Page 1

CD MECHANISM

6ZG-1S

6ZG-1S2

6ZG-1S3

• BASIC CD MECHANISM: 3ZG-2 E2

6ZG-1S

6ZG-1S2 D SH

6ZG-1S3 D SH

This mechanism has various derivation. Derivation name is indicated by

the Service Manual for eath model.

• TYPE: English

DERIVATION NAMEBASIC NAME

DSH

S/M Code No. 09-984-249-90T

Page 2

TABLE OF CONTENTS

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING/

Precaution to replace Optical block......................................................................................................... 3

SUFFIX NOTE ........................................................................................................................................ 4

TRANSISTOR ILLUSTRATION .............................................................................................................. 5

DISASSEMBLY INSTRUCTIONS........................................................................................................ 6-8

6ZG-1S

ELECTRICAL MAIN PARTS LIST ................................................................................................................9, 10

BLOCK DIAGRAM ......................................................................................................................................11, 12

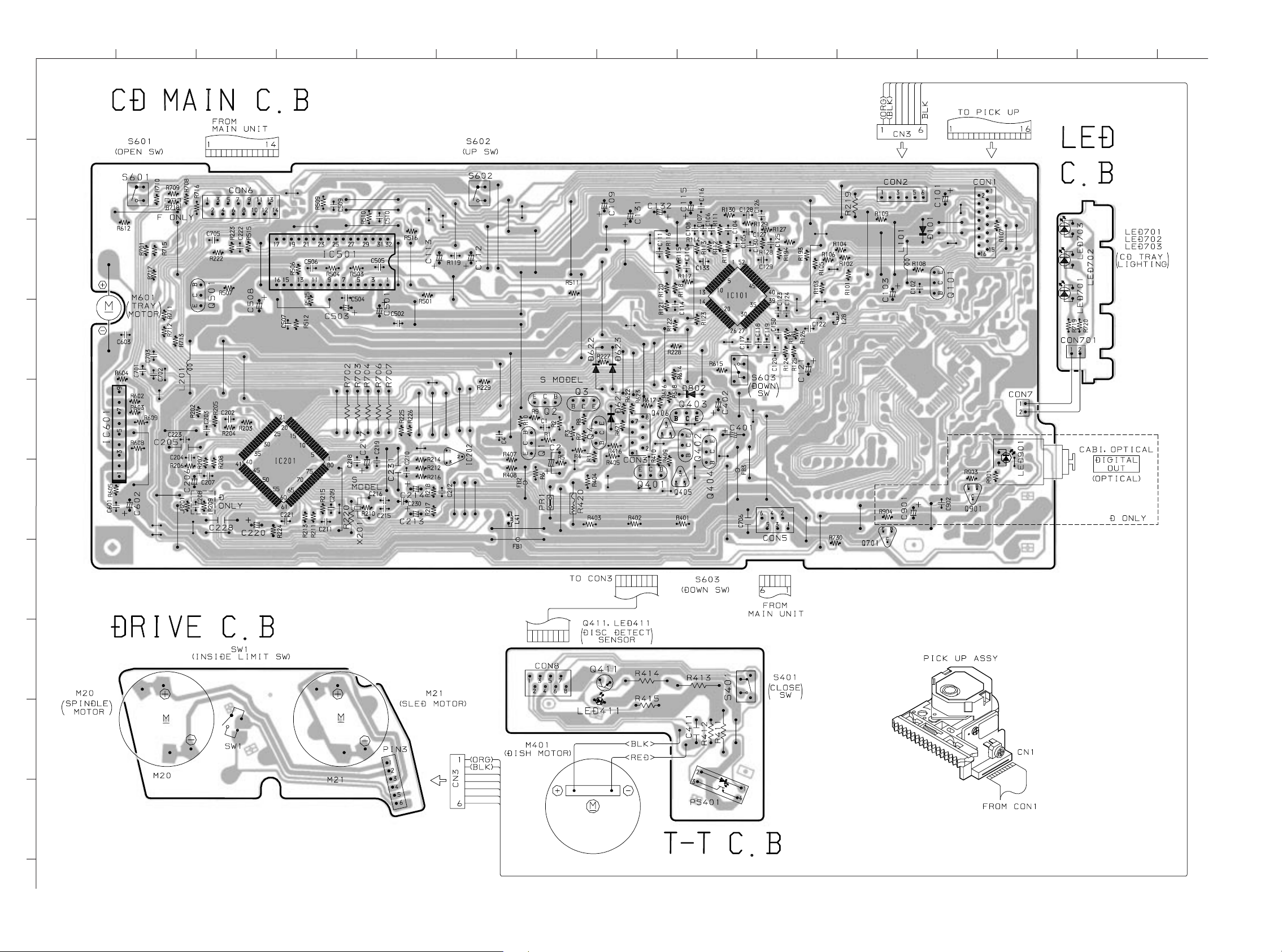

WIRING.......................................................................................................................................................13, 14

SCHEMATIC DIAGRAM .............................................................................................................................15, 16

IC DESCRIPTION........................................................................................................................................17-20

IC BLOCK DIAGRAM .......................................................................................................................................21

TEST MODE .....................................................................................................................................................22

MECHANICAL EXPLODED VIEW 1/1..............................................................................................................23

MECHANICAL PARTS LIST 1/1.......................................................................................................................24

CD MECHANISM EXPLODED VIEW/LIST (3ZG-1 E2) ...................................................................................25

6ZG-1S2

ELECTRICAL MAIN PARTS LIST ..............................................................................................................26, 27

IC BLOCK DIAGRAM .......................................................................................................................................29

BLOCK DIAGRAM ......................................................................................................................................30, 31

WIRING.......................................................................................................................................................32, 33

SCHEMATIC DIAGRAM .............................................................................................................................34, 35

IC DESCRIPTION.......................................................................................................................................36, 37

6ZG-1S3

ELECTRICAL MAIN PARTS LIST ..............................................................................................................38, 39

BLOCK DIAGRAM ......................................................................................................................................41, 42

WIRING.......................................................................................................................................................43, 44

SCHEMATIC DIAGRAM .............................................................................................................................45, 46

TEST MODE .....................................................................................................................................................47

USE MODEL LIST ................................................................................................................................ 48

2

Page 3

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

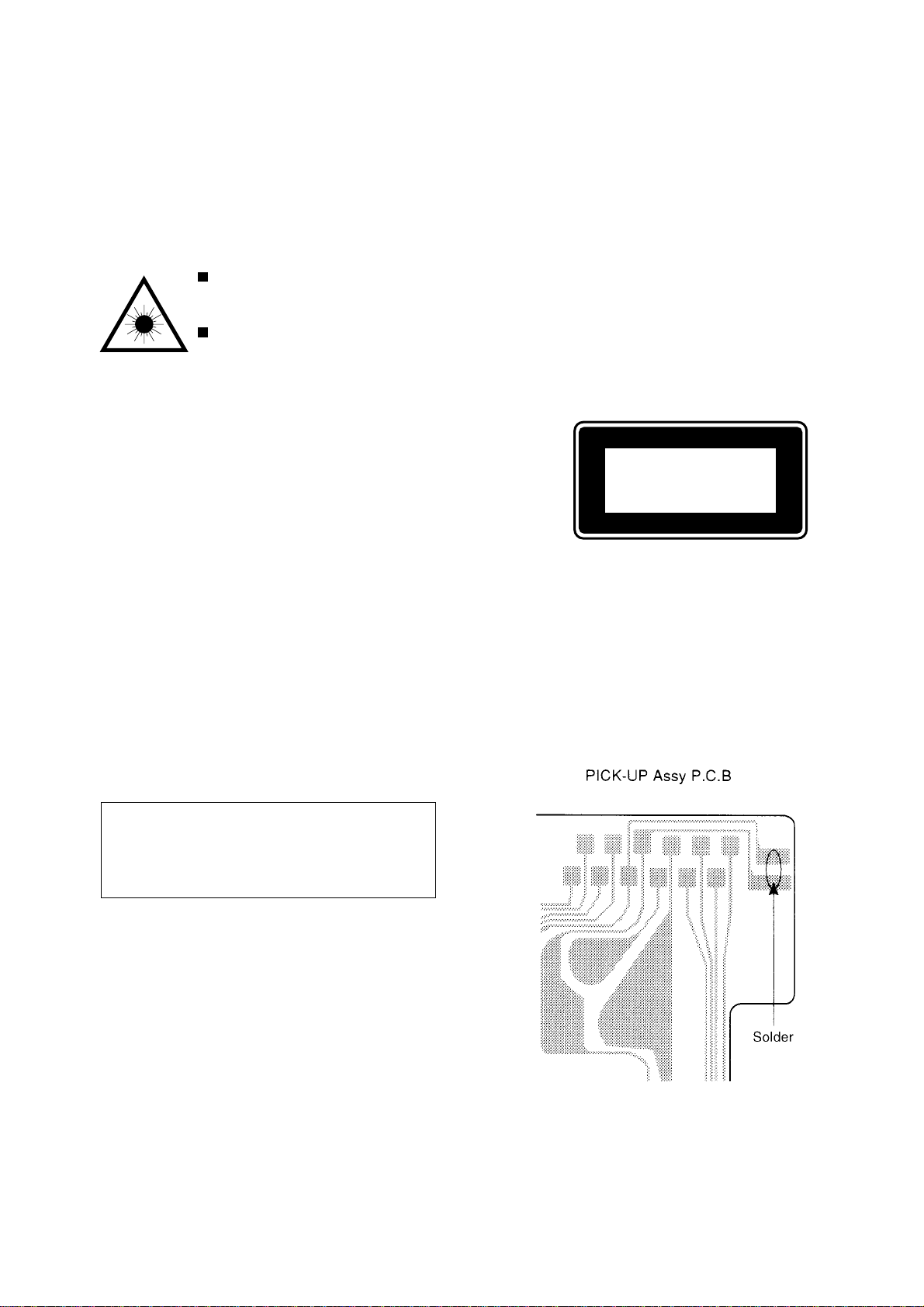

Precaution to replace Optical block

(KSS-213F)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

3

Page 4

This is the SERVICE MANUAL for the BASIC CD MECHANISM of BASIC NAME: 6ZG-

1. This BASIC NAME includes the following models as shown under the SUFFIX

name: DERIVATION NAME. Please use this manual with the separate SERVICE

MANUAL for DERIVATION NAME.

BASIC CD MECHANISM: 6ZG-1 DSH

SUFFIX

(DERIVATION NAME)

BASIC NAME: 6ZG-1S (SONY IC HIGH END MODEL)

6ZG-1S2 (The 2nd SONY IC MODEL)

6ZG-1S3 (The 3rd SONY IC MODEL)

BASIC NAME DERIVATION NAME

6ZG-1S D SH — — — —

6ZG-1S2 D SH — — — —

6ZG-1S3 D SH — — — —

DERIVATION NAME

D: Digital output function

SH: Pick up equipped with shutter

4

Page 5

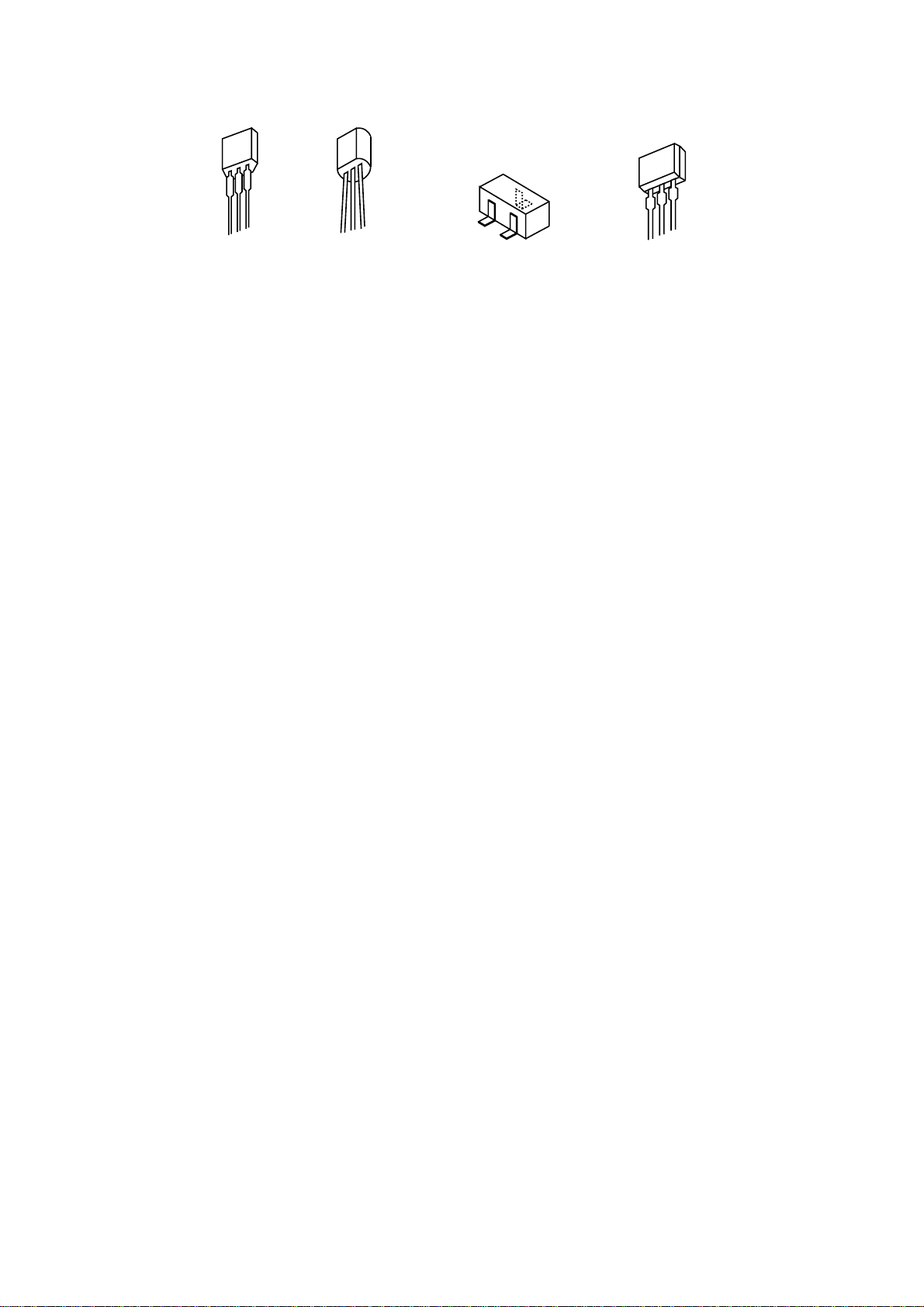

TRANSISTOR ILLUSTRATION

E C B

E C B

C

B

E

B C E

2SA933S

DTC114ES

2SA1015

2SC2001

2SD2172

2SD655

2SA1235

2SC2412

2SC2712

DTA114EK

DTC114EK

DTC114TK

DTC123JK

DTC143TK

2SB1329

5

Page 6

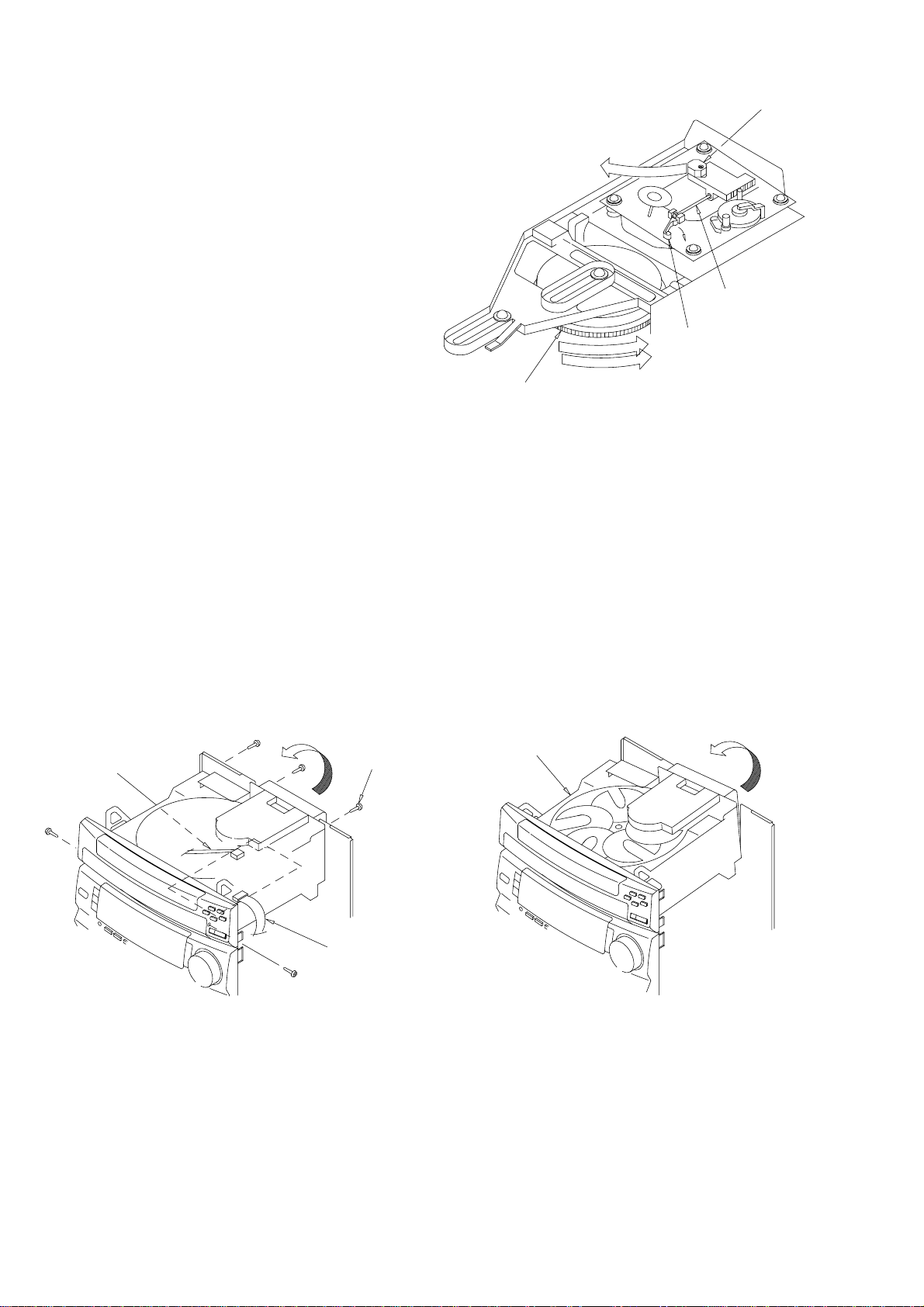

DISASSEMBLY INSTRUCTIONS

1. How to replace PICK UP.

1) Open the TRAY.

Push the stopper to arrow direction and release half of

the SHAFT SLED.

2) Turn GEAR MAIN CAM to the counterclockwise

(arrow “a”) direction, and lift up CD mechanism. (Fig-1)

3) Remove SHAFT SLED.

4) CD mechanism in down position, replace PICK UP.

5) Lift up CD mechanism (Fig-1), and Reassemble the

SHAFT SLED.

GEAR MAIN CAM

PICKUP

SHAFT SLED

STOPPER

°

Fig-1

2. How to remove the 5CD CHANGER BLOCK

(Fig-2)

1) Remove the two FFC of the CD circuit board, and

remove the five SCREWS.

2) Lift 5 CD CHANGER BLOCK from behind, and

remove it. (5CD CHANGER BLOCK can be removed

even if PANEL TRAY is not removed.)

FFC

SCREW

FFC

5CD CHANGER BLOCK

LIFT UP

Fig-2

6

Page 7

3. The disassemble and reassemble the TRAY

FFC

3-1. Disassembling procedure.

1) Push the PLATE GEAR’S Boss at the bottom part of

CHAS MECHA strongly to the outside (arrow “b”

direction). (Fig-3)

(Confirm that TRAY appears a little in the front.)

2) Draw TRAY to the open position.

3) Remove FFC, and push the two LEVERS at both side of

the CHAS MECH to remove TRAY. (Fig-4)

TRAY

LEVER

b

BOSS

5CD CHANGER BLOCK

LEVER

3-2. Reassembling procedure.

1) Confirm that LEVER TRAY is at the most right position

and check for the CD Mechanism to be in the down

position. (Fig-5)

2) Push in the TRAY along the rail of the CHAS MECHA.

Fig-3

Fig-4

3) After TRAY is half closed and FFC is put in, it can enter

by force until the end of TRAY closed. (Fig-6)

FFC

TRAY

LEVER TRY

Fig-5

Fig-6

7

Page 8

4. How to reassemble the TURN TABLE. (Fig-7)

1) Push LEVER TT in the direction of “C”, and put in the

TURN TABLE 5CD. (Fig-7)

After reassembly, one of the TURN TABLE DISC

TRAY (can be either one of the five disc trays) must be

aligned with TURN TABLE 5CD. (Fig-8)

That is, having no gap difference between the TURN

TABLE 5CD and the TRAY 5CD.

* When reassembling the TURN TABLE 5CD, it is

acceptable facing any CD number (1-5).

ALIGN

C

LEVER TT

Fig-7 Fig-8

TURN TABLE 5CD

TRAY 5CD

8

Page 9

MODEL NO. 6ZG-1S

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

IC

87-A20-547-010 C-IC,CXA1992AR

87-A20-546-010 C-IC,CXD2589Q

87-A20-592-040 C-IC,M51943 AML

87-070-305-010 IC,BA6897S

87-001-982-010 IC,TA7291S

TRANSISTOR

89-406-555-080 TR,2SD655 (0.5W)

87-026-463-080 TR,2SA933S (0.3W)

89-421-722-380 TR,2SD2172V/W

89-320-011-080 TR,2SC2001 (15W)

87-026-223-080 TR,DTC143TK

89-110-155-080 TR,2SA1015(0.4W)

87-026-608-080 C-TR,DTC 123 JK

89-327-125-080 CHIP TR,2SC2712GR<D>

DIODE

87-020-465-080 DIODE,1SS133 (110MA)

CD MAIN C.B

C1 87-010-196-020 C-CAP,S 0.1-25 F

C2 87-010-260-080 CAP, ELECT 47-25V

C4 87-010-197-020 C-CAP,S 0.01-25 B

C101 87-010-263-040 CAP,E 100-10

C102 87-010-178-020 C-CAP,S 1000P-50 B

C103 87-010-550-040 CAP,E 100-6.3 GAS

C104 87-010-182-020 C-CAP,S 2200P-50 B

C105 87-010-198-020 C-CAP,S 0.022-25 B

C106 87-016-081-020 C-CAP,S 0.1-16 RK

C107 87-016-081-020 C-CAP,S 0.1-16 RK

C108 87-016-081-020 C-CAP,S 0.1-16 RK

C109 87-010-497-040 CAP,E 4.7-35 GAS

C110 87-010-198-080 CAP, CHIP 0.022

C111 87-010-197-020 C-CAP,S 0.01-25 B

C112 87-010-402-040 CAP,E 2.2-50 SME

C113 87-010-382-040 CAP,E 22-25 SME

C114 87-010-213-020 C-CAP,S 0.015-25 B

C115 87-010-263-040 CAP,E 100-10

C116 87-010-197-020 C-CAP,S 0.01-25 B

C117 87-016-369-020 C-CAP,S 0.033-25 B K

C118 87-010-197-020 C-CAP,S 0.01-25 B

C119 87-016-369-020 C-CAP,S 0.033-25 B K

C120 87-010-197-020 C-CAP,S 0.01-25 B

C121 87-010-494-040 CAP,E 1-50 GAS

C122 87-010-154-020 C-CAP,S 10P-50 CH

C123 87-010-154-020 C-CAP,S 10P-50 CH

C124 87-010-154-020 C-CAP,S 10P-50 CH

C125 87-010-596-020 C-CAP,S 0.047-16 RK

C126 87-010-596-020 C-CAP,S 0.047-16 RK

C127 87-012-140-020 C-CAP,S 470P-50 CH

C128 87-010-596-020 C-CAP,S 0.047-16 RK

C129 87-010-198-020 C-CAP,S 0.022-25 B

C130 87-016-081-020 C-CAP,S 0.1-16 RK

C131 87-010-550-040 CAP,E 100-6.3 GAS

C132 87-010-550-040 CAP,E 100-6.3 GAS

C133 87-012-158-020 C-CAP,S 390P-50 J CH

C150 87-010-145-020 C-CAP,S 1P-50 C CH

C202 87-010-596-020 C-CAP,S 0.047-16 RK

C203 87-010-188-020 C-CAP,S 6800P-50 B

C204 87-012-156-020 C-CAP,S 220P-50 CH

C205 87-018-134-080 CAPACITOR,TC-U 0.01-16

C206 87-010-400-040 CAP,E 0.47-50

C207 87-010-197-020 C-CAP,S 0.01-25 B

C208 87-010-318-020 C-CAP,S 47P-50 CH<D>

C209 87-012-154-020 C-CAP,S 150P-50 J CH GRM

NO.

REF. NO PART NO. KANRI DESCRIPTION

C210 87-012-154-020 C-CAP,S 150P-50 J CH GRM

C211 87-010-176-020 C-CAP,S 680P-50 J SL

C212 87-010-176-020 C-CAP,S 680P-50 J SL

C213 87-010-382-040 CAP,E 22-25 SME<D>

C213 87-010-401-040 CAP,E 1-50 SME

C214 87-010-382-040 CAP,E 22-25 SME<D>

C214 87-010-401-040 CAP,E 1-50 SME

C215 87-010-318-020 C-CAP,S 47P-50 CH

C216 87-010-318-020 C-CAP,S 47P-50 CH

C217 87-010-380-040 CAP,E 47-16 SME

C218 87-010-197-020 C-CAP,S 0.01-25 B

C219 87-010-196-020 C-CAP,S 0.1-25 F

C220 87-010-370-040 CAP,E 330-6.3 SME

C221 87-010-197-020 C-CAP,S 0.01-25 B

C222 87-010-186-020 C-CAP,S 4700P-50 B

C223 87-016-081-020 C-CAP,S 0.1-16 RK

C228 87-018-209-080 CAP, CER 0.1-50V

C230 87-016-081-020 C-CAP,S 0.1-16 RK

C231 87-018-209-080 CAP, CER 0.1-50V

C401 87-010-403-080 CAP, ELECT 3.3-50V

C402 87-010-403-040 CAP,E 3.3-50 SME

C501 87-016-459-040 CAP,E 470-10 SMG

C502 87-010-197-020 C-CAP,S 0.01-25 B

C503 87-010-263-040 CAP,E 100-10

C504 87-010-196-020 C-CAP,S 0.1-25 F

C505 87-010-196-020 C-CAP,S 0.1-25 F

C506 87-010-196-020 C-CAP,S 0.1-25 F

C507 87-010-196-020 C-CAP,S 0.1-25 F

C508 87-016-459-040 CAP,E 470-10 SMG

C509 87-010-196-020 C-CAP,S 0.1-25 F

C510 87-010-196-020 C-CAP,S 0.1-25 F

C601 87-010-197-020 C-CAP,S 0.01-25 B

C602 87-016-251-040 CAP,E 220-16 SMG

C603 87-010-196-020 C-CAP,S 0.1-25 F

C701 87-010-322-020 C-CAP,S 100P-50 CH

C702 87-010-318-020 C-CAP,S 47P-50 CH

C703 87-010-318-020 C-CAP,S 47P-50 CH

C705 87-010-178-020 C-CAP,S 1000P-50 B

C706 87-018-199-080 CAP, CER 3300P

C901 87-010-260-040 CAP,E 47-25 SME<D>

C902 87-010-196-020 C-CAP,S 0.1-25 F<D>

CN3 86-ZG1-609-010 CONN ASSY,6P

FB1 87-003-223-080 FERRITE BEAD BL02RN2

FB2 87-003-223-080 FERRITE BEAD BL02RN2

FB3 87-003-223-080 FERRITE BEAD BL02RN2

FC1 86-ZG1-605-010 CABLE,FFC 16P

FC2 86-ZG1-608-010 CABLE,FFC 8P

L28 83-XM1-617-080 C-COIL,BK2125HM601

L41 83-XM1-617-080 C-COIL,BK2125HM601

L101 87-003-102-080 COIL, 10UH

L201 87-003-102-080 COIL, 10UH

LED901 87-A40-123-010 LED,SLZ-8128A-01-B<D>

M601 87-045-305-010 MOTOR, RF-500TB DC-5V (2MA)

!

PR1 87-026-689-080 PROTECTOR,1A 60V 491

R101 87-022-363-020 C-RES,S 68K-1/10W F

R102 87-022-363-020 C-RES,S 68K-1/10W F

R103 87-022-363-020 C-RES,S 68K-1/10W F

R104 87-022-363-020 C-RES,S 68K-1/10W F

R105 87-022-365-020 C-RES,S 100K-1/10W F

R106 87-022-365-020 C-RES,S 100K-1/10W F

R420 87-029-060-080 RES,FUSE 33-1/4 W

S601 87-036-109-010 PUSH SWITCH

S602 87-036-109-010 PUSH SWITCH

S603 87-036-109-010 PUSH SWITCH

X201 87-A70-046-010 VIB,XTAL 16.934MHZ

LED C.B

LED701 87-017-733-080 LED,SEL1250SM

LED702 87-017-350-080 LED,SEL1550CM

NO.

9

Page 10

REF. NO PART NO. KANRI DESCRIPTION

LED703 87-017-733-080 LED,SEL1250SM

T-T C.B

C411 87-018-214-080 CAP TC U 0.1-50F

LED411 87-070-288-010 LED,GL380

M401 87-A90-036-010 MOT ASSY,RF-300CA-11

PS401 87-A90-156-010 SNSR,SG-240

Q411 87-A30-031-010 P-TR,PT380F

S401 87-036-109-010 PUSH SWITCH

NO.

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

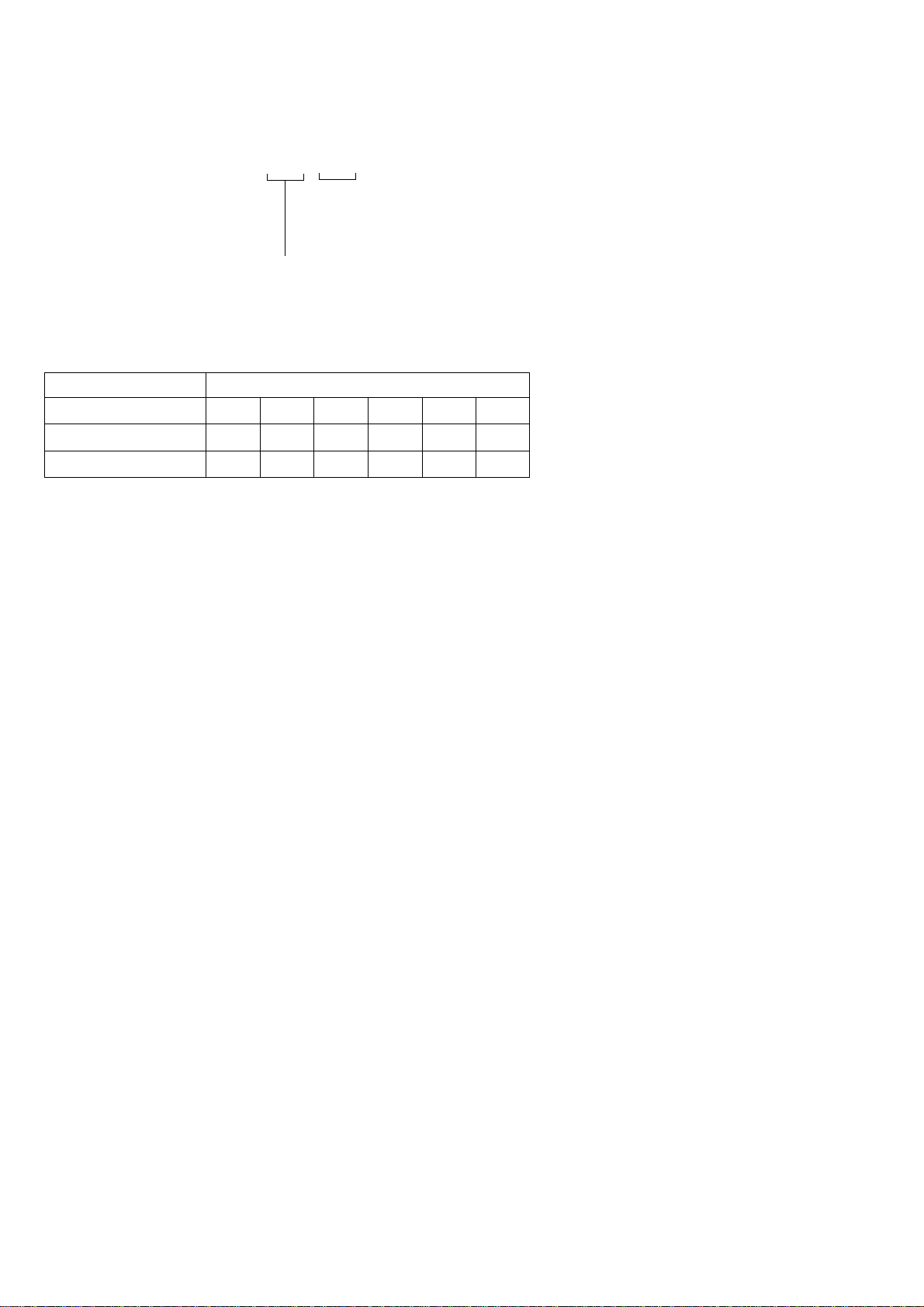

/ CHIP RESISTOR PART CODE

Chip Resistor Part Coding

8

8

Figure

Resistor Code

Value of resistor

Chip resistor

Wattage Type

1/16W

1/10W

1/8W

1608

2125

3216

Tolerance

5%

5%

5%

Symbol

CJ

CJ

CJ

/ Diamensions (mm)

/ Form

L

t

W

1.6

3.2

W

0.8

1.6

0.45

0.45

0.55

t

108

118

128

L

1.25

2

Resistor Code : A

10

Page 11

BLOCK DIAGRAM

RF

1211

Page 12

WIRING

A

B

C

D

1

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

1413

Page 13

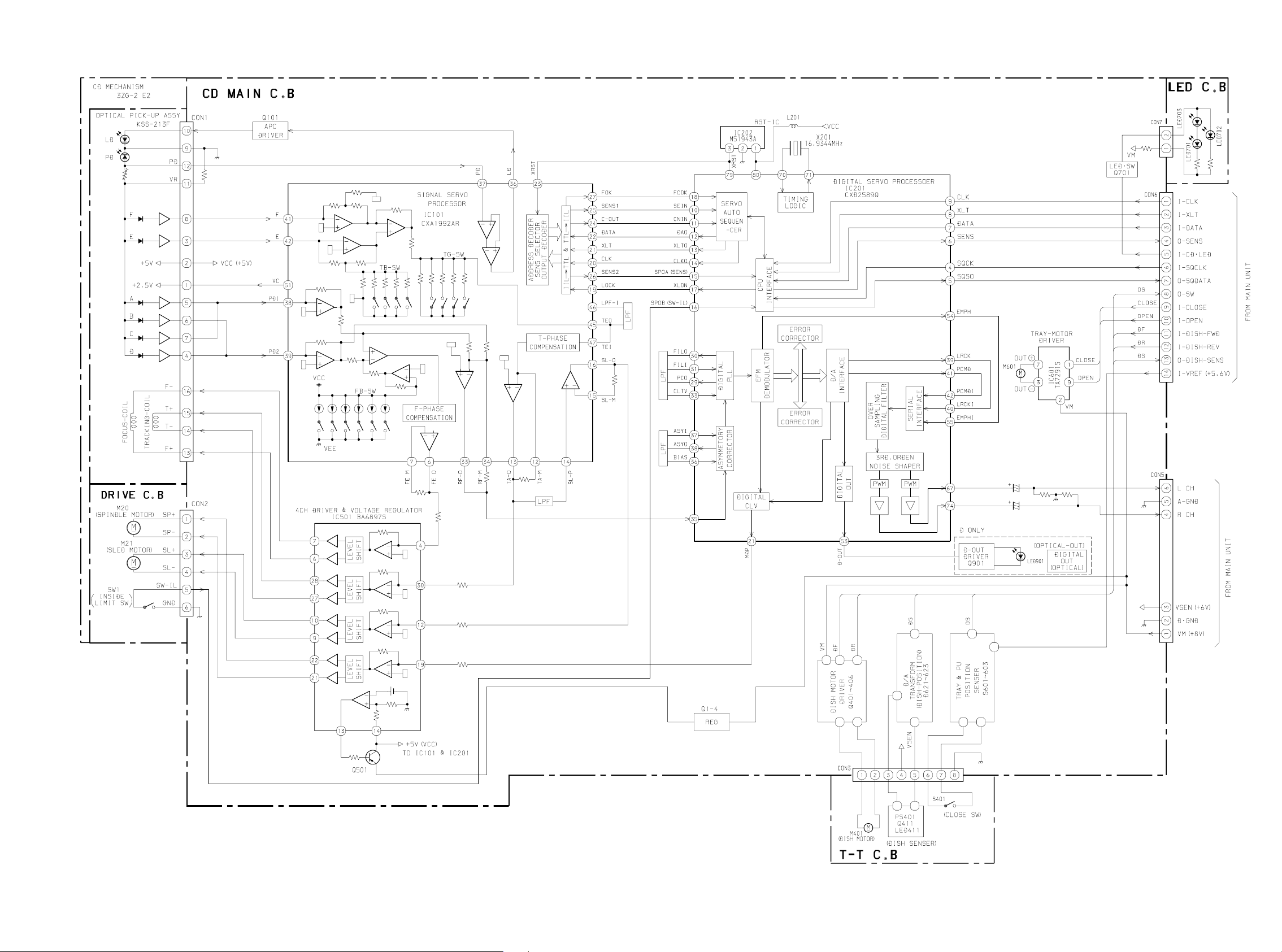

SCHEMATIC DIAGRAM

KSS-213F

1615

Page 14

IC DESCRIPTION

IC, CXA1992AR

Pin No. Pin Name I/O Description

1

FEO

Output terminal for focus error amplifier. Internally connected to window comparator

O

input for bias condition.

10

11

12

13

14

2

3

4

5

6

7

8

9

FEI

FDFCT

FGD

FLB

FE_O

FEM

SRCH

TGU

TG2

FSET

TA_M

TA_O

SL_P

Input terminal for focus error.

I

Capacitor connection terminal for time constant used when there is defect.

I

This pin is connected to GND via capacitor when high frequency gain of the focus

I

servo is attenuated.

This is a pin where the time constant is externally connected to raise the low frequency

I

gain of the focus servo.

Focus drive output.

O

Focus amplifier inverted input pin.

I

This is a pin where the time constant is externally connected to generate the focus

I

search waveform.

This is a pin where the selection time constant is externally connected to set the

I

tracking servo the high frequency gain.

This is a pin where the selection time constant is externally connected to set the

I

tracking high frequency gain.

Pin for setting peak of the phase compensator of the focus tracking.

I

Tracking amplifier inverted input pin.

I

Tracking drive output.

O

Sled amplifier non-inverted input pin.

I

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

SL_M

SL_O

ISET

Vcc

LOCK

CLK

XLT

DATA

XRST

C_OUT

SENS1

SENS2

FOK

CC2

CC1

Sled amplifier inverted input pin.

I

Sled drive output.

O

The current which determines height of the focus search, track jump and sled kick is

I

input with external resistance connected.

Power supply.

I

“L” setting starts sled disorder-prevention circuit. (Not pull-up resistance)

I

Clock input for serial data transfer from CPU. (No pull-up resistance)

I

Latch input from CPU. (No pull-up resistance)

I

Serial data input from CPU. (No pull-up resistance)

I

Reset system at “L” setting. (No pull-up resistance)

I

Signal output for track number counting.

O

FZC, DFCT1, TZC, BALH, TGH, FOH, or ATSC is output depending on the

O

command from CPU.

DFCT2, MIRR, BALL, TGL or FOL is output depending on the command from CPU.

O

Output terminal for focus OK comparator.

O

Input pin where the DEFECT bottom hold output is capacitance coupled.

I

DEFECT bottom-hold output terminal. Internally connected to interruption comparator

O

input.

30

31

CB

CP

Connection terminal for DEFECT bottom-hold capacitor.

I

Connection terminal for MIRR hold-capacitor.

I

Anti-reverse input terminal for MIRR comparator.

17

Page 15

Pin No. Pin Name I/O Description

32

RF_I

I

Input terminal by capacity combination of RF summing amplifier.

33

34

35

36

37

38, 39

40

41, 42

43

44

RF_O

RF_M

RFTC

LD

PD

PD1, PD2

FEBIAS

F, E

EI

VEE

O

O

I/O

—

—

Output terminal of RF summing amplifier. Checkpoint of Eye pattern.

Anti-reverse input terminal for RF summing amplifier.

I

The gain of RF amplifier is decided by the connection resistance between RF_M and

RFO terminals.

This is a pin where the selection time constant is externally connected to control the

I

RF level.

APC amplifier output terminal.

I

APC amplifier input terminal.

RFI-V amplifier inverted input pin.

I

These pins are connected to the A+C and B+C pins of the optical pickup, receiving by

currents input.

Bias adjustment pin of the focus error amplifier.

F and EIV amplifier inverted input pins.

I

These pins are connected to the F and E of the optical pickup, receiving by current

input.

Gain adjustment pin of the I-V amplifier E. (When not in use of BAL automatic

adjustment)

GND connection pin.

45

46

47

48

49

50

51

52

TEO

LPFI

TEI

ATSC

TZC

TDFCT

VC

FZC

O

Output terminal for tacking-error amplifier. Output E-F signal.

I

BAL adjustment comparator input pin. (Input through LPF from TEO)

I

Input terminal for tracking error.

I

Window-comparator input terminal for detecting ATSC.

I

Input terminal for tracking-zero cross comparator.

I

Capacitor connection pin for the time constant used when there is defect.

O

Output terminal for DC voltage reduced to half of VCC+VEE.

I

Input terminal for focus-zero cross comparator.

18

Page 16

IC, CXD2589Q

Pin No. Pin Name I/O Description

1, 20, 45, 60

VSS

—

GND.

10

11

12

13

14

15

16

17

18

2

3

4

5

6

7

8

9

LMUT

RMUT

SQCK

SQSO

SENS

DATA

XLAT

CLOK

SEIN

CNIN

DATO

XLTO

CLKO

SPOA

SPOB

XLON

FOK

Lch-“0” detect flag.

O

Rch-“0” detect flag.

O

Clock input for SQSO read out.

I

SubQ 80 bit serial output.

O

SENS signal output to CPU.

O

Serial data input from CPU.

I

Latch input from CPU, Latch serial data at fall down.

I

Clock input to serial data transfer from CPU.

I

SENS input from SSP.

I

Numbers of track jump are counted and input.

I

Serial data output to SSP.

O

Serial-data latch output to SSP. Latch at fall down.

O

Clock output for serial data transfer to SSP.

O

Microcomputer expansion interface. (Input A)

I

Microcomputer expansion interface. (Input B)

I

Microcomputer expansion interface. (Output)

O

Focus OK input terminal. Used for SENS output and servo-auto sequencer.

I

19, 46, 61, 80

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

VDD

MDP

PWMI

TEST

TESI

VPCO

VCKI

V16M

VCTL

PCO

FILO

FILI

AVSS

CLTV

AVDD

RF

BIAS

Power supply. (+5V)

—

Servo control for spindle motor.

O

External control input for spindle motor.

I

TEST terminal. (Connected to GND)

I

TEST terminal. (Connected to GND)

I

Charge pump output for extensive EFM PLL.

O

VCO2 oscillator input for extensive EFM PLL.

I

VCO2 oscillator output for extensive EFM PLL.

O

VCO2 control voltage input for extensive EFM PLL.

I

Charge pump output for master PLL.

O

Filter (slave = digital PLL) output for master PLL.

O

Filter input for master PLL.

I

Analog GND.

—

VCO control voltage input for master.

I

Analog power. (+5V)

—

EFM signal input.

I

Constant current input to asymmetry circuit.

I

37

38

39

40

41

42

ASYI

ASYO

LRCK

LRCKI

PCMD

PCMDI

Comparison voltage input to asymmetry circuit.

I

EFM full-swing output. (L=VSS, H=VDD)

O

D/A interface, LR clock output f=FS.

O

LR clock input.

I

D/A interface, serial data output. (2’s COMP, MSB first)

O

D/A interface, serial data input. (2’s COMP, MSB first)

I

19

Page 17

Pin No. Pin Name I/O Description

43

BCK

O

D/A interface bit clock output.

44

47

48

49

50

51

52

53

54

55

56

57

58

59

62

63

64

BCKI

XUGF

XPCK

GFS

C2PO

XTSL

C4M

DOUT

EMPH

EMPHI

WFCK

SCOR

SESO

EXCK

SYSM

AVSS

AVDD

I

D/A interface bit clock input.

O

XUGF output, MNT1 or RPCK output by switching command.

O

XPLCK output, MNT0 output by switching command.

O

GFS output, MNT3 or XRAOF output by switching command.

O

C2PO output, GTOP output by switching command.

I

X’tal select input terminal, X’tal: 16.9344MHz = “L” 33.8688MHz = “H”.

O

4.2336MHz output, Output 1/4 divided frequency of VCKI at CAV-W mode.

O

Digital Out connector output signal.

O

“H” when the playback disc has emphasis. “L” when it does not.

I

De-emphasis ON/OFF, “H” when ON, “L” when OFF.

O

WFCK output.

O

H output when the subcode sync S0 or S1 is detected.

O

Serial output for SubP-W.

I

SBSO read out clock input.

I

Mute input terminal, Active the “H” setting.

—

Analogue GND.

—

Analogue power supply. (+5V)

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

Note)

• PCMD is the two’s complement output with MSB first.

• GTOP monitors the protection status of the Frame Sync. (H: Sync protection window opened).

• XUGF is the Frame Sync negative pulse which is obtained from the EFM signal. This is the signal before the sync protection.

• XPLCK is the inverted signal of the EFM PLL clock. The PLL works so that the fall-down edge and the changed point of the

EFM signal agree.

• GFS is the signal that goes “H” when the Frame Sync and the internally inserted timing agree.

• RFCK is the signal having 136 micro-seconds (during normal speed) that is generated to have the same accuracy as X’tal.

• C2PO is the signal indicating the error status of the data.

• XRAOF is the signal that is generated when the 16k RAM goes outside the jitter margin ±4F.

AOUT1

AINI

LOUT1

AVSS

XVDD

XTAI

XTAO

XVSS

AVSS

LOUT2

AIN2

AOUT2

AVDD

AVSS

XRST

O

Lch/analogue output terminal.

I

Lch/OP AMP input terminal.

O

Lch/LINE output terminal.

—

Analogue GND.

—

Power supply for master clock.

Input terminal for crystal oscillator circuit.

I

Input external master clock from this terminal.

O

Output terminal for crystal oscillator circuit.

—

GND terminal for master clock.

—

Analogue GND.

O

Rch/LINE output terminal.

I

Rch/OP AMP input terminal.

O

Rch/analogue output terminal.

—

Analogue power supply. (+5V)

—

Analogue GND.

I

Reset system at “L” setting.

20

Page 18

IC BLOCK DIAGRAM

IC, TA7291S

PROTECTOR

CIRCUIT

(TSD)

STOP

BRAKE

: HI IMPEDANCE

NOTE : INPUT “H” ACTIVE

IC, BA6897S

21

Page 19

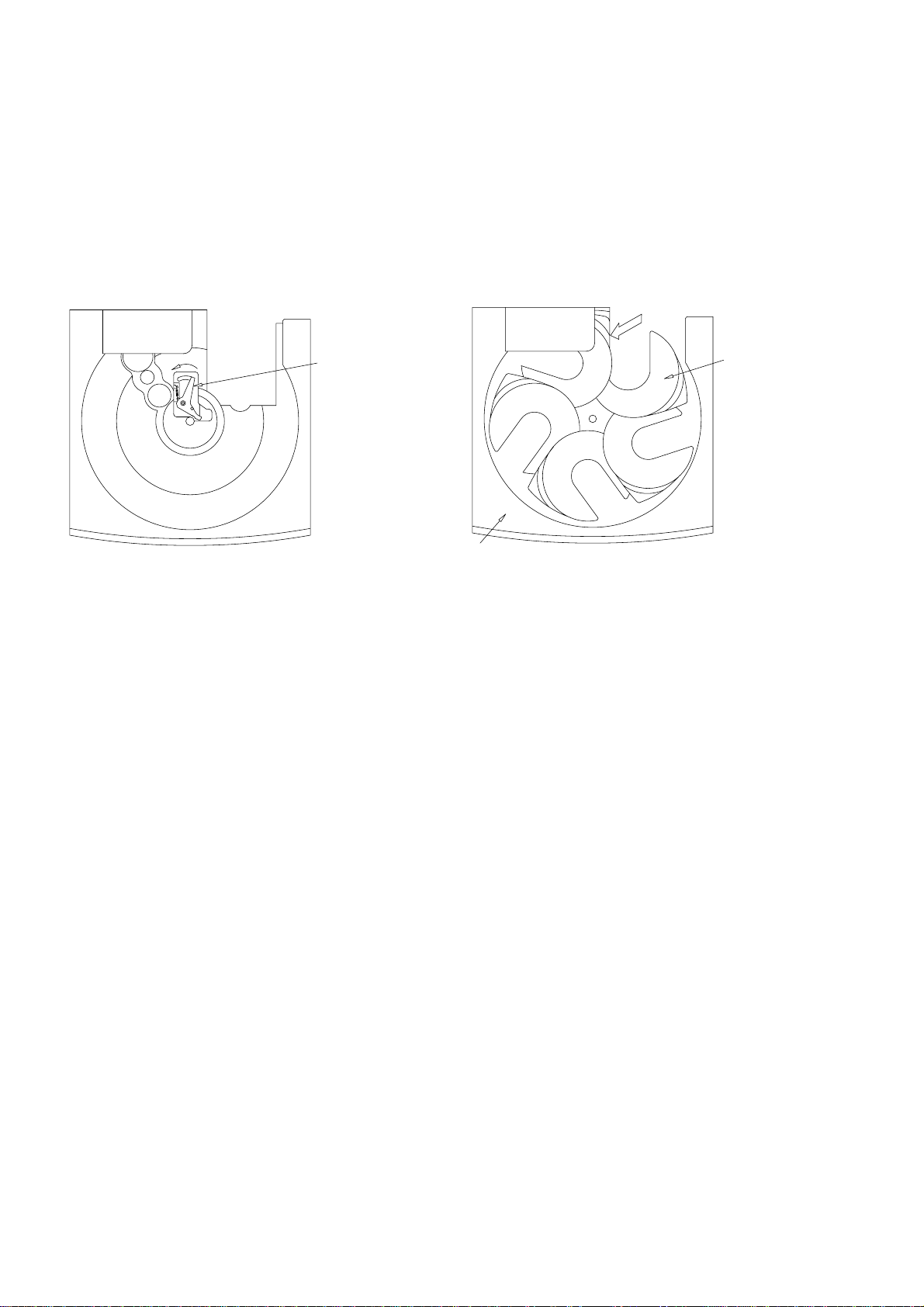

CD TEST MODE

< How to Enter the Test Mode >

Note: Target models of this test mode.

CX-ZR550

CX-ZVR55

While pressing the CD key, insert the AC power cord to

AC wall outlet.

< When the Machine Has Entered the Test

Mode >

The system is initialized and the main power is turned on.

During the test mode, the main power of the CD block is

turned on always. The test mode starts with the [Sled

mode].

< Types of Test Mode >

[Sled mode]

All displays of the FL tubes light. The optical pickup can

be moved by pressing [ ] or [ ] key.

Pressing the[ ] key establishes the [Focus mode].

Pressing the [ ] key establishes the [Play mode].

Pressing the [ ] key moves the sled to outer

circumference.

Pressing the [ ] key moves the sled to inner

circumference.

Pressing OPEN/CLOSE key opens or closes the tray.

[Play mode]

Lighting of all displays of the FL tubes are turned off and

returns to normal display. The focus search (numbers of

search is unlimited) is performed. When focus comes to

in-focus, the focus servo is locked in and the machines

enters the normal play mode.

During [Play mode], GFS and sound skipping are not

monitored.

When focus becomes out-of-focus, another attempt is

made to search for focus.

The tracking servo and the sled servo can be turned on

and off by pressing the [

Pressing the [ ] key establishes the [Sled mode].

The [ ] display can be turned on and off by pressing

the [ ] key .

While the [ ] display is turned off:

CLV-A Tracking servo: on

Sled servo: on

While the [ ] display is turned on:

CLV-A Tracking servo: off

Sled servo: off

Pressing the [ ] key decreases the track number to -1.

Pressing the [ ] key increases the track number to +1.

Pressing OPEN/CLOSE key opens or closes the tray.

The machine enters the [Sled mode].

] key.

< How to Exit the Test Mode >

[Focus mode]

Lighting of all displays of the FL tubes are turned off and

returns to normal display. The focus search is performed

in the focus mode regardless whether disc is inserted or

not, or focus OK or NG. (Numbers of times of focus

search is unlimited. Auto sequence is not used.)

Focus servo is not locked in even the focus is obtained.

Pressing the [ ] key establishes the [Play mode].

Pressing the [ ] key decreases the track number to -1.

Pressing the [ ] key increases the track number to +1.

Pressing OPEN/CLOSE key opens or closes the tray.

The machine enters the [Sled mode].

Remove the AC power cord from power outlet, or turn

off the system power.

22

Page 20

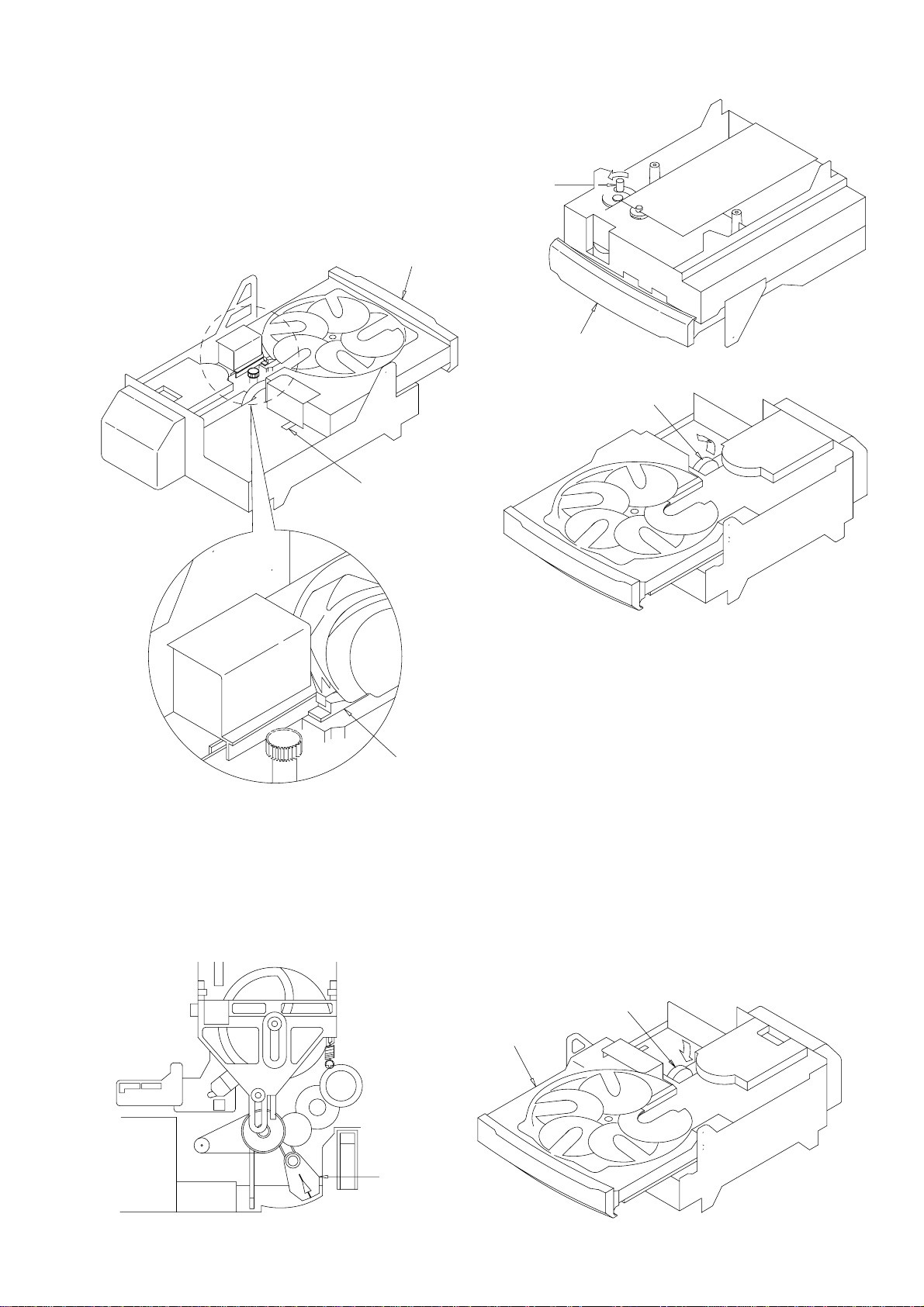

MECHANICAL EXPLODED VIEW 1/1

A

9

A

13

14

40

19

8

7

6

17

18

22

24

16

20

23

10

11

12

41

E

15

P.C.B

21

5

4

1

D

36

2

35

38

37

3

34

33

B

42

28

P.C.B

26

25

27

45

43

29

30

31

32

C

P.C.B

39

23

CUSH CD A

3ZG-2 E2

44

Page 21

MECHANICAL PARTS LIST 1/1

REF. NO PART NO. KANRI DESCRIPTION

1 86-ZG1-001-310 TRAY,5CD

2 81-ZG1-212-010 PULLY,LOAD MO

3 87-A90-036-010 MOT ASSY,RF-300CA-11

4 86-ZG1-228-110 GEAR,TT-B

5 86-ZG1-227-110 GEAR,TT-A

6 86-ZG1-223-110 GEAR,WORM-WHEEL TT

7 86-ZG1-224-110 LEVER,TT(*)

8 86-ZG1-226-010 SPR-E,LEVER TT

9 86-ZG1-002-210 TURN TABLE,5CD

10 86-ZG1-211-210 JOINT,CAM

11 86-ZG1-216-010 SPR-E,JT

12 86-ZG1-203-210 GEAR,MAIN CAM

13 86-ZG1-213-110 LEVER,LOAD

14 86-ZG1-214-110 LEVER,PROTECT

15 86-ZG1-004-010 REFLECTOR,CD

16 86-ZG1-205-110 GEAR,TRAY

17 84-ZG1-207-010 PULLEY,RELAY

18 84-ZG1-209-010 BELT,SQ1.8-117.7

19 86-ZG1-217-010 LEVER,SW

20 86-ZG1-206-110 GEAR,RELAY B

21 86-ZG1-220-110 SPR-P,LOCK

22 86-ZG1-204-110 GEAR,RELAY A

23 86-ZG1-218-110 PLATE,GEAR

24 86-ZG1-208-010 LEVER,TRAY

25 86-ZG1-209-110 SLIDER,CAM L(*)

26 86-ZG1-210-110 SLIDER,CAM R(*)

27 84-ZG1-244-310 CABI,OPTICAL<S2>

28 84-ZG2-228-010 PULLEY,MOT

29 83-ZG3-211-010 PLATE,DISC

30 83-ZG3-602-010 RING,MAG

NO.

REF. NO PART NO. KANRI DESCRIPTION

31 86-ZG1-215-010 HLDR,CHUCK

32 86-ZG1-238-010 HLDR,MAGNET 6ZG N

33 86-ZG1-225-010 BELT,SQ1.2-32.9

34 86-ZG1-221-010 PULLEY,TT

35 86-ZG1-231-010 SPR-C,WORM

36 84-ZG1-256-010 GEAR,WORM N2

37 86-ZG1-232-010 SPR-P,WORM

38 86-ZG1-229-010 HLDR,SENSOR

39 86-ZG1-230-010 HLDR,DISC SENSOR

40 86-ZG1-003-110 COVER,TRAY

41 86-ZG1-212-310 SLIDER,LOAD

42 86-ZG1-201-210 CHAS,MECHA<S2,S>

42 86-ZG1-240-010 CHAS,MECHA T2<S3>

43 86-ZG1-005-110 COVER,CHAS

44 86-ZG1-202-110 HLDR,MECHA

45 84-ZG1-261-010 LID,OPTICAL

A 87-078-148-010 VFT2+3-12(F10) BLK

B 87-251-072-410 U+2.6-5

C 81-ZG1-254-010 S-SCREW,MECH HLDR

D 87-067-579-010 TAPPING SCREW, BVT2+3-8

E 87-067-703-010 TAPPING SCREW, BVT2+3-10

NO.

24

Page 22

CD MECHANISM EXPLODED VIEW 1/1 (3ZG-1 E2)

11

12

8

A

A

2

6

A

A

1

5

3

4

SW1

M1

M2

DRIVE C.B

CD MECHANISM PARTS LIST 1/1 (3ZG-1 E2)

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 83-ZG2-247-210 CHAS ASSY,SHT5

2 83-ZG2-235-010 GEAR,A3

3 83-ZG2-205-210 GEAR,B

4 83-ZG2-236-010 GEAR MOTOR 3

5 83-ZG2-240-010 SHAFT,SLIDE 3

6 87-A90-836-010 PICKUP,KSS-213F

8 83-ZG2-227-010 TURN TABLE,C1

11 83-ZG2-245-110 LEVER,SHUTTER

12 83-ZG2-250-010 SPR-E,SHT 2

A 87-261-032-210 SCREW V+2-3

25

Page 23

MODEL NO. 6ZG-1S2

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

IC

87-A20-547-010 C-IC,CXA1992AR

87-A20-546-010 C-IC,CXD2589Q

87-A20-592-040 C-IC,M51943 AML<D>

87-001-792-080 IC,NJM2100M<D>

87-070-305-010 IC,BA6897S<D>

87-A20-856-010 IC,BA6898S

87-001-982-010 IC,TA7291S

86-ZG1-649-010 C-IC,UPD789026GB-510-MTX

TRANSISTOR

89-406-555-080 TR,2SD655 (0.5W)

87-026-245-080 TR,DTC114ES

87-026-235-080 CHIP-TR,DTC114EK

87-026-463-080 TR,2SA933S (0.3W)

89-324-123-080 C-TR,2SC2412K S<D>

87-026-227-080 CHIP-TR,DTA114EK<D>

89-421-722-380 TR,2SD2172V/W

89-320-011-080 TR,2SC2001 (15W)

87-026-239-080 TR,DTC114TK (0.2W)<D>

87-026-223-080 TR,DTC143TK

89-110-155-080 TR,2SA1015(0.4W)<D>

89-213-292-380 TR,2SB1329QR

87-026-608-080 C-TR,DTC 123 JK

87-A30-075-080 C-TR,2SA1235F<D>

89-327-125-080 CHIP TR,2SC2712GR<D>

DIODE

87-A40-348-080 ZENER,MTZJ3.3A

87-027-583-080 ZENER,HZ9B1L (200MA)

87-020-465-080 DIODE,1SS133 (110MA)<D>

87-A40-291-080 DIODE,1N4148 (CPT)

CD MAIN C.B

C1 87-010-196-080 CHIP CAPACITOR,0.1-25

C2 87-010-260-080 CAP, ELECT 47-25V

C3 87-010-221-040 CAP,E 470-10 SME

C4 87-010-197-020 C-CAP,S 0.01-25 B

C5 87-010-184-020 C-CAP,S 3300P-50 B

C101 87-010-263-040 CAP,E 100-10<D>

C101 87-010-550-040 CAP,E 100-6.3 GAS

C102 87-010-178-020 C-CAP,S 1000P-50 B

C103 87-010-550-040 CAP,E 100-6.3 GAS

C104 87-010-182-020 C-CAP,S 2200P-50 B

C105 87-010-198-020 C-CAP,S 0.022-25 B

C106 87-016-081-080 C-CAP,S 0.1-16 RK

C107 87-016-081-080 C-CAP,S 0.1-16 RK

C108 87-016-081-080 C-CAP,S 0.1-16 RK

C109 87-010-497-040 CAP,E 4.7-35 GAS<D>

C109 87-010-404-040 CAP,E 4.7-50 SME

C110 87-016-081-080 C-CAP,S 0.1-16 RK

C111 87-010-197-020 C-CAP,S 0.01-25 B

C112 87-010-402-040 CAP,E 2.2-50 SME

C113 87-010-382-040 CAP,E 22-25 SME

C114 87-010-213-020 C-CAP,S 0.015-25 B

C115 87-010-263-040 CAP,E 100-10

C116 87-010-197-020 C-CAP,S 0.01-25 B

C117 87-016-369-020 C-CAP,S 0.033-25 B K

C117 87-010-186-020 C-CAP,S 4700P-50 B<D>

C118 87-010-197-020 C-CAP,S 0.01-25 B

C119 87-016-369-020 C-CAP,S 0.033-25 B K

C120 87-010-197-020 C-CAP,S 0.01-25 B

C121 87-010-494-040 CAP,E 1-50 GAS<D>

C121 87-010-401-040 CAP,E 1-50 SME

C122 87-010-154-020 C-CAP,S 10P-50 CH

C123 87-010-154-020 C-CAP,S 10P-50 CH

C124 87-010-154-020 C-CAP,S 10P-50 CH

NO.

REF. NO PART NO. KANRI DESCRIPTION

C125 87-010-596-020 C-CAP,S 0.047-16 RK

C126 87-010-596-020 C-CAP,S 0.047-16 RK

C127 87-012-140-020 C-CAP,S 470P-50 CH

C128 87-010-596-020 C-CAP,S 0.047-16 RK

C129 87-010-198-020 C-CAP,S 0.022-25 B

C130 87-016-081-080 C-CAP,S 0.1-16 RK

C131 87-010-550-040 CAP,E 100-6.3 GAS

C132 87-010-550-040 CAP,E 100-6.3 GAS

C133 87-012-158-020 C-CAP,S 390P-50 J CH

C150 87-010-145-020 C-CAP,S 1P-50 C CH<D>

C202 87-010-596-020 C-CAP,S 0.047-16 RK

C203 87-010-188-020 C-CAP,S 6800P-50 B

C204 87-012-156-020 C-CAP,S 220P-50 CH

C205 87-018-133-080 CAPACITOR,CER 4700P-16V<D>

C205 87-018-134-080 CAPACITOR,TC-U 0.01-16

C206 87-010-400-040 CAP,E 0.47-50

C207 87-010-197-020 C-CAP,S 0.01-25 B

C208 87-010-318-020 C-CAP,S 47P-50 CH<D>

C209 87-012-154-020 C-CAP,S 150P-50 J CH GRM

C210 87-012-154-020 C-CAP,S 150P-50 J CH GRM

C211 87-010-176-020 C-CAP,S 680P-50 J SL

C212 87-010-176-020 C-CAP,S 680P-50 J SL

C213 87-010-400-040 CAP,E 0.47-50

C213 87-010-382-040 CAP,E 22-25 SME<D>

C214 87-010-400-040 CAP,E 0.47-50

C214 87-010-382-040 CAP,E 22-25 SME<D>

C215 87-010-318-020 C-CAP,S 47P-50 CH

C216 87-010-318-020 C-CAP,S 47P-50 CH

C217 87-010-101-040 CAP,E 220-16 SME

C217 87-010-380-040 CAP,E 47-16 SME<D>

C218 87-010-197-020 C-CAP,S 0.01-25 B

C219 87-010-196-020 C-CAP,S 0.1-25 F

C220 87-010-370-040 CAP,E 330-6.3 SME

C221 87-010-197-080 CAP, CHIP 0.01 DM

C222 87-010-186-020 C-CAP,S 4700P-50 B

C223 87-016-081-020 C-CAP,S 0.1-16 RK

C224 87-010-805-080 CAP, S 1-16

C228 87-018-134-080 CAPACITOR,TC-U 0.01-16

C230 87-018-209-080 CAP, CER 0.1-50V<D>

C231 87-018-209-080 CAP, CER 0.1-50V<D>

C231 87-018-134-080 CAPACITOR,TC-U 0.01-16

C301 87-010-101-080 CAP, ELECT 220-16<D>

C302 87-010-263-080 CAP, ELECT 100-10V<D>

C305 87-010-318-020 C-CAP,S 47P-50 CH<D>

C306 87-010-318-020 C-CAP,S 47P-50 CH<D>

C307 87-010-405-080 CAP, ELECT 10-50V<D>

C308 87-010-405-080 CAP, ELECT 10-50V<D>

C401 87-010-403-080 CAP, ELECT 3.3-50V

C402 87-010-403-040 CAP,E 3.3-50 SME

C501 87-010-555-040 CAP,E 100-10 GAS

C501 87-016-459-040 CAP,E 470-10 SMG<D>

C502 87-010-197-020 C-CAP,S 0.01-25 B

C503 87-010-263-040 CAP,E 100-10<D>

C503 87-010-555-040 CAP,E 100-10 GAS

C504 87-010-196-020 C-CAP,S 0.1-25 F

C505 87-010-196-020 C-CAP,S 0.1-25 F

C506 87-010-196-020 C-CAP,S 0.1-25 F

C507 87-010-196-020 C-CAP,S 0.1-25 F

C508 87-010-221-040 CAP,E 470-10 SME

C508 87-016-459-040 CAP,E 470-10 SMG<D>

C509 87-010-196-020 C-CAP,S 0.1-25 F

C510 87-010-196-020 C-CAP,S 0.1-25 F

C511 87-010-221-040 CAP,E 470-10 SME

C512 87-010-197-020 C-CAP,S 0.01-25 B

C601 87-010-197-020 C-CAP,S 0.01-25 B

C602 87-016-251-040 CAP,E 220-16 SMG<D>

C602 87-010-385-010 CAP,E 220-25

C603 87-010-196-020 C-CAP,S 0.1-25 F

C701 87-010-322-020 C-CAP,S 100P-50 CH<D>

C702 87-010-318-020 C-CAP,S 47P-50 CH<D>

NO.

26

Page 24

REF. NO PART NO. KANRI DESCRIPTION

C703 87-010-318-020 C-CAP,S 47P-50 CH<D>

C705 87-010-178-020 C-CAP,S 1000P-50 B<D>

C705 87-010-322-020 C-CAP,S 100P-50 CH

C706 87-018-209-080 CAP, CER 0.1-50V<D>

C801 87-010-263-040 CAP,E 100-10

C802 87-010-197-020 C-CAP,S 0.01-25 B

C803 87-010-318-020 C-CAP,S 47P-50 CH

C804 87-010-318-020 C-CAP,S 47P-50 CH

C807 87-010-318-020 C-CAP,S 47P-50 CH

C808 87-010-318-020 C-CAP,S 47P-50 CH

C809 87-010-318-020 C-CAP,S 47P-50 CH

C810 87-010-318-020 C-CAP,S 47P-50 CH

C901 87-010-260-080 CAP, ELECT 47-25V<D>

C901 87-010-260-040 CAP,E 47-25 SME<D>

C902 87-010-196-020 C-CAP,S 0.1-25 F<D>

C902 87-010-196-080 CHIP CAPACITOR,0.1-25<D>

CN2 86-ZG1-609-010 CONN ASSY,6P

CON1 87-A60-424-010 CONN,16P V TOC-B

CON2 87-009-034-010 CONN,6P PH V

CON3 87-A60-133-010 CONN,8P V FE

CON5 87-A60-154-010 CONN,6P H FE

CON6 87-099-033-010 16P 6216 H<D>

CON6 87-A60-160-010 CONN,12P H FE

CON301 87-009-346-010 CONN,3P PH H<D>

CON302 87-009-350-010 CONN,7P PH H<D>

FB9 87-A50-192-080 C-COIL,S BLM21P300S

FB50 87-A50-192-080 C-COIL,S BLM21P300S

FB75 87-008-372-080 FILTER, EMI BL OIRNI

FB84 87-008-372-080 FILTER, EMI BL OIRNI

FB90 87-003-223-010 FERRITE BEAD BLO2RN2

FB94 87-003-223-010 FERRITE BEAD BLO2RN2

FB101 83-XM1-617-080 C-COIL,BK2125HM601

FB301 87-008-372-080 FILTER, EMI BL OIRNI<D>

FB401 87-008-372-080 FILTER, EMI BL OIRNI<D>

FC1 86-ZG1-605-010 CABLE,FFC 16P

NO.

REF. NO PART NO. KANRI DESCRIPTION

FC2 86-ZG1-667-010 F-CABLE,8P 1.25 175MM BLACK

L31 87-003-102-080 COIL, 10UH

L101 87-003-102-080 COIL, 10UH

L201 87-003-102-080 COIL, 10UH<D>

LED901 87-A40-123-010 LED,SLZ-8128A-01-B<D>

M601 87-045-305-010 MOTOR, RF-500TB DC-5V (2MA)

R101 87-022-363-020 C-RES,S 68K-1/10W F

R102 87-022-363-020 C-RES,S 68K-1/10W F

R103 87-022-363-020 C-RES,S 68K-1/10W F

R104 87-022-363-020 C-RES,S 68K-1/10W F

R105 87-022-365-020 C-RES,S 100K-1/10W F

R106 87-022-365-020 C-RES,S 100K-1/10W F

R301 87-025-337-080 RESISTOR, 1/4W 47<D>

R420 87-029-060-080 RES,FUSE 33-1/4 W

S601 87-036-109-010 PUSH SWITCH

S602 87-036-109-010 PUSH SWITCH

S603 87-036-109-010 PUSH SWITCH

X201 87-A70-046-010 VIB,XTAL 16.934MHZ

X801 87-A70-075-080 VIB,CER 4.19MHZ CRHF

LED C.B

LED701 87-017-733-080 LED,SEL1250SM

LED702 87-017-350-080 LED,SEL1550CM

LED703 87-017-733-080 LED,SEL1250SM

T-T C.B

C411 87-018-214-080 CAP TC U 0.1-50F

CON8 87-A60-156-010 CONN,8P H FE

LED411 87-070-288-010 LED,GL380

M401 87-A90-036-010 MOT ASSY,RF-300CA-11

PS401 87-A90-156-010 SNSR,SG-240

Q411 87-A30-031-010 P-TR,PT380F

S401 87-036-109-010 PUSH SWITCH

NO.

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

/ CHIP RESISTOR PART CODE

Chip Resistor Part Coding

8

8

Figure

Resistor Code

Value of resistor

Chip resistor

/ Diamensions (mm)

Wattage Type

1/16W

1/10W

1/8W

1608

2125

3216

Tolerance

5%

5%

5%

Symbol

CJ

CJ

CJ

/ Form

L

W

0.8

1.25

1.6

t

0.45

0.45

0.55

L

1.6

t

W

2

3.2

Resistor Code : A

108

118

128

27

Page 25

Refer to the following pages for the common section.

IC DESCRIPTION...................................................................... See page 17

MECHANICAL EXPLODED VIEW............................................. See page 23

MECHANICAL PARTS LIST...................................................... See page 24

CD MECHANISM EXPLODED VIEW ........................................ See page 25

CD MECHANISM PARTS LIST ................................................. See page 25

28

Page 26

IC BLOCK DIAGRAM

IC, BA6898S

IC, TA7291S

PROTECTOR

CIRCUIT

(TSD)

STOP

BRAKE

: HI IMPEDANCE

NOTE : INPUT “H” ACTIVE

29

Page 27

BLOCK DIAGRAM

RF

3130

Page 28

WIRING

A

B

C

D

1

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

3332

Page 29

SCHEMATIC DIAGRAM

2589Q

REG.

3534

Page 30

IC DESCRIPTION

IC, µPD789026GB

Pin No. Pin Name I/O Description

1

2

O-SW1

O-SW2

O

Not used.

O

10

11

12

13

14

15

16

17

18

3

O-XRST

XRST input to DSP. Low output during 100 m seconds after about 100 m seconds of

O

resetting the system.

4

5

6

7

8

9

O-CLK

O-XTL

O-DATA

O-SQCK

I-SQ-DATA

I-SENS

_____________________

I-SHATTER

____________________

I-TGDOWN

NC

IC

X2

X1

VSS

VDD

______________

RESET

Clock input to DSP.

O

Latch input to DSP.

O

Data input to DSP.

O

SUB-Q data read-out clock to DSP.

O

SUB-Q input from DSP.

I

SENS input from DSP.

I

Connected to GND.

I

I

Not used.

—

Connected to GND.

—

Output terminal for external ceramic oscillator.

O

Input terminal for external ceramic oscillator.

I

GND of microprocessor.

—

Power supply of microprocessor.

—

Microprocessor reset input.

I

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

P53

P52

P51

__________________

I-1992BR

________

I-FB

________

I-TG

_________

I-TB

I-COMMAND

O-STATUS

I-SCLK

X-BUSY

P06

______________

100MS

O-AMUTE

O-PLAY

O-PAUSE

O-SERCH

—

—

—

O

I/O

—

—

O

O

O

O

Not used.

I

I

I

I

Command input from main microprocessor.

I

Data output to main microprocessor.

O-status read-out clock from main microprocessor/Clock for I-command.

I

Flag for confirmation of busy and ready with the main microprocessor.

Not used.

Connected to GND.

Low output during playback only.

High output during playback only

High output during pause only.

High output during search only.

36

37

38

39

40

O-STOP

NC

VDD

VSS

P17

High output during stop only.

O

Not used.

—

Power supply of microprocessor.

—

GND of microprocessor.

—

Not used.

—

36

Page 31

Pin No. Pin Name I/O Description

41

O-SW6

O

42

43

44

O-SW5

O-SW4

O-SW3

O

Not used.

O

O

37

Page 32

MODEL NO. 6ZG-1S3

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

IC

87-A20-547-010 C-IC,CXA1992AR

87-A20-546-010 C-IC,CXD2589Q

87-A20-592-040 C-IC,M51943 AML

87-001-792-080 IC,NJM2100M

87-070-305-010 IC,BA6897S

87-A20-856-010 IC,BA6898S<D>

87-001-982-010 IC,TA7291S

86-ZG1-649-010 C-IC,UPD789026GB-510-MTX<D>

TRANSISTOR

89-406-555-080 TR,2SD655 (0.5W)<D>

87-026-245-080 TR,DTC114ES<D>

87-026-235-080 CHIP-TR,DTC114EK<D>

87-026-463-080 TR,2SA933S (0.3W)

89-324-123-080 C-TR,2SC2412K S

87-026-227-080 CHIP-TR,DTA114EK

89-421-722-380 TR,2SD2172V/W

89-320-011-080 TR,2SC2001 (15W)

87-026-239-080 TR,DTC114TK (0.2W)

87-026-223-080 TR,DTC143TK<D>

89-110-155-080 TR,2SA1015(0.4W)

89-213-292-380 TR,2SB1329QR<D>

87-026-608-080 C-TR,DTC 123 JK

87-A30-075-080 C-TR,2SA1235F<D>

89-327-125-080 CHIP TR,2SC2712GR<D>

DIODE

87-A40-348-080 ZENER,MTZJ3.3A<D>

87-027-583-080 ZENER,HZ9B1L (200MA)<D>

87-020-465-080 DIODE,1SS133 (110MA)

87-A40-291-080 DIODE,1N4148 (CPT)<D>

CD MAIN C.B

C1 87-010-196-080 CHIP CAPACITOR,0.1-25<D>

C2 87-010-260-080 CAP, ELECT 47-25V<D>

C3 87-010-221-040 CAP,E 470-10 SME<D>

C4 87-010-197-020 C-CAP,S 0.01-25 B<D>

C5 87-010-184-020 C-CAP,S 3300P-50 B<D>

C101 87-010-263-040 CAP,E 100-10

C101 87-010-550-040 CAP,E 100-6.3 GAS<D>

C102 87-010-178-020 C-CAP,S 1000P-50 B

C103 87-010-550-040 CAP,E 100-6.3 GAS

C104 87-010-182-020 C-CAP,S 2200P-50 B

C105 87-010-198-020 C-CAP,S 0.022-25 B

C106 87-016-081-080 C-CAP,S 0.1-16 RK

C107 87-016-081-080 C-CAP,S 0.1-16 RK

C108 87-016-081-080 C-CAP,S 0.1-16 RK

C109 87-010-497-040 CAP,E 4.7-35 GAS

C109 87-010-404-040 CAP,E 4.7-50 SME<D>

C110 87-016-081-080 C-CAP,S 0.1-16 RK

C111 87-010-197-020 C-CAP,S 0.01-25 B

C112 87-010-402-040 CAP,E 2.2-50 SME

C113 87-010-382-040 CAP,E 22-25 SME

C114 87-010-213-020 C-CAP,S 0.015-25 B

C115 87-010-263-040 CAP,E 100-10

C116 87-010-197-020 C-CAP,S 0.01-25 B

C117 87-016-369-020 C-CAP,S 0.033-25 B K<D>

C117 87-010-186-020 C-CAP,S 4700P-50 B

C118 87-010-197-020 C-CAP,S 0.01-25 B

C119 87-016-369-020 C-CAP,S 0.033-25 B K

C120 87-010-197-020 C-CAP,S 0.01-25 B

C121 87-010-494-040 CAP,E 1-50 GAS

C121 87-010-401-040 CAP,E 1-50 SME<D>

C122 87-010-154-020 C-CAP,S 10P-50 CH

C123 87-010-154-020 C-CAP,S 10P-50 CH

C124 87-010-154-020 C-CAP,S 10P-50 CH

NO.

REF. NO PART NO. KANRI DESCRIPTION

C125 87-010-596-020 C-CAP,S 0.047-16 RK

C126 87-010-596-020 C-CAP,S 0.047-16 RK

C127 87-012-140-020 C-CAP,S 470P-50 CH

C128 87-010-596-020 C-CAP,S 0.047-16 RK

C129 87-010-198-020 C-CAP,S 0.022-25 B

C130 87-016-081-080 C-CAP,S 0.1-16 RK

C131 87-010-550-040 CAP,E 100-6.3 GAS

C132 87-010-550-040 CAP,E 100-6.3 GAS

C133 87-012-158-020 C-CAP,S 390P-50 J CH

C150 87-010-145-020 C-CAP,S 1P-50 C CH

C202 87-010-596-020 C-CAP,S 0.047-16 RK

C203 87-010-188-020 C-CAP,S 6800P-50 B

C204 87-012-156-020 C-CAP,S 220P-50 CH

C205 87-018-133-080 CAPACITOR,CER 4700P-16V

C205 87-018-134-080 CAPACITOR,TC-U 0.01-16<D>

C206 87-010-400-040 CAP,E 0.47-50

C207 87-010-197-020 C-CAP,S 0.01-25 B

C208 87-010-318-020 C-CAP,S 47P-50 CH<D>

C209 87-012-154-020 C-CAP,S 150P-50 J CH GRM

C210 87-012-154-020 C-CAP,S 150P-50 J CH GRM

C211 87-010-176-020 C-CAP,S 680P-50 J SL

C212 87-010-176-020 C-CAP,S 680P-50 J SL

C213 87-010-400-040 CAP,E 0.47-50<D>

C213 87-010-382-040 CAP,E 22-25 SME

C214 87-010-400-040 CAP,E 0.47-50<D>

C214 87-010-382-040 CAP,E 22-25 SME

C215 87-010-318-020 C-CAP,S 47P-50 CH

C216 87-010-318-020 C-CAP,S 47P-50 CH

C217 87-010-101-040 CAP,E 220-16 SME<D>

C217 87-010-380-040 CAP,E 47-16 SME

C218 87-010-197-020 C-CAP,S 0.01-25 B

C219 87-010-196-020 C-CAP,S 0.1-25 F

C220 87-010-370-040 CAP,E 330-6.3 SME

C221 87-010-197-080 CAP, CHIP 0.01 DM

C222 87-010-186-020 C-CAP,S 4700P-50 B

C223 87-016-081-020 C-CAP,S 0.1-16 RK

C224 87-010-805-080 CAP, S 1-16<D>

C228 87-018-134-080 CAPACITOR,TC-U 0.01-16<D>

C230 87-018-209-080 CAP, CER 0.1-50V

C231 87-018-209-080 CAP, CER 0.1-50V

C231 87-018-134-080 CAPACITOR,TC-U 0.01-16<D>

C301 87-010-101-080 CAP, ELECT 220-16

C302 87-010-263-080 CAP, ELECT 100-10V

C305 87-010-318-020 C-CAP,S 47P-50 CH

C306 87-010-318-020 C-CAP,S 47P-50 CH

C307 87-010-405-080 CAP, ELECT 10-50V

C308 87-010-405-080 CAP, ELECT 10-50V

C401 87-010-403-080 CAP, ELECT 3.3-50V

C402 87-010-403-040 CAP,E 3.3-50 SME

C501 87-010-555-040 CAP,E 100-10 GAS<D>

C501 87-016-459-040 CAP,E 470-10 SMG

C502 87-010-197-020 C-CAP,S 0.01-25 B

C503 87-010-263-040 CAP,E 100-10

C503 87-010-555-040 CAP,E 100-10 GAS<D>

C504 87-010-196-020 C-CAP,S 0.1-25 F

C505 87-010-196-020 C-CAP,S 0.1-25 F

C506 87-010-196-020 C-CAP,S 0.1-25 F

C507 87-010-196-020 C-CAP,S 0.1-25 F

C508 87-010-221-040 CAP,E 470-10 SME<D>

C508 87-016-459-040 CAP,E 470-10 SMG

C509 87-010-196-020 C-CAP,S 0.1-25 F

C510 87-010-196-020 C-CAP,S 0.1-25 F

C511 87-010-221-040 CAP,E 470-10 SME<D>

C512 87-010-197-020 C-CAP,S 0.01-25 B<D>

C601 87-010-197-020 C-CAP,S 0.01-25 B

C602 87-016-251-040 CAP,E 220-16 SMG

C602 87-010-385-010 CAP,E 220-25<D>

C603 87-010-196-020 C-CAP,S 0.1-25 F

C701 87-010-322-020 C-CAP,S 100P-50 CH

C702 87-010-318-020 C-CAP,S 47P-50 CH

NO.

38

Page 33

REF. NO PART NO. KANRI DESCRIPTION

C703 87-010-318-020 C-CAP,S 47P-50 CH

C705 87-010-178-020 C-CAP,S 1000P-50 B

C705 87-010-322-020 C-CAP,S 100P-50 CH<D>

C706 87-018-209-080 CAP, CER 0.1-50V

C801 87-010-263-040 CAP,E 100-10<D>

C802 87-010-197-020 C-CAP,S 0.01-25 B<D>

C803 87-010-318-020 C-CAP,S 47P-50 CH<D>

C804 87-010-318-020 C-CAP,S 47P-50 CH<D>

C807 87-010-318-020 C-CAP,S 47P-50 CH<D>

C808 87-010-318-020 C-CAP,S 47P-50 CH<D>

C809 87-010-318-020 C-CAP,S 47P-50 CH<D>

C810 87-010-318-020 C-CAP,S 47P-50 CH<D>

C901 87-010-260-080 CAP, ELECT 47-25V<D>

C901 87-010-260-040 CAP,E 47-25 SME<D>

C902 87-010-196-020 C-CAP,S 0.1-25 F<D>

C902 87-010-196-080 CHIP CAPACITOR,0.1-25<D>

CN2 86-ZG1-609-010 CONN ASSY,6P

CON1 87-A60-424-010 CONN,16P V TOC-B

CON2 87-009-034-010 CONN,6P PH V

CON3 87-A60-133-010 CONN,8P V FE

CON5 87-A60-154-010 CONN,6P H FE

CON6 87-099-033-010 16P 6216 H

CON6 87-A60-160-010 CONN,12P H FE<D>

CON301 87-009-346-010 CONN,3P PH H

CON302 87-009-350-010 CONN,7P PH H

FB9 87-A50-192-080 C-COIL,S BLM21P300S<D>

FB50 87-A50-192-080 C-COIL,S BLM21P300S<D>

FB75 87-008-372-080 FILTER, EMI BL OIRNI<D>

FB84 87-008-372-080 FILTER, EMI BL OIRNI<D>

FB90 87-003-223-010 FERRITE BEAD BLO2RN2<D>

FB94 87-003-223-010 FERRITE BEAD BLO2RN2<D>

FB101 83-XM1-617-080 C-COIL,BK2125HM601<D>

FB301 87-008-372-080 FILTER, EMI BL OIRNI

FB401 87-008-372-080 FILTER, EMI BL OIRNI

FC1 86-ZG1-605-010 CABLE,FFC 16P

NO.

REF. NO PART NO. KANRI DESCRIPTION

FC2 86-ZG1-667-010 F-CABLE,8P 1.25 175MM BLACK

L31 87-003-102-080 COIL, 10UH<D>

L101 87-003-102-080 COIL, 10UH

L201 87-003-102-080 COIL, 10UH

LED901 87-A40-123-010 LED,SLZ-8128A-01-B<D>

M601 87-045-305-010 MOTOR, RF-500TB DC-5V (2MA)

R101 87-022-363-020 C-RES,S 68K-1/10W F

R102 87-022-363-020 C-RES,S 68K-1/10W F

R103 87-022-363-020 C-RES,S 68K-1/10W F

R104 87-022-363-020 C-RES,S 68K-1/10W F

R105 87-022-365-020 C-RES,S 100K-1/10W F

R106 87-022-365-020 C-RES,S 100K-1/10W F

R301 87-025-337-080 RESISTOR, 1/4W 47

R420 87-029-060-080 RES,FUSE 33-1/4 W<D>

S601 87-036-109-010 PUSH SWITCH

S602 87-036-109-010 PUSH SWITCH

S603 87-036-109-010 PUSH SWITCH

X201 87-A70-046-010 VIB,XTAL 16.934MHZ

X801 87-A70-075-080 VIB,CER 4.19MHZ CRHF<D>

LED C.B

LED701 87-017-733-080 LED,SEL1250SM

LED702 87-017-350-080 LED,SEL1550CM

LED703 87-017-733-080 LED,SEL1250SM

T-T C.B

C411 87-018-214-080 CAP TC U 0.1-50F

CON8 87-A60-156-010 CONN,8P H FE

LED411 87-070-288-010 LED,GL380

M401 87-A90-036-010 MOT ASSY,RF-300CA-11

PS401 87-A90-156-010 SNSR,SG-240

Q411 87-A30-031-010 P-TR,PT380F

S401 87-036-109-010 PUSH SWITCH

NO.

• Regarding connectors, they are not stocked as they are not the initial order items.

The connectors are available after they are supplied from connector manufacturers upon the order is received.

/ CHIP RESISTOR PART CODE

Chip Resistor Part Coding

8

8

Figure

Resistor Code

Value of resistor

Chip resistor

/ Diamensions (mm)

Wattage Type

1/16W

1/10W

1/8W

1608

2125

3216

Tolerance

5%

5%

5%

Symbol

CJ

CJ

CJ

/ Form

L

W

0.8

1.25

1.6

t

0.45

0.45

0.55

L

1.6

t

W

2

3.2

Resistor Code : A

108

118

128

39

Page 34

Refer to the following pages for the common section.

IC DESCRIPTION...................................................................... See page 17

IC BLOCK DIAGRAM ................................................................ See page 21

MECHANICAL EXPLODED VIEW............................................. See page 23

MECHANICAL PARTS LIST...................................................... See page 24

CD MECHANISM EXPLODED VIEW ........................................ See page 25

CD MECHANISM PARTS LIST ................................................. See page 25

40

Page 35

BLOCK DIAGRAM

8

RF

4241

Page 36

WIRING

A

B

C

D

1

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

4443

Page 37

SCHEMATIC DIAGRAM

4645

Page 38

CD TEST MODE

< How to Enter the Test Mode >

While pressing the SLEEP&OPEN/CLOSE key, insert

the AC power cord to AC wall outlet.

< When the Machine Has Entered the Test

Mode >

The system is initialized and the main power is turned on.

During the test mode, the main power of the CD block is

turned on always. The test mode starts with the [Sled

mode].

< Types of Test Mode >

[Sled mode]

All displays of the FL tubes light. The optical pickup can

be moved by pressing [ ] or [ ]key.

Pressing the [

Pressing the [ ] key moves the sled to outer

circumference.

Pressing the [ ] key moves the sled to inner

circumference.

Pressing OPEN/CLOSE key opens or closes the tray.

] key establishes the [Play mode].

Pressing the [ ] key establishes the [Sled mode].

The [ ] display can be turned on and off by pressing

the [ ] key .

While the [ ] display is turned off:

CLV-A Tracking servo: on

Sled servo: on

While the [ ] display is turned on:

CLV-A Tracking servo: off

Sled servo: off

Pressing the [ ] key decreases the track number to -1.

Pressing the [ ] key increases the track number to +1.

Pressing OPEN/CLOSE key opens or closes the tray.

The machine enters the [Sled mode].

< How to Exit the Test Mode >

Remove the AC power cord from power outlet, or turn

off the system power.

[Play mode]

Lighting of all displays of the FL tubes are turned off and

returns to normal display. The focus search (numbers of

search is unlimited) is performed. When focus comes to

in-focus, the focus servo is locked in and the machines

enters the normal play mode.

During [Play mode], GFS and sound skipping are not

monitored.

When focus becomes out-of-focus, another attempt is

made to search for focus.

The tracking servo and the sled servo can be turned on

and off by pressing the [

] key.

47

Page 39

USE MODEL LIST

XC-30M

DX-Z9450

CX-NMT960

CX-ZR880

CX-ZR990

CX-ZR770

CX-ZR774

CX-NF959

CX-NF958

CX-ZR550

CX-NA959

CX-ZVR99

CX-ZVR80

CX-ZVR88

CX-NAVF960

CX-NMT960

CX-ZR700

48

Page 40

912162

Tokyo Japan

Printed in Singapore

Loading...

Loading...