 551 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 552 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 553 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 554 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 555 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 556 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 557 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 558 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 560 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

HV-MC90

KEJC

MAIN X W 561 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 562 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 563 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 564 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 565 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 566 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 567 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 568 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 569 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 570 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 571 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 572 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 573 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 574 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 575 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 576 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 577 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 578 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 579 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 580 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

All components used on this model at the production line are shown in this service manual.

However, please note that not all components will be available as spare parts for after-sales service.

Components marked S and O are designated as spare parts for service and will be stocked at the spare parts centers.

Components marked X and R are not designated as spare parts for after sales service, and will not be stocked at the spare parts centers.

-14-

Page 15

ELECTRICAL PARTS LIST - 8/8

! = ! SAFTY PARTS

C = Components marked

UNIT-NAME ! C REF-NO PARTS-NO PARTS-NAME SUFFIX&MODEL

HV-MC90

KEJC

MAIN X W 581 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 582 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 583 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 584 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 585 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 586 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 587 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 588 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 589 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 590 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 591 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 592 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 593 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 594 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 595 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 596 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 597 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 598 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 599 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5A1 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

HV-MC90

KEJC

MAIN X W 5A2 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5A3 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5A4 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5A5 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5A6 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5A7 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5A8 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5A9 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5C1 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5C2 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5C3 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5C4 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5C5 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5C6 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5C7 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5C8 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5C9 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5E1 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5E2 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5E3 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

HV-MC90

KEJC

MAIN X W 5E4 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5E5 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5E6 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5E7 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5E8 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5E9 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5F1 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5F2 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5F3 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5F4 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN X W 5F5 S8-740-00T-000 WIRE,COPPER 0.6 ROLL A

MAIN O X 301 S2-02R-AJ0-7E0 VIB,XTAL H49U 4433783H A

MAIN O X 302 S2-02R-AJ0-3E0 VIB,XTAL H49U 3579675H A

MAIN O X 501 S2-02R-BL0-5E0 VIB,XTAL NTC AXIAL 16MHZ A

MAIN O ZD 153 SD-Z56-000-9CB ZENER,MTZ5.6C A

MAIN S ZD 508 SD-Z62-260-9CA ZENER,GDZJ6.2C 26MM A

All components used on this model at the production line are shown in this service manual.

However, please note that not all components will be available as spare parts for after-sales service.

Components marked S and O are designated as spare parts for service and will be stocked at the spare parts centers.

Components marked X and R are not designated as spare parts for after sales service, and will not be stocked at the spare parts centers.

-15-

Page 16

TRNSISTOR ILLUSTRATION -1/1

E C B

SRA2203

SRC1203

E C B

2SA1980

2SC5343

2SC5344

E C B

KTA1273

KTC3205

-16-

Page 17

WIRING HARNESS DIAGRAM -1/1

PMD01 PMD01

PG+

1

PG-

2

M.GND

3

MCOM

4

W

5

V

6

U

7

PMC01 PMC01

GND

1

MOTOR GND

2

I-LIMIT

3

CAP CONTROL

4

12VA

5

CFG

6

CAP REV "H"

7

5.3VA

8

1

2

DRUM

3

4

MOTOR

5

6

7

1

2

3

4

CAPSTAN

5

MOTOR

6

7

8

MAIN C.B

P3D02 P3D02

CTL(+)

1

CTL(-)

2

A/E(-)

3

A/E(+)

4

A.REC

5

A.PB

6

MS501

GND

1

MODE S1

2

MODE S2

3

MODE S3

4

MODE S4

5

P3D03 P3D03

1

GND

2

FULL ERASE12

P3D01 P3D01

SP PB CH1

1

SP REC

2

3

SPPB CH2

1

2

3

ACE

4

HEAD

5

6

1

2

MS501

3

MODE SW

4

5

FULL ERASE

HEAD

CYL.

1

2

HEAD

3

PML01 PML01

12LD(+)

LD(-)

-17-

1

LOADING

2

MOTOR

Page 18

BLOCK DIAGRAM -1/4 (POWER SECTION)

R101

C103

R106

R102

D153 D151

+

TO SYS

13VA(Cap)

NOTES : Symbol denotes AC ground.

Symbol denotes DC chassis ground.

F101

C112C113

HOT GND

4

3

2

6

4

7

8

10

11

3

1

2

IC102

KP1010

IC103

KIA431

BK

(BR)

WH

(BL)

PW101

AC INPUT

TO SYS

12VA(DRUM)

TO A/V

13VA

TO A/V

5.0A

TO SYS.A/V

5.0V

TO SYS, A/V

5.3VA

FROM SYS

P.CTL "H"

BD101

LINE FILTER

BLOCK

(C101, L102, C102)

DRIVE & S/W

BLOCK

(IC101, C109, D103, R103,

R109, R125, R126, C135)

RECTIFIER &

SMOOTHING

(C116, D106,

L103, C117)

5V REG.

BLOCK

(Q153, R153, R159,

ZD153, C156, C153)

5V S/W

BLOCK

(Q155, R156, R157,

C154, D157)

PWR CTL

BLOCK

(Q156, R161)

FEED-BACK

BLOCK

(R116, R117, R118,

R119, R120, R121,

C114)

Q152

SW

RECTIFIER &

SMOOTHING

(D109, C120,

L104, C121)

SNUBBER

BLOCK

(D102, R104,

C105, C106)

T101

TRANSFORMER

HOT CIRCUIT

-18-

Page 19

BLOCK DIAGRAM - 2/4 (VIDEO SECTION)

¥ PB Mode

X302

3.58MHz

X301

4.43MHz

TO

SYSTEM CONTROL

SECTION

DATA

CLOCK

¥ REC Mode

TO

SYSTEM CONTROL

SECTION

PB CH2

FROM

CYL.HEAD

PB CH1

V.H.SW

V.ENV

81

CONTROL

84

HEAD1 HEAD2

PB-AMP

86

SP CH2

PB-AMP

89

SP CH1

IC301

HA118717F

VIDEO/AUDIO

PROCESSOR

79 78

73 71 75

X-tal

VCO/OSC

CTL Trap

ACC

2M LPF

TRAP

fh Trap

HIFI Trap

FM AGC P.EQ G.EQ D LIM Y LPF

22

62 6963

Serial Cont

interface

C LPF DEALY

DEMO

S LPF

60 58 55 54 35

C-CCD

CLOCK Drive

Y-CCD

VCA

Main

De-Empf

1413

CCD LPF

L- DET

Main

Conv2

Main

Conv1

NL

De-eMPH

CLAMP

CLAMP

TO

SYSTEM CONTROL

SECTION

APC/ACC

DET

BDBPF

YNR NC

LPF

LPF

C.K

2126242318 19

SYNC SEP

Sharpness

CONTROL

+

+

SQUEL CH

Video ALC

MIX

AMP

CLEAR

SYNC

FBC

MD3M1

(MODULATOR)

46

44

39

42

52

51

50

56

D-V SYNC

C-SYNC

5

V.IN

JK3M01

TO

SYSTEM CONTROL

SECTION

VIDEO

OUT

:PB VIDEO SIGNAL

:PB CHROMA SIGNAL

:PB Y SIGNAL

D-V SYNC

TO

SYSTEM CONTROL

SECTION

DATA

CLOCK

35

60

58 6269 63 7371

IC301

46

44

39

42

52

51

1

C-CCD

CLOCK Drive

Y-CCD

6dB

AMP

ATT

ATT

-10dB

-10dB

31

30 28 29 21 26 24 23 18 19 50 22 20 14 13 15

HA118717F

VIDEO/AUDIO

PROCESSOR

SQUEL CH

CLEAR

SYNC

FBC

Video ALC

VIDEO

AGC

ATT

-10dB

Y-LPF

AGC DET

LPF

APC/ACC

DET

SPFACC

CLAMP

Conv2

Conv2

D.E.

YNR

CLAMP

Main

Main

VCA

(-4dB)

C-LPF

C-LPF

NL Emph

SYNC

SEP

CCD

FBC

ALC

LPF

L-DET

Emph

Main

FM

MOD

f/0DEV

Adjst

Serial Cont

interface

B.E

C.K

LPF

MIX

ATT

f0=1.68M

HPF

X302

3.58MHz

VCO/OSC

REC

Trap

X-tal

TRAP

X301

4.43MHz

75

LPF

CONTROL

HEAD1 HEAD2

REC-AMP

SP CH2

VCA

REC-AMP

SP CH1

81

87

88

V.H.SW

TO

SYSTEM CONTROL

SECTION

TO

REC

CYL.HEAD

:REC VIDEO SIGNAL

:REC CHROMA SIGNAL

:REC Y SIGNAL

JK3M01

VIDEO

IN

+

C-SYNC

TO

SYSTEM CONTROL

SECTION

-19-

Page 20

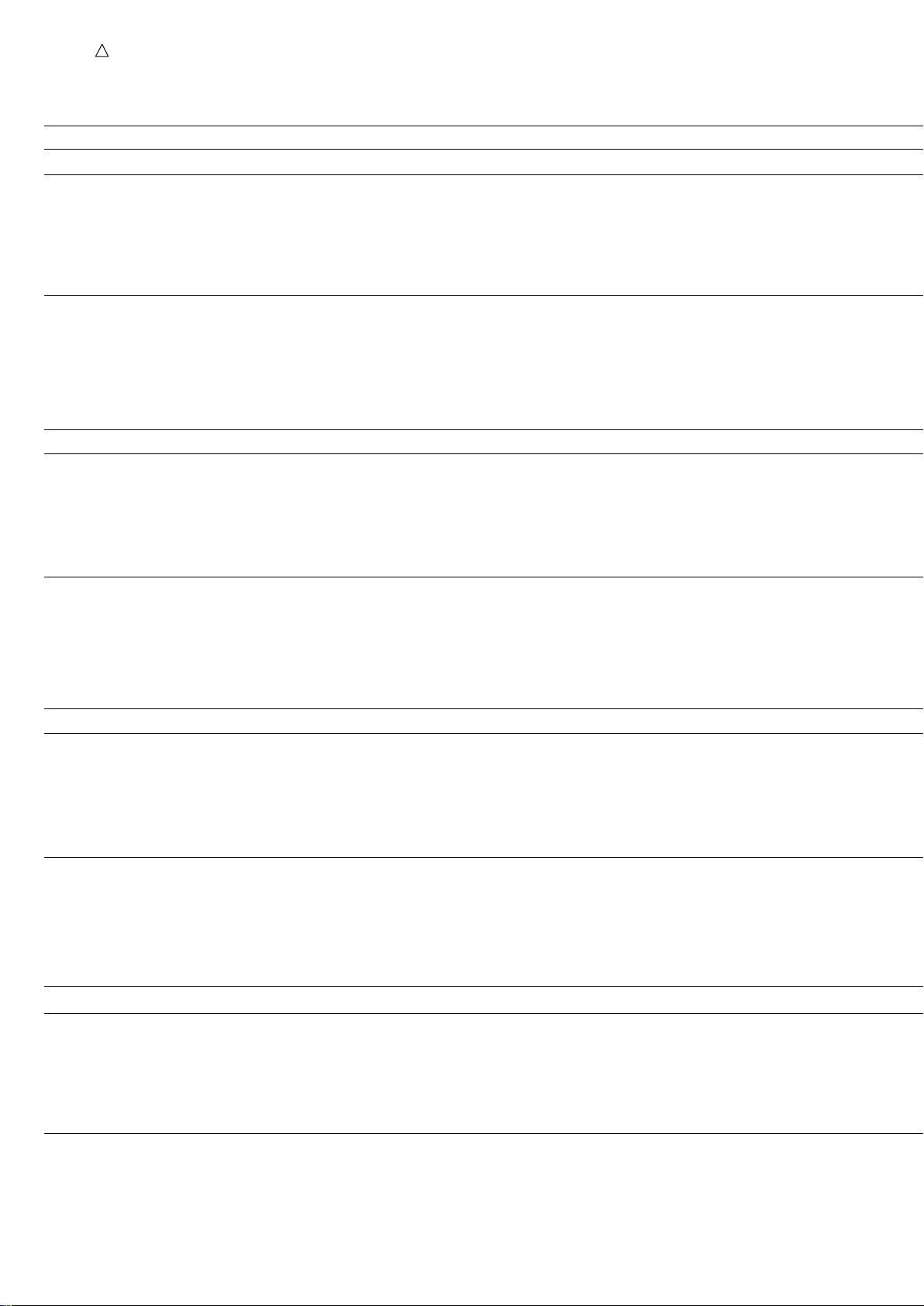

BLOCK DIAGRAM -3/4 (AUDIO SECTION)

HA118717F

VIDEO/AUDIO

PROCESSOR

IC301

JK3M1

AUDIO

IN

AUDIO

OUT

MD3M1

(MODULATOR)

A.IN

1

:AUDIO(REC) SIGNAL

:AUDIO(PB) SIGNAL

REC

AMP

9

8

7

TO

SYSTEM

CONTROL

SECTION

VCA

DET

5V

REC "H"

AMP

PB EQ

AMP

Q302,Q303 FL301,Q301

SW

4

11

2

BIAS

OSC

Q304-Q306 Q307

SW SW 5V

AUDIO

REC/PB

HEAD

AUDIO

ERASE

HEAD

FULL

ERASE

HEAD

REC "H"

TO

SYSTEM

CONTROL

SECTION

-20-

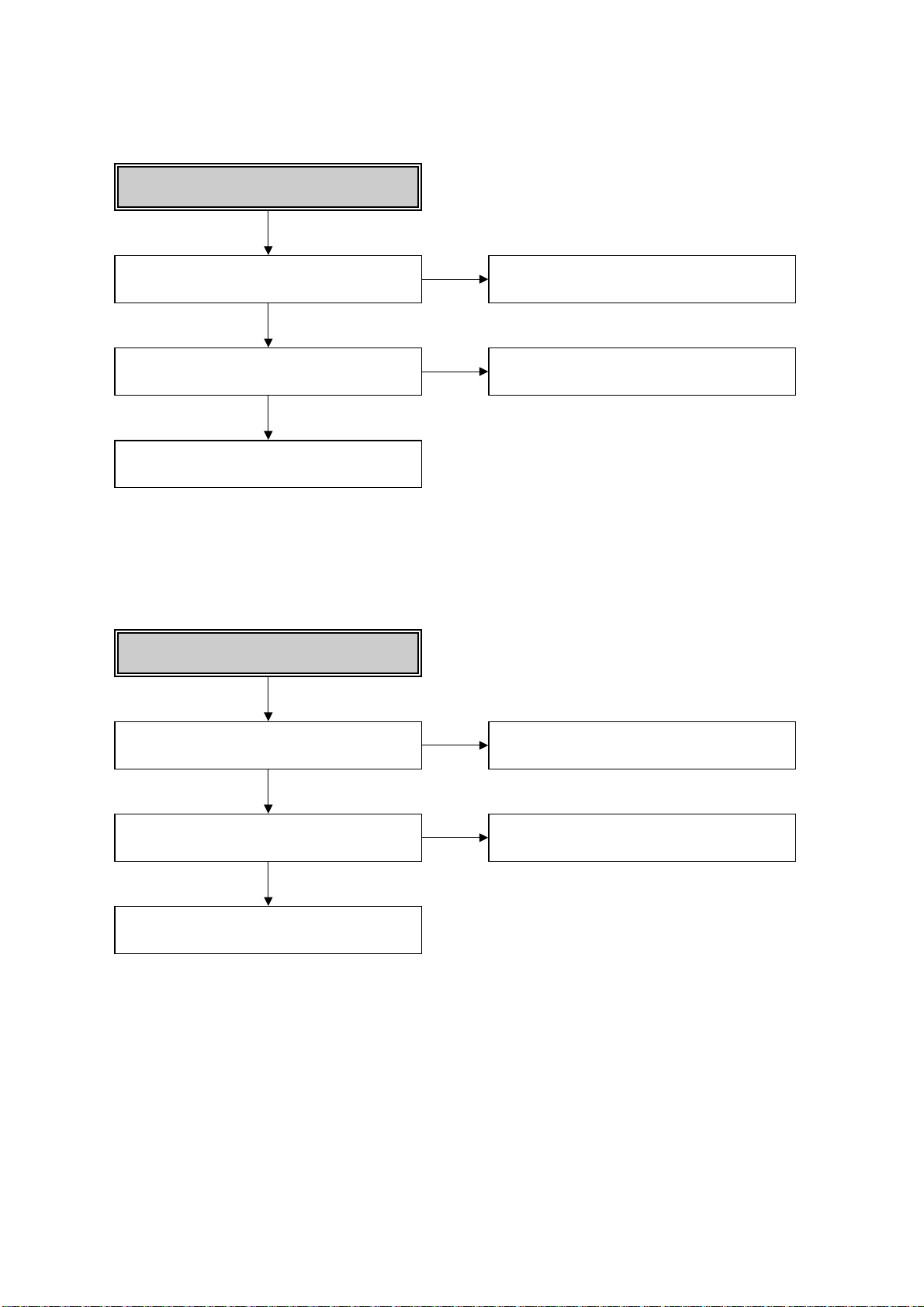

Page 21

BLOCK DIAGRAM - 4/4 ( SYSTEM CONTROL SECTION)

TO

LOADING

MOTOR

TO

DRUM

MOTOR

MOTOR DRIVE

TO

CTL

HEAD

P3D02

CTL(+)

CTL(-)

TO

CAPSTAN

MOTOR

PG.ADJ

RESET

-214-3BA

SYSTEM

CONTROL

u-COM

TO

AUDIO/VIDEO

SECTION

NTSC P.B

SW5T10-SW5T13

SW5T1,SW5T3-SW5T6

TO

POWER

SECTION

-21-

TSOP2838WE1

(REMOTE SENSOR)

Page 22

SCHEMATIC DIAGRAM - 1/3 (POWER SECTION)

MAIN(POWER SECTION)C.B

22uH

TO SYSTEM CONTROL

SECTION

C129

0.022u

HOT GND

SRA2203

L

TO AUDIO/VIDEO

SECTION

680

470pF

5.6K

PHOTO

1N5822

22uH

AC INPUT

NOTES) Symbol denotes AC ground.

NOTES) Symbol denotes DC chassis ground.

HOT CIRCUIT

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

-22-

TO SYSTEM CONTROL

SECTION

Page 23

SCHEMATIC DIAGRAM - 2/3 (AUDIO/VIDEO SECTION)

TV/

TO

SYSTEM

CONTROL

SECTION

TO

POWER

SECTION

To

CYL.

HEADS

MAIN(AUDIO/VIDEO SECTION)C.B

1/4

VIDEO/AUDIO

PROCESSOR

1/7

12

L310 100uH

3/7

4/7

VIDEO

OUT

IN

2SA1980G

7

8

6

4

Sharpness

control

99

11

12

12

12

10

BUFFER

C3M3

0.01u

AUDIO

OUT

IN

(MODULATOR)

MD3M1

AERIAL

/ANT

TO

SYSTEM

CONTROL

SECTION

To

ACE

HEADS

To

FULL ERASE

HEAD

4/4

SRC1203

2/7

7/7

SRA2203

3/4 2/4

2SC5344Y

2SA1980G

R306

2.2K

2SC5343

2SC5343

6/7

5/7

RF. OUT

2

3

1

3

3

4

WAVEFORM

:PB VIDEO SIGNAL

:PB CHROMA SIGNAL

:PB Y SIGNAL

:REC VIDEO SIGNAL

:REC CHROMA SIGNAL

:REC Y SIGNAL

:AUDIO(REC) SIGNAL

:AUDIO(PB) SIGNAL

-23-

Page 24

SCHEMATIC DIAGRAM - 3/3 (SYSTEM CONTROL SECTION)

MAIN(SYSTEM CONTROL SECTION)C.B

560uH

10/11 11/11

220

REC

PAUSE/STILL

REW/

PLAY

/ F.FWD

To

DRUM

MOTOR

To

LOADING

MOTOR

TO

AUDIO/VIDEO

SECTION

To

CAPSTAN

MOTOR

SYSYEM

OPR

STOP/EJECT

POWER

STANDBY/ON

MOTOR DRIVE

TOH-30M05G1

7

5

9

4 3

8 6

9/11

4/11

5/11

-214-3BA

SYSTEM

CONTROL

u-COM

6/11

2

8/11

RESET

7/8

2

8/8

3/11

5/8

2/11

PG.ADJ

1/11

TSOP2838WE1

(REMOTE SENSOR)

4/8

TO

AUDIO/VIDEO

SECTION

2/8

1/8

MODE SW

SG260

SG260

SRC1203

SRC1203

6/8

7/11

3/8

TO

POWER

SECTION

: WAVEFORM

-24-

Page 25

WIRING - 1/1 (MAIN C.B)

101112131415161718192021222324

1234567892526272829303132

BRN

BR

BLU

BL

AC200 ~ 240V

50Hz

MAIN C.B

PML01

To

LOADIG

MOTOR

PMC01

To

CAPSTAN MOTOR

PCM01

PMD01

To

DRUM MOTOR

PDM01

P3D02

To

AUDIO/CTR

HEADS

P3D01

To

CYL. HEADS

AUDIO

JK3M1

IN

OUT

VIDEO

MD3M1

AERIAL

/ANT

A

B

C

D

B

B

C

C

E

E

RF. OUT

E

E

E

CB

CB

F

B

C

E

E

1

2

1

5

24

6432

32

13

14

B

C

C

E

B

B

C

E

RF

2

1

V.H/S

P3D03

To

FULL ERASE

HEAD

G

H

I

J

12 11 10 9 8 7

E

CB

E

CB

CTL

K

L

M

N

O

E

CB

MODE SW

B

CE

135

42

13

E

C

B

42

13

B

C

E

3

1

P

Q

R

S

SW5T6 SW5T5 SW5T4

/ F.FWD

REW/PLAY

SW5T3 SW5T1

PAUSE/STILL

REC

3

1

RC501

REMOTE

SENSOR

POWER

AUTO

REPEAT

PAL

PLAY

MESECAM

REC

NTSC3.58

-25-

LP/EP

NTSC4.43

121

STAND-BY

NTSC P.B

SW5T10

SYSYEM

SW5T11

OPR

CS501

(CST/TAP SW)

SW5T12 SW5T13

STOP/EJECT

POWER

STANDBY/ON

T

U

Page 26

IC301 Pin 14

100mV/10msec DIV

VV/EE

(Main De-Emphasis out)

IC301 Pin 16

100mV/10msec DIV

PB

(Main De-Emphais

Peacking)

IC301 Pin 18, 21, 23

100mV/10msec DIV

VV/EE

Clamp Drive IN Pin 18

Y-out(to 1H CCD) Pin 21

Y-out(from 1H CCD) Pin 23

IC301 Pin 31

200mV/10msec DIV

EE

(VIDEO IN)

IC301 Pin 71

100mV/0.2msec DIV

PB/REC

(3.58MHz X-TAL IN)

IC301 Pin 78

100mV/5msec DIV

PB

(PB RF out)

IC301 Pin 86, 87, 88, 89

500mV/2msec DIV

SP REC

(REC RF)

IC301 Pin 58, 60

200mV/20msec DIV

VV/EE

from 1H CCD Pin 58

to 1H CCD Pin 60

IC301 Pin

1.0V/20msec DIV

VV/EE

(C-SYNC OUT)

IC301 Pin

500mV/10msecDIV

VV/EE

(VIDEO OUT)

IC301 Pin 54

200mV/20msec DIV

PB

(C.OUT)

IC301 Pin

100mV/0.2msec DIV

REC/PB

(2fsc)

(

()

)

WAVEFORMS -1/2

AUDIO/VIDEO SECTION

-26-

1

2

3 4

8

7

65

9

10

11

12

14

16

18

21

23

18

21

23

31

54

86 87

88

8971

78

50

52

44

58

60

58

60

Page 27

IC501 Pin 24

REC/PB

IC501 Pin 27

QUE/REV

IC501 Pin 31

REC

IC501 Pin 32

REC

IC501 Pin 39

REC/PB

IC501 Pin 54

REC/PB

IC501 Pin 38

REC/PB

IC501 Pin 37

PB

IC501 Pin 40

REC/PB

-27-

2 3

4

8

7

5

9

6

1

WAVEFORMS -2/2

SYSTEM CONTROL SECTION

24

96

31

100

97

85

86

89

93

Page 28

VOLTAGE CHART -1/2

1. POWER SECTION

IC101

PB REC

1

2

3

4

5

AC AC

0.009

0

17.4

0.3 0.2

0.01

0

17.6

IC102

PB REC

1

2

3

4

5.1 5.1

4.1

4.4

17.4

17.6

4.1

4.3

2. AUDIO/VIDEO SECTION

IC301

PIN PB REC

1 2.5 2.5

2 2.5 2.5

30 0

4 2.5 2.5

50 0

6 2.8 2.8

7 2.5 2.5

8 2.5 2.5

9 2.5 2.5

10 2.5 2.5

11 2.5 2.5

12 5 5

13 1.6 2.1

14 1.6 2.1

15 2.3 2.3

16 - 0

17 1.8 18 2.1 2.1

19 2.8 2.8

20 2.8 2.8

PIN

PB REC PIN PB REC

21

2.1 2.1 41 5.1 5.1

22

2.2 2.4 42 1.7 1.7

23

2.8 2.8 43 5.1 5.1

24

2.1 2.1 44 2.5 2.5

25

1.4 1.4 45 0 0

26

2.1 2.1 46 1.9 1.9

27

004700

28

2.8 2.8 48 0 0

29

1.9 1.9 49 0 0

30

2.8 2.8 50 - -

31

--51--

32

--52--722.2 2.2

33

- - 53 2.8 2.8

34

- - 54 1.9 1.9

35

2.7 2.7 55 2.1 2.1

36

5.1 5.1 56 2.8 2.8

37

--57--

38

5.1 5.1 58 2.8 2.8

39

2.7 2.7 59 2.8 2.8

40

5.1 5.1 60 2.8 2.8

IC103

Gate Anode Cathode

PB REC PB REC PB REC

IC103 2.5 2.5 0 0 4.1 4.1

TRANSISTOR

Emitter Collector Base

PB REC PB REC PB REC

Q152 12.9 13.1 12.8 13 0 0

Q153 5 5 5.3 5.3 5.7 5.7

Q155 5.3 5.3 5.3 5.2 4.6 4.5

Q156 0 0 0 0 0.7 0.7

PIN

61

62

63

64

65

66

67

68

69

70

71

73

74

75

76

77

78

79

80

PB REC

55

--

--

--

2.3 55

55

00

2.5 2.5

2.5 2.5

2.1 2.1

2.1 2.1

- 2.7

2.1 2.1

--

--

2.8 2.8

2.1 -

--

PIN PB REC

81 - 82 1.1 1.1

83 - 84 - 0

85 0 0

86 2.1 2.3

87 2.1 2.3

88 2.1 2.3

89 2.1 2.3

90 5.1 5.1

91 2.1 2.3

92 2.1 2.3

93 2.1 2.3

94 2.1 2.3

95 0 1.4

96 5 5

97 - 98 - 99 - -

100 2.5 2.5

TRANSISTOR

Emitter Collector Base

PB REC PB REC PB REC

Q301 0 0.1 0.25 4.78 0.25 0.43

Q302 5.19 5.14 0.25 5.18 5.19 4.45

Q303 0 0 5.19 0 0 4.72

Q304 5.15 4.7 5.1 -24.4 4.48 4.72

Q305 0 -20.1 0 0 0.71 -24.4

Q306 0 -20.0 0 0 0.73 -24.2

Q307 5.19 5.13 5.14 4.7 0 4.72

Q3M1 3.07 3.04 0 0 2.45 2.42

-28-

Page 29

VOLTAGE CHART -2/2

3. SYSTEM/CONTROL SECTION

IC501

PIN PB REC PIN PB REC PIN PB REC PIN PB REC PIN PB REC

1 - - 21 - - 41 5.2 5.2 61 5.16 5.16 81

2 - - 22 0 0 42 5.17 5.17 62 0 0 82

3 - - 23 - - 43 5.17 5.17 63 0 0 83

4 - - 24 - - 44 5.17 0 64 0 0 84

5 5.17 5.17 25 0 0 45 0 5.17 65 0 0 85

6 5.17 5.17 26 0 0 46 0 0 66 0 0 86

70 027- -4700670087

80 028- -480068

9--29 - - 49 5.17 5.17 69 5.2 1.27 89

10 - - 30 0 0 50 0 0 70 5.2 2.92 90

11 5.17 5.17 31 0 0 51 0 0 71 5.2 2.51 91

12 5.17 5.17 32 5.31 5.31 52 5.15 5.15 72 5.2 1.73 92

13 0

14 5.2 5.2 34 5.31 5.31 54 3.99 3.99 74 - - 94

15 16 0 0 36 0 0 56 2.80 2.80 76 - - 96

17 18 - - 38 0 0 58 4.91 4.91 78 - - 98

19 20 5.2 5.2 40 - - 60 - - 80 - - 100

33 0 0 53 5.15 5.15 73 - - 93

0

35 5.31 5.31 55 0 4.92 75 - - 95

-

37 5.17 5.17 57 2.38 2.38 77 0 0 97

-

39 5.04 5.04 59 0 0 79 - - 99

-

5.14/0 5.14/0

88

--

1.75 0

--

00

2.57 -

2.57 -

2.58 2.58

2.58 2.58

2.58 2.58

2.58 2.58

--

5.2 5.2

--

0

--

-

--

-

--

-

0

-

-

-

IC504

1

2

3

PB REC

5.2 5.2

0

5.2

0

5.2

-29-

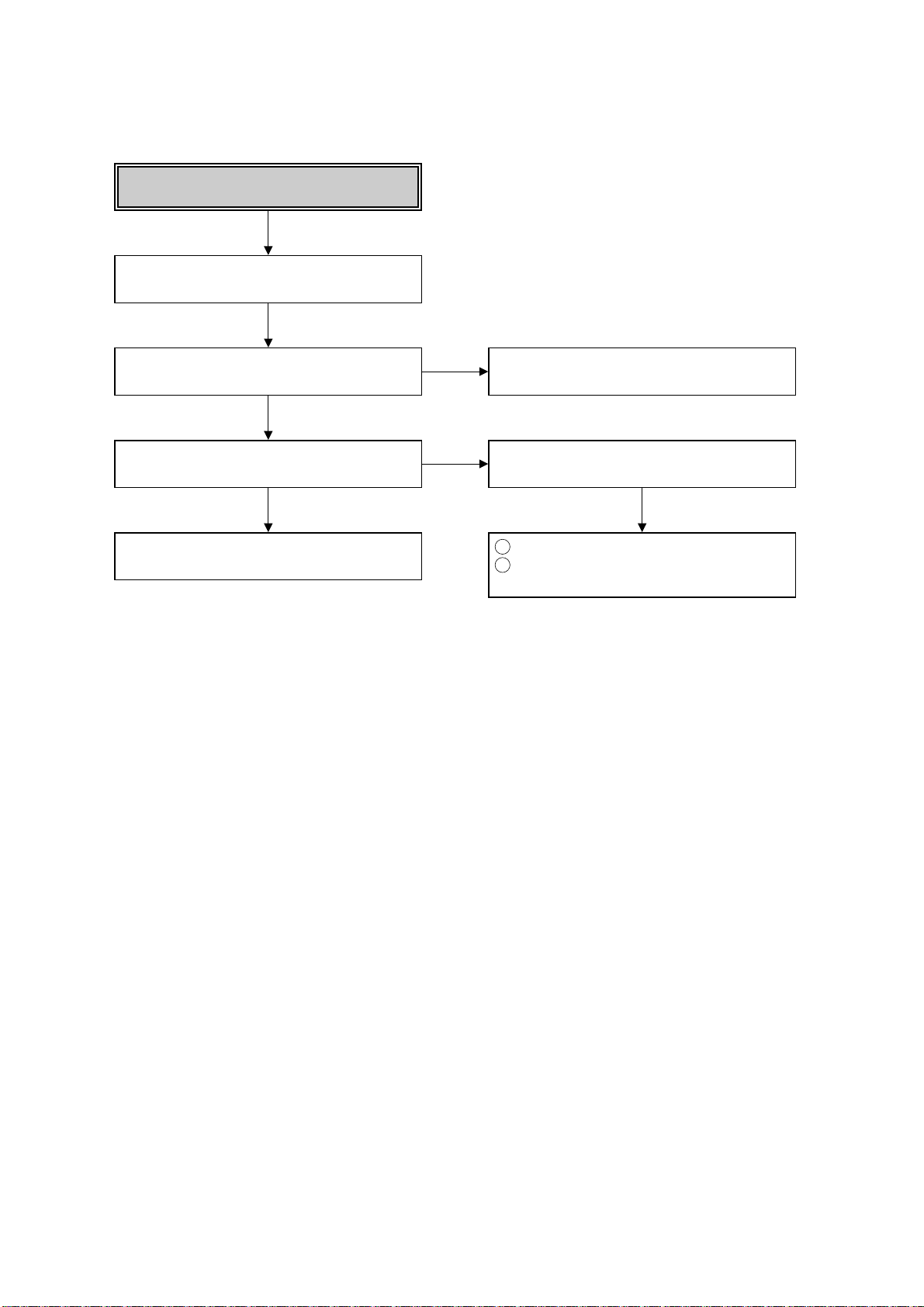

Page 30

ADJUSTMENT -1/1

VIDEO OUTPUT SIGNAL

Test Equipment

• Oscilloscope • + Driver • Digital Multimeter

• Video Signal Generator • Test Tape (SP) • Monitor Scope

• Level Meter • Recording Tape • Power Supply

MAIN C.B

V.OUT JACK

(JK3M1)

IC301

RF

H/SW

IC501

CTL

VR501

OSCILLOSCOPE

CH-1 CH-2

1. Servo Adjustment

1) PG Adjustment

MODE MEASUREMENT POINT ADJUSTMENT POINT SPECIFICATION

PLAYBACK (H/SW)VIDEO OUT JACK VR501 416µsec ± 32µsec

Purpose:

For the phase dividing of the Video A,B heads with 180° and the exact tracking of each track to meet

head switching point with VHS Spec.

Procedure:

a. Playback a PAL SP test tape. (At this time, the “ART” is lighting, after pressing the A. TR(+) or A. TR (-) and adjust the

X-Value).

b. Connect CH-1 terminal of oscilloscope to (H/SW) and CH-2 terminal to Video Out Jack of the unit.

c. Trigger the complex Video signal of CH2 to CH-1 (H/SW), and adjust VR501 so that the distancefrom A(B) head

selection point of H/SW signal to the starting point of Vertical synchronized signal is 416µsec ± 32µsec.

Reference:

1. ± PG adjustment is practiced in the state of maximum RF level and locked servo system.

2. The deviation between A/B Head Adjustment location should be within ± 20µsec.

3. The deviation between the specification of adjustment and the practical measurement value should be within

± 20µsec.

4. Oscilloscope and VCR set should be connected with GND.

• WAVEFORM

Composite Video Signal

-30-

Page 31

IC BLOCK DIAGRAM -1/1

VREG(5V)

3

8

FG

OUT

25

26

29

28

27

2

1

200Ω

THERMAL SHUT-DOWN

CIRCUIT

MASK CIRCUIT

WAKE-UP

CONTROL

C1

C2

PC OUT

VCO IN

CX

VC

FC

PG IN+ PG IN- PG OUT1 PG OUT2

CIRCUIT

PLL VCO 8 DIVIDER

200Ω

200Ω

4 5 6 11 12 10 13 15

TIMING

CONTROL

CIRCUIT

ROTOR

POSLTION DET.

CIRCUIT

SOFT

SWITCHING

DRIVE CIRCUIT

1kΩ

VREG

5kΩ

7

LD IN+ LD IN- VREF LD OUT+

CIRCUIT

OUTPUT DRIVE

UPPER SIDE SATURATE

PREVENTION CONTROL

CIRCUIT

OUTPUT DRIVE

LD OUT-

21

19

22

23

24

16

17

18

20

30

9

14

VCC

MCOM

U IN

V IN

W IN

U OUT

V OUT

W OUT

RF

GND

L VCC

L GND

-31-

Page 32

IC DESCRIPTION -1/1 (µPD784927GF-214-3BA) -1/3

Pin No. Pin Name I/O Description

-

1

2

3

4

5

6

7

8

9

10

11 ~ 13

14

DFG MON

DPG MON

CFG MON

CTL MON

OSD ENA

OSD CLOCK

OSD DATA

-

DRUM PWM

CAP. PWM

-

VCC

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

-

Not connected

O

Drum PWM control

O

Capstan PWMcontrol

-

Not connected

-

Power supply

15

16

17

18

19

20

21

22

23

24

25, 26

27

28

29

30

31

32

X-TAL1

X-TAL2

VSS

OSC2

OSC1

RESET

IC

-

A.H/SW

V.H/SW

-

IIC CLK

IIC DATA

C. ROTARY

H.AMP SW

D.V-SYNC

MODE4

O

O

I/O

O

-

-

-

I

I

I

-

-

-

I

-

-

I

Not connected

GND

Not connected

Not connected

Not connected

Not connected

Not connected

33

34

35

36

37

38

39

40

41

42

43

44

45

MODE3

MODE2

MODE1

NC

TV/VCR “H”

HSR “H”

PWR CTL “H”

VSS

VCC

STAND-BY LED

LP/EP LED

REC LED

PLAY LED

I

I

I

-

O

O

O

-

-

O

O

O

O

Not connected

GND

-32-

Page 33

IC DESCRIPTION -1/1 (µPD784927GF-214-3BA) -2/3

Pin No. Pin Name I/O Description

46

A.REPEAT LED

O

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62 ~ 64

65

POWER LED

CST-IN LED

-

CAP.REV. “H”

A.MUTE “H”

LD (+)

LD (-)

I-LIMIT

REC “H”

CAP ADJ

DRUM ADJ

R/C

OPTION

NC

PWR FAIL

-

SUP.SENSOR

O

O

O

I/O

O

-

-

-

-

-

-

I

-

I

Not connected

Not connected

Not connected

Not connected

Not connected

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

T-UP SENSOR

CST/TAB “H”

NTSC “H”

AVDD2

A.VREF

KEY RTN 1

KEY RTN 0

PG ADJ

-

-

MESECAM DET “H”

-

-

-

-

V.ENV

I

I

-

-

-

I

I

-

-

-

I

-

-

-

-

I

Not connected

Not connected

Not connected

83

84

85

86

87

88

AVSSW2

CTL DLY

CTL+

CTL-

CIL IN

CTL OUT1

-

I/O

I/O

I

O

-33-

Page 34

IC DESCRIPTION -1/1 (µPD784927GF-214-3BA) -3/3

Pin No. Pin Name I/O Description

89

CTL OUT2

O

90

91

92

93

94

95

96

97

98

99

100

VREFC

AVSS1

AVDD1

CFG

CFG AMP OUT

CFG AMP IN