AiM MyChron4 660 User Manual

USER MANUAL

MyChron4 660

User Manual

Release 1.03

INDEX

1 – HOW TO INSTALL MYCHRON4 660 .............................................................. 3

1.1 – How to install and replace the batteries ............................................... 3

1.2 – How to install MyChron4 660 on Junior Dragsters ............................. 5

1.3 – How to install the RPM wire ................................................................... 6

1.4 – How to install the EGT thermocouple ................................................... 7

1.5 – How to install the cylinder head thermocouple ................................... 9

1.6 – How to install the Speed sensor ......................................................... 10

1.7 – How to connect cables to MyChron4 660 ........................................... 13

2 – HOW TO USE MYCHRON4 660 .................................................................... 14

2.1 – The Keyboard ........................................................................................ 14

2.2 – How to switch ON/OFF the gauge ....................................................... 15

2.3 – Configuration functions ....................................................................... 16

2.3.1 – Configuration wizard ....................................................................... 16

2.4 – The Display ............................................................................................ 26

2.5 – Post Run Review ................................................................................... 27

3 – GPS MODULE AND MYCHRON4 660 .......................................................... 31

3.1 - How to connect GPS MODULE ............................................................ 31

Connection with internal power .................................................................. 31

Connection with external power ................................................................. 32

3.2 - How to install GPS module ................................................................... 32

3.3 - Configuration Wizard ............................................................................ 33

3.4 - MyChron4 660 Data visualization ........................................................ 34

3.5 - MyChron4 660 Datakey for data download ......................................... 35

3.6 GPS Module with QMan .......................................................................... 36

4 – MYCHRON4 660 AND THE PC ..................................................................... 38

4.1 – Downloading data with MyChron4 660 ............................................... 38

4.2 – How to use QMAn ................................................................................. 39

4.3 – QMAn installation ................................................................................. 40

4.3.1 – Installation under Microsoft Windows XP™ ................................... 40

4.3.2 – Troubleshooting .............................................................................. 46

4.3.4 – Installation under Microsoft Vista™ ................................................ 47

4.3.5 – Troubleshooting .............................................................................. 54

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

2

4.4 – QMAn Data Analysis ............................................................................. 55

4.4.1 – Test/Run manager .......................................................................... 56

4.4.2 – Analysis View.................................................................................. 60

4.4.3 – Time Plot ......................................................................................... 62

4.3.4 – Histogram ....................................................................................... 69

4.3.5 – XY Plot ............................................................................................ 71

4.3.6 – Channel info .................................................................................... 73

4.3.7 – How to set the time slip info ............................................................ 74

4.3.8 – How to set weather station data ..................................................... 75

4.3.9 – Test Loaded View ........................................................................... 76

4.3.10 – Run Info ........................................................................................ 78

4.3.11 – Time Slip ....................................................................................... 79

4.3.12 – Tachometer................................................................................... 80

4.3.13 – Weather ........................................................................................ 81

4.3.14 – How to send the test file via E-mail .............................................. 81

4.5 - Maintenance ........................................................................................... 82

4.5.1– How to upgrade the firmware .......................................................... 82

APPENDIX A: TECHNICAL CHARACTERISTICS ............................................. 84

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

3

1 – How to install MyChron4 660

Before installing MyChron4 660, please read these installation instructions

carefully. It is very important that your MyChron4 660 is correctly installed in

order to capture consistent and accurate data. Incorrect installation may result in

system malfunction.

Now you may start installation of MyChron4 660 on your Junior Dragster.

It is recommended to follow these instructions in order to preserve your

instrument and to capture consistent and accurate data.

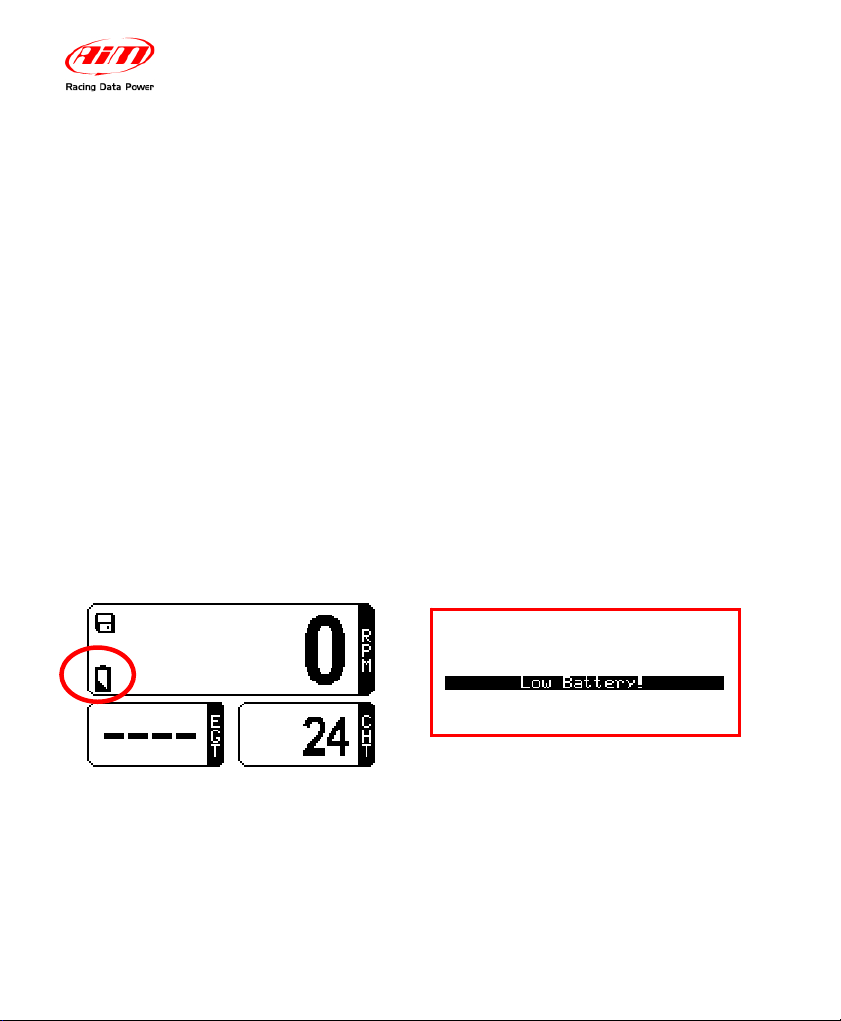

1.1 – How to install and replace the batteries

Your MyChron4 660 is powered by one 9V alkaline battery.

When the internal battery requires replacement, a battery indicator will blink in the

lower left corner of the display:

If you do not replace the battery and keep on running, the system might shut

down during a test. The following screen (above right) will appear a few seconds

before the gauge shuts off .

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

4

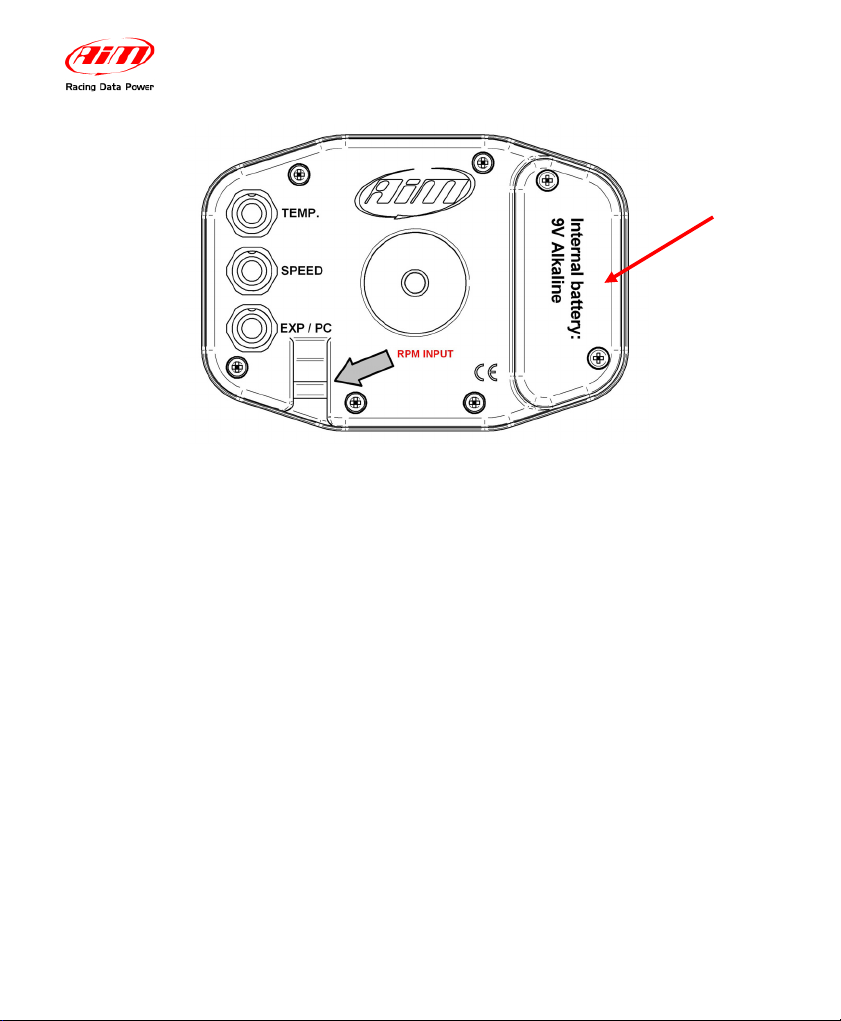

To change battery, remove the two screws on the back of the display unit. A 9V

battery will be connected to a two-wire power lead. Simply disconnect the battery

from the lead and replace with a new battery.

Do not over-tighten the screws when mounting the battery cover to the back

of the display unit.

open here to

change the

battery

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

5

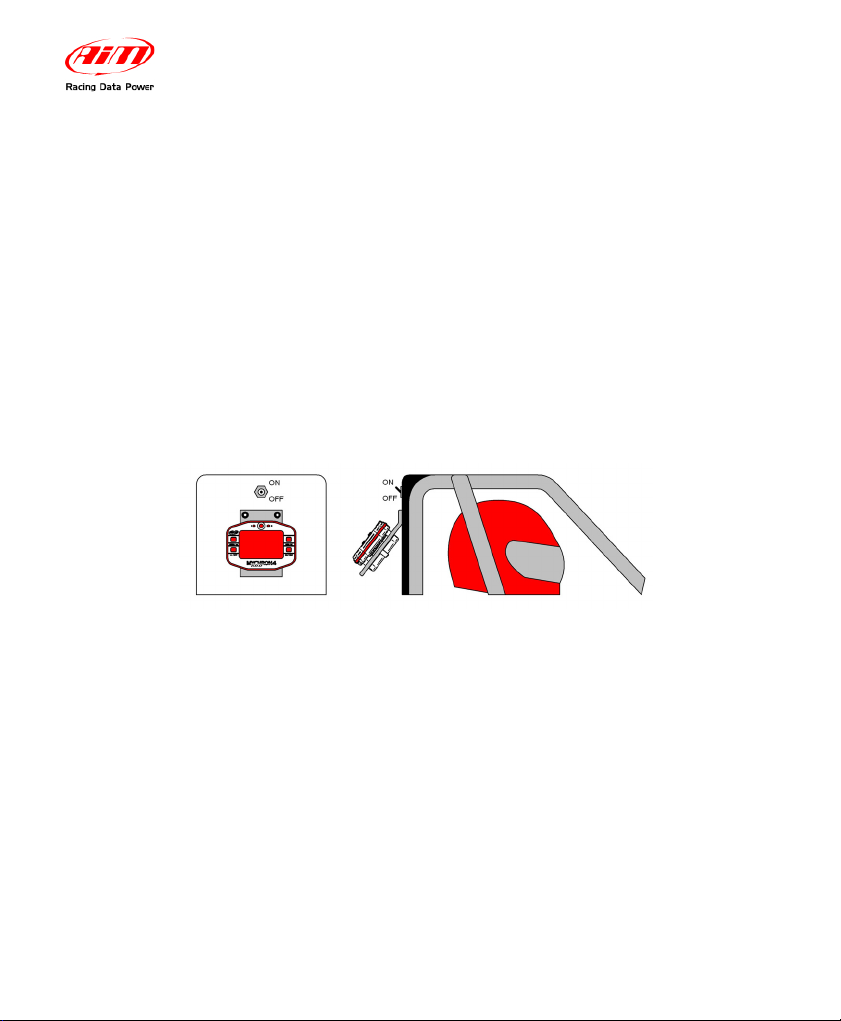

1.2 – How to install MyChron4 660 on Junior Dragsters

One of the main uses of the gauge is to allow the mechanics to set up engine’s

carburetion in the staging area immediately before the race start.

To make this easy, it is suggested to install the gauge in a place where the

mechanics may see the display while working on the engine.

Behind the body cell on the vertical metal bulkhead which separates the racer’s

seat from the engine is a commonly used location. More specifically, as shown in

the following drawing, AIM recommends all MyChron4 660 users to install the

gauge under the engine’s ON/OFF switch.

The gauge has to be mounted on a self-made bracket as shown in figure above.

The bracket has to be made of aluminium or steel, and its thickness must be

0.1 “(2.5 mm) or more in order to have a high stiffness and resist vibration when

the engine is turned on.

Firmly fix the bracket to the vertical metal bulkhead and then fix your MyChron4

660 to the bracket.

Do not over-tighten the 8 mm mounting nut. Over-tightening the nut may cause

damage to the display unit casing.

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

6

1.3 – How to install the RPM wire

The RPM wire has to be connected to the ON/OFF switch (kill switch). This switch

is usually a 2-poles switch (some switches are a single pole, but most are two):

one pole is COIL, the other one is RPM.

The RPM wire should be going to the coil side of the kill switch. Running it to the

grounded side of the switch causes the RPM signal to drop in and out and

sometimes not to work at all.

Because the ON/OFF switch is mounted on the opposite side of the bulkhead with

respect to the gauge, it is necessary to drill a 0.2” (5 mm) hole inside the

bulkhead.

Remember to insert the rubber wire-holder in order to protect the RPM wire

against tears and cuts.

While connecting the RPM wire to your MyChron4 660, please keep the

cable as far as possible from the temperature ones. If the RPM and

temperature wires are wrapped together, the temperature channels might be

very noisy.

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

7

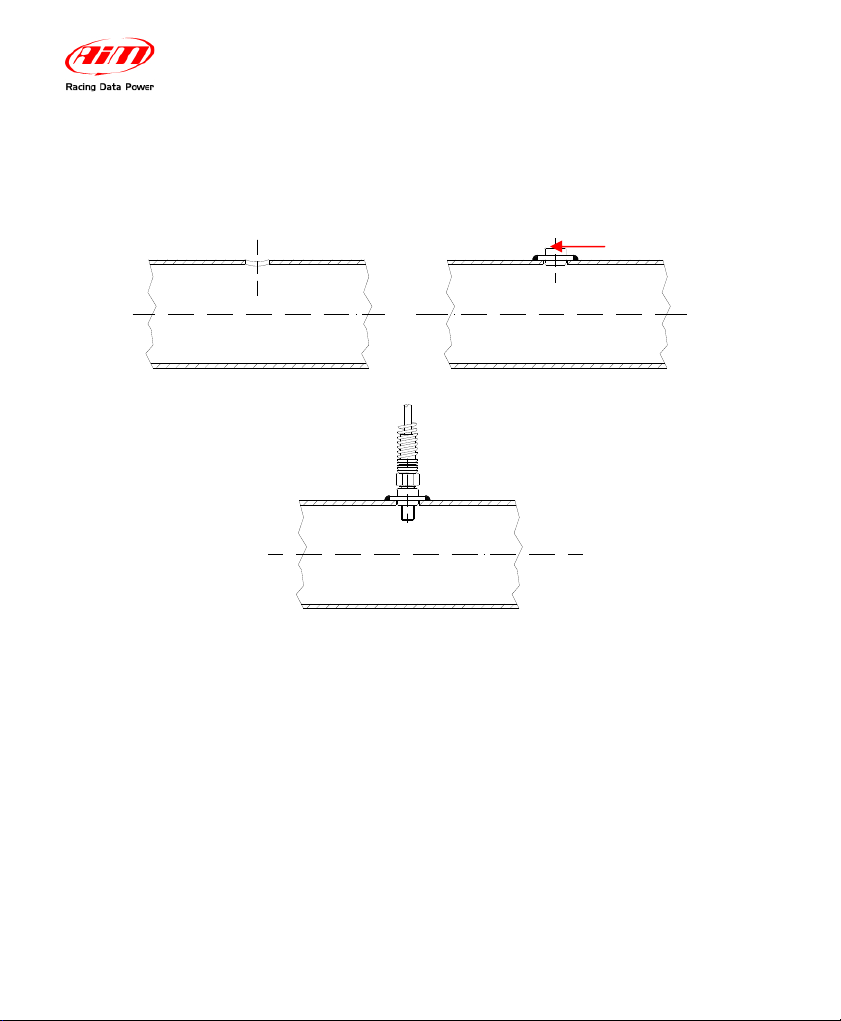

1.4 – How to install the EGT thermocouple

The Exhaust Gas Thermocouple (EGT) has to be installed inside the exhaust

header pipe at a distance of approximately 5.9“ (150 mm) from the exhaust port.

The figure below shows the proper way to install the EGT thermocouple and the

installation wrapper.

It is recommended to insert the sensor between 25% and 50% inside the exhaust

gas header.

To correctly install the EGT thermocouple, please follow these instructions:

1. Make a 0.2” (5 mm) hole inside the exhaust header

2. Fix the metal wrapper to the exhaust header pipe in the hole you have

drilled. It is reminded that the pipe’s hole and the wrapper’s threaded nut

must be coaxial

3. Screw the EGT thermocouple in the wrapper’s nut and firmly fix it. Plug

the thermocouple’s male Mignon connector to the EGT input wire of the

“2 temperatures split cable”.

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

8

The EGT thermocouple may also be installed using a steel adapter which has to

be welded to the exhaust header pipe, as described in the following drawing and

explained below.

Make a 0.4” (10 mm) hole inside the exhaust header

1. Weld the EGT adapter inside the hole

2. Screw the EGT thermocouple inside the EGT adapter

3. Plug the thermocouple’s male Mignon connector to the EGT input wire of

the “2 temperatures split cable”.

1

3

2

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

9

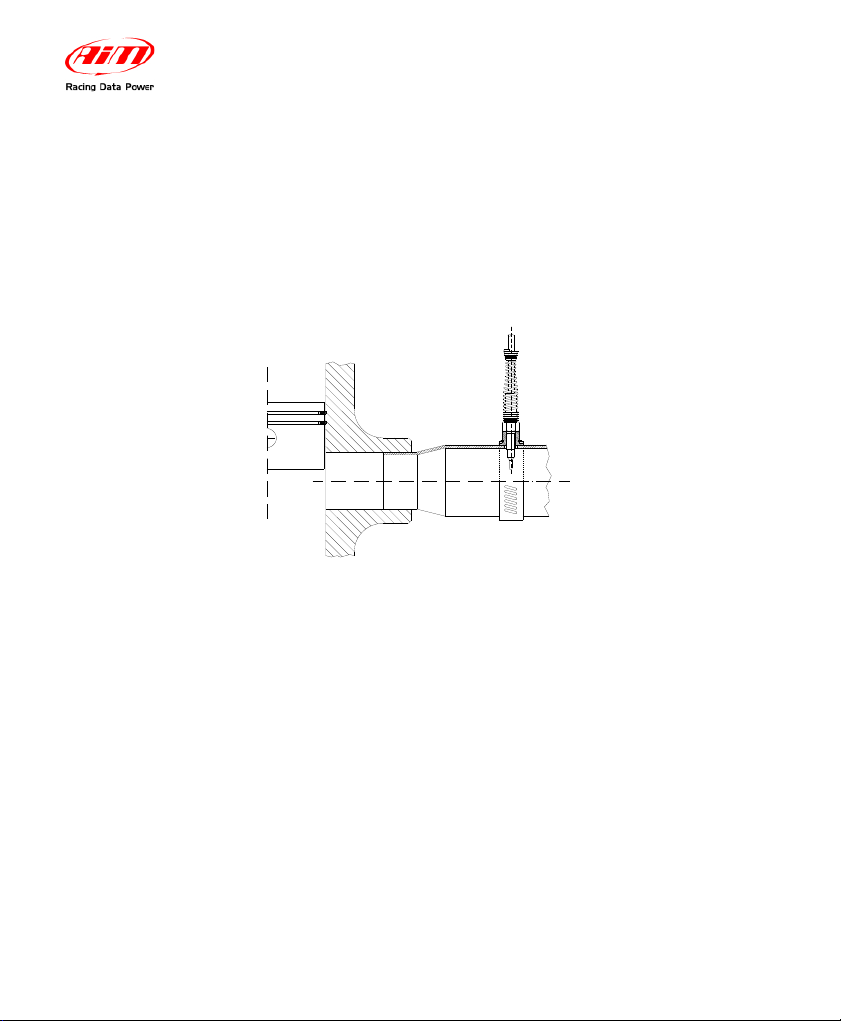

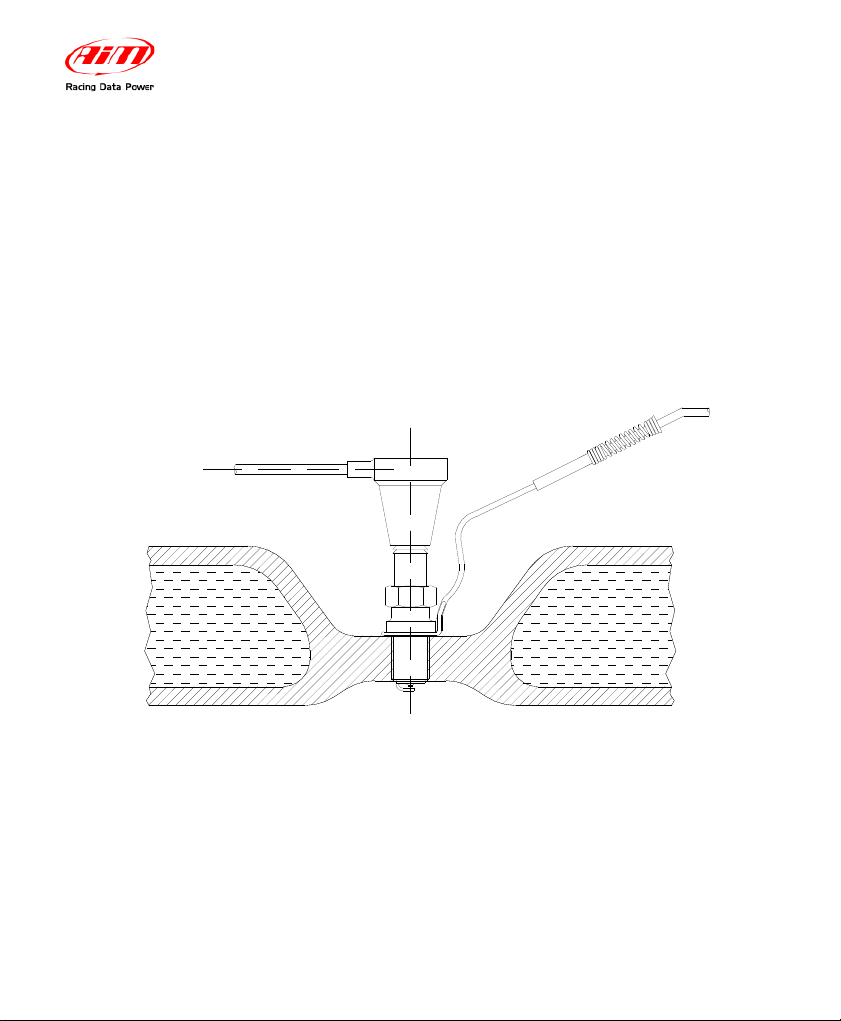

1.5 – How to install the cylinder head thermocouple

When using a Cylinder Head Thermocouple (CHT) sensor, always remove the

spark plug washer before inserting the spark plug into the sensor.

When tightening and loosening the spark plug, minimise movement of the sensor

to avoid damage.

The figure below shows how to correctly install the CHT sensor.

Once the sensor has been correctly installed, plug the thermocouple’s male

Mignon connector to the CHT input wire of the “2 temperatures split cable”.

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

10

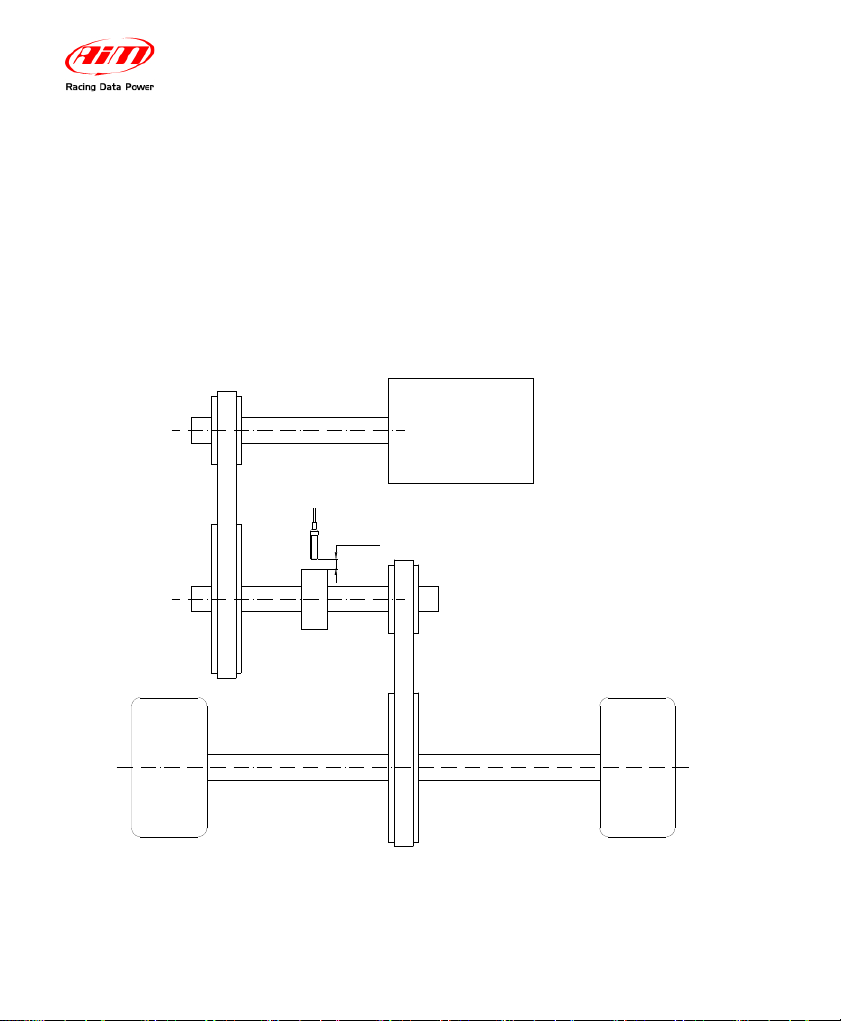

1.6 – How to install the Speed sensor

In order to sample the dragster’s speed, you have to install a phonic wheel

(jackshaft collar) on the jackshaft (¾” diameter) moved by the clutch. The

movement of the jackshaft and the movement of the wheel are related to the

crown/pinion ratio. An installation layout of the speed sensor and magnetic phonic

wheel is shown in the figure below.

Primary V-type belt drive

Rear wheel Rear wheel

Secondary chain drive

Phonic wheel

Sensing distance 4 - 8 mm [0.15 - 0.3 "]

Rear axleRear axle

Magnetoresistive speed sensor

ENGINE

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

11

The speed kit is composed of 1 phonic wheel and 1 magneto resistive speed

sensor.

The phonic wheel is made of Teflon and is composed of two separate parts: an

internal ring, which includes 4 magnets, and an external bushing, which protects

the internal ring. The external bushing is fixed to the internal one using 2 hex-key

screws. The magneto resistive speed sensor is composed of a sensing end,

included inside the brass threaded cylinder, and of a 10” (250 mm) long cable to

be plugged into the gauge’s SPEED input.

speed

input

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

12

To correctly install the speed kit, please follow these instructions:

1. To mount the phonic wheel on the jackshaft, please remove the pinion

and insert the phonic wheel (internal diameter ¾”) on the jackshaft

2. Fix the phonic wheel to the jackshaft by screwing the M5 locknut (use the

hex key supplied with the kit)

3. Install the magneto resistive speed sensor on a self-made bracket. It is

reminded that the

sensing distance (i.e. the distance between the sensor

and the phonic wheel)

must be 0.15 – 0.3” (4 - 8 mm)

Plug the speed sensor’s male connector into the gauge’s SPEED input

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

13

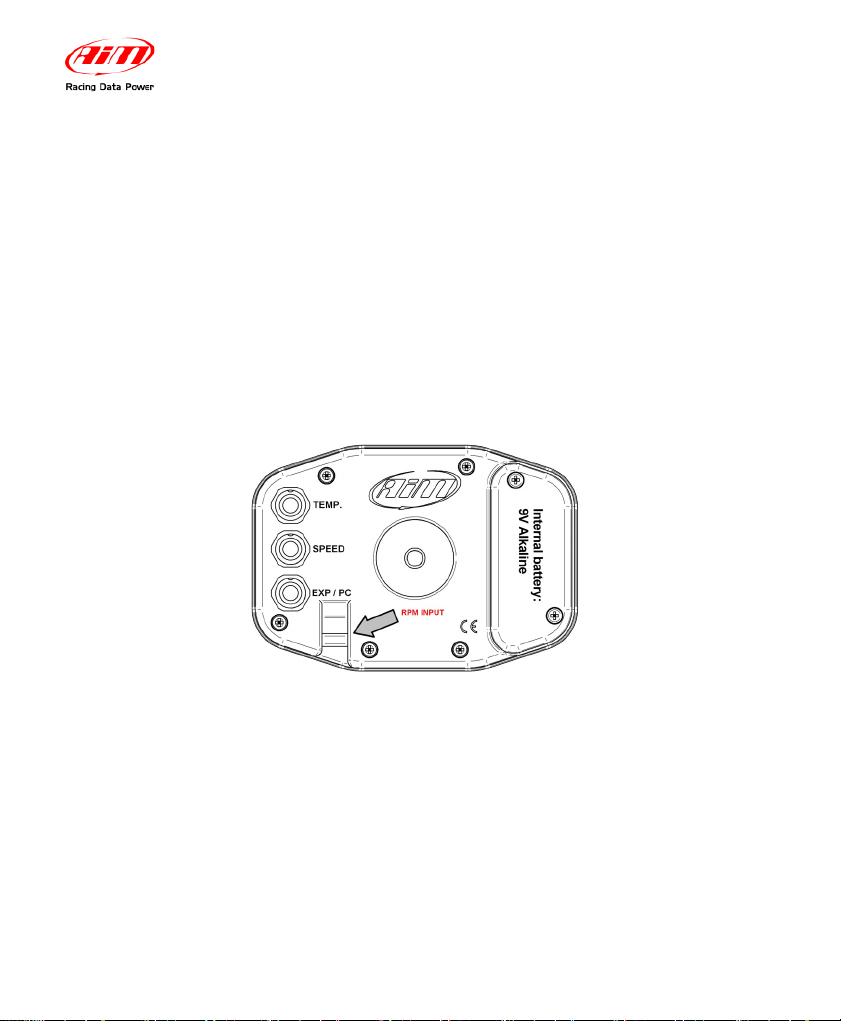

1.7 – How to connect cables to MyChron4 660

Once you have correctly installed all the sensors described above, you need to

connect them to your MyChron4 660. On the backside of the display unit you

have to plug the “2 temperatures split cable” to the connector labelled as

“TEMPERATURE” and the speed cable to the connector labelled as “SPEED”.

The EXP/PC connector is for Lambda, e-Box, data download purposes other CAN

Expansion accessories. The RPM wire is to be placed inside the two holes to the

bottom right of the EXP/PC connector as shown in the figure below.

While connecting the cables to the main display unit, it is strongly

recommended to keep the RPM wire separated from the thermocouple wires

in order to minimize any interference there may be between cables.

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

14

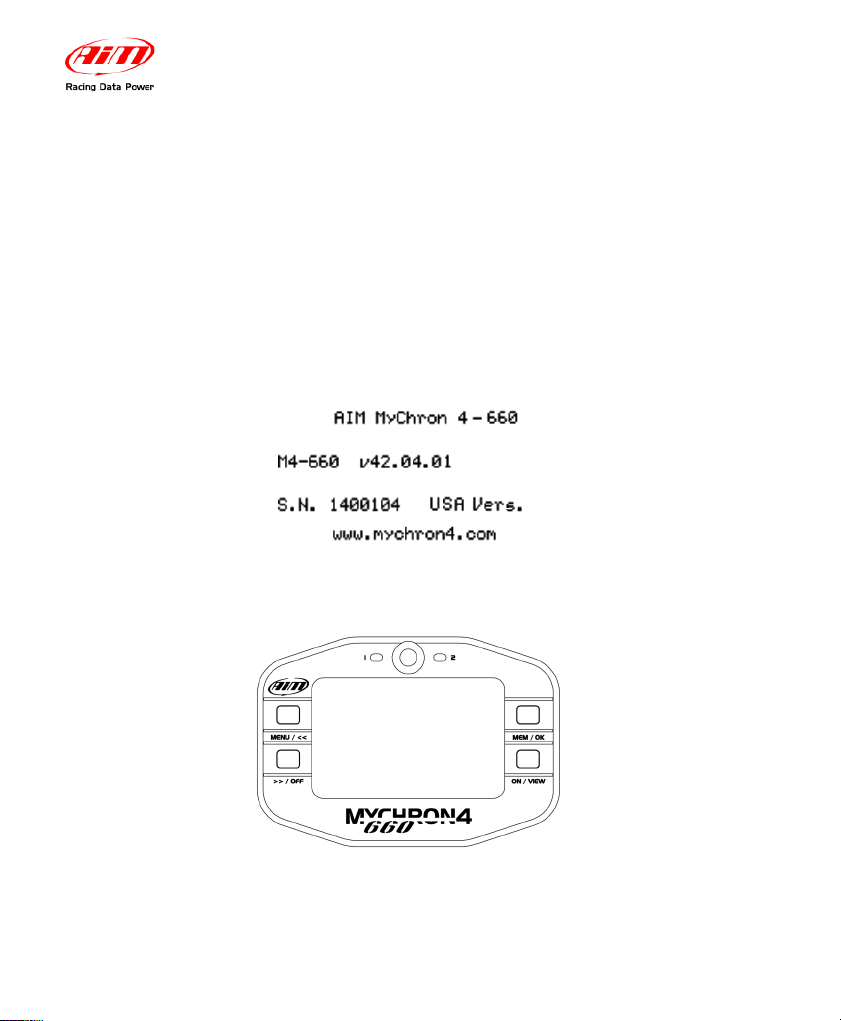

2 – How to use MyChron4 660

As you power on your MyChron4 660, the display shows the following information

(described in the same order as they appear):

1. AIM MYCHRON4 660 Instrument name

2. V42.04.01 Firmware version.

3. S.N.XXXXXXXX Serial number

2.1 – The Keyboard

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

15

The Keyboard is composed of four rubber push-buttons and is used to turn the

gauge ON and OFF, configure the system, recall recorded data from memory and

to clear the internal memory.

The four push-buttons are used to perform the following functions :

MENU/<<

Used to enter configuration mode, to switch to the previous

configuration option and to turn on backlight during a test.

>>/OFF

Used to switch to the next configuration option, to enter Check

mode and to switch the gauge OFF

MEM / OK

Used to CONFIRM a configuration and to retrieve recorded data.

ON/VIEW

Used to switch ON the gauge, to exit configuration menu, or to

switch the display from “RPM digital value” to “Current time”.

2.2 – How to switch ON/OFF the gauge

If you wish to switch ON the gauge, press button ON/VIEW, if you wish to switch

it OFF, keep >>/OFF pressed.

Your MyChron4 660 has an automatic power down feature that turns the power

off after 10 minutes of inactivity.

To run the system in DEMO MODE, switch it on by pressing button

ON/VIEW, then hold down MENU/<< and >>/OFF buttons for a couple of

seconds.

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

16

2.3 – Configuration functions

Before starting your system on-track, please configure your gauge in order

to acquire correct data from your system.

2.3.1 – Configuration wizard

You can enter the Configuration Menu pressing the MENU button.

The Wizard automatically switches on every time you enter the configuration

menu, until it ‘s fully completed at least once.

Following the Wizard steps, you need to configure:

•

Temperature Unit ( Fahrenheit or Celsius)

•

Maximum RPM (Bar Graph Maximum RPM)

•

RPM Tattle ( 0 = disabled)

•

Wheel Circumfrence (inch)

• Drivegear

• Drivengear

Adjust Hour

Adjust Minute

Adjust Year

Adjust Month

Adjust Day of Week

The points listed here above are quite intuitive and do not need further

explanations;

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

17

Your configuration Wizard has now finished and your MyChron4 660 is ready to

start running.

Explanation about the configuration can be found in the Configuration Menu

paragraph below.

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

18

Manual configuration

Please, switch ON the gauge (press ON/VIEW) and enter Configuration Mode

(push MENU/<< button) in order to set the configuration parameters (RPM scale,

RPM factor, Wheel circumference, etc…).

Buttons MENU/<< (back to previous option) and >>/OFF (forward to next option)

are used to scroll through the configuration menu.

To exit Configuration Mode and return to Main Display Mode, press ON/VIEW.

The parameters you may set in Configuration Mode are explained here below in

the same order they appear when you scroll through them by pressing the

>>/OFF button.

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

19

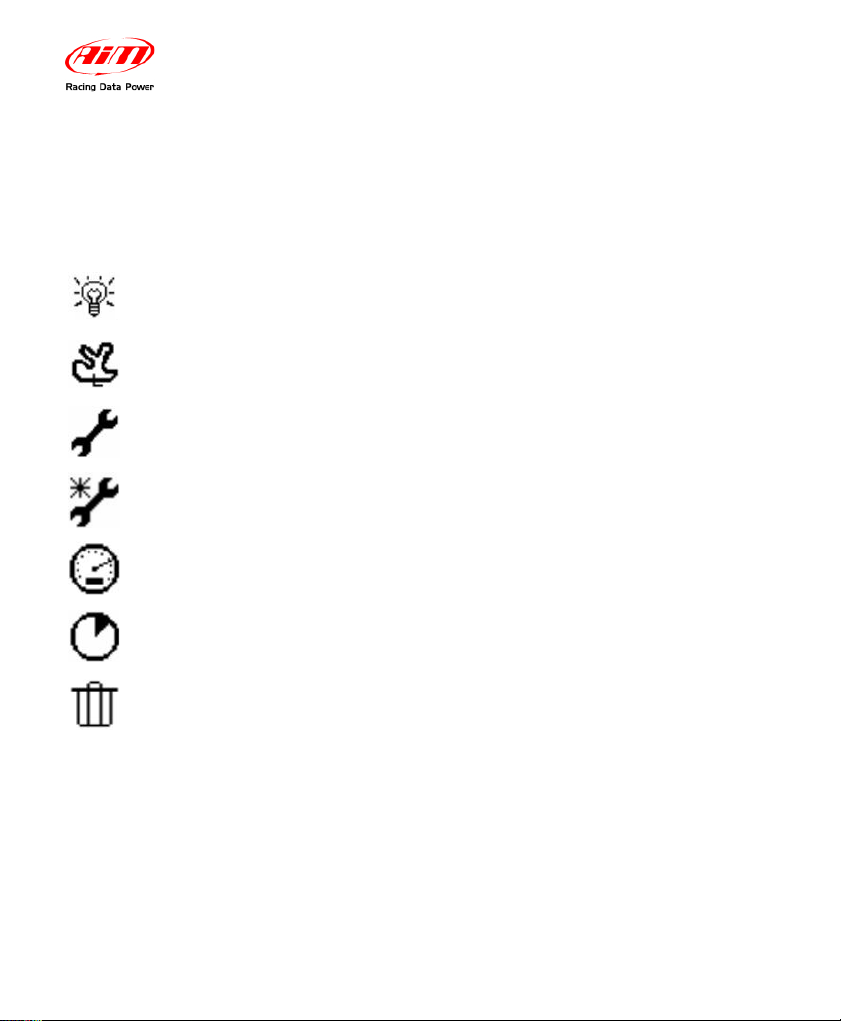

Configuration Menu

The Configuration Menu can be activated pressing MENU button. Once you have

completed the configuration Wizard at least once, the MENU screen appears as

in the picture here below:

BackLight

Track Name

Control Panel

Configuration Wizard

Speed Setup

Engine Pass Counter

Clear Test Data

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

20

The gauge’s display can be set to backlight display so that it

is visible during night racing or in low-visibility conditions.

To set the Night Vision ON or OFF, highlight backlight icon

and press MEM/OK:

Backlight

(Night Vision)

The Track Name is associated with every run recorded on your

MyChron4 660. This is extremely useful when you have many

runs, in order to understand when and where your data have been

recorded. The Track Name is also managed by our

RaceStudio2

Software, when you download your data on the PC.

You can fill in the name of the tracks in which you normally

race, and then select the current track among them

Track Name

This section will be analyzed later.

Control Panel

Through this function you get back to the beginning of the

configuration, when the logger asks you again to go ahead

with the configuration process as in the first time.

Configuration

Wizard

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

21

Speed Setup function sets these parameters:

Wheel circumference: this function allows to set the wheel

circumference in inches. This parameter is fundamental to

correlate the wheel angular speed and the dragster speed.

To run this function select ‘Speed Setup’ and press MEM/OK.

Push MEM/OK to enter edit mode: use menu/<< or >>/OFF

to increase/decrease wheel circumference (¼” steps).

When the correct circumference value has been set, press

MEM/OK to save or ON/VIEW to quit without saving.

Drive gear (pinion) teeth number: select the second line;

push MEM/OK to enter edit mode: use menu/<< or >>/OFF

to increase/decrease teeth number.

The pinion teeth number value can be set in a range included

between a minimum value of 5 and a maximum value of 49.

When the correct number of teeth has been set, press

MEM/OK to save or ON/VIEW to quit without saving.

Driven gear (crown) teeth number: select the third line,

push MEM/OK to enter edit mode: use MENU/<< or >>/OFF

to increase or decrease the number of teeth.

The crown teeth number value can be set in a range between

a minimum value of 5 and a maximum value of 199. Once

set, press MEM/OK to save or ON/VIEW to quit.

Speed Setup

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

22

The MyChron4 660 includes an internal run-counter which

lets the user know the number of runs the gauge has

recorded

The date shown in the function name represents the engine

pass when you erased the run-counter.

To run this function, after having entered the configuration

mode press the MENU/<< button until the following text is

displayed: Engine Pass Counter. Then press the MEM/OK

button twice to erase the run-counter or press ON/VIEW to

discard changes.

In the first channel you can visualize the total number test in

order to monitor the activity of your engines.

Engine Pass

Counter

The “Clear test data” option clears the data stored in the

gauge’s memory.

To run this function, press MENU/<<, place the highlight

selector on the Clear Test Data Icon (Trashcan Icon) by

pressing MENU/<< or >>/OFF and press the MEM/OK

button. A “Confirm Clear” screen will appear. Press MEM/OK

once more to confirm the clear data process or press

ON/VIEW to get back to the previous menu page without

clearing data.

Clear Test

Data

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

23

Now we will take a look at the Control Panel sub-menu.

This function sets the maximum scale for the RPM display

and the maximum acceptable RPM value sampled by your

MyChron4 660.

MyChron4 660 can be configured to manage a wide range

of RPM (from 8,000 to 16,000). Please remember to insert a

higher value than your Engine’s Maximum RPM to acquire

correct data.

To run this function, press the MENU/<< button, place the

highlight selector on the Control Panel Icon (upper Wrench

Icon) by pressing MENU/<< or >>/OFF to scroll, and press

the MEM/OK button. Select the RPM Setup Icon and press

MEM/OK. Select the Maximum RPM option, and press

MEM/OK to enter the Maximum RPM setup. You can

increase or decrease RPM value by pressing MENU/<< or

>>/OFF. Then press MEM/OK to confirm or ON/VIEW to

discard changes and get back to the previous menu.

RPM Setup

The temperature setup menu will allow you to switch

temperature units or to set the Alarm.

• Change the Temperature Unit between Fahrenheit (°F)

and Celsius (C°)

• TEMP EGT ALARM (Lower Value) -Range: OFF- 1000

Temperature

Setup

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

24

• TEMP CHT ALARM (Lower Value).-Range :OFF- 400

Select the key , press MEM/OK and use “>>” and “<<” button

to configure the alarm threshold.

Then press again MEM/OK to stored the changes or

ON/VIEW to discard them.

The system setup menu sets different options of the system:

• Set Time/Date: your MyChron4 660 is equipped

with an internal clock which allows the user to see

the current date and time on the display.

Moreover, this information is saved inside the test

file in order to time and date stamp every run you

make. To run this function, press the MENU/<<

button, highlight the Control Panel Icon (upper

Wrench Icon) by pressing MENU/<< or >>/OFF to

scroll and press the MEM/OK button. Select the

System Setup Icon and press MEM/OK. Select

the Set Time/Date, and press MEM/OK. You can

increase or decrease time values by pressing

MENU/<< or >>/OFF. When done, press

MEM/OK to confirm or ON/VIEW to discard

changes and get back to the previous menu.

The internal clock is powered by one 9V alkaline

System setup

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

25

battery: if battery is removed from the battery pack

for more than 60 seconds (approximately) you will

have to set date and time again.

• Reverse: Use Reverse to switch display dots from

white to black and vice-versa.

• System information: this function shows:

firmware version and gauge serial number.

To run this function, press the MENU/<< button,

highlight the Control Panel Icon (upper Wrench

Icon) by pressing MENU/<< or >>/OFF and press

the MEM/OK button. Select the System Setup

Icon and press MEM/OK. Select the System

Information option, and press MEM/OK to view

Firmware Version. Press ON/VIEW to get back to

the previous menu.

This function sets the driver’s name. This information is

saved inside the test file in order to name every run you

make. Save the settings by selecting the disk icon.

Driver

This function allows you to change the language in your

gauge. There are 2 options: English and Spanish

Language

MyChron4 660

User Manual

Release 1.03

www.aim-sportline.com

26

2.4 – The Display

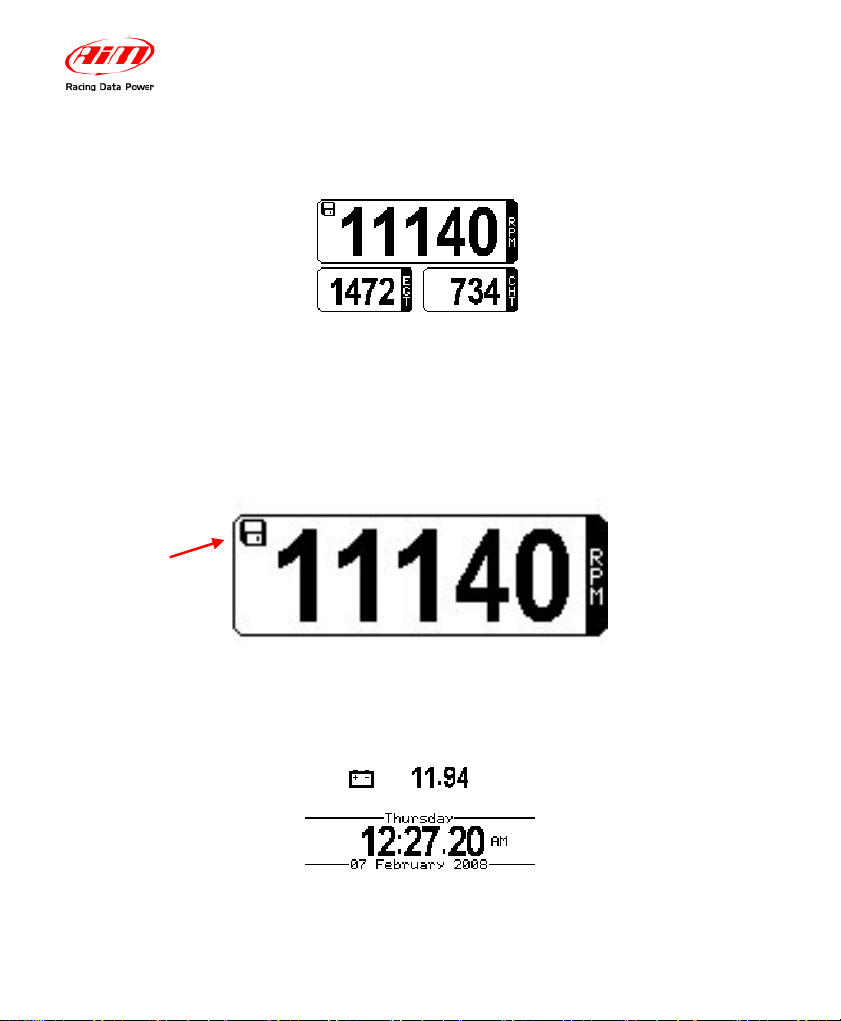

The wide display with backlight shows information such as RPM (digital value),

cylinder head temperature CHT (lower right corner of the display) and exhaust

gas temperature EGT (lower left corner)

When the disc icon appears in the upper left hand corner, the system has begun

recording data.

Pressing ON/VIEW button again will show the battery voltage status and the

calendar. Please refer to Set Date and Time paragraph for further info about

setting calendar values.

The system is

recording

Loading...

Loading...